Abstract

Low industrial water use efficiency has become a resource bottleneck to industrial development in China. The SBM-undesirable and meta-frontier models were used in combination with empirical data in 30 provinces in mainland China (Tibet excluded due to data missing from 1999 to 2013), to compare industrial water use efficiency in mainland China under meta-frontier and group-frontier, and explore the influencing factors. The empirical results of the study reveal that: (a) there is a large difference in the industrial water use efficiency between meta-frontier and group-frontier in mainland China, due to the heterogeneity in the levels of industrial water use technology; (b) given the low recycle rate of polluted industrial water, there is room for improvement in the industrial water use efficiency in the 30 provinces in mainland China. Further, the study finds that the current price of industrial water is distorted to some extent, failing to coordinate with the use of water resources. Policy implications indicate that industrial water use efficiency is not only related to technological heterogeneity in different regions, but also the control and treatment of industrial water pollution. Therefore, the current price of industrial water should be gradually raised. A scalar water pricing system as residential water could also be applied to industrial water.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Essential to the survival of life on earth, water is also an irreplaceable and limited natural resource to production and human livelihood. The degradation of the water quality leads to scarcities and conflicts (Malley et al. 2008) and water resources relates to sustainable development (Mwanza 2003). As previous research shown, China has been facing a water resource crisis. But on the other hand, water use efficiency in agriculture, industry and other sectors in China are much lower than that of the world level. Industrial water utilization efficiency, in particular, is far below that in developed countries. As industrialization deepens in China, the dependence of industrial development on water has been gradually increasing. Compared to the early stage of the “10th Five-Year” period, industrial water consumption increased by over 27 % at the end of the “11th Five-Year” period, with the average annual growth rate reaching 2.43 % and the proportion of industrial water consumption in the total water consumption increasing to 24.1 % from 20.7 %. During the corresponding period, however, the average annual growth rate of the total water supply in China was less than 1 %. What makes matters worse is that industrial water pollution is still a serious problem. Although the discharge of chemical oxygen demand (COD) and ammonia nitrogen (NH3-N) in industrial wastewater has decreased in past years, it is still remains at a high level. In response, the State Council of the People’s Republic of China released “Opinions on applying the strictest water resources management system” in January 2012. The Opinions says that currently, Chinese water resources are faced with a severe situation, including increasing problems with water shortage, water pollution, and deterioration of the water ecological environment, which has become a crucial bottleneck to the sustainable development of the economy and the society as a whole. The Opinions also propose a “red line” of water resources. Firstly, the total water consumption in China should be controlled within 70 billion m3 by 2030. Secondly, that the water utilization efficiency reaches or comes near to levels in the developed world. Thirdly, water consumption intensity (consumption over industrial added value) should be reduced to below 40 m3 per ten thousand Yuan. Thus, industrial development in China faces double constraints on water resources at present and in the future, namely, the total industrial water supply and industrial water pollution control. In this context, it is critical to gradually improve the industrial water utilization efficiency to maintain continuous industrial development in the medium and long terms.

In recent years, scholars have done some valuable research in regional water use efficiency. Qian and He (2011) used the input-orientated DEA model to compute the provincial utilization efficiency of water resources in China from 1998 to 2008, which first decreased and then increased. Spatially, different patterns were recognized among the eastern, central and western regions, with the eastern region showing the highest efficiency, followed by the central and western regions sequentially. They also pointed out that industry structure, import and export demands, as well as water resources endowment exerted significant impact on the utilization efficiency of water resources. In addition, previous studies have demonstrated that influencing factors concerned with water utilization efficiency mainly include: water price (Schneider and Whitlatch 1991; Bathla 1999), industry structure (Romano and Guerrini 2011; Pan et al. 2011), and the development of economy and industry (Hu et al. 2006). While many studies focus on water use efficiency in agriculture (Rimawi et al. 2009; Latinopoulos 2009; Chowdhury and Al-Zahrani 2014). Only a few scholars have paid attention to industrial water use efficiency (Sun et al. 2007; Lu 2008). Fujii et al. (2012) measured the efficiency of water usage in the Chinese industrial sector and estimated the shadow prices of fresh water and wastewater in each industry. In their opinion, shadow prices and inefficiencies differed among distinct provinces and business types from 1996 to 2007. Although numerous studies have been conducted to analyze water use efficiency across countries from different perspectives with various methods, few of them considered the impact of water pollution when measuring water use efficiency. Based on the data from China’s typical industrial provinces from 2003 to 2009, however, Yue and Zhao (2011) adopted the directional environmental distance function (DEDF) to measure the industrial water use efficiency, and argued that industrial water use efficiency in most provinces showed an increasing trend as time went by, with differences among regions. By using the Malmquist–Luenberger (ML) index decomposition method, the authors concluded that the efficiency change rate, other than technological progress, was the driving factor for improved industrial water use efficiency in China. Although the authors considered the impact of industrial water pollution on water use efficiency, there are still several deficiencies: (a) only 13 provinces were included as DMUs, which violated the strict empirical rule of DEA: the number of DMUs should not be less than twice the product of the number of input and output variablesFootnote 1 (Dyson et al. 2001); (b) industrial development discrepancies among different regions in China were ignored, which might dramatically affect water use efficiency; (c) the efficiency measured by the ML index here was actually not real industrial water use efficiency, but the efficiency of industrial growth that took into account industrial water use and industrial water pollution.

