Abstract

The development of modified fillers is one of the most promising research outcomes that address the challenges of papermaking such as reduced production cost, improved optical properties, better formation and improved drainage rate. In the present investigation, an attempt has been made to evaluate the interaction of xylan with precipitated calcium carbonate (PCC) through adsorption process with an aim to design novel functional composite filler as an alternative to conventional filler used in papermaking. PCC-xylan interactions were found to be more favourable at 40 °C and at neutral pH. However, adsorption increased when calcium chloride (0.1 M) was introduced as background electrolyte at pH 10.5. Adsorption was found to reach its saturation level within 5 h. In order to maximize the xylan adsorption, the roles of various additives such as slaked lime, polyaluminium chloride (PAC), chitosan and cationic polyacrylamide (CPAM) were explored in this paper. Further, the adsorption isotherms of xylan conducted under various conditions were well fitted to the Langmuir model. Alternatively, dual systems comprising PAC/chitosan and PAC/CPAM showed the best result considering the application of the xylan based composite PCC filler in papermaking. It is also quite interesting to note that isotherms data were best fitted to the Freundlich model in presence of chitosan (6%) or CPAM (0.2%) along with PAC indicating complex multilayer adsorption mechanism.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

In this arena of globalisation and tough competitive environment manufacturers are continually putting their conscientious effort to reduce the cost of production with improved quality of their end products. So is the case with paper manufacturers. Paper industries are now utilising most expensive cellulosic polysaccharide for paper production and facing persistent economic pressure on cost reduction. Therefore, different approaches are explored by the papermakers in replacing the fibre fraction with cheaper mineral fillers to minimize manufacturing cost and develop products with improved quality (Chauhan et al. 2011; Kuusisto and Maloney 2015). Fillers impart beneficial attributes such as smoothness, light scattering and printability to the sheet. However, conventional way of incorporating fillers stochastically into the sheet results in weakening of fibre–fibre bonds with reduced retention at high filler dose (Chauhan and Bhardwaj 2017). The current research depicts the picture of a very attractive study field involving filler modification process (Shen et al. 2009; Seo et al. 2017). This increases the filler dose level beyond its current limitations without compromising the other functional properties. Since neutral or alkaline based papermaking is advantageous, precipitated calcium carbonate (PCC) has gained a lot of attention worldwide (Gaudreault et al. 2015). More recently the authors have reported that by modifying PCC surface with inorganic silica, mechanical properties of the sheets can be significantly increased (Lourenço et al. 2016). Moreover, the utilization of PCC in developing cellulose-metal paper composites have shown much potentiality in adsorbing different gases (Yang et al. 2017).

The polyelectrolytes such as natural or synthetic polymers incorporated into sheets to enhance the strength and filler retention are compatible with cellulose fibres (Marton 1991; Nicu et al. 2011; Liu et al. 2017). Hence, there is an urge of modifying filler surface by adsorbing these polyelectrolytes onto them to confer the enhanced bonding ability between fillers and fibres (Yu et al. 2013; El et al. 2014; Huang et al. 2015; Peng et al. 2015). Adsorption may result from either direct physical interaction with the mineral fillers via electrostatic, non electrostatic, hydrogen bonding, chemical bonding or complexation and precipitation of the adsorbate by third component (Somasundaran 1985). The adsorbed polymers can either destabilize or stabilize colloidal particles depending on the degree of surface coverage, molar mass, charge density and type of polymer, solvent/polymer interaction as well as background electrolyte concentration (Gaudreault et al. 2015).

The polyelectrolyte used in this study is hardwood xylan which is anionic, low molecular weight semi crystalline comprising xylose units in their backbone and glucuronic acid as side chain residues (Österberg et al. 2001) (Mocchiutti et al. 2016). As a renewable natural polysaccharide, xylan is proved to be a potential additive in modifying certain properties of handsheets (Oksanen et al. 1997; Bai et al. 2012; Han et al. 2012). The inherent hydrogen bonding ability of xylan with the fibres aids in enhancing the individual fibre strength as well as mechanical properties of the sheet (Ban and van Heiningen 2011; Mansoor Ahmad 2012; Lee et al. 2015) without affecting optical properties (Hu et al. 2016). Increasing hemicelluloses content can decrease the energy consumption during refining (Geng et al. 2006) and prevent hornification during recycling (Duchesne et al. 2001). However, some authors have claimed that adsorbing negatively charged xylan onto cellulose is a difficult process due to electrostatic repulsion between the two (Lee et al. 2015; Danielsson and Lindström 2005). Adsorption can be enhanced either by introducing cationic groups in xylan or pre-treating pulp with cationic polyelectrolytes or by inclusion of salts (Claesson 1995; Kataja-aho et al. 2011).

The interaction between cationic and anionic polyelectrolytes has been extensively studied in papermaking chemistry where coagulation and flocculation play an important role (Korhonen et al. 2013, 2015). A recent study claims that polyelectrolyte complexes between cationic and anionic starches play a significant role in preparing cellulose bondable starch-based PCC filler composites (Fan et al. 2017). A similar concept has also been employed in clarifying the polluted waste water from different industries including pulp and paper, tannin and dye (Divakaran and Sivasankara Pillai 2002; Ahmad et al. 2008; Lertsutthiwong et al. 2009; Mehdinejad et al. 2009; Birjandi et al. 2013). Unlike calcium chloride which works by compression of double layer according to DLVO theory (Österberg et al. 2001), slaked lime (calcium hydroxide) can induce coagulation at high pH by destabilization of the suspended matter (Vandamme et al. 2012). Due to their cationic nature, polyaluminium chloride (PAC) and high molecular weight cationic polyacrylamide (CPAM) have not only been explored as retention aids in papermaking operations but also can be successfully used to remove organic matters from waste water (Jiang and Zhu 2014; Brovkina et al. 2015). On the other hand, numerous researchers focus on the potential application of chitosan as papermaking drainage additive due to its compatibility with stock components (Nicu et al. 2011; Yu et al. 2013). This biopolymer has also gained a lot of attention in waste water application due to its coagulating and flocculating effect (Mehdinejad et al. 2009). The flocculating ability of chitosan at high pH above 7 is an interesting topic and involves the precipitation of the polymer and entrapment of the colloid particles in the coiled polymeric network (Feng et al. 2017). Recently, studies reveal that low molecular weight xylan has the ability to form polyelectrolyte complexes with high molecular weight cationic polymers (Strom et al. 1985; Galván et al. 2015; Mocchiutti et al. 2016). In all cases, it is observed that stable and unstable polyelectrolyte complexes are formed depending on the charge ratio of the polymers. These xylan based polyelectrolyte complexes show high affinity towards cellulose pulp fibres and can significantly increase the strength properties of the sheet (Galván et al. 2015; Mocchiutti et al. 2016). Considering several advantages of xylan as a promising additive, the present study has focused on designing novel composite PCC filler for use in papermaking. To the best of our knowledge, no literature is available on adsorption of xylan onto PCC in order to improve bonding ability of the modified composite filler with cellulosic fibre.

