Abstract

Bisphenol A (BPA) is an essential and extensively utilized chemical compound with significant environmental and public health risks. This review critically assesses the current water purification techniques for BPA removal, emphasizing the efficacy of adsorption technology. Within this context, we probe into the synthesis of magnetic biochar (MBC) using co-precipitation, hydrothermal carbonization, mechanical ball milling, and impregnation pyrolysis as widely applied techniques. Our analysis scrutinizes the strengths and drawbacks of these techniques, with pyrolytic temperature emerging as a critical variable influencing the physicochemical properties and performance of MBC. We explored various modification techniques including oxidation, acid and alkaline modifications, element doping, surface functional modification, nanomaterial loading, and biological alteration, to overcome the drawbacks of pristine MBC, which typically exhibits reduced adsorption performance due to its magnetic medium. These modifications enhance the physicochemical properties of MBC, enabling it to efficiently adsorb contaminants from water. MBC is efficient in the removal of BPA from water. Magnetite and maghemite iron oxides are commonly used in MBC production, with MBC demonstrating effective BPA removal fitting well with Freundlich and Langmuir models. Notably, the pseudo-second-order model accurately describes BPA removal kinetics. Key adsorption mechanisms include pore filling, electrostatic attraction, hydrophobic interactions, hydrogen bonding, π-π interactions, and electron transfer surface interactions. This review provides valuable insights into BPA removal from water using MBC and suggests future research directions for real-world water purification applications.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Water is an essential natural resource for life on Earth, crucial for humans and the environment. However, in recent years (2017–2023), water quality has deteriorated significantly due to rapid industrialization, population growth, urbanization, and unsustainable resource use (Zamora-ledezma et al., 2021). This has led to a pressing issue in environmental studies, with plastic waste in water emerging as a significant concern due to its detrimental effects on public health and aquatic ecosystems. Notably, water pollution results from xenobiotic contaminants, including endocrine-disrupting chemicals (EDCs) and various pharmaceutical compounds, in drinking water and the release of wastewater into the environment (Rong et al., 2019a). Among these emerging pollutants, bisphenol A (BPA) is particularly noteworthy, given its widespread use in various plastic products, despite being classified as an EDC by the US Environmental Protection Agency (Chu et al., 2021). As such, research on removing BPA from water has become indispensable.

BPA is one of the most extensively produced synthetic chemical compounds globally, with an annual production exceeding three million tons (Mileva et al., 2014). It pervades our environment, with exposure occurring through drinking water, food, dental sealants, dermal contact, and even the ingestion of household airborne particles (R. ping Huang et al., 2017). Due to its persistent and non-biodegradable nature, BPA poses significant challenges for removal, making it crucial to explore effective techniques, as detailed in Table 1.

The motivation behind this review stems from the urgent need to address environmental contamination caused by bisphenol A (BPA) in aqueous solutions. BPA is a pervasive chemical compound used extensively in industrial processes, posing significant threats to public health and the environment. Conventional water purification methods often fall short in effectively removing BPA, necessitating the exploration of alternative techniques. Magnetic biochar (MBC) emerges as a promising solution due to its unique properties and adsorption capabilities. By reviewing the current state of research on MBC’s efficacy in BPA removal, this study aims to provide insights into its potential as a sustainable and efficient approach for wastewater purification.

This review presents a novel and broad exploration of removing bisphenol A (BPA), a significant environmental emerging pollutant from aqueous solutions. It critically assesses various water purification techniques and emphasizes the efficacy of adsorption technology, particularly MBC. The synthesis methods for MBC using diverse approaches, including co-precipitation, hydrothermal carbonization, mechanical ball milling, and impregnation pyrolysis, are thoroughly scrutinized.

In addition, the article highlights a critical research gap by pointing out the absence of dedicated reviews on BPA removal using MBC in aqueous solutions, emphasizing the novelty and importance of this work in addressing environmental and public health concerns related to BPA contamination while proposing directions for future research in water purification applications.

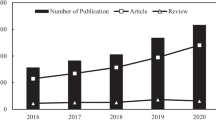

This review needs to deal with the environmental and public health concerns related to bisphenol A (BPA) contamination in aqueous solutions from 2017 to 2023. Specifically, the review aims to identify the efficacy of magnetically induced biochar in removing BPA from aqueous solutions. The study is indispensable to provide insights into sustainable and practical methods for BPA removal, which can contribute to developing efficient water treatment strategies.

Hence, the primary goal of this review is to address the environmental and public health concerns stemming from BPA contamination in aqueous solutions from 2017 to 2023. The specified review period, from 2017 to 2023, is chosen to ensure that the review remains pertinent to contemporary issues and scientific advancements related to BPA contamination in aqueous solutions. This timeframe captures the recent developments in BPA research and acknowledges potential advances in BPA removal technologies, thus providing up-to-date information on effective removal strategies. Specifically, it aims to assess the effectiveness of magnetically induced biochar in removing BPA from aqueous solutions. This review contributes to developing efficient water treatment strategies by elucidating sustainable and practical BPA removal methods.

BPA is a lipophilic compound that could be accrued in organisms via food webs and consequently may trigger damage to living beings (Lee et al., 2015). Its exposure may stimulate diverse public health concerns, like heart disease, diabetes, prostate cancer, and liver enzyme malfunctions (Katibi et al., 2021a, b, c). Several scientific studies have described numerous harmful effects of BPA on the ecosystem and their tendency to interfere with ecological stability. Recently, various reports have emphasized several health aftermaths connected with BPA, namely, obstruction with the endocrine system of living beings by affecting the synthesis, passage, release, metabolism, and generation of hormones within the body (Katibi et al., 2021a, b, c). Furthermore, there have been reports that have brought to light several ways through which this may occur, such as liver damage, disturbance of pancreatic cell function, interference with the process of thyroid hormone, and stimulation of obesity (Wang et al., 2019a, b). Hence, it is essential to consider efficient techniques to remove BPA caused by the accretion and stability of BPA.

Preparation of magnetic biochar

The abundant porous structure of biochar makes it highly receptive to aromatic organic compounds, thus making it a promising material for exterminating BPA from water (Liu & Zhang, 2011; Zhang et al., 2020a, b). Undesirably, the small particle nature and low biochar density make its recovery after the adsorption process challenging. Removing the biochar residue from the environmental medium following the adsorption process usually necessitates further steps, such as filtration and centrifugation, which may undermine the practicality of biochar applications and result in secondary pollution (Hairuddin et al., 2019; Huang et al., 2022). Based on these drawbacks, scientific studies have focused on exploring the potential of magnetism as an efficient, eco-friendly recovery strategy for biochar adsorbents (Santhosh et al., 2020; Zhang et al., 2023).

MBC can be detached and regenerated from the aqueous media using external magnets and recycled. MBC-based materials could enhance biochar’s chemical and physical characteristics and obtain a usable and regenerative property with other magnetic materials (Zhang et al., 2022). The magnetic medium increases the performance of biochar by loading magnetic species materials onto the biochar through chemical, physical, and other techniques (Huang et al., 2019a, b) (Fig. 1).

Chemical co-precipitation, Impregnation-pyrolysis, Hydrothermal carbonization, and mechanical ball milling Co-precipitation, hydrothermal carbonization, impregnation pyrolysis, and mechanical ball milling techniques are the primary synthesis techniques for the production of MBC (Fig. 2). The succeeding section will provide a detailed discussion of these techniques.

Co-precipitation (CP) technique

In the co-precipitation technique, the preparation of MBC involves the dispersal of biochar in a solution comprising transition metals, succeeded by the infusion of ammonium hydroxide or sodium hydroxide medium under a specific temperature, and stirring of the solution for a certain period under (9–11) pH. Afterwards, the supernatant is eliminated, the residue is rinsed, and later oven-dried to obtain MBC (Fig. 2a).

Lately, reports have been performed to scientifically compare the contaminant adsorption abilities of MBC prepared using the two techniques. For instance, Zhou et al., (2019a, b) observed that the MBC synthesized by impregnation pyrolysis eliminated fluoride more efficiently than the MBC prepared by the CP technique. Conversely, Wang et al. (2015) reported that MBC synthesized by the CP approach recorded an adsorption performance for arsenic that was almost seven times higher than that of MBC produced by impregnation pyrolysis. Thus, the physicochemical characteristics of target contaminants should be given adequate consideration during the preparation of MBC for contaminant remediation to assist in choosing the suitable preparation technique. The CP technique commonly utilizes Fe2+ and Fe3+ as magnetic precursor mediums (Eq. (1)). Moreover, the produced Fe3O4 is typically unsteady and transformed into Fe2+ and γ-Fe2O3 (Eq. (2)) (Feng et al., 2021).

