Abstract

Bisphenols as an important industrial raw material has endocrine disruption, reproductive toxicity, and neurotoxicity. Laccase (Lac) has demonstrated excellent catalytic oxidation performance for phenolic compounds. Micro-nano bubbles (MNB) have been extensively used in wastewater treatment, and the high efficiency of MNB-assisted laccase (MNB-Lac) as a hybrid technique for removing bisphenols from water has been established. In this study, MNB-Lac system was used to degrade bisphenols including bisphenol A (BPA), bisphenol B (BPB), bisphenol C (BPC), bisphenol E (BPE), and bisphenol F (BPF). A comparative analysis was conducted to evaluate the degradation of individual and mixed bisphenols by MNB-Lac. The results indicated that the degradation effect on all individual bisphenols was superior. Notably, BPC consistently demonstrated higher selectivity in the mixed degradation process. In the mixed bisphenol degradation process, a distinct degradation sequence between BPE and BPF was observed. The affinity order of BPA and BPE was found to be inconsistent with their individual degradation order, and the degradation reaction was found to conform to second-order kinetics. By gas chromatography mass spectrometry detection, it was found that the degraded products of BPA, BPB, BPC, BPE, and BPF were ring and chain compounds, and the degradation pathways of the five substances were also maintenance ring structure and direct ring opening. The possible transformation relationship of mixed bisphenols during degradation by MNB-Lac was proposed. Moreover, the industrial application of MNB-Lac was evaluated by increasing the wastewater volume of BPA.

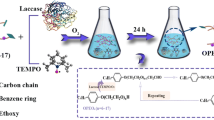

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Bisphenols are compounds that contain two phenolic groups per molecule [1, 2]. They belong to a synthetic class of chemicals that can be used in the production of polycarbonate plastics and epoxy resins, as well as other consumer products including toys, electronics, food, beverage packaging, store receipts, and medical device [3]. However, the comprehensive physical, biological, and chemical treatment of wastewater treatment plants is not efficient in removing bisphenols, resulting in serious pollution of discharged sewage streams [4]. Among which bisphenol A (BPA) is a reproductive biotoxic substance, which has been widely exposed and concerned. Since bisphenol B (BPB), bisphenol C (BPC), bisphenol E (BPE), and bisphenol F (BPF) are structurally similar to BPA, these bisphenols have similar endocrine disrupting capabilities that can adversely affect the reproductive system [5].

In recent years, the degradation of bisphenols has been widely investigated, and common technologies including membrane separation [6], adsorption [7], photodegradation [8] advanced oxidation are studied [9]. However, these methods have been found to be constrained by their high costs, low efficiency, and the generation of toxic by-products. Enzymatic hydrolysis has emerged as a prominent research focus both domestically and internationally for the treatment of diverse pollutants, including phenols, carboxylic acids, aromatic amines, and other types. The enzymatic treatment of pollutants in wastewater is advantageous due to its high catalytic efficiency, strong substrate specificity, mild operating conditions, low toxicity, and significant degradation of by-products [10], and has been extensively studied in scientific research. Currently, the biocatalysis of hydrolase and oxidoreductase is commonly used to remove most pollutants from wastewater [11, 12]. Especially, peroxidase is widely used to degrade some organic micropollutants [13,14,15].

Laccase (EC 1.10.3.2, Lac) is a copper-containing multifunctional oxidase widely found in plants, fungi, bacteria, and some insects [16]. Dissolved oxygen is usually used as the final electron acceptor for Lac, giving Lac good stability and catalysis [17]. Lac is widely used in industry and has excellent catalytic activity for the degradation of bisphenols. However, the current research on the degradation of mixed bisphenols by Lac remains to be explored [18,19,20]. Previously, a large number of studies focused on immobilized Lac to improve BPA degradation [21, 22]. A complex advanced oxidation process combining Lac and photocatalysis (PEC) has been proposed to degrade BPA [23] with excellent degradation efficiency. This similar Lac coupling technology represents an interesting starting point.

Micro-nano bubbles (MNB) are bubbles that are between tens of micrometers and hundreds of nanometers in diameter when bubbles occur. These properties have led to their extensive application in wastewater treatment due to their large specific surface area, prolonged residence time, enhanced mass transfer efficiency, and the generation of a substantial number of highly active free radicals [24]. Studies have been shown that hydroxyl radicals are potent oxidizing agents that play an important role in the degradation of phenols [25, 26]. The feasibility of MNB assisted Lac (MNB-Lac) as a hybrid technique for removing bisphenols from water has been proved in our previous study [27]. The results showed that MNB could induce hydroxyl radical formation to degrade bisphenols and increase laccase activity by 7.7–20.4%, thus promoting the degradation of bisphenols. The initial pollutant concentration, temperature, intake volume, pH, outlet pipe length, and Lac concentration had significant effects on the removal of BPA by MNB-Lac, and the degradation is as high as 95.5 ± 0.7% under optimal conditions. However, the degradation mechanism of mixed bisphenols degraded by MNB-Lac has not been perfected, and the degradation pathway and transformation relationship of bisphenols are still to be explored.

