Abstract

The synergistic effect of ultrasonication with deep eutectic solvent (DES) on pretreatment of oil palm empty fruit bunch (OPEFB) was investigated. Three different types of DESs, namely choline chloride:lactic acid (ChCl:LA), choline chloride:urea (ChCl:U) and choline chloride:glycerol (ChCl:G) were applied. The performance of the pretreatment was evaluated based on yield of reducing sugars, lignin content, crystallinity index, structural and morphology changes. ChCl:LA pretreated OPEFB attained the highest yield of reducing sugars (36.7%) under the action of ultrasonication for 15 min at sonication power 60% (210 W) and temperature 50 °C, followed by ChCl:U (35.8%) and ChCl:G (35.3%). Under these conditions, ChCl:LA pretreated OPEFB showed significant change in structural and morphology, associated with the lowest crystallinity and lignin content. ChCl:LA promoted the pretreatment process in view of its intrinsic properties of low viscosity and low surface tension. The incorporation of ultrasonication in DES pretreatment significantly increased the reducing sugars yield suggested the synergistic effect of ultrasonication with DES pretreatment. These signifies that ultrasound-assisted DES pretreatment could be a promising alternative pretreatment technique for lignocellulosic biomass.

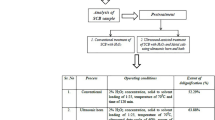

Graphic abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Extensive research has been conducted on biomass valorization, in view of the positive impacts created in both economic and environmental aspects. Valorization of agricultural waste or lignocellulosic biomass into biofuels provides a long-term sustainable energy as it could minimize the dependency of fossil fuels and to mitigate the greenhouse gas emission. One of the obstacles in biomass valorization is its low yield due to the recalcitrance properties of the biomass. To alleviate this problem, pretreatment is essential to break down the complex structure of the biomass, facilitates the release of sugars during enzymatic saccharification leading to better conversion to biofuel or biochemical products.

With the increasing demands of eco-friendly and sustainable processing, green solvents such as ionic liquids and deep eutectic solvents (DESs) are widely explored in biomass processing (Lee et al. 2015; Chen and Mu 2019; Liu et al. 2019b; Thi and Lee 2019). DESs are of latest interest as they are easy to synthesize, cheaper and exhibit tailor-ability properties (Chen et al. 2019b). Some DESs are also reported to exhibit favorable properties such as low toxicity, good thermal stability, biocompatible and biodegradability properties (Zhang et al. 2012; Chen et al. 2018, 2019b). DESs are formed through the combination of hydrogen-bond acceptor (HBA) and hydrogen-bond donor (HBD) from easily available natural chemicals (Francisco et al. 2012), or two or more molecular compounds through noncovalent interactions (known as eutectic molecular liquids) (Yu and Mu 2019), via a simple and convenient way of heating and mixing. The intramolecular hydrogen bonds in the DESs will facilitate the breaking of strong hydrogen bonds in the biomass, and results in high biomass solubility and conversion rate (van Osch et al. 2017). These features make DES a potential solvent for biomass processing (Chen and Mu 2019).

Thermal energy is essential during the pretreatment process as it mediates bond breaking between molecules in a reaction. Thermal energy can be supplied in the form of heat using conventional heating devices such as hot plate and heating mantles. These techniques are rather slow and create a temperature gradient within the sample (Singh et al. 2016). Therefore, utilization of non-conventional energy sources such as ultrasound in biomass pretreatment was studied (SriBala et al. 2016; Subhedar and Gogate 2016; Lee et al. 2020). The pretreatment effect of ultrasound is based on the principle of cavitation. Cavitation is a phenomenon in which spontaneous formation, growth, and subsequent collapse of microsize cavities (also known as bubbles) during the propagation of ultrasonic waves in liquid medium (Subhedar and Gogate 2016; Tey et al. 2019). The implosion of these cavities produces high local temperature and pressure gradients in microsecond duration, creating hot-spot effect in the liquid medium (Sawant et al. 2008; Li et al. 2020). Cavitation also generates powerful hydromechanical shear forces in the liquid medium, which disintegrate particles nearby (Singh et al. 2016). These bring a substantial alteration in biomass morphology and enhancement of biomass surface areas, leading to a higher rate of reaction (Mason et al. 2011).

Despite many works were conducted on ultrasonication for the pretreatment of lignocellulosic biomass, only limited reports on the incorporation of DES pretreatment with ultrasonication were found. The aim of the present work was to study the synergetic effect of DES pretreatment with ultrasonication on oil palm empty fruit bunch (OPEFB). OPEFB was selected as the subject of investigation as it has high content of fermentable sugars and widely available in Malaysia (Rahman et al. 2007; Thi and Lee 2019). In this work, type III DESs with choline chloride as HBA were applied in view of their high abundancy, cheap cost, biodegradability and low acute toxicity (Durand et al. 2013). In particular, choline chloride:lactic acid (ChCl:LA), choline chloride:urea (ChCl:U) and choline chloride:glycerol (ChCl:G) were investigated. The pretreatment efficacy was evaluated based on yield of reducing sugars in enzymatic saccharification, lignin content, structural and morphology changes in pretreated biomass.

