Abstract

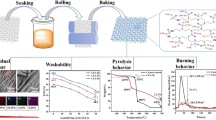

A novel flame retardant, Triethylenetetramine phosphonate ammonium (TECHPA), containing phosphonate and ammonium phosphate groups, was synthesized and characterized by 1H, 13C, and 31P nuclear magnetic resonance (NMR) spectroscopy. The results showed that the Limiting oxygen index (LOI) of cotton fabric treated with 40 g/L TECHPA reached 36.8%, which remained at 31.1% after 50 laundering cycles. The infrared spectra and durability test results suggested that the flame retardant was grafted onto the cotton fibers through P–O–C covalent bonds. TG and cone calorimetry results indicated that the cotton fabrics treated with TECHPA flame retardant showed excellent flame retardancy. The SEM and XRD results suggested that the cotton fibers retained their original structures. For treated cotton fabrics, their stiffness increased slightly, their tensile strength decreased a little, and their crease recovery was greatly improved. No formaldehyde was detected in the cotton fabric after treatment. Overall, simultaneously introducing phosphonate and ammonium phosphate groups provided an effective method to increase the durability of treated cotton fabrics.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Cotton is an important natural fiber used in clothing, upholstering, bedding, and other textiles due to its comfort and renewability (Huang et al. 2021). Cotton and cellulose-rich textiles are not inherently flame retardant, with Limiting oxygen index (LOI) values of 16–18% (Sumei et al. 2018; Chen et al. 2020; Peter 2021); therefore, many efforts have been made to develop flame retardants to suppress the combustion of cotton fabrics, especially those that include flame-retardant halogens, phosphorus, nitrogen, and some metal oxides (Islam and van de Ven 2021).

Halogen-based flame retardants exhibit excellent flame retardancy with a low dose during gas-phase processes, but the smoke produced during combustion, the release of corrosive hydrogen halides, and carcinogenic dioxins endanger human health and the atmosphere (Bourbigot and Fontaine 2010; Liu et al. 2020). Phosphorus-based compounds, sometimes in combination with nitrogen, sulfur, boron, silicon, and other mental contents, have been used as efficient alternatives to toxic halogenated compounds (Gao et al. 2015; Poon and Kan 2015; Kwon et al. 2021). Proban® and Pyrovatex CP® flame retardants, representative phosphorus-based compounds, display sufficient flame resistance when used to treat cotton textiles, but the finished cotton fabrics will release harmful formaldehyde (Zongyue Yang, Bin Fei 2012; Islam and van de Ven 2021). Thus, novel flame retardants with new reactive groups have been studied to avoid formaldehyde formation. Olefins, for instance, have been used as reactive groups to graft flame retardants to cotton fabrics; however, the results were not very satisfactory due to the homopolymerization of olefin-based flame retardants during the finishing process (Kaur and Verma 2010; Xing et al. 2011). In addition, triazine-based flame retardants with a thermostable triazine ring show good flame resistance but poor durability (Edwards et al. 2015). To mitigate the flame retardant post-treatment processes, other approaches such as nanocoatings (Miao et al. 2021), grafting graphene/graphene oxide (Zhang et al. 2020), microcapsulation (Liu et al. 2013), hybrid sol approaches (Bentis et al. 2019; Cheng et al. 2020), and layer-by-layer methods (Laufer et al. 2012; Fang et al. 2021a) have also been studied. Recently, some environment-friendly biomacromolecules (i.e., caseins (Xu et al. 2019), phytic acid/chitosan (Gao et al. 2019; Fang et al. 2021b), banana pseudostem sap (Basak et al. 2015), pomegranate rind (Basak and Ali 2017), and deoxyribonucleic acid (Bosco et al. 2017)) have been investigated for textile fireproofing because their chemical structures include classical flame-retardant elements phosphorus, nitrogen, and/or sulfur. These biomacromolecules can confer cotton specimens with self-extinguishing and flame-retardant properties, but their cost-effectiveness or large-scale extraction and durability are limited (Salmeia et al. 2016; Liu et al. 2021).

