Abstract

Functional polymers as solid-supported reagents and catalysts for organic synthesis were conventionally based on cross-linked polystyrene (PS). Polyacrylamide (PAM), modified PAM and their copolymers as hydrophilic support, alternatively can be used as heterogeneous systems in several areas of chemistry and industry. After Regen’s report in 1979 that applied cross-linked PAM as a solid phase cosolvent, PAM-supported reagents and catalysts manifest an excessively important function in various organic reactions. This review summarizes the entire features of PAM and its modified forms and focuses on their most recent and relevant applications in organic transformations. Oxidation–reduction reactions, C–C cross-coupling reactions, and Michael addition reactions are among the most important transformation in which PAM and its derivatives have been widely used. Other reactions like substitution reactions, H2O2 decomposition, 1,3-thiazoles synthesis, oxidative esterification, dichlorocyclopropanation, protection of carbonyl compounds, ring opening of epoxides, and dye decolorization have also been investigated. Furthermore, the efficiency, reusability, and limitations associated with these supported systems are discussed.

Graphical Abstract

Herein, applications of functional polymers based on polyacrylamide, modified PAM and their copolymers for the production of polymer supported reagents and catalysts are reviewed. This review summarizes the entire features of PAM and its modified forms and focuses on their most recent and relevant applications in organic transformations such as oxidation–reduction reactions, C–C cross-coupling reactions, Michael addition reactions etc. Furthermore, the efficiency, reusability, and limitations associated with these supported systems are discussed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

“Functional polymers” are insoluble macromolecules with chemically attached functional groups and have the potential benefits of small molecules having the same functional groups. Their effectiveness is associated with polymeric matrix and the pendant or main chain functionality. The main advantage of the heterogeneous polymeric systems is their easy separation from the reaction mixtures, usually by just a simple filtration. In addition, functional group affinity to the polymeric support may increase its stability and selectivity. On the contrary, experimental benefits of functional polymers may be compensated by a remarkable repletion in their reactivity related, for example, to diffusional restrictions. However, there are also a number of significant disadvantages that are usually found when comparing homogeneous catalysts with their heterogeneous counterparts. These shortcomings include high cost, reduction of activity and selectivity due to diffusion limitation (the reduction of catalyst activity can be compensated by increasing the reaction time or increasing the catalyst loading), the inability to separate the impurities attached to the polymer, and the accurate analysis of the species structure.

The first application of functional polymer in organic synthesis was introduced in 1963 by R. Bruce Merrifield when he synthesized oligopeptides through the solid phase method. Since that declaration, various type of functionalized polymeric materials has been investigated in organic transformations.

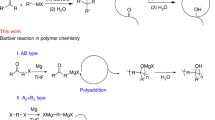

The most important polymeric catalysts beneficially applied in organic reactions are ion exchange resins, polymeric superacid and Lewis acids, polymeric PTCs (phase transfer catalysts), polymer-supported transition metal catalysts, and polymeric hydrolysing and decarboxylating systems. In addition, the main kinds of polymeric reagents are supported sulfonium salts, phosphine reagents, halogenating agents, condensing reagents, redox reagents, acylating, and alkylating reagents, and supported-bound nucleophiles. Traditionally, large numbers of functional polymers have mainly been synthesized by applying cross-linked PS, e.g., with divinylbenzene. Several functional polymers have been developed, such as polymer-supported reagents for organic synthesis and catalysts for various organic transformations rather than PS. These materials can be developed by polymerizing functionalized monomers or post-chemical modification of polymeric systems. Glycidyl methacrylate (GMA), vinyl pyrrolidone, acrylic acid, and acrylamide are some examples.

The polymers based on PAM and their copolymers are a varied family used in multitudinous applications, including hydrogel preparation, drinking water clarification, flocculants for wastewater treatment, oil recovery, biomedicine-like protein separation, and agriculture-like soil conditioning [1]. PAM is a controllable molecular weight polymer found in microbeads, powder solid form, aqueous solution, or inverse emulsions. This is one of the most important non-ionic hydrogels fabricated by cross-linking hydrophilic polymers. The synthesized gels show different swelling ratios depending on the synthesis method, type, and concentration of the cross-linking agent. Most are being used as biomaterials for diverse medical and industrial applications [2]. PAM has many applications due to its solubility in water and various chemical and physical properties. The PAM allows various applications like super-absorbent polymer technology, chromatography, electrophoresis, biophysics, and nanoscience, e.g., enzyme treatment or controlled drug delivery [3]. PAM is used in water treatment because it leads to flocculate solids in the liquid. Furthermore, it can increase water viscosity, and can increase oil recovery. It is widely used as an adhesive for pulp fibers in the paper industry, and in addition, it is used as an additive for wastewater treatment. PAM can be used as a soil conditioner in agriculture. Other applications of PAM include mining and ore processing.

However, acrylamide (AM) monomer toxicity is a concern, especially when the polymer is in direct contact with body fluids or is applied to manufacture therapeutic agents. There is no tendency to accept it as a safe material. Thus, the level of AM monomers in commercial polymers has been an important issue. Recently, many studies have been performed on the possibility of converting commercial PAM formulations to AM monomers [4, 5]. PAMs are usually produced via free-radical polymerization of AM in an aqueous solution or dispersion with the help of initiators such as azo, persulfates, or peroxides compounds, redox systems, and photochemical materials. The process of polymerizing AM affording PAM that has entirely distinct chemical and biological features to the monomer. The amide functional group of PAM can perform transformations, including hydrolysis, dehydration, transamidation, and Hofmann degradation reactions.

PAM and its modified forms and copolymer in the form of soluble or insoluble polymer support are successfully used in catalysis and synthesis. The compatibility of this polymer with aqueous media is the point of choosing this polymer in most cases that makes PAM a suitable base for many biological and medicinal investigations. PAM in the form of copolymer with PS used for the production of polymer grafted magnetic nanoparticles (NPs) like Fe3O4/poly (styrene-co-acrylamide) composite, which has attracted much regards in the last few decades because of their comprehensive applications in medicine and biology [6]. PAM and their modified forms and PAM-supported different metal complexes can also act successfully as heterogeneous catalysts in further transformations. In most cases, these polymeric catalysts could be reused multiple times without reducing their activity.

Herein, reagents and catalysts supported on PAM that recently has been widely used in various reactions are investigated. These reactions include oxidation–reduction reactions, C–C cross-coupling reactions, Michael addition reactions, condensation reactions, substitution reactions, the three-component reaction of aldehydes, alkynes, and amines (A3 coupling), decomposition of hydrogen peroxide, methanolysis reaction, 1,3-thiazoles synthesis, dichlorocyclopropanation reaction, oxidative esterification reaction, ethylene polymerization, protection of carbonyl compounds, ring opening of epoxides, dye decolorization and direct transformation of benzilic amines to carbonyls compounds. PAM-supported catalysts and reagents used in various organic transformations are summarized in Table 1.

1.1 Oxidation–Reduction Reactions

Alcohol oxidation to carbonyl compounds is one of the main reactions in preparing organic materials performed by different methods. One of the most widely reported methods is the oxidation of alcohols by catalysis of transition metals using environmentally friendly oxidants such as oxygen and hydrogen peroxide [7, 8]. Although several homogeneous catalyst systems without oxidants catalyzed by transition metals have been reported, these methods have problems such as difficulties in catalyst preparation [9], air sensitivity [10], and the requirement for additives [11,12,13]. Recently, catalysts supported by various polymeric backbones have been used to oxidize alcohols. The most important features of these methods are simple filtration, easy recovery from the reaction mixture, high selectivity, and low toxicity [14,15,16]. Polymeric transition metal-catalyzed systems are environmentally benign supports as they produce hydrogen, a precious energy source that prevents the oxidation of starting materials to carboxylic acids due to their mild reactivity [17].

