Poly(lactic acid)-poly(ethylene glycol) with Boc-glycine linked copolymer was synthesized from lactic acid, poly(ethylene glycol), and Boc-glycine. The synthesized polymers were characterized by thermogravimetric analysis, differential scanning calorimetry, IR, and NMR spectroscopic techniques. Drug release, stability, and anti-inflammatory studies were conducted in vitro. This targeted polymer may be used in medical applications as a potential drug carrier.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Biodegradable polymers are produced from natural renewable resources and used in many essential fields, for example agricultural, food packaging, cosmetics, and medical fields in the form of capsules, sutures, implant devices, drug carrier materials, etc. It also saves on petroleum feedstock. However, poly(lactic acid) is brittle and has weak hydrophilicity properties [1], and so its applications are limited. To improve these properties, the polymer structure is altered by either physical or chemical modification through techniques such as the use of plasticizers, fillers, fibers, covalently linked hydrophilic polymers, etc. Biodegradable polymers with modified properties are used in various suitable fields.

In this work poly(lactic acid) copolymer was synthesized from medical grade lactic acid, FDA-approved poly(ethylene glycol) [2,3,4,5], and Boc-glycine [6].

The objectives of the present work is the synthesis of poly(lactic acid)–poly(ethylene glycol) with Boc-glycine and biodegradable safe copolymers by using poly(lactic acid) and FDA-approved poly(ethylene glycol) linked with Boc-glycine end groups, and characterization of the synthesized polymer by various instrumental and biological studies in in vitro conditions.

The IR spectra of poly(lactic acid), poly(lactic acid)–poly(ethylene glycol), and poly(lactic acid)–poly(ethylene glycol)–Boc-glycine showed absorbance at 3470 cm–1, indicating that all three polymers have terminal hydroxyl groups. The absorbance near 1752 cm–1 is attributable to the carbonyl group of all three polymers. The peak absorbance near 2978 cm–1 indicates the C–H stretching frequency of PLA–PEG and PLA–PEG–Boc-glycine. The presence of N–H bending at 1641 cm–1, C–N stretching at 1174 cm–1, and C–H stretching at 2978 cm–1 indicates the conformation of Boc-glycine in the targeted synthesized polymer. The 1H NMR spectrum shows a chemical shift at δ 3.8, 5.5, 1.3, and 0.9 ppm, indicative, respectively, of R–O–C(CH3)3, N–H, alkyl methyl, and alkyl methylene, and confirms the Boc-glycine attachment in the synthesized polymer. The results of thermal studies of the synthesized polymers by TGA and DSC measurements are shown in Figs. 1 and 2. They show that the polymers withstand temperatures above 150°C.

The results of the biological studies of the targeted synthesized polymer are shown in Figs. 3, 4, and 5. They show that PLA–PEG–Boc-glycine gives good drug release at pH 5.5 and has stability and anti-inflammatory activity. The PLA–PEG–Boc-glycine copolymer was successfully synthesized, and this polymer showed good drug release properties at pH 5.5, stability at 72 h, and good anti-inflammatory activity. It can be used as a suitable drug carrier at pH 5.5 in medical applications.

Experimental

General. The infrared (IR) spectra were analyzed using a Shimadzu Tracer 100 instrument. The UV spectra were analyzed using a Labman 1900S Model UV–Vis spectrometer. Thermogravimetric analysis was performed using a TA Q500HI-RES instrument. The sample was scanned to a temperature of 600°C at the rate of 10°C in nitrogen atmosphere. Nuclear magnetic resonance (NMR) study was carried out using a Bruker Advance 500 MHz model instrument and dimethyl sulfoxide as solvent.

Materials. Medical grade lactic acid was purchased from Malladi Drugs & Pharmaceuticals Ltd., Chennai. Boc-glycine was purchased from Acros Organics. Curcumin (purity above 98% by HPLC) was obtained from Pharmaceutical Research Labs. Bovine serum albumin (BSA), stannous octoate (Sn(Oct)2), poly(ethylene glycol), TBTU, trimethylamine, solvents methanol and dimethyl formamide, and all other remaining chemicals used were purchased from Sigma Alrich and Merck Chemicals.

Preparation of Poly(lactic acid). Lactic acid (100 mL), 1% stannous octoate (Sn(Oct)2) catalyst, and 300 mL of toluene were added into a 1000-mL three-necked round bottom flask fitted with a Dean-Stark apparatus, mechanical stirrer, and nitrogen gas supply, and the mixture was heated to 160°C. The reaction was continued for 14 h under nitrogen atmosphere at 160°C and the water was concurrently removed from the reaction mixture. After completion of the polymerization reaction, the solvents and catalyst were removed by distillation. The synthesized polymer was washed with 50 mL methanol (many times) and dried in a vacuum oven at 65°C.

Preparation of PEG Polymer with Boc-glycine end Groups. The Boc-glycine (1.0 g, 0.570 mmol) was dissolved in DMF (20 mL) and TBTU solution (2.91 g, 0.685 mmol), and trimethylamine (1.19 mL, 0.856 mmol) was added. The mixture was stirred for 30 min at room temperature. Then PEG (1.0 g) was added and the whole was stirred for 24 h at room temperature. After that, the reaction mixture was as quenched with crushed ice, filtered, and dried in a vacuum.

Preparation of Poly(lactic acid)–Poly(ethylene glycol) with Boc-glycine end Group Copolymer. PLA–PEG with Boc-glycine [7] polymer was synthesized using a condensation polymerization technique. PLA (5 gm) and PEG (5 gm) of Boc-glycine were introduced into a 1000-mL three-necked round bottom flask fitted with a nitrogen gas supply and stirrer. Toluene (50 mL) was added to the flask and the mixture was stirred for 15 min. Then the catalyst (1% stannous octoate) was added and the mixture stirred for 10 min. The temperature of the reactants was steadily increased to 160°C and the reaction allowed to continue for 14 h. After completion of the polymerization reaction, the solvents and catalyst were removed by distillation. The synthesized polymer was washed with 50 mL methanol many times and dried in a vacuum oven at 65°C.

