Abstract

Previously, we reported the preparation of high-crystalline hydrogels from α-chitin nanofibers by a simple NaOH treatment at low temperatures. In the present study, mild conditions were applied to both α-chitin powder and nanofibers to make hydrogels using calcium chloride dehydrate-saturated methanol (Ca solvent). Interestingly, nanofibrillation of powder occurred during the treatment. Compared with the powder, here, both wet chitin nanofiber (WChNF) and methanol-treated chitin nanofiber (MChNF) sheets could easily form into hydrogels at room temperature without the reflux conditions. In this system, water was an important factor in limiting the destruction of chitin crystalline structures caused by calcium ions. This was evident in the WChNF-based hydrogel, which exhibited higher crystallinity and retained its original continuous nanofiber network structure. Finally, we examined the tensile properties of samples prepared from NaOH solution and Ca solvent in the wet state. Although the hydrogel made from Ca solvent was not formed via interdigitation, the WChNF-based one exhibited considerably high tensile strength at around 1.3 MPa, which was close to the NaOH/ethanol-treated sample (tensile strength: 1.8 MPa).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

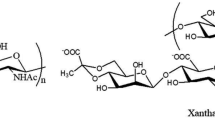

Chitin, one of the most abundant natural polysaccharides, consists of N-acetylglucosamine residues which have an acetamido group on the C2 position of d-glucose unit (Tokura et al. 1979). Because of strong inter- and intra-hydrogen bonding through the acetamide groups and hydroxyl groups, chitin has poor reactivity and processability, and its utilization is limited. Hydrogels are water-swollen polymeric materials that maintain three-dimensional networks, with the ability to absorb and retain a significant amount of water. There are two major types of hydrogels, synthetic and natural, depending on their origin. Chitin hydrogels, a kind of natural origin, and are considered to be one of the most promising materials because of their nontoxicity, biocompatibility and biodegradability (Lee et al. 1997; Nata et al. 2012). In previous researches, the main solvents used for preparing chitin hydrogels were chlorohydrins/inorganic acid, LiCl/DMAc, strong alkali solutions and NaOH/urea, etc. (Chakrabarty and Shahi 2014; Hu et al. 2007). Recently, calcium chloride dehydrate-saturated methanol system was found to be appropriate for preparing hydrogels under mild conditions (Tamura et al. 2006a; Nagahama et al. 2008). With this mild solvent system, molecular mass degradation can be avoided (Tamura et al. 2006b).

Poor mechanical properties have long been a problem for hydrogels owing to their high water content and soft structure. Many studies have attempted to overcome this shortcoming by using specific solvents or adding cross-linking agents and so on (Lee et al. 1997; Nagahama et al. 2008). For example, by mixing with GlcNAc and heating, the prepared hydrogel showed stronger mechanical properties because of the crosslinking effect by Maillard reaction (Nagahama et al. 2008). Via a solution pre-gelation method involving the blending of cellulose, hydrogel membranes with improved strength were obtained (Wu et al. 2010). However, these methods were either too complex or needing special conditions. Furthermore, few studies to date have been devoted to employing easy interactions to increase the tensile strengths of pure-chitin hydrogels, particularly those in the water-swollen state (Tokura et al. 1979; Kim and Lee 1995; Tamura et al. 2011).

Compared with powder, nanofibers have shown unique advantages in forming high-performance hydrogels, such as large surface area and entanglement (Abe and Yano 2012). Previously, we reported the preparation of high-crystalline interdigitated hydrogels based on α-chitin nanofibers using 20 wt% NaOH solutions (Chen et al. 2014). However, this method was relatively high in energy consumption because of the use of low temperatures. As a continuation and improvement to our previous work, we attempt to find an easier method to develop chitin nanofiber-based hydrogels under mild condition and evaluate their tensile properties.

Experimental

Materials

Commercial α-chitin powder from crab shells was purchased from Nacalai Tesque, Inc. and the degree of acetylation of the chitin was around 96 %. It was used without any further purification. All other chemicals were of laboratory grade and used as received.