The fundamental goal of the current study was to employ MNB-Lac system to degrade bisphenols including BPA, BPB, BPC, BPE, and BPF. The degradation effect of individual bisphenol and mixed bisphenols by MNB-Lac under the optimized conditions was compared in detail. The Michaelis–Menten kinetics was fully analyzed and the effect of the introduction of microbubbles on the degradation kinetics was studied. The possible degradation pathways of BPA, BPB, BPC, BPE, and BPF degraded by MNB-Lac were studied based on the degradation products. Moreover, the transformation relationship between five different bisphenol was further discussed. In addition, the industrial applicability of MNB-Lac was evaluated by increasing the amount of BPA wastewater. These research results will provide a theoretical basis for further treatment of degraded bisphenol wastewater and the industrial application of MNB-Lac.

2 Experimental

2.1 Materials

Trametes versicolor Lac (120 U·g−1) was supplied by Shanghai Yuanye Biological Co., LTD. BPA was supplied by Adamas Reagent Co., LTD. (Shanghai, China). BPB, BPC, and BPE were supplied by Tiantai Technology Co., LTD. (Shanghai, China). BPF was supplied by Macklin Biochemical Co., LTD. (Shanghai, China). Ethyl acetate, 1-octanol, and sodium hydroxide were supplied by Colon Chemical Co., LTD. (Chengdu, China). CLW-K20 purification system was supplied by Dry Lai Instrument Co., LTD. (Chongqing China). All the chemicals and reagents were analytical grade and were used as received without further purification.

2.2 Construction of MNB-Lac

MNB-Lac was constructed and operated in according with the findings of the previous investigation [27]. The inlet pipe (9.0 mm in diameter, 1.5 m in length) and outlet pipe (9.0 mm in diameter, 8.6 m in length) of the MNB generator (LF-1500, Shanghai Xingheng Technology Co., LTD., China) were placed into a glass container containing bisphenols and Lac solution (pH 7, 40 ℃). Furthermore, the pressure of the MNB generator is maintained at 0.5 MPa and the air intake is 30 mL·min−1.

2.3 Determination of Bisphenols

The content of bisphenols (BPA, BPB, BPC, BPE, BPF) was analyzed by GC (SCION 456C, Tianmei Scientific Instruments Co., LTD., China). Agilent DB-624 was used as a column (0.53 mm × 3.0 μm × 30 m) with N2 as carrier gas at a constant flow rate of 6 mL∙min−1, and the injection volume was 1 µL. The temperature of injector and FID is 260 °C and 300 °C respectively, and the operating in split mode at a split ratio of 20:1. The retention time of BPA, BPB, BPC, BPE, and BPF was 8.50 min, 9.60 min, 8.80 min, 8.20 min, and 7.85 min, respectively. The retention time of 1-octanol was 3.48 min. The temperature ramp was started at 70 °C, then increased to 100 °C at a rate of 100 °C·min−1 for 1 min, further increased to 260 °C at a rate of 100 °C·min−1 for 6 min.

2.4 Bisphenols Degradation by MNB-Lac

The degradation of bisphenols by MNB-Lac was shown in Fig. 1. The optimal parameters (the reaction time of 3 h, substrate concentration of 1 mM, enzyme concentration of 1.2 g∙L−1, temperature of 40 °C, air intake volume of 30 mL∙min−1, pH 8, and outlet pipe length of 8.6 m) were selected based on the previous study [27]. The degradation of BPA, BPB, BPC, BPE, and BPF with different concentrations (0.5, 1.0, 1.5, 3.0, 5.0 mM) was studied by MNB-Lac. Accordingly, the degradation of mixed bisphenols contained BPA, BPB, BPC, BPE, and BPF was carried out under the same conditions. Samples of 900 μL were taken at 0, 15, 30, 60, 120, and 180 min, and placed in a centrifuge tube. Then the same volume of internal standard solution (1 mM n-octanol in ethyl acetate) was added. After swirling for 20 s, centrifuge (GL-16S, Sichuan Shuke Instrument Co., LTD., China) at 20 °C for 2 min at 10,000 r/min, and take liquid to detect bisphenol.