The objective of the present study was to investigate the adsorption characteristics of xylan onto PCC under various process conditions and analyse the effect of different additives i.e. slaked lime, PAC, chitosan and CPAM in enhancing the xylan adsorption. It was hypothesized that all these additives would interact with negative sites of xylan molecules which could possibly result in polymer destabilization and deposition onto the surface of PCC. The main focus was to maximize the adsorbed quantity of xylan on PCC so as to explore the application of this xylan modified PCC as functional filler in papermaking during further studies.

Experimental

Materials

Water-soluble xylan from beechwood was purchased from TCI chemicals, India. Chitosan from shrimp shell with degree of deacetylation ≥ 75% was bought from Himedia. Precipitated Calcium carbonate (PCC), cationic polyacrylamide (CPAM) and Polyaluminium chloride (PAC) were obtained from a paper mill, India. The mean particle size of PCC was 5.12 μm as specified by the supplier. All other chemicals, hydrochloride acid (HCl), calcium chloride (CaCl2) and slaked lime (Ca(OH)2) were of analylitical grade.

Charge analysis of PCC, xylan and cationic additives

Since calcium carbonate gets decomposed at pH below 6, all adsorption experiments were designed in such a way that pH should not decrease below 7. Approximately, 0.1 g of the PCC sample was dispersed in 100 ml distilled water and ultra-sonicated for 30 min prior to the measurements (Fatehi et al. 2013a). The surface charge of PCC solution at both its initial pH and pH 7 (adjusted by HCl) was estimated using a ZetaPlus zeta potential analyzer (Brookhaven, Holtsville, NY, USA). All polymers used as cationic and anionic polyelectrolytes were freshly prepared to avoid any kind of degradation. The colloidal charge density of the filler slurry, xylan and all cationic additives were analyzed on BTG Mutek particle charge detector by polyelectrolyte titration method. A 0.001 N standard solution of polydiallyldimethylammonium chloride (PDADMAC) and polyethene sodium sulfonate (PES-Na) were used as cationic and anionic titrants respectively. PCC, xylan, CPAM and PAC gave their charge density in distilled water while the charge density of chitosan was calculated in 0.1 N HCl.

Adsorption studies

A typical batch adsorption method consisted of 250 ml Erlenmeyer flask in which 10 ml solution from 10% consistency PCC slurry was taken and made up to 50 ml with distilled water after adding desired amount of xylan solutions on the oven dried (OD) basis of PCC. 1% solution of xylan was prepared by dissolving in 100 ml of distilled water at 500 rpm for 1 h at 60 °C. PCC was dispersed for 2 h prior to the experiments by Remi mechanical stirrer. Mixture was then shaken for desired time in a water bath shaker at required temperature. The final solution pH was adjusted after adding xylan to the solution accordingly when needed. The conical flasks were tightly sealed to avoid any exchange of atmospheric CO2 and the final pH was recorded after adsorption. The solution was then centrifuged for 15 min at 3000 rpm by Laboratory Remi Centrifuge (R8C) and then the clear supernatant was collected to analyze the unadsorbed polymer at its equilibrium concentration by total organic carbon analyzer (TOC-LCPH, Shimadzu). The adsorbed amount (mg) of a given polymer/g of PCC (Qe) calculated from initial and final concentrations of the polymers is described by the equation below:

Co and Ce are initial and final equilibrium concentrations of the polymer in liquid phase respectively and expressed in mg/l. V is the volume of the polymer solutions (L) and m is the mass of OD PCC (g).

A set of preliminary experiments were conducted with various factors such as time, temperature, pH and CaCl2 at constant initial dose of xylan.

Effect of inorganic and organic additives on adsorption of xylan

Effect of slaked lime (calcium hydroxide), PAC, chitosan and CPAM was investigated as a third component in the system which was assumed to facilitate xylan adsorption. Among these additives, PAC and chitosan were found to decrease the solution pH (Fernandez-Kim 2004; Chauhan 2012). Therefore, the dose of these two was optimized to maintain the pH of the final solution not below 7. The dosage of each of these additives was optimized based on OD PCC to achieve the maximum adsorbed quantity of xylan onto PCC when initial dose of xylan was kept constant at fixed temperature and time obtained from previous experiments. The final solution pH was recorded after addition of each dose. Dual effects of Chitosan/PAC as well as CPAM/PAC on adsorption of xylan were also analyzed.

Effect of initial dose of xylan on adsorption was studied by carrying out adsorption isotherms ranging the initial dose of xylan from 20 to 70 mg/g of PCC at optimized process conditions and in presence of fixed amount of additives.

Results and discussions

Charge analysis

The charge density of PCC at its initial pH i.e. at pH 10.5 was − 4 μeq/g and zeta potential showed a value of − 15.67 mV indicating that PCC was slightly anionic in nature. At pH 7, the charge density reduced to − 2.1 μeq/g and zeta potential reached a value of − 11 mV. This clearly showed that at neutral pH the PCC also maintained its anionicity and the isoelectric point could not be achieved (Ferreira et al. 2005) in this pH range. The polyelectrolyte titration method showed that charge densities of chitosan, CPAM and PAC were + 7.37, + 0.788 and + 0.910 meq/g respectively. On the other hand, xylan showed an anionic charge density of − 0.71 meq/g.