Nanofibrillation of α-chitin powder

Chitin powders were dispersed in distilled water at a solid content of 0.8 wt%. Several drops of acetic acid were added to adjust the pH to 3 in order to facilitate fibrillation (Fan et al. 2008; Ifuku et al. 2009). The suspension was stirred overnight at room temperature and then passed through a grinder (MKCA6-2; Masuko Corp., Japan) twice at 1500 rpm. The grinding treatment was performed with a clearance gauge of −2.5 (corresponding to a 0.25 μm shift) from the zero position, which was determined as the point of slight contact between the two grinding stones (Abe et al. 2007).

Preparation of α-chitin hydrogel

Chitin powder (2 g) was added into 100 ml methanol saturated with calcium chloride dehydrate and refluxed overnight till forming transparent solution (Lee et al. 1997). Part of the chitin solution was removed into a mold and carefully washed with water to prepare a solid gel.

To prepare a sheet, chitin nanofiber suspension was diluted to 0.1 wt% with distilled water followed by vacuum-filtration using a polytetrafluoroethylene membrane filter. Afterwards, it was directly immersed into 100 ml saturated CaCl2·2H2O/CH3OH solution (850 g/L) for 12 h at room temperature and washed with plenty of water. One of the resulting wet sheets was dehydrated by solvent exchange (using methanol) for several days and then set into Ca solvent using the above procedure.

X-ray diffraction analysis

X-ray diffraction (XRD) measurements were conducted on a Rigaku X-ray diffractometer (UltraX 18HF; Rigaku Corp., Tokyo) with Cu-Kα radiation at 40 kV and 300 mA. Diffractograms were recorded in the range from 5° to 40°, at a scanning rate of 1°/min. The samples were freeze-dried and then pressed into sheets before testing. The crystalline index (CrI) was determined as: CrI110 = (I110 − Iam) × 100/I110, where I110 is the maximum intensity around 19.4°, and Iam is the intensity of amorphous diffraction at 16° (Nata et al. 2012).

Morphology

The morphological features of chitin samples were characterized using a field emission scanning electron microscope (FE-SEM). The freeze-dried samples were prepared by slowly dehydrating using ethanol (twice, 1 h each) followed by acetone (twice, 1 h each) t-butyl alcohol (twice, 1 h each) and then freeze-dried. The prepared samples were coated with platinum by an ion sputter coater and observed with an FE-SEM (JSM-6700F; JEOL Ltd., Tokyo, Japan) operating at 1.5 kV.

Mechanical properties

Test specimens of 35 mm × 5 mm in size were carefully cut from the hydrogel sheets and investigated using a universal material-testing machine (model 3365; Instron Corp., Canton, MA) at a crosshead speed of 10 mm/min. Tensile strength and fracture strain were reported as the average value from measurements of at least five specimens.

Degree of acetylation

The C, H, N contents of chitin samples were determined by elemental analysis. The degree of acetylation (DA) was calculated from the C and N content using the following equation (Lavall et al. 2007):

Swelling degree and shrinkage

The swelling degree in the hydrogel was defined as the ratio of swollen gel mass to dry gel mass after oven-dring at 110 °C for 12 h. The shrinkage rate was determined based on the diameter of the original sample.

Results and discussion

As reported, gelation of chitin could be achieved using calcium chloride dehydrate-saturated methanol (Ca solvent) (Lee et al. 1997; Nagahama et al. 2008; Tokura et al. 1996). This system is mild in comparison with the conventional solvent systems involving concentrated alcoholates or copper ammonium solutions (Hirano 2002).

Under these mild conditions, we prepared a 2 wt% chitin solution at the reflux temperature; the sample is shown in Fig. 1a. After washing with plenty of water, the transparent chitin solution turned into a white gel (DA 95 %) with a solid content of 3.5 % (Fig. 1b). Interestingly, under large magnification, part of the sample remained nanofiber network structure with an average width of 20 nm (Fig. 1c). However, we also observed typical regenerated morphology with coagulated masses in the same sample (Fig. 1d). The reaction mechanism could be explained as follows: Of the alkaline earth metal-alcohol solutions tested, the calcium chloride dihydrate-saturated methanol was the only effective solvent for chitin. In this system, calcium ions attack acetamide groups on the surface of the chitin molecular chains. The chelate formation between calcium ions and acetamide groups was the main force to the destruction of the strong intra- and inter-molecular hydrogen bonding network (Tokura et al. 1996), leading to the surface dissolution first. Later, calcium chloride can easily permeates into the inner chitin molecules and breaks the inside rigid crystalline structure. With this mild solvent system, molecular mass degradation can be avoided (Tamura et al. 2006a). This phenomenon suggested that nanofibrillation of chitin probably occurred initially when treated in Ca solvent and then gradually dissolved fully as the reaction proceeded. Consequently, we considered the interesting possibility of preparing nanofiber-based hydrogels directly from the powder form without mechanical nanofibrillation by controlling reaction conditions such as the time and temperature. However, the prepared samples in this study unfortunately showed partially dissolved morphology and we have not yet found optimum conditions for preparing good nanofiber-based hydrogels.