2.5 K m and V max of MNB-Lac for Bisphenols

The kinetic experiment was carried out by GC to detect the change of bisphenol concentration in 500 mL bisphenol (BPA, BPB, BPC, BPE and BPF) solution degraded by MNB-Lac within 60 min. The initial concentration of bisphenol was 0.5–5.0 mM, and the concentration of Lac was 1.2 g∙L−1. The kinetic constants, Km and Vmax (Maximum reactionrate), were calculated with five kinds of bisphenol by using the Lineweaver–Burk plots of the Michaelis–Menten equation.

2.6 Degradation Kinetics of Bisphenols by MNB-Lac

The degradation of individual bisphenol by MNB-Lac was studied further to explore the degradation kinetics of bisphenols. The same conditions were selected according to the Section 2.4, and the initial concentration of individual bisphenol was 0.5, 1.0, 1.5, 3.0, and 5.0 mM. After 500 mL bisphenols solution (BPA, BPB, BPC, BPE, and BPF) was degraded with MNB-Lac for 180 min. Samples of 900 μL were taken at 0, 15, 30, 60, 120, and 180 min, and the content of bisphenols was detected by GC. The bisphenol degradation was calculated, and the zero-order, first-order, and second-order kinetic models were fitted to obtain the rate constants and correlation coefficients.

Zero-order reaction rate equation: \({C}_{0}-{C}_{t}={k}_{0}t\)

First-order reaction rate equation:\(\text{In}\left(\frac{{C}_{0}}{{C}_{t}}\right)={k}_{1}t\)

Second-order reaction rate equation \(\begin{array}{c}\frac1{C_t}-\frac1{C_0}=k_2t\;\\t_\frac12=\frac1{k_2C_0}\end{array}\)

where, c0 represents the initial substrate concentration (mM). ct represents the substrate concentration (mM) in the reaction system at time t. k0 stands for the zero-order reaction rate constant (mM∙h-1). k1 stands for the first order reaction rate constant h-1. k2 stands for the second-order reaction rate constant (mM-1∙h-1).

2.7 Analysis of Degradation Products for Bisphenols

The degradation products of individual bisphenol and mixed bisphenols were determined by gas chromatography mass spectrometry (GC–MS, QP2020NX, Shimadzu, Japan). GC–MS was performed on a sh-rxi-5sil (0.25 mm × 0.25 μm × 30 m) column with N2 as carrier gas at a flow rate of 1.5 mL·min−1, column temperature of 70 ℃. Temperature profile: 40 °C/min from 70 °C to 120 °C hold 4 min, 20 °C/min to 250 °C hold 4 min, 20 °C/min to 300 °C hold 5 min. Sample size of 1 μL, ion source temperature of 220 °C, and interface temperature of 250 °C. The full scanning range of the analysis was 35–610 m/z with solvent delay of 2 min.

2.8 Influence of Wastewater Volume on BPA Degradation by MNB-Lac

Under the optimal reaction conditions described in Section 2.4, the effects of BPA volume (0.5, 0.8, 1.0, 1.5, and 2.0 L) on the degradation by MNB-Lac were investigated using 500 mL BPA solution for 180 min, and samples were taken at 0, 15, 30, 60, 120, and 180 min. The residual content of BPA was determined by GC, and the degradation, degraded BPA quality, and reaction rate of BPA by MNB-Lac at each volume were calculated.

