Abstract

An efficient, selective and cost-effective procedure has been developed for mono N-arylation of primary alkyl and benzyl carbamates with aryl iodides and bromides by incorporating CuI as an inexpensive and commercially available catalyst. Despite previous reports on C–N coupling reactions, this process does not need expensive ligands and takes advantage of readily available and inexpensive ethylenediamine (EDA) as the ligand. Reaction times were relatively short and related N-arylated carbamates were obtained in excellent yields. Interestingly, replacing CuI with Cu(OAc)2 allowed us to use arylboronic acids as coupling partner for this reaction. All products are well characterized by 1H- and 13C-NMR, MS, melting point, IR and CHNS techniques.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

N-Substituted carbamates are an attractive class of chemical compounds due to their widespread applications [1,2,3,4]. The biological effects of these substances have been disclosed greatly in many pharmaceutical compounds like anti-diabetic, anti-estrogenic, anticancer, anti-inflammatory, anti-osteoporosis, anti-malarial, antiviral, anti-obesity, antitumor, anti-Alzheimer and anti-HIV drugs [5,6,7,8,9,10].

These compounds also play considerable roles as intermediates in the synthesis of some polymers [11] and as protecting groups in organic synthesis [12]. Moreover, they perform a key role in modern drug design and medicinal chemistry (Fig. 1) [13, 14]. Therefore, synthesis of N-substituted carbamates has been a subject of interest in recent researches.

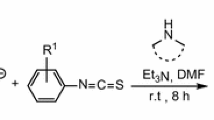

Many methods have been proposed for the preparation of N-substituted carbamates, some of which are illustrated in Scheme 1.

The oldest of these methods was the reaction of amines with phosgene, which due to its highly toxic nature [15] was replaced with 1,1,1-trichloromethylformate (diphosgene) [16], bis-(1,1,1-trichloromethyl) carbonate (triphosgene) [17], trichloroacetyl chloride [18], 1,1-carbonyl diimidazole (CDI) [19], diethyl carbonates (DEC) [20], and dimethyl carbonate (DMC) [21]. While these substitutes provided safer reaction conditions, toxicity was still a major drawback.

Oxidative carbonylation of amines was reported by Chen for the synthesis of N-substituted carbamates [22] whereby CO is used instead of the previous phosgene derivatives. This reaction has been demonstrated to be catalyzed by the presence of Pd, Ru, Ni, Zn, and Mn [23,24,25,26].

Another intriguing method was reductive carbonylation of nitro compounds which is takes place in the presence of certain transition metals such as Pd, Ru and Rh, as catalyst [27,28,29,30].

The reaction of amines, carbon dioxide and alcohols has been shown to be a reliable method to obtain N-substituted carbamates. These reactions are carried out in the presence of homogeneous catalysts like Sn, Ni, Ru, Ir, Cs [31,32,33] and heterogeneous catalysts such as CeO2, TiO2–Cr2O3/SiO2 and Cu–Fe/ZrO2–SiO2 [34,35,36].

In 2004, Wang provided these compounds via the alcoholysis of urea derivatives as carbonyl sources [37].

Many other interesting processes were also developed using Hoffman [38], Curtius [39], Lossen [40], and Schmidt [41] rearrangements.

In recent years there has been an ongoing effort by many research groups focused on finding novel and efficient methods for synthesis of N-substituted carbamates through C–N coupling reactions in the presence of Pd or Cu catalysts [42,43,44,45,46,47]. For example, tert-butyl carbamate was used separately by Hornberger [42] and Qin [43] to prepare N-aryl tert-butyl carbamate in the presence of aryl halides as coupling partners and Pd catalysts. In another report, CuI was used as the catalyst for Ullmann–Finkelstein–Ullmann reaction of amides, sulfonamides, and carbamates [44]. However, these procedures suffer from different unfavorable conditions like using an excess amount of base, high temperature and high reaction times.

Using Pd and Cu catalyzed coupling of isocyanate salts with aryl halides or arylboronic acids has been suggested for synthesis of N-aryl carbamates [45,46,47]. In this protocol, isocyanate is initially coupled with an aryl halide or arylboronic acid and then alcohol attacks the carbon center of N-aryl isocyanate to produce the desired carbamate. Recently a protocol was described by Chikkade et al. which takes advantage of a C–H activation method using a Cu catalyst and Di-tert-butyl peroxide (DTBP) to synthesize N-substituted carbamates in good yields [48].

