Abstract

Microencapsulated finishes are an important element in the development of new textiles. In this context, a large area to be explored is microencapsulation of essential oils in textiles. This technique offers the possibility of developing new products with many advantages over traditional fabrics, as traditional finishing may be ineffective for reasons related to uncontrolled release of the active principle while microencapsulation aims to achieve increased duration of the finishing effect. However, many studies present only the application of microcapsules in a textile but do not report how the release of the encapsulated material occurs or the influence of the textile matrix. This paper reports the mechanism and kinetics of controlled release of microencapsulated citronella oil in cotton and polyester. The microencapsulation was done by complex coacervation with gelatin and gum Arabic as shell materials. The resulting microcapsules were analyzed by optical microscopy, scanning electron microscopy, thermogravimetric analysis, and dynamic light scattering. They were then applied in cotton and polyester and evaluated by attenuated total reflection Fourier-transform infrared spectroscopy. Finally, the controlled release of citronella from the microcapsules deposited on the fabrics was studied in vitro. It was found that the release was directly influenced by the type of fiber: the microcapsules in polyester showed diffusion by a Fickian mechanism, while a non-Fickian kinetic model fit for the modified cotton. Comprehension of such controlled release processes is fundamental for achieving and developing more durable finishing effects.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Finishing of textile products is a fundamental factor in their commercialization (Salem 2010). Through such processing, textiles go beyond protection of the human body to interact in special ways with skin (Lv et al. 2014; Rubio et al. 2010; Wang et al. 2009). When a textile starts to exhibit particularly useful properties when in contact with the body, it becomes more interesting and attractive to the consumer.

Changes made during fabric improvement are called “finishes.” Some finishes applied to textile products suffer from great limitations in terms of application or durability. These limitations are related to the sensitivity of such substances, which may oxidize, be inhibited, or evaporate on mere contact with the environment (Feczkó et al. 2010; Özdemir and Gökmen 2015; Qv et al. 2005; Yang et al. 2014). There therefore exists a need to protect them from the environment in order to extend their service life and control the release of such products. According to Desai and Park (2005), Jamekhorshid et al. (2014), Leclercq et al. (2009), and Nesterenko et al. (2013), this can be achieved by creating an envelope around the product through microencapsulation.

Microencapsulation is a commonly used technique in food and pharmaceutical industries, but has been little explored for use in textile industry. In the 1990s, some commercial applications appeared (Nelson 2002), and over the years, manufacturers of textile articles have demonstrated increasing interest in fabrics with new properties to enable their improvement.

Applications of microcapsules in the textile field range from utilization as fire-retardant agents (Nelson 2002), protection against atmospheric agents (Annan et al. 2008; Souza et al. 2012; Zimet and Livney 2009), to functional finishes (Rubio et al. 2010; Cheng et al. 2009; Li et al. 2013; Hassan and Sunderland 2015; Matin et al. 2013). Utilization of microencapsulated active substances in cotton and polyester fabrics has attracted increasing attention with the development of functional fabrics with various effects to solve problems that cannot be addressed by traditional processing (Li et al. 2013; Ma et al. 2009; Sanchez et al. (2010).

Currently, among these possibilities, according to Frederiksen et al. (2003), in relation to the active principle, the greatest interest in microencapsulation in the textile industry is related to application of durable essential oils to fabrics to obtain controlled release in medical applications (Chatterjee et al. 2014). Such controlled liberation allows extension of the oil’s service life, thus avoiding its rapid evaporation and improving its performance (Martins et al. 2014; Tzhayik et al. 2012; Gillij et al. 2008).

The medical effect depends on the type of oil used. Several essential oils have already been applied, such as lavender, rosemary, and jasmine, exhibiting medicinal properties (Martin et al. 2013; Karaman et al. 2001; Piacentini et al. 2013; Fei et al. 2015; Wang et al. 2014; Shahid-ul-Islam and Mohammad 2013) as well as protection against disease vectors (El Asbahani et al. 2015; Prajapati et al. 2005; Solomon et al. 2012; Specos et al. 2010).

An oil that has drawn attention because of its functionality and effects is citronella essential oil (CIEO) from Cymbopogon nardus (El Asbahani et al. 2015; Solomon et al. 2012). According to the results of Specos et al. (2010), CIEO shows mosquito repellent action, especially against Aedes aegypti. On the other hand, some researchers have reported that this oil may be ineffective for reasons related to its uncontrolled release; it should be released in small quantities, or rapidly released with reduced protection duration. Therefore, controlling the release of such essential oils is a research area of great importance (Hsieh et al. 2006).

