Abstract

This paper presents a study on Chlef sand to examine the effect of fines content (Fc), relative density (RD) and initial conditions on the compressibility behavior. The interpretation of the results is based on the concept of the intergranular voids ratio (es) and two hypoplastic parameters model Hs and n for calculation of the maximum voids ratio. The œdometric tests results made in the laboratory show that the fines content transition (Fct) of Chlef sand is in good agreement with the results published in the literature. The results obtained indicate that the higher value of fines fraction (Fc) in the sand cause an increase in the compressibility coefficient (Cc) and the granular compressibility coefficient (Cc-s). Moreover increasing the density from 65 to 80% decreased both coefficients (Cc) and (Cc-s). The samples prepared with the moist tamping method (w = 3%) have compressibility coefficients greater than samples prepared by the dry pluviation method (w = 0%). We have shown that the fines content transition (Fct) depends on the initial state of the samples (relative density, preparation method and maximum void ratio). Finally the granulometric characteristics (D10, D50 and Cu) have a significant effect on compression behavior. Nevertheless a good exponential correlation has been found between the compressibility coefficient (Cc), the granular compressibility coefficient (Cc-s) and the effective diameter (D10), the average diameter (D50) and the uniformity coefficient (Cu).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

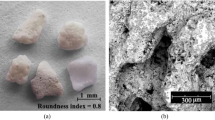

Several studies have been carried out to evaluate the liquefaction resistance of Chlef sand, e.g. Arab 2008; Della et al. 2010; Djafar Henni et al. 2013; Belkhatir et al. 2012; Cherif Taiba et al. 2015; Brahim et al. 2016; Mahmoudi et al. 2018 and Dennine et al. 2016. The aim of this study is to evaluate the compression behavior of Chlef sand using the œdometer apparatus. The sands in nature are found with admixtures of clay, silt or gravel. Most of the published works in the literature have largely studied the effect of the fine fraction on the mechanical behavior (shear strength, liquefaction resistance, pore water pressure, volumetric strain, mechanical parameters c and ϕ) of saturated, unsaturated and partially saturated sands, for example Chang et al. 1982; Zlatovic and Ishihara 1995; Lade and Yamamuro 1997; Covert and Yamamuro 1997; Amini and Qi 2000; Thevanayagam and Martin 2002; Arab et al. 2009; Belkhatir et al. 2010, and Arab et al. 2014. However, the research focused on the influence of fines fraction (silt) on the 1D compression behavior is limited. Most of studies have investigated the addition of clay to sand on the compression behavior using the œdometer apparatus. Monkul and Ozden (2007) carried out œdometric tests on kaolinite-sand mixtures based on the principle of the intergranular void ratio, their results indicate that the initial conditions, the percentage of fines and the stress conditions has an influence on the compression characteristics, the tests showed that up to a certain proportion of fines, called transition fines content (Fct), when the intergranular pores (es) are completely filled by fine fraction, the compression behavior of the sand-clay mixtures is mainly controlled by the sand grains, when the percentage of fines exceeds (Fct), kaolinite controls the compression behavior. Cabalar and Hasan (2013) used the concept of the intergranular void ratio and the transition fines content (Fct) to demonstrate the nature of the interaction between coarser particles (sand) and finer particles (clay), they used two different fluids, water and oil, and different shapes of the sand grains to demonstrate that the interstitial fluid with higher viscosity in a sample can cause lower compressibility. Also higher roundness (R) and sphericity (S) of sand grains resulted in higher values of (Fct) et Cc, The value of Cc also increased with smaller diameter of sand grains Cfa et al. (2013) have shown that there is a strong correlation between clay content and strength and compressibility parameters, Compressibility also increases with the clay content and a variable percentage of clay in a site must be analyzed to ensure that the appropriate designs are made to account for differential settlements due to varying clay content. Yin (1999) observed the results similar to those for other soils published in the literature, he demonstrated that there are correlations between the parameters of consolidation Cc, Cr, and Cα, Cv (index of compressibility, index swelling, secondary consolidation coefficient and consolidation coefficient) with IP (or Cv with WL). Lupogo (2012) studied the compression behavior of silty sand with several types of clay, he concluded that the compression behavior is not influenced by the type of fine up to the Fct and its plasticity, above Fct, compressibility of the mixture is controlled by the fine fraction and differs according to the mineralogical composition of fines. Thevanayamgam and Mohan (2000) have studied the behavior of sand consolidation with fine plastics, they have shown that the fine content transition is between 20 and 30%, their results have also shown that for a fine content ≤ 10% the sand dominates the compressibility of the mixture whereas for a fraction of the fines ≥ 40% the fines dominate the compressibility of mixture. Research published in the literature has indicated that the intergranular void ratio is the ideal parameter to evaluate the behavior of a soil composed of two matrices such as our case (sand-silt). Several studies have evaluated the intergranular void ratio (es), Kuerbis et al. (1988) used the intergranular void ratio to study the undrained shear strength and proposed Eq. 1:

Thevanayagam et al. (1998, 2002) proposed an equation for calculating the intergranular void ratio (Eq. 2 and 3):

where (es) is the index of intergranular voids, (Fc) the fines fraction, (e) the ratio of voids and (b) the amount of fines active.

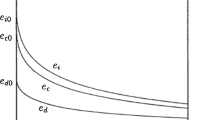

Many researchers used hypoplastic models for constitutive model able to predict the behavior of soil. Bauer (1999), Mašín (2012), Najser et al. (2012), Gudehus (1996), Herle and Gudehus (1999). In this study two parameters of the hypoplastic model (Hs and n) were used for the calculation of the maximum voids ratio emax according to Bauer (1999). Monkul and ozden (2007) have determined the transition fine content based on a constant emax (emax at 0 stress) but in reality emax is not constant and depends on the oedometric pressure applied. emax decreases with increasing oedometric pressure and consequently the transition fine content decreases and the behavior of sand-silt mixtures changes, because the transitional fine content changes with the change of emax. before the transitional fine content limit (Fct) the sand dominates the behavior, after this transitional fine content the silt controls the behavior which is important to the soil behaviour (Fig. 1).

Our objective is to study the influence of the fine content (Fc), relative density (RD) and the preparation methods on the compressibility behavior, and determine the transition fine content (Fct) for the different modes of preparation of Chlef sand on the basis on the concept of the intergranular void ratio (when \(e_{s} = e_{\max - c}\)) corresponding to monkul and ozden (2007). Bauer (1999) indicate that the maximum void ratio depends on the stress level using parameters of hypoplastic model, so emax is not constant Eq. 4.

ei: maximum void ratio depend on the stress level.

ei0: maximum void ratio at 0 stress level.

hs: granular hardness.

n: exponent.

ps: mean pressure.

The influence of the proportion of fines on the compressibility coefficients (Cc), and the granular compressibility coefficients (Cc-s) is also evaluated. Further, in addition to other papers published on the compression behavior, the relationship between compression coefficients (Cc) and (Cc-s) and the shape of the grading curve expressed by diameters (D10), (D50) and the coefficient of uniformity (Cu) is evaluated.

2 Materials, Apparatus used and experimental procedure

The tests were carried out on Chlef sand and Chlef silt, called “fines” in the following text, Specific gravity for clean sand is Gs = 2.65 and 2.68 for Chlef silt, Maximum and minimum void ratio were determined according to [ASTM D 4253] (2002), [ASTM D 4254] (2002). The diameters of mixtures (D10) and (D50) and the uniformity coefficient (Cu) are given in Table 1, and the particle size distribution curve is presented in Fig. 2.

The tests were carried out in oedometer cells of 70 mm diameter and 20 mm height according to the standard [ASTM D 2435/D 2435 M] (1997) (Fig. 3). The loads were applied by incremental loading steps, which were doubled every 24 h. The samples were prepared using two different preparation methods, dry pluviation (w = 0%) and moist tamping method (w = 3%) Castro.G (1969), Konrad JM (1993), Benahmed.N et al (1999), Bouri et al. (2019) and at two relative dry densities RD = 65% and 80%. The preparation procedure was the same for all samples, For samples with w = 0%, The time for mixing the sand with silt was shorter for w = 0% compared to samples with w = 3% where more time was needed to reach equilibrium. The mixture was then placed in the œdometer ring and compacted by dynamic blows until the desired density was reached, then the top cap was installed and sample was flooded to saturate, the loading stage started after 24 h of saturation.