Despite all merits of the aforesaid procedures, they suffer from major shortcomings including toxicity of reagents, limited scope of substrates, long reaction times, unfavorable reaction conditions, expensive ligands, expensive metals and moderate yields. Thus there is still a large demand for finding an efficient and reliable method for preparation of N-substituted carbamates.

In continuation of our ongoing research on the chemistry of carbamates [49] to find a novel, efficient, and cost-effective protocol for N-arylation primary carbamates [50] and efficiency of Cu catalysts in C–N bond formations [51,52,53,54,55,56,57,58], herein, we introduce an efficient and cost effective procedure for selective mono N-arylation primary carbamates to address some of the limitations of previous methods reported in the literature and to be applicable for N-arylation of a wide range of alkyl and benzyl carbamates by aryl halides and arylboronic acids in the presence of readily available and inexpensive Cu salt and diamine ligand.

2 Experimental

All chemicals were purchased from the Merck, Fluka and Aldrich Chemical companies in high purity.

The products were characterized by their spectral and physical data such as NMR, FT-IR, MS, CHNS and melting point. 1H and 13C NMR spectra were recorded with Bruker Avance DPX 250 MHz instruments with Me4Si or solvent resonance as the internal standard. Fourier transform infrared (FTIR) spectra were obtained using a Shimadzu FT-IR 8300 spectrophotometer. Elemental analysis was done on a 2400 series PerkinElmer analyzer. The mass spectra were recorded on a Shimadzu GC-MS QP 1000 EX instrument. Melting points were determined on a Mel–Temp apparatus and were uncorrected. Determination of the purity of the substrate and monitoring of the reaction were accomplished by thin-layer chromatography (TLC) on a silica–gel polygram SILG/UV 254 plates.

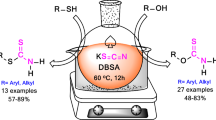

2.1 General Procedure for the Synthesis of Primary Carbamates

According to the reported procedure [49] a mixture of alcohol (1 mol), potassium cyanate (1.5 mmol) and DBSA (1.5 mmol) was pulverized in a mortar to provide a uniform powder. Then the mixture was maintained in an oven at 60 °C for 1 h. After completion of the reaction, which was determined by TLC monitoring, the resulting powder was extracted by the addition of CH2Cl2 (15 mL) and saturated aqueous solution of NaHCO3 (15 mL). Then the organic layer was washed with water (3 × 15 mL), dried over anhydrous Na2SO4 and concentrated to give the crude desired product, which was purified by recrystallization from diethyl ether.

2.2 General Procedure for the Synthesis of Alkyl Aryl Carbamates

CuI (10 mol%) and EDA (10 mol%) were added to a mixture of O-alkyl carbamate (1 mmol), NaOtBu (1.5 mmol) and aryl halide (1 mmol) in 2 mL toluene and the mixture was stirred for the appropriate time, which was determined by TLC monitoring, at 100 °C. After completion of the reaction, the catalyst was removed by filtration and 20 mL H2O was added to the filtrate. The resultant mixture was extracted with CHCl3. Then the organic phase was washed with water (2 × 10 mL) and dried over anhydrous Na2SO4. After evaporation of CHCl3 under reduced pressure, the corresponding crude product was purified by flash chromatography to give the desired pure cross-coupling product in good to excellent yield. In the case of using arylboronic acids as coupling partners, Cu(OAc)2 was employed instead of CuI.

3 Results and Discussion

Regarding Cu catalyzed C–N coupling history for nitrogen containing compounds and our initial effort on this reaction for synthesis of alkyl or aryl arylcarbamates, it was revealed that presence of a ligand is crucial for the reaction to proceed. Thus we started to explored the effect of different ligands (10 mol %) on the reaction of n-propyl carbamate (1 mmol) with phenyl iodide (1 mmol) as the model reaction in the presence of CuI (10 mol %), K2CO3 (1.5 mmol) and toluene (2 mL) at 100 °C. Various classes of bidentate ligands with nitrogen and oxygen chelating atoms were tested. As it is depicted in Fig. 2, ligands 1, 2 and 4 showed the highest reactivity. Based on an economic point of view, EDA, which is cheapest one, was selected as the best of choice ligand for the rest of study. This is a great achievement regarding the previous reports on the C–N coupling reactions in which expensive ligands had been consumed [59,60,61,62].

In the next step, the catalytic activity of various Cu sources, such as Cu powder, Cu(I) and Cu(II) salts, was studied on the model reaction in the presence of EDA (10 mol%). According to the obtained results (Table 1), although almost all Cu salts carry out the reaction with moderate to good yields, CuI is the best one (Table 1, entry 3) with shortest reaction time.