Flame retardants with ammonium phosphate reactive groups were synthesized for cotton fabrics. They could be grafted to cellulose through P–O–C covalent bonds (Wang et al. 2018; Zheng et al. 2018; Wan et al. 2019), and the durability only satisfied the AATCC 61–2013-1A washing standard (0.37% detergent and 10 steel balls at 40 °C) because the flame-retardant molecules contain several ammonium phosphate groups, but only a few of them reacted with cellulose. The ammonium ions in the unreacted ammonium phosphate groups exchanged with Ca2+, Mg2+, Na+, etc., which decreased the flame retardancy of the cotton fabrics; therefore, in this text, phosphonate groups and reactive ammonium phosphate groups were both introduced into the triethylenetetramine molecule to synthesize a Triethylenetetramine phosphonate ammonium (TECHPA) flame retardant. The –P=O(O–NH4+)2 groups of the flame retardants can react with the –OH groups of cellulose to form P–O–C covalent bonds that endowed the fabrics with flame resistance (Wang et al. 2018; Zheng et al. 2018; Wan et al. 2019). The introduction of –P=O(OCH3)2 groups reduced the exchange between ammonium ions and metal ions that decreased the flame retardancy of finished cotton fabrics. It can be expected that the TECHPA-treated cotton fabrics will obtain a durability that satisfies the AATCC 61–2013-2A laundry standard.

Experimental

Materials

Pure cotton fabric with a weight of 152.16 g/m2 was obtained from Chaotianmen Market (Chongqing, China). Triethylenetetramine was purchased from Shanghai Mclean Biochemical Technology Co., Ltd. (Shanghai, China). Phosphorous acid was provided by Chengdu Cologne Chemical Reagent Co., Ltd. (Chengdu, China). Dicyandiamide and anhydrous ethanol were supplied by Chengdu Cologne Chemical Co., Ltd. (Chengdu, China). Formaldehyde and ammonium hydroxide were acquired from Chongqing Chuandong Chemical Co., Ltd. (Chongqing, China). Dimethyl phosphite was obtained from Jinan Zhengkang Chemical Co., Ltd. (Jinan, China). All chemicals were used as received.

Synthesis of flame retardant

The synthesis of the flame retardant was divided into three steps. First, triethylenetetramine (70%, 0.1 mol, 20 mL), formaldehyde (37%, 0.2 mol, 15 mL), and dimethyl phosphite (0.18 mol, 19.8 g) were mixed in a 250 mL conical flask equipped with a stirrer at room temperature. Then, the mixture was heated to 90 °C and stirred for 3 h. Secondly, formaldehyde (37%, 0.2 mol, 15 mL) and phosphorous acid (0.18 mol, 14.4 g) were added into the vessel when the temperature of the reaction system reached room temperature. This mixture was stirred at 70 °C for 2 h. After the reaction was complete, ammonium hydroxide was added dropwise to the reaction solution to adjust its pH to nearly neutral. Finally, the product was purified using anhydrous ethanol and then dried in an oven at 60 °C, and triethylenetetramine phosphonate ammonium (TECHPA) was obtained.

The structure characterization data of TECHPA by 1H, 13C, and 31P NMR are as follows:

1H NMR (D2O, 600 MHz) δ (ppm): 4.72 (s, D2O), (s, 4 OCH3, H11, H12, H13, H14), 3.97 (2H, H1, H4), 3.34 (2H, H2, H3), 2.50 (2H, H5, H10), 2.65 (2H, H6, H9), 2.83 (2H, H7, H8), and 1.04 (2NH, H15, H16). 13C NMR (D2O, 600 MHz) δ (ppm): 57.49 (2C, C1, C4), 40.15 (2C, C2, C3), 53.05 (2C, C5, C10), 43.25(2C, C6, C9), 50.73 (2C, C7, C8), 51.34(2C, C11, C12, C13, C14). 31P NMR (D2O, 600 MHz) δ (ppm): –10.23 (2P, P1, P3), 0.04 (2P, P2, P4).