Effect of different process variables

Since the aim of the present work was to maximize the adsorbed quantity of xylan on PCC, first phase of the work was focused on the effect of different parameters like time, temperature, pH and ionic strength of the medium considering the initial xylan dosage as 20 mg/g PCC i.e. 2% on OD PCC.

It can be seen from Fig. 1a that polyelectrolyte could be adsorbed on PCC and reached its saturation level within 5 h with an adsorbed quantity of 6.5 mg/g PCC. Hereafter, all experiments were conducted for a fixed time of 5 h. The fractions of the xylan sugar units are negatively charged due to presence of uronic acid groups in their side chains. It has been postulated that in addition to attractive Van der Waals forces, another non electrostatic attractive force exists during adsorption of uncharged sugars as well as xylan on negatively charged mica surface (Claesson 1995; Österberg et al. 2001). Similar interactions might have developed between negatively charged PCC surface and polyelectrolyte segments. So overall, attractive forces prevailed over repulsion during adsorption of xylan onto PCC (Österberg et al. 2001; Fatehi et al. 2013a).

Temperature had a negligible impact up to 40 °C on adsorption as depicted in Fig. 1b. Beyond 40 °C adsorption remarkably decreased which implies that reaction is exothermic in nature. It is predicted that the enthalpy gain which should be lowered for favourable adsorption process was more preferred at low temperature. Thus low temperature induced more attractive hydrophobic–hydrophobic interactions for xylan adsorption. Figure 1c describes the effect of pH on the adsorption process. The maximum adsorbed quantity of xylan reached to 10.81 mg/g of PCC at pH 7. Since xylan is close to fully dissociated state at pH 10.5 more number of hydroxyl groups prevail in xylan segment (Österberg et al. 2001). Thats is why the polymer solvent interaction was quite high due to the formation of hydrogen bonds. This could have opposed the polymer to be separated from the solution leading to lower affinity of the polymer towards the surface of PCC. A very similar trend was observed when effects of temperature and pH were studied on adsorption of organic materials on PCC (Fatehi et al. 2013a). Figure 1d shows the effect of calcium chloride on adsorption at two different pH 10.5 and 7. It is noticeable that high pH favoured more adsorption when calcium chloride was used as a background electrolyte and the maximum xylan quantity asorbed was 11.5 mg/g PCC at 0.1 M concentration of electrolyte.

The increasing concentration of electrolyte from 0.01 to 0.1 M reduced the magnitude of repulsive forces between xylan and PCC. It can be concluded that Ca2+ could form intramolecular complexes within the same xylan chains or intermolecular complexes between two xylan chains. More complexes were favoured at high pH since all carboxylic groups were ionizable to interact with Ca2+. Higher adsorption at alkaline pH indicates that the conformation of the adsorbed layer consisted of more number of loops and tails. In the literature, a similar mechanism was explained by authors who studied the effect of calcium ions on adsorption of anionic polymers on different negatively charged surfaces (Claesson 1995; Ostolska 2013; Chibowski et al. 2009). It is possible that calcium ions would have formed bridges between carboxylic groups in xylan and negative charged sites (Österberg et al. 2001) in PCC. Moreover, it was observed that adsorbed amount of xylan decreased when calcium chloride was increased beyond 0.1 M at both pH. This is because complexation of the polyelectrolyte with Ca2+ vastly depends upon the molar concentration of the divalent metal salt (Chibowski et al. 2009; Şakar-Deliormanli et al. 2008). There might be a competitive interaction of Ca2+ with negative sites of PCC particles (Sang and Englezos 2012) which could possibly reduce the electrostatic interactions resulting in decreased adsorption sites.

Effect of different additives

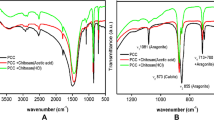

Effect of different additives like slaked lime, PAC, chitosan and CPAM was evaluated on the adsorption of xylan onto PCC considering initial xylan dose as 2%. The optimal dose for maximum adsorption of xylan is given in Table 1. A comparative study of the effect of slaked lime, PAC and chitosan on adsorption of xylan on PCC is depicted in Fig. 2.

Effect of calcium based inorganic flocculant

Earlier discussions showed that divalent Ca2+ ions played an important role in facilitating xylan adsorption. Therefore, a calcium based inorganic compound, a saturated solution of slaked lime was considered as an additive for enhancing xylan adsorption. As shown in Fig. 2, adsorption of xylan increased with increasing amount of slaked lime and then remained constant after the optimal dose. The mechanism of double layer compression by calcium ions cannot be explained as the pH of the suspension increased to 11.5 due to addition of slaked lime (Vandamme et al. 2012). High adsorption of xylan implies that Ca2+ of saturated lime might react with the glucuronic acid side chain residues favouring the intermolecular interaction between two xylan chains. Ca2+ ions induced xylan adsorption on cellulose was due to the crosslinking of two carboxylate ions of glucuronic acids (Pereira et al. 2017). This phenomenon might have resulted in the formation of insoluble xylan-calcium complexes and subsequent precipitation from the solution. The authors have shown that addition of lime can successfully remove organic sugars and acids with the formation of calcium mediated insoluble complexes (Wang et al. 2015; Randtke et al. 2016).

Effect of aluminium based inorganic flocculant

Adsorption of xylan onto PCC increased with increasing dose of PAC as depicted in Fig. 2. Since high alkalinity of PCC caused partial neutralization of PAC charge and the dominating hydrolyzed product was Al(OH) −4 (Libecki and Dziejowski 2008), large amount of coagulant was required to remove the xylan from the solution. Additionally, it was observed that pH decreased as PAC was introduced into the solution. It is reported that removal efficiency of the contaminants by PAC depends on the solution pH (Mohammadi et al. 2014). When PAC is added to water, it hydrolyzes into positive aluminium based species like Al(OH)2+, Al(OH)4+, and Al3(OH)5+ depending on the water pH. For optimized PAC dose, pH of the solution required to achieve the maximum possible adsorption lay between 7 and 7.5. It has been postulated that pH range between 6 and 8 promotes formation of high polymeric positive hydrolyzates and aluminium hydroxide (Mohammadi et al. 2014). Generally, flocculation by PAC at neutral pH is accompanied by enmeshment of particulate matters in the polymeric chain of the coagulant. This type of coagulation is termed as Sweeping mechanism (Schroeder and Rubin 1984). Therefore, Xylan–Al complexes might have formed when aluminium species interacted with the exterior negative charge of xylan molecules with the in situ formation of the sweep flocs Al (OH)3. This could destabilize and deposit the polymer onto PCC surface. Note that colloidal Al (OH)3 induced adsorption of starch on PCC was reported earlier (Fritz Hedborg Tom Lindström 1993).