Consequently, producing microcapsules of CIEO and applying them to textile products represents an alternative approach for controlled release. Chatterjee et al. (2014) noted that microcapsules loaded with essential oil and applied to a textile substrate could effectively interact with the skin, achieving functionalization of the material.

The novelty of this work is to produce gum Arabic/gelatin microcapsules with citronella oil as core active principle and to study how citronella is retained in the microcapsules. This is a preliminary study to clearly establish the potential for use of citronella microcapsules in cellulosic substrates without binder. Binders usually change many properties of the fabric and modify the mechanisms of delivery.

The specific goals of this work are to microencapsulate citronella essential oil and apply such microcapsules to two textiles, viz. cotton and polyester, then to model the controlled release of the oil from each fabric using the Higuchi (1963) and Korsmeyer et al. (1985) kinetic models (Korsmeyer et al. 1985; Shukla et al. 1993; Dash et al. 2010; Shimokawa et al. 2013).

Materials and methods

Materials

Materials used to prepare the microcapsules were type A gelatin (GE, Sigma Chemical, Germany), gum Arabic (GA, Sigma Chemical, Germany) as shell materials and citronella essential oil (WNFt, Brazil) as core material. Glutaraldehyde (50 %), sodium lauryl sulfate (SLS), citric acid, sodium hydroxide, and all other chemicals used were of analytical grade. Standard woven fabrics, namely cotton fabric (COT, bleached and desized cotton print cloth, style 400, 100 g m−2, ISO 105-F02) and spun polyester type 54 fabric (PES, style 777, 126 g m−2, ISO 105-F04), were used, both from Test Fabrics Inc. (USA).

Methods

Preparation of microcapsules by complex coacervation

The complex coacervation protocol was applied based on the works of Wang et al. (2014), Piacentini et al. (2013), Lv et al. (2013), Leclercq et al. (2009), and Desai and Park (2005), including insertion of two biopolymers, pH correction, and insertion of a cross-linking agent.

The process began with formation of three emulsions prepared separately in aqueous solution. The first one contained 3 g gelatin in 50 mL water under stirring and temperature of 50 °C. The second emulsion contained 50 mL water at 50 °C under stirring with 5 mL citronella essential oil and 0.3 g sodium lauryl sulfate (SLS). The third emulsion was prepared with 100 mL water and 3 g gum Arabic at ambient temperature under stirring.

The first and second emulsions were mixed until complete dissolution. In this stage, agitation was increased to 500 rpm to guarantee thorough dispersion of the oil and obtain small-diameter droplets. Then, the third emulsion was added to the main mixture followed by adjustment to pH 4 using citric acid, leaving this preparation for 90 min until total stabilization.

The resulting solution was cooled to temperature <8 °C, leaving it for 1 h. Then the pH of the solution was adjusted to 8–9 using NaOH, and 1 g glutaraldehyde (50 %) was added dropwise. The system was left for 12 h under stirring at room temperature, resulting in microcapsules for application to fabric substrates.

Application of microcapsules to the fabrics was done by the foulard process, followed by drying at room temperature (Carrera et al. 2013). COT and PES textile articles were impregnated for 1 min in 30 g L−1 microcapsule solution, then passed through a foulard at pressure of 2–3 bar and speed of 2 m min−1. The treated fabric samples were finally conditioned at 20 ± 2 °C and 65 ± 5 % relative humidity for 24 h before weighing and subsequent experiments.

Assessment of microcapsule morphology

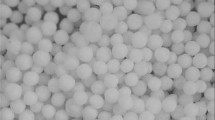

Optical microscopy and scanning electron microscopy (SEM) were performed to verify the distribution of the microcapsules, as shown in Fig. 1, revealing the homogeneity of the solutions, as well as the size distribution of the microcapsule shells. BX43 (Olympus) equipment was used at magnification of 500× and 1000× and a JEOL-JSM 5610 scanning electron microscope at magnification of ~1820×.

Efficiency of encapsulation

The efficiency of encapsulation was obtained indirectly by following the methodology presented by Wang et al. (2014) in liquid phase by ultraviolet–visible (UV–Vis) spectroscopy (UV-240 LPC, Shimadzu) with UVProbe photometric software (version 2.43).

Absorbance readings were taken for the solution prepared according to “Preparation of microcapsules by complex coacervation” section, and the maximum peak absorbance at 333 nm was used. The efficiency of the encapsulation process was determined using Eq. (1):

where C t is the theoretical concentration of microencapsulated essential oil and C d is the concentration of essential oil remaining in the bath solution.

