Abstract

Sustainable development is critical today due to increasing demand for natural resources in a fast-growing globe. To facilitate efficient used products recycling management, this paper develops a tripartite evolutionary game model in order to examine the complex interactions between suppliers, manufacturers, and retailers while deciding on their used products collection strategies. Evolutionary stable strategies of the system entities are determined by solving the replicator dynamics and evaluating the stability requirements of the critical points. Numerical simulations are done to verify the plausibility of the model and explore the effects of parameters on the participants’ long-term strategies. The results show that, in a high procurement competition and low-profit environment, the manufacturer’s best long-term stable strategy is to procure used products, whereas the entire population of suppliers and retailers is expected to use a non-procurement strategy. However, under weak procurement competition and significant gain environment, each population’s stable behavior trends to favor purchasing of used products. Even though suppliers and retailers exhibit different stable behaviors in different situations, the manufacturer never changes; it always prefers the used products collection strategy.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The issue of sustainability has become increasingly pressing as a result of the burgeoning global population and the adoption of affluent lifestyles, leading to a rise in demand for natural resources. The concept of sustainable development was introduced in the Brundtland Report, which was commissioned by the World Commission on Environment and Development (WCED) in 1987. This report emphasized the importance of meeting the needs of the current generation without compromising the ability of future generations to meet their own needs (WCED, 1987). In essence, sustainable development aims to strike a balance between social, economic, and environmental concerns in order to promote a better future for all. People around the world are recognizing the importance of sustainable practices such as recycling and green supply chain concepts. Increasing consumer awareness and pressure from the global community have led many companies to adopt sustainable practices. Industry leaders such as Caterpillar, Patagonia, Canon, Kodak, Xerox, Boeing, and Levis have transformed their operations to embrace sustainability. At the same time, demand for consumer electronics has risen, but companies such as EPSON, HP, Huawei, Xiaomi, Dell, and Apple Inc. have developed sustainable supply chains to address this growth while minimizing environmental impact (Mondal & Giri, 2020). In 2017, Apple’s annual sustainable marketing report revealed that, by collecting 100,000 used iPhone 6 devices, they recycled 1900 kgs of aluminum, 800 kgs of copper, 550 kgs of cobalt, 7 kgs of silver, and 0.3 kg of gold (He et al., 2019). Recycling has become an increasingly valuable market, with its value increasing from $100 billion to $286 billion in just eight years, accounting for \(8.89\%\) of all US sales in 2014 (Chen & Chen, 2016; Wu et al., 2018). Even when recycling is not legally mandated, many firms choose to recycle their used products since it can increase their overall earnings. In fact, a research shows that product recycling reduces production costs by 40–65% (Ginsburg, 2001), and recycling an end-of-life product is 40–60% less expensive than producing a new product (Giutini & Gaudette, 2003). As a result, over the past two decades, the concepts of reverse logistics, remanufacturing, recycling, and closed-loop supply chain (CLSC) management have gained widespread acceptance in both industry and academia (Savaskan & Van Wassenhove, 2006; Agrawal et al., 2015; Giri & Sharma, 2016; Hong et al., 2017).

Recycling initiatives have become an essential aspect of modern-day sustainability efforts, and their success heavily relies on the collection of used products. This process ensures a reliable supply of materials for remanufacturing and enables original equipment manufacturers (OEMs) to establish a sustainable supply chain. However, OEMs often face the challenging decision of whether to establish a dedicated recycling channel alongside existing reverse channels. Hewlett Packard Corporation has led the way in implementing sustainable practices by introducing various efforts, including offering prepaid mailboxes to customers and contracting retailers to procure used items through a trade-in program (Liu et al., 2017). By 2017, these initiatives had resulted in over 271,400 tons of equipment and materials for closed-loop remanufacturing (Fan et al., 2022). In some cases, OEMs and neutral third parties compete in procurement efforts to acquire used products. For instance, Kodak engages in competitive procurement efforts to obtain disposable cameras during the remanufacturing process, competing with third-party collectors (Bulmus et al., 2014). Closed-loop supply chains, in particular, have emerged as a critical strategy for achieving sustainable production and consumption. Not only does this approach significantly reduce the environmental impact of manufacturing, but it also offers potential cost savings for companies through reduced raw materials and energy consumption.

Effective implementation of a reverse channel structure for assembling used items in a CLSC is critical for maximizing profit and enhancing supply chain performance. Savaskan et al. (2004) and Mondal and Giri (2020) studied the challenges associated with choosing the appropriate framework for a reverse channel to procure used items from end-consumers. In today’s business landscape, numerous organizations have developed successful strategies for collecting used goods, including industrial design, recycling infrastructure, advertising, and employee training programs. One such example is Xerox, which leverages innovative technologies to produce eco-friendly products and offers recycling programs that have enabled them to recycle millions of cartridges each year, reducing waste and positively impacting the environment. Moreover, suppliers and retailers are capitalizing on manufacturers’ incentives by procuring used products from the market. Canon India, for instance, has partnered with manufacturer responsibility organizations to accumulate used electronic waste, including rejected copiers, printers, scanners, ink/toner cartridges, and camera batteries, for responsible and environmentally friendly recycling practices.Footnote 1 In the same vein, Nike has implemented a program called Nike Grind, which collects used Nike products from retailers and consumers and repurposes the materials for use in the production of new products, such as sports surfaces and playgrounds. P &G has also implemented the P &G Product Stewardship Program, which involves collaboration with retailers to collect used P &G products and packaging that are then recycled to extract materials for use in the production of new products. These programs reflect a commitment to sustainability and environmental responsibility, setting a high standard for responsible reverse logistics practices in today’s business world. Furthermore, in some cases, the supplier, manufacturer, and retailer collaborate to collect used products in a competitive marketplace. This is a trend that has gained traction in India, with numerous companies implementing such programs. For instance, Tata Steel has initiated a program called Tata Steel Recycling, which involves collaborating with retailers to collect used steel products such as appliances and automobiles. The collected steel is then recycled to extract materials for use in the production of new steel products.Footnote 2 Similarly, HCL has implemented the HCL Renew program, which allows customers to trade in their used electronic products for credit toward new purchases or to have their products recycled. HCL works with retailers to collect used products and has even established collection centers where customers can drop off their used products.Footnote 3 Additionally, Reliance Industries has established the e-waste Recycling program, which allows consumers to return their used plastic products to participating retailers.Footnote 4 These programs reflect a strong commitment to sustainability and environmental responsibility, setting a high standard for responsible reverse logistics practices in industries.

Using the evolutionary game model within the context of CLSC, our research endeavor seeks to highlight the importance of a long-term collection strategy for supply chain entities operating in a competitive environment. Our objective in this article is to explore the following key points:

-

What is the optimal long-term strategy for supply chain members to collect used products?

-

To what extent do collection competition and profit of supply chain entities impact the evolutionary game process?

-

What measures can be taken to incentivize manufacturers to collect used products through profitable remanufacturing, and how does this impact the other entities in the supply chain?

To address the above issues, a tripartite evolutionary game model is developed that includes a representative supplier, a manufacturer, and a retailer from each population. Eight different scenarios are considered, each of which represents a unique set of circumstances for the supply chain entities. In the first three scenarios, the entities individually collect used products from the market. In the remaining five scenarios, the entities collect used products collectively, thereby becoming rivals for collection. To apply EGT, the payoffs of the supply chain entities are contracted for various collection models. The replicator dynamics are then utilized to determine the equilibrium points for the supplier, manufacturer, and retailer, and investigate the stability of the critical points. By identifying the evolutionary stable strategies (ESS), this study aims to provide valuable insights into the effects of collection competition and profit on the long-term behavior of the supply chain entities. Additionally, it seeks to examine how the gain from remanufacturing can drive the manufacturer to collect used products, and how this affects the other supply chain entities.

This article highlights the collective decision-making process of supply chain players in the collection of used products: The low collection profit and high competition can lead to a decision not to collect, while high profit and low competition incentivize collection efforts. It also emphasizes that the rate of adoption of the collection strategy varies with the profitability of the collection process, and the decision-making of suppliers is affected by their collection rate. In contrast, the collection rate of manufacturers has no impact, and the decision-making of retailers is influenced by their collection rate and the level of competition in the market. Moreover, the study demonstrates that the evolutionary stable behavior of the population is influenced by variations in collection competition, but not variations in collection profits. The findings provide a better understanding of how supply chain entities make decisions regarding the collection of used products and how these decisions are shaped by different factors. In summary, this study makes an important contribution to the field and has the potential to influence and transform the way in which businesses approach the collection of used products in the future.