After optimization of the copper source, the effect of different bases was examined in toluene as the solvent, which the related results are presented in Table 2. According to these results, sodium tert-butoxide show to be the most effective base (Table 2, entry 5), although the other inorganic bases like K2CO3, CsCO3 and K3PO4 are also somehow efficient (Table 2, entries 1–4).The effect of several common solvents was also examined and the model showed to be the most efficient in toluene (Table 2, entry 5) and, except in dioxane that the yield of reaction was 88% (Table 2, entry 6), the model reaction did not proceed at all in the other solvents (Table 2, entries 7–9). Optimizing of temperature showed that the reaction has its highest efficiency at 100 °C and the yield of the model reaction decreases at lower temperatures (Table 2, entry 10) and running the reaction at higher temperature is not led to any improvement in efficiency of the reaction (Table 2, entry 11).

Finally, the effect of different amounts of CuI and EDA was explored on the reaction of n-propyl carbamate (1 mmol) and phenyl iodide (1 mmol) in toluene and in the presence of NaOtBu. According to the data summarized in Table 2, the best result is obtained when 10 mol% of EDA and CuI are employed (Table 2, entry 5). The results of optimization study revealed that the best reaction conditions are: alkyl carbamate (1 mmol), aryl halide (1 mmol), NaOtBu (1.5 mmol), CuI (10 mol%), EDA (10 mol%), toluene (2 mL) at 100 °C.

With the optimized conditions in hand, generality, versatility, and scope of reaction were explored. For this purpose, a wide range of primary alkyl carbamates was chosen as starting material and their C–N coupling reaction with aryl iodide was investigated, which their results are represented in Table 3. According to the information obtained, primary alkyl carbamates carry out the reaction very well and produce the corresponding alkyl arylcarbamates in excellent yields and interestingly in short reaction times compared to the majority of methods reported in the literature [42,43,44,45,46]. The protocol is also effective for N-arylation of tert-butyl carbamate, which is widely used as protecting group in organic synthesis (Table 3, entry 7). Benzyl carbamates, which are important compounds in organic synthesis, undergo the C–N coupling reaction as well as the other primary carbamates and give the desired products in good to excellent yields (Table 3, entries 10–17). The presence of substitution in the ortho position, such as methyl group in 2-methyl iodobenzene, causes a drastic decrease in the yield of reaction after 6 h (Table 3, entry 12), which might be due to steric effect.

N-arylation of aryl carbamates was also carried out but all efforts for isolation and purification of the desired products via chromatographic techniques were failed probably because of their instability, which had been mentioned before by Buchwald et al. [47].

In addition, the coupling reaction of n-propyl carbamate with aryl halides was examined, which its results are exhibited in Table 4. According to these data, various aryl iodides with electron donating and electron withdrawing substituents undergo the C–N coupling reaction efficiently and give the corresponding secondary carbamates in excellent yields. However, aryl iodides bearing electron withdrawing groups give slightly higher yields. Moreover, 3-iodothiophene, as a heterocyclic aromatic iodide, reacts with n-propyl carbamate and produces the desired product in high yield (Table 4, entry 8).

Also the results registered in Table 4 disclose which aryl bromides carry out the reaction as well as aryl iodides but with slightly lower yields. Among aryl bromides, those with electron withdrawing groups show a positive effect on the reaction yield and reaction time. In contrast to aryl iodides and bromides, aryl chlorides are inactive toward C–N bond formation reaction.

Regarding to the difference in reactivity among aryl iodides, bromides and chlorides, the selective C–N coupling reaction of various dihalobenzenes, such as 1-chloro-4-iodobenzene, 1-bromo-4-chlorobenzene, and 1-bromro-4-iodobenzene, with n-propyl carbamate was studied in the presence of CuI. The results revealed that C–I is more reactive than C–Br, and C–Br than C–Cl, and N-arylation of the abovementioned dihalobenzenes produces n-propyl 4-bromophenyl carbamate and n-propyl 4-chlorophenyl carbamate quantitatively (Table 4, entries 6 and 7).

To broaden the scope of protocol, mono arylation of primary carbamates with arylboronic acids was also explored. Therefore, phenylboronic acid (1 mmol) was treated with n-propyl carbamate (1 mmol) in the presence of CuI(10 mol%), EDA (10 mol%) and NaOtBu (1.5 mmol) in toluene (2mL) at 100 °C. After 12 h, the isolated yield of product, n-propyl phenylcarbamate, was only 28%. Surprisingly, using Cu(OAc)2 instead of CuI, as the catalyst, provided a drastic improvement in the yield of reaction (82%) after 6 h. 4-Methylphenylboronic acid and 4-nitrophenylboronic acid also underwent the C–N bond formation reaction in high yields however in longer reaction times compared to the related aryl iodides. (Scheme 2).