Therefore, the research discovers industrial water use efficiency under double constraints of resource and environment in 30 provinces (excluding Tibet due to data missing) in mainland China. In addition, a series of influencing factors on industrial water use efficiency are studied, especially the price of industrial water. Several contributions have been made. Firstly, industrial waste was incorporated into the measurement of industrial water use efficiency. For instance, chemical oxygen demand (COD) and ammonia nitrogen (NH3-N) discharges were put into the water use efficiency model as undesirable outputs. Secondly, the meta-frontier function was employed to investigate the effects of industrial development on industrial water use efficiency, due to the heterogeneity of industrial development among provinces in China. Thirdly, several influencing factors were selected as control variables. Specifically, the effects of industrial water price on water use efficiency were taken into account. Finally, the current water price and the shadow price were compared to explore whether the current price of industrial water has been distorted.

The meta-frontier model, SBM-undesirable model and data sources are introduced in Sect. 2, respectively. In Sect. 3, industrial water use efficiency is elaborated under meta-frontier and group-frontier in the eastern, central and western regions in China. Section 4 presents the empirical results. Section 5 compares the shadow price with the current price of industrial water and discusses price distortion. Finally, some conclusions and policy implications related to the article are put up.

2 Methodology and data

2.1 Meta-frontier model

When using data envelopment analysis (DEA) to measure industrial technology efficiency in different regions, the underlying assumption is that decision making units (DMUs) have the same or similar technology levels, so as to explore a potential technology gap and management levels. In addition to industrial development and technology discrepancies, however, there are huge differences among the provinces in China in terms of industrial structure, resources endowment, and the level of urbanization, leading to various production frontiers in different provinces in mainland China. Thus, it will be difficult to accurately measure the real industrial development efficiency and industrial water use efficiency in mainland China if these differences are not considered into the research. In response to this issue, meta-frontier was first presented by Battese and Rao (2002). They divided DMUs into different groups based on a certain criteria and then used the stochastic frontier method (SFA) to identify the different group-frontiers and meta-frontier. Finally, they estimated technical efficiency scores and the technology gap ratio (TGR) under group-frontier and meta-frontier. However, SFA assumes that all DMUs have the potential to reach the same technological frontier, meaning that the meta-frontier will not be able to envelope all group-frontiers. In addition, SFA fails to deal with the multi-input and output situation (Rao et al. 2003). Therefore, Battese et al. (2004) expanded their research and addressed the aforementioned problems using the DEA model.

2.1.1 Meta-frontier and group-frontier

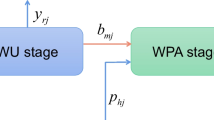

While the meta-frontier indicates the potential technology level of all DMUs, the group-frontier is the actual technology level of DMUs in each group. Thus, the main difference between them is the technology set. For this reason, the 30 provinces in mainland China (excluding Tibet due to data missing) are divided into eastern, central and western groupsFootnote 2 according to the homogeneity of industrial development. Though the three regions are roughly partitioned here, they have always been adopted in regional economy and industrial development in China. According to the rule of thumb of DEA on the number of variables and DMUs, it is more suitable to divide the groups generally. Besides, there is a tendency of gradient development in the three regions in terms of water resources per capital, natural resources, level of urbanization, industrial structure, level of industrialization etc. The differences within regions are smaller than those between regions. Therefore, it is necessary and reasonable to divide the provinces into three groups to investigate industrial water use efficiency under each group-frontier and meta-frontier. As a demonstration, using a meta-frontier model with one input and one output, the group-frontiers and meta-frontier are shown in Fig. 1.