The rest of the article is structured as follows: In Sect. 2, the previous relevant literature is reviewed and the motivation for the study is discussed. In Sect. 3, assumptions and notations for developing the proposed models are given. Subsequently, the problem is described and different collection models are developed, which serve as illustration for the EGT. Section 4 develops the proposed tripartite EGT model. The evolutionary stable strategies that can be used to analyze the long-term stable behavior of the supply chain members are discussed. Section 5 describes numerical simulations and sensitivity analysis. In Sect. 6, the main findings and managerial implications are discussed. Finally, Sect. 7 draws some concluding remarks and provides suggestions for future research.

2 Literature review

The literature review is composed of three main parts—closed-loop supply chain, collection rate of used products, and the evolutionary game theoretic approach in supply chain management.

2.1 Closed-loop supply chain

In past few years, the closed-loop supply chain has progressively evolved into one of the most important research topics. Giovanni et al. (2016) explored a dynamic closed-loop supply chain (CLSC) composed of a retailer and a manufacturer who both made investment in a recycling program to increase product return rates with benefits for operations, maintenance and advertising. Employing a bargaining structure, Maiti and Giri (2017) evaluated the effectiveness of a cooperative game for trading a specific product in a two-echelon CLSC consisting of a producer and a retailer. Barbosa-Póvoa et al. (2018) concluded that game theoretic approach might be used when a variety of objectives were available, some of which would even appear to be at conflict with each other. This would allow the development of win-win situations. Reimann et al. (2019) found that remanufacturing is more likely to be implemented in a decentralized supply chain than in a centralized one and that excessive investment in remanufacturing can reduce the environmental impact of production as a whole, even when environmental factors are not specifically taken into account during the decision-making process. In a closed-loop supply chain, Zhang et al. (2020) proposed a coordination method with dual-channel revenue sharing after taking into account two forms of return, including damaged and used goods. The relation between quality of product and supply chain’s optimal profit is uncertain. Taleizadeh et al. (2020) developed a Stackelberg game approach to examine pricing and backward channel estimation in a CLSC, considering that the demand is a function of both selling price and marketing level. Zhou et al. (2021) established a consumer awareness paradox in CLSC, according to which the producer flips the decision from remanufacturing to no remanufacturing when more customers are prepared to pay for the product. Remanufacturing techniques are often used by organizations to enhance the effectiveness of reverse logistics. Through the application of the modified MaTrace model on a case analysis of car engines over a 50-year period, Zhang et al. (2021) compared their findings to a situation where all used items were recycled and found that the overall physical loss of steel, nickel, and chromium is reduced by 3, 2, and 5%, respectively. In response to consumer demand, Soleimani et al. (2022) addressed real-world limitations for location, assignment, and inventory choices in a CLSC framework. For the purpose of solving a practical numerical case, they also compiled a set of effective Lagrangian relaxation formulas and fast algorithms. According to Luo et al. (2022), a carbon tax can encourage manufacturers to reduce carbon emissions by investing in technology or remanufacturing, and the decision on whether to impose the tax or not depends on the price between manufacturers and retailers, rather than the amount of carbon saved by remanufactured products under a decentralized pricing scheme. Aliahmadi et al. (2023) developed a mathematical model for a CLSC network to maximize the net present value (NPV) under uncertain parameters while analyzing the impact of actual demand on pricing decisions for final and returned products. Suvadarshini et al. (2023) analyzed the best way to design a closed-loop supply chain involving an OEM, a retailer, and a third-party recollection agent, taking into account competition, efficiency, rationality, and information asymmetry across three return channel structures.

2.2 Collection rate of used products

Savaskan et al. (2004) initially established a generalized game theoretic framework to identify the effective design of a backward channel for accumulating used items. They explicitly considered a manufacturer selecting one of the following three modes for used products collection: (i) the manufacturer accumulates those directly from the customers, (ii) the manufacturer subcontracts procurement activity to a third party, or (iii) the producer outsources collection efforts to a retailer. Extending the method of Savaskan et al. (2004) and assuming that the cost structure of used goods procurement varies based on both procurement quantity and procurement rate, Atasu et al. (2013) investigated how procurement cost structure affects manufacturers’ choice of a backward channel between retailer- and manufacturer-managed procurement channels. He et al. (2019) assumed the issue of customers’ experiencing inconvenience while returning used products to a CLSC that consists of a producer and a retailer. They demonstrated that although while participating in the collection rivalry is always in the retailer’s best interest, the effectiveness of recovery and reuse is not increased by this rivalry. In a two-period CLSC with market demand based on sales price, green level, and sales effort, Mondal and Giri (2020) studied pricing and used items collection strategies. They demonstrated that increasing marketing activity, greening level, or both can increase channel performance. Liu et al. (2021) looked into dual regulation’s effects on supply chain strategies’ four main components: the brand owner’s procurement strategy, the OEM’s option of remanufacturing, the profitability of the two participants, and environmental management systems. Fan et al. (2022) demonstrated that collecting delegation always works to the manufacturer’s advantage, while there are some circumstances in which it might work against the retailer. To be more precise, in a retail channel structure, collecting delegation has no impact on the retailer if the value of used items is low, but it harms the retailer if the value is significant. Cai et al. (2022) conceptualized a retail fashion brand, which promotes its used clothing collection (UAC) program, and investigated operational issues related to enterprises collecting worn clothing from customers. The retail fashion brand then assesses the collected apparel items and either distributes them to charity or sends them to recycle, depending on their condition.

However, the articles discussed above, including those investigating the leadership of actions in CLSCs, create models based on the assumption that the collection amount is determined by enterprises’ collection efforts. As a result, a significant number of articles build models of procurement rivalry based on procurement prices between enterprises in CLSCs rather than collecting efforts (Feng et al., 2017; Li et al., 2017; Kleber et al., 2020; Wu et al., 2020).

2.3 Evolutionary game theory in supply chain

In 1973, Smith intrduced the evolutionary game theory (EGT), which combines game theory and biologically developing populations (Smith, 1982). In addition, economists, sociologists, anthropologists, and philosophers have started to express an interest in it. In actual business, supply chain participants’ behavior may evolve over time, i.e., the decisions of supply chain entities are naturally dynamic. Therefore, a number of researchers have employed evolutionary game theory to evaluate the long-run decisions of supply chain participants. Chen and Hu (2018) used evolutionary game theory to integrate the economic and environmental benefits of how producers respond to different systems of taxes and incentives for carbon footprints, given the fact that products produced have the same carbon characteristics. Sun et al. (2019) researched the best course of action under the government subsidy program for manufacturers and suppliers in a supply chain by using the dynamic game technique. On a two-echelon supply chain composed of manufacturers and suppliers, Zhiwen et al. (2020) developed an evolutionary game theory-based supply chain logistics information collaboration (SCLIC) technique for benefit maximization. Zhang et al. (2020) focused on a competitive CLSC with two OEMs and two third-party remanufacturers to choose the best option among these used product recycling modalities through an evolutionary process. To demonstrate how supply chain entities have evolved dynamically and how stable strategies are heavily influenced by green sensitivities, Long et al. (2021) illustrated an ideal evolutionary game model with an emphasis on policy considerations. Qu et al. (2021) included the involvement of downstream entities as an important input of local government intervention in the selection of low-carbon supplier behaviors in order to investigate the challenge of multi-player cooperative governance of conservation of energy and carbon reduction from the viewpoint of the less carbon supply chain. Hosseini-Motlagh et al. (2022) presented the effects of long-run oriented stable behavior of supply chains on their decisions to coordinate or not to engage in cooperative profit surpluses, involving two symmetrically competing manufacturers and a retailer in an EGT. He et al. (2022) developed a tripartite evolutionary game theoretic model with bounded rationality for the three parties in order to investigate the regulatory requirements of the governments (i.e., punishment and reward policy) for a straw-based biofuel supply chain composed of power stations and farmers. To analyze the various external and internal factors that influence the behavior of game participants and the evolutionary stable behavior of synchronized emission reduction, Liu et al. (2022) applied an evolutionary game theory model to a two-echelon green supply chain composed of environmentally conscious suppliers and producers.