Synthesis of MBC using the CP approach is facile and modifiable, and the acquired product has superior purity (Feng et al., 2021; Yi et al., 2020). For instance, a magnetic detachable nanocomposite with elevated magnetic characteristics was produced by embedding manganese ferrite nanoparticles on biochar via the CP technique and exhibited a high Pb(II) sorption capacity of (249.00 mg/g) in water. This technique has the superiority of being a time-saving and streamlined process, easier reaction conditions, and superior product purity, is more controllable, and permits the magnetic solution to be firmly stuck to the biochar medium. However, it is more complex than the impregnation pyrolysis technique.

Conversely, difficulty in scaling up the MBC production, the prospect of toxic chemical residues from the process, complications in achieving a homogenous MBC material with desired characteristics, the requirement of an enormous amount of alkaline reagents, and incremental operational cost are some of the drawbacks of the CP technique (Feng et al., 2021). Not only that, but alkaline solutions also need to be simultaneously treated for environmental sustainability.

The production of MBC using the CP technique is typically carried out in batch systems in the laboratory. However, scaling up the synthesis process to produce large quantities of MBC is highly desirable for practical applications. There is still a need to conduct long-term stability, risk, and toxicity studies to better understand environmental and public safety in addition to the efficacy of MBC.

Impregnation pyrolysis (IP) technique

MBC can be prepared using the impregnation pyrolysis technique. Preparing MBC typically involves impregnating the biomass/feedstock in a solution containing transition metal ions, the magnetic precursor. Afterwards, the solvent is evaporated, and the resultant dried residue material is pyrolyzed in an oxygen-free or inert atmosphere environment, using a muffle furnace, at a temperature ranging from 300 to 1000 ℃ to produce MBC (Qu et al., 2022a, b) (Fig. 2b). Hence, in this context, pyrolysis, as well as magnetization, takes place successively, thus safeguarding that the adsorption capacity and physicochemical characteristics of the MBC are likely to be strongly regulated by the pyrolysis variables (such as inert gas, pyrolytic temperature, and operating time) (Du et al., 2020). The processes for synthesizing MBC using iron salt (magnetic medium) via this approach are described in Eqs. (3)–(5):

The pyrolysis temperature plays an indispensable role in the production of MBC and can influence the nature of the resultant output generated (H. Li et al., 2017a, b). For instance, as the temperature rises during the synthesis of FeCl3-saturated biochar, iron oxide (γ-Fe2O3) is transformed to Fe3O4, enhancing magnetic capability.

However, continuous increases in the temperature could lead to a decline in magnetism and transformation of Fe3O4 to ferrous monoxide (FeO) (T. Chen et al., 2020a, b). Thus, choosing the appropriate temperature to achieve the desired magnetic output is essential. This technique possesses some desirable benefits, including the following: (a) The magnetic properties were augmented since the impregnation of biochar with iron species was successful by pyrolysis, resulting in the build-up of magnetic particles within the biochar matrix, which can advance its magnetic strength. (b) The IP technique can enhance the robustness of biochar by expanding its resilience to leaching as well as lowering its susceptibility to degradation, and (c) the MBC generated using this approach can demonstrate better adsorption uptake owing to the existence of magnetic compounds, which can accelerate the extermination of pollutants from water.

However, this technique is not devoid of the following drawbacks: (a) Exorbitant cost of the manufacture of MBC due to the expensive nature of the iron materials and the energy requirement for pyrolysis. (b) This technique is mainly constrained to small-scale production, making it challenging to scale up to an industrial production level. (c) The procedure of impregnating the biochar with transition metal ions and then exposing it to pyrolysis can be time-demanding, undermining its applicability and efficacy in specific contexts. (d) Applying transition metal ions during the impregnation process can present a hazard of environmental pollution if not appropriately handled, harming public health and the flora and fauna. (e) The IP process demands specific equipment and expertise to operate efficiently, which can compromise its ease of access and adoption by small-scale producers and researchers. Developing more environmentally friendly impregnation pyrolysis methods or effective mitigation strategies for its drawbacks could be further explored in future studies. Hence, the IP method to synthesize MBC is a promising field of research with several potential applications in environmental remediation, biomedical, and agriculture fields. Process optimization studies could be further investigated for various applications.

Hydrothermal carbonization (HTC) technique

This technique requires a mixed reaction of feedstock material with a transition metal ion mixture in a vessel under a temperature of 100–300 ℃, which is lower than that in pyrolysis and under an inherent pressure produced by the reaction (Fig. 2c). This technique is more desirable since the reaction conditions are milder than the others and lack a strong alkali reductant.

For instance, Cai et al. (2019a) reported that MBC prepared via this technique recorded the highest adsorption uptake (142.86 mg/g) for Cr(VI), notably higher than that of the majority of MBCs synthesized using IP (Yi et al., 2019a, b, c), reductive co-deposition (Y. Zhu et al., 2018), or CP (Shang et al., 2016). Correspondingly, Zhang et al., (2018a, b) prepared MBC using the HTC method from iron-laden sludge and sludge at 200 ℃ and applied the resultant output as a Fenton-inspired catalyst to eliminate methylene blue. The HTC technique can enhance the magnetic properties of the biochar by introducing magnetic materials during the carbonization process (N. Zhou et al., 2017).

This presents MBC as a suitable material for various applications, including environmental remediation research. The HTC method can expand the carbon yield of the biochar by transforming an increased percentage of the feedstock into the carbon owing to the high-temperature and high-pressure conditions that elevate carbonization and lessen the volume of the organic matter lost during the process. Also, greenhouse gas emissions can be minimized by transforming biomass residue into a carbon-loaded material during the HTC process. This can assist in alleviating the environmental hazard of waste disposal and decrease the overall carbon footprint of the process.

The HTC technique can be employed for an ample range of biomass feedstocks, including agricultural waste, forestry residues, and sewage sludge. This makes it a flexible technology that can be used to prepare MBCs from various waste streams. Hence, HTC is a promising technology for environmental remediation and sustainable waste management (Tan et al., 2015).

However, several drawbacks are faced in using the HTC technique, including partial carbonization of the organic material, leading to decreased biochar yields and weak magnetic strength, agglomeration of magnetic nanoparticles, and loss of magnetic strength, resulting in reduced efficacy of the ultimate MBC output; probable contamination, which may be challenging for specific applications; reproducibility difficulties, resulting in inconsistency in the magnetic strength of the resultant biochar product; and increased process expenses, which may make it less practicable for specific applications. Hence, the HTC technique has considerable potential for transforming biomass streams into value-added products and remains a promising technique for MBC production, and future studies are required to address these shortcomings and optimize the process for specific applications. Also, the optimization of HTC parameters for MBC synthesis deserves focused attention. Tuning the HTC process variables, including temperature, pressure, and feedstock composition, could significantly enhance the magnetic properties and overall effectiveness of MBCs. Furthermore, a more detailed environmental impact assessment is essential to quantify the benefits of MBCs in diminishing greenhouse gas emissions, curtailing waste, and lowering the overall carbon footprint compared to alternative materials.

Mechanical ball milling (MBM) technique

The procedure of ball milling involves using mechanical energy from moving balls within a machine to grind and break down materials, resulting in the development of an improved and transformed surface that takes place in a solid state. This non-equilibrium process continuously mixes and grinds the input materials, resulting in a finer and more homogeneous final product (Lyu et al., 2017).

MBC samples can be prepared using a high-energy or planetary ball milling device enclosed within iron oxides or oxide, biochar, and agate jars under ambient temperature (Fig. 2d). Finely dispersed MBC obtained by the ball milling technique exhibited better acidic surface functional groups and elevated internal and external surface area, demonstrating remarkable adsorption uptake in eliminating heavy metals from an aqueous medium (Liang et al., 2021).

