Abstract

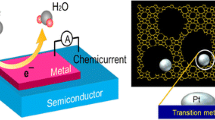

A pulse of high kinetic energy electrons can be generated after deposition of external energy to a metallic surface, such as the absorption of light or exothermic chemical processes. These energetic electrons are not at thermal equilibrium with the phonons of the metal atoms and are called “hot electrons”. The detection of hot electrons on the surface of a catalyst is an active subject in the field of surface science. More significantly, it has been found that surface processes, including desorption, diffusion, and chemical rearrangement of atomic and molecular species, are driven by the flow of hot electrons on the surface. The strong correlation between hot electron generation and surface phenomena suggests that hot electrons can be used to control surface chemical reactions, which is known as hot electron chemistry. In this Perspective, research strategies for electronic control of catalytic reactions by engineering metal–oxide interfaces and manipulating hot electron flux are discussed. Catalytic nanodiodes consisting of a metal catalyst film, semiconductor layers, and Ohmic contact pads have revealed a strong correlation between the hot electron flux (chemicurrent) and catalytic activity under CO oxidation and hydrogen oxidation. We highlight recent results on new architecture for hot electron collection, including a Au/TiO2 nanodiode and a graphene/TiO2 nanodiode, that show that hot electrons can be used for quantitative measurement of catalytic activity. We show that the direct conversion of photon energy to hot electron flows can be achieved in metal–semiconductor nanodiodes. Hot electrons and surface plasmons can be used to change the catalytic activity using metal–oxide nanocatalysts. This strategy requires an understanding of both the electronic and chemical properties of metal–oxide interfaces, as well as the combined measurement of electronic and chemical signals on nanoscale electronic devices during catalytic reactions, and therefore can be referred to as “catalytronics”, which is the combination of catalysis and electronics.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Elucidating molecular energy transfer processes at metal surfaces is challenging because the energy dissipates within femtoseconds or picoseconds by non-adiabatic electronic excitation (i.e., e–h pairs) or adiabatic lattice vibration (i.e., phonons), respectively [1, 2]. Owing to great endeavors in both experimental and theoretical studies, it has been recently proposed that energetic electrons, which are often called “hot electrons”, play a crucial role in determining surface reactions (Fig. 1). In particular, transport of these hot electrons at a metal–oxide interface has been presumed to be a decisive electronic origin of the enhanced activity and selectivity on the surface of catalysts [3,4,5,6].

a Schematic of non-adiabatic electron excitation and generation of hot electrons on a metallic surface via the deposition of energy from photons, exothermic reactions, and electrons. b Scheme of hot electron-driven surface processes, including desorption, diffusion, chemical rearrangement, and catalytic reaction

Early experimental evidence of electron-mediated energy transfer on the surface was primarily found in simple reaction processes (e.g., adsorption of atoms, dissociative chemisorption of gas molecules, and by monitoring chemiluminescence or exoelectron emission on well-defined metal surfaces at low operating pressure) [1]. In these processes, it is possible to observe non-adiabatically induced electrons on the metal surface during the reactions because the kinetic energy of the electrons is greater than the work function of the metal (Fig. 1a). Although these phenomena emphasize the importance of electronic excitation in surface reactions, detection of hot electrons during practical catalytic reactions of lower exothermicity has been far more technically demanding due to their quick thermalization. The development of catalytic nanodiodes to measure the flow of hot electrons generated at metal–oxide interfaces has proven that exothermic catalytic reactions on platinum induce a steady flux of hot electrons. Based on the simultaneous measurement of hot electrons and chemical reactions, it was found that chemicurrent correlates with turnover frequency (TOF) [7,8,9,10,11]. Thus, charge transport across the metal–oxide interface also influences the catalytic activity and product distribution of multipath reactions. In the surface chemistry community, it has been found that surface processes, including desorption, diffusion, and chemical rearrangement of atomic and molecular species, are driven by the flow of hot electrons on the surface (Fig. 1b) [12,13,14,15]. The strong correlation between hot electron generation and surface phenomena implies a new concept of hot electron-driven surface chemistry.

In this Perspective, we discuss hot electrons generated under various structural schemes (i.e., metal alone, metal–semiconductor, and metal–insulator–metal). To probe the hot electron flux generated at gas–solid and liquid–solid interfaces, metal–semiconductor (MS) Schottky diodes have been employed as unique hot electron detectors; this area of research is outlined in Sect. 2. In Sect. 3, we highlight recent results on energy conversion from photon energy to electrical energy using hot electron detection in metal–semiconductor nanodiodes. In Sect. 4, we discuss possible strategies for the electronic control of catalytic reactions by engineering the metal–oxide interfaces and manipulation of the hot electron flux. Hot electrons and surface plasmons can be used to change the catalytic activity using metal–oxide nanocatalysts. We suggest that combined research efforts that employ nanoscale electronic devices under catalytic reactions refers to the new concept of “catalytronics”, which is the combination of catalysis and electronics.

