Abstract

Brown cotton fibers (SA-1 and MC-BL) studied were inferior to a white cotton fiber (Sure-Grow 747) in fiber quality, i.e., a shorter length, fewer twists, and lower crystallinity, but showed superior thermal resistance in thermogravimetric, differential thermogravimetric, and microscale combustion calorimetric (MCC) analyses. Brown cotton fibers yielded 11–23 % smaller total heat release and 20–40 % greater char. Washing fibers in water and a 1 % NaOH solution showed that rich natural inorganic components and the condensed tannins present in brown cotton are responsible for the unusual thermal property. The loss of inorganics from white cotton during a water wash increased the thermal decomposition temperature of cellulose, resulting in no char yield. However, the stronger binding of metal ions for brown cotton as well as its dominant adsorption of sodium ions after a 1 % NaOH wash facilitated the low-temperature thermal-reaction route; the sodium content showed a significant negative correlation with the heat release capacity of the fiber. Condensed tannins greatly enhanced the adsorption of sodium ions to the fiber and exhibited inherent thermal stability. The limiting oxygen indices (LOI) calculated from the MCC parameters indicated the slower burning characteristic of brown cotton, and its LOI was further increased upon adsorption of sodium ions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Naturally colored cotton (Gossypium hirsutum L.) produces a variety of fiber shades ranging from light green to tan and brown. These colors appear when the seed pod opens to expose fibers to oxygen and sunlight (Hustvedt and Crews 2005). As compared with white cotton fiber, colored cotton fiber is shorter and weaker, making it unsuitable for spinning and conventional weaving machines. However, colored cotton fiber can be readily processed in nonwoven fabrication, i.e., needle-punching and hydroentanglement (Hinchliffe et al. 2015), finding many potential applications such as for upholstery and protective barriers. Moreover, developments in genetic breeding technology have enabled the production of superior quality colored cotton fibers, which have been successfully processed in traditional textile processing machines (Fox 1996; Kohel 1985; May et al. 1994).

Advances in technology along with a growing market for eco-friendly materials of natural occurrence have stimulated studies on colored cotton, which actually has revealed many benefits over white cotton. Natural colors in the fiber were found to be saturated with exposure to light (Dickerson et al. 1999; Williams and Horridge 1996), and textiles made of colored cotton provided greater ultraviolet protection for wearers, which persisted after exposure to xenon light and accelerated laundering (Hustvedt and Crews 2005). In terms of moisture sorption, brown cotton fiber has a higher equilibrium moisture content (21 %) than white cotton fiber (17.8 %) at 95 % RH, and its monolayer sorption has been shown to increase with color depth (Ceylan et al. 2014). Colored cotton has also exhibited excellent antibacterial activities against S. aureus and K. pneumonia (Ma et al. 2013) as well as improved resistance to mildew and slower biodegradation in soil (Chen and Cluver 2010). These natural defense characteristics have been attributed to the chemical nature of the colorants.

Moreover, several reports on the flame resistance of colored cotton have drawn manufacturers and consumers’ attention, because the flame-retardant finishes required for highly flammable white cotton products can cause a negative influence on the hand of textiles and raise health and environmental concerns (Lewin 2005). The twill fabrics made of Coyote and Buffalo brown cotton fibers were shown to exhibit slower burn rates (4.4–4.5 cm/min) to meet the requirement of Motor Vehicle Safety Standard No. 302 (Fox 1996; VanZandt et al. 1997). Consistent with this result, the burning times of brown cotton needle-punched and hydroentangled nonwoven fabrics were almost 30 and 4 times longer, respectively, than those of corresponding white cotton fabrics in 45° flammability tests (Hinchliffe et al. 2015). The limiting oxygen index (LOI) of camel brown cotton fabric (22.5 %) was higher than the LOI of white cotton fabric (19.0 %), and the volatilization temperature of thermally degraded products was higher for brown cotton in a differential scanning calorimetry study (Parmar and Chakraborty 2001). A thermogravimetry (TG) study reported decreased initial thermal decomposition temperatures and smaller activation energies for thermal decomposition of colored cotton as compared with white cotton (Corradini et al. 2009). Under isothermal conditions in air at 180 °C for 60 min, the weight losses of nanofibers obtained by acid hydrolysis were shown to be in the following order: white > brown > ruby > green (Teixeira et al. 2010). This indicated the higher thermal resistance of colored nanofibers.

The unusual thermal property of colored cotton has been explained in several ways. Greater amounts of heavy metals, chromium and zinc, present in colored cotton fiber have been proposed as being responsible for its thermal stability (Parmar and Chakraborty 2001). A recent finding that hydroentangling or traditional textile wet processes reduced the flame resistance, ash content, and color space of brown cotton nonwoven fabrics suggested their correlation, i.e., the higher levels of flame-resistant phosphorous and boron and unknown factors related to coloration enhanced flame resistance (Hinchliffe et al. 2015). Other studies have focused on the composition and crystallinity of colored cotton fiber. Colored cotton fiber contains greater amounts of hemicellulose and waxiness but a lesser amount of cellulose than white cotton fiber (Zhang et al. 2009). The crystallinity of colored cotton fiber was shown to be lower than that of white cotton fiber (Corradini et al. 2009; Ying and Xinyuan 2006). The influence of non-cellulosic materials on the hydrogen bond of cellulose Iβ (Zhang et al. 2009) and colorants that are bonded to cellulose molecules (Ying and Xinyuan 2006) were related to the reduced crystallinity. These compositional and structural characteristics of colored cotton were considered to be unfavorable to the thermal stability of fiber (Corradini et al. 2009; Zhang et al. 2009). Corradini et al. (2009) reported that white cotton has higher thermal stability than colored cotton.