MBM is a green technology requiring zero toxic chemicals or solvents, making it an eco-friendly alternative for producing MBC. MBM is a versatile and effective technique that could manufacture large-scale MBC materials. Various scientific studies have reported the utilization of ball-milled MBC biosorbent materials during the adsorption process. The MBM technique has been extensively utilized to improve the surface area, reduce particle size, or augment the surface functional groups of adsorbents. This is because the method offers several benefits, such as easy operation, high efficiency, and affordability (Zhuang et al., 2021). For instance, in the study performed by He et al. (2021), it was reported that the biochar and iron sulfide matrix was employed to synthesize (FeS@BC) MBC using MBM effectively. The final MBC was utilized together with persulfate for the oxidative disintegration of tetracycline (TC).

The findings of the MBC characterization revealed that it is promising to prepare FeS@BC with minute particle size. The resultant milled FeS@BC also showed ample ferromagnetic behavior. At the optimal conditions, the highest TC percentage removal achieved was 87.4%. In 2020, Xiao et al. (2020) published findings that indicated augmentations in the chemical and physical nature of MBC-based composites produced from cow waste bones milled into micro-nano-sizes and generated at 600 °C. These MBC composites were efficient in eliminating heavy metals, particularly cadmium (Cd), lead (Pb), and copper (Cu).

Li et al., (2020a, b, c) use wheat straw alongside FeCl3/FeCl2 to synthesize MBC by employing an integrated impregnation pyrolysis approach in another study. The synthesized neat MBC under varying temperatures was subsequently ball-milled to augment the surface properties of the biochar. The ball-milled biochar demonstrated superior oxygen amount on the surface of the modified biochar under varied temperatures than the resultant nascent MBC. Also, ball milling successfully enhanced the surface area of the MBC and yielded excellent elimination (≥ 99%) of Hg (II) and tetracycline (TC). Correspondingly, the MBM technique synthesized dual nanoscale MBC/Fe3O4 alongside activated carbon/Fe3O4 composite tailored to remove pharmaceutical chemicals from water (Shan et al., 2016). The two adsorbents synthesized after 2-h milling time demonstrated elevated adsorption uptake of 94.2 mg g−1 for TC and 62.7 mg g−1 for CBZ (Tables 2, 3 and 4).

The MBM technique can produce MBC with high magnetic properties due to the substantial surface area and the prospect of incorporating magnetic particles during the milling process. The MBM approach can also generate MBC with a high surface area, which significantly benefits the adsorption process and can be applied to uniformly distribute magnetic particles in the biochar matrix, resulting in enhanced magnetic properties. The MBM technique is simple, is inexpensive, and can be scaled up for large-scale production of MBC with superior purity since it can eliminate impurities and contaminants during the mechanical milling process (Amusat et al., 2021).

However, there are some shortcomings in the MBM technique, such as difficulty obtaining homogenous dispersal of magnetic strength throughout the biochar since the milling process produces non-uniform stress and strain distribution, resulting in variations in magnetic properties. There is limited control over particle shape alongside size, giving rise to the manufacture of particles with different shapes and sizes, which can impact the magnetic strength and stability of the resultant MBC (Y. Yu et al., 2022). Table 4 presents an overview of the merits and drawbacks of different methods of producing MBC.

The research findings highlight the need for more environmentally sustainable synthesis methods for MBC, cost-effective approaches, and strategies to mitigate drawbacks associated with each technique. Future studies could focus on refining current techniques or developing novel approaches to enhance the synthesis of MBC. Additionally, investigating the potential environmental impacts of these techniques and exploring ways to minimize them are crucial for sustainable biochar production.

Magnetic biochar (MBC) is a promising adsorbent material that amalgamates the benefits of biochar and magnetic properties. However, unmodified MBC may exhibit limited adsorption performance for pollutants due to its physicochemical properties. Therefore, there is a need to modify MBC to expand its surface area and pore structure, enhance its adsorption capacity, tailor its properties to specific environmental pollution scenarios, and improve its general performance through various modification techniques.

The selection of modification methods should be tailored to the specific environmental pollution scenario, and the surface properties of MBC can be enhanced through various modification techniques. By modifying MBC, it is possible to develop a highly effective and versatile adsorbent material that can be used across various fields to address environmental pollution challenges.

Modification approaches of magnetic biochar

The adsorption capability of MBC is typically influenced by its chemical and physical properties. The magnetic medium often obstructs the pores of BC, resulting in a lowered surface area and a less porous structure. As a result, unmodified MBC generally exhibits limited adsorption performance for contaminants (Zhou et al., 2018a, b; Zoroufchi Benis et al., 2020). Consequently, various modification techniques have been employed to enhance its surface characteristics. These techniques primarily include oxidation, acid and alkaline modifications, element doping, surface functional modification, loading of nanoparticles, and biological alteration.

Oxidation modification technique

Oxidation modification presents a means to enhance the pore structures of MBC and augment the variety and quantity of functional groups on its surface, thereby substantially improving its adsorption performance (Tang et al., 2021). This technique of modification encompasses electrochemical oxidation and Fenton oxidation (Deng et al., 2019). For instance, Xu et al. (2020) utilized H2O2 solutions to treat MBC for 120 min, resulting in Fenton oxidation improving the MBC with a 9.8-fold increase in adsorption capacity for Cr(VI) compared to pristine MBC, owing to the introduction of C–O, C–O, and COOH groups. Also, Tian et al. (2021) developed an Fe3O4-based magnetic biochar (EC-Fe3O4/BC) through the pyrolysis of FeCl3-pretreated corn straw–derived BC under an electric field generated by a graphite electrode. The electrochemical modification introduced a greater number of oxygen-containing functional groups, principally C–O, leading to an excellent Pb(II) adsorption capacity of 113 mg/g and a remarkable recovery capacity. Hence, oxidation modification procedure offers a novel and efficient approach to enhancing the adsorptive properties of MBC by integrating functional groups on its surface, thereby offering potential benefits in environmental treatment.

Alkaline-acid modification technique

Alkali modification signifies a viable approach to enhance the adsorption ability of MBC (Nguyen et al., 2021). The fundamental objective of alkaline modification is to increase the surface area and upsurge the presence of oxygen-containing functional groups, such as carboxylic, lactonic, and phenolic groups, as observed in the studies by Fang et al. (2021) and Huang et al. (2021). The augmented amount of oxygen-containing groups accelerates hydrophobic interaction and enhances the trapping ability of the adsorbent via surface complexation (Rizwan et al., 2020; Zhou et al., 2021). Sodium hydroxide (NaOH) and potassium hydroxide (KOH) are the commonly utilized alkalescent agents (Chen et al., 2021a, b; Nguyen et al., 2021). For example, Ma et al. (2021) synthesized a novel KOH-activated MBC for imidacloprid (IMI) adsorption, demonstrating that the new MBC exhibited abundant porosity and superior IMI removal capacity (738 mg/g). Compared to single-modification techniques, alkali-acid composite–modified MBC demonstrates higher surface area and pore volume, along with a profusion of surface functional groups that augment the adsorption performance of MBC. Similarly, Zhou et al., (2019a, b) utilized an alkali-acid combination procedure to modify MBC derived from municipal sludge, resulting in a remarkable adsorption capacity for tetracycline (TC) of up to 286.913 mg/g. The interaction between hydrogen bonding between the oxygen-containing groups and π-π electron-donor–acceptor on the modified MBC surface and the hydroxyl groups in TC molecules accelerated TC adsorption.

Also, acid modification technique is another efficient approach that advances the adsorption capacity of MBC. In this context, the main purpose of acid modification is to exterminate impurities such as heavy metal ions from the surface of MBC and establish functional groups containing acids, such as carboxyls and amines. These functional groups enrich the MBC’s affinity for heavy metals by promoting complexation and ion exchange, as demonstrated in studies by Fang et al. (2021) and Tang et al. (2021). Various common acids, including sulfuric acid, hydrochloric acid, nitric acid, oxalic acid, phosphoric acid, and citric acid, can be applied during the functionalization process. For instance, Zhou et al., (2018a, 2018b) employed iminodiacetic acid to modify MBC (denoted as MBCI), introducing carboxyl groups onto the MBC surface, and assessed its efficacy in adsorbing Cd(II) from aqueous solutions. The findings demonstrated that MBCI with carboxyl groups exhibited a high adsorption capacity for Cd(II) (197.96 mg/g) and excellent reusability, retaining 82.18% of its adsorption capacity after five consecutive cycles. Hence, the alteration of MBC surface area and functional groups following acid and alkali treatments contributed to the enhancement of MBC’s adsorption capacity towards environmental contaminants.