2 Hot Electron Generation by Chemical Reaction

Tremendous effort has been spent to understand the fundamental nature of heterogeneous reactions in gas and solution phase over the past two centuries, which is of great interest in the chemical and energy industries. However, because of the complexity of energy dissipation channels at gas–solid or liquid–solid interfaces, a detailed understanding of the reactive processes at catalytic surfaces still remains ambiguous [1]. During chemical reactions on a metal surface, energy from the reactions can be transferred into both nuclear and electronic degrees of freedom of the substrate, producing quantized phonons and electronic excitation, respectively. It is now well known that non-adiabatic electron transfer is a dominant channel for energy dissipation from surface reactions where electron–hole pairs are excited with kinetic energy of 1–3 eV [1, 2]. Even though it has been assumed that these energetic hot electrons play a critical role in many chemical processes, they are subject to lose their energy within a few femtoseconds via electron–electron scattering and electron–phonon coupling [16]. Because of the quick relaxation of hot electrons, it is challenging to observe and analyze their dynamics during chemical reactions on metal surfaces.

Conventional experimental evidence of hot electron generation during atomic or molecular surface processes reports the production of exoelectrons and chemiluminescence [1, 16]. On metal surfaces, chemically excited electrons can be detected before reaching thermal equilibrium only when the electrons have sufficient energy to overcome the surface barrier leading to emission into a vacuum; thus, these experiments are limited to surface reactions with a very electronegative atom or molecule adsorbed on a metal with a low work function. Comparing theory to the measured vibrational state distribution of scattered molecules on a metal surface also demonstrates electron-mediated energy transfer during surface reactions; however, the interpretation is still incomplete [16, 17].

One breakthrough for the detection of hot electrons under chemical reactions is the development of the Schottky diode, which is a unique hot carrier detector composed of an ultrathin metal film and a semiconductor [18, 19]. According to the basic concept of this approach, hot electrons are detected as a current signal because the potential barrier formed at the metal–semiconductor interface allows the immediate separation of electron–hole pairs as they are created by chemical reactions on the metal surface, thus resulting in an irreversible flow of hot electrons. A similar principle can be adapted in the structures of metal–oxide–semiconductors and metal–insulator–metals to obtain the so-called “chemicurrent” [1]. Initial experiments successfully demonstrated that the adsorption of atomic H on a transition metal surface produces hot electrons via a non-adiabatic energy transfer mechanism by measuring the chemicurrent on a Ag/n-Si Schottky diode [18]. Through a series of studies, electron-mediated energy transfer was confirmed in the chemisorption of various atomic or molecular gases (e.g., D, O, Xe, NO, NO2, C2H4, and C6H6). Furthermore, due to advantages of the Schottky diode in the detection of hot electrons under chemical reactions, Schottky diodes have been applied to studies of the dynamics of hot electrons generated on various catalytic surfaces during more complex surface reactions (e.g., catalytic oxidation of CO and H2) to describe a clear correlation between reaction rates and the magnitude of the hot electron flow [8, 11, 20].

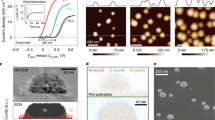

Recently, it has been desirable to develop nanomaterials with well-defined surfaces for enhanced catalytic activity and selectivity. The worth of metal nanocatalysts stems not only from the high surface-to-volume ratio, but more importantly from the size-, shape-, and composition-dependent catalytic properties. Although it is well known that significant changes in catalytic performance are shown with metal nanoparticles (NPs) 1–10 nm in size, the clear origin of these phenomena is still veiled because of a lack of sophistication in the experimental measurements [2]. To study the dynamics of hot electrons generated on nanocatalysts, a modified hybrid nanodiode was proposed by Park et al. where Pt NPs of a defined size are deposited as two-dimensional arrays on a Au/TiO2 Schottky nanodiode (Fig. 2a) [10]. Because the thin Au film is chemically inert and provides an electrical connection between the separated NPs, hot electron flows created on the Pt NPs during exothermic catalytic reactions are measured as a chemicurrent across the Schotttky barrier formed at the Au/TiO2 interface (Fig. 2b). With a comparable study of the catalytic activity of Pt NPs under CO oxidation, it was clearly confirmed that the chemicurrent is proportional to the turnover rate and is affected by the type of capping layers on the NPs.