3 Results and discussion

3.1 Effect of fines content and method of preparation on the compressibility behavior of Chlef sand

Figures 4a, b and 5a, b show the variation of the void ratio versus the œdometric pressure, the obtained results show an exponential relationship between the void ratio and the œdometric pressure, the samples prepared by RD = 65% give larger void ratio than the samples prepared by 80% due to the lower compaction and higher void ratio. The initial water content has effect on the void ratio values. For low fines contents and high RD, void ratio is higher for moist tamping method (w = 3%) than for dry pluviation method (w = 0%), which is caused by strengthening effect of water menisci on soil structure, For other fines contents and relative densities, the effect of the initial water content on the initial void ratio appears not to be significant, it is observed from our results that the void ratio decreases with the increasing proportion of fine fraction up to 30% and decreases with further increase of fines up to 40%, It shows that description of the compression behavior by the overall void ratio is not satisfactory. Belkhatir et al. (2010) indicated that the overall void ratio cannot represent the amount of grain contacts in the mixed sand-silt soil. When granular soil contains fines, the overall soil void ratio (e) can no longer be used to describe soil behavior. Indeed, up to a certain fines content, Fc (ratio between the weight of silt and the total weight of the sand-silt mixture), fines occupy only the void spaces and do not significantly affect the mechanical behavior of the mixture, For this reason, the use of the intergranular void ratio has been suggested. The following expressions are suggested to evaluate the void ratio (e) which is a function of the œdometric pressure (σ′):

Table 2 illustrates the coefficients a, b, c and the corresponding coefficient of determination (R2) for the Chlef sand-silt mixtures under consideration.

Belkhatir et al (2010) indicated that the concept of the intergranular void ratio (es) assumes that the fines content does not actively participate in the maintenance of internal forces, if the fines content significantly increases, the behavior of the soil is governed by the fine contacts, and the coarse grains (the sand in this study) float in the fines (Fig. 6).

Adapted from Belkhatir et al. 2010)

Schematic diagram showing sand-silt mixtures: a Coarse grains are in contact with each other, b Coarse grains are swimming in the matrix of fines. (

Figures 7a, b and 8a, b illustrate the variation of the intergranular void ratio (es) versus the œdometric pressure (σ′). The intergranular void ratio (es) was calculated according the equation of Monkul and Onal (2006):

Gs and Gf are the specific gravity of sand and the fines, respectively, G is the specific gravity of sand-silt mixture. The obtained results show that the increase of the density from 65 to 80% and the œdometric pressure (σ′) decreases the intergranular void ratio (es), the samples prepared by dry pluviation method (w = 0%) has an intergranular void ratio (es) greater than those prepared by moist tamping method (w = 3%), the results show also that increasing the fines fraction from 0 to 40% increases the intergranular void ratio (es). The following expressions are suggested to evaluate the intergranular void ratio (es), which is a function of the œdometric pressure (σ′):

Table 3 illustrates the coefficients a, b, c and the corresponding coefficient of determination (R2) for the Chlef sand-silt mixtures under consideration.

The compression coefficients versus the percentage of silt are shown in Figs. 9a, b and 10a, b, These coefficients were calculated according to the equation of Monkul and Ozden (2005). The calculation of the granular compression index (Cc-s), is similar to the computation of the compression index (Cc):

The coefficients of compressibility (Cc) and (Cc-s) for the four curves are not the same one because of their initial conditions. The increase of the density from 65 to 80% reduces the risk of settlement, the compression coefficients for a density RD = 65% is greater than 80%. It is interesting to point out that, unlike in the case of strength, where a threshold between the behavior predominantly affected by coarse fraction and behavior predominantly affected by fine fraction can be observed, the effect of FC on compressibility behavior is gradual. It is clear that the samples prepared by wet tamping method (w = 3%) have larger compression coefficients than the samples prepared by dry pluviation method (w = 0%). As both samples had (apart of low FC sample at high RD) similar overall void ratios, the difference in the behavior is attributed to different internal structure of the samples caused by water menisci present in w = 3% samples. It is observed that the compression coefficients (Cc) and (Cc-s) increase exponentially with the increase of the fines fraction (Fc). The following expressions are suggested to evaluate the compression coefficients (Cc) and (Cc-s) which are a function of the fines fraction (Fc):

Tables 4 and 5 illustrate the coefficients a, b, c and the corresponding coefficient of determination (R2) of Eq. 10 and 11 for the Chlef sand-silt mixtures under consideration.