2.4 Research gaps and contributions

The review of the past literature reveals that decisions of supply chain members are typically treated as static in CLSC. Notably, there has been no prior research that examines the dynamic behavior of supply chain entities with relation to used products collection. This research aims to bridge the gap by examining the dynamic behavior of participants in a CLSC. Specifically, we demonstrate that different fractions of suppliers and retailers adopt the used products collection strategy under different conditions, while the entire population of manufacturers implements the collection strategy. The contribution of the present research with respect to the previous works reported in the literature is reflected in Table 1.

3 Evolutionary game model composed of three parties

3.1 Assumptions

In this study, we consider a three-echelon supply chain that consists of a supplier, a manufacturer, and a retailer. These participants are each represented as key players of the population, and are all characterized by risk-averse nature and a shared pursuit of maximizing individual profits. The following succinctly summarizes the underlying assumptions of this study:

Assumption 1

The market demand D is price dependent, i.e., \(D=d+\alpha p\). The supplier (S), manufacturer (M), and retailer (R) each collect a portion of the total demand, represented by the fractions \(\tau _1\), \(\tau _2\), and \(\tau _3\), respectively. Thus the return quantities to S, M, and R are therefore \(\tau _1 D\), \(\tau _2 D\), and \(\tau _3 D\), respectively, such that when they all simultaneously collect used products, the overall return quantity is \(D_r = (\tau _1 + \tau _2 + \tau _3)D\), where \(0 \le \tau _1 + \tau _2 + \tau _3 \le 1\). More precisely, it is noted that \(\tau _1 + \tau _2 + \tau _3 = 0\) which signifies that no used products are returned, whereas \(\tau _1 + \tau _2 + \tau _3 = 1\) indicates that all used products are returned. When only one of the channel members collects used products, the other members’ collected share is zero. For instance, if the supplier is the only one to collect used products, then \(\tau _2 = \tau _3 = 0\). Similarly, when the supplier and the manufacturer simultaneously collect the used products, we have \(\tau _3 = 0\).

Assumption 2

The supplier’s, manufacturer’s, and retailer’s investments are \(H_1\tau _1^2\), \(H_2\tau _2^2\) and \(H_3\tau _3^2\), respectively, when they solely collect the used products. However, if two supply chain participants from the supplier, manufacturer, and retailer simultaneously collect used products, then each participant’s investment for collecting used products relies on its own investment (i) as well as that of its competitor (j), i.e., each of them must invest \(\frac{(H_i\tau _i^2 + \epsilon H_j \tau _j^2)}{1-\epsilon ^2}\), where \(i,j \in {1,2,3}\) and \(i \ne j\) (Wei et al., 2018). When the supplier, manufacturer, and retailer collect used products simultaneously, each of them has to invest \(\frac{H_1\tau _1^2 + \epsilon H_2\tau _2 + \epsilon H_3\tau _3^2}{1 - 2\epsilon ^2}\), \(\frac{H_2\tau _2^2 + \epsilon H_1\tau _1 + \epsilon H_3\tau _3^2}{1 - 2\epsilon ^2}\) and \(\frac{H_3\tau _3^2 + \epsilon H_1\tau _1 + \epsilon H_2\tau _2^2}{1 - 2\epsilon ^2}\), respectively. For the sake of simplicity, we consider \(H_1 = H_2 = H_3 = H\). For single collection mode, \(\epsilon = 0\).

Assumption 3

Although the quality of returned used products may vary, in order to concentrate on the other crucial factors, we suppose that returned used products are all of the same quality and have the same manufacturing cost \(c_r\) (\(< c_m\)) (Savaskan et al., 2004; Choi et al., 2013; Taleizadeh et al., 2020).

Assumption 4

After remanufacturing, only a small portion \(\mu\) of the used products can be reconditioned with the same quality as the new products (Mitra, 2016; Mondal & Giri, 2020). The remaining fraction is sold in a different market at a price \(w_r\).

Assumption 5

The supplier and/or the manufacturer and/or the retailer pay(s) \(A_1\) per unit to the customers while collecting used products from the market and the supplier and/or the retailer transfer(s) used products to the manufacturer at a price \(B (>A_1)\) per unit (Mondal & Giri, 2020).

3.2 Problem description and payoffs under different strategy profiles

An explanation of the problem at hand and an overview of the notations used throughout the paper are provided in this section. A summary of notations is provided in Table 2. Subsequently, a thorough discussion of diverse strategy profiles is presented, forming the bedrock for constructing the tri-partite game model that facilitates the exploration of interactions among the supplier, manufacturer, and retailer populations. Based on the interdependencies among suppliers, manufacturers, and retailers within the game, eight distinctive strategy profiles emerge, and are summarized by the payoff matrix shown in Table 3.

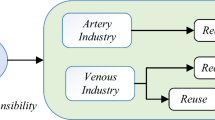

We consider a CLSC with a single supplier, a single manufacturer, and a single retailer. The manufacturer is presumed to be accountable for producing new items and remanufacturing the collected used products. The supplier supplies raw materials and also provides collected used products if it acquires them from consumers. Additionally, the retailer has the option to collect used products from the market while selling new products. In such a situation, each participant in the supply chain has two pure strategies for used product collection: to collect or not to collect. Based on the selected strategies of the supplier, manufacturer, and retailer, eight distinct strategy profiles are evaluated. These profiles are described comprehensively and presented in Fig. 1.

3.2.1 No-one collects used products (0-Model)

Assume that no participants in the supply chain acquire used products from the market for remanufacturing. As a result, the manufacturer only produces new items at the manufacturing cost of \(c_m\) to meet the market demand. He purchases the necessary raw materials from the supplier at a price of \(w_s\). These newly produced goods are then distributed to consumers through the retail channel. Therefore, the payoffs of the supplier, manufacturer, and retailer are defined as follows:

3.2.2 Supplier collects used products (S-Model)

In this case, only the supplier is responsible for collecting used products from the market, acquiring them for a unit cost of \(A_1\), and delivering them to the manufacturer along with raw materials at a combined cost of B and \(w_s\), respectively. The supplier’s total cost for collecting used products is \(H \tau _1^2\), with the total quantity collected being \(\tau _1 D\). A fraction \(\mu\) of the recycled products is as good as new products and can be sold in the same market. The manufacturer generates revenue by charging \(w_r\) per unit for the residual recycled items of lower quality. Therefore, the payoffs for the supply chain entities are determined as follows:

3.2.3 Manufacturer collects used products (M-Model)

Here, we assume that the manufacturer not only produces and markets new items to potential customers through the retail market, but also simultaneously remanufactures used products collected directly from customers at a price of \(A_1\) per unit. We also presume that the manufacturer invests \(H\tau _2^2\) in collecting \(\tau _2 D\) amount of used products and purchases the remaining raw materials from the supplier. Similar to the S-model, lower-quality recycled products are sold in a separate market at a price \(w_r\). Therefore, the profits of the supply chain members are given by

3.2.4 Retailer collects used products (R-Model)

Here we assume that the manufacturer solely buys used products from the retailer in exchange for B per unit transfer fee, which the retailer collects from the customers. We postulate that the retailer, at a cost of \(H\tau _3^2\), acquires \(\tau _3 D\) quantity of used products. In order to meet the market demand, the manufacturer therefore recycles used products in addition to producing fresh products at a cost of \(c_ m\). The remaining remanufactured products, which are of lower quality than new products, are then sold to other markets at a price \(w_r\) per unit. Subsequently, the consumers are provided with newly manufactured products via the retail market. Thus, the payoffs of the supply chain entities are, respectively, elucidated as follows:

3.2.5 Supplier and manufacturer both collect used products (SM-Model)

In this scenario, both the supplier and manufacturer engage in collecting used products from the consumer market for remanufacturing at a cost of \(A_1\) per unit. They acquire a portion \(\tau _1 + \tau _2\) of the market demand and only a fraction \(\mu\) of this portion is fit for new product production after remanufacturing. Due to the competition between the supplier and the manufacturer for clients who return used products, they make investment of \(\frac{H(\tau _1^2 + \epsilon \tau _2^2)}{1 - \epsilon ^2}\) and \(\frac{H(\epsilon \tau _1^2 + \tau _2^2)}{1 - \epsilon ^2}\), respectively, for used product collection. After production, new products are supplied to customers through the retail channel. The payoffs of the supply chain participants are evaluated as follows:

3.2.6 Manufacturer and retailer both collect used products (MR-Model)

In this situation, both the manufacturer and the retailer participate in collecting used products from the market. The retailer then transfers those products to the manufacturer, resulting in a total of \((\tau _2 + \tau _3)D\) units of collected used products. Given that both entities compete to collect used products and they make investments of \(\frac{H(\tau _2^2 + \epsilon \tau _3^2)}{1 - \epsilon ^2}\) and \(\frac{H(\epsilon \tau _2^2 + \tau _3^2)}{1 - \epsilon ^2}\), respectively. After production and remanufacturing, the new and recycled products are supplied to the customers via the retail market. The profits of the supplier, manufacturer, and retailer are, respectively, given by

3.2.7 Supplier and retailer both collect used products (SR-Model)

In this scenario, only the supplier and retailer sell used products to the manufacturer and they charge a transfer fee of B per unit, which is paid for by the customers. However, since the supplier and retailer are competing for collecting used products, they make investment of \(\frac{H(\tau _1^2 + \epsilon \tau _3^2)}{1 - \epsilon ^2}\) and \(\frac{H(\epsilon \tau _1^2 + \tau _3^2)}{1 - \epsilon ^2}\), respectively. After acquiring used products, the manufacturer produces fresh products at a production cost of \(c_m\). Additionally, the manufacturer remanufactures used products that are of similar quality to new products, while the low-quality residual recycled products are sold in a separate market for \(w_r\) per unit. The new products are then supplied to the customers through the retail channel. The payoffs of supply chain members are obtained as follows:

3.2.8 Supplier, manufacturer and retailer collect used products (SMR-Model)

In this scenario, the supplier, manufacturer, and retailer jointly collect used products with a total demand fraction of \(\tau _1 + \tau _2 + \tau _3\). The manufacturer receives used products from the supplier and retailer for a transfer fee of B per unit, and they all pay \(A_1\) per unit to the market for collection. As in the previous models, only a fraction \(\mu\) of the remanufactured products are sold as new products, and the rest are sold in a separate market. Since the supplier, manufacturer, and retailer compete for collecting used items, they make investment of \(\frac{H(\tau _1^2 + \epsilon \tau _2^2 + \epsilon \tau _3^2)}{1 - 2\epsilon ^2}\), \(\frac{H(\epsilon \tau _1^2 + \tau _2^2 + \epsilon \tau _3^2)}{1 - 2\epsilon ^2}\), and \(\frac{H(\epsilon \tau _1^2 + \epsilon \tau _2^2 + \tau _3^2)}{1 - 2\epsilon ^2}\), respectively. The profits of the supply chain members are given by

4 Evolutionary game model and analysis

4.1 EGT model development

Let x denote the probability that the supplier collects used products, and \(1-x\), the probability that the supplier does not collect used products. Similarly, let y be the probability that the manufacturer procures used products, and \(1-y\), the probability that the manufacturer does not procure used products. Finally, let the probabilities of collecting or not collecting used products by the retailer be z and \(1-z\), respectively.

Based on the payoff matrix presented in Table 3, we evaluate the expected payoffs of the supplier collecting used products and not collecting used products, represented by \(E_{11}\) and \(E_{12}\), respectively, as

Now, the average expected payoff (\(\bar{E_1}\)) is given by

Hence, the replicator dynamics for the supplier is given by

where \(X_1 = B-A_1-\mu (w_s - c_s)\).

Similarly, from Table 3, the expected payoffs of the manufacturer collecting used products and not collecting used products, represented by \(E_{21}\) and \(E_{22}\), respectively, can be obtained as

Now, the average expected payoff (\(\bar{E_2}\)) is given by

Hence, the replicator dynamics for the manufacturer is given by

where \(X_2 = -(A_1 + c_r) + \mu (c_m + w_s) + w_r(1-\mu )\).

Likewise, we can determine the expected payoffs of the retailer for collecting used products and not collecting used products. These anticipated payoffs are, respectively, denoted by \(E_{31}\) and \(E_{32}\).

The average expected payoff (\(\bar{E_3}\)) is

and the replicator dynamics for the retailer is

where \(X_3 = B-A_1\).

Now, the replicator dynamics for a tripartite evolutionary game can be constructed as

From (21), clearly the points \((x,y,z) \in [0,1]\times [0,1]\times [0,1]\) are equilibrium points.

Proposition 1

In terms of the pure strategies, the equilibrium points of the system of equations (21) are (0,0,0), (1,0,0), (0,1,0), (0,1,1), (1,0,1), (0,1,1), and (1,1,1), whereas the mixed strategy is

and

where \(L_1 = \left( \frac{\tau _1^2 + \epsilon \tau _2^2 + \epsilon \tau _3^2}{1-2\epsilon ^2} - \frac{\tau _1^2 + \epsilon \tau _3^2}{1-\epsilon ^2} - \frac{\tau _1^2 + \epsilon \tau _2^2}{1-\epsilon ^2} +\tau _1^2 \right)\), \(L_2 = \left( \frac{\tau _1^2 + \epsilon \tau _2^2}{1-\epsilon ^2} - \tau _1^2\right)\), \(L_3 = \left( \frac{\tau _1^2 + \epsilon \tau _3^2}{1-\epsilon ^2} - \tau _1^2 \right)\), \(L_4 = \left( \tau _1^2 - \frac{X_1 \tau _1 D}{H}\right)\), \(M_1 = \left( \frac{\epsilon \tau _1^2 + \tau _2^2 + \epsilon \tau _3^2}{1-2\epsilon ^2} - \frac{\tau _2^2 + \epsilon \tau _3^2}{1-\epsilon ^2} - \frac{\tau _2^2 + \epsilon \tau _1^2}{1-\epsilon ^2} +\tau _2^2 \right)\), \(M_2 = \left( \frac{\tau _2^2 + \epsilon \tau _3^2}{1-\epsilon ^2} - \tau _2^2\right)\), \(M_3 = \left( \frac{\tau _2^2 + \epsilon \tau _1^2}{1-\epsilon ^2} - \tau _2^2 \right)\), \(M_4 = \left( \tau _2^2 - \frac{X_2 \tau _2 D}{H}\right)\), \(N_1 = \left( \frac{\epsilon \tau _1^2 + \epsilon \tau _2^2 + \tau _3^2}{1-2\epsilon ^2} - \frac{\epsilon \tau _2^2 + \tau _3^2}{1-\epsilon ^2} - \frac{\epsilon \tau _1^2 + \tau _3^2}{1-\epsilon ^2} +\tau _3^2 \right)\), \(N_2 = \left( \frac{\epsilon \tau _1^2 + \tau _3^2}{1-\epsilon ^2} - \tau _1^2\right)\), \(N_3 = \left( \frac{\tau _3^2 + \epsilon \tau _2^2}{1-\epsilon ^2} - \tau _1^2 \right)\), \(N_4 = \left( \tau _3^2 - \frac{X_3 \tau _3 D}{H}\right)\).

Proof

Proofs of the Proposition 1 and all subsequent propositions are given in the Appendix. \(\square\)

4.2 Analysis of evolutionary stable strategies (ESS)

In this section, we investigate the stability of nine equilibrium points of the three-dimensional dynamic system. To determine the stability of the equilibrium points of the system, Lyapunov’s method is used, which is similar to the approach used by Friedman (1991), Weibull (1997), Wang et al. (2020). An equilibrium point is considered as an evolutionarily stable strategy (ESS) if and only if all the eigenvalues of the Jacobian matrix have negative real parts, where the Jacobian matrix is

This approach will help to determine which equilibrium points are stable and will provide insight into the evolutionary stability of the system. First, we discuss the long-term based stable mixed strategy for the system. It is quite difficult to mathematically verify that the Jacobian matrix’s eigenvalues have negative real parts. So, we use numerical simulations to determine the mixed strategies and verify the ESS of the equilibrium points of the system.

Proposition 2

The equilibrium point (\(x^*, y^*, z^*\)) = (0,0,0) is an evolutionary stable strategy (ESS), i.e., the long-term-based strategies of the populations of supplier, manufacturer, and retailer are not to collect used products if \(X_1 \tau _1 D - H\tau _1^2 < 0\), \(X_2\tau _2D - H\tau _2^2 < 0\) and \(X_3\tau _3D - H\tau _3^2 < 0\).