Thermogravimetric analysis

The thermal stability of the microcapsules was studied by thermogravimetric analysis (TGA, SDTA851, Mettler Toledo) with STARe software (version SW 9.01). The thermal behavior of gelatin, gum Arabic, citronella essential oil, and microcapsules (dry) was analyzed using heating rate of 10 °C min−1, temperature range of 30–800 °C, and nitrogen atmosphere.

Size distribution of microcapsules and complexes

The microcapsule size was analyzed by the dynamic light scattering (DLS) method using Nanoplus equipment (EDS) with Nanoplus common software (coxtin method), with 70 accumulations for each sample.

ATR-FTIR assessment of substrate finishes

Fourier-transform infrared (FTIR) spectroscopy was used to investigate the functional groups present. A Frontier device (PerkinElmer) with resolution of 1 cm−1 was used with 64 accumulations in attenuated total reflectance (ATR) mode in the intermediate infrared range from 650 to 4000 cm−1.

Quantification and mathematical model fitting of controlled release of citronella essential oil

The release profiles of citronella essential oil from the textile substrates were determined in vitro in triplicate as follows: After treatment with microcapsules, cotton and polyester fabrics were placed in a bath thermostated at 37 °C ± 0.5 °C under agitation in a WNB14 shaker (Memmert). Aliquots of 2 mL were extracted and filtered at predetermined times, and their absorbance was determined by spectroscopy in the ultraviolet range at 333 nm (oil) using a UV-240LPC (Shimadzu). Mathematical adjustments to obtain the drug release from the polymeric matrices were derived from the Higuchi (1963) equation for planar films:

where \(\frac{M_t}{M_\infty }\) is the percentage of drug released at each time point t relative to the percentage released at equilibrium and K is the Higuchi constant for drug release.

Other aspects of the release mechanism were evaluated using the model of Korsmeyer et al. (1985):

where n is a diffusion exponent indicating the type of release mechanism as Fickian diffusion (n = 0.5), anomalous diffusion (0.5 < n < 1.0), or non-Fickian diffusion (n = 1.0).

For statistical analysis, triplicate data are presented as mean ± standard deviation (SD). Statistical significance (p < 0.05) was determined by one-way analysis of variance (ANOVA) using OriginPro version 8.5.1.

Results

Morphology

A homogeneous distribution of microcapsules was observed in terms of size and shape (mostly spherical), as shown in Fig. 1a. After the microcapsules had been dried, they were well defined without cluster formation. It can also be observed from Fig. 1a that the formed microcapsules had multiple cores, in agreement with the results of Jamekhorshid et al. (2014).

Multicore microcapsules generally exhibit more regular controlled release compared with those with a single core, as observed in the work of Wang et al. (2014). This is because multicore microcapsules can release the encapsulated active substance slowly over time, while those with a single core normally release the ingredient in a burst, that is, in a single short instant.

Another noteworthy factor is the reduced size of the formed microcapsules, facilitating their absorption and penetration into the fabric surface during the finishing process. Li et al. (2013) also considered such reduced size to be advantageous for controlled dosage and increased durability of the textile finish.

Figure 1b shows a scanning electron microscopy (SEM) image of microcapsules, verifying the uniform distribution and reduced size seen by optical microscopy. One can also note from Fig. 1b that a small fraction of the microcapsules do not have perfect spherical shape but are elongated ellipsoids, similar to microcapsules found in the work of Krishnan et al. (2005). According to Leclercq et al. (2009), this occurs due to strong stirring during the coacervation stage and limited concentration of the negatively charged colloid (gum Arabic in this case).

Yield analysis of citronella oil encapsulation process

To assess the microencapsulation efficiency, one must determine the maximum absorbance peak for citronella essential oil. Wavelength scanning was done from 250 to 550 nm, revealing peak absorbance for CIEO at 333 nm. The oil concentration was then calculated using Eq. (4):

where C oil is the concentration of citronella essential oil (in mL mL−1) and abs333 is the absorbance at 333 nm (%).

The average yield of microencapsulated oil measured in this way was 51.37 ± 3.33 %, within the range of results presented by Solomon et al. (2012), who performed citronella oil microencapsulation by a simple coacervation method with yield of 36.20–62.80 %. Our yield is also within the range of results presented by Yang et al. (2014), who microencapsulated vanilla oil by complex coacervation.