In the next step, two experiments were designed to confirm selectivity of the present method toward mono N-arylation of primary carbamates. In the first experiment, 1 mmol n-propyl carbamate was treated with 2 mmol phenyl iodide under the optimized reaction condition. It was observed that in spite of using an excess amount of phenyl iodide, only mono N-arylation took place and the product of diarylation was not detected in the reaction mixture by TLC monitoring (Scheme 3). In the second experiment, 1 mmol n-propyl phenylcarbamate, as a secondary carbamate, was treated with 1 mmol phenyl iodide under the optimized reaction conditions but in the contrast to the reported methods in the literature in which secondary carbamates had been successfully converted to tertiary carbamates in the reaction with aryl halides [63, 64], n-propyl phenylcarbamate did not undergo N-arylation and remained intact (Scheme 3).

According to the literature reports [45, 46, 65] and the results obtained from this study, the following probable mechanism can be suggested. In the first step, with sequential deprotonation and anion exchange, complex II is formed. Oxidative addition of ArX results in the Cu(III) complex III. Then reductive elimination provides IV as the final product and regenerates Cu(I) complex I (Fig. 3).

4 Conclusions

In conclusion, we have introduced an efficient, selective, cost-effective and operationally simple method for the mono N-arylation of various primary alkyl carbamates. The other highlights of this protocol are: (a) using less toxic and inexpensive catalyst (CuI), (b) using inexpensive and available ligand (EDA), (c) broad scope regarding carbamate substrate, (d) producing high to excellent yield of secondary carbamates in relatively short reaction time and (e) tolerance of most of functional groups under reaction conditions. This protocol opens a new opportunity for efficient, selective and cost-effective synthesis of secondary N-aryl carbamates via a C–N arylation reaction.

References

Nasr M, Paull KD, Narayanan V (1985) J Pharm Sci 74:831

Wu TT, Huang J, Arrington ND, Dill GM (1987) J Agric Food Chem 35:817

Pandey RK, Dagade SP, Dongare MK, Kumar P (2003) Synth Commun 33:4019

Vauthey I, Valot F, Gozzi C, Fache F, Lemaire M (2000) Tetrahedron Lett 41:6347

Giannessi F, Pessotto P, Tassoni E, Chiodi P, Conti R, De Angelis F, Dell’Uomo N, Catini R, Deias R, Tinti MO (2003) J Med Chem 46:303

Ouellet R, Rousseau J, Brasseur VL, Diksic M, Westera G (1984) J Med Chem 27:509

Li QY, Zu YG, Shi RZ, Yao LP (2006) Curr Med Chem 13:2021

Wu YJ, Su WG (2001) Curr Med Chem 8:1727

Deaton DN, Tavares FX (2005) Curr Top Med Chem 5:1639

Posner GH, Oh CH, Gerena L, Milhous WK (1992) J Med Chem 35:2459

Lee BS, Chun BC, Chung YC, Sul KI, Cho JW (2001) Macromolecules 34:6431

Pothukanuri S, Winssinger N (2007) Synfacts 09:994

Ghosh AK, Brindisi M (2015) J Med Chem 58:2895

Ren L, Jiao N (2014) Chem Commun 50:3706

Eckert H, Forster B (1987) Angew Chem Int Ed Engl 26:894

Kurita K, Matsumura T, Iwakura Y (1976) J Org Chem 41:2070

Cotarca L, Delogu P, Nardelli A, Unji V (1996) Synthesis 1996:553

Wynne JH, Jensen SD, Snow AW (2003) J Org Chem 68:3733

Duspara PA, Islam MS, Lough AJ, Batey RA (2012) J Org Chem 77:10362

Tundo P, McElroy CR, Aricò F (2010) Synlett 10:1567

Kumar S, Jain SL (2013) New J Chem 37:2935

Chen B, Chuang SSC (2003) Green Chem 5:484

Fukuoka S, Chono M, Kohno M (1984) J Chem Soc 6:399

Li KT, Peng Y (1993) J Catal 143:631

Wan B, Liao S, Yu D (1999) Appl Catal A 183:81

Jones WD, Reynolds KA, Sperry CK, Lachicotte RJ, Godleski SA, Valente RR (2000) Organometallics 19:1661