Figure 11a, b show the variation of maximum void ratios determinate from Eq. 4 of Bauer 1996 versus the oedometer pressure. The maximum void ratios decreases with the increasing stress level.

Figure 12 show the variation of the intergranular void ratio (es) versus the fines content (Fc) for the œdometric pressures applied during the tests (σ′). The border \(e_{s} = e_{\max - c}\) is represented by the dashed line in figures. Figure 5 shows the upper limit, under which the matrix of coarser grains forms a continuous frame with grain-grain contacts Monkul and Ozden (2005), but in reality the maximum void ratio emax is not a constant but depends on the stress level according to Bauer. E (1999) Fig. 11. Table 6, Figs. 11a, b shows the hypoplastic parameters for the determination of emax and curves of emax versus stress level.

The intersection between the dotted line and the curves allows to find the transition content of the fines (Fct). In this study the samples were prepared by several different ways, which resulted in different fines content transition (Fct), summarized in Table 7. Table 7 shows that the fines content transition (Fct) increases with the increasing œdometric pressure (σ′).

3.2 Effect of granulometric composition on the compressibility behavior

3.2.1 Effect of effective diameter (D10)

Several studies (Chang et al. 1982; Vaid et al. 1991; Belkhatir et al. 2011; Monkul et al. 2016, 2017) have been conducted on the influence of particle size on the mechanical behavior (effect of particle size on liquefaction resistance), the results have indicated that the decrease of the diameters (D10)\({\mathrm{D}}_{10}\) and (D50)\({\mathrm{D}}_{50}\) (increase of the fines fraction) reduces the liquefaction resistance. On the other hand the decrease of coefficient uniformity (Cu) improves liquefaction resistance. Belkhatir et al. (2011) found a linear relationship between liquefaction resistance and the average diameter (D50) and uniformity coefficient (Cu)\({\mathrm{C}}_{\mathrm{U}}\), however, the effect of the particle size on the compression behavior has not been studied in such a detail. Figures 13a, b and 14a, b show the effect of the particle size on the compressibility coefficients (Cc) and (Cc-s), it is observed that the coefficients (Cc) and (Cc-s) decrease exponentially with the increase of the diameter (D10) for the two cases of relative density 65% and 80% and for the two different preparation method (Dry pluviation method w = 0% and moist tamping method w = 3%), the decrease of the compressibility coefficient with the increase of the effective diameter (D10) is associated with decreasing amount of the silt in the sand, it means that silt contributes to higher compressibility of the mixture. The following expressions are suggested to evaluate the compression coefficients (Cc) and (Cc-s) which is a function of the effective diameter (D10):

Tables 8 and 9 illustrate the coefficients a, b, c and the corresponding coefficient of determination (R2) of Eqs. 12 and 13 for the Chlef sand-silt mixtures under consideration.

3.2.2 Effect of the average diameter (D50)

Figures 15a, b and 16a, b show the variation of the compression coefficients (Cc) and (Cc-s) as a function of the average diameter (D50) for the different preparation modes, it is noted that the compression coefficients increase with the increase of the fines fraction (Fc) which leads to the decrease of the average diameter (D50), this decrease of the average diameter (D50) is due to the increase in the amount of silt in the sand, which generates higher compressibility. The following expressions are suggested to evaluate the compression coefficients (Cc) and (Cc-s) which is a function of the average diameter (D50):

Tables 10 and 11 illustrates the coefficients a, b, c and the corresponding coefficient of determination (R2) of Eqs. 14 and 15 for the Chlef sand-silt mixtures under consideration.