Based on the meta-frontier (Battese et al. 2004) (Model 1), the meta-technology set incorporated in undesirable outputs is:

where the vectors of the input, desirable output and undesirable output are denoted by x, y g and y b, respectively. The corresponding production possibility frontier (meta-frontier) is:

Let D m (x, y g, y b) represent the input meta-distance function defined using the meta-technology T m, which is defined by:

Dividing 30 provinces in mainland China into three groups (i = 1, 2, 3) according to the level of industrial development, the group-technology set is:

The corresponding production possibility frontier (group-frontier) is:

Let D i(x i , y g i , y b i ) denote the input group-distance function for region i (i = 1, 2, 3) technology, which is defined by:

For any input vector, x i belongs to the boundary of \(P^{i} \left( {y^{g} , \, y^{b} } \right)\), \(D^{i} \left( {x_{i} , \, y_{i}^{g} ,y_{i}^{b} } \right) > 1\), and if x i belongs to the interior of \(P^{i} \left( {y^{g} , \, y^{b} } \right)\), then D i(x i , y g i , y b i ) = 1.

To ensure the convexity property, the study defines the meta-technology as the convex hull of three group-technologies, denoted by \(T^{m} = {\text{Convex}}\,{\text{Hull}}{\kern 1pt} \,\left\{ {T^{1} \cup T^{2} \cup T^{3} } \right\}\).

2.1.2 Technology gap ratio

The input-orientated technical efficiency of an observed input–output set \((x_{i} , \, y^{g} , \, y^{b} )\), with respect to the technology of group i (i = 1, 2, 3), is defined as:

The input-orientated technology gap ratio can be defined using the distance functions from technologies T m and T i as:

For example, in province R in Fig. 1, the technology gap ratio is:

The technology gap ratio combines the meta-frontier with the group-frontier and measures the same DMU’s difference of technical efficiency under meta-frontier and group-frontier. If the TGR is higher (or TGR equals 1), the actual efficiency will be close to the potential production efficiency. Moreover, it can be used to judge the necessity of dividing into different groups. If the mean of the TGR is less than 1, dividing different groups is appropriate and necessary, and vice versa.

2.2 SBM-undesirable model

Many DEA models can solve the group-distance and meta-distance functions that include industrial water pollution (Liu and Wu 2011). However, such methods, including the transposed method, the hyperbolic method and the direction distance function, either violate the essence of production or have obvious limitations. For instance, when undesirable output and desirable output will decrease and increase proportionally, it cannot address the slacks in input–output models. However, the SBM model (Tone 2004) directly introduces the slack values of input and output to the objective function, which solves the aforementioned problem and radial orientation bias. Therefore, the industrial water use efficiency is measured under the SBM-undesirable model, evaluating the relative efficiency of DMU0 incorporated the industrial pollutants as followings (Model 2):

where X, Y g, Y b represent the input, desirable output and undesirable output for one province each year, respectively. The meta-frontier represents 30 provinces, while the group-frontier includes corresponding provinces for each group in the eastern, central and western regions. Moreover, s −, s g and s b denote the slacks of input, desirable output and undesirable output, respectively. The objective function strictly decreases with respect to \(s_{{^{i} }}^{ - } \left( {\forall i} \right)\), s g r (∀r), s b r (∀r) and the objective function value satisfies 0 < ρ * ≤ 1. An optimal solution of the above program is (ϕ *, s −*, s g*, s b*). The DMU0 is efficient in the presence of undesirable outputs if and only if ρ * = 1, i.e., \(s^{ - *} = 0,s^{g*} = 0,\,{\text{and}}\,{\kern 1pt} s^{b*} = 0\). If the DMU0 is inefficient, i.e., ρ * < 1, it can be improved and become more efficient by deleting the excesses in inputs and undesirable outputs.

If the industrial water consumption (X w ) and its slacks (S − w ) are isolated from the input variable vector (X), the industrial water use efficiency under meta-frontier can be denoted by \({\text{TE}}_{w}^{m} = (X_{w}^{m} - S_{w}^{ - m} )/X_{w}^{m}\), while the industrial water use efficiency under group-frontier is \({\text{TE}}_{w}^{i} = (X_{w}^{i} - S_{w}^{ - i} )/X_{w}^{i}\) (i = 1, 2, 3). Similarly, the study can define the TGR of industrial water as \({\text{TGR}}_{w} = {\text{TE}}_{w}^{m} /{\text{TE}}_{w}^{i}\). And whether the means of \({\text{TE}}_{w}^{m}\) and \({\text{TE}}_{w}^{i}\) show a huge difference or TGR w is significantly smaller than one, the partition of three groups is necessary to study the industrial water use efficiency.