TGA of microcapsules

Thermograms are essential for analysis of microcapsule formation, providing information on each constituent of the microcapsules for comparison. Figure 2 shows the TGA curves (Fig. 2a) and their first derivatives (Fig. 2b) as functions of time. Table 1 summarizes the most important thermographic results.

The thermogravimetric curves in Fig. 2a and the data in Table 1 reveal distinct mass losses for each component, indicating thermal decomposition in different stages. Citronella presents mass loss in a single stage, while gelatin and gum Arabic present two, and the microcapsules present three stages. These thermal events are equivalent to those reported by Otálora et al. (2015) for microencapsulation of betalains obtained from Opuntia ficus-indica cactus fruit.

Mass loss of citronella essential oil started at about 30 °C and ended at around 200 °C, close to the temperature range for evaporation of citronella essential oil of 201–207 °C reported by El Asbahani et al. (2015). Analysis of the thermogram curve and its first derivative shows that the oil evaporated completely. Thus, this oil is highly volatile and requires protection to extend its durability when applied to surfaces. This is analogous to the thermal behavior of jasmine oil as observed by Lv et al. (2014), indicating that most of the mass of the sample was lost below 150 °C with no thermal durability.

For gelatin and gum Arabic, the first mass loss stage indicates evaporation of all residual water present in these compounds (Torini et al. 2005). The liberation of humidity seen in the TGA and dTGA curves for mass loss in Fig. 2 occurs in the initial temperature range of the analysis, approximately up to the boiling temperature of water. In this case, the mass loss extends to 124 °C for gelatin and 116.2 °C for gum Arabic. Quantitatively, 7.7 % (m/m) and 8.5 % (m/m) is lost, respectively.

Pyrolysis of gelatin and gum Arabic occurs in the same decomposition range of 200–500 °C, denoted as stage 2. These two compounds present similar behavior in the decomposition zone in terms of mass loss (61.7 and 61.4 %, respectively) and residual mass (19.6 and 18.7 %, respectively).

In the thermogram for the microcapsules, three thermal events are observed: a first stage of mass loss at a temperature 2.4 % higher than the boiling temperature of water, close to that found by Yang et al. (2014), i.e., 2.2 % higher for microcapsules prepared using chitosan and gum Arabic as shell materials.

The second stage of mass loss occurred in the upper temperature range, beginning at 233 °C and extending up to 272 °C. In this stage, 53.1 % mass loss occurred, close to the value of 56 % presented by Fei et al. (2015) for microencapsulation of rose essential oil. This value corresponds to the amount of microencapsulated active principle released due to initial degradation of the constituent chains of the shell materials (~53.1 %). This loss is also close to the amount of microencapsulated active substance released due to degradation of protein shell chains, as verified by Lv et al. (2013).

Figure 2 shows that the second stage of the curve for the microcapsules occurs in a few seconds, due to the high volatility of the citronella oil, as can also be observed in the corresponding first derivative curve. A similar result was obtained in the work of Yang et al. (2014), where microcapsules were prepared using chitosan and gum Arabic as shell materials.

Stage 3 corresponds to pyrolysis of the microcapsules in the decomposition range from 280 to 429 °C. This range agrees with the pyrolysis temperatures of gelatin and gum Arabic; it should be stressed that only in this stage are both materials totally decomposed, as shown by Al-Shannaq et al. (2015).

The overall results of the thermal analysis reveal that incorporation of citronella essential oil by the microencapsulation process results in a complex with high thermal stability compared with the free oil, indicating that microencapsulation protects the oil, making it more resistant to evaporation.

Microparticle diameter estimation by DLS

Figure 3 shows the size histogram and corresponding accumulated distribution for the microcapsules. These results demonstrate that the microcapsules of citronella essential oil had a restricted diameter distribution in the range from 1 to 18 μm, with the greatest proportion of particles (around 90 %) in the range from 3.5 to 7.5 μm. This homogeneous distribution is confirmed by Fig. 1 and by the cumulative particle size distribution in Fig. 3, which reveals that only small fractions of the microcapsules had small or large diameter.

The average microcapsule diameter was 5.435 μm (Table 2), in agreement with the work presented by Jamekhoshid et al. (2014), who pointed out that the range of average diameter for microcapsules formed by the coacervation method is 2 to 1200 μm, as well as that of Prata and Grosso (2015), but smaller than that given by Qv et al. (2005), who microencapsulated lutein using complex coacervation to obtain an average microcapsule diameter of 14.98 μm.

Application to textile substrates

The results of application of the microcapsules are presented in Table 3.