3.2.3 Effect of uniformity coefficient (Cu)

Figures 17a, b and 18a, b show the effect of the coefficient of uniformity (Cu) on the compression coefficients (Cc). We note that the increase of the coefficient of uniformity and the fines fraction (Fc) increases the compression coefficients (Cc) and (Cc-s), this increase in compression coefficients is due to the increase in the amount of fines in the sand which increases the compressibility of the sand-silt mixtures. The following expressions are suggested to evaluate the compression coefficients (Cc) and (Cc-s) which is a function of the uniformity coefficient (Cu):

Tables 12 and 13 illustrate the coefficients a, b, c and the corresponding coefficient of determination (R2) of Eq. 16 and 17 for the Chlef sand-silt mixtures under consideration.

4 Conclusions

A series of œdometric tests were carried out on sand-silt mixtures extracted from a liquefied site in the banks of the Chlef River (Algeria). Several parameters were investigated on mixtures of sand with 0 to 40% of silt In the first part we studied the effect of the relative density, the effect of initial water content on the sample preparation and the effect of the content of fines. Further, the effect of the particle size distribution on the compressibility behavior of the Chlef sand was evaluated. The following conclusions can be drawn:

The relative density and the initial preparation method have a significant influence on the compressibility of the soil, samples prepared with a density RD = 65% have a larger void ratios and intergranular void ratios than the samples prepared by a relative density RD = 80%, and consequently coefficients of compressibility (Cc) and (Cc-s) are higher. Samples prepared by moist tamping method (w = 3%) gave compression coefficients greater than those prepared by dry pluviation method (w = 0%). As both samples had (apart of low FC sample at high RD) similar overall void ratios, the difference in the behavior is attributed to different internal structure of the samples caused by water menisci present in w = 3% samples. It is interesting to point out that, unlike in the case of strength, where a threshold between the behavior predominantly affected by coarse fraction and behavior predominantly affected by fine fraction can be observed, the effect of FC on compressibility behavior is gradual.

The increase of the fines fraction in the sand causes larger compression coefficients (Cc) and (Cc-s). For low fines content the compression behavior is dominated by coarse grains. As the fines fraction becomes larger in the soil, the compression coefficients become also larger.

The transition fines content (Fct) is not constant and depends on the stress level and maximum void ratio calculate from parameters of hypoplastic parameters model (hs and n). It is shown from this study that the particle size influences the coefficients of compressibility (Cc) and (Cc-s).

From our results it can be said that the influence of relative density, the method of sample preparation and fines fraction on the compression behavior is similar to the liquefaction behavior, a large quantity of silt fraction in the soil has a negative effect on the soil in terms of liquefaction behavior (the studies published in the literature cited at the beginning of this paper) and compression behavior (Cc) and (Cc-s), on the other hand increased density improves the mechanical response of soils in terms of liquefaction resistance (published results in the literature) and compression behavior (this study). The particle size has a significant effect on the compression behavior, and has shown that there are exponential relationships between the compression coefficient and the diameters (D10), (D50) and the coefficient of uniformity (Cu).

Abbreviations

- Gs :

-

Specific gravity of sand

- Gf :

-

Specific gravity of fines

- G:

-

Specific gravity of sand-silt mixture

- D10 :

-

Effective diameter

- D50 :

-

Average diameter

- Cc :

-

Compressibility coefficient

- Cc-s :

-

Intergranular compressibility coefficient

- Fc :

-

Fines content

- Fct :

-

Fines content transition

- Cu :

-

Coefficient of uniformity (Cu = D60/D10)

- emax :

-

Maximum void ratio

- emin :

-

Minimum void ratio

- e:

-

Initial void ratio

- es :

-

Intergranular void ratio

- RD:

-

Relative density

- R2 :

-

Coefficient of determination

- σ′:

-

ŒDometer pressure

- WL :

-

Liquid limit

- w:

-

Water content

- ϕ:

-

Internal friction angle

- CMTDP:

-

Cohesion Moist tamping Dry pluviation

References

Amini F, Qi GZ (2000) Liquefaction testing of stratified silty sands. J Geotech Geoenviron Eng Proc ASCE 126(3):208–217

Arab A. (2008). Behaviour soils under monotonic and cyclic loading, Ph.D. dissertation, Universityof Scienceand technology of Oran, Oran, Algeria.