Fabrics finished by the flame retardant

Various concentrations (10, 20, 30, and 40 g/L) were prepared by diluting the TECHPA solution with distilled water. 6% dicyandiamide catalyst and 3% urea as penetrant were also dissolved in the solutions. The pre-treated cotton fabrics were impregnated with the prepared flame retardant solutions at 60 °C for 10 min with a bath ratio of 1:20 (material-to-liquid ratio). Then, they were padded through a nip to obtain an average wet pick-up of 100%. Later, the padded cotton fabrics were treated at 185 °C for 5 min in an automatic continuous baking machine. Next, the finished fabrics were rinsed thoroughly with running water and dried in an oven at 80 °C.

The following formula was the add-on calculation of treated fabrics, where M was the weight of APEPA treated cotton fabric, and M0 represented the mass of the untreated cotton fabric.

Characterization techniques

Fourier-transform infrared (FTIR) spectra were analyzed in the range of 500–4000 cm−1 via a Spectrum GX spectrometer (Perkin Elmer Co., USA) with a resolution of 4 cm−1 using KBr pellets. The crystallinity was analyzed using X-ray diffraction (XRD) at scattering angles of 5–50° with a step size of 0.02° (λ = 1.5406 Å) using a Rigaku XD-3 instrument at 35 kV and 25 mV (Beijing Purkinje General Instrument Co., Ltd., Beijing, China).

Vertical flame measurements and LOI tests were used to evaluate the flame retardancy of the treated cotton fabrics. The vertical flammability of samples was tested by a YG815B vertical fabric FR tester (Nantong Sansi Electromechanical Science & Technology Co., Ltd., China) according to the ASTM D6413-99 test criterion. The LOIs were investigated according to the ASTM D2863-2000 standard using an M606B digital display oxygen index instrument (Qingdao Shanfang Instrument Co. Ltd., China). The washing resistance of treated cotton fabrics was determined using a soaping fastness tester (Roaches Co., England) in reference standard AATCC 61–2013-2A containing 0.15% detergent and 50 steel balls at 49 °C.

Thermogravimetric analysis was performed using a Pyris 1 thermogravimetric analyzer (Perkin Elmer Co. Ltd., USA) under nitrogen and air atmospheres from 40 to 700 °C with a heating rate of 20 °C/min. The combustion behavior of cotton samples was studied by an FTT 007 cone calorimeter (Fire Testing Technology Co., Ltd., UK) at 35 kW/m2 heat flux based on the ASTME1354 standard.

The surface morphologies of the samples were observed using scanning electron microscopy (SEM, Phenom Scientific Co., Ltd., The Netherlands) at an acceleration voltage of 20 kV (Figs. 1, 2).

Mechanical property tests were performed on an electronic tension tester (Nantong Hongda Experiment Instruments Co., Ltd., China) and an automatic fabric stiffness tester (YG(B)022D, Wenzhou DarongTextile Machinery Co., Ltd., Zhejiang, China). The formaldehyde content of the fabric after treatment was carried out on TU-1810 UV–visible spectrophotometer (Beijing General Analysis Instrument Co., Ltd. China) to judge the serviceability and safety of the flame-retardant cotton fabrics according to the standard GB/T 2912.1–2009 "Determination of formaldehyde in Textiles—Part 1: Free and hydrolyzed formaldehyde (water extraction method)".

Results and discussion

FTIR analysis

FTIR spectra can be used to qualitatively analyze the structures and functional groups of molecules. As shown in Fig. 3, there were absorption peaks at 3372 cm−1 and 2900 cm−1 for both control and treated cotton, which were caused by the stretching vibration of O–H and C–H, respectively (Liu et al. 2020). The vibration absorption peaks of the C–O–C group appeared at 1110 cm−1 (Kaur and Verma 2010). Simultaneously, several new absorption peaks appeared in the treated cotton. The absorption peak at 831 cm−1 was ascribed to the stretching vibration of P–O–H and the one at 1205 cm−1 was attributed to the stretching vibration of P = O (Zongyue Yang, Bin Fei 2012). In addition, the absorption peak at 994 cm−1 corresponded to the P(= O)–O–C stretching vibration (Bourbigot and Fontaine 2010), and the peak at 866 cm−1 was due to the P–N stretching vibration. The strong stretching vibration peak at 3435 cm−1 was assigned to –NH2. The LOI test results revealed that the treated cotton showed excellent washable performance, indicating that strong P(=O)–O–C covalent bonds formed between the flame retardant and cellulose of cotton fiber.