3 Results and Discussion

3.1 Degradation of Individual Bisphenol by MNB-Lac

The degradation of individual bisphenol (BPA, BPB, BPC, BPE, and BPF) at different concentrations was shown in Fig. 2. When the concentration of BPA increased from 0.5 mM to 5.0 mM, the degradation of BPA showed a decreasing trend, as shown in Fig. 2a. Especially, the degradation of BPA decreased significantly when the initial concentration of BPA exceeded 3.0 mM, and the highest degradation of BPA was 95.5 ± 0.7% (3 h). For BPB, BPC, and BPE, the nearly degradation was observed at 0.5–1.5 mM, as shown in Fig. 2b-d. Interestingly, the increasing BPF degradation was obtained from 0.5 mM to 1.5 mM, as shown in Fig. 2e. This was related to the concentration providing the driving force to overcome the mass transfer resistance. The higher the concentration provided the greater the driving force. Therefore, the degradation of BPF increased with the increase of concentration. Nevertheless, at 0.5 mM for BPB, BPC, and BPE, the concentration was high enough that degradation would no longer be controlled by mass transfer [28,29,30]. However, the degradation of BPA decreased significantly at 1.0 mM, and the degradation of BPB, BPC, BPE and BPF also decreased significantly after 1.5 mM. That is, their initial substrate concentration was already high enough, and a higher concentration load would lead to the accumulation of more free radicals and blocked the active site of the enzyme, resulting in enzyme inactivation [31]. The highest degradation of BPB, BPC, BPE, and BPF observed at 1.5 mM was 97.7 ± 1.0% (2 h), 98.9 ± 0.1% (2 h), 95.0 ± 1.0%(2 h), and 91.5 ± 0.1%(3 h), respectively. The degradation of the five compounds by MNB-Lac was as follows: BPC > BPB > BPA > BPE > BPF. However, this was inconsistent with the published results of different bisphenols by Lac. Previously, Lac was found to have a better removal effect on bisphenols with simpler structure, and lower molecular weight. Theoretically, the degradation of the five bisphenols by MNB-Lac was as follows: BPF > BPE > BPA > BPB > BPC [32, 33]. This is related to the fact that the degradation of bisphenols by MNB-Lac is carried out under alkaline conditions rather than acidic conditions. The hydrogen bond formation ability of five bisphenols is changed under alkaline conditions, so Lac has different affinity and specificity for substances. Previous studies have shown that the affinity of laccase is related to substrate hydrogen bond, and the increase in enthalpy generated by hydrogen bond may be conducive to the increase of substrate affinity to the enzyme, resulting in a higher degree of degradation [34].

3.2 Degradation of Mixed Bisphenols by MNB-Lac

The degradation of mixed bisphenols (BPA, BPB, BPC, BPE, and BPF) at different concentrations (0.5, 1.0, 1.5, and 3.0 mM) was investigated, as shown in Fig. 3. The results showed that in the mixed system, the degradation was higher at low concentration and lower at high concentration, which was consistent with that at individual degradation. When the concentration of the mixture was 0.5 mM, the degradation of BPB was the highest, and the degradation of five substances showed a trend of BPB > BPC > BPA > BPF > BPE. With increasing concentration, BPC always showed higher selectivity. The degradation efficiency of the five substances changed to BPC > BPB > BPA > BPF > BPE. Such a transformation may be the fact that BPB is a product of BPC. The amount of BPB in the mixed solution is higher than that of BPC. In addition, in mixed degradation, the degradation of BPA, BPB and BPC decreased with increasing concentration. With the increase of concentration, the degradation of BPE and BPF showed a trend of decreasing first and then increasing. This suggests that there may still be some transformational relationship between the five substances, and competitive biotransformation between phenolic heterobiogenic mixtures has been previously shown in the literature [35]. However, BPE is always negative when the mixing concentration is less than 3.0 mM. This may be the substance produced by MNB-Lac when it degrades the mixture has the same retention time as BPE, resulting in more substances being detected during this retention time.

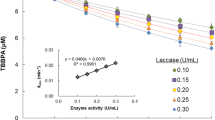

3.3 Michaelis–Menten Kinetics of Individual Bisphenol with MNB-Lac

The Lineweave-Burk plots between the rates, V, and individual bisphenol concentration S are given in Fig. 4. Km reflects the affinity of Lac to substrate. The lower the Km value, the greater the affinity, and the easier the enzyme reacts with the substrate [36], the order of Km of the five bisphenols was as follows: BPA > BPE > BPF > BPB > BPC. Compared with the other four bisphenols, Lac has slightly greater affinity with BPC, that is, Lac is easier to react with BPC, and the degradation effect is slightly better. Compared with the other four bisphenols, Lac had a slightly greater affinity with BPC. This result is consistent with the conclusion that BPC degradation is the highest in 3.1. However, the affinity order of BPA and BPE was not consistent with the conclusion 3.1. The observed differences in affinity may be attributed to the fact that BPA is more likely to react with specific reaction intermediates during mixture degradation [37]. Additionally, the degradation of BPB, BPC, BPE, and BPF was conducted under the optimal conditions for BPA but not for BPB, BPC, BPE, or BPF. This suggests that there are distinct affinity differences related to the reactivity of these compounds.

3.4 Degradation Kinetics of Individual Bisphenols with MNB-Lac

The rate constants and correlation coefficients of different kinetic models of bisphenols degradation by MNB-Lac were evaluated. As can be seen from Table 1 that BPA, BPB, BPE and BPF all highly follow second-order kinetics at five different concentrations (1.0, 1.5, 3.0, and 5.0 mM), while BPC highly follows second-order kinetics at 1.0, 2.0, and 3.0 mM. At 5.0 mM, the first-order kinetic correlation coefficient of BPC is closer to 1. However, the difference between the second-order kinetic correlation coefficient and the first-order kinetic correlation coefficient is very small, both greater than 0.9, which can also indicate that BPC conforms to the second-order dynamics. It can be seen that when the initial concentrations of BPA, BPB, BPC, BPE and BPF are 1.0, 1.5, 3.0 and 5.0 mM, the correlation coefficients of the second-order kinetic equation are all greater than 0.9, indicating that the reaction of degradation of bisphenol by MNB-Lac was more consistent with the second-order kinetic reaction. This conclusion was consistent with previous experiments on Lac degradation of BPA [38, 39], which demonstrated that the introduction of microbubbles had no effect on the reaction process.