Arab A (2009) Monotonic and cyclic behaviour of silty sand. C R Mecanique 337:621–631

Arab A, Sadek M, Belkhatir M, Shahrour I (2014) Monotonic preloading effect on the liquefaction resistance of Chlef silty sand. Arab J Sci Eng 39:685–694

ASTM D 2435, D 2435M (1997) Standard test method for One dimensional consolidation properties of soil using incremental loading. Annual Book of ASTM Standards, West Conshohocken, PA, p 19428

ASTM D 4253–00 (2002) Standard test method for maximum index density and unit weight of soils using a vibratory table. American Society for Testing and Materials, West Conshohocken, Annual Book of ASTM Standards, pp 1–14

ASTM D 4254–00 (2002) Standard test method for minimum index density and unit weight of soils and calculation of relative density. American Society for Testing and Materials, West Conshohocken, Annual Book of ASTM Standards, pp 1–9

Bauer E (1999) Analysis of shear band bifurcation with a hypoplastic model for a pressure and density sensitive granular material. Mech Mater 31(1999):597–609

Belkhatir M, Arab A, Della N, Schanz T (2012) Experimental study of undrained shear strength of silty sand: effect of fines and gradation. Geotech Geol Eng 30(5):1103–1118

Belkhatir M, Arab A, Della N, Missoum H, Schanz T (2010) Influence of inter-granular void ratio on monotonic and cyclic undrained shear response of sandy soils. C R Mecanique 338:290–303

Belkhatir M, Arab A, Schanz T, Missoum H, Della N (2011) Laboratory study on the liquefaction resistance of sand-silt mixtures: effect of grading characteristics. Granul Matter 13:599–609

Benahmed N, Canou J, Dupla JC (1999) Influence of the initial conditions and the type of loading on the stability of the undrained behavior of loose sand. Twelfth European Conference on Soil Mechanics and Geotechnical Engineering, Amsterdam (2):687–690

Bouri.D, Krim.A, Brahim.A, Arab.A (2019) Shear strength of compacted Chlef sand: effect of water content, fines content and others parameters. Studia geotechnica et mechanica.https://doi.org/10.2478/sgem-2019-0027

Brahim A, Arab A, Belkhatir M, Shahrour I (2016) Laboratory study of geotextiles performance on reinforced sandy soil. J Earth Sci 27(6):1060–1070

Cabalar AF, Haasan RA (2013) Compressional behaviour of various size/shape sand–clay mixtures with different pore fluids. Eng Geol 164:36–49

Castro.G (1969). Liquefaction of sands. PhD thesis, Harvard University, Cambridge, USA

Cfa A, Bernard O, Seth ON, Kwabena OO (2013) The influence of observed clay content on shear strength and compressibility of residual sandy soils. IJERA 3(4):2538–2542

Chang, N.Y., Yey, S.T., Kaufman, L.P. (1982). Liquefaction potential of clean and silty sand. In: Proceedings of 3rd International Earthquake Microzonation Conference, Seattle, USA, pp. 1018–1032.

Cherif Taiba A, Belkhatir M, Arab A, Kadri A, Mahmoudi Y, Schanz T (2015) Experimental study of undrained shear strength of silty sand: effect of fines and gradation. Geotech Geol Eng 30(5):1103–1118

Covert, K. M., Yamamuro, J. A. (1997). Static liquefaction of silty sands. 5th Great Lakes Geotechnical/Geoenvironmental Conference, Michigan, pp. 1–20.

Della N, Arab A, Belkhatir M (2010) A laboratory study of the initial structure and the overconsolidation effects on the undrained monotonic behavior of sandy soil from Chlef region in northern Algeria. Arab J Geosci 4(5–6):983–991

Denine S, Della N, Muhamad DR, Feia S, Canou J, Dupla JC (2016) Effect of geotextile reinforcement on shear strength of sandy soil: laboratory study. Geotech Geol Eng 30(5):1103–1118

Djafar Henni A, Arab A, Belkhatir M, Hamoudi SA, Khelafi H (2013) Undrained behavior of silty sand: effect of the overconsolidation ratio. Arab J Geosci 6(2):297–307

Gudehus G (1996) A comprehensive constitutive equation for granular materials’. Soils Found. 36(1):1–12

Herle I, Gudehus.G, (1999) Determination of parameters of a hypoplastic constitutive model from properties of grain assemblies. Mech Cohes Frict 4:461–486

Konrad JM (1993) Undrained response of loosely compacted sands during monotonic and cyclic compression tests. Geotechnique 43(1):69–89

Kuerbis R, Negussey D, Vaid YP (1988) Effect of gradation and fines content on the undrained response of sand. Geotechnical Special Publication, no. 21, pp. 330–345.