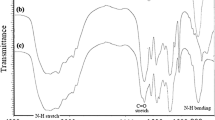

In 1988, poly(N-bromoacrylamide) (PBAM) as a novel insoluble polymeric oxidizing and brominating agent was detected to oxidize 1° and 2° alcohols under favorable circumstances. Owing to the polar hydrophilic temper of the PBAM, more polar solvents facilitate the oxidation reaction [18]. Similar oxidizing reagents have been obtained by N-bromo derivatives of poly(acrylamide-co–N,N'-methylene bis-acrylamide)s (PAMA) (Scheme 1) and used for the oxidation of some 1° and 2° alcohols to the analogous aldehydes and ketones. In this study, the impact of the cross-link density on the function of the oxidizing agents was investigated [19].

Prabhakaran et al. used poly(vinyl amine) (PVAm) as a polymeric support reagent. Cross-linked PAM was manufactured via the free radical copolymerization of AM and divinyl benzene (DVB), and it was transformed to cross-linked PVAm through Hofmann’s degradation reaction in the presence of hypobromite. The permanganate group treated the prepared PVAm to acquire the polyvinyl ammonium permanganate resin (PVAmMnO4). Then, permanganate ion supported over cross-linked PVAm with a capacity of 3.3 meq/g applied for alcohols (primary and secondary) oxidation [20].

Another interesting study was reported by Tamami and coworkers, who synthesized modified PAM-supported chlorochromate (PACC) (Scheme 2) and utilized it as a new polymeric oxidizing reagent for the oxidation of diverse organic materials, like alcohols, silyl ethers, oximes, and thiols. Excessive oxidation of aldehydes to acids was not perceived, and the polymeric oxidant was insoluble in the reaction media. The chromium (VI) ions attached firmly to the PAM support even after reaction completion [21].

Anchoring metal complexes on polymeric supports shows practicable advantages like simpleness in separation and handling, recovery and reusability, non-toxic features, and compatibility for an ongoing procedure. B. Tamami et al. reported a novel polymeric Schiff base-cobalt complex supported on modified cross-linked PAM (PAHISCo) and used for the alkenes and haloalkanes oxidation using hydrogen peroxide in water as a green reaction medium [22].

In addition, a heterogenous system based on silver NPs encaged in chitosan (CS)/PAM interpenetrating polymer network (Ag@IPN) was introduced. PAM improves the Ag NP’s stability and avoids its subsequent leching and aggregation. Ag@IPN catalytic system was applied for the oxidation of diverse aromatic, heteroaromatic and aliphatic alcohols in the absence of oxidant in an environmentally friendly oxidation procedure [23].

Song et al. reported a composite microsphere-supported system based on PAM (Scheme 3). Initially, the microgel of PAM is swelled with peroxotungstophosphate (PTP) solution as a core system. Then, the swelled microgels are dispersed in an H2O2 solution, including cetyltrimethylammonium bromide (CTAB). Finally, CTAB-PTP is constructed on the surface of PAM as a shell. The CTAB-PTP/PAM microspheres are applied as recyclable catalysts in the oxidation of dibenzothiophene (DBT) that decrease the release of organic solvent into nature [24].

Rogers et al. chose modified PAM hydrogels as a suitable support for photosensitizer hematoporphyrin (PAM-HP) due to PAM adaptability with polar and nonpolar solvents. Then it is utilized in the photooxidation of anthracene and sensor green probe using singlet O2 (produced by sensitizer resin) in an aqueous and organic solvent, respectively [25].

Mathew et al. prepared palladium complexes supported on cross-linked polyvinylpyridine (PVP) and poly(acry1amide-methacrylic acid) copolymer grafted on SiO2 (CPVPAM), and applied them as catalysts for the oxidation of azo and nitro compounds. Compared with silica-free polymer-Pd catalysts, these catalysts showed much higher activity [26]. To understand the influence of polymer coating on the catalyst activity, palladium is anchored to different silica-coated polymers such as PAM and poly N-vinylimidazole (PNVIM) (Scheme 4). The resulting catalysts (PNVIM/Pd) were active towards the hydrogenation of olefins and alkynes under mild conditions and represented reusability and selectivity in reducing alkynes and dienes to alkenes in the presence of alkenes [27].

Romanazzi et al. presented a nickel catalyst supported by an acryl amidic polymer (Ni(AAEMA)2-pol) according to Scheme 5. They evaluated its catalytic efficiency for the reduction of nitro compounds in water as green medium. This catalyst is applicable for at least five cycles while maintaining its catalytic activity and selectivity. Recyclability, high selectivity and keeping away the formation of hydro-dehalogenated by-products were major benefits of this polymeric Ni catalyst [28].

An efficient catalytic system, PAM-stabilized palladium NPs supported on γ- Fe2O3 (Pd0-PAM/- γFe2O3), was synthesized by the adsorption of the Pd0-PAM systems on maghemite. This catalyst was applied for the hydrogenation of phenylacetylene gently, and catalyst activity was enhanced by decreasing the size of palladium NPs [29].

Farooqi et al. synthesized a multi-responsive microgel consists of responsive poly(N-isopropylacrlamide-methacrylic acid-acrylamide) [P(NIPAM-MAA-AM)] terpolymer via conventional radical emulsion polymerization and employed for the fabrication of silver NPs. This hybrid system is applied in the reduction of 4-nitrophenol (4-NP) compound [30].

A novel water-based and convenient method was developed to produce a hydrogel consists of a ternary PAM-based composite with low-temperature thermally functionalized Ag and graphene (G) NPs (PAM/G/Ag) (Fig. 1). It was used in the catalytic reduction of an azo dye, 4-NP, and methylene blue properly. These hydrogels based on PAM indicate interconnected structure with porous composition which introduce them as catalyst molecule adsorbents [31].

Ejaz Ahmed and coworkers synthesized a microgel comprised poly(N-isopropylacrylamide-co-acrylamide) [P(NIPAM-co-AM)] via precipitation polymerization approach. Afterward, the silver ions were inserted into the polymer network and then reduced to silver NPs. The as-prepared microreactor [P(NIPAM‐co‐AM)] was applied in the catalytic hydrogenation of 4-NP compound [32]. In a similar report, Farooqi et al. introduced Ag NPs incorporated into the poly(N-isopropylacrylamide-acrylic acid-acrylamide) [P(NIPAM-AAc-AM)] microgel. AM components extended the pH stability scope of P(NIPAM-AAc-AM)-Ag compared to P(NIPAM-AAc)-Ag hybrid system [33].

Zhang and coworkers introduced an excellent procedure for producing dispersed Ag NPs supported by PAM-modified poly(glycidyl methacrylate) (PGMA) microspheres (PGMA-PAM). PAM improved the function of PGMA support due to abundant amide groups that provide the functionality for the growth of silver NPs. The as-prepared Ag composites revealed superior catalytic activity in the reduction of nitro compound (Fig. 2) [34].

Another elegant example reported by Kumar et al., who created the nanocomposite composed of multi-responsive CS-PAm-Cu NPs hydrogel using free-radical polymerization. In this system, CS, Am, Cu NPs, ammonium persulfate and glutaraldehyde are performing the role of substrate, monomer, initiator, and cross-linking agent, respectively. The as-prepared CS-PAm-Cu NPs compound exhibited high conversion capability for the conversion of 4-NP into 4-AP [35].

Similar catalytic activity was obtained by Ag NPs supported on nanosheets comprised polyacrylamide, polypyrrole, and graphene oxide (PAM/PPy/GO). GO with a vast surface area and superior two-dimensional architecture improved silver NP immobility. In addition, PPy raised the rate of electron transport in the reduction of 4-NP because of its high electric conductivity. In this catalytic system, PAM had the role of an effective linker among silver NPs and PPy/GO nanosheets facilitated the efficient interaction between 4-NP and silver NPs [36].

Lignin as the second natural polymer in nature is used to enhance the catalytic activity of Ag NPs by crosslinking polymers with each other and forming a three-dimensional network architecture. Taking this as inspiration, Gao et al. prepared three-dimensional hydrogels composed of silver, lignin, and PAM (Ag/L/PAM) favorably and employed them for the hydrogenation of 4-NP compound [37].