Some contradictory results pertaining to colored cotton likely result from the limited analysis and lack of understanding of its thermal behavior, which can be influenced by many internal factors. For example, Zhang et al. (2009) and Corradini et al. (2009) judged the thermal stability of fiber by initial decomposition temperature, leading to the conclusion that colored cottons with lower initial decomposition temperatures were less thermally stable. However, considering the role of natural inorganic salts present in cotton fiber in catalyzing cellulose dehydration at low temperatures (Nam et al. 2014), it is necessary to examine both pyrolysis and combustion parameters for any change in the thermal reaction pathway. Also, a previous study (Hinchliffe et al. 2015) indicates the need for adopting a systematic approach to verifying the factor related to coloration, which was thought to enhance the flame resistance of brown cotton. In this study, we have confirmed the presence of condensed tannins, which are known to be associated with the color of brown cotton, using a CP/MAS 13C NMR and two selected brown cotton fiber genotypes (SA-1 and MC-BL) having varying levels of inorganic elements, crystallinity, and tannins. The effects of inorganic elements and tannins were investigated by analyzing TG and microscale combustion calorimetry (MCC) parameters before and after washing fiber in various solutions. The results of these investigations allowed us to gain insight into the factors that have been proposed in earlier studies, i.e., inorganic components are more dominant than crystallinity in influencing the thermal characteristics of cotton fiber, and condensed tannins contribute to the slower burning of brown cotton due to their capability to adsorb metal ions and intrinsic thermal resistance.

Experimental

Materials and sample preparation

Two naturally colored cotton fibers, MC-BL and SA-1, and one conventional white cotton fiber, Sure-Grow 747 (SG747), were used in this study. MC-BL is a brown fiber cotton genotype that probably originated in Mexico or Central America as part of the primitive race stock collections. SA-1 (PI No. 528418) is a brown obsolete cotton variety known as “Nankeen Brown” that originated in China. SG747 is a conventional elite cotton variety that was released in 1999 (Lege 1999). Cotton plants were grown in an experimental plot in New Orleans, LA from 2011 to 2014 using standard agricultural practices for cotton cultivation. Mature cotton fibers were hand-harvested and ginned on a laboratory roller gin. For the washing experiment, 300 mg of dried fiber were soaked in 50 ml of Millipore water, 1 % NaOH, 5 % NaOH, 1 M NaCl, 4 M urea, or 1 % sodium dodecyl sulfate (SDS) for 2 h. Both SDS and urea denature proteins, but urea (4–6 M) is more efficient for stable proteins and is typically used to extract total proteins including cell wall proteins in plant tissues (Kim et al. 2008). The fibers were then washed with Millipore water three times for 30 min to eliminate residual solution traces.

CP/MAS 13C NMR

CP/MAS 13C NMR spectra were obtained on a Bruker DSX-300 NMR spectrometer equipped with a standard Bruker 4 mm MAS probe. All samples, which were ground to a powder using a Mini Wiley Mill (Thomas Scientific, Swedesboro, NJ) with a 40 screen, were packed into 4 mm outer diameter zirconia rotors and spun at 8 kHz. The radio frequencies of 1H and 13C were 300.13 and 75.47 MHz, respectively. All spectra were recorded under high-power proton decoupling. The 1H 90° pulse width was 4 µs. A contact time of 1 ms, a recycle delay of 5 s, and 5000 scans were employed. Adamantine was used for Hartmane Hahn matching calibration, and tetramethylsilane was used as an external standard for calibrating the 13C chemical shifts.

Elemental analysis

Elemental analysis was carried out at Elemental Analysis, Inc. in Lexington, KY using an Element 2™ high-resolution inductively coupled plasma mass spectroscope (ICP-MS, Thermo Fisher Scientific, Waltham, MA). The fiber sample was digested in a MARS 6 Microwave Reaction System (CEM Corp., Matthews, NC), and 0.5 g of the sample was placed in a reaction vial with 10 ml of 8 N nitric acid. The sample was ramped to 200 °C for 20 min and held at the same temperature for 10 min, followed by a 15 min cooling cycle. For the ICP-MS analysis, 200 µl of the digested sample was diluted to 10 ml. For higher contents of elements, an additional 1000-fold dilution was conducted. The calibration range was 0.1–1000 ppb, and 9–15 scans were used for each isotope.