Lade PV, Yamamuro JA (1997) Effects of non-plastic fines on static liquefaction of sands. Can Geotech J 34:918–928

Lupogo K (2012) Effect of fines mineralogy on the oedometric compressional behavior of sandy soils. J Civ Eng Constr Technol 4(7):232–238

Mahmoudi Y, Cherif Taiba A, Belkhatir M, Arab., A., Schanz, T. (2018) Laboratory study on undrained shear behaviour of overconsolidated sand–silt mixtures: effect of the fines content and stress state. Int J Geotech Eng 12(2):118–132

Mašín D (2012) Asymptotic behaviour of granular materials. Granul Matter 14(6):759–774

Monkul, M. M., Ozden, G. (2005). Effect of intergranular void ratio on one-dimensional compression behavior. Proceedings of International Conference on Problematic Soils, International Society of Soil Mechanics and Geotechnical Engineering. Famagusta, Turkish Republic of Northern Cyprus, pp. 1203–1209.

Monkul MM, Onal O (2006) A visual basic program for analyzing oedometer test results and evaluating intergranular void ratio. Comput Geosci Elsevier Sci 32:696–703

Monkul M, Ozden G (2007) Compressional behaviour of clayey sand and transition fines content. Eng Geol 89:195–205

Monkul MM, Ehsan E, Aykut Ş (2016) Influence of coefficient of uniformity and base sand gradation on static liquefaction of loose sands with silt. Soil Dyn Earthq Eng 89:185–197

Monkul MM, Ehsan E, Aykut Ş (2017) Coupled influence of content, gradation and shape characteristics of silts on static liquefaction of loose silty sands. Soil Dyn Earthq Eng 101:12–26

Najser J, Maší D, Bohác J (2012) Numerical modelling of lumpy clay landfill. Int J Numer Anal Meth Geomech 36:17–35

Thevanayagam S (1998) Effect of fines and confining stress on undrained shear strength of silty sands. J Geotech Geoenviron Eng 124(6):479–491

Thevanayagam S, Martin GR (2002) Liquefaction in silty soils-screening and remediation issues. Soil Dyn Earthq Eng 22(9–12):1035–1042

Thevanayagam S, Mohan S (2000) Inter-granular state variables and stress-strain behaviour of silty sands. Geotechnique 50(1):1–23

Thevanayagam S, Shenthan T, Mohan S, Liang J (2002) Undrained fragility of clean sands, silty sands, and sandy silts. J Geotech Geoenviron Eng 128(10):849–859

Vaid YP, Fisher JM, Kuerbis RH (1991) Particle gradation and liquefaction. J Geotech Eng 116(4):698–703

Yin JH (1999) Properties and behaviour of Hong Kong marine deposits with different clay contents. Can Geotech J 36(6):1085–1095

Zlatovic, S., Ishihara, K. (1995). On the influence of non-plastic fines on residual strength. In: Proceedings of the First International Conference on Earthquake Geotechnical Engineering. Tokyo, pp. 14–16.

Acknowledgements

Charles University authors thank to the financial support by the research grant LTACH19028 Inter-Excellence (Inter-Action) of the Czech Ministry of Education, Youth and Sports and by the Center for Geosphere Dynamics (UNCE/SCI/006).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bouri, D.E., Brahimi, A., Krim, A. et al. Compression Behaviour of Chlef Sand and Transition of Fines Content Using Pressure-Dependent Maximum Void Ratios of Sand. Geotech Geol Eng 40, 1675–1692 (2022). https://doi.org/10.1007/s10706-021-01985-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-021-01985-8