The recorded data imply that, at the end of the process, it was possible to observe microcapsules on the surface of the fabrics. Cotton, the more hydrophilic fiber, exhibited higher microcapsule retention (o.w.f. %) (7.10 ± 0.22) than polyester (5.35 ± 0.09). This is due to the functionality of COT, as revealed by the ATR-FTIR results (Fig. 4).

ATR-FTIR evaluation of substrate finishes

ATR-FTIR spectroscopy was applied to cotton (Fig. 4) and polyester (Fig. 5) with no surface treatment and when treated. Figure 4a (COT) shows the spectrum for the original cotton fabric, and Fig. 4b (COT–MIC) after the application of the microcapsule finish. Equivalently, Fig. 5a (PES) and 5b (PES–MIC) show spectra for the original polyester fabric and after application of the microcapsule finish, respectively.

After treatment (Fig. 4b, COT–MIC), one can observe the appearance of a band at 1545.55 cm−1, characteristic of amide II group (Silvestrin and Alecastro 2007), confirming the presence of microcapsules. During the coacervation process, carboxylic groups of the polysaccharide (gum Arabic) interact with amine groups of the protein (gelatin). The same result was presented by Rocha-Selmi et al. (2013) for microencapsulation of aspartame with gelatin and gum Arabic. The disappearance of the band at 1734 cm−1 corresponding to C–O–C bond reveals the interaction between the substrate and finish. Also, one can observe displacement of the axial aliphatic CH deformation from 2922 to 2900 cm−1, indicating possible hydrogen-bonding interactions according to Carrera et al. (2013). This hints at the formation of hydrogen bonds between the cotton fiber and microcapsules.

Comparing the results for polyester fabric (Fig. 5a, b), the presence of new bands can be verified in the regions of 661 and 900 cm−1, being characteristic of CH bond present in gum Arabic (Lopes and Fascio 2004). One can also notice the presence of a band at 1450 cm−1, corresponding to C=C of aromatic alkenes present in gelatin (Lopes and Fascio 2004), showing that there was treatment, but only superficial without any interaction.

Release kinetics of citronella essential oil

Many mathematical models have been developed to describe active substance release from microcapsules, but the most frequently used are those of Higuchi and Korsmeyer et al. (1985), Eqs. (2) and (3). In vitro studies were carried out over 24 h and the release profile modeled using Origin 8.0® software.

Analyzing the controlled release profiles (Fig. 6), one can observe that the process of CIEO liberation occurred in two distinct steps: in the first step, free oil on the fabric surface was lost by evaporation. As seen in Figs. 4 and 5, this step corresponds to disappearance of the aldehyde group band. The second step corresponds to release of microencapsulated oil. However, each textile product presented different behavior, being closely related to the specific interactions between each fiber and the microcapsules.

From Fig. 6a, one can see that, after 35 min, there was a change in the slope of the release curve, highlighting a change in the release mechanism. Similarly, in Fig. 6b, the controlled release of oil from polyester also shows two steps, with the first stage ending after 15 min.

It can be observed that, in the controlled release of citronella essential oil applied to cotton (Table 4), the Korsmeyer–Peppas model gives the best correlation coefficient (R 2 = 0.9540) and chi-squared value (0.0053). In this stage of release, the Korsmeyer–Peppas model gave n = 0.5833 ± 0.0573, indicating that the system shows an anomalous diffusion mechanism, i.e., non-Fickian transport (Korsmeyer et al. 1985; Lee 1985). According to Lee (1985), this is due to relaxation of the polymeric matrix, giving rise to more than one type of release of the active principle.

This double release mechanism occurs because cotton is a hydrophilic fiber; its greater affinity for water swells the textile matrix when in contact with water (Salem 2010), causing relaxation of the chains and modifying the interaction between the fiber and essential oil, making the water less available for release.

The release of essential oil from 100 % polyester fabric shows that, in the first stage of release, about 40 % of the active substance was lost, leading to a higher kinetic constant than for cotton (K = 0.2189 ± 0.0304 for polyester versus K = 0.0611 ± 0.0015 for cotton; Table 4). This can be explained as a consequence of the high hydrophobicity of polyester (Fité 1995). On the other hand, the diffusion coefficients for oil release from the fabrics were relatively similar, with D f values of approximately 0.20 × 10−2 min−1 for polyester and 0.15 × 10−2 min−1 for cotton.