Xrd

X-ray diffraction (XRD) patterns were obtained using an XDS 2000 diffractometer (Scintag Inc., Cupertino, CA) with Cu Ka radiation (1.54056 Å). The generator was working at 43 kV and 38 mA. Approximately 0.12 g of the ground sample was pressed in a hydraulic press and cut into a circular sample with a 2.5 cm diameter. Angular scanning was conducted from 8° to 50° at 0.6°/min. No background correction was made. The crystal size, τ (Å), in the direction perpendicular to the (200) lattice plane was calculated by the Scherrer equation (Langford and Wilson 1978; Scherrer 1918):

where K is the correction factor (0.9), λ is the wavelength of the X-ray radiation, β is the full width at half maximum of the diffraction peak in radians, and θ is the diffraction angle of the peak. The crystallinity index (CI) was calculated by the Segal equation (Segal et al. 1959):

where I t is the total intensity of the (200) peak at 22.7° 2θ, and I a is the intensity at the minimum in diffraction intensity near 18° 2θ for the amorphous contribution.

TG/DTG

Thermogravimetric (TG) and differential thermogravimetric (DTG) analyses were carried out using a TGA Q500 thermal gravimetric analyzer (TA Instruments, New Castle, DE) under a nitrogen atmosphere. The nitrogen flow into the furnace was maintained at a rate of 90 ml/min. About 5 mg of the ground sample were evenly placed at the bottom of a platinum pan. The temperature was increased from 30 ± 5 °C to 1000 °C with a heating rate of 10 °C/min. TG and DTG thermograms were analyzed using the Universal Analysis 2000 software (TA Instruments). Five measurements were performed to obtain an average of the thermal decomposition parameters.

MCC

Microscale combustion calorimetric (MCC) analysis was conducted using a MCC-2 (Deatak, McHenry, IL) according to ASTM D 7309-13. Approximately 5 mg of the ground fiber sample were placed in an MCC ceramic cup and weighed on an Excellence Plus XP205 analytical balance (Mettler-Toledo Inc., Columbus, OH). The sample was then heated to 650 °C at a heating rate of 1 °C/s in a stream of nitrogen flowing at 80 cm3/min. The volatile thermal decomposition products formed in a pyrolyzer were swept by the gas stream of nitrogen and oxygen to a combustor, where the decomposed products were completely oxidized at 900 °C for 10 s. The oxygen depletion involved in the combustion was determined by the oxygen concentration and flow rate of the combustion gases to measure a heat release rate (HRR). The parameters obtained by the MCC Curve Fit v.2 software (Deatak) are as follows: the specific HRR (W/g) obtained by dividing HRR by the initial sample mass; the peak heat release rate (PHRR, W/g), which is the maximum specific HRR; temperature at PHRR (TPHRR, °C); the heat release capacity (HRC, J/g K) obtained by dividing PHRR by the heating rate; the total heat release (THR, J/g), which is the area under the specific HRR peak; and char content determined by weighing the sample before and after pyrolysis. An average of three measurements was presented.

Limiting oxygen index (LOI) was estimated from the MCC parameters using the following equation (Lyon et al. 2007b; Yang et al. 2010):

where OI ≈ 13.5 % is the minimum oxygen volume fraction for combustion of gaseous fuels at the lower flammability limit, a = 2.5 (kW/m2)/(% O2) is the proportionality constant between oxygen concentration in the atmosphere and the flame heat flux, σ = 5.6704 × 10−8 W/m2 K4 is the Boltzmann radiation constant, χ = 1 is the combustion efficiency of the fuel gases in well-ventilated flaming combustion, µ is the char fraction in the MCC, HRR * ≈ 20 kW/m2 is the critical HRR at ignition/extinction, and η g ≈ 40 J/g K is the heat absorption capacity in terms of the heat of gasification.

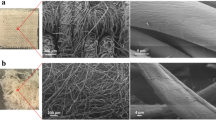

Microscopy

Photographs of fiber bundle samples were taken using a digital camera (NV3, Sony). The microstructure of fiber was observed using a KH-8700 digital microscope (Hirox-USA Inc., Hackensack, NJ) at 350X with the assistance of polarized light filters.

Results and discussion

Before wash

Figure 1 shows the photographs and microscopic images of the SG747, SA-1, and MC-BL cotton fibers. The brown color was darker for the MC-BL fiber than for the SA-1 fiber. Both of these brown cotton fiber genotypes were shorther and thinner than the white SG747 fiber. The length of the brown cotton fiber was approximatly 14 mm, just over half the length of the white cotton fiber (27 mm). As compared with the SG747 fiber, the SA-1 and MC-BL fibers were less twisted and less flattened. The XRD patterns of the white and brown cotton fibers are compared in Fig. 2. The diffraction pattern of the SA-1 fiber was similar to that of the SG747 fiber; their crystallite size and CI were 52.4 Å and 87.7 %, respectively. The MC-BL fiber exhibited a small difference in its diffraction pattern—a slightly broader (200) peak and increased intensity at the minimum in diffraction intensity near 18° 2θ for the amorphous contribution—indicating that its crystallite size and CI were smaller than those of the SG747 fiber. The crystal size and CI of the MC-BL fiber were 50.7 Å and 84.5 %, respectively. It was noted that the diffraction peaks of the brown cotton shifted slightly to higher 2θ angles. This larger d-spacing, signifying the greater size of the cellulose Iβ unit cell, is associated with the loss of crystalline perfection or a reduction in crystal size (Nishimura et al. 1981; Wada et al. 1993).