Kunin AJ, Noirot MD, Gladfelter WL (1989) J Am Chem Soc 111:2739

Skoog SJ, Campbell JP, Gladfelter WL (1994) Organometallics 13:4137

Cenini S, Crotti C, Pizzotti M, Porta F (1988) J Org Chem 53:1243

Ragaini F, Cenini S, Demartin F (1994) Organometallics 13:1178

Abla M, Choi JC, Sakakura T (2001) Chem Commun 21:2238

Abla M, Choi JC, Sakakura T (2004) Green Chem 6:524

Ion A, Doorslaer CV, Parvulescu V, Jacobs P, De Vos D (2008) Green Chem 10:111

Honda M, Sonehara S, Yasuda H, Nakagawa Y, Tomishige K (2011) Green Chem 13:3406

Hualiang A, Zhang L, Baoguo Y, Xinqiang Z, Yanji W (2014) Chin J Chem Eng 22:607

Wang P, Ma Y, Liu S, Zhou F, Yang B, Deng Y (2015) Green Chem 17:3964

Wang J, Li Q, Dong W, Kang M, Wang X, Peng S (2004) Appl Catal A 261:191

Moriarty RM, Chany CJ, Vaid RK, Prakash O, Tuladhar SM (1993) J Org Chem 58:2478

Lebel H, Leogane O (2005) Org Lett 7:4107

Hamon F, Prié G, Lecornué F, Papot S (2009) Tetrahedron Lett 50–6800

Wolff H (1946) Org React 3:307

Bhagwanth S, Waterson AG, Adjabeng GM, Hornberger KR (2009) J Org Chem 74:4634

Qin L, Cui H, Zou D, Li J, Wu Y, Zhu Z, Wu Y (2010) Tetrahedron Lett 51:4445

Toto P, Gesquiere JC, Cousaert N, Deprez B, Willand N (2006) Tetrahedron Lett 28:4973

Kianmehr E, Baghersad MH (2011) Adv Synth Catal 353:2599

Yang X, Zhang Y, Ma D (2012) Adv Synth Catal 354:2443

Vinogradova E, Park NH, Fors BP, Buchwald SL (2013) Org Lett 15:1394

Chikkade PK, Kuninobu Y, Kanai M (2015) Chem Sci 6:3195

Sardarian AR, Inaloo ID (2015) RSC Adv 5:76626

Sardarian A, Zangiabadi M, Dindarloo I (2016) RSC Adv 6:92057

Nguyen TT, Phan NTS (2014) Catal Lett 144:1877

Németh J, Debreczeni N, Gresits I, Bálint M, Hell Z (2015) Catal Lett 145:1113

Hosseinzadeh R, Aghili N, Tajbakhsh M (2016) Catal Lett 146:193

Jiao J, Murakami K, Itami K (2016) ACS Catal 6:610

Ley SV, Thomas AW (2003) Angew Chem Int Ed 42:5400

Rao DN, Rasheed S, Vishwakarma RA, Das P (2014) Chem Commun 50:12911

Rao DN, Rasheed S, Kumar KA, Reddy AS, Das P(2016) Adv Synth Catal 358:2126

Sahoo H, Mukherjee S, Grandhi GS, Selvakumar J, Baidya M (2017) J Org Chem 82:2764

Larsson PF, Correa A, Carril M, Norrby PO, Bolm C (2009) Angew Chem Int Ed 48:5691

Sharma KK, Sharma S, Kudwal A, Jain R (2015) Org Bio Mol Chem 13:4637

Jiang L, Job GE, Klapars A, Buchwald SL (2003) Org Lett 5:3667

Yuan H, Chen Y, Song J, Chen C, Chen B (2013) Chin J Chem 31:1247

Mallesham B, Rajesh BM, Reddy PR, Srinivas D, Trehan S (2003) Org Lett 5:963

Kang SK, Kim DH, Park JN (2002) Synlett 3:427

Strieter ER, Bhayana B, Buchwald SL (2009) J Am Chem Soc 131:78

Acknowledgements

Authors gratefully acknowledge the financial support of this work by the research council of Shiraz University.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Sardarian, A.R., DindarlooInaloo, I. & Zangiabadi, M. Selective Synthesis of Secondary Arylcarbamates via Efficient and Cost Effective Copper-Catalyzed Mono Arylation of Primary Carbamates with Aryl Halides and Arylboronic Acids. Catal Lett 148, 642–652 (2018). https://doi.org/10.1007/s10562-017-2277-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-017-2277-0