Effect of amine containing biopolymer

Unlike slaked lime and PAC, chitosan was not effective in removing xylan from the solution at a low dose below 0.7% resulting in decreased adsorption as shown in Fig. 2. This indicated the formation of a stable colloid type polyelectrolyte complex between xylan and chitosan molecules. Complexation might be the result from strong hydrogen bonding as well as electrostatic interactions between OH groups in glucuronic acid residues in beech xylan and O–H, N–H groups prevailing in chitosan (Luo et al. 2014). However, maximum amount of xylan adsorbed was found at a chitosan dose of 6% with a final pH of 7.5. Adsorption did not show significant changes beyond this dose. Since charge density of NH3+ on chitosan decreases at high pH (Cheng et al. 2010), it is assumed that the long rod like stiff polymer chain coiled and entangled itself with the disappearance of electrostatic repulsion between the chains in high alkaline condition created by PCC. Upon increasing the concentration of chitosan, small xylan molecules got entrapped and assembled into the coiled structure of chitosan chain resulting in destabilization and co-deposition of xylan-chitosan complex facilitating adsorption of xylan on PCC surface. Restabilization of colloidal xylan occurred at higher dose of chitosan. Chitosan’s ability to co-deposit various low molecular weight components like proteins, nano particles has also been reported in the literature (Kim et al. 2015). The mechanism behind the formation of stable and unstable polyelectrolyte complexes is represented in Fig. 3. In the literature, formation of unstable complexes was observed by the authors when chitosan was added to the xylan solution resulting in large aggregates (Mocchiutti et al. 2016).

Effect of combined dosage of chitosan and PAC for xylan adsorption

Since in the earlier studies many authors have claimed that turbidity removal efficiency increased with the combined dose of chitosan and PAC (Mohammadi et al. 2014), an attempt was made to observe synergic effect of chitosan and PAC on the adsorption of xylan onto PCC. It is concluded from Fig. 4 that xylan adsorption depended on the order of addition of PAC and chitosan. Adsorption was comparatively higher when fixed dose of PAC was added to xylan and PCC mixture before different doses of chitosan were introduced. The final pH of the solution reached 7 with combined dose of PAC and chitosan. It was discussed earlier in a study that aluminium released from hydrolysis of PAC in water interacted with amine molecules in chitosan when PAC/chitosan composite coagulant was used for removal of natural organic matters (NOMS) (Ng et al. 2012). It is envisaged from the result that a certain dose of salt i.e. PAC, which acts as an electrolyte, entered the polyelectrolyte complex (PEC) by interacting with both xylan and chitosan and might have formed a bridge between the two polymer chains. This mechanism perhaps resulted in aggregation of the complex. The authors (Strom et al. 1985; Zhang et al. 2015b) have seen unstable complexes at stoichiometric or nonstoichiometric ratio of low and high molecular weight polymers in presence of low ionic strength. PAC could also screen the repulsive forces between two PECs via colloidal aluminium species resulting from PAC hydrolysis enhancing xylan adsorption. It can be clearly stated that in presence of excess chitosan, hydrolysis of PAC to colloidal aluminium species was retarded (Ng et al. 2012) and serious stabilization of the colloidal xylan occurred instead of xylan-chitosan co-precipitation on PCC. More stable complexes were formed when PAC was introduced after addition of fixed dose of chitosan to xylan–PCC mixture.

Effect of amine based synthetic polymer

Another set of experiments were carried out to study the effect of most popular papermaking retention aid, CPAM on the adsorption of xylan. Since the initial high pH of PCC i.e. 10.5 showed that TOC of the supernatant significantly increased with increasing dose of CPAM from 0.1 to 2% as shown in Fig. 5, adsorption amount could not be measured. The final pH was observed to be the same after adsorption. This helped us to predict that at high pH, partial hydrolyzed chains of CPAM (Peng and Garnier 2010) could have interacted with xylan molecules to form stable polyelectrolyte complexes. The interaction between pine xylan and CPAM resulting in both stable and unstable complexes at their non-stoichiometric ratio has already been discussed earlier (Strom et al. 1985). For this reason, the initial pH of the solution and lower dosage of CPAM were considered. As observed from Fig. 6, two experimental conditions were taken into consideration. (a) Addition of CPAM at low pH, since at this pH it maintains its cationic charge density (b) Addition of CPAM in presence of PAC. As shown in Fig. 6 adsorption was more when CPAM was introduced along with PAC as compared to when CPAM was used alone at pH 7. In both cases, adsorption decreased after the optimal dose.

In the literature, it is well established that water-soluble complexes can be formed between oppositely charged polyelectrolytes based on several factors like presence of salt or significant differences between the molecular weights of two polyelectrolytes (Aryee and Nickerson 2014; Zhang et al. 2015b). From our result it is anticipated that the formed PEC particles between xylan and CPAM might be stabilized by the segments of xylan that charged the PEC surface at pH 7 as low amount of CPAM failed to neutralize the charge on xylan molecules. Hence, it prevented further formation of unstable complexes inhibiting xylan adsorption on PCC. Stable PECs were proved to be formed at highly non-stoichiometric ratio of polycation and polyanion (Zhang et al. 2015b). Figure 7 depicts a schematic picture of possible interaction of xylan with CPAM at low and high pH that might happen during the process of adsorption.

However, in presence of a fixed dose of PAC, xylan adsorption increased at a very little CPAM dosage 0.08%. Possibility of chemical interaction of aluminium of PAC with oxygen on CONH2 group on CPAM has already been established earlier (Zhou et al. 2015). It can be concluded that at certain dose of PAC, hydrolyzed Al species interacted with xylan and CPAM chains thus facilitating the aggregation and deposition of the complex from the solution. Similar mechanism might have occurred when PAC was used with chitosan for xylan adsorption. An overdose of CPAM induced steric and electrostatic repulsive columbic forces among the xylan chains resulting in restabilization of the colloidal xylan. Possible mechanisms that might involve in dual PAC/Chitosan or PAC/CPAM are shown by the schematic representation in Fig. 8.