Figure 3 shows the CP/MAS 13C NMR spectra of SG747, SA-1, and MC-BL fibers. The main peaks were assigned to the C1-C6 carbon atoms of the β-d-glucose of cotton cellulose (Atalla and Vanderhart 1984, 1999; Kono et al. 2002): 105 ppm—C1; 89 ppm, 84 ppm—C4; 75 ppm—C3; 73 ppm—C2, C5; and 65 ppm, 63 ppm—C6. Additional small resonances were observed when the intensity in the up- and down-field regions was amplified. A broad, weak peak at about 175 ppm was assigned to carboxyl resonance arising from pectin, fatty acids, or protein. A small peak at 33 ppm was assigned to the CH2 of the wax. The typical amounts of pectin, protein, and wax present in the raw white cotton fiber after ginning and mechanical cleaning are 0.7–1.2, 1.1–1.9, and 0.4–1.0 %, respectively, based on the dry weight of the fiber (Wakelyn et al. 2006). The peak intensities of such non-cellulosic components were slightly greater for the brown cotton, agreeing with reports of increased amounts of wax and protein for brown cotton (Pan et al. 2010; Zhang et al. 2009). It was noticed that the MC-BL fiber exhibited peaks at about 145 and 154 ppm for oxygen substituted aromatic carbons as well as at about 130 ppm for aromatic carbons, arising from flavonoids in condensed tannins (Pizzi and Stephanou 1993). The aliphatic carbons peak from tannins appearing at 27–28 ppm overlapped the peak of wax and was broadened. Tannins are complex, poly-phenol, and amorphous compounds that are present in plants. Histochemical staining and colorimetric reactions of developing and mature cotton fibers showed that condensed tannins are responsible for the color of brown cotton fiber (Hua et al. 2007; Li et al. 2012; Xiao et al. 2007). Consistently, the intensity of the characteristic peaks of condensed tannins was diminished for the SA-1 fiber with a lighter brown shade.

The inorganic elements present in the white and brown cotton fibers studied are shown in Table 1. The total amounts of inorganics were measured in following order: MC-BL > SA-1 > SG747: the amount for the MC-BL fiber (11,273 mg/kg) was 2.3 and was 1.9 times greater than those for the SG747 (4914 mg/kg) and SA-1 (6032 mg/kg) fibers, respectively. The most abundant inorganic element was K, whose concentration is distinctively different between the fibers: 9043 mg/kg for MC-BL, 4427 mg/kg for SA-1, and 3576 mg/kg for SG747. A similar trend was also observed for Mg, P, Fe, and Cu. However, the concentrations of Ca, Zn, and Mn were similar between the MC-BL and SA-1 fibers but were decreased for the SG747 fiber. The concentrations of Na, Bi, and Sb were not significantly different between the SG747 and SA-1 fibers but were significantly increased for the MC-BL fiber.

The pyrolysis and combustion properties of the white and brown cotton fibers were analyzed using TG, DTG, and MCC. Figure 4 shows the TG and DTG thermograms of the SG747, SA-1, and MC-BL fibers obtained under a nitrogen environment at a heating rate of 10 °C/min. All three fibers exhibited three stages of weight loss: the water loss, decomposition of cellulose with a high weight-loss rate, and decomposition of char with a low-weight loss rate. The second stage was characterized by determining an onset decomposition temperature (T o ), an end decomposition temperature (T e ), and a maximum decomposition rate temperature (T m ). These characteristic temperatures and corresponding weight losses as well as char yields are presented in Table 2. The T o values of the brown cotton fibers were approximately 10 °C higher than that of the white fiber, indicating the thermal decomposition resistance of low-molecular-weight components of the brown cotton. It was reported that natural condensed tannins started to decompose between 150 and 200 °C, and its major thermal decomposition occurred at ca. 280 °C (Gaugler and Grigsby 2009). According to Celzard et al. (2011, 2009), condensed tannins have flame-retardant characteristics, i.e., tannin-based cellular materials exhibited low smoke emission and prolonged burning time (Tondi et al. 2009). The T m and T e of brown cotton were also increased for brown cotton, but their corresponding weight losses, WL m and WL e , were smaller than those of white cotton. The resulting shift of the DTG peak to higher temperatures (inset in Fig. 4) was consistent with the DSC study (Parmar and Chakraborty 2001), in which the temperature of the endothermic peak for brown cotton (390 °C) was higher than that for white cotton (370 °C). The slightly lower T m for the MC-BL fiber as compared with T m for the SA-1 fiber may result from its smaller crystal size and CI (Corradini et al. 2009). As the temperature further increased, the brown cotton fiber was consumed to a lesser degree, yielding a larger amount of char than the white cotton fiber. The char yields at 700 °C for the MC-BL and SA-1 fibers, respectively, were 22.3 and 19.0 %, which were 1.4 and 1.2 times greater than the yield of the SG747 fiber.