Surface modification technique

Surface modification plays an important role in shaping the porosity and adsorption abilities of MBC, and the formation of surface functional groups also impacts the surface charges of carbonaceous materials in aqueous environments. Zahedifar et al. (2021) synthesized a novel multi-functional MBC by grafting carboxylic acid (–COOH), amine, thioamide, and amide groups onto the activated BC surface, with Fe3O4 immobilization, leading to excellent removal capacities for Pb(II) (61.25 mg/g) and Cd(II) (53.75 mg/g) separately. This was attributed to the presence of functional groups containing heteroatoms (O, N, S) on the adsorbents, aiding the formation of complexes conducive to heavy metal removal. Also, Xiong et al. (2021) successfully prepared magnetic Fe-loaded BC (MBC700) for butachlor (BTR) adsorption, demonstrating that MBC700, with ample porosity, could remove BTR within 30 min, achieving a removal amount of up to 158.5 mg/g due to the presence of grafts such as –C–O, –COOR, C = O, –COOH, and –OH groups. Hence, the alteration of surface functional groups is critical for enhancing the adsorption capacity of MBC for pollutants in aqueous solutions.

Elemental doping technique

Metal and non-metal element doping

Element doping modification involves both metal and non-metal element doping, with metal elements including Ce, Ca, La, As, and Mn, while non-metal elements include F and N. These modifications can be achieved via techniques such as co-precipitation and hydrothermal treatment. Such modifications have the potential to significantly transform the surface properties of carbon materials and efficiently enhance the adsorption performance of MBC (Qu et al., 2022a, b).

Metal element doping has been recognized as a promising strategy to enhance the adsorption capabilities of MBC. For instance, Jia et al. (2021) prepared an iron-based adsorbent using BC as the carrier via sol–gel and co-precipitation techniques to remove zero-valent mercury (Hg0). Iron-based modified BC doped with two metals (such as Co and Cu) exhibited superior adsorption efficiency for Hg0 compared to single-metal doping, attributing to more abundant chemical functional groups and larger pore structure after doping two metals. Correspondingly, Wang et al., (2019a, b) developed novel MBCs doped with and lanthanum (La) and cerium (Ce) using a co-precipitation method (Ce/Fe3O4-BC and La/Fe3O4-BC). The results indicated that Ce and La doping resulted in an increase in specific surface area as well as the point of zero charge, thus improving phosphate adsorption capacity. The phosphate adsorption capacity increased from 7.0 mg/g on Fe3O4-BC to 20.5 mg/g and 12.5 mg/g on La/Fe3O4-BC and Ce/Fe3O4-BC, respectively. These findings underscore the potential of various metal elements, including Ce, Co, La, Cu, and Mn, as promising candidates for doping with MBC to enhance its adsorption performance for pollutants from environmental mediums.

In addition to metal element doping, non-metal element doping has also shown significant potential in expanding the adsorption capacity of MBC. Huang et al., (2019a, b) synthesized MBC nanofibers co-doped with nitrogen (N) and fluoride (F) via carbonization and electrospinning (FN-MCFS). The co-doping of N and F in MBC nanofibers supplied more active sites on the adsorbent surface, imparting exclusive electronic properties and rich surface chemical properties to MBC. This substantially enhanced the adsorption performance of MBC for environmental remediation, as demonstrated by the significant removal of Cr(VI), with adsorption capacity of 153.61 mg/g. Thus, both metal and non-metal element doping hold promise in enhancing the environmental contaminant removal performance of modified MBC.

Nanomaterials loading technique

The advancement of modern technology and nanoscience has led to the loading of an increasing number of nanomaterials onto MBC to enhance its physicochemical properties. For instance, Chen et al., (2021a, b) developed a novel type of BC loaded with FeS nanomaterials and chitosan composites (chitosan-FeS@BC) for the removal of U(VI) ions from water. This approach efficiently prevented FeS nanomaterials from agglomerating and demonstrated elevated physical stability. The equilibrium adsorption capacity of chitosan-FeS@BC for U(VI) reached 92.45 mg/g at pH 4.16. Similarly, Zhang et al. (2021) synthesized La(OH)3-decorated magnetic porous BC (MPBC) via KHCO3 activation and hydrothermal processes. The resulting MPBC exhibited exceptional adsorption performance in purifying low-concentrated phosphate (P) due to surface charge changes under different pH conditions after loading La(OH)3. Therefore, the loading of nanomaterials onto the surface of MBC holds immense potential for the adsorption of pollutants and the enhancement of its chemical and physical properties.

Biological modification technique

This approach involves the biological preliminary treatment of carbon materials using bacteria/micro-organisms. The adsorption processes of biologically modified MBC for pollutants are both environmentally friendly and inexpensive (Ahmad et al., 2021), garnering significant attention from researchers. For instance, Wang et al. (2021) synthesized a new composite material on Fe3O4-BC (MBB) using Bacillus sp. K1 to effectively remove Cd(II) and As(III) from water. The binding with Bacillus sp. K1 provided new bioadsorption sites on the composite surface, leading to a dramatic 230% increase in Cd(II) removal capacity compared to the original MBC. The maximum removal amount of Cd(II) and As(III) reached 25.04 and 4.58 mg/g in this system, indicating the composite’s potential for the simultaneous remediation of Cd(II) and As(III). Also, Qiao et al. (2020) introduced an effective method for adsorbing high-molecular-weight polycyclic aromatic hydrocarbons (HMW-PAHs) using an immobilized microbial MBC complex, which exhibited excellent HMW-PAH removal ability and superior floatability. The removal efficiencies of pyrene, benzo(a)pyrene, and indeno(1,2,3-cd) pyrene by immobilized cells were 89.8%, 66.9%, and 78.2%, respectively. Thus, biological pre-treatment presents a valid approach to modifying MBC, enhancing its adsorption capacity, and expanding its applications across various fields.

The application of various modification techniques has been presented. Therefore, in this context, regarding technical complexity, element doping and surface modification are relatively facile, while oxidation, nanomaterial loading, and acid-alkaline modifications require careful handling across multiple procedures. From a practical and economic viewpoint, oxidation and alkaline-acid modifications typically involve inexpensive chemical reagents and are highly applicable. Conversely, element doping and nanomaterial loading modifications may at times lessen material applicability due to metal clusters or nanomaterials agglomeration. In the context of environmental friendliness, biological modification is a preferred choice, while oxidation and acid-alkaline modifications may pose environmental hazards due to the noxiousness and corrosiveness of residual alkali, acid, and oxidants, which require further treatment. Thus, the choice of modification techniques should be tailored to the specific environmental pollution scenario. In cases of urgent and severe environmental pollution, effective and rapid modification techniques such as surface modification, nanomaterial loading, and element doping should be prioritized. On the other hand, for long-term and non-urgent environmental pollution projects, economic and environmentally friendly modification techniques, such as biological modification, should be given major consideration.

Plant-based biomass materials and iron species for magnetic biochar

The feedstock (raw materials) required for producing MBC hinges on the synthesis methods (X. Li et al., 2020a, b, c). For instance, to prepare MBC using impregnation pyrolysis, there is a need for agricultural residue as well as transition metal salts, while co-precipitation involves transition metal salts, feedstock, and alkaline substances. Plenty of biomass residues are available for making MBC, including plants, animals, and sludge. However, scientific studies indicated that most (80%) materials used to prepare MBC were derived from plants (Yi, Huang et al., 2019a). This is likely due to the glut and variety of plant sources and the fact that employing plant waste is a form of environmentally benign recycling (Cai et al., 2019b; Yi, Huang, et al., 2019b). Based on this context, this study succinctly summarized some of the most widely used plant-based biomass materials for the production of MBC, as presented in Table 3. Various varieties of plant sources, including banana (Rong et al., 2019b), bamboo (Heo et al., 2019), palm kernel shell (Katibi et al., 2021a), grapefruit (J. Wang & Zhang, 2020), waste wood (Douglas fir) (Karunanayake et al., 2017), corn straws (Y. Li et al., 2020a), rice straw (H. Li et al., 2017a, b), and oak bark (Mohan et al., 2014), have been utilized in the production of MBCs for various contaminants removal.