3.5 Degradation Products of Bisphenols by MNB-Lac

The degradation products of BPA, BPB, and BPC were consistent with previous literature [27] are shown in Fig. 5a-c. The products of BPE and BPF based on the analysis of GC–MS are shown in Fig. 5d-e. The mass-to-charge ratio (m/z) is used to describe the m/z of the peaks, which allows the structure of the compound to be inferred. Eight peaks of products of BPA (m/z: 340, 312, 130, 122, 116, 114, 92, and 88). Nine peaks of products of BPB (m/z 312, 286, 228, 144, 116, 122, 114, 102, and 92). Six peaks of products of BPC (m/z 326, 312, 144, 116, 114, and 92). Seven peaks of products of BPE (m/z 206, 178, 144, 130, 126, 116, and 92). Six peaks of products of BPF (m/z 144, 136, 130, 122, 116, and 92). The products of BPA and BPB with m/z of 312 were the same substance. The products of BPB, BPC, BPF and BPF with m/z of 144 were the same substance. The product of BPA with m/z of 130 was the same substance as the product of BPE. The product of BPA with m/z of 122, the product of BPB, and the product of BPF were the same substance. The product of the five substances with m/z of 116 and 92 was the same substance. The product of three substances (BPA, BPB, and BPC) with m/z of 114 was the same substance. Compared with previous studies [40], the structure of the products of bisphenol degradation by MNB-Lac was simpler, the molecular weight was lower, and the ring-opening products were more. This may be the introduction of microbubbles to improve the activity of Lac, and substances are degraded more thoroughly.

3.6 Degradation Pathway of Bisphenols by MNB-Lac

According to the results of mass spectrum analysis, the degradation path can be deduced. As can be seen from Fig. 5a-c that the possible degradation pathways of BPA, BPB, and BPC were as follows: First, BPA,BPB, and BPC captured electrons from the aromatic ring to form phenol free radicals [41], and further reacted to form products with more complex structures. Second, BPA,BPB, and BPC were broken down into xylene, which produced toluene in a free radical reaction [42], and then which in turn gave rise to phenylethanol. The last was the difference found in the obtained product, which suggest that BPA, BPB, and BPC have reacted with some intermediates. The aromatic intermediates could be oxidized to produce a variety of ring opening compounds by ring breaking reaction [43]. There were two possible degradation paths for BPE and BPF in Fig. 5d-e. First, BPE and BPF were p-xylene, and then them reacted with free radicals to produce toluene, and then reacted with some intermediates to produce other products. Second, the aromatic intermediates of BPE and BPF were oxidized to form ring-opening compounds through a ring-breaking reaction.

In summary, the five bisphenols have two major degradation pathways. The first is to maintain the ring structure, and eventually to produce benzene compounds. The second reaction opens the ring directly, producing a chain product containing oxygen. These two degradation pathways are similar to bisphenol degradation pathways previously studied [44]. BPA, BPB, BPC, BPE, and BPF share many of the same products. In addition, BPA, BPB, BPC, BPE and BPF have similar degradation paths, and these also indicate that there is a certain transformation relationship.

3.7 Transformation Relationship of Bisphenols Degradation

The possible transformation relationships of BPA, BPB, BPC, BPE and BPF are shown in Fig. 6. According to the above 3.2 experimental conclusions, in the mixed degradation, the removal efficiency of BPB and BPC were significantly higher than those of BPA, BPE, and BPF. Due to the similarity of the structure of bisphenols, it can be seen from Fig. 5 that many identical and similar products can be observed after degradation of different bisphenols, and their transformation paths were also similar. It can be inferred that BPA, BPC and BPF are one of the degradation products of BPB. The degradation products of BPC are BPA, BPB and BPF. BPB and BPF are one of the degradation products of BPF. In addition, BPA, BPB and BPC are one of the degradation products of BPF. However, in the experimental results of 3.6, such a complete conclusion was not found, which may be the complete transformation of bisphenol substances in the individual degradation process, and other bisphenols as intermediate products were not detected.