Materials and Methods

Materials

OPEFB was sponsored by Kwantas Oil Sdn. Bhd., Lahad Datu, Sabah, Malaysia. It was ground and sieved to a particle size of approximately 0.5 mm. The ground OPEFB was dried overnight in an oven (Carbolite AX 120, Verder Scientific, UK) at 60 °C for moisture removal and the dried biomass was stored in a drying cabinet. Chemicals including choline chloride (98.0% purity), lactic acid (88.0% purity), pure urea and glycerol were purchased from Friendemann Schmidt, Malaysia. Onozuka R-10 cellulase was from Merck (Germany). All the chemicals were used as received without further purification.

Preparation of deep eutectic solvents (DESs)

Heating under mixing method was used in preparing DESs (Francisco et al. 2012; Perez-Sanchez et al. 2013). ChCl:LA was prepared by mixing choline chloride (ChCl) and lactic acid (LA) at molar ratio of 1:5. This ratio was selected as it found to be effective in cellulose digestibility and delignification (Suopajärvi et al. 2019). The mixture was heated at 60 °C with continuous stirring at 350 rpm until it turned homogenous. The mixture was kept in screwed cap bottle once it was cooled to room temperature. Similar procedures were repeated for ChCl:U and ChCl:G at molar ratio of 1:2, which reported to be able to form eutectic mixtures.

Deep eutectic solvents (DESs) pretreatment

Pretreatment was conducted by adding 20 mg of ground OPEPB into a test tube containing ChCl:LA with substrate loading of 10% (w/v). Same procedure was repeated for ChCh:U and ChCl:G. All samples were heated in an ultrasonic bath (SK7210 HP, Kudos, China) at 40 °C with sonication power of 60% (210 W) for 3 h. Samples were collected throughout the reaction. For collected samples, distilled water was added to precipitate the OPEFBs. The samples were filtered and the solid residues of pretreated OPEFBs were washed with distilled water to remove DESs residue. The pretreated OPEFBs were oven-dried at 60 °C for 24 h prior to enzymatic saccharification, structural and morphology studies. The experiment was repeated for different temperatures: 50 °C and 60 °C, and sonication powers: 80% (280 W) and 100% (350 W). All the experiment was performed in duplicate.

Enzymatic saccharification

Enzymatic saccharification of pretreated OPEFBs (solid loading of 2%, w/v) was conducted with Onozuka R-10 cellulase enzyme solution at a concentration of 30–50 FPU/g substrate in 1 mL of acetate buffer (50 mM, pH 4.8). The saccharification reaction was conducted in water bath (TW8, Julabo, Germany) at 50 °C for 48 h. The hydrolysates were collected and heated in boiling water for 5 min before subjected to centrifugation (SIGMA 2-6E, Sigma, Germany) at 3000 rpm for 5 min. The supernatant was collected for 3–5-dinitrosalicylic acid (DNS) assay (Miller 1959). The yield of reducing sugars was calculated using Eq. (1):

where wRS and wpretreated biomass represent the weight of reducing sugars in the hydrolysate (mg) and weight of pretreated OPEFB (mg), respectively.

Determination of lignin content in oil palm empty fruit bunch (OPEFB)

Lignin content in untreated and pretreated OPEFBs were determined following the National Renewable Energy Laboratory (NREL) standard procedure (Sluiter et al. 2012). Exactly 300 mg of biomass sample (untreated/pretreated OPEFB) was hydrolyzed with 3 mL of 72% sulfuric acid at 30 °C in a water bath for 1 h. The sample was diluted by adding 84 mL of distilled water and the mixture was evenly mixed prior to autoclave at 121 °C for 1 h. The autoclaved sample was cooled to room temperature. Both liquid and solid samples were separated by subjecting the mixture to vacuum filtration through a filtering crucible. The liquid sample was collected for acid soluble lignin content determination using spectroscopic absorbance measurement at 240 nm; while the solid residue retained in the crucible was washed with distilled water several times prior to acid insoluble lignin determination through weight determination, having had the solid sample dried at 105 °C. Total lignin content is the summation of acid soluble lignin and acid insoluble lignin.

Fourier transform infra-red spectroscopy (FT-IR) analysis

Fourier transform infra-red spectroscopy (FT-IR) (Nicolet iS5, Thermo Fisher Scientific, USA) analysis was conducted to determine the presence of certain functional groups in the biomass and to calculate the crystallinity index of the untreated and pretreated biomass. Both untreated OPEFB and pretreated OPEFB samples were pressed into a disc with attenuated total reflection (ATR). The technique of ATR enabled the sample to examine directly in its phase without further preparation. The spectrum was attained using average of 20 scans over the range between 800 and 4000 cm−1 in 4 cm−1 spectral resolution. Crystallinity of OPEFB samples was determined by measuring the total crystallinity index (TCI) (Nelson and O’Connor 1964). The index can be computed from the FT-IR data by taking two infrared ratios as presented in Eq. (2):

where A1378 cm-1 and A2900 cm-1 represent the transmittance at wavelength 1378 and 2900 cm−1 respectively.

Scanning electron microscopy (SEM) analysis

Surface morphology analysis was performed for both untreated and pretreated OPEFBs using scanning electronic microscopy (SEM) (Inspect S50, FEI, Japan). The images were acquired under 20 kV acceleration voltage and observed at magnification of 1000 × .