2.3 Data

In the research, industrial water consumption (indu_water), industrial workers (labor), and industrial net assets (net_asset) are selected as input indicators, while output indicators include desirable output: industrial added value (VA) and undesirable outputs of chemical oxygen demand (COD) and ammonia nitrogen (NH3-N) emissions in industrial wastewater. After industrial water use efficiency scores are determined, the influencing factors on efficiency will be examined. The data have been derived from the China environment Statistical Yearbook (2000–2014), China Statistical Yearbook and 30 Provinces Statistical Yearbook (2000–2014), China’s water resources bulletin (1999–2013), China Compendium of Statistics 1949–2008, and other databases such as SouShuFootnote 3 and Ceinet statistics databaseFootnote 4 etc. All price indicators are deflated to the 1999 constant price. The level of industrialization is denoted by the ratio of industrial added value over total GDP, the prices of industrial water of cities at prefectural level for each province are collected from China Water Net (1999–2013),Footnote 5 and the average prices are treated as proxies of the price of industrial water for corresponding provinces. The mean of prices is also taken in prefecture-level cities. Descriptive statistics about input and output indicators and the influencing factors of industrial water use efficiency are shown in Table 1.

3 Industrial water use efficiency

According to the testing results, the mean of technology gap ratios is significantly smaller than 1. The average technology gap ratio in the eastern group is at a higher level (close to 1) from 1999 to 2013, indicating that the eastern group is close to the meta-frontier. The central and western groups, however, are far from it. It proves again that dividing the provinces into three groups is reasonable according to the level of industrial development.

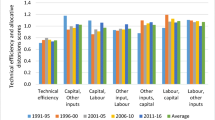

Firstly, the industrial water use efficiency in the eastern, central and western regions is estimated under meta-frontier and group frontier along the temporal trend using a meta-frontier model. The results are displayed in Figs. 2, 3.

Figure 2 indicates that, in average, the efficiency in the eastern region under meta-frontier between 1999 and 2013 is higher than that in the central and western regions. In particular, industrial water use efficiency in the eastern region is higher, though it supposes a downward trend. However, the efficiency values in the central and western regions are lower. Therefore, the technology frontiers in the central and western regions are far behind the meta-frontier in the eastern region, indicating more room for technology improvement.

The efficiency trend under group frontier is not the same as that under meta-frontier, which further proves the necessity to divide the provinces into three groups. In practical terms, the average efficiency value in the eastern region shows a downward trend from 1999 to 2009 (except in 2003 and 2004). It goes upward in 2010, but declines again from 2011 to 2013. However, the average efficiency value in the central and western regions changes slightly, as Fig. 3 showed.

Moreover, this paper compares the average efficiency scores of the 30 provinces in mainland China under meta-frontier and group frontier between 1999 and 2013 (Table 2).

As for the average technology gap ratio, the TGR in the eastern region is 0.9777, meaning that the eastern-frontier reaches 97.77 % of the meta-frontier. This is mainly due to the fact that the eastern region enjoys the best economy and pays much attention to the introduction and dissemination of technologies. Similarly, the central and western regions reach 66.86 and 47.70 %, respectively. In terms of the average efficiency in the eastern, central and western regions under meta-frontier, there is much room for improvement in the three regions (22.53, 47.86 and 61.64 %, respectively). As for the average efficiency score group-frontier, it is 20.76, 22.02 and 19.60 % for the eastern, central and western regions, respectively.

As for the industrial water use efficiency among the provinces, Beijing, Tianjin, Shanghai, Shandong in the eastern region and Heilongjiang in the central region under meta-frontier and group frontier exhibit the best performance, with a full score of 1. Hainan performs the worst in the eastern region, with a score of 0.2504. Similarly, Jilin is the worst in the central region under meta-frontier, and Hubei under group frontier, with efficiency scores of 0.3226 and 0.5049, respectively. In the western region, Inner Mongolia performs the best, and Qinghai the worst under meta-frontier, with room for efficiency improvement of 17.82 and 84.54 %, respectively. As for the group frontier, the efficiency scores are 1 for Inner Mongolia, Guangxi and Shaanxi, while the lowest score is in Qinghai, 0.5070, which implies room for efficiency improvement of 49.30 %.

Thus, there is a vast difference for the industrial water use efficiency between meta-frontier and group-frontier, probably because large technology gaps exist among the 30 provinces in mainland China with respect to the two technology frontiers. Overall, only a few provinces enjoy high industrial water use efficiency in the three regions. Most provinces, particularly those in the central and western regions, get scores of less than 50 %. So the conclusion comes to that industrial water use efficiency is generally low in mainland China. In other words, industrial water is still extensively used in China, which might be caused by low level of water use technologies, low price of industrial water, unreasonable industrial structure and other factors.

4 Major influencing factors of industrial water use efficiency

4.1 The mechanism for influencing industrial water use efficiency

According to the general law of economics, industrial water use efficiency in China might be influenced by the following factors.

The first factor is the abundance of water resources. Apparently, if a region has a large amount of water, it will have a low price. Consequently, people will be less aware of water-saving activities, thus leading to low industrial use water efficiency. This paper uses the total water resources and water resources per capita in mainland China to measure the efficiency. Compared with total water resources, analysis of water resources per capita considers demographic factors. Therefore, both indicators are used to better explore the negative effect of the first factor on the efficiency.