Phase transfer catalysis (PTC) is an impressive synthetic tool for accelerating phase-separated reactions (liquid–liquid as well as liquid–solid) and manufacturing specialty chemicals. However, these catalysts are generally not recoverable, and the work-up becomes tedious process due to the formation of stable emulsions of ammonium and phosphonium salts. In this regard, supported catalytic systems have been developed to control these difficulty [38].

Tamami et al. reported an onium salt amino modified cross-linked PAM (poly[N-(2-aminoethyl)acrylamido]trimethyl ammonium halide resin) (PAMAAMTAHa) as a well-organized heterogenous PTC (Scheme 6). This polymeric PTC is applied for the carbonyl compounds reduction (aldehyde and ketones) using NaBH4 chemoselectively. It has been proven that this supported PTC is extremely regioselective in reducing α,β-unsaturated aldehydes and ketones [39].

Furthermore, in mild conditions and in the presence of zinc powder in water, it converts aromatic nitro compounds into the corresponding amino counterparts with high yields. This method is environmentally friendly for the synthesis of anilines because hazardous nitrogen containing by-products (hydrazine, hydroxylamines, diazo, and nitroso compounds) were not obtained during the reduction of nitroarenes [40].

Leng and coworkers fabricated a photo responsive double-layer hydrogel by grafting light responsive cinnamic moieties onto a PAM network to synthesize photo-sensitive layer. Silver NPs were dispersed on the photoresponsive layer through in situ reduction of silver salt (Ag-PCAM/PAM) and applied as a catalyst for the sodium fluorescein (SF) reduction in the presence of sodium borohydride. For analyzing photoswitchable behavior, γ>260 nm and γ<260 nm light stimuli were chosen as the primary illumination sources. Due to the cycloaddition of cinnamic moieties when radiated by UV light with γ>260 nm, the cross-linking degree increased and the availability and diffusion of reactants in the solution decreased. Therefore, the rate of catalytic reaction slowing (Scheme 7) [41].

For the first time, Hu and coworkers reported the pseudo-zero-order kinetics for catalytic reduction pathways. This catalytic rout is flexible by altering the structure of a tricomponent composite catalyst constituted of Ag ions, G, and PAM. They incorporated varying amounts of GO nanosheets into the PAM matrix (PAM/GO). This combination generates a dual cross-linking network capable of encapsulating silver nanocatalysts as they are being generated in situ during the catalytic reduction reaction. Consequently, the catalytic reduction of 4-NP and methylene blue is significantly improved. The results showed that the higher GO content leads to a discernible rise in the amount of Ag+ ions, which provides many catalytic sites for 4-NP [42].

In 2020, the electrochemical production of silver NPs immobilized within a PAM hydrogel (Ag-PAM) was announced by Fox et al. PVP-protected silver NPs generated by reduction of Ag+ in the vicinity of poly(N-vinylpyrrolidone) and then incorporated into a PAM hydrogel composite. This system showed good efficiency in the reduction of 4-NP to 4-AP applying sodium borohydride, which also prevents oxidation or corrosion of the silver NPs and gives the hydrogel–Ag composite stability and reusability [43].

In 2021, a report was written about how 2,2,6,6-tetramethylpiperidine-N-oxyl (TEMPO) changed the primary alcohol groups of polysaccharides into carboxyl groups. Two significant issues plagued this process. First, oxidation led to the cellulose backbone’s depolymerization, which ultimately reduced the cellulose’s mechanical properties. Second, TEMPO is a toxic material for marine life and is difficult to recover from wastewater. Scientists have come up with various ways to deal with these problems. TEMPO [P(AM-co-VAm)-T] was found to be an excellent catalytic system for the oxidation of cellulose selectively by Liu and coworkers in 2021 when they developed a support compose of vinylamine and acrylamide P(AM-co-VAm) recyclable copolymer with –NH2 groups that reacted with carboxylic groups in TEMPO [44].

1.2 C–C Cross-Coupling Reactions

Pd NPs play crucial role as a catalyst in the C–C coupling reaction as one of the main processes in the improvement of organic chemistry [45]. Palladium catalysts are mainly incorporating in organic or inorganic supports, G [46,47,48,49,50], and CNT [51,52,53,54,55] due to their possibility for easy recovery and mostly used in Heck, Suzuki and Sonogashira coupling reactions.

Mahdavi et al. synthesized a novel heterogeneous catalyst on an amphiphilic PAM supported by palladium NPs (Pd/PAM) and then employed it in Suzuki cross-coupling reaction. Stable Schiff base ligands were used to link the palladium NPs to the support in the presence of air and moisture (Scheme 8) [56].

PdCl2 supported on PAM hydrogel (PdCl2/PAM) created an inexpensive catalyst that was applied for Suzuki–Miyaura cross-coupling reaction. Diverse iodo- and bromoarenes were coupled with phenylboronic acid to produced biphenyl compounds under phosphine-free condition in EtOH with excellent yield [57].

G and GO with distinctive chemical, physical, and surface characteristics, have been widely used to support the immobility of active species and metal-free catalysis. Modification of GO surface by polar and hydrophilic PAM led to improved dispersion of GO in a solvent. Then, Pd NPs were immobilized on the PAM-g-rGO surface, and the nanocomposite was applied in the Suzuki–Miyaura cross-coupling reaction. PAM-g-rGO/Pd catalytic system showed high catalytic activity in a green solvent under mild condition (Scheme 9) [58].

Tamami et al. revealed an intriguing example of a catalyst for the Mizoroki–Heck and Suzuki–Miyaura coupling reactions using Pd NPs supported on cross-linked PAM, modified with phosphinite ligand as an effective polymeric catalyst (PPAMPh) (Scheme 10). This process is distinguished by its rapid reaction time, simple purification of products, high efficiency, and recycling of catalyst, and negligible leaching of Pd. Due to this catalyst's resistance to air, all reactions can be carried out in the air [59]. Furthermore, they used this catalyst for the Sonogashira reaction without copper or amine in NMP in an aerobic environment [60].

Ghasemi and coworkers synthesized PAM grafted onto silica gel (SiO2-g-PAM) through “grafting to” and “grafting from” strategy by using the RAFT polymerization technique. A system of heterogeneous catalyst was developed through the modification of SiO2-g-PAM with phosphinite ligand and the following complexation of modified ligand with Pd salt. The Mizoroki–Heck cross-coupling reaction illustrates this catalyst’s appropriate activity and recyclability [61,62,63].

A three-component hybrid system combining halloysite nanoclay and cyclodextrin-conjugated PAM (Hal-P-CD) was synthesized by Sadjadi and coworkers. The heterogenous support was produced by the grafting of PAM brushes on the surface of modified halloysite nanotubes and then introducing β-cyclodextrin. Pd(0) NPs were immobilized on the as-prepared support, and a ternary hybrid catalyst, Pd@Hal-P-CD, was developed favorably (Scheme 11). The catalyst utilized in the Heck and Sonogashira carbon–carbon coupling reactions in an aqueous environment [64].

Recent research by Sewald and colleagues has resulted in the development of a smart catalyst for the Suzuki coupling of peptides and amino acids. This catalyst is based on PAM microgels copolymerized with carboxylic acid and tertiary amine segments. The Suzuki–Miyaura cross-coupling reaction was performed using phenylboronic acid with Nα-Boc-4-iodophenylalanine and Nα-Boc-7 bromo-tryptophan using four different types of microgels loaded with palladium. These four catalytic systems are polypropylacrylamide (PPAM) and PNIPAM, which were copolymerized with methacrylic acid (MAA) or N-[3-(dimethylamino) propyl]methacrylamide (DAPMA), each of which introduced a carboxylic acid or a third amine in the network [65].

1.3 Condensation Reactions

In a condensation reaction, two molecules join to produce one, typically with the loss of a smaller component. Aldol and Knoevenagel condensations, which both create water as a side product, and Claisen and Dieckman condensations (intramolecular Claisen condensations) that yield alcohols, are examples of condensation reactions that are frequently encountered. An exciting example of amino-functionalized PAM was obtained by transamidation reaction between PAM and hexamethylenediamine and used as an effective and chemoselective polymeric catalyst for condensation reaction (Scheme 12). Knoevenagel reaction was performed among aliphatic and aromatic aldehydes and carbanion precursor compounds e.g., malononitrile, cyanoacetamide, and ethyl cyanoacetate under solventless and aqueous conditions [66, 67].