However, one of the significant drawbacks is selecting the appropriate pristine feedstock material. As previously elucidated, the quantity of biomass residue materials is enormous and continues to grow as waste management becomes more demanding. Hence, the pertinent properties of raw biomass waste, including carbon content, moisture content, surface area, and ash content, should be given adequate attention during the choice of pristine biomass waste residues for the manufacture of MBC, since these properties considerably influence the morphology as well as characteristics of the resultant MBC. Biomass residues, compared to other carbon-containing wastes, are more effortlessly available, particularly when considering large-scale production of MBC. However, since the iron proportion in these biomass materials is naturally low, a magnetic precursor is necessary to manufacture MBC.

To produce MBC, three kinds of magnetic precursors are applied: transition metal salts, iron oxides, and natural iron ores. The transition metal salt is not magnetic; hence, it must be subjected to a thermal reduction reaction or chemical precipitation to become a magnetic substance. These includes Fe(NO3)3·nH2O (Khan et al., 2020), NiCl2·nH2O (Niu et al., 2020), and MnSO4 (Yao et al., 2020). Natural iron metals can also serve as magnetic agents of MBC, such as hematite (Y. Zhao et al., 2019), pyrite (Chu et al., 2021b), magnetite (Bombuwala Dewage et al., 2019), and siderite (Zhao et al., 2019), which can be converted into magnetic materials after some thermal and chemical processes. Red mud can also produce MBC since it comprises iron oxides (Cho et al., 2018). This perception can address the challenges of red mud disposal and attract certain economic value through the produced MBC.

Iron oxide species is an essential constituent of MBC. Magnetic particles are stuck to the surface of biochar by transforming a magnetic precursor into MBC using either a physicochemical reaction or heat treatment after it has been incorporated into the feedstock. Iron oxides in MBC are highly significant for water purification since iron oxides have a strong affinity for various pollutants such as organic compounds, including BPA and heavy metals. In this context, when MBC is introduced into water containing these pollutants, the iron oxides in the biochar efficiently adsorb the pollutants onto their surface. This adsorption process is then succeeded by magnetic separation, which aids the MBC to be easily detached from the water and the adsorbed contaminants. This makes MBC a highly efficient and sustainable technique for water purification (Liang et al., 2021).

Various iron species such as magnetite (Fe3O4) (Yu et al., 2022), hematite (γ-Fe2O3) (Rong et al., 2019b), cobalt ferrite (CoFe2O4) (Li et al., 2020a), maghemite (Chu et al., 2021), and manganese ferrite (MnFe2O4) (L. Zhang et al., 2019) are typically used during the preparation of MBC for water purification (Table 3). However, the most widely utilized iron species for MBC preparation in water purification are magnetite (Fe3O4) and maghemite (γ-Fe2O3), as indicated in Table 3. These iron oxide particles are added to the biochar during production and serve as the magnetic component, allowing the resulting magnetic biochar to be facilely separated from water using an external magnet.

In addition to their magnetic properties, the iron species can also play a role as a catalyst for eliminating pollutants from water using MBC (Feng et al., 2021). Besides, the iron species can accelerate the oxidation of organic compounds, including BPA and pharmaceuticals, making them easier to degrade.

MBC with iron species is an efficient water purification agent for various pollutants, including BPA. Iron oxide nanoparticles embedded in MBC can also be functionalized with specific molecules to enhance their ability to remove particular contaminants from water. For example, surface modification with carboxylic acids can improve the removal of BPA. Furthermore, iron oxide and iron-based materials can also be utilized to remove pollutants from wastewater generated by various industries, such as textiles, pulp and paper, and pharmaceuticals. This can help remediate the environmental impact of these industries and ensure compliance with regulations regarding wastewater (D. Chen et al., 2020a, b; Yu et al., 2022). Among these three species of magnetic agents, transition metal salts and iron oxides have high purity but are costly, while natural iron ores are abundant in amount and inexpensive but possess low purity, and an enormous amount is required during MBC preparation.

Hence, iron species are a crucial component of MBC for water purification, providing both the magnetic properties required for separation and the catalytic properties necessary for pollutant removal.

Application prospects of biochar in pollution remediation

Biochar, a solid material derived from the carbonization of biomass in oxygen-limited conditions, has garnered significant interest recently owing to its promising properties and capabilities in adsorbing various organic and inorganic contaminants from water and soil systems (Mohan et al., 2014). Several reports have described carbonaceous-based materials as excellent biosorbents in the elimination of organic contaminants from aqueous medium owing to their numerous exceptional chemical and physical properties, such as vast surface area, chemical constituents, excellent stability, and superior removal efficiency (Gao et al., 2022; Scaria et al., 2022). Activated carbons produced from biomass residues are frequently utilized as adsorbents in the adsorption process to eliminate emerging contaminants because of their vast surface area and adsorptive ability, enabling them to swiftly and efficiently eliminate BPA. However, producing activated carbons from biomass residues is often (W. Liu et al., 2008; Rong et al., 2019a). Biochar, a carbonaceous material with abundant pore structure synthesized from various biomass resources, has been developed into a promising biosorbent for environmental remediation on account of its excellent properties, including balanced chemical properties, rich surface functional groups, unique pore structure, elevated porosity, an enormous specific surface area, and low cost (Li et al., 2023a, b; Zhao et al., 2020). Biochar biosorbents are eco-friendly, promptly obtainable materials in ample amounts. Biochar is a porous, finely grained, carbon-loaded material generated from the thermal decomposition of organic biomass in an oxygen-deficient environment. Also, biochar has been demonstrated to be an efficacious biosorbent for the adsorption of a diverse range of organic and inorganic contaminants from an aqueous medium (Xie et al., 2023; Xue et al., 2012). Moreover, it demonstrates exceptional efficacy in capturing and eliminating organic pollutants, such as BPA, thus contributing to the quality of the environment. Additionally, biochar particles at the nanoscale can tolerate alterations to their surfaces, achieved by incorporating magnetic materials like iron oxides, organic ligands, and groups, significantly enhancing the adsorption properties (Huang, et al., 2019a).

Recently, biochar has turned out to be an emerging sorbent owing to its unique characteristics, including profuse functional groups, environmental-friendliness, and non-organic mineral varieties, comprising meso-/micro-porous structures and elevated adsorption ability, which were extensively utilized to eliminate the pollutants from effluent (Feng et al., 2021; Yi et al., 2020). Furthermore, biochar raw materials are obtained from various agricultural materials, and the synthesis does not require activation, indicating that biochar exhibits excellent potential for pollution remediation (Liu & Zhang, 2011).

It is worth noting that several studies have reported various thermochemical degradation techniques for preparing biochar materials. The most widely applied methods include traditional carbonization/fast pyrolysis, slow pyrolysis, gasification, flash, and microwave-aided pyrolysis (Abdel Maksoud et al., 2020). However, mainstream pyrolysis activity can be split into three categories: conventional pyrolysis, rapid pyrolysis, and flash pyrolysis, influenced by the operational conditions (Thines et al., 2017). The traditional pyrolysis procedure occurs under a slow heating rate, which permits the manufacture of solid, liquid, and gaseous emissions in compelling portions. Regarding the laboratory scale, the pyrolysis process is typically carried out using microwave or traditional heating techniques. Figure 1 describes the biomass pyrolysis process using various feedstocks as inputs, a reactor/furnace chamber as the processing unit, and the resultant outputs (pyrolysis gas, bio-oil, and biochar), respectively.

Influence of pyrolysis operational conditions on the property of biochar

As illustrated in Fig. 1, residence time, working temperature, nature of raw materials (feedstock), gas flow rate, heating rate, and thermochemical transformation techniques are the pertinent operational factors that could influence the properties and applicability of biochar output. Therefore, these operational factors can significantly impact the efficacy of biochar’s adsorption ability toward various pollutants, with temperature being the most critical variable.

In particular, pyrolysis temperature has been shown to significantly impact the physical, chemical, and structural properties of biochar and its isotherms compared to the nature of agro-raw materials used (Tan et al., 2015; Yao et al., 2023). For example, Cheng et al., (2021a, b) stated that the biomaterial’s pyrolysis temperature influenced the biochar adsorption performance towards a compound, as it influenced the degree of carbonization. A higher pyrolysis temperature resulted in the complete carbonization of the biomass’s organic matter, significantly increasing the surface area and developing more nanopores. This led to a rapid increase in the adsorption rate of naphthalene. Correspondingly, elevated adsorption capacity with higher pyrolytic temperature was also reported by Xu et al. (2019), who recorded similar findings regarding the relationship between pyrolysis temperature and adsorption capacity. They investigated the effect of pyrolysis temperature on the physicochemical properties and NH4+ adsorption capacities of multiple biomass materials, such as rice straw, sawdust, phragmites communis, and eggshells. Changes in pyrolysis temperature led to transformations in the physicochemical characteristics of the biochars, including effective surface area, zeta potential, and pH. Their study revealed that biochars produced at 500 ℃ exhibited the highest NH4+ adsorption capacities, while those generated at 300 ℃ had lower adsorption capacities.