X-ray diffraction results (Fig. 2) indicated that the treated sample maintained stable structures of α-chitin, because two broad crystalline reflections at 9.5° and 19.4° were observed in the 2θ range of 5–40° which indexed as (020) and (110) (Wada and Saito 2001). The reduction in crystallinity was caused by the partial dissolution of chitin as well as the generation of some amorphous chitin (Iwamoto et al. 2007).

In our previous study, we prepared interdigitated chitin nanofiber-based hydrogels with the assistance of cold ethanol at low temperatures. The nanofiber-based samples showed improved properties over powder-based one (Chen et al. 2014). Thus, here, we also attempt to use chitin nanofibers as the base material to make hydrogel using Ca solvent under mild condition.

First, a wet chitin nanofiber sheet (WChNF) prepared by vacuum filtration was immersed in Ca solvent for 12 h. Surprisingly, a tough hydrogel was directly formed without any other treatment. During the reaction, color of the sheet became semi-transparent with 10 % shrinkage but turned back to white after washing (Fig. 3a). To verify the sample obtained was a real hydrogel, we prepared chitin nanofiber suspension and carefully poured Ca solvent into the beaker. Subsequently, the suspensions floated on the top of the solution regardless of the calcium concentration. After washing with plenty of water, it turned into a solid gel (DA 92 %) with a water content of 92 wt% (Fig. 3b).

According to Tamura’s report (2006a), the amount of water in this system is the main factor affecting the reaction. It means that water may influence the formation of hydrogels. Therefore, the prepared chitin nanofiber sheet was completely dehydrated by solvent exchange using methanol. Afterwards, it was immersed in Ca solvent at room temperature without stirring. During this process, colour of the sheet quickly changed from white to transparent and could be took out owing to the high fiber content (Fig. 4). As the reaction proceeded, the sheet became soft and easily broken. After washing, it exhibited approximately 15 % shrinkage and turned into a white hydrogel (DA 90 %) because of the removal of calcium ions and methanol.

Figure 5 shows the morphology of chitin nanofiber sheet before (a) and after (b, c) Ca solvent treatment. Interestingly, the WChNF-based hydrogel retained a fine nanofiber network structure similar to that of the original chitin nanofiber. The only difference seems to be the increase in fiber diameter from 20 to 50 nm due to aggregation and surface entanglement during the reaction. However, surface of the MChNF-based hydrogel exhibited typical regenerated morphology with porous structure and forming coagulation without any nanofiber shape. This implies that compared with powder, nanofibers with a much larger surface area could be directly and quickly dissolved in Ca solvent, without passing through the nanofibrillation process before fully dissolved.

In XRD studies (Fig. 5d), the obtained WChNF gel showed excellently high crystallinity, similar to the untreated sample due to the well-preserved of original chitin structure. In addition, as reported, calcium ions interacted only weakly with the polymer. Therefore, during the removal of calcium chloride and methanol using water for washing, the recrystallization of GlcNAc groups occurred and caused a mild reduction in crystallinity (Tamura et al. 2006b). On the other hand, crystallinity of the methanol-saturated nanofiber sheet (MChNF) decreased from 92 to 84 % after Ca solvent treatment because of the full regeneration of chitin, and the subsequent destruction of the crystalline structure (Tamura et al. 2006a, b; Tokura et al. 1996).

Combining with these results, the only difference between the two samples was the presence of water. Thus, it implied that in this Ca system, water was a dominate factor that could limit the destruction from calcium ions and lead to preservation of the nanofiber structure and form a high-crystalline, tough hydrogel.