When the supplier’s total profit from supplying the collected used products instead of the portion of raw materials to the manufacturer is less than its collection cost in the absence of collection competition, i.e., \([(B - A_1)- \mu w_s] \tau _1 D < H\tau _1^2\), and the extra profit from collection and remanufacturing is less than the total cost of collecting used products without any competition, i.e., \([-(A_1 + c_r) + \mu (c_m + w_s) + w_r(1-\mu )]\tau _2D < H\tau _2^2\), and the profit for collection is less than the cost associated with collecting used products in the absence of collection competition, i.e., \((B-A_1)\tau _3D < H\tau _3^2\), then the system reaches (0,0,0) as ESS. This implies that each of the supplier, manufacturer, and retailer’s stable strategy is not to collect used products. The above conditions emphasize the importance of ensuring that the benefits of collecting and remanufacturing used products outweigh the associated costs. Additionally, it highlights the impact of competition in the collection of used products on the stability of the system, as it can lead to lower profits and potentially unstable strategies.

The conditions for other critical points to be ESS are given in Table 4.

Here, we discuss three different scenarios where an equilibrium point might be an ESS. In the first scenario, there is no competition for collecting used products and a supply chain entity can collect used products from the market freely. In the second scenario, there is only one competitor competing for collecting used products. In the third scenario, there are multiple competitors competing for collecting used products. The conditions necessary for the critical points (1,0,0), (1,1,0), and (1,1,1) be ESS are given in Table 4.

For the first scenario, first condition in Table 4 indicates that if (i) in absence of competition, the supplier’s overall profit from providing the manufacturer with the collected used products in exchange of a portion of raw materials is more than the cost of collection, (ii) the total extra profit of the manufacturer due to collection and remanufacture is less than the total collection cost due to competition with the supplier, and (iii) the profit from collection is less than the cost associated with collecting used products while competing with supplier, then the system reaches the ESS (1,0,0). This means that the manufacturer’s and the retailer’s long-term behaviors are not to collect, as they do not have any incentive for collection of the used products while competing with the supplier. However, the supplier’s stable strategy is to collect used products, as it can generate a profit from collecting and providing those to the manufacturer.

In the second scenario, (1,1,0) will be the ESS of the system when (i) the profit earned by the supplier by providing the collected used products to the manufacturer instead of a portion of the raw materials is greater than the cost incurred in collecting those items, (ii) in a competitive situation with both the supplier and the manufacturer, the total extra profit from collection and remanufacture is more than the total cost of collection, and the profit for collection is less than the cost associated with collecting used products. If these two conditions are satisfied, both the supplier and the manufacturer will have a stable strategy of collecting used products, while the retailer will not.

In the third scenario, to achieve ESS, all the supply chain participants choose to collect used products if (i) the supplier’s total profit from supplying the collected used products to the manufacturer, rather than providing raw materials, exceeds the cost of collecting the used products when competing with both the manufacturer and the retailer, (ii) the total extra profit from collecting and remanufacturing used products is greater than the total cost of collecting them in a competitive situation with both the supplier and the retailer, and (iii) the profit from collecting used products is greater than the cost associated with collecting them in a competitive situation with all parties involved. More precisely, the long-term behaviors of the supplier, manufacturer and retailer are to collect used products.

The criteria for the remaining equilibrium points to be ESS can be categorized into the three scenarios mentioned above. Here we highlight the necessary conditions for ESS in different scenarios, which can be valuable in developing strategies for managing and optimizing the collection and reuse of used products in a competitive marketplace.

5 Numerical simulations and sensitivity analysis

In this section, we present numerical simulations that illustrate the optimal evolutionary stable strategies discussed in the previous section. These simulations serve to provide an intuitive representation of the dynamic evolution of the three-party system under different scenarios of used products procurement strategies. MATLAB R2021a is used to conduct these simulations. However, due to limited access to reliable industrial data, hypothetical parameter values are used for the model. These parameter values are consistent with the data available in the existing literature of Mondal & Giri (2020), but with some necessary adjustments. The parameter values are summarized in Table 5:

The above parameter values ensure the ESS conditions for (0,1,0), given in Table 4. Figure 2 represents the evolutionary path of the population toward the used products collection strategy over time. The arrows indicate the direction in which the frequencies of strategies change. Axes x, y and z, respectively, represent the proportions of suppliers, manufacturers, and retailers who intend to adopt the used products collection scheme in the long term. The arrows depicted in Fig. 2 reveal that the entire manufacturer population will eventually prefer the used products collection strategy in the long term. However, both the supplier and retailer populations would choose not to collect used products, irrespective of whether they decide on collection or non-collection in their short-term strategies. Figure 3 displays the frequencies of strategies for \(\frac{dx(t)}{x(t)}\), \(\frac{dy(t)}{y(t)}\), and \(\frac{dz(t)}{z(t)}\) of suppliers, manufacturers, and retailers, respectively, in the population under three different initial conditions. It shows that, from each initial condition, with the passage of time, the manufacturer achieves equilibrium quickly, and selects the strategy for collecting used products to remanufacture. The retailer also attains equilibrium at a fast pace, opting not to collect used products. On the other hand, it takes the supplier the most extended period to reach equilibrium, ultimately deciding not to collect used products as a strategy.

Now, we choose another dataset with low collection competition between three supply chain members and the price paid by the manufacturer to the retailer and supplier is significantly higher than their costs for collecting used products from the consumer market (i.e., \(B>> A_1\)) and the other parameter values remain unchanged (see Table 6).

The above parameter values satisfy the ESS conditions for (1, 1, 1), as given in Table 4. The evolutionary trajectory is depicted in Fig. 4, which illustrates the evolution of the population’s behavior over time due to used products collection strategy. The diagram shows that the entire manufacturer population will opt for the collection of used products in the long run. Additionally, the supplier and retailer populations will also lean toward collecting used products. Further analysis of the results is presented in Fig. 5, which exhibits the frequencies of strategies for suppliers, manufacturers, and retailers under three distinct initial conditions. The findings suggest that the manufacturers rapidly reach equilibrium and select the collection strategy for used products. Similarly, the retailers also attain equilibrium quickly and opt for the strategy of collecting used products. However, it takes the longest time for the suppliers to reach equilibrium, and ultimately, they also select the strategy of collecting used products.

The above findings reveal that the collection of used products is a desirable strategy for the manufacturers and retailers, whereas suppliers might require more motivation to adopt it. For the previous dataset, only the manufacturer adopts collection strategy as his long-term-based strategy but here all the supply chain members adopt the used products collection strategy as the competition rate is low and the profit for collecting used products is high for the supplier and the retailer, which can be observed in real-world situations.

To gain a deeper understanding of how changes in key parameters affect the suppliers’, manufacturers’, and retailers’ strategies, we conduct a sensitivity analysis.

5.1 Effect of different collection rates

In this subsection, we analyze the influence of \(\tau _1\), \(\tau _2\), and \(\tau _3\) on the dynamic evolution of the supply chain entities’ strategies.

5.1.1 Effect of \(\tau _1\)

We set the values of \(\tau _1\) as 0.1, 0.3, and 0.5 and \(\epsilon = 0.2\) for analyzing the dynamic behavior of entities in case of collection competition. The results based on the replicator dynamics are displayed in Fig. 6a. As shown in Fig. 6a, when \(\tau _1 = 0.1\), i.e., the suppliers’ collection rate is low, both x and y continuously increase and tend to move toward \(x = 0.540708\) and \(y = 0.999994\), respectively. This shows that \(54\%\) of the supplier population and almost the whole manufacturer population adopt the collection strategy. In this case, with rapid decreasing, z finally stabilizes at 0, meaning that the whole retailer population selects the non-collection strategy as the stable strategy. Hence, it can be concluded that, in the case of a low collection rate of suppliers, the ESS of the system is (0.540708, 0.999994, 0). For an increase in \(\tau _1\), e.g., \(\tau _1 = 0.3\) or 0.5, both x and z continuously decrease and tend to move closer to \(x = 0\) and \(z = 0\), respectively. Thus the long-term based strategy of the populations of supplier and retailer is not to collect used products. Here, the manufacturer population’s strategy is to collect used products as y stabilizes at 1.