XRD analysis

XRD was used to analyze the polymorph identification and crystallinity for cellulose of cotton fiber. In Fig. 4, the diffraction peaks at 14.78°, 16.74°, and 22.86° in both control and treated cotton samples corresponded to the (1–10), (110), and (200) planes of cellulose I. The shoulder appeared at 20.58° was correspond to the (012) and (102) reflections (French 2014). The intensity difference to the three main peaks before and after TECHPA treatment may be because the total cellulose portion was reduced mildly after TECHPA grafting to cellulose, resulting in weaker diffraction pattern (Zheng et al. 2016). The intensity at 20.58° increased slightly, maybe because the flame retardant entered into the amorphous region and affected a part of crystalline region, afterword, weak (012) and (102) reflections formed. Overall, no remarkable changes were observed in the main peak locations in the finished cotton, indicating that flame retardant finishing only had a minimal affection to the crystalline particles.

Flame retardancy and durability

The flame retardancy of the pure cotton fabric and flame-retardant composites were evaluated through vertical burning and LOI tests (Kundu et al. 2020). The LOI of control cotton fabric was 16.5%, and once exposed to flame, it quickly ignited and eventually burned almost without residue. Compared with control cotton, the treated cotton fabrics could not be ignited under these conditions, and the complete charcoal frame remained in the ignition area, without further combustion or smoldering. These results showed that the higher the flame retardant concentration, the shorter the length of burn damage, which indicated that the treated cotton fabrics had good fire resistance (Fig. 5 and Table 1).

From the data listed in Table 2, upon increasing the TECHPA concentration, the LOIs of the cotton fabrics increased gradually, and the flame resistance was improved. It also presented good durability after dozens of laundry cycles. The cotton fabrics treated with 10 g/L TECHPA had an LOI of 27.8% but nearly lost their flame retardancy after 20 washes (Yang and He 2011; Abou-Okeil et al. 2013). When the flame retardant concentration gradually increased from 20 to 40 g/L, the LOIs increased to 33.7% and 36.8%, respectively. After 50 Laundry cycles (LCs), the LOI reached 27.7% and 31.1%, indicating excellent flame retardancy and durability.

Compared with the flame retardants containing only ammonium phosphate groups that just met the AATCC61-2013 1A standard (Wang et al. 2018; Zheng et al. 2018; Wan et al. 2019), the TECHPA-treated cotton fabrics exhibited excellent durability and met the AATCC 61–2013-2A standard. This was because after phosphonate groups were introduced into the flame retardant molecule, ammonium ions were exchanged by metal ions such as Ca2+, Mg2+, etc., which greatly decreased the flame retardancy of the treated cotton fabrics. Then, the TECHPA treated cotton fabrics showed improved durability. These results suggested that introducing phosphonate groups and ammonium phosphate groups enhanced the durability of the treated cotton fabrics (Table 3).

Thermal analysis

In Fig. 6, the TG and DTG results under nitrogen and air were tested to investigate the thermal and thermo-oxidative stabilities of the original cotton and cotton treated with 40 g/L TECHPA. The pyrolysis process was divided into three stages under a nitrogen atmosphere. In the initial stage, the control and treated cotton had a small weight loss at 40–327.3 °C and 40–250.5 °C, respectively, due to the volatilization of water that was hydrogen-bonded to cellulose. In the second stage, intense thermal degradation occurred from 327.3 to 393.3 °C in control cotton, while the treated cotton fabric degraded rapidly in the range of 250.5–313.5 °C. The thermal cracking temperature was about 80 °C earlier than that of the control cotton, which was attributed to volatile products (such as levoglucosan and solid residues) formed during pyrolysis (Besshaposhnikova et al. 2017; Tian et al. 2019). In the third stage, the degradation rate slowed down, and the final residual mass of the control cotton was 3.1%, and that of treated cotton was 41.1%.