Another example was reported by Parvanak Boroujeni, who synthesized magnetite-containing sulfonated PAM through 2-acrylamido-2-methyl-1-propanesulfonic acid (AMPS) and AM polymerization, following by treatment with Fe3O4 NPs (Scheme 13). The as-prepared poly (AMPS-co-AM) containing Fe3O4 NP was used for one-pot preparation of biscoumarin derivatives via domino Knoevenagel/Michael reaction among 4-hydroxy biscoumarin and different aldehydes [68]. Furthermore, poly (AMPS-co-AM) was employed for grafting to GO. The poly (AMPS-co-AM)-GO catalytic system as a recyclable catalyst was utilized to prepare 1,8-dioxo-octahydroxanthenes via the condensation reaction of different aldehydes with dimedone (5,5-dimethyl-1,3-cyclohexanedion) in aqueous media [69].

In addition, poly (APMS-co-AM) was grafted to multiwalled carbon nanotubes (MWCNTs) successfully (Scheme 14). The poly (APMS-co-AM)-MWCNT demonstrated significant catalytic activity in the electrophilic substitution reaction of indole with diverse aldehydes and preparation of 1,8-dioxo-octahydroxanthenes via condensation of aldehydes and dimedone. In this study, poly (APMS-co-AM) with long chain, high polarity, and steric bulkiness break the van der Waals attractions between MWCNTs and improve the dispersion of poly (APMS-co-AM)-MWCNT in both aqueous and organic media. Furthermore, the ability of amide and sulfonic acid groups to undergo hydrogen bonding increase the solubility of the heterogeneous catalyst in protic solvent [70].

1.4 Substitution Reactions

Substitution reactions are divided into electrophilic and nucleophilic in organic synthesis. This classification is influenced by factors such as the type of reagent or whether the reactive intermediate engaged in the reaction is a free radical, a carbocation, or a carbanion, as well as if the starting material is aliphatic or aromatic. Good examples of a substitution reaction are the formation of haloalkanes, hydrolysis, and halogenation, which occur in the vicinity of diverse catalysts. Nucleophilic substitution reactions on haloalkanes in the presence of PTCs are one of the remarkable reactions in organic chemistry. PTCs do not fully recover and form stable emulsions despite increasing the reaction rate and facilitating separation. For this purpose, heterogeneous catalysts are used, such as polymer-supported matrixes. In 2008, Tamami et al. introduced the application of efficient heterogeneous PAM-based PTC (poly [N-(2-aminoethyl) acrylamido] trimethyl ammonium chloride) (PAAAC) for the preparation of cyanides, thiocyanates, azides, and ethers derivatives from their haloalkanes counterparts. The most important feature of this catalytic system is its recoverability and reusability and application of water as a safe and green solvent in substitution reactions [71].

1.5 Michael Addition Reaction

One of the best ways for mildly creating C–C bonds is the Michael addition reaction, during which the nucleophilic addition of a nucleophile e.g. carbanion to an α,β-unsaturated carbonyl substrate containing an electron-withdrawing substituent takes place. In 2006, Tamami et al. used PAM-supported phenolate (PAPh) as a new polymeric catalyst in aza- and thio-Michael addition reactions between ß-unsaturated electrophiles and both aliphatic and aromatic amines and thiols in aqueous solution at room temperature without any side reactions. This catalyst was prepared by modification of PAM through transamidation with 1,6-diaminohexane and subsequent reaction with 4-hydroxybenzaldehyde (Scheme 15) [72].

1.6 Three-Component A3 Coupling of Amines, Aldehydes, and Alkynes

An alkyne, an amine, and an aldehyde combine in the A3 coupling, a multicomponent reaction, to yield propargyl-amine. A metal catalyst, usually based on Ru/Cu, Ag, or Au, is required for the reaction to proceed through direct dehydrative condensation. Recently many attempts have been made to synthesize propargylamines due to their widespread medicinal importance of these compounds, their role as a main constituent in the production of nitrogen containing chemicals, and their function as essential intermediate for the synthesis of natural products. Gholinejad et al. introduced PAM containing a phosphinite ligand by the reaction of 2-aminophenol with acryloyl chloride followed the treatment with chlorodiphenylphosphine and subsequent polymerization with AIBN (Scheme 16). Afterward, Au NPs supported on PAM included a phosphinite ligand (PAAPh-Au) as a polymeric catalyst to produce propargylamines through three-component A3 coupling between aldehydes, amines, and alkynes. Reactions are carried out in pure water as an environmentally friendly solvent with remarkable yield [73].

1.7 Decomposition of Hydrogen Peroxide

Hydrogen peroxide as the simplest peroxide (compounds with O–O single bond) is reactive oxygen containing species that decomposes when exposed to light or a variety of redox-active ions. Metal complexes supported by PAM crosslinked with triethyleneglycol dimethacrylate (TEGDMA) [TEGDMA-PAM] exhibit catalase-like activity in the decomposition of H2O2. (Scheme 17). In this research, the catalysis activity of the metal ions like Pb (II), Mn (II), Fe (III), Cr (III), and Cu (II) has been explored, and the results showed that the percentage conversion of H2O2 was determined to be as follows: Mn (II) > Cu (II) > Fe (III) > Cr (III) > Pb (II) [74].

In 1998, glycine modified PAM crosslinked with N,N'-methylene-bisacrylamide (NNMBA) supported metal complexes (NNMBA-PAM) were synthesized. The efficiency of these heterogenous metal complexes was examined in the H2O2 decomposition. According to this research, the degree of NNMBA cross-linking significantly affects the efficiency of these cross-linked polymeric complexes [75].

Tamami et al. introduced some nickel, cobalt, copper, and manganese complexes of Schiff base modified NNMBA cross-linked PAM (M-NNMBA-PAM) and tested them for the H2O2 decomposition as a sample reaction. This study represented that increasing the support's cross-linking density and the spacer arm's length improves the H2O2 decomposition activity of the catalyst [76]. In consequence of the work on the preparation metal complexes of Schiff base modified cross-linked PAM resin for H2O2 decomposition, poly (NIPAM-co-AM), a thermoresponsive copolymer of N-isopropylacrylamide and acrylamide, was introduced to create some new polymeric Schiff base-metal complexes (Scheme 18). The effect of various factors like changing Schiff-base and metal kind and reaction temperature on the catalyst activity was investigated, and it was observed that Mn complex that applied pyridine-2-carbaldehyde for making imine functional group is the most active catalyst. The catalyst revealed high catalytic activity at temperatures higher than the polymer's lower critical solution temperature (LCST). Indeed, at temperatures lower than LCST, PNIPAM was completely dissolved in water, and by heating in above LCST, they formed insoluble dehydrated state and separated from reaction mixture [77].

A novel green polymeric catalyst based on starch-g-polyacrylamide (St-g-PAM) modified by amino acids was synthesized (Scheme 19) and proved effective catalytic function for H2O2 decomposition at various pHs. Based on the results, amino acid modified St-g-PAM/iron(III) complex showed good catalytic activity in treating industrial effluents and wastewater containing organic pollutants [78].

The significant potential for the decomposition of many organic materials in polluted wastewaters has been expressed by electro-Fenton technology. In this process, hydrogen peroxide is catalyzed by iron and powerful oxidants, generating strong radical oxidants ⋅OH. Bocos et al. investigated a hydrogel consist of Fe-loaded PAM catalyst, Fe-PH, for electro-Fenton decomposition of two dyes, Blue Sella Solid and Reactive Black 5. They found that a mixture of Fe2+ and Fe3+ salt supported PAM hydrogel increased the electro-Fenton dye decolorization treatment. Experimental investigations revealed that Fe-PH catalyst could perform effectively under alkaline conditions in the electro-Fenton process and its recoverability after multiple runs was also verified [79].