The high affinity of the active substance to the medium as opposed to the fiber is explained by Salem (2010) as being due to the fact that polyester fiber does not interact in any way; rather, there is repulsion of chemical products in contact with the fiber surface, facilitating removal of the finish. The microcapsules do not interact with the polyester matrix, remaining on the fabric surface only.

It can be observed that, in the case of polyester (Table 4), the Korsmeyer–Peppas model also gave the best correlation coefficient (R 2 = 0.9477) and chi-squared value (0.0056). Based on the exponential parameter in the Korsmeyer–Peppas equation, the release mechanism is Fickian with n = 0.3177 ± 0.0329, not depending on chain relaxation (Fité 1995), and contact with water does not cause swelling and interslip. Sóti et al. (2015) showed in their work that the hydrophobicity of the matrix can change the release mechanism, as well as influence the release constant.

Carreras et al. (2013) showed in their work that microcapsules applied to polyester displayed the highest kinetic constant of 2.90 min−1, while for cotton the kinetic constant was 0.09 min−1, revealing the weak interaction between polyester and the finish, as also seen in this study.

Conclusions

Microcapsules of citronella essential oil with almost perfectly spherical shape were obtained, allowing better penetration into fiber interstices. In addition, cotton as a hydrophilic fiber was shown to be more suitable to receive citronella oil microcapsules. ATR-FTIR analysis suggested the possible emergence of hydrogen bonds between cotton fiber and the microcapsules, strengthening the controlled release of oil from the cellulose matrix, even without use of binders. This represents an innovation, since there would be no change in the essential physical characteristics of the fabric, such as strength, touch, and resilience, which are usually modified by the presence of ligands.

Thermal analysis revealed that microencapsulation of the oil improved its thermal characteristics, making it less volatile and thus applicable to textile substrates in high-temperature processes. Protection of citronella essential oil is also important to prolong its release, because excessive oil release with reduced protection duration would result in inefficient repellent action in applications.

The low diffusion coefficients obtained in this work indicate controlled release depending on the substrate, just as the release kinetic mechanism was also influenced by the type of fiber. Therefore, depending on the desired characteristics of the final product, textile fibers can be selected from a wide variety of natural or synthetic polymers to achieve different release properties.

References

Al-Shannaq R, Farid M, Al-Muhtaseb S, Kurdi J (2015) Emulsion stability and cross-linking of PMMA microcapsules containing phase change materials. Sol Energy Mater Sol Cells 132:311–318

Annan NT, Borza AD, Hansen LT (2008) Encapsulation in alginate-coated gelatin microspheres improves survival of the probiotic Bifidobacterium adolescentis 15703t during exposure to simulated gastro-intestinal conditions. Food Res Int 41:184–193

Carreras N, Acuna V, Martí M, Lis MJ (2013) Drug release system of ibuprofen in PCL-microspheres. Colloid Polym Sci 291:157–165

Chatterjee S, Salaün F, Campagne C (2014) Development of multilayer microcapsules by a phase coacervation method based on ionic interactions for textile applications. Pharmaceutics 6:281–297

Cheng SY, Yuen MCW, Kan CW, Cheuk KKL, Chui CH, Lam KH (2009) Cosmetic textiles with biological benefits: gelatin microcapsules containing vitamin C. Int J Mol Med 24:411–419

Dash S, Murthy PN, Nath L, Chowdhury P (2010) Kinetic modeling on drug release from controlled drug delivery systems. Acta Pol Pharm 67:217–223

Desai KGH, Park HJ (2005) Recent developments in microencapsulation of food ingredients. Dry Technol 23:1361–1394

El Asbahani A, Miladi K, Badri W, Sala M, Aït Addi EH, Casabianca H, El Mousadik A, Hartmann D, Jilale A, Renaud FNR, Elaissari A (2015) Essential oils: from extraction to encapsulation. Int J Pharm 483:220–243

Feczkó T, Kokol V, Vončina B (2010) Preparation and characterization of ethylcellulose-based microcapsules for sustaining release of a model fragrante. Macromol Res 18:636–640

Fei X, Zhao H, Zhang B, Cao L, Yu M, Zhou J, Yu L (2015) Microencapsulation mechanism and size control of fragrance microcapsules with melamine resin shell. Colloids Surf A Physicochem Eng Asp 469:300–306

Fité FJC (1995) Dying polyester at low temperatures: kinetics of dying with disperse dyes. Text Res J 65:268–362

Frederiksen HK, Kristensen GH, Pedersen M (2003) Solid lipid microparticle formulations of the pyrethroid gamma-cyhalothrin—incompatibility of the lipid and the pyrethroid and biological properties of the formulations. J Control Release 86:243–252