The second factor is the water price. According to the general theory of economics, the price is the most effective means for market regulation to determine the resource use efficiency. Generally, the higher the water price is, the higher the industrial water use efficiency will be in a region. Thus, the price of industrial water has a positive effect on the efficiency. The price of industrial water in any prefecture-level cities of a province (further calculating their mean as the water price of the province) is able to unveil its effects.

The third factor is the level of economic development and industrialization. The study investigates whether the industrial water use efficiency improves with increasing GDP per capita or exhibits an inverted U-shaped as some literature suggest, meaning that the efficiency improves first and then decreases as the GDP per capita increases. The level of industrialization is also an important factor that influences the efficiency. In fact, it directly determines industrial water consumption and affects the efficiency through the income effect and the technology effect. On the one hand, when the industry is more developed, the income will be higher and the sensitivity to water price lower, leading to weaker water-saving awareness and thus lower efficiency for enterprises. On the other hand, developed industry encourages enterprises to use more efficient water-saving technologies, thus improving the industrial water use efficiency. So this influencing factor represents two conflicting effects. If the technology effect is greater than the income effect, the efficiency will improve, and vice versa.

The fourth factor is water-saving technology and regulation of industrial water pollution. The technology can be expressed by industrial water consumption per ten thousand Yuan industrial value-added and industrial water reuse rate. Obviously, the lower the water consumption per unit output is, the higher industrial water use efficiency will be. Likewise, the higher the industrial water reuse rate is, the higher industrial water use efficiency will be. In addition, since the environmental quality is considered when measuring the industrial water use efficiency in this paper, the investment in industrial pollution regulation may also exert a significant impact on the industrial water use efficiency.

4.2 Modeling and regression results

To better discover the industrial water use efficiency and its differences, the paper is focusing on the investigation of its influencing factors. The regression equations between the industrial water use efficiency under meta-frontier and group-frontier and influencing factors (such as the price of industrial water) are as follows (Model 3):

where Y t includes three variables: the logarithm of GDP per capital (lny), its square and the level of industrialization (ind). Z j includes three variables: the water consumption per ten thousand Yuan industrial value added (tc), industrial water reuse rate (cycle) and the logarithm of investment in industrial water pollution regulation (lninvest).

Since the efficiency scores in some provinces in mainland China are 1, this paper uses the model of special dependent variable to distinguish the differences among these provinces. It is a Tobit model that can truncate from the left and right tails (Two-limit Tobit). Since the treated efficiency scores are between 0 and 100, the right of the Tobit model is truncated at 100. Additionally, the estimator of the fixed-effect Tobit model for panel data is proved to be biased (Anderson and Hsiao 1982). Honoré (1992) has developed a semi-parametric estimator for the fixed-effect Tobit, model with some conditional restrictions in the process. There is, however, no effective solution for this problem, so the academic community mostly uses the random-effects Tobit model at present. Its form is as follows (Model 4):

where \(e_{it}^{*}\), e it , \(E_{it}^{{\prime }}\), v i and ɛ it state a latent variable, an observed variable, a vector of explanatory variables, a random variable that changes with individuals rather than time and a random variable that changes with individuals and time, respectively. The latter two random variables are independent and follow normal distribution. η is a constant, and δ is a parameter vector.

Regression results of the Tobit model between industrial water use efficiency and influencing factors (the current price of industrial water) under meta-frontier and group frontier are shown in Table 3.

Table 3 illustrates that p values of the four models are all zero, meaning that they are significant. In addition, rho values are all above 0.82, showing that the efficiency change is mainly explained by the change of individual effect.

As for the logarithm of GDP per capita and its square, the relationship is U-shaped, showing a trend that the industrial water use efficiency decreases first and then increases with the growth of the logarithm of GDP per capita. The turning point of the U-shaped is around 18,582.95 Yuan. The actual GDP per capita in mainland China is 7,555.27, which is still at the left side of the turning point. So the industrial water use in mainland China is still in the period when industrial water use efficiency declines with the increase of GDP per capita.