Reprinted from Refs. [21, 22] with permission. Copyright 2015 Wiley [21] and copyright 2016 American Chemical Society [22]

a Schematic of a catalytic Pt NPs/Au/TiO2 nanodiode for hot electron detection under chemical reactions. b Energy band diagram for the Pt NPs/Au/TiO2 nanodiode. Hot electrons generated on the Pt surface during exothermic chemical reactions can be detected as a steady-state current overcoming the Schottky barrier. c Impact of the size of Pt NPs on hot electrons proved by temperature dependence of the chemicurrent, measured on Au/TiO2 nanodiodes with various sizes of Pt NPs and thicknesses of Au film. TEM images of 1.7 and 4.5 nm Pt NPs. d Chemicurrent as a function of TOF for H2 oxidation, measured using graphene-based catalytic nanodiodes at different concentrations of H2. Inset shows schematic (top) and energy band diagram (bottom) for a Pt NPs/graphene/TiO2 nanodiode.

Furthermore, it was clarified that the magnitude of the hot electron flow is dependent on the size of the NPs, leading to a variation in the catalytic activity [21]. As shown in Fig. 2c, the chemicurrent measured from smaller Pt NPs (i.e., 1.7 nm) presents a significantly increased signal compared with larger Pt NPs (i.e., 4.5 nm) during H2 oxidation under identical reaction conditions because the catalytic activity of the smaller Pt NPs improved. This demonstrates a tendency for the chemicurrent to decrease as the size of the Pt NPs increases, which is attributed to attenuation of the hot electrons that results in the decline in catalytic activity. Apart from the size effect of NPs, catalytic reaction kinetics was also investigated using Arrhenius plots of the chemicurrent and turnover rate, in which the activation energy obtained from the chemicurrent measurement is higher than the turnover rate. This feature is different from the results from thin-film catalysts, indicating that the capping layer that exists on the surface of the NPs causes an additional potential barrier for the transport of hot electrons.

To more accurately quantify the generation of hot electrons on catalytic NPs during chemical reactions, Lee et al. focused on developing a new graphene-based catalytic nanodiode where a single graphene layer is incorporated on the device instead of the thin Au layer used in previous research [22]. The schematic and the energy band diagram of the Pt NPs/graphene/TiO2 catalytic nanodiode are shown in the inset of Fig. 2d. Because graphene has fascinating and unique electronic, thermal, and chemical properties, it has been widely accepted as an alternative material for existing applications. In particular, integration of graphene in catalytic materials has recently gained great attention because of the possibility for facilitating electron transport and improving catalytic activity [23]. Indeed, when the chemicurrent produced from Pt NPs was measured using a graphene-based catalytic nanodiode under H2 oxidation reaction conditions, it was observed that the detection efficiency for hot electrons was significantly enhanced because the potential barrier at the Pt NP/graphene interface decreased. Thus, the chemicurrent has a clear linear relationship with the turnover rate for H2 oxidation on Pt NPs (Fig. 2d), indicating that the utilization of a single graphene layer is beneficial for the detection of hot electrons and the study of reaction kinetics on various nanocatalysts.

Most recently, an additional effort to investigate the reaction processes associated with hot electrons at the liquid–solid interface has been accomplished using a metal–semiconductor Schottky nanodiode [24, 25]. Because non-adiabatically excited electrons on the surface of metal catalysts during exothermic reactions are transported across the Schottky barrier formed inside the catalytic nanodiode, the hot electrons can be probed as a chemicurrent even during chemical reactions in a liquid medium (Fig. 3a). To evaluate this phenomenon, the chemicurrent was measured during the catalytic decomposition of an aqueous hydrogen peroxide (H2O2) solution on Ag/n-Si and Pt/n-Si Schottky nanodiodes, where the thickness of the metal film is in the range of 5–15 nm, which is comparable to the mean free path of hot electrons [24]. While the reaction rate was monitored using a gas chromatograph and pressure gauge, the signal of chemicurrent measured on the catalytic nanodiode showed a linear correlation with the rate of oxygen evolution. Given the fact that the magnitude of the hot electron flow is dependent on both the concentration of H2O2 and temperature, it is obvious that the chemicurrent indeed originated from the catalytic reaction occurring at the liquid–solid interface. For further clarification, the activation energies for hot electron generation and the corresponding rate of oxygen evolution on the catalytic surface were determined from the slopes of the Arrhenius plots of chemicurrent and turnover rate, respectively [25]. The activation energy for the decomposition of H2O2, determined using the chemicurrent measured on the Pt/n-Si nanodiode, is comparable to the value obtained from the turnover rate measurement (Fig. 3b), implying that hot electrons play an important role in chemical reaction processes on the metallic surface under aqueous conditions. It is also worthwhile to note that the detection probability of hot electrons can be up to 10−1 electrons/O2 molecule during a solution-based reaction, while the detection probability is much less for gas–solid reactions on the same nanodiodes. Thus, it is shown that the quantitative description of the dynamics of hot electrons using catalytic nanodiodes is a powerful technique for obtaining a microscopic understanding of non-adiabatic energy transfer during catalytic reactions. Consequently, catalytic nanodiodes can be easily adapted for various reactions and applications in the field of catalysis.