Figure 5 shows the typical plots of the specific HRR versus temperature for the SG747, SA-1, and MC-BL fibers. The HRR was calculated based on the quantity of oxygen consumed for combustion of the products that had been decomposed in a pyrolyzer. Both the white and brown cotton fibers produced a single peak. Consistent with the DTG thermograms, the peaks of the brown cotton fibers shifted to higher temperatures, and the extent of the shift was slightly greater for the SA-1 fiber. The SG747 fiber exhibited a lower onset temperature but a higher HRR value than the SA-1 and MC-BL fibers throughout the combustion process. The higher HRR for the SG747 fiber was maintained even after the HRR values of the SA-1 and MC-BL fibers dropped to zero. This indicates that the SG747 fiber continued to release combustible products during the charring process. In contrast to the sharp, tall peak of the SG747 fiber, the relatively broad, short peak of the MC-BL fiber reflects its milder combustion reactions with a lower total heat release. The MCC parameters, including HRC, PHRR, TPHRR, THR, and char yield, are presented in Table 3. As expected, the magnitudes of HRC, PHRR and THR were measured in the following order: MC-BL < SA-1 < SG747: their magnitudes for the MC-BL fiber were approximately equivalent to 75 % of those for the SG747 fiber. Consistent with the TG data, the char yield of the MC-BL fiber increased by 43 % as compared with that of the SG747 fiber. One of the advantages of MCC analysis is that its parameters are correlated with the flammability characteristics of materials (Lyon et al. 2007a; Yang et al. 2010; Yang and He 2012). Based on HRC and char yield, the LOI was estimated using the Eq. (3). The LOI values of the SG747, SA-1, and MC-BL fibers were calculated to be 19.9, 20.4, and 21.4 %, respectively. Since the LOI of the MC-BL fiber was above 21 %, which is the oxygen content in air, the MC-BL fiber was considered to burn more slowly in air. A previous study (Hinchliffe et al. 2015) showed that the nonwoven fabrics made of brown cotton fiber self-extinguished and did not support an open flame in 45° flammability tests.

After wash

The TG and MCC data have shown the high thermal resistance of brown cotton. It should be emphasized that the MC-BL fiber, which has the smallest crystal size and the lowest crystallinity among the fibers studied, exhibited the smallest HRC and the highest char yield. This indicates that the crystallinity proposed as an important factor influencing the thermal property of cellulose fibers (Corradini et al. 2009; Zhang et al. 2009) is less dominant. A previous study (Nam et al. 2014) showed a link between the thermal stability of cellulose and naturally occurring inorganic components in white cotton. To examine this mechanistic link for brown cotton, SG747 and SA-1 fibers were washed in various solutions, and the resulting HRC values were compared. Figure 6 shows strong HRC dependency for both white and brown cotton fibers on the washing solution. A water wash greatly increased the HRC of the SG747 fiber, but only a minor increase occurred for the SA-1 fiber. Similar increases in HRC were also observed for 4 M urea and 1 % SDS solutions, indicating an insignificant effect of the removal of proteins. Interestingly, the increase in HRC for the SG747 fiber was suppressed in NaOH and NaCl solutions, while for the SA-1 fiber even decreases in HRC (of about 13 %) were observed in NaOH solutions, whose concentration showed no significant difference. The washing experiment suggests that the extraction of inorganics and the adsorption of sodium ions play dominant roles in the combustion property of cotton fiber, and that the degrees of such extraction and adsorption differ between white and brown cotton fibers. The following reports the results observed when these effects were further examined with a focus on water and a 1 % NaOH solution.

As shown in Table 1, a water wash removed most K, P, and Na from the white cotton fiber, but significant amounts of inorganic elements remained on the brown cotton fiber. Washing K and P was more efficient in a 1 % NaOH solution. The removal of Ca, Mg, and Si in water and a 1 % NaOH solution, however, was not as pronounced. The 1 % NaOH wash significantly increased the sodium content in the fiber, indicating that adsorption of sodium ions occurred. The amount of sodium measured was distinctively different between fibers: about two times for the SG747 fiber, 82 times for the SA-1 fiber, and 105 times for the MC-BL fiber as compared with the corresponding unwashed fibers. The greater adsorption of sodium ions for the brown cotton is attributed to the presence of natural condensed tannins. The hydroxyls of a flavonoid unit in condensed tannins readily adsorb sodium ions, and metal-flavonoid complexes can be formed (Fig. 7) (Slabbert 1982; Zhan et al. 2001; Zhan and Zhao 2003). As a result, the MC-BL fiber containing sufficient tannins detectable by CP/MAS 13C NMR (Fig. 3) adsorbed the largest amount of sodium. It was also observed that the amounts of Fe and Zn for the MC-BL fiber increased after a 1 % NaOH wash. In terms of total concentration, the loss of inorganics from the SG747 fiber (85.8 %) in water was greater than those from the SA-1 (66.5 %) and MC-BL (69.3 %) fibers. Not only was the concentration of inorganic components greater in brown cotton, but also their bindings were stronger with brown cotton than with white cotton.