Firstly, there are only negative relationships between water resources per capita and industrial water use efficiency under meta-frontier and group frontier, i.e., the higher the water resources per capita is, the lower industrial water use efficiency will be. Secondly, the relationship between industrial water use efficiency under meta-frontier and water consumption per ten thousand Yuan GDP is negative, while the relationships between them under three group frontiers are positive, though not statistically significant. Thirdly, industrial water use efficiency under meta-frontier and the technology gap ratio are positively correlated and the coefficient is 76 %, which proves again it necessary and reasonable to divide the provinces into three groups when measuring industrial water use efficiency. Fourthly, the relationship between industrial water use efficiency and the industrial water reuse rate is significantly positive as a whole. The higher the industrial water reuse rate is, the higher the industrial water use efficiency will be. Fifthly, the relationships between the level of industrialization and industrial water use efficiency under meta-frontier and group frontier are positive. It indicates that the technology effect will be larger than the income effect when the level of industrialization is higher. Sixthly, under meta-frontier, the relationship between industrial water use efficiency and the current price of industrial water is positive, but not significant. Though the relationship under the eastern group is negative yet not significant, they are significant under the central group and the western group, with one positive and the other negative. The results indicate that the current price of industrial water fails to reflect the actual status of water resources accurately. Finally, the relationship between industrial water use efficiency and the investment in industrial water pollution management is not significantly positive, meaning the latter does not play an appropriate role in improving efficiency.

5 Further discussion of price distortion

According to the results above, the current price of industrial water fails to accurately reflect the scarcity of water resources in the eastern, central and western regions. The main reason is probably that the price of industrial water in mainland China follows a non-market pricing behavior. It has followed the government pricing model for a long time. Additionally, to maximize tax revenue under a fiscally decentralized system, many local governments implement various preferential policies, such as the low price of land, water, electricity, etc., to attract foreign investment, leading to further distortion of industrial water price. Therefore, the research not only collects the current price of industrial water, but also estimates the shadow price of industrial waterFootnote 6 to measure the real market price and compare the difference. Then, the study examines the effects of the two prices on industrial water use efficiency, respectively, and determines whether the price of industrial water has been distorted. The estimation of that the current industrial water price does not play an appropriate role in improving the efficiency and is much lower than the shadow price. The shadow price of industrial water is more likely to exert more positive effects on efficiency improvement than the current price.

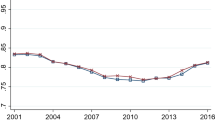

To reveal the underlying relationship between the price of industrial water and its efficiency, the shadow price is used to investigate the effect of real market price on industrial water use efficiency. The difference between the shadow price and the current price of industrial water is shown in Fig. 4.

There is a big gap between the current price and the shadow price of industrial water, which is calculated by the dual price of the SBM model under meta-frontier (see the “Appendix”). The current price of industrial water is 2.7 Yuan/m3 during the research period, while the shadow price is 36.3 Yuan/m3, which is 12 times higher than the former. This difference is clearly indicated in Fig. 4. So the research reveals that the lower price of industrial water has been seriously deviated from the real price in a complete market, leading to the adverse effect on efficiency. To test this estimate, the current price of industrial water is replaced with the shadow price under meta-frontier and group-frontier, and kept the other variables unchanged. To testify this estimate, the current price of industrial water is replaced with the shadow price under meta-frontier and group frontier, while the other variables kept unchanged.

The regression results of the Tobit model between industrial water use efficiency and the influencing factors (including the shadow price of industrial water), with the current price replaced with the “real” price of industrial water, under meta-frontier and group-frontier are shown in Table 4.

Compared with that in Table 3, the relationship between industrial water use efficiency and GDP per capita also exhibits a U-shaped (Table 4). Besides under meta-frontier, the turning points under group-frontier in the eastern, central and western regions are at around 10,488.14 Yuan, which is higher than the actual GDP per capita. The correlation between industrial water use efficiency under meta-frontier and the shadow price is significantly positive, while for the current price, it is not significant in Table 3. So these results illustrate that the shadow price of industrial water can better reflect the scarcity of water resources, thus helping to improve industrial water use efficiency. The correlation between efficiency and the shadow price is not significant in the eastern region, but the significance level in the central and western regions changes from 10 to 1 % relative to the current price, meaning that the shadow price will have a more significant positive effect on efficiency improvement.

The effects of shadow price on the efficiency in the three regions of China are different, which largely stems from the different level of economic development, the specific natural resource conditions and the unbalanced industrial development. To better explain the effect of the change in shadow price for example on the efficiency. In order to describe in numerical values the effect of the change in shadow price on the efficiency, the data graph is obtained as below:

As shown in Fig. 5, a sensitivity analysis shows the effect of the changes. The efficiency improves 0.3 % when the shadow price of industrial water raises 1 Yuan and is statistically significant.

6 Conclusions and policy implications

The shortage of water resources has become a bottleneck for industrial development in mainland China, and industrial water pollution further deteriorates industrial water supply and industrial development. So it is necessary to study industrial water use efficiency under both constraints. The research investigates the industrial water use efficiency of 30 provinces in mainland China under the two constraints of industrial water resources and industrial water pollution. Then, the research introduces an undesirable output (industrial water pollutants) to the DEA-SBM model and tests the industrial water use efficiency of 30 provinces using the meta-frontier model according to the difference of industrial development technology in detail. Finally, the effect of industrial water price and its distortion on industrial water use efficiency is obtained. In summary, the conclusions are as following:

-

(a)

The empirical results show that the technology gap ratio in the eastern region is close to 1, while it successively decreases in the central and western regions. The values of the TGR in the central and western regions are 0.632 and 0.401, respectively. So it would be difficult to accurately measure the industrial water use efficiency in these 30 provinces if the heterogeneity of industrial technology among these three regions is neglected. The research adopts the meta-frontier and SBM-undesirable models to address this issue.