Reprinted from Ref [25] with permission. Copyright 2016 American Institute of Physics

a Schematic of the concept detecting hot electrons during catalytic reactions at metal–liquid interfaces using a catalytic metal/semiconductor nanodiode. Inset shows (1) excitation and (2) ballistic transport of a hot electron across the Schottky contact. b Activation energies determined from Arrhenius plots of chemicurrent and rate of oxygen evolution from the surface of the 10 nm Pt/n-Si nanodiode during the decomposition of a 5% aqueous H2O2 solution.

3 Hot Electron Generation by Photons

Hot electrons generated at the metal surface by incident light are detected as a steady-state current by the Schottky barrier at a metal–semiconductor junction [26]. Hot electrons have a mean free path several tens of nanometers in length; thus, they can be efficiently captured in a metal film thinner than the mean free path [27]. However, as the thickness of the metal becomes thinner, the amount of absorbed light decreases and the generation of hot electrons is also reduced. To increase the efficiency of photovoltaics based on hot electrons generated in thin metal, localized surface plasmon resonance (LSPR) has received much attention and has been investigated in various forms [28, 29]. LSPR can occur when light enters a metal nanostructure in which confined free electrons oscillate with the same frequency as the radiation, which results in an increase in the intensity of the electromagnetic field [30]. Consequently, plasmonic nanostructures can efficiently capture light. Lee et al. proposed a scheme for amplifying the hot electrons by enhanced light absorption using LSPR via a connected gold island nanostructure modified from thin film gold by annealing the thin film in air [31]. Figure 4a shows the incident photon-to-current efficiency (IPCE) measured on a plasmonic Au/TiO2 nanodiode as a function of photon energy. To verify the presence of LSPR, the IPCE data were fitted to Fowler’s law, which indicates a relationship between the hot electron flux and photon energy in a process of internal photoemission [32]. Note that there is a peak at about 2.3 eV that deviates from Fowler’s law. This peak corresponds to the LSPR of gold and the increase in IPCE means that the production of hot electrons was enhanced as light absorption on the gold increased.

Reprinted from Refs. [31, 34, 36] with permission. Copyright 2011 American Chemical Society [31], copyright 2015 Institute of Physics Science [34], and copyright 2016 Nature [36]

a IPCE as a function of photon energy measured on a plasmonic Au/TiO2 nanodiode. The red line represents the Fowler’s law fit with fitting parameters of n = 2 and ESB = 1.2 eV. The inset shows the plasmonic Au/TiO2 nanostructure. b Left scale photocurrent measured on a Au–TiO2–Ti tunneling nanodiode with different thicknesses of TiO2. Right scale the calculated tunneling probability. The inset shows the tunneling of a hot electron in the metal–insulator–metal structure. c A comparison of the power factor obtained from the Fowler’s law fitting on the IPCE measured on single, bi, triple graphene/TiO2 and Au/TiO2 diodes. Inset shows the graphene/TiO2 diode. d Schemes for nanowire-Au/TiO2 and nanotube-Au/TiO2 3D-Schottky nanodiodes.

In the Schottky barrier structure, there is a limitation that only hot electrons having energy higher than the barrier height can be detected as current. To overcome this restriction, metal–insulator–metal structures capable of capturing hot electrons with energy lower than the barrier were studied [33]. Figure 4b shows photocurrents measured depending on the thickness of the insulator in a metal–insulator–metal tunneling nanodiode consisting of Au/TiO2/Ti [34]. By fabricating an insulator layer that is very thin (i.e., <10 nm), hot electrons generated in the gold can tunnel through the TiO2 layer and be collected in the Ti, thus resulting in the production of steady-state current.

Recently, interest in the role of graphene for enhancing hot electron generation has increased. In graphene, a single electron with high energy from impact ionization, exhibited by the linear and gapless band structure of graphene, produces multiple electron–hole pairs, which is referred to as carrier multiplication [35]. To utilize the hot electrons generated by carrier multiplication in graphene, Lee et al. suggest the graphene/TiO2 Schottky nanodiode shown in Fig. 4c [36]. The photocurrents and IPCE were measured on the graphene/TiO2 nanodiode, and the exponent α (i.e., the power factor) was obtained by fitting the IPCE data to Fowler’s law. The α of graphene/TiO2 is around 4.2, which is much higher than that for most metals (i.e., 2) [32]. This is clear evidence that carrier multiplication contributes significantly to the generation of hot electrons in graphene.