Choi and Kan (2019) observed that increasing the pyrolysis temperature of alfalfa-based biochar from 350 to 650 ℃ produced a significant upsurge in effective surface area and carbonization. The biochar produced at 650 ℃ exhibited superior adsorption performances for BPA and SMX than those synthesized under 350–550 ℃. The removal of functional groups containing hydrogen and oxygen with augmenting operating temperature increased the hydrophobicity of the biochar, resulting in improved adsorption of relatively hydrophobic compounds. Based on the research findings, pyrolysis temperature remains the most critical variable that needs to be adequately considered and monitored during the biochar pyrolysis. The pyrolysis temperature could undermine or advance the quality of output of the pyrolysis process. Reported findings have indicated that higher pyrolysis temperatures could produce biochar materials with superior properties, excellent adsorption capacity, and outstanding contaminants removal efficiency. A pyrolysis temperature range between 500 and 650 ℃ could be considered for biochar production for contaminants removal. The characteristics of biochar significantly rely on the pyrolysis temperature, which mainly varies from 400 to 900 ℃ (Lehmann et al., 2006), as well as the feedstock materials (H. Li et al., 2017a, b).

However, elevated pyrolysis temperature can reduce yield and potentially damage the biochar pore’s structure. This phenomenon could cause a significant decline in functional groups essential for adsorbing pollutants. Conversely, a lower temperature may inhibit the proper formation of the pore structure, leading to a lack of adequate functional groups (Li et al., 2017a, b). Hence, to select an appropriate pyrolysis temperature, it is highly desirable to thoroughly evaluate the nature of the biomass feedstock and MBC produced under various temperatures.

Treatment protocols for the removal of BPA

The mitigation of the hazardous effects of emerging contaminants, including BPA molecules, has emerged as a pressing global concern, with nations dedicating substantial resources towards identifying sustainable approaches that can successfully reduce or eliminate their impact. Water pollution, a significant consequence of emerging contaminants, has resulted in ecological imbalances and has impacted over 40% of the world’s population, posing a threat to public health (Q. Wang et al., 2019a, b). Various methods have been utilized to eliminate BPA from water, including membrane technology, advanced oxidation processes, catalytic and photocatalytic degradations, and adsorption technique utilizing activated carbon, and demonstrated good BPA removal from wastewater and drinking water (Katibi et al., 2021a, b, c; Rodriguez-Narvaez et al., 2017; Rout et al., 2021).

Photocatalytic degradation of BPA

The catalytic degradation procedure aims to accelerate the degradation rate of BPA, which can be further enhanced by integrating either photo-radiation or organic enzymes (Luo et al., 2020). Fundamentally, the catalyst provides an alternative reaction pathway with lower excitation energy compared to the uncatalyzed mechanism. Several studies have investigated the use of various catalysts to enhance the degradation of BPA. Catalysts, such as metal oxides, nanoparticles, and organic compounds, have demonstrated effectiveness in accelerating the breakdown of BPA molecules. The catalytic degradation process often involves the generation of reactive species, such as hydroxyl radicals, which play a crucial role in breaking down BPA into less harmful by-products. For instance, a study on the catalytic degradation of BPA by heterogeneous Fenton-like processes found that 2.5% wt of Cu/TUD-1 showed an optimum catalytic activity of 90.4% BPA degradation. Also, 3% CNTs/Fh exhibited the highest catalytic activity, with 96% BPA degradation achieved in 30 min. The study also reported a total organic carbon (TOC) removal efficiency of 79.1% using 3% CNTs/Fh (Nath et al., 2022). Furthermore, a study on the catalytic degradation of BPA by heterogeneous bimetal reported that BPA was difficult to remove completely by H2O2, with a mineralization efficiency below 40% under most reaction conditions (He et al., 2023). Moreover, a review surveying recent research on BPA removal investigated the degradation of BPA using a novel hybrid catalytic approach. It revealed that 98.2% BPA removal was achieved in 80 min using a specific catalyst (Abu Hasan et al., 2023). In addition, a study on the photocatalytic degradation of BPA from aqueous solution using bismuth ferric magnetic nanoparticles reported that the maximum efficiency (100%) of BPA removal was obtained at pH = 4.042, with a catalyst dose of 7.617 g/100 mL (Mahmoudian et al., 2022). Findings from these studies suggest that catalytic degradation can be a viable and efficient method for BPA removal from water sources. However, factors such as catalyst type, concentration, and reaction conditions could influence the overall efficiency of the process.

Similarly, photodegradation is another viable and promising approach for BPA removal. For instance, Ahsan et al. (2019) synthesized of Cu-BDC@GrO and Cu-BDC@CNT hybrid nanocomposites and their application as adsorbents for the removal of bisphenol A (BPA) from water. A remarkable adsorption capacity of 182.2 and 164.1 mg/g for the Cu-BDC@GrO and Cu-BDC@CNT hybrid nanocomposites, respectively, towards the removal of BPA from water was achieved. Zacharakis et al. (2013) investigated the degradation of BPA under synthetic solar irradiation in the presence of TiO2 or ZnO catalysts immobilized onto glass panels. It was discovered that the use of TiO2 or ZnO in the photocatalytic degradation with low energy demand is a promising and efficient technique to eliminate BPA from water.

Phytoremediation (enzymatic degradation) is another novel remediation and a promising technique for the elimination of organic contaminants in wastewater. Studies have shown that fungal, bacterial, and algal strains, as well as mixed-culture micro-organisms, play a critical role during the remediation process (Rajendrachari et al., 2021). Enzymatic degradation also depends on the micro-organism activities, although the degree of degradation has a strong correlation with several environmental factors, such as pH, nutrient, and temperature (Becker et al., 2017). Some of these bio-enzymes used in the enzymatic degradation process include oxidoreductases: laccases, tyrosinases, polyphenol oxidases, manganese peroxidase, lignin peroxidase, horseradish peroxidase, and bitter gourd peroxidase.

Macellaro et al. (2014) examined the degradation of five different EDCs using four distinct fungal laccases, subject to the availability of both synthetic and natural mediators. The results obtained from this study revealed that all laccases could oxidize different EDCs, with BPA exclusively oxidized under all conditions tested. In addition, mediators remarkably increase the performance of enzymatic treatment and enhance the degradation of substrates refractory to laccase oxidation. Two main possible limitations of this study were the tedious nature of the experiment procedure and challenges in adapting enzymes capable of eliminating the target compounds with an affinity constant of the same order of magnitude concerning the typical proportions of EDCs in the surroundings.

Advanced oxidation processes for the degradation of BPA

Another advanced technique that is used in the removal of BPA is advanced oxidation processes. Advanced oxidation processes (AOPs) are generally applied for the elimination of persistent and recalcitrant EDC constituents from municipal and industrial wastewaters. In this context, AOP techniques can become very favorable methods for purifying wastewater comprising hardly biodegradable or non-biodegradable organic compounds with excessive poisonousness (Li et al., 2023a, b).

. For instance, Li et al. (2016) studied the application of the Mn-Fenton process enhanced with microwave for the elimination of BPA in the water. Significant removal efficiency of BPA (99.7%) was achieved with 34.0 mg/L of H2O2 concentration, 2.7 mg/L of Fe2+ ion concentration, and 100.0 mg/L initial BPA concentration at pH 4. The authors pointed out that the complete removal of BPA can be achieved at minimal initial proportions. However, the optimal pH of 2.5–4.0 used in this study could lead to the production of intricate multi-nuclear complex metals in the secondary sludge which are not suitable for discharge in this state. Lv et al. (2020) developed a novel MOFs@COFs hybrid-based photocatalytic platform coupling with sulfate radical–involved advanced oxidation processes for enhanced degradation of BPA. The developed solar/MOFs@COFs/PS system demonstrated the excellent degradation ability toward BPA and an excellent degradation efficiency of 99%.