Results and discussion

Effect of pretreatment temperature and time on yield of reducing sugars of pretreated OPEFBs

Yield of reducing sugars for the three different types of DES pretreatments at different times and temperatures is depicted in Fig. 1. For all the DES pretreatments, reducing sugars yields at 40 °C were the lowest compared to pretreatment conducted at higher temperatures of 50 °C and 60 °C. Temperature dependent pretreatment performance of DES could be due to the effect of viscosity of the solvents. Viscosity of DESs is greatly affected by temperature. DESs at lower temperature of 40 °C reported to have higher viscosities (as summarized in Table 1). Considering the fact that viscosity is an indication of intrinsic resistance to flow, the mobility of DESs were restricted when pretreatment was conducted at 40 °C. This led to poorer biomass dissolution and lower yield of reducing sugars.

Another plausible reason is the increase in surface tension with decrement in temperature as shown in Table 1. Surface tension is the cohesive tension resulted from the intermolecular attractive forces between the molecules on the fluids’ interface, which tends to minimize the surface area of the interface. Higher surface tension was reported to render the formation and growth of cavitation bubbles. But, surface tension forces increase the rate of collapse of a cavitation bubble (Kuvshinov 1991; Liu et al. 2009). Therefore, pretreatment conducted at lower temperature of 40 °C was expected to have less cavitation as bubble formation was inhibited. Besides, the energy release from cavitation at lower pretreatment temperature was lower. This is because, smaller bubbles were reported to have lower internal temperature (Merouani et al. 2014), and thus, lower implosion energy released during cavitation. These factors contributed to the least ultrasonic irradiation pretreatment efficiency at sonication temperature 40 °C.

Increasing the pretreatment temperature during ultrasonication effected the enzymatic saccharification differently, depending on the types of DESs. From Fig. 1, it can be observed that ChCl:U and ChCl:G pretreated OPEFB had the highest reducing sugars yields at 60 °C. In contrary, ChCl:LA pretreated OPEFB had the highest reducing sugars yields at a lower temperature of 50 °C. Among the DESs investigated, ChCl:LA has the lowest viscosity and surface tension. In view of its lowest viscosity and surface tension, ChCl:LA solvent aided biomass dissolution. Hence, a relative lower temperature was needed in ChCl:LA pretreatment compared to ChCl:U and ChCl:G to attain the same reducing sugars yield. At high sonication temperature of 60 °C, ChCl:LA pretreated OPEFB was reported to have a lower yield of reducing sugars compared to pretreatment conducted at 50 °C.When pretreatment was conducted at high temperature, clumping of pretreated biomass was observed for ChCl:LA pretreatment. Clumping of pretreated biomass significantly reduced the surface area for enzymatic saccharification and hence a lower conversion of biomass to sugars was attained. Same observation was also reported in earlier work (Sai and Lee 2019; Thi and Lee 2019), where biomass clumping was observed for ChCl:LA pretreatment.

Effect of sonication power on yield of reducing sugars of pretreated OPEFBs

Performance of ultrasonication in biomass pretreatment is highly influenced by sonication power. This is because, sonication power was reported to affect the cavitation intensity as it controls the number of cavitation bubbles formed, the bubble lifetime, and the pressure pulse generated at implosion (Subhedar and Gogate 2016). The effect of sonication power on yield of reducing sugars is illustrated in Fig. 2. From the figure, it was obvious that sonication power of 60% yielded the highest amount of reducing sugars despite the difference in sonication time, temperature and type of DESs. Yields of reducing sugars at sonication power 60% were at least three times greater than at sonication power of 80% and 100%. High sonication power was not favorable in biomass pretreatment as excess formation of cavitation bubbles was found to be concentrated around the transducer at high power, which impeded the transfer of ultrasonic energy from the transducer to the liquid medium, and subsequently to the biomass (Gogate et al. 2011). This phenomenon is known as “decoupling effect”. Higher sonication power also leads to uneconomical operation and formation of by-products such as degraded sugars. A higher sonication power imparts more intense mechanical shear and malicious shock (Subhedar and Gogate 2015), and as a result, there is a potential for the sugars produced during pretreatment to be degraded. Similar finding was also reported in earlier work for organosolv pretreatment (Lee et al. 2020), whereby sonication power 60% exhibited better pretreatment performance compared to other sonication powers.

Performance evaluation on incorporation of ultrasound in DES pretreatment

The performance of ultrasonication in DES pretreatment was evaluated by comparing the performance of DES pretreatment with elimination of ultrasonication but to include conventional heating using a water bath. Figure 3 shows the yields of reducing sugars (bar) and lignin contents (point) in pretreated OPEFBs for different DES pretreatments with ultrasonication and conventional heating. From the figure, it is obvious that DES pretreatment incorporated with ultrasonication gave relatively higher yields of reducing sugars compared to DES pretreatment without ultrasonication. The greatest improvement was observed for ChCl:G, which was approximately seven times higher when ultrasonication was introduced, followed by ChCl:U (triple in reducing sugars yield) and ChCl:LA (double in reducing sugars yield).