-

(b)

Although industrial water use technology has improved continuously, industrial water use efficiency does not increase over the years, and even decreases when industrial water pollution is taken into consideration. After controlling other influencing factors, such as regional economic development, the level of industrialization, industrial water-saving technology, and industrial water pollution governance, the current price of industrial water does not exert any positive impact on efficiency improvement.

-

(c)

After estimating the “real” market price of industrial water, there is a big difference between the shadow price and the current price of industrial water. The current price has been distorted and fails to play an appropriate role in improving the allocation of water resources. By replacing the current price with the shadow price, it shows that the industrial water use efficiency will increase by 2.63 % when the shadow price increases by 1 %. The regression results in three regions display the same trend.

The above results have important policy implications, which are as follows:

-

(a)

The industrial water use efficiency is influenced by not only industrial development and the utilization status of water resources, but also industrial water pollution control. So water resources governance also plays an important role in improving industrial water use efficiency. Therefore, to improve industrial water use efficiency, the value and sustainability of water resources should be taken into account.

-

(b)

When exploring industrial water use efficiency, the difference in the industrial water use technologies in three regions should be also considered. The eastern region enjoys more advanced water-saving technologies. Hence, the eastern region should effectively promote economic development in the process of industrial transfer by using the advanced industrial water-saving technology. In addition, the study supposes more investment in water-saving technologies in the central and western regions to upgrade the industrial water use technologies, so as to improve industrial water use efficiency.

-

(c)

It is necessary to gradually raise the price of industrial water according to the current situation of water resources and water pollution governance. The ladder pricing system of industrial water should also be implemented to redress the current price distortion gradually. When the price of industrial water accurately reflects the value of water resources, it will address the problem of industrial wastewater more effectively.

Notes

The authors selected 13 provinces as DMUs and indicators of three inputs and three outputs. The number of DMU is less than twice the product of the number of input and output variables.

The east group includes Beijing, Tianjin, Hebei, Liaoning, Shanghai, Jiangsu, Zhejiang, Fujian, Shandong; the central group includes Shanxi, Jilin, Heilongjiang, Anhui, Jiangxi, He’nan, Hubei, Hu’nan; the west group includes Inner Mongolia, Guangxi, Chongqing, Sichuan, Guizhou, Yunnan, Shaanxi, Gansu, Qinghai, Ningxia, Xinjiang.

The shadow price of industrial water can be interpreted as the economic cost of industry when reducing unit water consumption and reflects the marginal cost of industrial water.

References

Anderson, T. W., & Hsiao, C. (1982). Formulation and estimation of dynamic model using panel data. Journal of Econometrics, 18, 47–82.

Bathla, S. (1999). Water resource potential in northern India: Constraints and analyses of price and non-price solutions. Environment, Development and Sustainability, 1(2), 105–121.

Battese, G. E., O’Donnell, C. J., & Rao, D. S. P. (2004). A meta-frontier frameworks production function for estimation of technical efficiency and technology gap for firms operating under different technology. Journal of Productivity Analysis, 21(1), 91–103.

Battese, G. E., & Rao, D. P. (2002). Technology gap, efficiency, and a stochastic metafrontier function. International Journal of Business and Economics, 1(2), 87–93.

Chowdhury, S., & Al-Zahrani, M. (2014). Fuzzy synthetic evaluation of treated wastewater reuse for agriculture. Environment, Development and Sustainability, 16(3), 521–538.

Coggins, J. S., & Swinton, J. R. (1996). The price of pollution: A dual approach to valuing SO2 allowances. Journal of Environment Econometrics Management., 30(1), 58–72.

Dyson, R. G., Allen, R., Camanho, A. S., et al. (2001). Pitfalls and protocols in DEA. European Journal of Operational Research, 132, 245–259.

Fujii, H., Managi, S., & Kaneko, S. (2012). A water resource efficiency analysis of the Chinese industrial sector. Environmental Economics, 3(3), 82–92.

Honoré, B. E. (1992). Trimmed LAD and least squares estimation of truncated and censored regression models with fixed effects. Econometrica., 60(3), 533–565.

Hu, J. L., Wang, S. C., & Yeh, F. Y. (2006). Total-factor water efficiency of regions in China. Resources Policy., 31, 217–230.