Now, we analyze the influence of \(\tau _1\) on ESS, when used products collection competition is very low or negligible. We take \(\epsilon = 0.05\) in the same situation. The findings based on the replicator dynamics are displayed in Fig. 6b. As can be seen from Fig. 6b, when \(\tau _1 = 0.1\), both x and y continuously increase and approach toward \(x = 0.760861\) and \(y = 0.999999\), respectively. This means that approximately \(76\%\) of the supplier population and nearly the entire manufacturer population adopt the collection strategy. In this case, z stabilizes at 0, implying that the retailer population’s stable strategy is the non-collection strategy. These observations lead to the conclusion that when \(\tau _1\) is low, the system’s ESS is (0.760861, 0.999999, 0). However, for an increase in \(\tau _1\), e.g., \(\tau _1 = 0.3\) or 0.5, both x and z continuously decrease. This trend indicates that the populations of supplier and retailer are moving toward \(x = 0\) and \(z = 0\), respectively. Hence the long-term strategy of both supplier and retailer populations is to avoid collecting used products. However, as y approaches a stable value 0.999961, the manufacturer population’s stable strategy would be to collect used products. It is further observed that, depending on \(\tau _1\), the adoption rate of the collection strategy of both supplier and retailer populations changes but, except the adoption rate, almost the whole manufacturer population’s long term strategy to collect used products remains unchanged.

The discussion regarding the long-term strategies of the supply chain participants, based on the collection rates of the manufacturer (\(\tau _2\)) and retailer (\(\tau _3\)), is omitted because it is similar to the discussion about the impact of \(\tau _1\) above.

5.2 Effect of collection competition factor (\(\epsilon\))

Here, the values of \(\epsilon\) are taken as 0, 0.1, 0.2, 0.3, and 0.4. The ESS is examined from no competition to high level competition. First, the dataset given in Table 5 is taken into consideration to examine the influence of \(\epsilon\) on the stable strategy of the supply chain entities for the situation of less profit due to collection of used products. The results are shown in Fig. 7a. Upon examining Fig. 7a, it is evident that, in the absence of any competition among the participants (i.e., \(\epsilon = 0\)), the values of x and z experience a continuous decline. Additionally, both the supplier population and the retailer population gradually converge toward the stable points \(x =0\) and \(z=0\), respectively. This shows that the populations of supplier and retailer adopt the non-collection strategy as their long-term-based strategy. In this case, y stabilizes at 0.999745, which implies that the collection strategy is the stable strategy of almost the whole manufacturer population. For an increase in the value of \(\epsilon\), e.g., \(\epsilon = 0.1\), 0.2, 0.3, or 0.4, the long-term-based decisions of the supply chain entities remain the same but the adoption rates of collection strategies of the populations of supply chain members change.

Now, we consider the dataset given in Table 6 to analyze the influence of \(\epsilon\) on the stable strategy of the supply chain entities for the situation of higher profit due to collection of used products. Figure 7b shows that when \(\epsilon = 0\), i.e., there is no collection competition between the participants, x, y, and z continuously increase and approach toward \(x = 0.990529\), \(y = 0.999968\) and \(z = 0.973091\), respectively. This shows that almost the whole populations of supplier, manufacturer, and retailer adopt the collection strategy. When \(\epsilon = 0.1\), i.e., there is low collection competition between the participants, the ESS is \(x = 0.672722\), \(y = 0.999749\) and \(z = 0.395005\). This means that almost the whole manufacturer population adopts the collection strategy, but \(67\%\) of the supplier population and \(39\%\) of the retailer population adopt the collection strategy, which are less than the fractions of the populations adopting collection strategy at the no-competition situation. We observe from Fig. 7b that, for higher profit and higher competitive situation, the long-term-based strategies of almost the whole populations of supplier and retailer are not to collect used products.

Here, we observe that the fractions of supplier and retailer populations who adopt long-term-based collection strategy, and the adoption rates of the collection strategy all change depending on the collection competition at a situation of high profit due to collection, whereas only the adoption rates change in case of low profit. However, almost the whole manufacturer population’s long term strategy to collect used products remains unchanged except the adoption rates for both the cases.

5.3 Effect of \(A_1\) and B

Here, we perform the sensitivity analysis by considering different values of \(A_1\) while keeping the other parameter values given in Table 5 unchanged. We take values of \(A_1\) as 5, 10, 15, and 20. The computational results are presented in Fig. 8a. Figure 8a shows that when \(A_1 = 5\) (indicating a high profit due to used products collection), both y and z gradually increase and move toward \(y = 0.999913\) and \(z = 0.955882\), respectively. This implies that almost the entire manufacturer population and approximately \(95\%\) of retailer population adopt the collection strategy as their long-term strategy. Furthermore, x rapidly decreases and eventually stabilizes at 0.07444622, indicating that the stable strategy of \(74\%\) of the retailer population is collection of used products. When \(A_1 = 10\), both x and z rapidly decrease and approach zero, indicating that supplier and retailer populations adopt non-collection strategy as their long-term strategy. As y stabilizes at 1, the entire manufacturer population’s stable strategy is the collection strategy. For \(A_1 = 15\) or 20, the long-term decisions of the supply chain entities remain the same as in the case of \(A_1 = 5\) or 10. However, with an increase in \(A_1\), the adoption rates of collection strategy of supplier, manufacturer and retailer populations change.

To analyze the impact of the parameter B, we take the values of B as 20, 25, 30, and 35, while keeping other parameter values unchanged. The results are presented in Fig. 8b which shows that, when \(B = 20\), both the supplier and retailer populations adopt non-collection strategy as their long-term strategy. However almost the entire manufacturer population ( \(y = 0.999926\)) selects the collection strategy as its stable strategy. For \(B=25\) or 30, the long-term decisions of the supply chain entities remain unchanged. However, when \(B = 35\), almost the whole manufacturer population (\(y = 0.999976\)) and approximately \(96\%\) of the retailer population adopt the collection strategy as their long-term strategy. In this case, x finally stabilizes at 0.0731805, implying that most of the retailer population’s stable strategy is to choose the collection strategy.

From the above, it can be observed that parameters \(A_1\) and B have opposite effects on the long-term decisions of supply chain entities.

5.4 Effect of collection cost coefficient (H)

In this case, we take the values of H as 1000, 1200, and 1400, and the results are reflected in Fig. 9a. When H is set to 1000, both x and z decrease rapidly to 0, indicating that the entire supplier and retailer populations adopt the non-procurement strategy as their long-term-based strategy. Conversely, almost the entire manufacturer population selects the collection strategy as its stable strategy. Moreover, a higher value of H such as \(H = 1200\) or 1400 affects the adoption rates of the collection strategy but does not affect the long-term decisions of the supply chain entities.

We now consider the high-profit scenario and plot the results in Fig. 9b for H = 1000, 1200, and 1400. When \(H = 1000\), the manufacturer and retailer populations move toward the stable values of \(y = 0.999944\) and \(z = 0.997603\), respectively, indicating that the collecting approach is universally adopted by these entities as their long-term strategy. In contrast, x stabilizes at 0.281569, meaning that only \(28\%\) of the supplier population selects the collection strategy as their stable strategy. When \(H = 1200\), x and z move toward \(x = 0.382768\) and \(z = 0.0260852\), respectively, which suggests that \(38\%\) of the supplier population and \(2\%\) of the retailer population adopt the collection strategy as their long-term-based strategy. Here, y stabilizes at 0.999616, indicating that almost the whole manufacturer population’s stable strategy is to choose the used products collection strategy. As H increases to 1400, both supplier and retailer populations’ long-term strategy is not to collect used products, whereas the entire manufacturer population’s strategy is to collect used products.

6 Result discussions and managerial implications

Utilizing a tripartite evolutionary game theoretic framework, the problem of selecting a used product collection mode is explored in this study in the context of collection competition. The stable behavior of the supply chain population is analyzed using the Lyapunov method, and ESSs are identified for various conditions. Upon conducting a thorough analysis, several significant results and implications have been drawn, which are as follows:

-

(i)

When faced with a situation where there is low profit to be gained from collecting used products, but significant competition exists in the collection market, both suppliers and retailers within the population are likely to opt for a long-term strategy of not collecting used products from consumers and instead trading them to the manufacturer. Conversely, in the long run, the entire population of manufacturers is expected to adopt a strategy of collecting used products. This happens because, in such a situation, the cost of collecting used products from consumers exceeds the revenue generated from reselling them. Therefore, suppliers and retailers within the population may choose to forgo collecting used products and instead trade them with the manufacturer. On the other hand, manufacturers are likely to collect used products in the long run because doing so enables them to reduce their production costs by reusing materials and components.