The OPEFBs were in static contact with DESs when there was no ultrasonication. The contact of biomass with solvent remain the same throughout the pretreatment duration. In other words, limited active sites were available for reaction if pretreatment was conducted with conventional heating. To improve the performance of DES pretreatment, stirring can be incorporated during heating as stirring will improve the mass transfer and hence the solvent diffusion rate for better reaction, but this incurs extra operating cost. On the other hand, dynamic contact between biomass and solvent was achieved when ultrasound was incorporated during the pretreatment. With ultrasonication, propagation of ultrasound waves allowed the formation and collapse of cavities in the liquid medium, in this case, DES. The significantly high energy densities in the vicinity of a collapsing cavity led to a higher rate of solid–liquid mass transfer. The instantaneous collapse of cavities also produced strong shear force that able to break the chemical bonds of the biomass resulting morphology change and a lower molecular weight polymers (Ranjan et al. 2010; Kunaver et al. 2012). In addition, the collapse of cavities in split second created a local hotspot due to the insufficient time for large amount of energy generated to be dissipated the surrounding (Kunaver et al. 2012). The high temperature can also destroy the crystalline structure of the biomass. These collectively enhanced the rate of reaction and pretreatment efficiency of lignocellulosic biomass.

Although there are reports found on the enhancement of enzymatic saccharification performance with degree of delignification, the results obtained in this work did not support the claim especially in ultrasonication pretreatment. Despite the higher lignin contents in ChCl:LA and ChCl:G pretreated OPEFBs under ultrasonication, ChCl:LA pretreated OPEFB gave slightly higher yield of reducing sugars than ChCl:U pretreated OPEFB though the latter had the lowest lignin content. This suggested that other factors could have contributed to the enhancement of pretreatment performance in ultrasonication, such as, crystallinity (Wang et al. 2020) and morphology changes. This is because, ultrasonication works based on the principle of cavitation which could greatly impart the structural and morphology changes in the biomass, as discussed earlier.

Nevertheless, DES pretreatments without ultrasonication exhibited an inversely proportional trend in reducing sugars yield and lignin content. A higher lignin content in pretreated biomass resulted in a lower yield of reducing sugars. This suggested that degree of delignification plays a significant role in determining the pretreatment performance for DES pretreatment if ultrasound was not incorporated. The performance of DES pretreatment depends on the effectiveness of DES in cleaving the lignin-carbohydrate complexes in lignocellulose, which is determined by the molecular interactions between the HBA and HBD in the DES.

In this context, ChCl:LA was the best performed DES in biomass pretreatment, followed by ChCl:U and ChCl:G. The sequence is agreed well with Tan et al. (2018), whereby acidic DESs demonstrated better efficiency in lignin extraction and biomass fractionation than basic and neutral DESs. Liu and his colleagues (2019c) also reported that ChCl:LA was highly efficient in lignin dissolution. In other works by Alvarez-Vasco et al. (2016); Fang et al. (2017) and Procentese et al. (2015), ineffective lignin solubilization and biomass fractionation were reported for neutral DES of ChCl:G pretreatment. ChCl:G exhibited weak competing interactions towards the linkages in the lignin-carbohydrate complexes because the intramolecular hydrogen bonds in ChCl:G were constrained by anionic hydrogen bonds (Cl−-glycerol) and cationic hydrogen bonds (Ch+-glycerol). The strength of these hydrogen bonds were weaker compared to those in lignin, following the sequence: lignin-lignin > Cl−-glycerol > Ch+-glycerol. The weaker hydrogen bonds in ChCl:G suggesting its inability to break the hydrogen bonds in lignin (Xia et al. 2018). Xia and his colleagues also reported that the absence of active protons and acidic sites in ChCl:G contributed to its ineffectiveness to cleave ether bond linkages in the lignin-carbohydrate complexes. These collectively suggested the weak delignification properties of ChCl:G.

There are also numerous studies found on the influence of Kamlet-Taft (KT) solvatochromic parameters on cellulose solubility and delignification. KT solvatochromic method is a quantitative tool to estimate the chemical properties of DESs. There are three KT solvatochromic parameters, i.e. hydrogen bond acidity (α), hydrogen bond basicity (β) and dipolarity or polarizability (π*). Liu et al. (2019a) has introduced KT linear solvation energy relationship (LSER) for quantifying solvent effects by correlating the solubility and the KT solvatochromic parameters. DESs with high α and β values reported to be effective in lignin extraction during biomass pretreatment (Brandt et al. 2011; van Osch et al. 2017). This is because, DESs with high α value can easily liberate H+ ions by donating hydrogen bonds, and high β value has high hydrogen bond accepting capacity. A linear correlation was obtained for β and capability of the solvent in disrupting the hydrogen bond network, hence a higher degree of delignification and cellulose dissolution (Brandt et al. 2011; Ren et al. 2016; van Osch et al. 2017). However, no correlation was found between cellulose solubility and π* (Ren et al. 2016). Among the DESs investigated, ChCl:G has the lowest β value of 0.49 (Pandey et al. 2017) which coincides with its lowest delignification properties.

As discussed earlier, solvent with high viscosity will have lower solvent mobility. This weakened the solvent–solute interaction with lignin, resulting in the decreased lignin extraction efficiency (Tan et al. 2019). Among all the DESs investigated, ChCl:LA was less viscous compared to ChCl:U and ChCl:G. Apart from this, it was reported that the presence of hydroxyl group in DES (ChCl:G) would lead to a higher surface tension due to their hydrogen-bonding ability compared to carboxylic acid-based DES (ChCl:LA) (Hayyan et al. 2013; de Maria 2014; García et al. 2015). As discussed earlier, a higher surface tension led to a lesser cavitation and a lower implosion energy. These characteristics collectively contribute to the better pretreatment performance of ChCl:LA than ChCl:U and ChCl:G.