The DTG and MCC thermograms for the SG747 and MC-BL fibers before and after washes in water and a 1 % NaOH solution are shown in Fig. 8. Showing excellent agreement between the DTG and MCC data, the shape and location of the thermogram peaks were significantly influenced by washing in the two solutions. The peaks for the SG747 fiber, which nearly overlapped those for the MC-BL fiber, shifted to higher temperatures and became deep and sharp after a water wash, while the peaks for the MC-BL fiber exhibited minor changes. The white cotton fiber washed in water underwent more drastic thermal reactions and consumed more oxygen for combustion. Previous studies (DeGroot and Shafizadeh 1984; Kelly et al. 1991; Nam et al. 2014; Piskorz et al. 1989) showed that trace quantities of inorganic salts modified the cellulose pyrolysis pathways to inhibit the formation of volatile levoglucosan. Apparently, inorganic salts in white cotton catalyzed the cellulose dehydration at low temperatures, leading to slow-rate thermal decomposition (Nam et al. 2014). The increased T o , T m , and T e for the SG747 fiber washed in water (Table 2) confirmed the shift toward the high-temperature thermal-reaction route upon removal of inorganic salts. Such suppression of the low-temperature pathway, which is known to produce most char, resulted in no char yield (0.2 ± 0.6 %). On the other hand, sufficient amounts of inorganics that remained on the MC-BL fiber allowed thermal behavior that was similar to what occurred before the water wash.

Another interesting observation is that although the 1 % NaOH wash further reduced the total concentration of inorganic elements from the SG747 fiber (610 mg/kg as compared with 696 mg/kg from a water wash), the characteristics of the expected high-temperature pathway were less recognizable, i.e., 10.3 ± 1.1 % of char yield. This result suggests a predominant effect of sodium among the inorganic elements on the thermal reaction route of cellulose. In fact, the greater amount of sodium adsorbed onto the MC-BL fiber in a 1 % NaOH solution yielded noticeable peak shifts to low temperatures: the T m and TPHRR were lowered by 15 and 11 °C, respectively. The increased WL o as well as decreased WL m and WL e for the 1 % NaOH washed MC-BL fiber further support the facilitated thermal decomposition at low temperatures (Table 2). The smaller activation energy in the early stage of the thermal decomposition of cellulose has been observed in the presence of natural inorganic salts (Nam et al. 2014).

Various metal ions introduced by ion exchange have been shown to affect the thermal behavior of cellulose (Mayer et al. 2012; Richards and Zheng 1991; Soares et al. 1998). The dominant role of sodium in cellulose combustion was demonstrated by the variations in HRC and char yield with the concentration of Na, K, and P, as shown in Fig. 9. Relatively modest changes in both HRC and char yield for brown cotton were attributed to the smaller reduction in the total concentration of inorganic elements after washes (Table 1). It was noticed that almost all natural sodium was removed from the SG747 and SA-1 fibers in water, whereas approximately 72 % of the sodium remained on the MC-BL fiber. This difference indicates that sodium bound reversibly to the fiber, but the sodium bound to tannins was not easily removed by a water wash. After a 1 % NaOH wash, which removed more than 90 % of the K and P from brown cotton, the decreased HRC and increased char yield clearly signified the contribution of sodium. The 1 % NaOH wash increased the LOI values of the SA-1 and MC-BL fibers to 21.0 and 22.4 %, respectively. The poor adsorption of sodium ions for the SG747 fiber yielded opposite results: an increase in HRC from 163 to 192 J/g K and a decrease in char yield from 16 to 12 % as compared with the unwashed fiber.

Figure 10 shows significant correlations of the logarithmic concentration of Na with HRC and LOI (p < 0.05) but no such correlations for K. Two other elements, Mg and Fe, also showed significant correlations with HRC (r = −0.787 and −0.685, respectively) and LOI (r = 0.724 and 0.868, respectively) at the 95 % confidence level. It can also been seen based on Fig. 9 and Table 1 that, although the concentrations of inorganics including sodium for the water-washed MC-BL fiber were either smaller than or comparable to those for the unwashed SG747 fiber, the water-washed MC-BL fiber exhibited a lower HRC and a larger char yield than the unwashed SG747 fiber. The better thermal stability of the MC-BL fiber maintained after a water wash proved the contribution of the condensed tannins that were present in the fiber. A study on tannin-based cellular foams (Celzard et al. 2011) has shown the exceptional fire-resistant characteristics of tannins, i.e., difficult ignition, a low HRR, and a steady peak HRR under increased external heat flux, which were ascribed to the formation of a stable and impervious char that shielded the heat transfer.

Conclusion

Washing brown (SA-1 and MC-BL) and white (SG747) cotton fibers in water and a 1 % NaOH solution showed that the high thermal resistance of brown cotton observed from TG, DTG, and MCC analyses was associated with the presence of rich natural inorganic components and condensed tannins. Earlier studies (Mayer et al. 2012; Richards and Zheng 1991) reported that inorganic compounds introduced to wood cellulose by ion exchange influenced its pyrolysis and combustion, depending on the types and concentration of metals present. This study showed that sodium plays an important role in lowering the thermal decomposition temperature of cellulose, which resulted in reduced oxygen consumption for combustion and increased char yield. The logarithmic concentration of sodium exhibited significant correlations with the HRC and LOI of the fiber. Sodium on the white cotton was easily removed in water but was strongly bound to the brown cotton due to the presence of condensed tannins. Comparing the unwashed SG747 fiber with the water-washed MC-BL fiber proved the inherent thermal resistance of condensed tannins. The calculated LOI for brown cotton containing greater condensed tannin content indicated the slower burning characteristic, and its LOI was further increased with the adsorption of sodium ions. These finding suggested the potential utility of brown cotton in nonwoven applications that require a healthy, environmentally friendly self-extinguishing function. Also, the utilization of sodium by direct impregnation into cotton fiber is expected to reduce the burning rate of the fiber.