1.8 Methanolysis Reaction

The reaction of a material with methanol at high temperature and pressure is called methanolysis, and this inexpensive method is currently used for depolymerizing post-consumer such as scrap bottles, fiber waste, and used films into primary monomers, which can be used as a starting component for the production of valuable polymeric materials. PAM is highly water absorbent and forms a soft gel while exposed to water and makes water beads. These beads are non-poisonous, safe, and biodegradable. The water beads of PAM were applied to support metal NPs (M@PAM) and employed for the conversion of methanol to hydrogen gas in the presence of sodium borohydride in methanolysis reaction (Scheme 20). Among Cu, Ni, Ag, and Co catalysts, Ag@PAM showed the best catalytic activity in hydrogen production in comparison with the other metal supported catalyst [80].

1.9 Thiazoles Synthesis

Thiazole is a heterocyclic organic material containing nitrogen and sulfur that has anti-cancer and anti-inflammatory properties. Thiazoles are synthesized by diverse catalysts and laboratory methods, including combining isothiocyanates with acetamide or using thioamides and α-halocarbonyl compounds. Sulfonated PAMs possess outstanding properties, including hydrophilicity, proton conductivity, and great strength. In 2019, Shahbazi-Alavi and coworkers were prepared Fe3O4 NPs coated with sulfonated cross-linked PAM (cross-PAA-SO3H) (Scheme 21) and used it for the synthesis of 1,3 thiazoles. It has been used to synthesize derivatives of 3-alkyl-4-phenyl-1,3-thiazole-2(3H)-thione using a three-component reaction composed of a primary amine, CS2, and phenacyl bromide or 4-methoxyphenyl bromide. Easy accessibility, high productivity, quicker reaction times, catalyst reusability, and low catalyst amount are some of this method’s advantages [81].

1.10 Dichlorocyclopropanation Reaction

The dichlorocyclopropanation of alkenes is a chemical reaction in which chloroform is deprotonated in the vicinity of a powerful base to form a dichlorocarbene, and alkenes can be added to this carbene to give a cyclopropane. Various factors like the concentration of base, stirring rate, and catalyst quantity, affect the reaction speed of dichlorocyclopropanation. Organic compounds obtained from the reaction have many uses in the fields of agriculture, medicine, and perfumery. Catalysts like PTCs are widely used for this reaction. The highly branched quaternized PAM (QHBPA) was designed by Mahdavi et al. and utilized as a successful multi-site PTC for adding dichlorocarbene to olefin in dichlorocyclopropanation reaction. Highly branched PAM synthesized by self-condensing vinyl polymerization (SCVP) technique possesses abundant amide groups on its peripheral surface. These amide functional groups can be transformed into quaternary onium salts and used as PTC under biphasic reaction conditions (Scheme 22) [82].

1.11 Oxidative Esterification Reaction

The most common method for producing esters is the esterification of carboxylic acid or its derivatives with alcohols, catalyzed by Brønsted or Lewis acids. Multiple steps are required to complete these processes and many undesirable by-products may be produced. Cross-coupling aryl halides with alcohols can produce esters, requiring a high-temperature reaction. Recently, a method that has received much attention is the direct oxidative esterification of aldehydes with alcohols that performed under very mild conditions using transition metal catalysts [83]. For the first time, Kang et al. produced an inorganic salt induced stable ionic liquid–water gel (IL-water gel) and applied it to create metal nanocatalysts supported by meso- and macropores in a single step. This new method synthesized different tiny metal nanocatalysts on various supports due to their unique morphologies and structures for different reactions. This method was used to prepare metal − organic framework (Cu-MOF), Pd/Cu(2-pymo)2, Au/SiO2, Ru/SiO2, and Au/PAM nanocatalysts exhibited an extremely high level of activity, stability, and selectivity. These catalysts combined the advantages of small nanocatalysts and porous supports and were used to oxidize benzyl alcohol to benzaldehyde, benzyl alcohol to methyl benzoate through oxidative esterification, and benzene conversion to cyclohexane [84].

1.12 Ethylene Polymerization

Ethylene polymerization is an additional polymerization in which thousands of ethylene molecules join together in the presence of a catalyst to form a polyethylene polymer. Cheng et al. prepared SiO2/PAM composite through AM emulsion polymerization in the affinity of silica sol and was subsequently utilized to support the metallocene catalyst for the polymerization of ethylene. The SiO2/PAM-metallocene supported catalyst are applied to synthesize PE nanocomposite in situ because of fragile SiO2/PAM secondary particles [85].

1.13 Protection of Carbonyl Compounds

Carbonyl groups play a very important and key role in organic chemistry, so they must be protected against various reagents in multi-step synthesis. Common protective groups of carbonyl compounds include acetal, 1–3-dioxolane, mixed metals, thioketal, N-bromosuccinimide, and tricholoroisocyanoric acid, easily removed to regenerate the original starting compounds. Converting the protected group to parent carbonyl compounds under mild conditions with high efficiency requires the use of efficient catalysts. In 2008, poly (N-bromoacrylamide) (PNBA) was first utilized as a catalytic system for the carbonyl groups protection in aldehydes and ketones (Scheme 23). This method offers high productivity, short reaction time, operational simplicity, and chemoselectivity. Due to its neutral reaction medium, it is very useful for substrates that are highly sensitive to acid [86].

1.14 Ring-Opening of Epoxide

Epoxides are three-membered rings that are one of the key components in the synthesis of organic compounds and have high ring tension and, despite not having a good leaving group, are highly reactive with nucleophiles such as alcohols, phenols, amines, and acids, and produce products such as glycols, β-amino alcohols, hydroxyalkyl esters, and aliphatic polyether materials. Quaternized PAM (Poly[N-(2-aminoethyl)acrylamido]trimethyl ammonium halide resin) [PAATAH] was presented as an impressive polymeric PTC in synthesizing halohydrins [87], azidohydrins [88], thiocyanohydrins [89], and nitroalcohols [90]. Furthermore, it was applied in the ring opening of epoxide regioselectivity and for the production of bis[β-hydroxyalkyl]sulfide in the presence of NaBH4. This resin possesses the properties of a polymeric PTC, such as filterability, regeneration, reusability, and operating simplicity (Scheme 24) [91].

1.15 Direct Transformation of Benzilic Amines to Carbonyl Compounds

Direct transformation of amines into carbonyl substrates is a very valuable method in organic synthesis, but this conversion requires large amounts of toxic and expensive reagents, so it requires the use of catalysts that make it safe and cost-effective. PAM-bound tungstate directly transfers benzilic amines to carbonyl compounds under PTC conditions (Scheme 25). Using PNIPAM polymers as a catalyst-supported material was useful in developing recyclable reaction systems [92].

2 Conclusion and Future Outlook

PAM and its modified forms and copolymer have been used successfully as a supported soluble or insoluble catalyst and reagent in organic synthesis. This review discusses the various reactions that successfully used PAM as a catalyst or regent support. Important reactions include oxidation–reduction reactions, C–C cross-coupling reactions, Michael addition reactions, condensation reactions, substitution reactions, three-component A3 coupling reactions, decomposition of H2O2, methanolysis, and ring opening of epoxides, etc. The above views were suggested for the potential development of a more efficient catalyst and reagent synthesis technology. Hopefully, with more research and development efforts, effective steps can be taken to develop acceptable and cost-effective synthetic methods over conventional methods.

In the years since Merrifield’s revolutionary publication on functional polymers, much has been achieved, but much remains to be done. Taking advantage of the unique capabilities of polyacrylamide-supported reagents and catalysts, researchers have developed these catalysts for various types of chemical reactions to pave the way for their commercialization and implementation in more industrial processes. Since the physical properties of polyacrylamide are very adjustable and by changing the synthesis method and modification, its characteristics can be controlled and a structure suitable for the desired application can be produced, it is ideal for development with specific applications and an exciting future is envisioned for it. Considering this issue, future studies should be aimed at increasing their application areas, saving costs and energy, as well as increasing the productivity and yields of products. Our vision for the future is to take full advantage of the extraordinary properties of polyacrylamide-based catalysts and reagents for new reactions and environmental challenging projects that humans are dealing with all over the planet today like producing essential primary chemicals from carbon monoxide and carbon dioxide, or remove pollutants from factories that have entered seas and rivers and threaten the lives of thousands of living creatures.