Gillij YG, Gleiser RM, Zygadlo JA (2008) Mosquito repellent activity of essential oils of aromatic plants growing in Argentina. Bioresour Technol 99:2507–2515

Hassan MM, Sunderland M (2015) Antimicrobial and insect-resist wool fabrics by coating with microencapsulated antimicrobial and insect-resist agents. Prog Org Coat 85:221–229

Higuchi T (1963) Mechanism of sustained-action medication. Theoretical analysis of rate of release of solid drugs dispersed in solid matrices. J Pharm Sci 52:1145–1149

Hsieh W, Chang C, Gao Y (2006) Controlled release properties of chitosan encapsulated volatile citronella oil microcapsules by thermal treatments. Colloid Surf B 53:209–214

Jamekhorshid A, Sadrameli SM, Farid M (2014) A review of microencapsulation methods of phase change materials (PCMs) as a thermal energy storage (TES) medium. Renew Sustain Energy Rev 31:531–542

Karaman S, Digrak M, Ravid U, Ilcim A (2001) Antibacterial and antifungal activity of the essential oils of Thymus revolutus Celak from Turkey. J Ethnopharmacol 76:183–186

Korsmeyer RW, Gurny R, Doelker E, Buri P, Peppas NA (1985) Mechanisms of solute release from porous hydrophilic polymers. Int J Pharm 15:25–35

Krishnan S, Kshirsagar AC, Singhal RS (2005) The use of gum Arabic and modified starch in the microencapsulation of a food flavoring agent. Carbohydr Polym 62:309–315

Leclercq S, Harlander KR, Reineccius GA (2009) Formation and characterization of microcapsules by complex coacervation with liquid or solid aroma cores. Flavour Fragr J 24:17–24

Lee PI (1985) Kinetics of drug release from hydrogel matrices. J Control Release 2:277–288

Li L, Song L, Hua T, Au WM, Wong KS (2013) Characteristics of weaving parameters in microcapsule fabrics and their influence on loading capability. Text Res J 83:113–121

Lopes WA, Fascio M (2004) Esquema para interpretação de espectros de substâncias orgâmicas na região do infravermelho. Quím 27:670–673

Lv Y, Zhang X, Zhang H, Abbas S, Karangwa E (2013) The study of pH-dependent complexation between gelatin and gum arabic by morphology evolution and conformational transition. Food Hydrocoll 30:323–332

Lv Y, Yang F, Li X, Zhang X, Abbas S (2014) Formation of heat-resistant nanocapsules of jasmine essential oil via gelatin/gum arabic based complex coacervation. Food Hydrocoll 35:305–314

Ma ZH, Yu DG, Branford-White CJ (2009) Microencapsulation of tamoxifen: application to cotton fabric. Colloid Surface B 69:85–90

Martin A, Tabary N, Leclercq L, Junthip J, Degoutin S, Aubert-Viard F, Cazaux F, Lyskawa J, Janus L, Bria M, Martel B (2013) Multilayered textile coating based on a β-cyclodextrin polyelectrolyte for the controlled release of drugs. Carbohydr Polym 93:718–730

Martins IM, Barreiro MF, Coelho M, Rodrigues AE (2014) Microencapsulation of essential oils with biodegradable polymeric carriers for cosmetic applications. Chem Eng J 245:191–200

Nelson G (2002) Application of microencapsulation in textiles. Int J Pharm 242:55–62

Nesterenko A, Alric I, Silvestre F, Durrieua V (2013) Vegetable proteins in microencapsulation: a review of recent interventions and their effectiveness. Ind Crop Prod 42:469–479

Otálora MC, Carriazo JG, Iturriaga L, Nazareno MA, Osorio C (2015) Microencapsulation of betalains obtained from cactos fruit (Opuntia fícus-indica) by spray drying using cactus cladode mucilage and maltodextrin as encapsulating agents. Food Chem 187:174–181

Özdemir K, Gökmen V (2015) Effect of microencapsulation on the reactivity of ascorbic acid, sodium chloride and vanillin during heating. J Food Eng 167:204–209

Piacentini E, Giorno L, Dragosavac MM, Vladisavljevic GT, Holdich RG (2013) Microencapsulation of oil droplets using cold water fish gelatine/gum arabic complex coacervation by membrane emulsification. Food Res Int 53:362–372

Prajapati V, Tripathi AK, Aggarwal KK, Khanuja SPS (2005) Insecticidal, repellent and oviposition-deterrent activity of selected essential oils against Anopheles stephensi, Aedes aegypti and Culex quinquefasciatus. Bioresour Technol 96:1749–1757