Structural study by FT-IR analysis

FT-IR analysis was conducted to study the structural changes of OPEFBs by comparing the FT-IR spectra of untreated and pretreated OPEFBs as shown in Fig. 4. A strong and broad absorption was observed at wavelength region of 3338 cm−1 for ChCl:LA (ultrasonication and conventional heating), ChCl:U (conventional heating) and ChCl:G (conventional heating) pretreated OPEFBs. This band was assigned to hydrogen bond (O–H) stretching adsorption (Schwanninger et al. 2004). O–H stretching region at this wavelength of OPEFB spectra was more identical to the O–H stretching region of cellulose I rather than cellulose II and its relative band height increased with cellulose content (Isroi et al. 2012). The intense band observed in ChCl:LA (ultrasonication and conventional heating), ChCl:U (conventional heating) and ChCl:G (conventional heating) at this wavelength suggested the high cellulose I content in the biomass. Changes in band intensity were also found at wavenumber 1032 cm−1 which was assigned to the C-O stretch in cellulose and hemicellulose (Isroi et al. 2012). The increase in intensity at this wavelength might be attributed to increment in hemicellulose content after DES pretreatments especially in ChCl:LA (ultrasonication and conventional heating), ChCl:U (conventional heating) and ChCl:G (conventional heating) pretreated OPEFBs. Another band corresponded to hemicellulose is 1732 cm−1, which describes the stretching of C=O groups in acetyl content of hemicellulose (Zhao et al. 2010). The presence of this band in pretreated OPEFBs signified that DES did not remove hemicellulose during the pretreatment process.

Band in the wavelength region of 2918 cm−1 was assigned to symmetric vibration of the CH2 group. These bands are similar to FT-IR spectra from hardwood and hardwood lignin (Pandey 1999). This indicated that the lignin structure in OPEFB was similar to hardwood lignin. Other lignin characteristics bands are at 1634 cm−1, 1375 cm−1 and 1328 cm−1, which corresponded to OH bending of adsorbed water (Oh et al. 2005), CH deformation (Oh et al. 2005) and syringyl units in lignin (Zhang et al. 2010). The presence of these bands indicated that lignin still present in pretreated OPEFBs, which correlates well with the detection of lignin in all pretreated OPEFBs as presented in “Performance evaluation on incorporation of ultrasound in DES pretreatment” section.

FT-IR spectra can be used as quantitative measurement by determining the total crystallinity index (TCI) of the biomass (Nelson and O’Connor 1964). TCI is closely related to the crystallinity of the biomass. Sample with a low TCI value indicates a greater portion of amorphous domain in its biomass structure; meanwhile a larger TCI value indicates a greater portion of crystal domain. As shown in Table 2, all pretreated samples had lower TCI values compared to untreated OPEFB except ChCl:G with ultrasonication. This confirmed the potential of DES in pretreating OPEFB by disruption and exposing its carbohydrate contents to enzymatic saccharification. The lowest TCI value was attained by ChCl:LA with ultrasonication. The finding concurred with its highest yield of reducing sugars. However, other factors such as morphology, linkages in lignin-carbohydrates complexes and their contents should be taken into consideration in evaluation of pretreatment efficacy. This was proven when OPEFBs pretreated with conventional heating had lower yield of reducing sugars despite their lower TCI values, which suggested that crystallinity solely may not give a good prediction on pretreatment efficacy.

Morphological study by SEM analysis

The changes in surface morphology of OPEFB during pretreatment was evaluated using the images generated by SEM analysis. Figure 5 shows the images of untreated and DES-pretreated OPEFBs with ultrasonication and conventional heating. Untreated OPEFB images showed a relatively smooth, non-porous and rigid surface structure. This indicated the intact of all components of cellulose, hemicellulose and lignin in untreated OPEFB. All ultrasound-assisted DES pretreated OPEFBs (Fig. 5c, e, g) showed considerably removal of cementing substances from the fiber surface, led to a higher porosity and a larger effective surface area for enzymatic saccharification. The obvious change in morphology of fiber surface after ultrasound-assisted DES pretreatment could be due to the disruption of hydrogen bonds, breakage the linkages in the lignin-carbohydrate complexes, and dissolution of parts of the hemicellulose and lignin in the biomass. These caused the fiber surface to be separated.

SEM for untreated and pretreated OPEFBs in different DES pretreatments with ultrasonication and conventional heating: a and b untreated; c ChCl:LA with ultrasonication; d ChCl:LA with conventional heating; e ChCl:U with ultrasonication; f ChCl:U with conventional heating; g ChCl:G with ultrasonication; and h ChCl:G with conventional heating

As compared to OPEFBs pretreated with DES under ultrasonication, OPEFBs pretreated with DES under conventional heating (Fig. 5d, f, h) had minor change in fiber surface structure. Smaller pores and breakage of the fiber structure were found in all DES pretreatments under conventional heating. This implied that the significantly high energy densities created in the vicinity of collapsing cavities in ultrasonication led to a higher rate of solid–liquid mass transfer processes, modified the surface morphology and enlarged the surface area of pretreated biomass. These collectively led to better pretreatment performance of ultrasound-assisted DES pretreatment of OPEFB. The observed enhancement of enzymatic saccharification is therefore likely a result of the combined effect of reduced biomass crystallinity, reduced lignin content and morphology changes.