For high conversion efficiency, Schottky diodes based on a planar interface where the metal film is deposited onto a semiconductor are not suitable because they only allow hot electrons to be captured in a single direction [37]. In addition, under illumination at the normal incidence angle, hot electrons that follow the momentum of the electric field perpendicular to the light initially travel parallel to the interface and not towards it, resulting in a lower probability of injection into the semiconductor [38]. One approach to overcome this restriction is a three-dimensional structure that can maximize the collection of hot electrons by detection in all directions [39]. Knight et al. demonstrated that 3D Schottky structures created by embedding a Au nanowire into silicon have a 25-fold higher energy conversion efficiency than a planar structure [40]. Furthermore, by fabricating a vertical nanowire or nanohole structure (Fig. 4d), it is expected that the increased lateral Schottky interface of the 3D nanostructure can amplify photocurrent production [41].

4 Strategies for Hot Electron-Mediated Catalytic Reactions

Electronic control of a catalytic reaction is an important goal. Recently, Deshlahra et al. found a reversible C–O stretching frequency peak shift on a Pt/TiO2 diode under forward and reverse bias created by an electric field [42]. Under negative voltage on the Pt film, resulting from electron back donation to the pi states of the CO molecules, the C–O bond was weakened and the peak was red-shifted. On the other hand, under forward bias, the CO stretching frequency peak was blue-shifted. Also, Baker et al. showed the external control of the CO oxidation rate on a catalytic Pt thin film using a Pt/n-Si catalytic nanodiode by switching the applied bias [43]. The 4 nm Pt thin film acted as the catalyst, and a Schottky barrier was formed at the Pt/n-Si junction. Under reverse bias on the Pt/n-Si junction, a negative charge accumulates on the Pt thin film and a positive charge accumulates on the n-Si. This charge accumulation can increase band bending in the n-Si, thus resulting in a high electric field at the Pt/n-Si junction (Fig. 5a). Because of the good rectification behavior of the catalytic nanodiode, reverse bias could not induce a current flow and only a high electric field was induced at the Pt/n-Si interface. Exposing the catalytic nanodiode to reaction conditions at 443 K for approximately 10 h serves as a pretreatment for deactivating the catalyst to observe the enhancement by reverse bias. The oxidized Pt thin film after pretreatment was not active in open circuit (i.e., no applied bias). However, due to the negative charge on the Pt film catalysts under reverse bias, enhancement of the catalytic activity for the production of carbon dioxide was observed. This enhancement under reverse bias is reversible, so the catalytic reaction can be turned on and off by alternating between the bias states of the device (Fig. 5b). On an oxidized Pt thin film after pretreatment, the CO oxidation reaction proceeds via a Mars-van Krevelen type mechanism in which adsorbed CO molecules react with lattice oxygen in the Pt; activation of the Pt–O bond is a rate-limiting step. Some previous studies show that a negative charge on the metal catalyst can activate the metal–O bond, thus explaining the increase in catalytic activity when the Pt catalyst has a negative bias [44].

a Band diagrams of the Pt/n-Si catalytic nanodiode in open circuit (i.e., no applied bias) and during reverse bias. Under reverse bias on the Pt/n-Si Schottky junction, a negative charge accumulates on the Pt thin film and a positive charge accumulates on the Si. b The effect of the applied reverse bias for CO oxidation on the Pt/n-Si catalytic nanodiode. The TOF is given as the number of CO2 product molecules per Pt site per minute. c TOF for CO oxidation on a Pt–CdSe–Pt nanodumbbell hybrid nanocatalyst with and without light at 533–563 K. d Catalytic activity of a Pt–CdSe–Pt nanodumbbell catalyst without light, with light having a high photon energy (2.0 eV < hν < 3.0 eV), and with light having a low photon energy (1.0 eV < hν < 2.0 eV) under CO oxidation.