3.8 Evaluate the Applicability of MNB-Lac

It can be seen from Fig. 7a-b that the degradation of BPA decreases with the increase of the volume, while the relative degradation quality of BPA increased and then decreased with the increase of the volume. The reaction rate of BPA also decreased with the increase of volume. This may be the substrate volume increases, the presence of pollutants will also increase, which will lead to the gradual decline of Lac's degradation effect on BPA. With the increase of pollutants, the degradation quality will decrease with the increase of volume. This may be the fact that when the volume increases, excessive pollutants will hinder the active site of Lac, and the degradation quality will decrease [31]. Therefore, the catalytic degradation ability of enzymes is not enough to deal with a large number of pollutants, and it provides a theoretical basis for further study of practical scale production.

4 Conclusions

The degradation of individual bisphenols (BPA, BPB, BPC, BPE and BPF) and mixed bisphenols by MNB-Lac technique was studied. In individual degradation, the degradation of BPA, BPB, BPC, BPE and BPF all exceeded 90%, and it indicated the applicability of MNB-Lac technology, and BPC always showed higher selectivity in mixed degradation. A comprehensive analysis was conducted on the Michaelis–Menten kinetics governing the degradation of BPA, BPB, BPC, BPE, and BPF via the MNB-Lac method. It was observed that MNB-Lac exhibited the lowest Km value for BPC degradation, suggesting a marginally greater affinity for BPC than for the other bisphenols. At the same time, it was found that the degradation reaction of five kinds of bisphenols was highly consistent with the second-order kinetic reaction. In addition, it was found that the five bisphenols have two major degradation pathways. The first was to maintain the ring structure, and eventually to produce benzene compounds. The second reaction opened the ring directly, producing a chain product containing oxygen. It has been concluded that BPA, BPC, and BPF are among the degradation products resulting from the breakdown of BPB. Additionally, BPA, BPB, and BPF are identified as degradation products of BPC. Furthermore, BPB and BPF are determined to be degradation products of BPF. It is also concluded that BPA, BPB, and BPC are among the degradation products of BPF. The relative degradation quantity and reaction rate of BPA decreased with the increase of the volume, and the degradation first increased and then decreased. These findings provided a theoretical basis for further exploring the removal of bisphenols from actual wastewater. In actual industrial applications, the challenge of economically and effectively enhancing the degradation of bisphenols following the expansion of wastewater volume has yet to be addressed.

References

Frankowski R, Zgoła-Grześkowiak A, Smułek W, Grześkowiak T (2020) Removal of Bisphenol A and Its Potential Substitutes by Biodegradation. Appl Biochem Biotechnol 191:1100–1110

Li M, Gong J, Ge L, Gao H, Yang J, Yang C, Kang J, Fang Y, Xu H (2022) Development of human retinal organoid models for bisphenol toxicity assessment. Ecotoxicol Environ S 245:114094

Onundi Y, Drake BA, Malecky RT, DeNardo MA, Mills MR, Kundu S, Ryabov AD, Beach ES, Horwitz CP, Simonich MT, Truong L, Tanguay RL, Wright LJ, Singhal N, Collins TJ (2017) A multidisciplinary investigation of the technical and environmental performances of TAML/peroxide elimination of Bisphenol A compounds from water. Green Chem 19:4234

Siracusa JS, Yin L, Measel E, Liang S, Yu X (2018) Effects of bisphenol A and its analogs on reproductive health: A mini review. Reprod Toxicol 79:96–123

Yüksel S, Kabay N, Yüksel M (2013) Removal of bisphenol A (BPA) from water by various nanofiltration (NF) and reverse osmosis (RO) membranes. J Hazard Mater 263:307–310

Meng AN, Chaihu LX, Chen HH, Gu ZY (2017) Ultrahigh adsorption and singlet-oxygen mediated degradation for efficient synergetic removal of bisphenol A by a stable zirconium-porphyrin metal-organic framework. Sci Rep 7:6297

Pérez-Moya M, Kaisto T, Navarro M, Del Valle LJ (2016) Study of the degradation performance (TOC, BOD, and toxicity) of bisphenol A by the photo-Fenton process. Environ Sci Pollout Res 24:6241–6251

Xi Y, Sun Z, Hreid T, Ayoko GA, Frost RL (2014) Bisphenol A degradation enhanced by air bubbles via advanced oxidation using in situ generated ferrous ions from nano zero-valent iron/palygorskite composite materials. Chem Eng J 247:66–74

de Freitas EN, Bubna GA, Brugnari T, Kato CG, Nolli M, Rauen TG, Peralta Muniz Moreira RdF, Peralta RA, Bracht A, de Souza CGM, Peralta RM (2017) Removal of bisphenol A by laccases from Pleurotus ostreatus and Pleurotus pulmonarius and evaluation of ecotoxicity of degradation products. Chem Eng J 330:1361–1369