Conclusion

The incorporation of ultrasound in DES pretreatment had proven to exhibit better conversion of biomass to sugars. Reducing sugars yield increased up to seven times when ultrasound was introduced in DES pretreatment. In this work, ChCl:LA pretreated OPEFB had the highest reducing sugar yield of 36.7% when pretreatment was conducted for 15 min under sonication power 60% (210 W) and temperature 50 °C. In view of the intrinsic properties of ChCl:LA including low viscosity and surface tension, its pretreated OPEFB had the lowest crystallinity and showed significant morphology changed. These concluded that ultrasound-assisted ChCl:LA pretreatment could be a promising alternative pretreatment technique for lignocellulosic biomass.

References

Alvarez-Vasco C, Ma R, Quintero M et al (2016) Unique low-molecular-weight lignin with high purity extracted from wood by deep eutectic solvents (DES): A source of lignin for valorization. Green Chem 18:5133–5141. https://doi.org/10.1039/c6gc01007e

Brandt A, Ray MJ, To TQ et al (2011) Ionic liquid pretreatment of lignocellulosic biomass with ionic liquid-water mixtures. Green Chem 13:2489–2499. https://doi.org/10.1039/c1gc15374a

Chen Y, Mu T (2019) Application of deep eutectic solvents in biomass pretreatment and conversion. Green Energy Environ 4:95–115. https://doi.org/10.1016/j.gee.2019.01.012

Chen W, Xue Z, Wang J et al (2018) Investigation on the thermal stability of deep eutectic solvents. Acta Phys Chim Sin 34:904–911. https://doi.org/10.3866/PKU.WHXB201712281

Chen Y, Chen W, Fu L et al (2019) Surface tension of 50 deep eutectic solvents: Effect of hydrogen-bonding donors, hydrogen-bonding acceptors, other solvents, and temperature. Ind Eng Chem Res 58:12741–12750. https://doi.org/10.1021/acs.iecr.9b00867

Chen Y, Yu D, Lu Y et al (2019) Volatility of deep eutectic solvent choline chloride: N-methylacetamide at ambient temperature and pressure. Ind Eng Chem Res 58:7308–7317. https://doi.org/10.1021/acs.iecr.8b04723

D’Agostino C, Harris RC, Abbott AP et al (2011) Molecular motion and ion diffusion in choline chloride based deep eutectic solvents studied by 1H pulsed field gradient NMR spectroscopy. Phys Chem Chem Phys 13:21383–21391. https://doi.org/10.1039/c1cp22554e

de Maria PD (2014) Recent trends in (ligno)cellulose dissolution using neoteric solvents: switchable, distillable and bio-based ionic liquids. J Chem Technol Biotechnol 89:11–18

Durand E, Lecomte J, Villeneuve P (2013) Deep eutectic solvents: synthesis, application, and focus on lipase-catalyzed reactions. Eur J Lipid Sci Technol 115:379–385. https://doi.org/10.1002/ejlt.201200416

Fang C, Thomsen MH, Frankær CG et al (2017) Reviving pretreatment effectiveness of deep eutectic solvents on lignocellulosic date palm residues by prior recalcitrance reduction. Ind Eng Chem Res 56:3167–3174. https://doi.org/10.1021/acs.iecr.6b04733

Francisco M, van den Bruinhorst A, Kroon MC (2012) New natural and renewable low transition temperature mixtures (LTTMs): screening as solvents for lignocellulosic biomass processing. Green Chem 14:2153–2157. https://doi.org/10.1039/c2gc35660k

Francisco M, van den Bruinhorst A, Zubeir LF et al (2013) A new low transition temperature mixture (LTTM) formed by choline chloride + lactic acid: characterization as solvent for CO2 capture. Fluid Ph Equilib 340:77–84. https://doi.org/10.1016/j.fluid.2012.12.001

García G, Aparicio S, Ullah R, Atilhan M (2015) Deep eutectic solvents: physicochemical properties and gas separation applications. Energy Fuels 29:2616–2644. https://doi.org/10.1021/ef5028873

Gogate PR, Sutkar VS, Pandit AB (2011) Sonochemical reactors: important design and scale up considerations with a special emphasis on heterogeneous systems. Chem Eng J 166:1066–1082. https://doi.org/10.1016/j.cej.2010.11.069

Hayyan A, Mjalli FS, AlNashef IM et al (2013) Glucose-based deep eutectic solvents: physical properties. J Mol Liq 178:137–141. https://doi.org/10.1016/j.molliq.2012.11.025

Isroi IMM, Millati R et al (2012) Structural changes of oil palm empty fruit bunch (OPEFB) after fungal and phosphoric acid pretreatment. Molecules 17:14995–15012. https://doi.org/10.3390/molecules171214995

Kunaver M, Jasiukaityte E, Čuk N (2012) Ultrasonically assisted liquefaction of lignocellulosic materials. Bioresour Technol 103:360–366. https://doi.org/10.1016/j.biortech.2011.09.051

Kuvshinov GI (1991) Effect of surface tension and viscosity on the collapse of a cavitation bubble. J Eng Phys 60:34–37. https://doi.org/10.1007/BF00871608

Lee KM, Ngoh GC, Chua ASM (2015) Ionic liquid-mediated solid acid saccharification of sago waste: kinetic, ionic liquid recovery and solid acid catalyst reusability study. Ind Crops Prod 77:415–423. https://doi.org/10.1016/j.indcrop.2015.09.016