These results indicated that TECHPA altered the pyrolysis pathway of cotton fiber. First, the phosphorus-based flame retardant fragmented at a lower temperature than the cotton fiber to release substances such as phosphoric acid and polymetaphosphate, which promoted char formation. A char layer with poor thermal conductivity adhered to the surface of the cotton fiber, which blocked heat, protected the inner fibers, and inhibited further thermal decomposition of the cotton. Likewise, the remaining char increased remarkably.

Under an air atmosphere (Figs. 6b, d), the pyrolysis processes were similar to those in nitrogen, but an obvious difference occurred in the third stage. Compared with the original cotton, the weight loss of treated cotton fibers decreased more quickly because of oxygen in the air. The residue was oxidized by oxygen at high temperatures, and the final residue amount under nitrogen decreased greatly.

Cone calorimetry tests

Cone calorimetry tests were utilized to further investigate the combustion behavior of cotton samples. In Fig. 7a, the Heat release rate (HRR) of untreated cotton rapidly reached a peak value of 254.3 kW/m2 and then dropped to 0, indicating that flames spread rapidly and burned intensely after ignition; however, the value of treated cotton was 56.2 kW/m2, which was 80% lower than that of the original cotton fabric. From Fig. 7b, the Total heat release (THR) of treated cotton decreased by 37.1% compared with that of raw cotton. The CO2/CO of treated cotton fabric was 22.9, which was much lower than that of control cotton. The Time to ignition (TTI) of control cotton fabric was 5 s, whereas the treated cotton fabric could not be ignited. These results indicated that TECHPA interfered with the combustion of cotton fabric (Özgür et al. 2013; Beyler et al. 2017; Bentis et al. 2019).

Surface morphology

The surface morphology of the control cotton, treated cotton (40 g/L TECHPA), and burnt cotton after treatment were observed by SEM (Fig. 8). The control cotton fibers (Fig. 8a, d, g) were flat and banded (Huang et al. 2019). The cotton fibers treated with flame retardant (Fig. 8b, e, h) had a similar structure to the control cotton fibers with swelling and a smooth surface without the attachment of other substances. This indicated that TECHPA penetrated and reacted with the fibers instead of sticking to their surface. Figure 8c, f, and i showed a complete carbon frame after burning, which indicated that TECHPA maintained the original form of control cotton during combustion. A large amount of char residue embodied the mechanism of condensed phase flame retardant. There were some bubbles on the surface of the carbon frame after burning because the flame retardant contained nitrogen components that released ammonia, nitrogen gases, etc. during combustion. The existence of these bubbles helped inhibit heat transfer and diluted combustible gases and oxygen, thus reducing the possibility of further combustion.

Formaldehyde content

The formaldehyde content was analyzed to judge the serviceability and safety of the flame-retardant cotton fabric. The original cotton and cotton treated with 40 g/L TECHPA were extracted in a 40 °C water bath. Then, the extraction solution was colored with acetylacetone to determine the free formaldehyde content of the finished cotton fabric. The results showed that there was almost no difference between the untreated and processed cotton in the color of acetylacetone. The result of the finished cotton was "not detected" by an ultraviolet spectrophotometer, i.e., the free formaldehyde content on the fabric was less than 25 mg/kg. This revealed no detrimental effect on the safety performance, meeting the requirements for infant textiles.

Mechanical properties

Table 4 shows the tensile strength, bending length, and crease recovery angle of the cotton samples. Compared with the control cotton, the tensile strengths of the cured cotton were lower and decreased at higher flame retardant concentrations. This was attributed to fabric damage by phosphoric acid produced during finishing at a high temperature (185 °C for 5 min); however, when the concentration reached 40 g/L, the strengths of the treated cotton remained at 68% of the value of the original cotton, which satisfied many application requirements.