Effect of initial dose of xylan

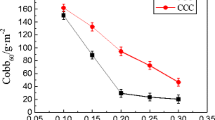

Firstly, adsorption of xylan at equilibrium was investigated as a function of initial polymer concentration under various process conditions like temperature, pH and calcium chloride as shown in Fig. 9. It was observed that at initial condition i.e. at pH 10.5 and 30 °C, adsorption decreased beyond a xylan dose of 20 mg/g of PCC. On the contrary, adsorption improved with increasing dose of xylan at neutral pH and 40 °C. Addition of electrolyte (calcium chloride) at pH 10.5 further enhanced the saturation level to a xylan dose of 50 mg/g of PCC. Figure 10 shows the adsorption of xylan on PCC in presence of slaked lime, PAC, chitosan, CPAM, PAC/chitosan, PAC/CPAM at their certain fixed doses when initial polymer concentration was varied. It shows that in presence of slaked lime adsorption reached a saturation level at a xylan dose of 30 mg/g PCC and then decreased beyond 60 mg/g PCC. PAC proved to be a better coagulant than slaked lime and attained a maximum saturation level for a xylan dose of 60 mg/g PCC. However, in presence of chitosan, adsorption of xylan was lower than in presence of PAC up to a dose of 60 mg/g PCC. Further, the saturation level could not be achieved in the whole range of added polymer. Similar trend was also observed by combined effect of chitosan and PAC with slightly enhanced adsorption. Thus it is anticipated that low molecular weight inorganic PAC could not enhance the adsorption of xylan beyond 60 mg/g PCC indicating that more aluminium species were needed to neutralize the charge of xylan. In contrast, chitosan could destabilize the xylan molecules even beyond 60 mg/g indicating that long polymer chain had enough sites available for complexation with xylan facilitating adsorption of xylan at its high dose. It is also evident from Fig. 10 that with increasing dose of CPAM from 0.08 to 0.2%, adsorption increased when initial xylan dose was increased. Therefore, the long chains of the polymer aided in aggregation of the xylan via charge interaction and subsequent destabilization from the solution. It was reported in the literature that higher concentration of CPAM at neutral pH enhanced the adsorption of organic matter of prehydrolysis liquor on PCC (Fatehi et al. 2013a).

All experimental adsorption data were plotted to determine the adsorption behaviour of xylan under various process conditions and in presence of additives. Two adsorption isotherms namely Langmuir and Freundlich models were adapted to fit the experimental data by linear regression analysis. The assumptions of Langmuir model are that a saturated continuous monolayer of the adsorbent on the adsorbate surface exists, no interaction between adsorbate and adsorbent takes place and there is presence of equivalent sites on the adsorbent where adsorbate can be attached. The linearized form of the Langmuir equation is expressed as follows (Tekin et al. 2005; Fatehi et al. 2013a; Rasteiro et al. 2015)

where θmax is the maximum amount of polymers adsorbed on PCC to form a saturated monolayer on the surface and expressed as mg/g of PCC. ce is the equilibrium concentration of the polymer after adsorption expressed in mg/l. k is the constant related to the binding affinity with the surface.

The dimensionless separation factor RL is defined by the Langmuir model and is expressed by the following equation:

The adsorption is assumed to be favourable if 0 < RL < 1. Linear adsorption occurs when R L = 1 and unfavourable adsorption takes place if R L > 1 (Tekin et al. 2005)

The assumptions of freundlich model are that adsorption is governed by multilayer adsorption mechanism on heterogeneous surface. The linearized form of the model is given by the following expression (Zhang et al. 2015a)

qe (mg/g of PCC) is the amount of polymer adsorbed at equilibrium concentration ce (mg/l). Kf is the freundlich constant and related to adsorption capacity. 1/n defines the strength of adsorption. 1/n less than unity or n values lying between 1 and 10 represent a favourable adsorption (Dada et al. 2012) The parameters for Langmuir and Freundlich isotherm are represented in Table 2.

Figure 11a and c showed that experimental data were fitted well to Langmuir model with correlation coefficient R2 values ranging from 0.96 to 0.99 when plot ce/qe vs. ce produced a straight line. All R L values for xylan adsorption on PCC varied between 0.01 and 0.80 indicating that adsorption process under every condition was favourable. However, it is interesting to note that in presence of dual PAC/chitosan system, freundlich model was best fitted indicating a complex multilayer adsorption mechanism with R2 value 0.99. Another interesting phenomenon observed while studying dual PAC/CPAM system was that isotherm was more fitted to Freundlich model at higher CPAM dose as seen from Fig. 11d. This suggests that there might be a possibility of multilayer adsorption (Fatehi et al. 2013b) of xylan at higher dose of CPAM. R2 value was found to be 0.98 and value of n greater than unity suggests that adsorption was favourable. Among all the additives studied Qmax for xylan in presence of dual PAC/Chitosan was the maximum. It was also observed that in presence of same quantity of PAC, about 5 times lesser amount of CPAM (0.2%) than chitosan (1%) was required to achieve almost same value of Qmax.

Potential commercial applications

The contribution of xylan in modifying sheet properties provides new opportunity for the paper makers to further enhance the performance of this renewable raw material as a novel additive (Ban and van Heiningen 2011; Mansoor Ahmad 2012). Because of these reasons, the utilisation of xylan as a value added additive in filler modification technology will pave the way for developing sustainable and eco-friendly products in papermaking industries. In the present study, it was found that dual system comprising PAC/chitosan or PAC/CPAM gave promising results in enhancing xylan adsorption onto PCC to induce modified functional filler. As a consequence, it is quite predictable that xylan based polyelectrolyte complexes deposited on PCC surface can improve the bondability of modified filler composites with cellulose fibres (Galván et al. 2015; Mocchiutti et al. 2016; Yu et al. 2013; El et al. 2014; Peng et al. 2015). This technology may be a good approach to reduce the negative effect of high filler loading with subsequent improvement of paper strength (Yu et al. 2013; Chen et al. 2014; Kuusisto and Maloney 2015). This also may open a new alternative way to increase filler amount in paper without affecting the critical properties (Lourenço et al. 2016). Hence, overall cost of production can be minimized by partial replacement of fibres with these mineral filler composites which will benefit the paper makers in terms of economy. Therefore, the xylan based PCC filler composites have much potential in papermaking considering its end-use applications as functional filler.