Yang S, Hai FI, Nghiem LD, Price WE, Roddick F, Moreira MT, Magram SF (2013) Understanding the factors controlling the removal of trace organic contaminants by white-rot fungi and their lignin modifying enzymes: a critical review. Bioresour Technol 141:97–108

Ji C, Nguyen LN, Hou J, Hai FI, Chen V (2017) Direct immobilization of laccase on titania nanoparticles from crude enzyme extracts of P. ostreatus culture for micro-pollutant degradation. Sep Purif Technol 178:215–223

Mishra B, Varjani S, Agrawal DC, Mandal SK, Ngo HH, Taherzadeh MJ, Chang JS, You S, Guo W (2020) Engineering biocatalytic material for the remediation of pollutants: A comprehensive review. Environ Technol Innov 20:101063

Varga B, Somogyi V, Meiczinger M, Kováts N, Domokos E (2019) Enzymatic treatment and subsequent toxicity of organic micropollutants using oxidoreductases - A review. J Clean Prod 221:306–322

Ji C, Hou J, Wang K, Zhang Y, Chen V (2016) Biocatalytic degradation of carbamazepine with immobilized laccase-mediator membrane hybrid reactor. J Membr Sci 502:11–20

Stadlmair LF, Letzel T, Drewes JE, Graßmann J (2017) Mass spectrometry based in vitro assay investigations on the transformation of pharmaceutical compounds by oxidative enzymes. Chemosphere 174:466–477

Zerva A, Zervakis GI, Christakopoulos P, Topakas E (2016) Degradation of olive mill wastewater by the induced extracellular ligninolytic enzymes of two wood-rot fungi. J Environ Manage 203:791–798

Jin X, Yu X, Zhu G, Zheng Z, Feng F, Zhang Z (2016) Conditions Optimizing and Application of Laccase-mediator System (LMS) for the Laccase-catalyzed Pesticide Degradation. Sci Rep 6:35787

Asif M, Bhalla TC (2016) Hydroxynitrile Lyase of Wild Apricot (Prunus armeniaca L.): Purification, Characterization and Application in Synthesis of Enantiopure Mandelonitrile. Catal Letter 146:1118–1127

Morsy SAGZ, Ahmad Tajudin A, Ali MSM, Shariff FM (2020) Current Development in Decolorization of Synthetic Dyes by Immobilized Laccases. Front Microbiol 11:572309

Bilal M, Iqbal HMN, Barceló D (2019) Mitigation of bisphenol A using an array of laccase-based robust bio-catalytic cues - A review. Sci Total Environ 689:160–177

Catherine H, Penninckx M, Frédéric D (2016) Product formation from phenolic compounds removal by laccases: A review. Environ Technol Innov 5:250–266

Patel SKS, Gupta RK, Kim SY, Kim IW, Kalia VC, Lee JK (2020) Rhus vernicifera Laccase Immobilization on Magnetic Nanoparticles to Improve Stability and Its Potential Application in Bisphenol A Degradation. Indian J Microbiol 45:45–54

Wang Z, Ren D, Cheng Y, Zhang X, Zhang S, Chen, (2022) W Immobilization of laccase on chitosan functionalized halloysite nanotubes for degradation of Bisphenol A in aqueous solution: degradation mechanism and mineralization pathway. Heliyon 8(7):e09919

Li J, Ding Y, Gao J, Yan K, Zhang J (2022) Laccase-coupled photoelectrocatalytic system for highly efficient degradation of bisphenol A. Chemosphere 308:136245

Haris S, Qiu X, Klammler H, Mohamed MMA (2020) The use of micro-nano bubbles in groundwater remediation: A comprehensive review. Groundwater Sustain Dev 11:100463

Liu Y, Zhang H, Sun J, Liu J, Shen X, Zhan J, Zhang A, Ognier S, Cavadias S, Li P (2018) Degradation of aniline in aqueous solution using non-thermal plasma generated in microbubbles. Chem Eng J 345:679–687

Chen Z, Fu M, Yuan C, Hu X, Bai J, Pan R, Lu P, Tang M (2021) Study on the degradation of tetracycline in wastewater by micro-nano bubbles activated hydrogen peroxide. Environ Technol 43(23):3580–3590

Zhang J, Tan LR, Peter-Leon H, Wang RQ, Li W, Wu SW, Tan XM, Xu H, Zhou X (2022) Micro-nano bubbles assisted laccase for biocatalytic degradation of bisphenols. J Water Process Eng 48:102880