-

(ii)

In an environment where there are high profits to be gained from collecting used products, and there is little competition in the collection market, the entire population of suppliers and retailers is likely to adopt a long-term strategy of collecting used products from consumers and trading them with the manufacturer. In a similar vein, manufacturers are also expected to prefer collecting used products as part of their long-term strategy. This is because, in such an environment, the revenue generated from collecting used products exceeds the cost of collecting them, making it profitable for suppliers, retailers, and manufacturers alike. With little competition in the collection market, the population of suppliers and retailers can secure a larger market share by collecting used products. Manufacturers can also reduce their production costs by reusing materials and components obtained from used products, as well as maintain their production capacity by sourcing raw materials from used products.

-

(iii)

When collection profits are modest, the evolutionary stable behavior of the population is not influenced by variations in collection competition, but the rate of adoption varies. This means that in situations where the profit margins for collecting used products are modest, the overall population of suppliers, manufacturers, and retailers may not drastically change their strategies in response to increased competition in the collection market. However, the rate at which these parties adopt used product collection strategies varies based on the level of competition. In a highly competitive environment, adoption rates are slower due to the increased risk and uncertainty associated with collecting used products. In contrast, in a less competitive environment, the adoption rates are higher, as there is less risk and more potential for profit.

-

(iv)

In situations where profits from collecting used products are high, increased competition in the collection market can lead to a reduction in the number of suppliers and retailers who adopt the strategy of collecting used products due to increased costs and risks. However, the long-term strategy of manufacturers, which involves collecting used products, remains unchanged as it allows them to reduce production costs and improve profitability, even in the face of increased competition.

-

(v)

If the supplier’s rate of collecting used products is low, then as competition in the collection market increases, the number of suppliers who choose to collect used products decreases. However, the decisions of manufacturers and retailers remain unchanged. In contrast, if the supplier’s collection rate is already relatively high, then collection competition has no impact on the decisions of manufacturers and retailers regarding the collection of used products.

-

(vi)

The manufacturer’s rate of collecting used products from customers does not significantly influence the long-term decisions made by other participants in the supply chain regarding the collection of used products. However, the adoption rate of the evolutionary stable strategy is varied by the factor.

-

(vii)

The retailer’s collection rate of used products can influence the decisions made by the supply chain entities, including the retailer, supplier, and manufacturer. If the retailer’s collection rate is low, increasing competition in the collection market may lead to a decline in the fraction of retailers using the collection strategy. However, the decisions made by the supplier and manufacturer regarding the collection of used products remain the same. On the other hand, if the retailer’s collection rate is relatively high, increasing competition in the collection market does not appear to have a significant impact on the decisions made by the supply chain entities regarding the collection of used products. This suggests that the retailer’s collection rate is an important factor in determining the overall sustainability of the supply chain.

Based on the findings discussed above, here are some suggestions that managers can consider implementing in their businesses:

-

Before making any decisions regarding the collection of used products, it is important to evaluate the profitability of doing so. This evaluation entails analyzing both the costs associated with collecting these products, as well as the potential revenue that can be generated through their resale or reuse. By comprehending the profitability of collecting used products, a manager can make an informed decision on whether this strategy is viable for their businesses.

-

The extent of competition in the collection market can greatly influence the decision to collect used products. In cases where there is intense competition and low profitability for collecting used products, it may be advantageous to trade these products with the manufacturer instead of collecting them directly from consumers. Conversely, in situations where the collection market is less competitive and there is high profitability for collecting used products, it may be more beneficial to gather these products from consumers and resell or reuse them. Thus, when contemplating the collection of used products, it is crucial to consider the level of competition in the collection market and its potential impact on the profitability of the business.

-

The success of collecting used products can be influenced by the adoption rates of the population. Therefore, when considering the implementation of a used product collection strategy, managers should take into account not only the level of competition in the collection market and the profitability of collecting used products, but also the potential adoption rates of the population. In cases where adoption rates are low, managers may need to consider implementing additional incentives or alternative strategies to encourage the collection of used products. By assessing the adoption rates and implementing appropriate measures to increase the uptake of used product collection, managers can enhance the effectiveness and profitability of their business operations.

-

The collection rate of used products by a retailer can significantly impact the decisions made by supply chain entities. Therefore, it is important for managers to assess the retailer’s collection rate and develop strategies to improve it if deemed necessary. This may involve implementing various measures, such as providing incentives to encourage consumers to return their used products, improving the convenience of the collection process, or raising awareness of the benefits of collecting used products. By enhancing the retailer’s collection rate of used products, managers can improve the overall efficiency of the supply chain and increase profitability for all entities involved. Thus, it is crucial for managers to monitor and improve the collection rate of used products by retailers to ensure the success of their business operations.

-

Finally, managers should actively monitor and evaluate the performance of their used products collection strategies. This entails tracking the adoption rates of the population, evaluating the profitability of collecting used products, and monitoring the impact of these strategies on the overall sustainability of the supply chain. By closely monitoring performance, managers can identify areas for improvement and make necessary adjustments to their strategies. This continuous evaluation process is critical in ensuring the long-term success and profitability of the business, while also promoting sustainable practices within the supply chain. Hence, it is essential for managers to actively assess and improve their used products collection strategies to achieve optimal results.

Hence, the key to successfully implementing used product collection strategies is to carefully evaluate the profitability of collecting used products, consider the level of competition in the collection market, and collaborate with suppliers and manufacturers to develop a coordinated approach. By focusing on these key factors and monitoring and evaluating performance, managers can develop effective used product collection strategies that benefit both their businesses and the environment.

7 Conclusions

This study employs evolutionary game theory to elucidate the long-term collective decision-making process among supply chain entities, including supplier, manufacturer, and retailer, regarding the collection of used products. Numerical simulations are utilized to analyze evolutionary stable strategies and their corresponding stability conditions in relation to collection rates, collection costs, and other important factors, while also placing emphasis on population adoption rates for collection strategies. The findings of this study highlight the significance of collection rate, collection competition, and collection profits, emphasizing how these factors play a crucial role in determining collection strategies within closed-loop supply chain management. The study offers a novel research perspective for the theoretical advancement of evolutionary computation and makes important contributions to the field of closed-loop supply chain management.

Nevertheless, this study admits certain limitations that demand further consideration and exploration. First, using stochastic evolutionary game theory, one can take chaos into consideration for the dynamical system and generate more efficient decisions for the collection parties. Second, by employing a third-party collector to acquire used items from customers, a four-party EGT model can be easily established. Third, to give more realistic direction for remanufacturing operations with collection plans, one might consider the manufacturer and supplier functioning together to remanufacture used products. Last but not the least, one can include government intervention and a low-carbon policy when recycling in CLSC.

Data availability

All data and materials generated or analyzed during this study are included in this article.