Concluding remarks

In this paper adsorption of beech wood xylan was studied onto anionic PCC. Some key findings of this study are as follows. Firstly, the magnitude of adsorption was rather low at alkaline pH. Secondly, interaction of xylan with PCC was found to depend on several process conditions like time, temperature, pH and background electrolytes. In particular, adsorption was favourable at neutral pH and lower temperature. Further, driving force for xylan could be enhanced when calcium chloride was introduced as a background electrolyte in the system.

The next phase of this work describes the role of various additives such as slaked lime, PAC, chitosan, CPAM in aiding xylan adsorption onto PCC. At low initial dosage of xylan, slaked lime was found to be more efficient in removing xylan from the solution and in depositing on PCC as compared to PAC and chitosan. However, it appeared to be least efficient among the additives at higher dosage of xylan. Our study reveals that chitosan proved to be a good coagulant even at higher xylan dose. However, maximum adsorbed quantity of xylan was achieved with combined effect of PAC and chitosan. At the same time, in presence of PAC, 5 times smaller dose of CPAM was required to attain almost equal amount of maximum adsorbed quantity of xylan as obtained with chitosan. All the adsorption experimental data obtained under applied conditions were well fitted to the Langmuir isotherm model except in cases of chitosan/PAC and CPAM/PAC. From the environmental point of view, due to high biodegradability, chitosan/PAC dual system was considered to give the most encouraging results in enhancing xylan adsorption onto PCC surface. Thus the findings show much potential in producing xylan based PCC filler composites as functional additives for papermaking applications.

References

Ahmad AL, Wong SS, Teng TT, Zuhairi A (2008) Improvement of alum and PACl coagulation by polyacrylamides (PAMs) for the treatment of pulp and paper mill wastewater. Chem Eng J 137:510–517. https://doi.org/10.1016/j.cej.2007.03.088

Aryee FNA, Nickerson MT (2014) Effect of pH, biopolymer mixing ratio and salts on the formation and stability of electrostatic complexes formed within mixtures of lentil protein isolate and anionic polysaccharides (k-carrageenan and gellan gum). Int J Food Sci Technol 49:65–71. https://doi.org/10.1111/ijfs.12275

Bai L, Hu H, Xu J (2012) Influences of configuration and molecular weight of hemicelluloses on their paper-strengthening effects. Carbohydr Polym 88:1258–1263. https://doi.org/10.1016/j.carbpol.2012.02.002

Ban W, van Heiningen ARP (2011) Adsorption of hemicellulose extracts from hardwood onto cellulosic fibers. I. Effects of adsorption and optimization factors. Cellul Chem Technol 45:57–65

Birjandi N, Younesi H, Bahramifar N et al (2013) Optimization of coagulation-flocculation treatment on paper-recycling wastewater: application of response surface methodology. J Environ Sci Heal Part A 48:1573–1582. https://doi.org/10.1080/10934529.2013.797307

Brovkina J, Shulga G, Neiberte B, et al (2015) Difference in the treatment effectiveness of woodworking wastewater between polyaluminium chloride-based coagulants. In: Proceedings of the 10th international scientific and practical conference, pp 64–70

Chauhan VS (2012) Optimization of alkaline sizing to reduce the sizing cost. Yamuna Nagar, India

Chauhan VS, Bhardwaj NK (2017) Efficacy of dispersion of magnesium silicate (talc) in papermaking. Arab J Chem 10:S1059–S1066. https://doi.org/10.1016/j.arabjc.2013.01.012

Chauhan VS, Sharma A, Chakrabarti SK, Varadhan R (2011) Energy savings through increased filler loading in paper vol 23, pp 171–176

Chen Z, Li C, Song Z, Qian X (2014) Modification of precipitated calcium carbonate filler for papermaking with adsorption of cationically derivatized chitosan and carboxymethyl chitosan. BioResources 9:5917–5927

Cheng Y, Luo XL, Betz J et al (2010) In situ quantitative visualization and characterization of chitosan electrodeposition with paired sidewall electrodes. Soft Matter 6:3177–3183. https://doi.org/10.1039/c0sm00124d

Chibowski S, Grządka E, Patkowski J (2009) Influence of a type of electrolyte and its ionic strength on the adsorption and the structure of adsorbed polymer layer in the system: polyacrylic acid/SiO2. Croat Chem Acta 82:623–631

Claesson P (1995) Interactions between mica surfaces in presence of carbohydrates. J Colloid Interface Sci 172:415–425

Dada A, Olalekan A, Olatunya A, Dada O (2012) Langmuir, freundlich, temkin and dubinin—radushkevich isotherms studies of equilibrium sorption of Zn2+ unto phosphoric acid modified rice husk. J Appl Chem 3:38–45

Danielsson S, Lindström ME (2005) Influence of birch xylan adsorption during kraft cooking on softwood pulp strength. Nord Pulp Pap Res J 20:436–441. https://doi.org/10.3183/NPPRJ-2005-20-04-p436-441

Divakaran R, Sivasankara Pillai VN (2002) Flocculation of river silt using chitosan. Water Res 36:2414–2418. https://doi.org/10.1016/S0043-1354(01)00436-5

Duchesne I, Hult E, Molin U et al (2001) The influence of hemicellulose on fibril aggregation of kraft pulp fibres as revealed by FE-SEM and CP/MAS13C-NMR. Cellulose 8:103–111. https://doi.org/10.1023/A:1016645809958

El A, Khiari R, Bettaieb F, et al (2014) Preparation and application of chemically modified kaolin as fillers in Egyptian kraft bagasse pulp. Appl Clay Sci 101:626–631. https://doi.org/10.1016/j.clay.2014.09.032