Data Availability

Not Applicable.

Abbreviations

- PAM:

-

Polyacrylamide

- AM:

-

Acrylamide

- PS:

-

Polystyrene

- NPs:

-

Nanoparticles

- PBAM:

-

Poly(N-bromoacrylamide)

- PVAm:

-

Poly(vinyl amine)

- DVB:

-

Divinyl benzene

- CTAB:

-

Cetyltrimethylammonium bromide

- PTP:

-

Peroxotungstophosphate

- DBT:

-

Dibenzothiophene

- PVP:

-

Polyvinylpyridine

- poly(NVIM):

-

Poly (N-vinylimidazole)

- Ni(AAEMA)2-pol:

-

Nickel supported polyacrylamide

- 4-NP:

-

4-Nitrophenol

- G:

-

Graphene

- NIPAM:

-

N-Isopropylacrylamide

- PPAM:

-

Polypropylacrylamide

- AAc:

-

Acrylic acid

- NA:

-

Nitroaniline

- NB:

-

Nitrobenzene

- PGMA:

-

Poly(glycidyl methacrylate)

- CS:

-

Chitosan

- CuNPs:

-

Copper nanoparticles

- PPy:

-

Polypyrrole

- PTC:

-

Phase transfer catalyst

- GO:

-

Graphene oxide

- MB:

-

Methylene blue

- RAFT:

-

Reversible addition-fragmentation chain transfer

- MWCNTs:

-

Multiwalled carbon nanotubes

- LCST:

-

Lower critical solution temperature

- MNPs:

-

Metal nanoparticles

- SCVP:

-

Self-condensing vinyl polymerization method

- MOF:

-

Metal − organic framework

- 2-pymo:

-

2-Pyrimidinolate

References

Xiong B, Loss RD, Shields D et al (2018) Polyacrylamide degradation and its implications in environmental systems. npj Clean Water 1:17

Bashir S, Hina M, Iqbal J, Rajpar AH, Mujtaba MA, Alghamdi NA, Wageh S, Ramesh K, Ramesh S (2020) Fundamental Concepts of hydrogels: synthesis, properties, and their applications. Polymers 12:2702

Seybold CA (1994) Polyacrylamide review: soil conditioning and environmental fate. Commun Soil Sci Plant Anal 25:2171

Solomon DH, Caulfield MJ, Qiao GG (2002) Some aspects of the properties and degradation of polyacrylamides. Chem Rev 102:3067–3083

Solomon DH, Caulfield MJ, Hao X, Qiao GG (2003) Degradation on polyacrylamides. Part I Linear Polyacryl Polym 44:1331–1337

Yi CH, Huang J, Pen H, Xu Z (2008) Magnetic Fe3O4/poly(styrene-co-acrylamide) composite nanoparticles prepared by microwave-assisted emulsion polymerization. React Funct Polym 68:332–339

Sheldon RA (2015) Recent advances in green catalytic oxidations of alcohols in aqueous media. Catal Today 247:4–13

Ye ZH, Fu Z, Zhong S, Xie F, Zhou X, Liu F, Yin D (2009) Selective oxidation of alcohols with hydrogen peroxide catalyzed by hexadentate binding 8-quinolinolato manganese (III) complexes. J Catal 261:110–111

Iwasawa T, Tokunaga M, Obora Y, Tsuji Y (2004) Homogeneous palladium catalyst suppressing Pd black formation in air oxidation of alcohols. J Am Chem Soc 126:6554–6555

Boring E, Geletii YV, Hill CL (2001) A Homogeneous catalyst for selective O2 oxidation at ambient temperature. Diversity-based discovery and mechanistic investigation of thioether oxidation by the Au (III) Cl2NO3(thioether)/O2 system. J Am Chem Soc 123:1625–1635

Dijksman A, Arends IWCE, Sheldon RA (1999) Efficient ruthenium–TEMPO-catalysed aerobic oxidation of aliphatic alcohols into aldehydes and ketones. Chem Commun 16:1591–1592

Hanyu A, Takezawa E, Sakaguchi S, Ishii Y (1998) Selective aerobic oxidation of primary alcohols catalyzed by a Ru(PPh3)3Cl2/hydroquinone system. Tetrahedron Lett 39:5557–5560

Csjernyik G, Ell AH, Fadini L, Pugin B, Bäckvall JE (2002) Efficient ruthenium-catalyzed aerobic oxidation of alcohols using a biomimetic coupled catalytic system. J Org Chem 67:1657–1662

Miceli M, Frontera P, Macario A, Malara A (2021) Recovery/reuse of heterogeneous supported spent catalysts. Catalysts 11:591

Kazemnejadi M, Nikookar M, Mohammadi M, Shakeri A, Esmaeilpour M (2018) Melamine-Schiff base/manganese complex with denritic structure: an efficient catalyst for oxidation of alcohols and one-pot synthesis of nitriles. J Colloid Interface Sci 527:298–314

Sarmah B, Satpati B, Srivastava R (2018) Selective oxidation of biomass-derived alcohols and aromatic and aliphatic alcohols to aldehydes with O2/air using a RuO2-supported Mn3O4 catalyst. ACS Omega 3:7944–7954

Abd-El-Aziz AS, Strohm EA (2012) Transition metal-containing macromolecules: En route to new functional materials. Polymer 53:4879–4921

Pillai VNR, George BK (1988) Poly(N-Bromoacrylamide): a new polymeric recyclable oxidizing and brominating reagent. Macromolecule 21:1867–1870

Pillai VNR, George BK (1989) N-bromoderivatives of N, N′-methylene-bis-acrylamide-crosslinked polyacrylamide gels as oxidizing reagents: a synthetic and structural investigation. Eur Polym J 25:1099–1102

Prabhakaran PV, Venkatachalam S, Ninan KN (1999) Permanganate ion supported over crosslinked polyvinylamine as an oxidising agent for alcohols. Eur Polym J 35:1743–1746

Tamami B, Heiran R, Riazi Montazer E (2012) Modified polyacrylamide-supported chlorochromate as a new polymeric oxidizing agent. J Serbian Chem Soc 77:685–697

Tamami B, Ghasemi S (2011) Modified crosslinked polyacrylamide anchored Schiff base–cobalt complex: a novel nano-sized heterogeneous catalyst for selective oxidation of olefins and alkyl halides with hydrogen peroxide in aqueous media. Appl Catal Gen 35:242–250

Jayaram RV, Kurhe DK, Fernandes TA, Deore TS (2015) Oxidant free dehydrogenation of alcohols using chitosan/polyacrylamide entrapped ag nanoparticles. RSC Adv 5:46443–46447

Song SH, Shen SH, Yang J, Hu D et al (2012) A green synthesis of CTAB–PTP/PAM microhydrogel and its application in oxidation of DBT. J Mater Sci 47:2501–2508

Wentworth P, Janda JKD, Rogers CJ, Dickerson TJ (2005) A High-swelling reagent scaffold suitable for use in aqueous and organic solvents. Tetrahedron 61:12140–12144

Srinivasan M, Mathew JP (1992) Silica—supported polymer-palladium complexes as catalysts for the reduction of nitro and azo groups. Polym Int 29:I79-184

Mathew JP, Srinivasan M (1991) Studies on the hydrogenation of alkenes and alkynes using polymer coated silica-Pd catalysts. Polym Int 24:249–254

Dell’Anna MM, Romanazzi MG, Fiore AM, Mali M, Rizzuti A et al (2018) Polymer supported nickel nanoparticles as recyclable catalyst for the reduction of nitroarenes to anilines in aqueous medium. Mol Catal 446:31–38

Talgatov ET, Auyezkhanova AS, Seitkalieva KS, Akhmetova SN, Zharmagambetova AK et al (2019) Effect of the size of polyacrylamide-stabilized palladium nanoparticles supported on γ-Fe2O3 on their catalytic properties in the hydrogenation of phenylacetylene. Theor Exp Chem 55:331–336