Zhang Y, Zhang D, Zhou L, Zhao Y, Chen J, Chen Z, Wang F (2017) Polypyrrole/reduced graphene oxide aerogel particle electrodes for high-efficiency electro-catalytic synergistic removal of Cr(VI) and bisphenol A. Chem Eng J 336:690–700

Zhang Y, Wang F, Ou P, Zhu H, Lai Y, Zhao Y, Shi W, Chen Z, Li S, Wang T (2018) High efficiency and rapid degradation of bisphenol A by the synergy between adsorption and oxidization on the MnO2@nano hollow carbon sphere. J Hazard Mater 360:223–232

Cao J, Zhao H, Cao F, Zhang J, Cao C (2008) Electrocatalytic degradation of 4-chlorophenol on F-doped PbO2 anodes. Electrochim Acta 54:2595–2602

Xu DY, Yang Z (2013) Cross-linked tyrosinase aggregates for elimination of phenolic compounds from wastewater. Chemosphere 9(4):391–398

Zdarta J, Antecka K, Frankowski R, Zgoła-Grześkowiak A, Ehrlich H, Jesionowski T (2017) The effect of operational parameters on the biodegradation of bisphenols by Trametes versicolor laccase immobilized on Hippospongia communis spongin scaffolds. Sci Total Environ 615:784–795

Dellafiora L, Galaverna G, Reverberi M, Dall’Asta C (2017) Degradation of aflatoxins by means of laccases from trametes versicolor: An in silico insight. Toxins 9(1):17

Peng B, Liu M, Han Y, Wanjaya ER, Fang M (2019) Competitive biotransformation among phenolic xenobiotic mixtures: Underestimated risks for toxicity assessment. Environ Sci Tech 53:12081–12090

Nicolucci C, Rossi S, Menale C, Godjevargova T, Ivanov Y, Bianco M, Mita L, Bencivenga U, Mita DG, Diano N (2010) Biodegradation of bisphenols with immobilized laccase or tyrosinase on polyacrylonitrile beads. Biodegradation 22:673–683

De Freitas EN, Bubna GA, Brugnari T (2010) Removal of bisphenol A and evaluation of ecotoxicity of degradation products by laccases from pleurotus ostreatus and pleurotus pulmonarius. Chem Eng J 330:1361–1369

Ghobadi Nejad Z, Borghei SM, Yaghmaei S (2018) Kinetic studies of Bisphenol A in aqueous solutions by enzymatic treatment. Int J Environ Sci Technol 16:821–832

Liu M, Hu B, Zhang H, Zhang Y, Wang L, Qian H, Qi X (2017) Inhibition study of red rice polyphenols on pancreatic α-amylase activity by kinetic analysis and molecular docking. J Cereal Sci 76:186–192

Navada KK, Sanjeev G, Kulal A (2018) Enhanced biodegradation and kinetics of anthraquinone dye by laccase from an electron beam irradiated endophytic fungus. Int Biodeter Biodegr 132:241–250

Daâssi D, Prieto A, Zouari-Mechichi H, Martínez MJ, Nasri M, Mechichi T (2016) Degradation of bisphenol A by different fungal laccases and identification of its degradation products. Int Biodeter Biodegr 110:181–188

Cabana H, Jones JP, Agathos SN (2007) Elimination of Endocrine Disrupting Chemicals using White Rot Fungi and their Lignin Modifying Enzymes: A Review. Eng Life Sci 7:429–456

Gassara F, Brar SK, Verma M, Tyagi RD (2013) Bisphenol A degradation in water by ligninolytic enzymes. Chemosphere 92(56):1356–1360

Porcar-Santos O, Cruz-Alcalde A, Sans C (2023) Aqueous oxidation of bisphenol analogues by ozone: Relevance of substituents on reactivity. J Environ Chem Eng 10:52–67

Acknowledgements

The study has been supported by National Natural Science Foundation of China (No. 32301280), Natural Science Foundation Project of CSTC (No. cstc2021jcyj-msxmX0710), Science and Technology Research Program of Chongqing Municipal Education Commission (No. KJQN202215127, No. KJQN202000812, No. KJQN202100818), and Research Project of Chongqing Technology and Business University (No. 2152024), Graduate Innovation Research Project of Chongqing Technology and Business University (No. yjscxx2023-211-139).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wu, H., Liu, J., Zhou, X. et al. Degradation of Bisphenols by Micro-Nano Bubbles Assisted Laccase: Kinetics, Michaelis–Menten Kinetics, Degradation Pathway, and Transformation Relationship. Catal Lett (2024). https://doi.org/10.1007/s10562-024-04745-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10562-024-04745-4