Fan J, Li T, Ren Y et al (2017) Interaction between two oppositely charged starches in an aqueous medium containing suspended mineral particles as a basis for the generation of cellulose-compatible composites. Ind Crops Prod 97:417–424. https://doi.org/10.1016/j.indcrop.2016.12.048

Fatehi P, Hamdan FC, Ni Y (2013a) Adsorption of lignocelluloses of pre-hydrolysis liquor on calcium carbonate to induce functional filler. Carbohydr Polym 94:531–538. https://doi.org/10.1016/j.carbpol.2013.01.081

Fatehi P, Shen J, Hamdan FC, Ni Y (2013b) Improving the adsorption of lignocelluloses of prehydrolysis liquor on precipitated calcium carbonate. Carbohydr Polym 92:2103–2110. https://doi.org/10.1016/j.carbpol.2012.11.046

Feng B, Peng J, Zhu X, Huang W (2017) The settling behavior of quartz using chitosan as flocculant. J Mater Res Technol 6:71–76. https://doi.org/10.1016/j.jmrt.2016.09.004

Fernandez-Kim S-O (2004) Physicochemical and functional properties of crawfish chitosan as affected by different processing protocols. Seol National University

Ferreira P, Velho J, Figueiredo M (2005) Effect of thermal treatment on the structure of PCC particles. Tappi J 4:18–22

Hedborg F, Lindström T (1993) Adsorption of cationic starch on a CaCO3 filler. Nord Pulp Pap Res J 8:319–325. https://doi.org/10.3183/NPPRJ-1993-08-03-p319-325

Galván MV, Peresin MS, Mocchiutti P et al (2015) Effects of charge ratios of xylan-poly(allylamine hydrochloride) complexes on their adsorption onto different surfaces. Cellulose 22:2955–2970. https://doi.org/10.1007/s10570-015-0706-z

Gaudreault R, Di Cesare N, Van De Ven TGM, Weitz DA (2015) Structure and strength of flocs of precipitated calcium carbonate induced by various polymers used in papermaking. Ind Eng Chem Res 54:6234–6246. https://doi.org/10.1021/acs.iecr.5b00818

Geng ZC, Sun JX, Liang SF et al (2006) Characterization of water- and alkali-soluble hemicellulosic polymers from sugarcane bagasse. Int J Polym Anal Charact 11:209–226. https://doi.org/10.1080/10236660600649095

Han W, Zhao C, Elder T et al (2012) Study on the modification of bleached eucalyptus kraft pulp using birch xylan. Carbohydr Polym 88:719–725. https://doi.org/10.1016/j.carbpol.2012.01.025

Hu G, Fu S, Liu H, Lucia LA (2016) The role of absorbed hemicelluloses on final paper properties and printability. Fibers Polym 17:389–395. https://doi.org/10.1007/s12221-016-4838-z

Huang X, Qian X, Li J et al (2015) Starch/rosin complexes for improving the interaction of mineral filler particles with cellulosic fibers. Carbohydr Polym 117:78–82. https://doi.org/10.1016/j.carbpol.2014.09.047

Jiang Z, Zhu J (2014) Cationic polyacrylamide: synthesis and application in sludge dewatering treatment. Asian J Chem 26:629–633. https://doi.org/10.14233/ajchem.2014.16055

Kataja-aho J, Haavisto S, Asikainen J, Vuoti S (2011) The influence of cationized birch xylan on wet and dry strength of fine paper. BioResources 7:1713–1728

Kim E, Xiong Y, Cheng Y et al (2015) Chitosan to connect biology to electronics: fabricating the bio-device interface and communicating across this interface. Polymers (Basel) 7:1–46. https://doi.org/10.3390/polym7010001

Korhonen MHJ, Holappa S, Stenius P, Laine J (2013) Flocculation of fillers with polyelectrolyte complexes. Nord Pulp Pap Res J 28:239–247. https://doi.org/10.3183/NPPRJ-2013-28-02-p239-247

Korhonen MHJ, Rojas OJ, Laine J (2015) Effect of charge balance and dosage of polyelectrolyte complexes on the shear resistance of mineral floc strength and reversibility. J Colloid Interface Sci 448:73–78. https://doi.org/10.1016/j.jcis.2015.01.075

Kuusisto JE, Maloney TC (2015) The effect of carbonation conditions on the properties of carbohydrate-calcium carbonate hybrid pigments. BioResources 10:3277–3292. https://doi.org/10.15376/biores.10.2.3277-3292

Lee SH, Lee HL, Youn HJ (2015) Adsorption of xylan onto cellulose fibers pretreated with cationic polyelectrolyte and its effect on paper properties. BioResources 10:851–865

Lertsutthiwong P, Sutti S, Powtongsook S (2009) Optimization of chitosan flocculation for phytoplankton removal in shrimp culture ponds. Aquac Eng 41:188–193. https://doi.org/10.1016/j.aquaeng.2009.07.006

Libecki B, Dziejowski J (2008) Optimization of humic acids coagulation with aluminum and Iron(III) salts. Polish J Environ Stud 17:397–403

Liu Z, Li X, Xie W (2017) Carrageenan as a dry strength additive for papermaking. PLoS ONE 12:1–11. https://doi.org/10.1371/journal.pone.0171326

Lourenço AF, Simões RS, Costa AP et al (2016) Papermaking trials in a pilot paper machine with a new silica coated PCC filler. Nord Pulp Pap Res J 31:341–346. https://doi.org/10.3183/NPPRJ-2016-31-02-p341-346

Luo Y, Pan X, Ling Y et al (2014) Facile fabrication of chitosan active film with xylan via direct immersion. Cellulose 21:1873–1883. https://doi.org/10.1007/s10570-013-0156-4

Mansoor Ahmad Z (2012) Xylan as strength enhancing additive. KTH Royal Institute of Technology

Marton J (1991) Paper chemistry. Springer, Netherland

Mehdinejad MH, Bina B, Nikaeen M, Attar HM (2009) Effectiveness of chitosan as natural coagulant aid in removal of turbidity and bacteria from turbid waters. J Food Agric Environ 7:845–850

Mocchiutti P, Schnell CN, Rossi GD et al (2016) Cationic and anionic polyelectrolyte complexes of xylan and chitosan. Interaction with lignocellulosic surfaces. Carbohydr Polym 150:89–98. https://doi.org/10.1016/j.carbpol.2016.04.111