Lee KM, Zanil MF, Chan KK et al (2020) Synergistic ultrasound-assisted organosolv pretreatment of oil palm empty fruit bunches for enhanced enzymatic saccharification: an optimization study using artificial neural networks. Biomass Bioenerg. https://doi.org/10.1016/j.biombioe.2020.105621

Li M, Jiang H, Zhang L et al (2020) Synthesis of 5-HMF from an ultrasound-ionic liquid pretreated sugarcane bagasse by using a microwave-solid acid/ionic liquid system. Ind Crops Prod. https://doi.org/10.1016/j.indcrop.2020.112361

Liu X-M, He J, Lu J, Ni X-W (2009) The effect of surface tension on bubble oscillation near a rigid boundary. Acta Phys Sin 58:4020–4025

Liu Q, Mou H, Chen W et al (2019) Highly efficient dissolution of lignin by eutectic molecular liquids. Ind Eng Chem Res 58:23438–23444. https://doi.org/10.1021/acs.iecr.9b05059

Liu Q, Yuan T, Fu Q et al (2019) Choline chloride-lactic acid deep eutectic solvent for delignification and nanocellulose production of moso bamboo. Cellulose 26:9447–9462. https://doi.org/10.1007/s10570-019-02726-0

Liu Q, Zhao X, Yu D et al (2019) Novel deep eutectic solvents with different functional groups towards highly efficient dissolution of lignin. Green Chem 21:5291–5297. https://doi.org/10.1039/c9gc02306b

Mason TJ, Cobley AJ, Graves JE, Morgan D (2011) New evidence for the inverse dependence of mechanical and chemical effects on the frequency of ultrasound. Ultrason Sonochem 18:226–230. https://doi.org/10.1016/j.ultsonch.2010.05.008

Merouani S, Hamdaoui O, Rezgui Y, Guemini M (2014) Energy analysis during acoustic bubble oscillations: relationship between bubble energy and sonochemical parameters. Ultrasonics 54:227–232. https://doi.org/10.1016/j.ultras.2013.04.014

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Nelson ML, O’Connor RT (1964) Relation of certain infrared bands to cellulose crystallinity and crystal latticed type. Part I. spectra of lattices types I, II, III, and of amorphous cellulose. J Appl Polym Sci 8:1311–1324. https://doi.org/10.1002/app.1964.070080322

Oh SY, Il YD, Shin Y et al (2005) Crystalline structure analysis of cellulose treated with sodium hydroxide and carbon dioxide by means of X-ray diffraction and FTIR spectroscopy. Carbohydr Res 340:2376–2391. https://doi.org/10.1016/j.carres.2005.08.007

Pandey KK (1999) A study of chemical structure of soft and hardwood and wood polymers by FTIR spectroscopy. J Appl Polym Sci 71:1969–1975. https://doi.org/10.1002/(sici)1097-4628(19990321)71:12%3c1969::aid-app6%3e3.3.co;2-4

Pandey A, Bhawna DD, Pandey S (2017) Hydrogen bond donor/acceptor cosolvent-modified choline chloride-based deep eutectic solvents. J Phys Chem B 121:4202–4212. https://doi.org/10.1021/acs.jpcb.7b01724

Perez-Sanchez M, Sandoval M, Hernaiz MJ, Domínguez de María P (2013) Biocatalysis in biomass-derived solvents: The quest for fully sustainable chemical processes. Curr Org Chem 17:1188–1199. https://doi.org/10.2174/1385272811317110006

Procentese A, Johnson E, Orr V et al (2015) Deep eutectic solvent pretreatment and subsequent saccharification of corncob. Bioresour Technol 192:31–36. https://doi.org/10.1016/j.biortech.2015.05.053

Rahman SHA, Choudhury JP, Ahmad AL, Kamaruddin AH (2007) Optimization studies on acid hydrolysis of oil palm empty fruit bunch fiber for production of xylose. Bioresour Technol 98:554–559. https://doi.org/10.1016/j.biortech.2006.02.016

Ranjan A, Patil C, Moholkar VS (2010) Mechanistic assessment of microalgal lipid extraction. Ind Eng Chem Res 49:2979–2985. https://doi.org/10.1021/ie9016557

Ren H, Chen C, Wang Q et al (2016) The properties of choline chloride-based deep eutectic solvents and their performance in the dissolution of cellulose. BioResources 11:5435–5451. https://doi.org/10.15376/biores.11.2.5435-5451

Sai YW, Lee KM (2019) Enhanced cellulase accessibility using acid-based deep eutectic solvent in pretreatment of empty fruit bunches. Cellulose 26:9517–9528. https://doi.org/10.1007/s10570-019-02770-w

Sawant SS, Anil AC, Krishnamurthy V et al (2008) Effect of hydrodynamic cavitation on zooplankton: a tool for disinfection. Biochem Eng J 42:320–328. https://doi.org/10.1016/j.bej.2008.08.001

Schwanninger M, Rodrigues JC, Pereira H, Hinterstoisser B (2004) Effects of short-time vibratory ball milling on the shape of FT-IR spectra of wood and cellulose. Vib Spectrosc 36:23–40. https://doi.org/10.1016/j.vibspec.2004.02.003

Singh R, Krishna BB, Kumar J, Bhaskar T (2016) Opportunities for utilization of non-conventional energy sources for biomass pretreatment. Bioresour Technol 199:398–407. https://doi.org/10.1016/j.biortech.2015.08.117