Drug Releasing Study. Preparation of Drug-polymer Matrix: the polymer (50 mg) was dispersed in 1 mL of methanol, and curcumin [8,9,10] (20 mg/0.2 mL of chloroform) was added dropwise. The mixture was stirred for 24 h. The maximum quantity of supernatant was removed using a micropipette, and the absorbance was recorded at 432 nm. The quantity of the loaded drug was calculated (LP: 16.39% of curcumin, DLE: 81.95%) from the absorbance of the known curcumin solution.

Kinetic Studies of Curcumin Release in vitro. The drug release [11,12,13,14] study was conducted in vitro. The drug (curcumin) release from PLA–PEG–Boc-glycine with time was investigated at room temperature in phosphate buffer (pH 5.5, 6.8, and 7.4). The prepared polymer-drug matrix (10 mg/10 mL) material was placed in a dialysis membrane tube with a 12,000 Da molecular cutoff (Himedia, Dialysis membrane-110). This tube was dipped into a beaker containing 50 mL of phosphate buffer solution. At time intervals of 0.5, 10, 15, 20, and 25 h, 2 mL of the solution was taken from the release medium and replaced by fresh PBS buffer. The quantity of curcumin released was determined at various time intervals by measuring the absorbance of the release medium by a spectrophotometer at 432 nm.

Stability Study of PLA–PEG–Boc-glycine. The stability study for the polymer was performed according to Sribalan et al. [15]. The polymer was dissolved in a minimum quantity of dimethylformamide made up of phosphate buffer (pH 7.4, 5 mL) at 1 mM concentration. From the solution, 200 μL of the sample was diluted in 2 mL of phosphate buffer. The synthesized polymer solution was incubated at 37°C for 10 min. The absorbance (270 nm), which is considered as the initial time of degradation, was recorded. The sample solutions were again kept at 37°C, and the experiment was repeated for 3 days at different time intervals. The stability of the polymer was determined from the decrease in absorbance by a UV visible spectrophotometer.

References

R. K. Kulkarni, K. C. Pani, C. Neuman, and F. Leonard, Arch. Surg, 93 (5), 839 (1966).

K. Kim, M. Yu, X. Zong, J. Chiu, D. Fang, Y.-S. Seo, B. S. Hsiao, B. Chu, and M. Hadjiargyrou, Biomaterials, 24 (27), 4977 (2003).

R. Gref, M. Luck, P. Quellec, M. Marchand, E. Dellacherie, S. Harnisch, T. Blunk, and R. Muller, Colloids Surf. B. Biointerfaces, 18 (3–4), 301 (2000).

A. J. Bradley, K. L. Murad, K. L. Regan, and M. D. Scott, Biochim. Biophys. Acta, 1561 (2), 147 (2002).

A. P. Zhu, P. Lu, and H. Wu, Appl. Surf. Sci., 253 (6), 3247 (2007).

X. Li and X. Yuan, Prog. Chem., 19 (6), 973 (2007).

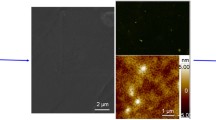

A. K. Salem, S. M. Cannizzaro, M. C. Davies, S. J. B. Tendler, C. J. Roberts, P. M. Williams, and K. M. Shakesheff, Biomacromolecules, 2 (2), 575 (2001).

R. L. Thangapazham, A. Sharma, and R. K. Maheshwari, Adv. Exp. Med. Biol., 595, 343 (2007).

B. Agarwal, A. Kumar, and A. C. Bharti, Anticancer Res., 23, 363 (2003).

A. Goel, A. B. Kunnumakkara, and B. B. Aggarwal, Biochem. Pharmacol., 75, 787 (2008).

W. Gao, J. M. Chan, and O. C. Farokhzad, Mol. Pharm., 7, 1913 (2010).

R. Kotcherlakota, A. K. Barui, S. Prashar, M. Fajardo, D. Briones, A. Rodriguez-Dieguez, C. R. Patra, and S. Gomez-Ruiz, Biomater. Sci., 4, 448 (2016).

R. Dhivya, J. Ranjani, J. Rajendran, M. Rajasekaran, and J. Anna Raj, Adv Mater. Lett., 6 (6), 505 (2015).

Win H. De Jong and Paul J. A. Borm, Int. J. Nanomed., 3 (2), 133 (2008).

R. Sribalan, G. Shakambari, G. Banupriya, P. Varalakshmi, E. Subramanian, S. Sudhakar, and V. Padmini, Chem. Select., 3, 2976 (2018).

Acknowledgment

The authors sincerely thank Malladi Drugs and Chemicals, Chennai for the supply of medical grade lactic acid, Biochemie Innovations Lab for biological studies, Department of Chemistry, Indian Institute of Technology, Madras, and Omega Inspection & Analytical Laboratory for support of the thermal studies.

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in Khimiya Prirodnykh Soedinenii, No. 1, January–February, 2022, pp. 17–19.

Rights and permissions

About this article

Cite this article

Kalaimagal, G., Devarajan, S. & Soundararajan, S. Synthesis and Characterization of Poly(Lactic Acid) – Poly(Ethylene Glycol) Copolymer with Boc-Glycine End Groups in Medical Applications. Chem Nat Compd 58, 14–17 (2022). https://doi.org/10.1007/s10600-022-03589-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10600-022-03589-x