The bending length is related to the softness and handle of cotton fabrics. As shown in Table 4, the bending length increased upon increasing the flame retardant concentration. Under the maximum concentration, the bending length increased by 22.4% for warp and 31.9% for the weft. The crease recovery angle substantially increased after flame-retardant treatment. Once the flame-retardant concentration reached 30 g/L, the crease recovery angle of the finished cotton was twice that of the original cotton and increased only slightly afterward. This behavior occurred because the flame retardant molecules contained four reactive P–OH groups, and each flame retardant molecule combined with four –OH groups on cellulose. Thus, the crease recovery of treated cotton fabrics was improved.

Conclusions

A novel flame retardant, TECHPA, containing phosphonate and ammonium phosphate groups was synthesized. Cotton fabric treated with this flame retardant displayed excellent flame retardancy and durability. The cotton finished with 40 g/L TECHPA had an LOI of 36.8%, which remained at 31.1% after 50 LCs. TG tests showed that the residue of the treated cotton fabrics increased significantly. The HRR and THR of the treated cotton fabric decreased markedly compared with that of the original specimen. The TG and cone calorimetry tests suggested that the treated cotton fabrics had excellent flame retardancy. The FTIR and durability results showed that the flame retardant was grafted to the cotton fibers through P–O–C covalent bonds. All results suggested that introducing phosphonate and ammonium phosphate groups increased the durability of the treated cotton fabrics.

References

Abou-Okeil A, El-Sawy SM, Abdel-Mohdy FA (2013) Flame retardant cotton fabrics treated with organophosphorus polymer. Carbohydr Polym 92:2293–2298. https://doi.org/10.1016/j.carbpol.2012.12.008

Basak S, Ali SW (2017) Leveraging flame retardant efficacy of pomegranate rind extract, a novel biomolecule, on ligno-cellulosic materials. Polym Degrad Stab 144:83–92. https://doi.org/10.1016/j.polymdegradstab.2017.07.025

Basak S, Samanta KK, Chattopadhyay SK et al (2015) Flame retardant cellulosic textile using bannana pseudostem sap. Int J Cloth Sci Technol 27:247–261. https://doi.org/10.1108/IJCST-12-2013-0135

Bentis A, Boukhriss A, Grancaric AM et al (2019) Flammability and combustion behavior of cotton fabrics treated by the sol gel method using ionic liquids combined with different anions. Cellulose 26:2139–2153. https://doi.org/10.1007/s10570-018-2206-4

Besshaposhnikova VI, Mikryukova ON, Gal’braikh LS, (2017) Influence of Aflammit KWB on the Process of Pyrolysis and the Properties of Cellulose Fabrics. Fibre Chem 49:246–250. https://doi.org/10.1007/s10692-018-9877-3

Beyler C, Croce P, Dubay C et al (2017) Oxygen consumption calorimetry, William Parker: 2016 DiNenno Prize. Fire Sci Rev 6:1–7. https://doi.org/10.1186/s40038-016-0016-z

Bosco F, Casale A, Gribaudo G et al (2017) Nucleic acids from agro-industrial wastes: A green recovery method for fire retardant applications. Ind Crops Prod 108:208–218. https://doi.org/10.1016/j.indcrop.2017.06.035

Bourbigot S, Fontaine G (2010) Flame retardancy of polylactide: An overview. Polym Chem 1:1413–1422. https://doi.org/10.1039/c0py00106f

Ceylan Ö, Alongi J, Lieve Van Landuyt AFKDC (2013) Combustion characteristics of cellulosic loose fibre. FIRE Mater 37:482–490

Chen Y, Wang D, Liu S et al (2020) A novel P-N-based flame retardant with multi-reactive groups for treatment of cotton fabrics. Cellulose 27:9075–9089. https://doi.org/10.1007/s10570-020-03387-0

Cheng XW, Tang RC, Guan JP, Zhou SQ (2020) An eco-friendly and effective flame retardant coating for cotton fabric based on phytic acid doped silica sol approach. Prog Org Coatings 141:105539. https://doi.org/10.1016/j.porgcoat.2020.105539