Moreover, compared with chitin powder, gelation using nanofibers as base material could be conducted under static conditions without reflux or sustained stirring. Also, by using this method, we can prepare not only sheet gel, but also free-shaped gel under this mild condition as the Fig. 3b showed.

Figure 6 showed the tensile performance of chitin nanofiber-based hydrogels prepared by different methods. All samples maintained the same swelling degree of around 12.5. Obviously, the nanofiber sample treated with 20 wt% NaOH and ethanol exhibited the highest tensile strength in excess of 1.8 MPa, because it was formed via interdigitation which could give excellent mechanical properties (Abe et al. 2006; Chen et al. 2014). The WChNF-based hydrogel prepared from Ca solvent also showed considerable tensile strength around 1.3 MPa, despite being made under mild conditions. Both of these two samples retained high crystallinity and well-preserved nanofiber network structure, that lead to high mechanical properties. In contrast, the remaining two gels were much weaker due to serious damage to the chitin structure. These observations are consistent with previous studies in which regenerated chitin hydrogels were always quite fragile with poor mechanical properties (Nagahama et al. 2008; Tamura et al. 2011; Chen et al. 2014).

Here, we conclude that chitin hydrogels could be prepared from both powder and nanofibers under mild conditions. However, compared with powder-based hydrogels with random structures, using nanofibers as base materials showed some characteristics: (1) both ChNF-based hydrogels could be prepared easily at room temperature without the assistance of stirring and reflux conditions; (2) ChNF-based hydrogels can directly retain the sheet shape without casting process which is convenient for tensile testing; (3) by vacuum filtration, ChNF sheets form with a planar-oriented layer structure, that also leads to the high tensile strength of hydrogels. In fact, even the ChNF-based regenerated gel shows better mechanical properties compared with the gel made from powder. However, this study showed an interesting possibility, that is, chitin nanofiber-based hydrogel may be directly prepared from chitin powder without any nano-fibrillation treatment by controlling some conditions during the reaction.

Additionally, as mentioned, the most common regenerated pure-chitin hydrogels showed poor mechanical performance especially in the wet state, which greatly limited their application (Lee et al. 1997; Kim et al. Kim and Lee 1995). Recently, the common methods for improving hydrogels’ mechanical strength include the addition of chemicals, such as crosslinking agents and application of chemical modification and so on (Tamura et al. 2011; Huang et al. 2008; Ifuku et al. Ifuku and Saimoto 2012), which are relatively difficult and high-cost. Therefore, preparation of high strength chitin hydrogels at room temperature is quite meaningful. Combined with our previous study (Chen et al. 2014), we have found two methods for preparing high tensile performance chitin nanofiber-based hydrogels without the use of any specific solvents or cross-linking agents.

Conclusions

In this study, both α-chitin powder and nanofibers could be made into hydrogels using calcium chloride dehydrate-saturated methanol. This system is mild in comparison with the conventional methods involving concentrated alcoholates or copper ammonium solutions. During the reaction of chitin powder in Ca solvent at reflux conditions, dissolution seems occur after the nanofibrillation. However, similar with our previous study, this method is energy-intensive. For improvement, WChNF and ChNF sheets were treated in Ca solvent and then prepared hydrogels at room temperature. XRD and FE-SEM results indicated that the water inside the nanofiber sheet was the main factor for preserving the original nanofiber network structure and reducing the loss of crystallinity. Unlike conventional regenerated hydrogels, both chitin hydrogels prepared from 20 wt% NaOH solutions (1.8 MPa) and Ca solvent (1.3 MPa) showed high tensile properties in the wet state. Although recently there have been a few reports on the modification of the mechanical performance of chitin hydrogels (Lee et al. 1997; Kim et al. Kim and Lee 1995; Nagahama et al. 2008), the method here was relatively easier without use of any specific solvents or cross-linking agents and can be conducted at room temperature. In the present study, we focused on the preparation of high wet-strength chitin nanofiber-based hydrogels in two ways. As the next step, detailed reaction mechanisms for these processes will be studied. We hope these high wet-strength chitin hydrogels are useful in expanding the application area of natural materials.