References

Atalla RH, Vanderhart DL (1984) Native cellulose: a composite of two distinct crystalline forms. Science 223:283–285

Atalla RH, Vanderhart DL (1999) The role of solid state 13C NMR spectroscopy in studies of the nature of native celluloses. Solid State NMR 15:1–19

Celzard A, Fierro V, Amaral-Labat G, Pizzi A, Torero J (2011) Flammability assessment of tannin-based cellular materials. Polym Degrad Stab 96:477–482

Ceylan Ö, Goubet F, Clerck K (2014) Dynamic moisture sorption behavior of cotton fibers with natural brown pigments. Cellulose 21:1149

Chen H, Cluver B (2010) Biodegradation and mildew resistance of naturally colored cottons. Text Res J 80:2188

Corradini E, Teixeira EM, Paladin PD, Agnelli JA, Silva ORRF, Mattoso LHC (2009) Thermal stability and degradation kinetic study of white and colored cotton fibers by thermogravimetric analysis. J Therm Anal Calorim 97:415–419

DeGroot WF, Shafizadeh F (1984) The influence of exchangeable cations on the carbonization of biomass. J Anal Appl Pyrolysis 6:217–232

Dickerson DK, Lane EF, Rodriguez DF (1999) Naturally colored cotton: resistance to changes in color and durability when refurbished with selected laundry aids. California Agriculture Technology Institute #990901

Fox SV (1996) Naturally flame resistant cotton. Patent 5496623 A

Gaugler M, Grigsby WJ (2009) Thermal degradation of condensed tannins from radiata pine bark. J Wood Chem Technol 29:305–321

Hinchliffe DJ, Condon B, Delhom CD, Chang S, Montalvo J, Madison C, Reynolds M, VonHoven T, Santiago Cintrón M (2015) Physical and combustion properties of nonwoven fabrics produced from conventional and naturally colored cottons. Text Res J 85:1666–1680

Hua S, Wang X, Yuan S, Shao M, Zhao X, Zhu S, Jiang L (2007) Characterization of pigmentation and cellulose synthesis in colored cotton fibers. Crop Sci 47:1540–1546

Hustvedt G, Crews PC (2005) The ultraviolet protection factor of naturally-pigmented cotton. J Cotton Sci 9:47

Kelly J, Mackey M, Helleur RJ (1991) Quantitative analysis of saccharides in wood pulps by quartz-tube pulse pyrolysis-polar phase gas chromatography. J Anal Appl Pyrolysis 19:105–117

Kim HJ, Kato N, Kim S, Triplett B (2008) Cu/Zn superoxide dismutases in developing cotton fibers: evidence for an extracellular form. Planta 228:281–292

Kohel RJ (1985) Genetic analysis of fiber color variants in cotton. Crop Sci 25:793–797

Kono H, Yunoki S, Shikano T, Fujiwara M, Erata T, Takai M (2002) CP/MAS 13C NMR study of cellulose and cellulose derivatives. 1. Complete assignment of the CP/MAS 13C NMR spectrum of the native cellulose. J Am Chem Soc 124:7506–7511

Langford JI, Wilson AJC (1978) Scherrer after sixty years: a survey and some new results in the determination of crystallite size. J Appl Crystallogr 11:102–113

Lege KE (1999) Sure-grow 747, a new early-maturing picker variety. In: Proceedings of the beltwide cotton conferences, vol 1, pp 69–71

Lewin M (2005) Unsolved problems and unanswered questions in flame retardance of polymers. Polym Degrad Stab 88:13–19

Li T, Fan H, Li Z, Wei J, Lin Y, Cai Y (2012) The accumulation of pigment in fiber related to proanthocyanidins synthesis for brown cotton. Acta Physiol Plant 34:813–818

Lyon RE, Walters RN, Stoliarov SI (2007a) Screening flame retardants for plastics using microscale combustion calorimetry. Polym Eng Sci 47:1501–1510

Lyon RE, Walters RN, Stoliarov SI (2007b) Thermal analysis of flammability. J Therm Anal Calorim 89:441–448

Ma M, Li R, Du Y, Tang Z, Zhou W (2013) Analysis of antibacterial properties of naturally colored cottons. Text Res J 83:462

May OL, Green CC, Roach SH, Kittrell BU (1994) Registration of PD 93001, PD 93002, PD 93003, and PD 93004 germplasm lines of upland cotton with brown lint and high fiber quality. Crop Sci 34:542

Mayer ZA, Apfelbacher A, Hornung A (2012) A comparative study on the pyrolysis of metal- and ash- enriched wood and the combustion properties of the gained char. J Anal Appl Pyrolysis 96:196–202