Edwards B, Hauser P, El-Shafei A (2015) Nonflammable cellulosic substrates by application of novel radiation-curable flame retardant monomers derived from cyclotriphosphazene. Cellulose 22:275–287. https://doi.org/10.1007/s10570-014-0497-7

Fang Y, Sun W, Li J et al (2021a) Eco-friendly flame retardant and dripping-resistant of polyester/cotton blend fabrics through layer-by-layer assembly fully bio-based chitosan/phytic acid coating. Int J Biol Macromol 175:140–146. https://doi.org/10.1016/j.ijbiomac.2021.02.023

Fang Y, Sun W, Li L, Wang Q (2021b) Bio-based Phytic Acid/chitosan and Polycarboxylic Acid for Eco-friendly Flame Retardant and Anti-crease of Cotton Fabric. J Nat Fibers 00:1–12. https://doi.org/10.1080/15440478.2021.1964123

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896. https://doi.org/10.1007/s10570-013-0030-4

Gao WW, Zhang GX, Zhang FX (2015) Enhancement of flame retardancy of cotton fabrics by grafting a novel organic phosphorous-based flame retardant. Cellulose 22:2787–2796. https://doi.org/10.1007/s10570-015-0641-z

Gao YY, Deng C, Du YY et al (2019) A novel bio-based flame retardant for polypropylene from phytic acid. Polym Degrad Stab 161:298–308. https://doi.org/10.1016/j.polymdegradstab.2019.02.005

Huang S, Zhong L, Li S et al (2019) A novel monosodium-glutamate-based flame retardant containing phosphorus for cotton fabrics. Cellulose 26:2715–2728. https://doi.org/10.1007/s10570-018-02241-8

Huang G, Huang J-Q, Chen X-Y, Zhu Y-X (2021) Recent Advances and Future Perspectives in Cotton Research. Annu Rev Plant Biol 72:437–462. https://doi.org/10.1146/annurev-arplant-080720-113241

Islam MS, van de Ven TGM (2021) Cotton-based flame-retardant textiles: A review. BioResources 16:4354–4381

Kaur I, Verma SK (2010) Living radical polymerization and grafting of diethyl (acryloyloxy) ethylthiophosphoramidate onto cotton fabric to impart flame retardancy. Surf Coatings Technol 205:2082–2090. https://doi.org/10.1016/j.surfcoat.2010.08.097

Kundu CK, Li Z, Song L, Hu Y (2020) An overview of fire retardant treatments for synthetic textiles: From traditional approaches to recent applications. Eur Polym J 137:109911. https://doi.org/10.1016/j.eurpolymj.2020.109911

Kwon D, Yi S, Jung S, Kwon EE (2021) Valorization of synthetic textile waste using CO2 as a raw material in the catalytic pyrolysis process. Environ Pollut 268:115916. https://doi.org/10.1016/j.envpol.2020.115916

Laufer G, Kirkland C, Morgan AB, Grunlan JC (2012) Intumescent multilayer nanocoating, made with renewable polyelectrolytes, for flame-retardant cotton. Biomacromol 13:2843–2848. https://doi.org/10.1021/bm300873b

Liu J, Liu C, Liu Y et al (2013) Study on the grafting of chitosan-gelatin microcapsules onto cotton fabrics and its antibacterial effect. Colloids Surfaces B Biointerfaces 109:103–108. https://doi.org/10.1016/j.colsurfb.2013.03.040

Liu S, Wan C, Chen Y et al (2020) A novel high-molecular-weight flame retardant for cotton fabrics. Cellulose 27:3501–3515. https://doi.org/10.1007/s10570-020-03020-0

Liu J, Zhang Z, Sun L et al (2021) Synthesis of a novel synergistic flame retardant based on cyclopolysiloxane and its flame retardant coating on cotton fabric. Cellulose 28:9505–9523. https://doi.org/10.1007/s10570-021-04127-8