Recently Dai et al. (2023) explored the use of metal-free biochar-catalyzed periodate-based advanced oxidation process (PI-AOPs) for the degradation of BPA. The research reveals two nonradical pathways for BPA degradation: a surface hydroxyl group-induced nonradical pathway for biochar pyrolyzed at 350 ℃, and a carbon-mediated electron-transfer mechanism for biochar pyrolyzed at 800 ℃. Biochar catalysts clearly increased BPA degradation, indicating a distinct synergistic effect between PI and biochar.

Membrane separation technology for the removal of BPA

The removal of BPA using membrane technology is one of the promising economical techniques that is suitable for efficient water purification process due to its facile synthesis, ease of operation, zero chemical supplements or phase changes, comparatively low energy requirement, and superior separation performance (Katibi et al., 2021a, b, c).

For instance, Yüksel et al. (2013) investigated the rejection of BPA from model solutions using selected reverse osmosis (RO) and nanofiltration (NF) membranes. They achieved excellent BPA rejection rates (> 98%) with three polyamide RO membranes. However, despite these significant removal rates, the high energy demand and the requirement for multiple modular units (membranes) remained the major drawbacks, rendering the process economically unfeasible, particularly for full-scale applications.

Zielińska et al. (2016) combined microfiltration (MF) and NF to remove endocrine-disrupting chemicals (EDCs) from biologically treated wastewater. They found that both processes achieved complete removal of BPA at an initial concentration of 0.3 ± 0.14 mg/L, with NF membranes recording removal efficiencies of 61–75%. The authors concluded that MF membranes could be a favorable solution for subsequent wastewater treatment containing BPA, especially at lower transmembrane pressures (TMPs) compared to NF. However, limitations such as decreased filtration capacity due to fouling and rapid fouling in MF membranes were observed, resulting in reduced removal efficiency from 37 to 24%.

Al-Rifai et al. (2011) reported a higher removal efficiency of 97% when MF and RO were combined for treating EDCs. However, despite this efficiency, BPA was still detected in the effluent at a concentration of 500 ng/L after treatment, necessitating higher energy demands. Additionally, Bing-Zhi et al. (2010) conducted a study on the rejection of BPA using a polysulfone (PS) membrane. They found that the adsorption capacity of BPA onto the membrane depended on the material, with polysulfone exhibiting excellent removal rates. However, limitations such as susceptibility to adsorptive fouling, accumulation of contaminants, and changes in the feed solution matrix leading to leakages were observed in polysulfone membranes. Zhu et al. (2013) tailored adsorption behaviors and mechanical properties of a composite membrane toward BPA via ultraviolet (UV) irradiation graft polymerization. The study showed that the membrane could achieve 80% BPA removal and other EDCs with different characteristics through adsorption onto the grafted surface. They also found that the composite membrane possesses a better double-layer structure without delamination, and the used membrane can be quickly recovered and reused.

Unfortunately, most of the techniques mentioned above are faced with associated weaknesses during the removal of BPA from water matrices, leading to complications in the supply of safe water provisions and thus not suitable for the broad-scale treatment of BPA. Furthermore, several reports have demonstrated the significant drawbacks of these treatment technologies, including prolonged treatment, high capital and maintenance costs, complex procedures leading to increased operating expenses, generation of toxic by-products, limiting their applicability in developing nations, large working footprint, production of harmful residuals, concentrated residues, lethal sludge, and complicated processes, which undermines their broader applicability (Chai et al., 2021; Dutta et al., 2021; Ho et al., 2017; Katibi et al., 2021a, 2021b, 2021c; Khanzada et al., 2020; Ohore & Songhe, 2019; Tijani et al., 2013). The strengths and limitations of different treatment techniques for eliminating BPA are presented in Table 2.

Notably, among these approaches, the adsorption technique stands out as more suitable, environmentally friendly, relatively economical, robust, and simple. It can be efficiently employed in large-scale applications without generating harmful by-products, making it an attractive option. The adsorption method has garnered considerable attention over the past two decades for removing BPA pollutants due to its ease of configuration and application, high efficiency, insensitivity to toxic compounds, low cost, and relatively small footprint compared to other water treatment methods (Xiang et al., 2019a, 2019b). Due to the shortage of potable water and the escalating issue of water pollution (Maroušek et al., 2019), the scientific community is showing significant interest in adsorption-based techniques for water purification.

Adsorptive removal of BPA via magnetic biochar

To unravel the persistent water pollution, there is a crucial need to explore inexpensive techniques such as the adsorption process, which could utilize low-cost materials in remediating pollutants from water. Adsorption technique has attracted significant attention, favored among several water purification technologies for pollutant removal in wastewater, and widely regarded as an efficient approach for eliminating BPA contaminants from water matrices during the past two decades, owing to its insensitivity to poisonous compounds, relatively high contaminants removal efficiency, inexpensive, environmentally benign, ease of configuration and application, and relatively small footprint and could effectively be utilized in broader scale purposes as compared with other water-purification technologies (Attia & Lima, 2018; Xiang et al., 2019a, 2019b; Xiang et al., 2019a, 2019b). In light of this, adsorption is regarded as an efficient, practical, and rapid technique suitable for economically and efficiently eliminating BPA from several environmental media contaminated with various contaminants (Godwin et al., 2019; Xiang et al., 2020). Besides, the significant advantages of the adsorption treatment technique include the potential to recycle and recover the contaminated substances as well as relatively low/zero residue formation (J. X. Yu et al., 2013).

Recently, some studies have reported the efficient removal of BPA using MBC from various sources. MBC offers several advantages for removing BPA from water. This is because MBC is a highly porous material with a large surface area, providing ample sites for BPA adsorption. Also, the magnetic species in MBC will allow for easy separation from water using an external magnetic (Yu et al., 2023; Zhao et al., 2019). This property makes MBC a highly efficient and inexpensive adsorbent material for BPA removal. The utilization of MBC for BPA removal has been recognized as both environmentally friendly and inexpensive (Feng et al., 2021). With its high porosity, superfluous surface area, magnetic properties, and affordability, MBC offers several advantages for eliminating BPA from water systems. Thus, MBC is a promising material for tackling BPA pollution challenges across various applications.

Interestingly, MBC synthesized from plant biomass stands out from several novel functional materials used for water purification as well as environmental applications, being a highly efficient adsorbent, thanks to its inexpensive nature, wide-ranging source of materials, and deficiency of ecological impact (Qiu et al., 2021).

Consequently, the sorption performance of MBC on BPA tends to be varied. For example, Lu et al. (2017) observed an adsorption uptake of 84.19 mg/g when MBC adsorbent was obtained from Ulva prolifera (marine macroalgae) to eliminate BPA from water. Similarly, Heo et al. (2019) developed a magnetic CuZnFe2O4 biochar composite from bamboo to remediate BPA alongside SMX from an aqueous medium. Their findings indicate that a superior BPA adsorptive uptake of 263.2 mg g−1 was recorded upon the completion of the adsorption process. Also, the author reported that the prime mechanisms for BPA and SMX adsorption comprised hydrophobic, π-π electron donor-receiver, and charge-assisted H bonding interactions. A study performed by J. Wang and Zhang (2020) explored the elimination of BPA from an aqueous medium using magnetic grapefruit peel biochar synthesized using a co-precipitation approach. Almost 229.19 mg/g was adsorbed during the batch test, indicating that the BPA was excellently adsorbed. In addition, MBC laden with γ-Fe2O3 exhibits outstanding magnetic separation capacity but can also attain almost 80% of the starting adsorption capacity following four adsorption cycles. It was also observed that the π-π electron donor-receiver and H bond interplay were the primary forces for MBC to adsorb BPA.

Zhang et al., (2020a, 2020b) synthesized nanosized MBC from bagasse via the ball-milling-co-precipitation technique and immobilized it with the laccase (Trametes versicolor) enzyme. Their findings indicate that BPA, with an initial concentration of 25 mg/L, was eliminated within 75 min through MBC adsorption and enzymatic degradation. Moreover, even after seven rounds of reuse, the L-MBC retained a BPA removal efficiency of over 85%.