Nam S, Condon BD, Foston MB, Chang S (2014) Enhanced thermal and combustion resistance of cotton linked to natural inorganic salt components. Cellulose 21:791–802

Nishimura H, Okano T, Asano I (1981) Fine structure of wood cell walls II. Crystallite size and several peak positions of X-ray diagram of cellulose I. Mokuzai Gakkaishi 27:709–715

Pan Z, Sun D, Sun J, Zhou Z, Jia Y, Pang B, Ma Z, Du X (2010) Effects of fiber wax and cellulose content on colored cotton fiber quality. Euphytica 173:141–149

Parmar MS, Chakraborty M (2001) Thermal and burning behavior of naturally colored cotton. Text Res J 71:1099–1102

Piskorz J, Radlein D, Scott DS, Czernik S (1989) Pretreatment of wood and cellulose for production of sugars by fast pyrolysis. J Anal Appl Pyrolysis 16:127–142

Pizzi A, Stephanou A (1993) A comparative 13C NMR study of polyflavonoid tannin extracts for phenolic polycondensates. J Appl Polym Sci 50:2105–2113

Richards GN, Zheng G (1991) Influence of metal ions and of salts on products from pyrolysis of wood: applications to thermochemcial processing of newsprint and biomass. J Anal Appl Pyrolysis 21:133–146

Scherrer P (1918) Bestimmung der Grösse und der inneren Struktur von Kolloidteilchen mittels Röntgenstrahlen. Nachr Ges Wiss Göttingen 26:98–100

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using X-ray diffractometer. Text Res J 29:786–794

Slabbert N (1982) Complexation of condensed tannins with metal ions, vol 59. Plenum Press, Springer, New York

Soares S, Camino G, Levchik S (1998) Effect of metal carboxylates on the thermal decomposition of cellulose. Polym Degrad Stab 62:25–31

Teixeira EM, Corrêa AC, Manzoli A, Leite FL, Oliveira CR, Mattoso LHC (2010) Cellulose nanofibers from white and naturally colored cotton fibers. Cellulose 17:595

Tondi G, Zhao W, Pizzi A, Du G, Fierro V, Celzard A (2009) Tannin-based rigid foams: a survey of chemical and physical properties. Bioresour Technol 100:5162–5169

VanZandt MJ, Horridge P, Dever JK (1997) Flame resistance and physical characteristics of upholstery-weight naturally colored cotton. Cloth Text Res J 15:246–251

Wada M, Sugiyama J, Okano T (1993) Native celluloses on the basis of two crystalline phase (Iα/Iβ) system. J Appl Polym Sci 49:1491–1496

Wakelyn PJ, Bertoniere NR, French AD, Thibodeaux DP, Triplett BA, Rousselle M, Goynes WR Jr, Edwards JV, Hunter L, McAlister DD, Gamble GR (2006) Cotton fiber chemistry and technology. CRC Press, Boca Raton

Williams BL, Horridge P (1996) Effects of selected laundering and drycleaning pretreatments on the colors of naturally colored cotton. Fam Consum Sci Res J 25:137–158

Xiao YH, Zhang ZS, Yin MH, Luo M, Li XB, Hou L, Pei Y (2007) Cotton flavonoid structural genes related to the pigmentation in brown fibers. Biochem Biophys Res Commun 358:73–78

Yang CQ, He QL (2012) Textile heat release properties measured by microscale combustion calorimetry: experimental repeatability. Fire Mater 36:127–137

Yang CQ, He Q, Lyon RE, Hu Y (2010) Investigation of the flammability of different textile fabrics using micro-scale combustion calorimetry. Polym Degrad Stab 95:108–115

Ying C, Xinyuan S (2006) Effect of coloring materials on microstructure of naturally colored cotton. Colourage 53:55–58

Zhan XM, Zhao X (2003) Mechanism of lead adsorption from aqueous solutions using an adsorbent synthesized from natural condensed tannin. Water Res 37:3905–3912

Zhan XM, Miyazaki A, Nakano Y (2001) Mechanism of lead removal from aqueous solutions using a novel tannin gel adsorbent synthesized from natural condensed tannin. J Chem Eng Jpn 34:1204–1210

Zhang L, Jianxin H, Wang SY (2009) Structure and thermal properties of natural colored cottons and bombax cotton. J Therm Anal Calorim 95:653–659

Acknowledgments

We thank Pierre Burnside at Tulane University for XRD measurements and thank Dr. Alfred D. French for his comments on the XRD result. We also thank Tracy Condon for her assistance with sample preparation. This research received no specific Grant from any funding agency in the public, commercial, or not-for-profit sectors. Mention of trade names or commercial products in this publication is solely for the purpose of providing specific information and does not imply recommendation or endorsement by the US. Department of Agriculture. USDA is an equal opportunity provider and employer.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nam, S., Kim, H.J., Condon, B.D. et al. High resistance to thermal decomposition in brown cotton is linked to tannins and sodium content. Cellulose 23, 1137–1152 (2016). https://doi.org/10.1007/s10570-016-0871-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-016-0871-8