Miao Z, Yan D, Zhang T et al (2021) High-Efficiency Flame Retardants of a P-N-Rich Polyphosphazene Elastomer Nanocoating on Cotton Fabric. ACS Appl Mater Interfaces 13:32094–32105. https://doi.org/10.1021/acsami.1c05884

Peter Z (2021) Order in cellulosics: Historical review of crystal structure research on cellulose. Carbohydr Polym 254:117417. https://doi.org/10.1016/j.carbpol.2020.117417

Poon CK, Kan CW (2015) Effects of TiO2 and curing temperatures on flame retardant finishing of cotton. Carbohydr Polym 121:457–467. https://doi.org/10.1016/j.carbpol.2014.11.064

Salmeia KA, Gaan S, Malucelli G (2016) Recent advances for flame retardancy of textiles based on phosphorus chemistry. Polymers. https://doi.org/10.3390/polym8090319

Sumei L, Xin L, Peng L et al (2018) A Review on Microstructure and Properties of Cotton Fiber. China Acad J Electron Publ House 45:4–8

Tian P, Liu M, Wan C et al (2019) Synthesis of a formaldehyde-free flame retardant for cotton fabric. Cellulose 26:9889–9899. https://doi.org/10.1007/s10570-019-02751-z

Wan C, Tian P, Liu M et al (2019) Synthesis of a phosphorus-nitrogen flame retardant endowing cotton with high whiteness and washability. Ind Crops Prod 141:111738. https://doi.org/10.1016/j.indcrop.2019.111738

Wang D, Zhong L, Zhang C et al (2018) A novel reactive phosphorous flame retardant for cotton fabrics with durable flame retardancy and high whiteness due to self-buffering. Cellulose 25:5479–5497. https://doi.org/10.1007/s10570-018-1964-3

Xing W, Jie G, Song L et al (2011) Flame retardancy and thermal degradation of cotton textiles based on UV-curable flame retardant coatings. Thermochim Acta 513:75–82. https://doi.org/10.1016/j.tca.2010.11.014

Xu F, Zhong L, Zhang C et al (2019) Novel High-Efficiency Casein-Based P-N-Containing Flame Retardants with Multiple Reactive Groups for Cotton Fabrics. ACS Sustain Chem Eng 7:13999–14008. https://doi.org/10.1021/acssuschemeng.9b02474

Yang Z (2009) Bin Fei XW and JHX (2012) A novel halogen-free and formaldehyde-free flame retardant for cotton fabrics. Finnish-Swedish Flame Days 36:31–39. https://doi.org/10.1002/fam

Yang CQ, He Q (2011) Applications of micro-scale combustion calorimetry to the studies of cotton and nylon fabrics treated with organophosphorus flame retardants. J Anal Appl Pyrolysis 91:125–133. https://doi.org/10.1016/j.jaap.2011.01.012

Zhang H, Zheng D, Cai Z et al (2020) Graphitic Carbon Nitride Nanomaterials for Multicolor Light-Emitting Diodes and Bioimaging. ACS Appl Nano Mater 3:6798–6805. https://doi.org/10.1021/acsanm.0c01197

Zheng D, Zhou J, Zhong L et al (2016) A novel durable and high-phosphorous-containing flame retardant for cotton fabrics. Cellulose 23:2211–2220. https://doi.org/10.1007/s10570-016-0949-3

Zheng D, Zhou J, Wang Y et al (2018) A reactive flame retardant ammonium salt of diethylenetriaminepenta(methylene-phosphonic acid) for enhancing flame retardancy of cotton fabrics. Cellulose 25:787–797. https://doi.org/10.1007/s10570-017-1543-z

Acknowledgments

This work was supported by the Open Project Program (BTBUFR21-2) from the Petroleum and Chemical Industry Engineering Laboratory of Non-halogen Flame Retardants for Polymers, Beijing Technology and Business University, China.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lu, Y., He, Q., Chen, Y. et al. Synthesis of triethylenetetramine phosphonate ammonium flame retardant and its application to cotton fabrics. Cellulose 29, 2107–2118 (2022). https://doi.org/10.1007/s10570-022-04416-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-022-04416-w