Prata AS, Grosso CRF (2015) Production of microparticles with gelatin and chitosan. Carbohyd Polym 116:292–299

Qv XY, Zeng ZP, Jiang JG (2005) Preparation of lutein microencapsulation by complex coacervation method and its physicochemical properties and stability. Food Hydrocoll 25:1596–1603

Rocha-Selmi GA, Bozza FT, Thomazini M, Bolini HMA, Fávaro-Trindade CS (2013) Microencapsulation of aspartame by double emulsion followed by complex coacervation to provide protection and prolong sweetness. Food Chem 139:72–78

Rubio L, Alonso C, Coderch L, Parra JL, Martí M, Cebrián J, Navarro JA, Lis M, Valldeperas J (2010) Skin delivery of caffeine contained in biofunctional textiles. Text Res J 80:1214–1221

Salem V (2010) Tingimentos têxteis: fibras, conceitos e tecnologias. Blucher, São Paulo

Sanchez P, Sanchez-Fernandez MV, Romero A (2010) Development of thermoregulating textiles using paraffin wax microcapsules. Thermochim Acta 498:16–21

Shahid-ul-Islam Shaid M, Mohammad F (2013) Perspectives for natural product based agents derived from industrial plants in textile applications—a review. J Clean Prod 57:2–18

Shimokawa K, Saegusa K, Wada Y, Ishii F (2013) Physicochemical properties and controlled drug release of microcapsules prepared by simple coacervation. Colloids Surf B 104:1–4

Shukla P, Rajagoplan N, Sivaram S (1993) Starch urea–formaldehyde matrix encapsulation IV. influence of solubility and physical state of encapsulant on rate and mechanism of release. J Appl Polym Sci 7:1209–1222

Silvestrin RM, Alecastro RB (2007) Identificação espectrométrica de compostos orgânico, Rio de Janeiro: Livros Técnicos e Científicos 429:2007

Solomon B, Sahle FF, Gebre-Mariam T, Asres K, Neubert RHH (2012) Microencapsulation of citronella oil for mosquito-repellent application: formulation and in vitro permeation studies. Eur J Pharm Biopharm 80:61–66

Sóti PL, Nagy ZK, Serneels G, Vajna B, Farkas A, Gucht FV, Fekete P, Vigh T, Wagner I, Balogh A, Pataki H, Mezö G, Marosi G (2015) Preparation and comparison of spray dried and electrospun bioresorbable drug delivery systems. Eur Polym J 68:671–679

Souza FN, Gebara C, Ribeiro MCE, Chaves KS, Gigante ML, Grosso CRF (2012) Production and characterization of microparticles containing pectin and whey proteins. Food Res Int 49:560–566

Specos MMM, Garcia JJ, Tornesello J, Marino P, Della Vecchia M, Defain Tesoriero MV, Hermida LG (2010) Microencapsulated citronella oil for mosquito repellent finishing of cotton textiles. Trans R Soc Trop Med Hyg 104:653–658

Torini L, Argillier JF, Zydowicz N (2005) Interfacial polycondensation encapsulation in miniemulsion. Macromolecules 38:3225–3236

Tzhayik O, Cavaco-Paulo A, Gedanken A (2012) Fragrance release profile from sonochemically prepared protein microsphere containers. Ultrason Sonochem 19:858–863

Wang JM, Zheng W, Song QW, Zhu H, Zhou Y (2009) Preparation and characterization of natural fragrant microcapsules. J Fiber Bioeng Inform 4:293–300

Wang B, Adhikari B, Barrow CJ (2014) Optimisation of the microencapsulation of tuna oil in gelatin-sodium hexametaphosphate using complex coacervation. Food Chem 158:358–365

Yang Z, Peng Z, Li J, Li S, Kong L, Li P, Wang Q (2014) Development and evaluation of novel flavor microcapsules containing vanilla oil using complex coacervation approach. Food Chem 145:272–277

Zimet P, Livney YD (2009) Beta-lactoglobulin and its nanocomplexes with pectin as vehicles for ω-3 polyunsaturated fatty acids. Food Hydrocoll 23:1120–1126

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bezerra, F.M., Carmona, O.G., Carmona, C.G. et al. Controlled release of microencapsulated citronella essential oil on cotton and polyester matrices. Cellulose 23, 1459–1470 (2016). https://doi.org/10.1007/s10570-016-0882-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-016-0882-5