Latinopoulos, D. (2009). Multicriteria decision-making for efficient water and land resources allocation in irrigated agriculture. Environment, Development and Sustainability, 11(2), 329–343.

Lee, M. (2005). The shadow price of substitutable sulfur in the US electric power plant: A distance function approach. Journal Environment Manage., 77, 104–110.

Liu, Y. H., & Wu, P. (2011). Energy consumption, carbon dioxide emission and regional economic growth in the APEC economies. Economic Review., 6, 109–120. (In Chinese).

Lu, L. (2008). Research on industrial water efficiency of Zhejiang province. Zhejiang: School of Economics, Zhejiang University. (In Chinese).

Malley, Z. J. U., Taeb, M., Matsumoto, T., & Takeya, H. (2008). Linking perceived land and water resources degradation, scarcity and livelihood conflicts in southwestern Tanzania: Implications for sustainable rural livelihood. Environment, Development and Sustainability, 10(3), 349–372.

Mwanza, D. D. (2003). Water for sustainable development in Africa. Environment, Development and Sustainability, 5(1–2), 95–115.

Pan, D., Huang, W., Wang, S. P., et al. (2011). DEA-based study on water use efficiency: A case study of Yunnan Province. Journal of Yangtze River Scientific Research Institute., 28(12), 15–18. (In Chinese).

Qian, W. J., & He, C. F. (2011). China’s regional difference of water resource use efficiency and influencing factors. China Population, Resource and Environment., 21(2), 54–60. (In Chinese).

Rao, D. S. P., O’Donnell, C. J., & Battese, G. E. (2003). Metafrontier functions for the study of inter-regional productivity differences. Working paper no. 01/2003, Centre for Efficiency and Productivity Analysis, School of Economics, The University of Queensland.

Rimawi, O., Jiries, A., Zubi, Y., & El-Naqa, A. (2009). Reuse of mining wastewater in agricultural activities in Jordan. Environment, Development and Sustainability, 11(4), 695–703.

Romano, G., & Guerrini, A. (2011). Measuring and comparing the efficiency of water utility companies: A data envelopment analysis approach. Utilities Policy., 19, 202–209.

Schneider, M., & Whitlatch, E. (1991). User-specific water demand elasticities. Water Resources Planning and Management, 117(1), 52–73.

Sun, A. J., Dong, Z. C., & Wang, D. Z. (2007). Prediction of technical efficiency and water consumption of industrial use water in China based on time series. Journal of China University of Mining & Technology, 36(4), 547–553. (in Chinese).

Sun, C. Z., & Liu, Y. Y. (2009). Analysis of the spatial-temporal pattern of water resources utilization relative efficiency based on DEA-ESDA in China. Resources Science, 31(10), 1696–1703. (in Chinese).

Tone, K. (2004). Dealing with undesirable outputs in DEA: A slacks-based measure (SBM) approach. Presentation at NAPW III, Toronto, pp. 44–45.

Yue, L., & Zhao, H. T. (2011). China’s water use efficiency of industry under environmental constraints based on data of 13 industrial regions during the period 2003 to 2009. Resources Science, 33(11), 2071–2079. (in Chinese).

Acknowledgments

The research is supported by the National Natural Science Foundation of China under Grants (Nos. 71103057 and 71473068). We greatly appreciate the assistance from Prof. Yanrui Wu at the Business School, University of Western Australia for our research.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

1.1 The derivation process of the shadow price of industrial water incorporating the industrial water pollution

The dual form of the SBM-undesirable model can be written as follows:

where s = s1 + s2, and denote v ∊ R m, u g ∊ R s1 and u b ∊ R s2 as the virtual price of input, desirable output and undesirable output, respectively. Similarly, this paper isolates the dual variable (V W ) of industrial water input from v. Assuming that absolute shadow price of the desirable output is equal to its market price, so the relative shadow price of industrial water compared with industrial production is as follows: \(p^{w} = p^{{y^{g} }} \cdot {{v_{w} } \mathord{\left/ {\vphantom {{v_{w} } {u^{g} }}} \right. \kern-0pt} {u^{g} }}\). It can be interpreted as water price per unit industrial output, or the reduced industrial output by saving per unit water (Coggins and Swinton 1996; Lee 2005). The shadow price can measure the real price of industrial water when it cannot be got directly or distorted seriously. This paper mainly compares the average price of 30 provinces in mainland China with the shadow price to investigate whether the current price of industrial water has been distorted. In addition, this paper explores its effect on industrial water use efficiency.

Rights and permissions

About this article

Cite this article

Li, J., Ma, Xc. Econometric analysis of industrial water use efficiency in China. Environ Dev Sustain 17, 1209–1226 (2015). https://doi.org/10.1007/s10668-014-9601-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10668-014-9601-2