Farooqi Z, Ajmal M, Siddiq M (2013) Silver nanoparticles containing hybrid polymer microgels with tunable surface plasmon resonance and catalytic activity. Korean J Chem Eng 30:2030–2036

Xin JH, Hu H, Hu H (2014) PAM/Graphene/Ag ternary hydrogel: synthesis, characterization and catalytic application. J Mater Chem A 2:11319–11333

Farooqi ZH, Ahmed E, Naseem K, Ashraf S, Sharif A, Rehan R (2017) Catalytic reduction of 4-nitrophenol using silver nanoparticles-engineered poly(N-isopropylacrylamide-co-acrylamide) hybrid microgels. Appl Organometal Chem 31:1–8

Begum R, Naseem K, Ahmed E, Sharif A, Farooqi ZH (2016) Simultaneous catalytic reduction of nitroarenes using silver nanoparticles fabricated in Poly(N-Isopropylacrylamide-Acrylic Acid-Acrylamide) microgels. Colloids Surf 511:17–26

Zhang L, Zhang W, Sun Y (2016) Fabrication of High Efficient silver nanoparticle catalyst supported on poly(Glycidyl Methacrylate)−polyacrylamide. Ind Eng Chem Res 55:12398–12406

Kumar R, Deepak SS, Kumar A, Afgan S (2017) Stimuli-responsive polymeric hydrogel-copper nanocomposite material for biomedical application and its alternative application to catalytic field. ChemistrySelect 2:11281–11287

Song X, Mao H, Ji C, Liu M, Sun CD, Xing Z et al (2018) Enhanced catalytic activity of Ag nanoparticles supported on polyacrylamide/polypyrrole/graphene oxide nanosheets for the reduction of 4-nitrophenol. Appl Surf Sci 434:522–533

Zhai S, An Q, Gao C, Wang X (2019) Enhanced catalytic activity of nanosilver with lignin/polyacrylamide hydrogel for reducing p-nitrophenol. Int J Biol Macromol 1:202–209

Patel N, Singh Nagar SA, Sood R, Bharatam PV (2018) NL2+ systems as new-generation phase-transfer catalysts. Chem Rev 118:8770–8785

Tamami B, Mahdavi H (2003) Quaternized amino functionalized cross-linked polyacrylamide as a new solid-liquid phase transfer catalyst in reduction of carbonyl compounds with NaBH4. Tetrahedron 56:821–826

Mahdavi H, Tamami B (2005) Reduction of nitro-aryl compounds with zinc in the presence of poly[N-(2-aminoethyl)Acrylamido]Trimethylammonium Chloride as a phase-transfer catalyst. Synth Commun 35:1121–1127

Leng J, Li S, Yang M, Hu J (2019) Double-Layer hydrogel with photoresponsive shape memory features for controllable catalysis. J Mater Res 34:1795–1804

Hu H, Zhang Y, Qiao Y, Chen D (2020) Catalytic reduction reactions over the silver ions embedded in polyacrylamide/graphene composite hydrogels: kinetics and performance. Appl Surf Sci 508:144835

Fox CM, Yu T, Breslin CB (2020) Electrochemical Formation of silver nanoparticles and their catalytic activity immobilised in a hydrogel matrix. Colloid Polym Sci 298:549–558

Sun T, Wang H, Liu J, Chu X, Xing X, Liu S, Tang E, Liu X, Hildebrandt D (2021) Recoverable acrylamide-vinylamine copolymer immobilized TEMPO mediated oxidation of cellulose with good catalytic performance and low cellulose degradation. Cellulose 28:4151–4164

Horbaczewskyj CS, Fairlamb IJS (2022) Pd-catalyzed cross-couplings: on the importance of the catalyst Quantity descriptors, mol % and ppm. Org Process Res Dev 26:2240–2269

Yang W, Zhang Y, Feng H, Li S, Feng YS (2022) Novel graphene-supported palladium complex catalyst with flexible-bridge-chains and its recycling carbon-carbon cross-coupling activity. Appl Catal A 646:118852

Khan M, Shaik MR, Adil SF, Kuniyil M, Ashraf M, Frerichs H, Sarif MA, Siddiqui MRH, Al-Warthan A, Labis JP, Islam MS, Tremel W, Tahir MN (2020) Facile synthesis of Pd@graphene nanocomposites with enhanced catalytic activity towards Suzuki coupling reaction. Sci Rep 10:11728

Sarkar R, Sarkar FK, Gajurel S, Kyndiah L, Sahab M, Pal AK (2023) Palladium nanoparticles supported on reduced graphene oxide (Pd@rGO): an efficient heterogeneous catalyst for Suzuki-Miyaura, Heck-Matsuda and Double Suzuki-Miyaura cross-coupling reactions. New J Chem 47:10659–10671

Mirza-Aghayan M, Mohammadi M, Addad A, Boukherroub R (2020) Pd nanoparticles supported on reduced graphene oxide as an effective and reusable heterogeneous catalyst for the Mizoroki-Heck coupling reaction. Appl Organomet Chem 34:e5524

Gholinejad M, Naghshbandi Z, Nájera C (2019) Carbon-derived dupports for palladium nanoparticles as catalysts for carbon-carbon bonds formation. Chem Cat Chem 11:1792–1823

Cornelio B, Rance GA, Laronze-Cochard M, Fontana A, Sapib J, Khlobystov AN (2013) Palladium nanoparticles on carbon nanotubes as catalysts of cross-coupling reactions. J Mater Chem A 1:8737–8744

Zhao C, Yang J, Sang Y, Zhang R, Zhu LT, Xu H (2021) Ultrafine palladium nanoparticles supported on poly(4-vinylpyridine)-grafted carbon nanotubes as heterogeneous catalysts for cross-coupling reaction between organoindium halide and alkyl iodide. Colloids Surf A Physicochem Eng Asp 627:127215

Siamaki AR, Lin Y, Woodberry K, Connellc JW, Gupton BF (2013) Palladium nanoparticles supported on carbon nanotubes from solventless preparations: versatile catalysts for ligand-free Suzuki cross coupling reactions. J Mater Chem A 1:12909–12918

Lbulo AH, Martincigh BS, Omondi B, Nyamori VO (2017) Advances in carbon nanotubes as efficacious supports for palladium-catalysed carbon–carbon cross-coupling reactions. J Mater Sci 52:9225–9248

Zhao M, Wu Y, Cao JP (2020) Carbon-based material-supported palladium nanocatalysts in coupling reactions: discussion on their stability and heterogeneity. Appl Organomet Chem 34:e5539

Mahdavi H, Hashemi P (2013) Synthesize, characterization and application of phosphine-free polymer supported palladium nanoparticles as effective catalyst in suzuki-miyaura cross-coupling reactions. J Chin Artic Chem Soc 60:425–436

Rosa GR, Alvarenga G, Ruas CP, Vicenti JRM, Duarte FA, Gelesky MA (2016) PdCl2 immobilized in polyacrylamide: a Low Cost and eco-friendly catalyst for suzuki-miyaura reactions. J Braz Chem Soc 27:787–793

Mahdavi H, Rahmani O (2016) Polyacrylamide-g-reduced graphene oxide supported Pd nanoparticles as a highly Efficient catalyst for suzuki-miyaura reactions in water. Catal Lett 146:2292–2305

Tamami B, Ghasemi S (2010) Palladium Nanoparticles supported on modified crosslinked polyacrylamide containing phosphinite ligand: a novel and efficient heterogeneous catalyst for carbon-carbon cross-coupling reactions. J Mol Catal Chem 322:98–105

Tamami B, Ghasemi S (2011) Copper- and amine-free sonogashira-hagihara coupling reaction catalyzed by Pd (0) nanoparticles supported on modified crosslinked polyacrylamide. Collect Czech Chem Commun 76:1967–1978

Ghasemi S, Karim S (2018) Controlled synthesis of modified polyacrylamide grafted nano-sized silica supported Pd nanoparticles via RAFT polymerization through “Grafting to” approach: application to the heck reaction. Colloid Polym Sci 296:1323–1332