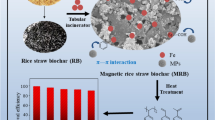

Li et al. (2020b) observed strong magnetic properties and superior degradation of BPA with ball-milled corn straw–based biochar loaded with CoFe2O4 nanoparticles than pure CoFe2O4 in peroxymonosulfate. A comparative study was conducted by Chu et al. (2021) to investigate the elimination of BPA using rice husk (RH-MBC) and rice bran (RB-MBC), together with their combination (RBH-MBC) MBCs produced via iron co-precipitation technique as a catalyst. Among the developed MBCs, the RB-MBC demonstrated an excellent BPA removal rate of 94.25%. The performance of RB-MBC was due to its highly established surface area and pore distribution with well-crystalline maghemite nanomaterials, demonstrating superior BPA degradation efficacy compared with MBCs synthesized with RH-MBC and their mixtures. The authors concluded that RB-MBC has ample magnetic strength to be reclaimed from water using a conventional external magnet and displays stability to be reapplied in the mixed sono-Fenton process.

In 2021, Katibi et al. (2021a) focused on utilizing palm kernel shell MBC to eliminate BPA from an aqueous medium during a batch study. Their findings revealed that the magnetically loaded palm kernel shell biochar recorded the highest removal efficacy of BPA with 94.2%, compared with the pristine biochar.

The efficiency of MBC in removing BPA can be investigated in wastewater treatment plants or contaminated groundwater to provide more insights into the practical application of MBC as a remediation technique for BPA-contaminated water. Moreso, the findings of sorption kinetics studies offer a basis for exploring the heterogeneous catalytic reaction and the chemical adsorption mechanism. The kinetics studies of MBC are of significance to the elimination of BPA. The study of BPA adsorption by MBCs usually involves two fundamental kinetic models: the pseudo-first-order (PFO) kinetic model and the pseudo-second-order (PSO) kinetic model. Table 5 outlines the most frequently employed kinetic models for analyzing the removal of BPA contaminants by MBCs. For instance, Lu et al. (2017) applied PFO and PSO models to investigate the sorption mechanism of BPA using Ulva prolifera marine macroalgae-derived MBC. The kinetic result matched better with the PSO model. Similarly, Wang and Zhang (2020) observed analogous findings by exploring the adsorption mechanism of BPA onto grapefruit peel–derived MBC. In addition, Katibi et al. (2021b) discovered that the adsorption kinetic process of BPA fitted well to the PSO model when palm kernel shell–based MBC was used to adsorb BPA. Besides, some other findings also revealed that the PSO model can illustrate the adsorption kinetic process of BPA by MBCs. The summary of results on the adsorption of BPA onto MBC is presented in Table 5. As shown in Table 5, most of the isotherms of BPA contaminant by MBCs match either the Freundlich or Langmuir isotherm model, depending on the nature of the adsorbent and the working conditions.

Another promising approach is the application of MBC as a catalyst to degrade BPA. MBC is a composite material that combines the properties of biochar (a carbonaceous material derived from biomass) and magnetic nanoparticles. It has been reported to have excellent catalytic properties for various organic pollutant degradations, including BPA (Zhen et al., 2021). Hence, MBC has emerged as a promising catalyst for BPA degradation due to its high catalytic activity, magnetic properties, and low cost of production.

Several studies have investigated using MBC as a catalyst to degrade BPA. For instance, Rong et al. (2019b) analyzed using MBC obtained from banana peel waste as a catalyst to degrade BPA. Their findings revealed that the MBC had high catalytic activity and complete removal of BPA degraded within 20 min of treatment. Similarly, Li et al. (2020b) explored using MBC derived from corn straw as a catalyst for BPA degradation. Their findings showed that the MBC acquired high catalytic activity, with a BPA removal efficiency of 86% within 8-min reaction time. In addition, several other studies have reported corresponding results, demonstrating the efficacy of MBC catalysts for BPA degradation. For example, Shi et al. (2022) used Fe3C/biochar catalyst for BPA degradation and found that it exhibited superior BPA degradation performance, in which 0.5 g/L of catalyst could degrade 0.05 mM BPA in 30 min of treatment. Similarly, Jiang et al. (2019a) utilized MBC developed from sawdust as a catalyst for the removal of BPA and observed that under optimal conditions (0.15 g/L catalyst and 0.2 g/L PMS), 20 mg/L of BPA could be eliminated within 5 min of treatment using Fe-BC-700. In their recent study, Chen et al. (2022) reported a rise in BPA degradation efficiency from 37.6 to 95.1% when MBC prepared from citrus peel waste was used as a catalyst for BPA degradation.

The mechanism of BPA degradation by MBC is considered to involve a combination of physical adsorption and catalytic oxidation, while the magnetic properties of the material enable it to be easily separated from the treated water, making it a highly efficient and convenient method for BPA removal (Zhai et al., 2020). Undesirably, metal leaching and the production of poisonous residue are some of the limitations of homogenous processes which present constraints for practical exploitation (Zhen et al., 2021).

Hence, future investigations on utilizing MBC as a catalyst for BPA degradation could explore several areas including the optimization of synthesis operational variables to enhance the catalytic activity and the stability of MBC. Researchers could investigate different materials and techniques to achieve this goal. Secondly, mechanistic studies could be performed to identify the underlying degradation mechanisms involved in the process. This could include examining the development of reactive oxygen species, the role of the magnetic strength of the material, and the influences of various environmental factors on the reaction kinetics. Thirdly, future studies could focus on evaluating the effectiveness of MBC in real-world scenarios, such as in industrial wastewater treatment plants or the remediation of contaminated water sources. Fourthly, it is essential to consider the potential toxicity of the degradation products and any other by-products that may be produced during the process. Toxicity and by-product formation of BPA degradation using MBC could be investigated to evaluate this approach’s overall feasibility and safety. Finally, studies should also consider the scalability and cost-effectiveness of the technology. Researchers could explore the feasibility of large-scale production and application of MBC, as well as the economic viability of using this technology compared to other treatment methods. By focusing on these areas, future studies can further advance the capacity of MBC as a catalyst for BPA degradation.

Adsorption mechanisms of magnetic biochar to BPA

Insight into the sorption mechanism is essential for the systematic application of MBC in water purification. Since BPA is classified as an environmental hormone, endocrine disruptor, and phenolic compound, the adsorption of BPA could be strongly influenced by pH. The pH range at which the highest adsorption occurs for MBC and BPA can vary, subject to the specific study and experimental conditions. However, certain reports have stated that the highest adsorption of BPA onto MBC occurs at a pH range of 4–7 (Feng et al., 2021; Shan et al., 2016). Moreover, in another study, the highest adsorption of BPA onto MBC was found to occur at a pH of around 6 (Li et al., 2019). It is worth noting that the optimal pH for adsorption may also depend on the nature and concentration of other ions in the solution and the properties of the MBC used. The surface characteristics of MBC, including surface area (SA), pore distribution and volume, surface charge, and functional groups, are closely associated with the adsorption of BPA onto it (C. Zhang et al., 2018a, b). The primary mechanisms involved in BPA adsorption were the development of various hydrogen bonds and the ℿ-ℿ bond.

The conventional mechanisms of BPA pollutant adsorption include electrostatic attraction, π-π interactions, hydrophobic interactions, pore filling effects, hydrogen bonding, chemical reduction, electron transfer, and surface complexation (Li et al., 2020a, b, c; L. Liu & Dai, 2021). Figure 3 demonstrates the mechanisms of BPA adsorption onto MBC, comprising electrostatic interaction, hydrogen bond surface complexation, chemical precipitation, and ion exchange, among others. The mechanisms of BPA adsorption are influenced by the functional groups’ pore structure and chemical bonds existing on the MBC surface. Studies have revealed that the usual mechanisms of BPA pollutant adsorption include pore filling effects, hydrophobic interactions, electrostatic attraction, chemical reduction, hydrogen bonding, electron transfer surface complexation, and π-π interactions (Katibi et al., 2021b).

Electrostatic attraction is the core of ionic bond development, which comprises electrostatic repulsion and attraction. Verliefde et al. (2008) stated that an ionic bond as a chemical bond emerges from the attraction between anions and cations formed when atoms gain or lose electrons. Studies conducted by Chen et al. (2018) and Paunovic et al. (2019) have demonstrated that electrostatic attraction is the principal mechanism involved in the adsorption of BPA onto biochar. Electrostatic interaction occurs during the BPA adsorption by carbonaceous materials. When in a neutral solution, the surface of MBC contains a positive charge. Conversely, due to its electron-loaded benzene rings, BPA possesses a negative charge. This makes it easy for MBC to eliminate BPA through electrostatic interactions.