Hybrid nanocatalysts consisting of metal–semiconductor junctions [45, 46] have been used to study the role of the metal–semiconductor interfaces and hot electron flows for catalytic reactions. Recently, Kim et al. reported that hot electrons generated under light illumination on Pt–CdSe–Pt nanodumbbells significantly change the catalytic reaction [47]. A both-sided Pt-tipped Pt–CdSe–Pt nanodumbbell hybrid nanostructure was synthesized by selectively growing metal tips onto semiconductor quantum nanorods. CO oxidation on the Pt–CdSe–Pt nanodumbbell hybrid nanocatalyst with and without light was carried out at 533–563 K. Under light illumination from a halogen lamp, this hybrid nanocatalyst shows a higher catalytic activity by a factor of two than when in the dark, thus representing that hot electrons generated on the CdSe nanorods by light irradiation affect the catalytic activity for CO oxidation (Fig. 5c). For the Pt–CdSe–Pt nanodumbbell hybrid nanocatalyst, photoexcited electron–hole pairs can be formed on the CdSe semiconductor upon absorption of photons; these hot electrons can then be injected into the Pt NPs and enhance the catalytic activity for CO oxidation. Additionally, catalytic activity enhancement increased linearly with light intensity. Bare Pt NPs on a silicon oxide substrate did not show any change under light irradiation because of low light absorption on the Pt NPs compared with that on the semiconductor. The effect of photon energy on the enhancement of catalytic activity was found by using two types of wavelength filter: a short-wave pass filter (SWF) that passes light with a photon energy between 2.0 and 3.0 eV, and a long-wave pass filter (LWF) that passes light with a photon energy between 1.0 and 2.0 eV. The Pt–CdSe–Pt nanodumbbells irradiated by light with a SWF that passes a higher photon energy exhibit two times higher activity for CO oxidation, compared with LWF passing a lower photon energy. In the case when irradiating with lower photon energy, the catalytic activity for CO oxidation was very similar to the dark condition (Fig. 5d). Therefore, this additional experiment explains that hot electrons can be generated under light irradiation when the light has more energy than the bandgap energy (~1.9 eV) of the CdSe nanorods, which provides more clear evidence for the direction of hot electron flow. Similar hot electron effects on the catalytic activity under light irradiation were observed for Pt NPs on a GaN substrate [48] and Au NPs on a CeO2 substrate [49]. It was found that the activity of Pt NPs on a p-doped GaN wafer increased by 17–33% under light irradiation while Pt NPs on an n-doped GaN wafer decreased by 8–15% under light irradiation, compared with no irradiation (i.e., in the dark). From these changes in the TOF of the Pt/GaN nanocatalysts, it is concluded that both the size of the metal NPs and the doping type of the semiconductor play important roles in changing the reactivity of Pt NPs. The size-dependent reactivity of the Pt NPs is explained by the mean free path of the hot carriers where more hot electrons can easily arrive at the Pt surface of smaller NPs. Doping-type-dependent activity is related to the flow direction of electrons and holes under light irradiation. In the case of Pt NPs on n-doped GaN nanocatalysts, the recombination of electrons from the Pt NPs with holes from the n-type GaN semiconductor under illumination is expected with a given energetic alignment. Likewise, electron transfer to the Pt NPs is expected for the p-type GaN supports. Similarly, Au/n-doped CeO2 exhibited lower catalytic activity when under light illumination [49], which confirms the role of hot electrons and doping of the oxide on the change in catalytic activity.

A plausible mechanism for how hot electrons are generated from external light irradiation and induce catalytic CO oxidation on metal surfaces with oxygen activation involves the presence of negatively charged reaction intermediates. Generally, CO oxidation has two competing processes for CO desorption and oxygen activation. CO is easily desorbed before the oxygen is activated to react because the energy required for CO desorption is considerably lower than the barrier for CO2 formation. However, if hot electrons are transferred to the metal–O band to facilitate the activation of oxygen, which requires higher energy than CO desorption, the formation of the CO2 product can be promoted by providing a novel reaction pathway, which is never allowed in a thermally excited system. Based on these results, it is clearly demonstrated that the flow of hot electrons across the metal–oxide interface influences the chemical processes occurring at the metal surfaces; therefore, we conclude that hot electrons are an excellent mediator for converting solar energy to chemical energy in heterogeneous catalysts.