Mohammadi AS, Mobarakian A, Taherkhani F et al (2014) Effect of Chitosan as a coagulant aid combined with poly aluminum chloride removing of turbidity from drinking water. Avicenna J Env Heal Eng. https://doi.org/10.5812/ajehe.187

Ng M, Liana AE, Liu S et al (2012) Preparation and characterisation of new-polyaluminum chloride-chitosan composite coagulant. Water Res 46:4614–4620. https://doi.org/10.1016/j.watres.2012.06.021

Nicu R, Bobu E, Desbrieres J (2011) Chitosan as cationic polyelectrolyte in wet-end papermaking systems. Cellul Chem Technol 45:105–111

Oksanen T, Buchert J, Viikari L (1997) The role of hemiocelluloses in the hornification of bleached kraft pulps. Holzforschung 51:355–360

Österberg M, Laine J, Stenius P et al (2001) Forces between xylan-coated surfaces: effect of polymer charge density and background electrolyte. J Colloid Interface Sci 242:59–66. https://doi.org/10.1006/jcis.2001.7752

Ostolska I (2013) Influence of the electrolyte type on the adsorption and electrokinetic properties of the ionic polyamino acids—Cr2O3 system. Ann UMCS Chem 68:75–93

Peng P, Garnier G (2010) Effect of cationic polyacrylamide adsorption kinetics and ionic strength on precipitated calcium carbonate flocculation. Langmuir 26:16949–16957. https://doi.org/10.1021/la103410j

Peng Y, He B, Zhao L (2015) Lime mud CaCO3 for use as a filler material in papermaking: impact of its preflocculation with cationic polyacrylamide

Pereira CS, Silveira RL, Dupree P, Skaf MS (2017) Effects of xylan side-chain substitutions on xylan-cellulose interactions and implications for thermal pretreatment of cellulosic biomass. Biomacromol 18:1311–1321. https://doi.org/10.1021/acs.biomac.7b00067

Randtke SJ, Thiel CE, Liao MY et al (2016) Removing soluble organic contaminants by lime-softening. Am Water Work Assoc 74:192–202

Rasteiro MG, Pinheiro I, Ahmadloo H et al (2015) Correlation between flocculation and adsorption of cationic polyacrylamides on precipitated calcium carbonate. Chem Eng Res Des 95:298–306. https://doi.org/10.1016/j.cherd.2014.11.007

Şakar-Deliormanli A, Çelik E, Polat M (2008) Adsorption of anionic polyelectrolyte and comb polymers onto lead magnesium niobate. Colloids Surf A Physicochem Eng Asp 316:202–209. https://doi.org/10.1016/j.colsurfa.2007.09.004

Sang Y, Englezos P (2012) Flocculation of precipitated calcium carbonate (PCC) by cationic tapioca starch with different charge densities. II: Population balance modeling. Colloids Surf A Physicochem Eng Asp 414:520–526. https://doi.org/10.1016/j.colsurfa.2012.07.028

Schroeder RP, Rubin JA (1984) Aggregation and colloidal stability of fine-particle coal suspensions. Environ Sci Technol 18:264–271

Seo YB, Choi JS, Ji SG (2017) Stability of pre-treated fillers for high loaded printing paper. Korean Chem 55:1–6

Shen J, Song Z, Qian X, Liu W (2009) Modification of papermaking grade fillers: a brief review. BioResources 4:1190–1209. https://doi.org/10.15376/BIORES.4.3.1190-1209

Somasundaran P (1985) 1&1 surface precipitation of inorganics and surfactants and its role in adsorption and flotation. Colloids Surf 13:151–167

Strom G, Barla P, Stenius P (1985) The formation of polyelectrolyte. Colloids Surf 13:193–207

Tekin N, Demirbaş Ö, Alkan M (2005) Adsorption of cationic polyacrylamide onto kaolinite. Microporous Mesoporous Mater 85:340–350. https://doi.org/10.1016/j.micromeso.2005.07.004

Vandamme D, Foubert I, Fraeye I et al (2012) Flocculation of Chlorella vulgaris induced by high pH: role of magnesium and calcium and practical implications. Bioresour Technol 105:114–119. https://doi.org/10.1016/j.biortech.2011.11.105

Wang Z, Wang X, Fu Y, Qin M (2015) RSC Advances Saccharide separation from wood prehydrolysis liquor: comparison of selectivity toward non- saccharide compounds with separate techniques. RSC Adv 5:28925–28931. https://doi.org/10.1039/C4RA17017B

Yang Q, Zhang M, Song S, Yang B (2017) Surface modification of PCC filled cellulose paper by MOF-5 (Zn3(BDC)2) metal–organic frameworks for use as soft gas adsorption composite materials. Cellulose 24:3051–3060. https://doi.org/10.1007/s10570-017-1331-9

Yu Y, Xue G, Gu C et al (2013) Preparation of Chitosan modified talc and its application in high filler content paper. J Appl Polym Sci 129:2692–2698. https://doi.org/10.1002/app.38992

Zhang H, Wang Y, Bai P et al (2015a) Adsorptive separation of acetic acid from dilute aqueous solutions: adsorption kinetic, isotherms, and thermodynamic studies. J Chem Eng Data 61:213–219. https://doi.org/10.1021/acs.jced.5b00481

Zhang Y, Yildirim E, Antila HS et al (2015b) The influence of ionic strength and mixing ratio on the colloidal stability of PDAC/PSS polyelectrolyte complexes. Soft Matter 11:7392–7401. https://doi.org/10.1039/C5SM01184A

Zhou FS, Li J, Zhou L, Liu Y (2015) Preparation and mechanism of a new enhanced flocculant based on bentonite for drinking water. Adv Mater Sci Eng. https://doi.org/10.1155/2015/579513

Acknowledgments

The research grant for this work was funded by the Ministry of Human Resources and Development, Government of India.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghosh, I., Sharma, C. & Tandon, R. Role of additives to improve adsorption of xylan on precipitated calcium carbonate. Cellulose 25, 1583–1598 (2018). https://doi.org/10.1007/s10570-018-1666-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-018-1666-x