Ghasemi S, Karim S (2017) Mizoroki¬Heck Cross-coupling reaction of haloarenes mediated by a well-controlled modified polyacrylamide brush grafted silica/Pd nanoparticle system. Bull Chem Soc Jpn 90:485–490

Ghasemi S, Karim S (2018) Organic/inorganic hybrid composed of modified polyacrylamide grafted silica supported Pd nanoparticles using RAFT polymerization process: controlled synthesis, characterization and catalytic activity. Mater Chem Phys 205:347–358

Sadjadi S, Ataib M (2018) Ternary hybrid system of halloysite nanotubes, polyacrylamides and cyclodextrin: an efficient support for immobilization of Pd nanoparticles for catalyzing coupling reaction. Appl Clay Sci 153:78–89

Sabadasch V, Dachwitz S, Hannappel Y, Hellweg T, Sewald N (2022) Acrylamide-based Pd-nanoparticle carriers as smart catalysts for the suzuki-miyaura cross-coupling of amino acids. Synthesis 54:3180–3192

Tamami B, Fadavi A (2005) Amino group immobilized on polyacrylamide: an efficient heterogeneous catalyst for the knoevenagel reaction in solvent-free and aqueous media. Catal Commun 6:747–751

Tamami B, Fadavi A (2006) A polymeric heterogeneous catalyst based on polyacrylamide for knoevenagel reaction in solvent free and aqueous media. Iran Polym J 15:331–339

Boroujeni KP, Hadizadeh S, Hasani S, Fadavi A, Shahrokh M (2017) Magnetite-containing sulfonated polyacrylamide as a nanocatalyst for the preparation of biscoumarins. Acta Chim Slov 64:692–700

Boroujeni KP, Tohidiyan Z, Fadavi A, Eskandari MM, Shahsanaei HA (2019) Synthesis and catalytic application of Poly(2-acrylamido-2-methyl-1-propanesulfonic acid-Co-acrylamide) grafted on graphene oxide. ChemistrySelec 4:7734–7744

Boroujeni KP, Asadi F, Kazemi R, Fadavi A (2019) Carbon Nanotubes grafted with sulfonated polyacrylamide as a heterogeneous catalyst for the preparation of bis(Indolyl)methanes. J Nanoparticle Res 21:151–184

Tamami B, Ghasemi S (2008) Nucleophilic substitution reactions using polyacrylamide-based phase transfer catalyst in organic and aqueous media. J Iran Chern Soc 5:26–32

Tamami B, Fadavi A, Tamami M (2006) Polyacrylamide supported phenolate as a heterogeneous, efficient, recyclable, and selective catalyst for Aza- and Thio-michael addition in aqueous media. Iran Polym J 15:799–807

Gholinejad M, Nájera C, Hamed F (2016) Gold nanoparticles supported on polyacrylamide containing a phosphorus ligand as an efficient heterogeneous catalyst for three-component synthesis of propargylamines in water. Synlett 27:1193–1201

Pillai VNR, Jose L (1998) Catalase-like activity of triethyleneglycol dimethacrylate-crosslinked polyacrylamide supported metal complexes. Polymer 39:229–233

Mathew B, Vinodkumar GS (1998) Polymer-Metal complexes of glycine functions supported on N, N′-methylene-Bis-acrylamide (NNMBA)-crosslinked polyacrylamides: synthesis, characterisation and catalytic activity. Pure Appl Chem 35:495–510

Tamami B, Ghasemi S (2015) Catalytic activity of schiff-base transition metal complexes supported on crosslinked polyacrylamides for hydrogen peroxide decomposition. J Organomet Chem 794:311–317

Ghasemi S, Andami Z (2017) Polymeric Schiff base metal complexes based on thermo-responsive PNIPAM: synthesis, characterization and catalytic activity. ChemistrySelect 2:5864–5870

El-Hamshary H, Al-Sigeny S (2004) Catalytic activities of amino acid modified, starch-grafted acrylamide for the decomposition of hydrogen peroxide. J Appl Polym Sci 93:630–636

Bocos E, Pazos M, Sanromán MA (2014) Electro-fenton decolourization of dyes in batch mode by the use of catalytic activity of iron loaded hydrogels. J Chem Technol Biotechnol 89:1235–1242

Ali F, Bahadar Khan S, Asiri AM (2020) Metal nanoparticles supported on polyacrylamide water beads as catalyst for efficient generation of H2 from NaBH4 methanolysis. Int J Hydrog Energy 45:1532–1540

Shahbazi-Alavi H, Khojasteh-Khosro S, Safaei-Ghomi J, Tavazo M (2019) Crosslinked sulfonated polyacrylamide (Cross-PAA-SO3H) tethered to nano-Fe3O4 as a superior catalyst for the synthesis of 1,3-thiazoles. BMC Chem 2019:13

Hossein M, Mehdi A (2012) Kinetic study of dichlorocarbene addition to olefins via a quaternized highly branched polyacrylamide as a new multi-site phase transfer catalyst. Iran Polym J 21:641–649

Xie R, Wang X, Wang J, Ye J, Zhou M, Zang S (2017) Oxidative esterification of aldehydes with alcohols using imidazolium perrhenate catalysts. J Saudi Chem Soc 21:817–821

Han B, Kang X, Zhang J, Shang W, Wu T, Zhang P, Wu Z, Mo G, Xing X (2014) One-step synthesis of highly efficient nanocatalysts on the supports with hierarchical pores using porous ionic liquid-water gel. J Am Chem Soc 136:3768–3771

Tang T, Cheng W, Wang Z, Ren C, Chen H (2007) Preparation of silica/polyacrylamide/polyethylene nanocomposite via in situ polymerization. Mater Lett 61:3193–3196

Tamami B, Firouzabadi H, Ebrahimzadeh F, Fadavi A (2009) Poly(N-bromoacrylamide): an efficient and useful catalyst for the protection of carbonyl compounds as dithiolanes, dithianes and oxathiolanes under solvent-free and microwave conditions. J Iran Chem Soc 6:722–728

Tamami B, Mahdavi H (2002) Synthesis of halohydrins from epoxides using quaternized amino functionalized cross-linked polyacrylamide as a new solid-liquid phase transfer catalyst. React Funct Polym 51:7–13

Tamami B, Mahdavi H (2001) Synthesis of azidohydrins from epoxides using quaternized amino functionalized cross-linked polyacrylamide as a new polymeric phase-transfer catalyst. Tetrahedron Lett 42:8721–8724

Tamami B, Mahdavi H (2002) Synthesis of thiocyanohydrins from epoxides using quaternized amino functionalized cross-linked polyacrylamide as a new solid-liquid phase-transfer catalyst. Tetrahedron Lett 43:6225–6228

Mahdavi H, Tamami B (2005) Synthesis of 2-nitroalcohols from epoxides using quaternized amino functionalized cross-linked polyacrylamide as a new polymeric phase transfer catalyst. React Funct Polym 64:179–185

Mahdavi H, Tamami B (2005) Synthesis of β-dihydroxysulfides by cleavage of epoxides using quaternized amino-functionalized cross-linked polyacrylamide as a new polymeric phase transfer catalyst. Phosphorus Sulfur Silicon Relat Elem 180:1929–1936

Hamamoto H, Suzuki Y, Takahashi H, Ikegami S (2007) Direct transformation of benzilic amines to carbonyls using polyacrylamide-bound tungstate under phase-transfer catalysis conditions. Tetrahedron Lett 38:4239–4242

Acknowledgements

The authors would greatly have appreciated the partial support of this study by Shiraz University Research Council.

Funding

Not Applicable.

Author information

Authors and Affiliations

Contributions

SG and HR wrote the main manuscript text and HR prepared Figures and Schemes. SG reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical Approval and Consent to Participate.

Not applicable.

Consent for Publication

Not Applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ghasemi, S., Kafshboran, H.R. Polyacrylamide Supported Reagents and Catalysts in Various Organic Reactions. Catal Surv Asia 28, 1–25 (2024). https://doi.org/10.1007/s10563-023-09407-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10563-023-09407-w