References

Agrawal, S., Singh, R. K., & Murtaza, Q. (2015). A literature review and perspectives in reverse logistics. Resources, Conservation & Recycling, 97, 76–92. https://doi.org/10.1016/j.resconrec.2015.02.009

Aliahmadi, A., Ghahremani-Nahr, J., & Nozari, H. (2023). Pricing decisions in the closed-loop supply chain network, taking into account the queuing system in production centers. Expert Systems with Applications, 212, 118741. https://doi.org/10.1016/j.eswa.2022.118741

Atasu, A., Toktay, L. B., & Van Wassenhove, L. N. (2013). How collection cost structure drives a manufacturer’s reverse channel choice. Production and Operations Management, 22(5), 1089–1102. https://doi.org/10.1111/j.1937-5956.2012.01426.x

Barbosa-Póvoa, A. P., da Silva, C., & Carvalho, A. (2018). Opportunities and challenges in sustainable supply chain: An operations research perspective. European Journal of Operational Research, 268(2), 399–431. https://doi.org/10.1016/j.ejor.2017.10.036

Bulmus, S. C., Zhu, S. X., & Teunter, R. (2014). Competition for cores in remanufacturing. European Journal of Operational Research, 233(1), 105–113. https://doi.org/10.1016/j.ejor.2013.08.025

Cai, Y. J., Choi, T. M., & Zhang, T. (2022). Commercial used apparel collection operations in retail supply chains. European Journal of Operational Research, 298(1), 169–181. https://doi.org/10.1016/j.ejor.2021.05.021

Chen, J., & Chen, B. (2016). Competing with customer returns policies. International Journal of Production Research, 54(7), 2093–2107. https://doi.org/10.1080/00207543.2015.1106019

Chen, W., & Hu, Z.-H. (2018). Using evolutionary game theory to study governments and manufacturers’ behavioral strategies under various carbon taxes and subsidies. Journal of Cleaner Production, 201, 123–141. https://doi.org/10.1016/j.jclepro.2018.08.007

Choi, T.-M., Li, Y., & Xu, L. (2013). Channel leadership, performance and coordination in closed loop supply chains. International Journal of Production Economics, 146(1), 371–380. https://doi.org/10.1016/j.ijpe.2013.08.002

De Giovanni, P., Reddy, P. V., & Zaccour, G. (2016). Incentive strategies for an optimal recovery program in a closed-loop supply chain. European Journal of Operational Research, 249(2), 605–617. https://doi.org/10.1016/j.ejor.2015.09.021

Fan, X., Guo, X., & Wang, S. (2022). Optimal collection delegation strategies in a retail-/dual-channel supply chain with trade-in programs. European Journal of Operational Research, 303(2), 633–649. https://doi.org/10.1016/j.ejor.2022.02.053

Feng, L., Govindan, K., & Li, C. (2017). Strategic planning: Design and coordination for dual-recycling channel reverse supply chain considering consumer behavior. European Journal of Operational Research, 260(2), 601–612. https://doi.org/10.1016/j.ejor.2016.12.050

Friedman, D. (1991). Evolutionary games in economics. Econometrica: Journal of the Econometric Society. https://doi.org/10.2307/2938222

Ginsburg, J. (2001). Manufacturing: Once is not enough. Bloomberg.

Giri, B. C., & Sharma, S. (2016). Optimal production policy for a closed-loop hybrid system with uncertain demand and return under supply disruption. Journal of Cleaner Production, 112, 2015–2028. https://doi.org/10.1016/j.jclepro.2015.06.147

Giri, B. C., Mondal, C., & Maiti, T. (2019). Optimal product quality and pricing strategy for a two-period closed-loop supply chain with retailer variable markup. RAIRO-Operations Research, 53(2), 609–626. https://doi.org/10.1051/ro/2017061

Giutini, R., & Gaudette, K. (2003). Remanufacturing: The next great opportunity for boosting US productivity. Business Horizons, 46(6), 41–48.

He, Q., Wang, N., Yang, Z., He, Z., & Jiang, B. (2019). Competitive collection under channel inconvenience in closed-loop supply chain. European Journal of Operational Research, 275(1), 155–166. https://doi.org/10.1016/j.ejor.2018.11.034

He, N., Jiang, Z. Z., Huang, S., & Li, K. (2022). Evolutionary game analysis for government regulations in a straw-based bioenergy supply chain. International Journal Production Research. https://doi.org/10.1080/00207543.2022.2030067

Hong, X., Govindan, K., Xu, L., & Du, P. (2017). Quantity and collection decisions in a closed-loop supply chain with technology licensing. European Journal of Operational Research, 256(3), 820–829. https://doi.org/10.1016/j.ejor.2016.06.051

Hosseini-Motlagh, S. M., Choi, T. M., Johari, M., & Nouri-Harzvili, M. (2022). A profit surplus distribution mechanism for supply chain coordination: An evolutionary game-theoretic analysis. European Journal of Operational Research, 301(2), 561–575. https://doi.org/10.1016/j.ejor.2021.10.059

Kleber, R., Reimann, M., Souza, G. C., & Zhang, W. (2020). Two-sided competition with vertical differentiation in both acquisition and sales in remanufacturing. European Journal of Operational Research, 284(2), 572–587. https://doi.org/10.1016/j.ejor.2020.01.012

Li, Y., Xu, F., & Zhao, X. (2017). Governance mechanisms of dual-channel reverse supply chains with informal collection channel. Journal of Cleaner Production, 155, 125–140. https://doi.org/10.1016/j.jclepro.2016.09.084

Liu, L., Wang, Z., Xu, L., Hong, X., & Govindan, K. (2017). Collection effort and reverse channel choices in a closed-loop supply chain. Journal of Cleaner Production, 144, 492–500. https://doi.org/10.1016/j.jclepro.2016.12.126

Liu, Z., Li, K. W., Tang, J., Gong, B., & Huang, J. (2021). Optimal operations of a closed-loop supply chain under a dual regulation. International Journal of Production Economics, 233, 107991. https://doi.org/10.1016/j.ijpe.2020.107991

Liu, Z., Qian, Q., Hu, B., Shang, W. L., Li, L., Zhao, Y., Zhao, Z., & Han, C. (2022). Government regulation to promote coordinated emission reduction among enterprises in the green supply chain based on evolutionary game analysis. Resources, Conservation & Recycling, 182, 106290. https://doi.org/10.1016/j.resconrec.2022.106290

Long, Q., Tao, X., Shi, Y., & Zhang, S. (2021). Evolutionary game analysis among three green-sensitive parties in green supply chains. IEEE Transactions on Evolutionary Computation, 25(3), 508–523. https://doi.org/10.1109/TEVC.2021.3052173

Luo, R., Zhou, L., Song, Y., & Fan, T. (2022). Evaluating the impact of carbon tax policy on manufacturing and remanufacturing decisions in a closed-loop supply chain. International Journal of Production Economics, 245, 108408. https://doi.org/10.1016/j.ijpe.2022.108408

Maiti, T., & Giri, B. C. (2017). Two-way product recovery in a closed-loop supply chain with variable markup under price and quality dependent demand. International Journal of Production Economics, 183, 259–272. https://doi.org/10.1016/j.ijpe.2016.09.025

Mitra, S. (2016). Optimal pricing and core acquisition strategy for a hybrid manufacturing/remanufacturing system. International Journal of Production Research, 54(5), 1285–1302. https://doi.org/10.1080/00207543.2015.1067376

Mondal, C., & Giri, B. C. (2020). Pricing and used product collection strategies in a two-period closed-loop supply chain under greening level and effort dependent demand. Journal of Cleaner Production, 265, 121335. https://doi.org/10.1016/j.jclepro.2020.121335

Qu, G., Wang, Y., Xu, L., Qu, W., Zhang, Q., & Xu, Z. (2021). Low-carbon supply chain emission reduction strategy considering the supervision of downstream enterprises based on evolutionary game theory. Sustainability, 13(5), 2827. https://doi.org/10.3390/su13052827

Reimann, M., Xiong, Y., & Zhou, Y. (2019). Managing a closed-loop supply chain with process innovation for remanufacturing. European Journal of Operational Research, 276(2), 510–518. https://doi.org/10.1016/j.ejor.2019.01.028

Savaskan, R. C., Bhattacharya, S., & Van Wassenhove, L. N. (2004). Closed-loop supply chain models with product remanufacturing. Management Science, 50(2), 239–252. https://doi.org/10.1287/mnsc.1030.0186

Savaskan, R. C., & Van Wassenhove, L. N. (2006). Reverse channel design: The case of competing retailers. Management Science, 52(1), 1–14. https://doi.org/10.1287/mnsc.1050.0454

Smith, J. M. (1982). Evolution and the theory of games. Cambridge University Press.

Soleimani, H., Chhetri, P., Fathollahi-Fard, A. M., Mirzapour, A. H., & Shahparvari, S. (2022). Sustainable closed-loop supply chain with energy efficiency: Lagrangian relaxation, reformulations and heuristics. Annals of Operations Research, 318(1), 531–556. https://doi.org/10.1007/s10479-022-04661-z

Suvadarshini, P., Biswas, I., & Srivastava, S. K. (2023). Impact of reverse channel competition, individual rationality, and information asymmetry on multi-channel closed-loop supply chain design. International Journal of Production Economics. https://doi.org/10.1016/j.ijpe.2023.108818