Skulcova A, Russ A, Jablonsky M, Sima J (2018) The pH behavior of seventeen deep eutectic solvents. BioResources 13:5042–5051. https://doi.org/10.15376/biores.13.3.5042-5051

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker DLAP (2008) Determination of structural carbohydrates and lignin in biomass. Lab Anal Proced 1617(1):1–16

SriBala G, Chennuru R, Mahapatra S, Vinu R (2016) Effect of alkaline ultrasonic pretreatment on crystalline morphology and enzymatic hydrolysis of cellulose. Cellulose 23:1725–1740. https://doi.org/10.1007/s10570-016-0893-2

Subhedar PB, Gogate PR (2015) Ultrasound-assisted bioethanol production from waste newspaper. Ultrason Sonochem 27:37–45. https://doi.org/10.1016/j.ultsonch.2015.04.035

Subhedar PB, Gogate PR (2016) Use of ultrasound for pretreatment of biomass and subsequent hydrolysis and fermentation. Biomass Fract Technol Lignocellul Feed Based Biorefinery. https://doi.org/10.1016/B978-0-12-802323-5.00006-2

Suopajärvi T, Ricci P, Karvonen V et al (2019) Acidic and alkaline deep eutectic solvents in delignification and nanofibrillation of corn stalk, wheat straw, and rapeseed stem residues. Ind Crops Prod. https://doi.org/10.1016/j.indcrop.2019.111956

Tan YT, Ngoh GC, Chua ASM (2018) Evaluation of fractionation and delignification efficiencies of deep eutectic solvents on oil palm empty fruit bunch. Ind Crops Prod 123:271–277. https://doi.org/10.1016/j.indcrop.2018.06.091

Tan YT, Ngoh GC, Chua ASM (2019) Effect of functional groups in acid constituent of deep eutectic solvent for extraction of reactive lignin. Bioresour Technol 281:359–366. https://doi.org/10.1016/j.biortech.2019.02.010

Tey WY, Lee KM, Sidik NAC, Asako Y (2019) Delfim-Soares explicit time marching method for modelling of ultrasonic wave in microalgae pre-treatment. IOP Conf Ser Earth Environ Sci 268:012106. https://doi.org/10.1088/1755-1315/268/1/012106

Thi S, Lee KM (2019) Comparison of deep eutectic solvents (DES) on pretreatment of oil palm empty fruit bunch (OPEFB): cellulose digestibility, structural and morphology changes. Bioresour Technol 282:525–529. https://doi.org/10.1016/j.biortech.2019.03.065

van Osch DJGP, Kollau LJBM, van den Bruinhorst A et al (2017) Ionic liquids and deep eutectic solvents for lignocellulosic biomass fractionation. Phys Chem Chem Phys 19:2636–2665. https://doi.org/10.1039/c6cp07499e

Wang Z-K, Li H, Lin X-C et al (2020) Novel recyclable deep eutectic solvent boost biomass pretreatment for enzymatic hydrolysis. Bioresour Technol. https://doi.org/10.1016/j.biortech.2020.123237

Xia Q, Liu Y, Meng J et al (2018) Multiple hydrogen bond coordination in three-constituent deep eutectic solvents enhances lignin fractionation from biomass. Green Chem 20:2711–2721. https://doi.org/10.1039/c8gc00900g

Yadav A, Pandey S (2014) Densities and viscosities of (choline chloride + urea) deep eutectic solvent and its aqueous mixtures in the temperature range 293.15 K to 363.15 K. J Chem Eng Data 59:2221–2229. https://doi.org/10.1021/je5001796

Yadav A, Trivedi S, Rai R, Pandey S (2014) Densities and dynamic viscosities of (choline chloride + glycerol) deep eutectic solvent and its aqueous mixtures in the temperature range (283.15-363.15) K. Fluid Ph Equilib 367:135–142. https://doi.org/10.1016/j.fluid.2014.01.028

Yu D, Mu T (2019) Strategy to form eutectic molecular liquids based on noncovalent interactions. J Phys Chem B 123:4958–4966. https://doi.org/10.1021/acs.jpcb.9b02891

Zhang M, Qi W, Liu R et al (2010) Fractionating lignocellulose by formic acid: characterization of major components. Biomass Bioenerg 34:525–532. https://doi.org/10.1016/j.biombioe.2009.12.018

Zhang Q, De Oliveira VK, Royer S, Jérôme F (2012) Deep eutectic solvents: syntheses, properties and applications. Chem Soc Rev 41:7108–7146. https://doi.org/10.1039/c2cs35178a

Zhao X, Zhang L, Liu D (2010) Pretreatment of Siam weed stem by several chemical methods for increasing the enzymatic digestibility. Biotechnol J 5:493–504. https://doi.org/10.1002/biot.200900284

Acknowledgments

The authors gratefully acknowledged the contribution of Client Support Laboratory, Schlumberger for providing the SEM facilities.

Funding

This study is funded by the UCSI University Pioneer Scientist Incentive Fund (Grant number: Proj-In-FETBE-043).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lee, K.M., Hong, J.Y. & Tey, W.Y. Combination of ultrasonication and deep eutectic solvent in pretreatment of lignocellulosic biomass for enhanced enzymatic saccharification. Cellulose 28, 1513–1526 (2021). https://doi.org/10.1007/s10570-020-03598-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-020-03598-5