References

Abe K, Yano H (2012) Cellulose nanofiber-based hydrogels with high mechanical strength. Cellulose 19:1907–1912

Abe K, Iwamoto S, Yano H (2007) Obtaining cellulose nanofibers with a uniform width of 15 nm from wood. Biomacromolecules 8:3276–3278

Chakrabarty T, Shahi VK (2014) Modified chitosan-based, pH-responsive membrane for protein separation. RSC Adv 4:53245–53252

Chen CC, Li DG, Abe K, Yano H (2014) Dissolution and gelation of α-chitin nanofibers using a simple NaOH treatment at low temperatures. Cellulose 21:3339–3346

Fan Y, Saito T, Isogai A (2008) Preparation of chitin nanofibers from squid pen β-chitin by simple mechanical treatment under acid conditions. Biomacromolecules 9:1919–1923

Hirano S (2002) Some functional biofibers based on chitin and chitosan. Bioindustry 19:62–70

Hu X, Du Y, Tang Y, Wang Q, Feng T, Yang J et al (2007) Solubility and property of chitin in NaOH/urea aqueous solution. Carbohydr Polym 70:451–458

Huang ZH, Dong YS, Chen CL, Lin PH (2008) Electrochemistry assisted reacting deposition of hydroxyapatite in porous chitosan scaffolds. Mater Lett 62:3376–3378

Ifuku S, Saimoto H (2012) Chitin nanofibers: preparations, modifications, and applications. Nanoscale 4:3308–3318

Ifuku S, Nogi M, Abe K, Yoshioka M, Morimoto M, Saimoto H et al (2009) Preparation of chitin nanofibers with a uniform width as α-chitin from crab shells. Biomacromolecules 10:1584–1588

Iwamoto S, Nakagaito A, Yano H (2007) Nano-fibrillation of pulp fibers for the processing of transparent nanocomposites. Appl Phys A 89:461–466

Kim SS, Lee YM (1995) Synthesis and properties of semi-interpenetrating polymer networks composed of β-chitin and poly(ethylene glycol) macromer. Polymer 36:4497–4501

Lavall RL, Assis OBG, Campana-Filho SP (2007) Beta-Chitin from the pens of Loligo sp.: extraction and characterization. Bioresour Technol 98:2465–2472

Lee YM, Kim S, Kim SH (1997) Synthesis and properties of poly(ethylene glycol) macro/β-chitosan hydrogels. J Mater Sci Mater Med 8:537–541

Nagahama H, New N, Jayakumar R, Furuike T, Tamura H (2008) Preparation of chitinous compound/gelatin composite and their biological application. Macromol Symp 264:8–12

Nata I, Wang S, Wu T, Lee C (2012) Carbonaceous hydrogels based on hydrothermal carbonization of glucose with chitin nanofibers. Soft Matter 8:3522–3525

Tamura H, Nagahama H, Tokura S (2006a) Preparation of chitin hydrogel under mild conditions. Cellulose 13:357–364

Tamura H, Sawada M, Nagahama H, Higuchi T, Tokura S (2006b) Influence of amide content on the crystal structure of chitin. Holzforschung 60:480–484

Tamura H, Furuike T, Nair SV, Jayakumar R (2011) Biomedical applications of chitin hydrogel membranes and scaffolds. Carbohydr Polym 84:820–824

Tokura S, Nishi N, Noguchi J (1979) Studies on chitin. III. Preparation of chitin fibers. Polym J 11:781–786

Tokura S, Nishimura S, Sakairi N, Nishi N (1996) Biological activities of biodegradable polysaccharide. Macromol Symp 101:389–396

Wada M, Saito Y (2001) Lateral thermal expansion of chitin crystals. J Polym Sci Part B Polym Phys 39:168–174

Wu J, Liang S, Dai H et al (2010) Structure and properties of cellulose/chitin blended hydrogel membranes fabricated via a solution pre-gelation technique. Carbohydr Polym 79:677–684

Acknowledgments

This work was financially supported by National Natural Science Foundation of China (NSFC 31170514, 31370557), Doctorate Fellowship Foundation of Nanjing Forestry University, Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD), Graduate Cultivation Innovative Project of Jiangsu Province and Doctorate Tutor Foundation of Department of Education (20113204110011).

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Chen, C., Yano, H., Li, D. et al. Preparation of high-strength α-chitin nanofiber-based hydrogels under mild conditions. Cellulose 22, 2543–2550 (2015). https://doi.org/10.1007/s10570-015-0654-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-015-0654-7