The intrinsic correlation between catalytic reaction and hot electron flows across a metal–semiconductor junction suggests several model systems for electronic control of catalytic activity. Various schemes have been suggested to utilize hot electrons for catalytic reaction (Fig. 6). For example, the catalytic reaction can be tuned by an electric field because charge depletion occurs when there is an external bias between the metal–semiconductor Schottky junction (Fig. 6a) [42, 43]. Excitation of electron–hole pairs upon photon absorption on the semiconductor can lead to the injection of hot carriers onto the catalytic metal surface, followed by a change in the catalytic activity (Fig. 6b) [47, 50]. Utilizing surface plasmon resonance (SPR), which is a strong electromagnetic field near the surface of noble metal nanostructures created by resonant oscillation of free electrons at the same wavelength as the incident photons, is another intriguing way for controlling catalytic reactions [51, 52]. Wang et al. found that a high concentration of hot electrons can tunnel through the insulating layer and generate photocurrent in a metal–insulator–metal device [53]. Figure 6c shows a proposed similar scheme in which there are plasmonic noble metal nanostructures and catalytic portions separated by thin insulating layers that work as the tunneling barrier. During light illumination, photons can be absorbed on the plasmonic noble metal nanostructures and the generated hot electrons are injected into the catalytic portions across the thin oxide layers, which leads to a change in catalytic activity. The major shortcoming of the metal catalyst is the short range of the electron mean free path, which can induce extinction of hot electrons before they arrive at the metal surface. To overcome this problem with a short electron mean free path in the metal, another proposed scheme is an inverse catalyst that is composed of a reactive oxide for the catalytic components and a noble metal for the SPR source (Fig. 6d). Hot carriers, generated by SPR upon absorption of photons on the plasmonic noble metal nanostructure, can transfer into the reactive oxide and arrive at the oxide surface and have an effect on the catalytic activity. A three-terminal catalytic device with a source, drain, and gate can provide new opportunities for electronic control of a catalytic reaction by altering the electric field in the pathway of the hot electrons (Fig. 6e). Overall, the intrinsic relation between catalytic activity and the generated hot electron flux indicates the intriguing possibility for tailoring chemical reactions by manipulating hot electron flows across metal–oxide interfaces. This research into the electronic control of catalysts requires a fundamental understanding of both the elementary processes of catalytic reactions and simultaneous measurement or utilization of hot electron flows through the metal–oxide interfaces.

Scheme for utilization of hot electrons and surface plasmons to affect catalytic reactions. Scheme to change the catalytic activity a via charge build-up on metal–semiconductor diodes by controlling the external bias and b via photon irradiation on the semiconductor. Scheme to change the catalytic activity using surface plasmons c on a metal–insulator–metal catalyst with a tunneling barrier and d on a metal–oxide inverse catalyst. e Scheme to change the catalytic activity by changing the gate bias of the three terminal devices

5 Concluding Remarks

In conclusion, we discussed aspects of electron dissipation at surfaces and the relation between charge transfer occurring at metal–oxide interfaces. We discussed strong metal–support interaction effects for various catalytic systems to address the role of metal–oxide interfaces in heterogeneous catalysis. Hot electron flow through a catalytic nanodiode provides insights into the role of electronic excitation that leads to energy conversion processes using heterogeneous metal catalysis. We found that hot electron flux is well correlated with the turnover rates of catalyzed reactions, which suggests possible applications for chemical sensors and novel energy conversion. Strategies for hot electron- and surface plasmon-driven catalytic reactions were discussed. These strategies require an understanding of both the electronic and chemical properties of metal–oxide interfaces, obtained via the combined measurement of electronic and chemical signals on nanoscale electronic devices under catalytic reactions, and can therefore open up the new field of “catalytronics”, which is the combination of catalysis and electronics.

References

Nienhaus H (2002) Surf Sci Rep 45:1

Park JY, Kim SM, Lee H, Nedrygailov II (2015) Acc Chem Soc 48:2475

Somorjai GA, Park JY (2007) Catal Lett 115:87

Somorjai GA, Park JY (2008) Top Catal 49:126

Freund H-J (2016) J Am Chem Soc 138:8985

Calaza F, Stiehler C, Fujimori Y, Sterrer M, Beeg S, Ruiz-Oses M, Nilius N, Heyde M, Parviainen T, Honkala K, Häkkinen H, Freund H-J (2015) Angew Chem Int Ed 54:12484

Renzas JR, Somorjai GA (2010) J Phys Chem C 114:17660

Park JY, Renzas J, Hsu BB, Somorjai GA (2007) J Phys Chem C 111:15331

Somorjai GA, Bratlie KM, Montano MO, Park JY (2006) J Phys Chem B 110:20014

Park JY, Lee H, Renzas JR, Zhang Y, Somorjai GA (2008) Nano Lett 8:2388

Hervier A, Renzas JR, Park JY, Somorjai GA (2009) Nano Lett 9:3930

Shen T, Wang C, Abeln G, Tucker J (1995) Science 268:1590

Fomin E, Tatarkhanov M, Mitsui T, Rose M, Ogletree DF, Salmeron M (2006) Surf Sci 600:542

Choi B-Y, Kahng S-J, Kim S, Kim H, Kim HW, Song YJ, Ihm J, Kuk Y (2006) Phys Rev Lett 96:156106

Henzl J, Mehlhorn M, Gawronski H, Rieder K-H, Morgenstern K (2006) Angew Chem Int Ed 45:603

Wodtke AM (2016) Chem Soc Rev 45:3641

Bünermann O, Jiang H, Dorenkamp Y, Kandratsenka A, Janke SM, Auerbach DJ, Wodtke AM (2015) Science 350:1346

Nienhaus H, Bergh H, Gergen B, Majumdar A, Weinberg W, McFarland E (1999) Phys Rev Lett 82:446

Nienhaus H, Bergh HS, Gergen B, Majumdar A, Weinberg WH, McFarland EW (2000) Surf Sci 445:335

Park JY, Somorjai GA (2006) ChemPhysChem 7:1409

Lee H, Nedrygailov II, Lee C, Somorjai GA, Park JY (2015) Angew Chem Int Ed 54:2340

Lee H, Nedrygailov II, Lee YK, Lee C, Choi H, Choi JS, Choi C-G, Park JY (2016) Nano Lett 16:1650

Guo S, Dong S, Wang E (2009) ACS Nano 4:547

Nedrygailov II, Lee C, Moon SY, Lee H, Park JY (2016) Angew Chem 128:11017

Nedrygailov II, Lee C, Moon SY, Lee H, Park JY (2016) Rev Sci Instrum 87:114101

McFarland EW, Tang J (2003) Nature 421:616

Hohlfeld J, Wellershoff S-S, Güdde J, Conrad U, Jähnke V, Matthias E (2000) Chem Phys 251:237

Knight MW, Sobhani H, Nordlander P, Halas NJ (2011) Science 332:702

Atwater HA (2007) Sci Am 296:56

Clavero C (2014) Nat Photonics 8:95

Lee YK, Jung CH, Park J, Seo H, Somorjai GA, Park JY (2011) Nano Lett 11:4251

Fowler RH (1931) Phys Rev 38:45

Wang F, Melosh NA (2011) Nano Lett 11:5426

Lee C, Nedrygailov II, Lee YK, Ahn C, Lee H, Jeon S, Park JY (2015) Nanotechnology 26:445201

Plotzing T, Winzer T, Malic E, Neumaier D, Knorr A, Kurz H (2014) Nano Lett 14:5371

Lee YK, Choi H, Lee H, Lee C, Choi JS, Choi C-G, Hwang E, Park JY (2016) Sci Rep 6:27549

Scales C, Berini P (2010) IEEE J Quantum Electron 46:633

Schuck PJ (2013) Nat Nanotechnol 8:799

White TP, Catchpole KR (2012) Appl Phys Lett 101:073905

Knight MW, Wang Y, Urban AS, Sobhani A, Zheng BY, Nordlander P, Halas NJ (2013) Nano Lett 13:1687

Lee YK, Lee H, Lee C, Hwang E, Park JY (2016) J Phys 28:254006

Deshlahra P, Schneider WF, Bernstein GH, Wolf EE (2011) J Am Chem Soc 133:16459

Baker LR, Hervier A, Kennedy G, Somorjai GA (2012) Nano Lett 12:2554

Zhang Z, Yates JT Jr (2010) J Am Chem Soc 132:12804

Mokari T, Sztrum CG, Salant A, Rabani E, Banin U (2005) Nat Mater 4:855

Saunders AE, Popov I, Banin U (2006) J Phys Chem B 110:25421

Kim SM, Lee SJ, Kim SH, Kwon S, Yee KJ, Song H, Somorjai GA, Park JY (2013) Nano Lett 13:1352

Kim SM, Park D, Yuk Y, Kim SH, Park JY (2013) Faraday Discuss 162:355

Kim SM, Lee H, Goddeti KC, Kim SH, Park JY (2015) J Phys Chem C 119:16020

Schäfer S, Wyrzgol SA, Caterino R, Jentys A, Schoell SJ, Hävecker M, Knop-Gericke A, Lercher JA, Sharp ID, Stutzmann M (2012) J Am Chem Soc 134:12528

Barnes WL, Dereux A, Ebbesen TW (2003) Nature 424:824

Eustis S, El-Sayed MA (2006) Chem Soc Rev 35:209

Wang F, Melosh NA (2013) Nat Commun 4:1711

Acknowledgements

This work was supported by the Institute for Basic Science (IBS) [IBS-R004-A2-2017-a00].

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Park, J.Y., Lee, S.W., Lee, C. et al. Strategies for Hot Electron-Mediated Catalytic Reactions: Catalytronics. Catal Lett 147, 1851–1860 (2017). https://doi.org/10.1007/s10562-017-2092-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-017-2092-7