Abstract

A novel catalytic system based on palladium nanoparticles (Pd-NPs) immobilized onto the surface of graphene oxide (GO) modified by poly 2-acrylamido-2-methyl-1-propansulfonic acid decorated with magnetic Fe3O4 was designed, prepared and fully characterized. It was successfully examined as a highly efficient heterogeneous catalyst in the Suzuki–Miyaura cross coupling reaction. The results showed excellent catalytic activity for the cross coupling of aryl bromides, alkyl iodides as well as aryl chlorides as the challenging substrates. It was easily separated by an external magnet and reused without any pre-activation at least in seven consecutive runs without any loss in its catalytic activity as well as any detectable Pd leaching. This study demonstrates the great potential of polymeric-functionalized GO as a support owing to its high loading and suitable dispersing of Pd-NPs, for the development of metal–graphene nanocomposites in industrial scale.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Historically, from the date discovered, Pd-catalyzed C–C bond formation has always attracted much intention and stirred up the interest of synthetic organic chemists [1,2,3,4,5,6,7,8,9]. In addition, it has a significant impact on the academia as well as chemical industries, especially those working on the total synthesis of natural products or producing intermediates for the currently prescribed drugs, respectively [10, 11]. Transition metal-catalyzed cross-coupling reactions undoubtedly, are the most important processes for constructing carbon–carbon bonds [12]. Among them, the Pd-catalyzed cross-coupling reactions, and in particular “Suzuki–Miyaura reaction” [13,14,15] is the most admired and practically employed which led to awarding the 2010 Nobel Prize in Chemistry to Professor Akira Suzuki, shared with Richard Heck and Ei-ichi Negishi [16].

The increasing trend in Suzuki–Miyaura coupling is mostly due to the commercially or readily availability of the starting materials which are mostly non-toxic and easy to handle [17]. The biaryls as the products of Suzuki reaction are the involved as scaffold in various natural products. They are frequently used as suitable ligands and also are the key intermediates in the productions of different drugs, herbicides etc. [18,19,20,21].

The original Suzuki reaction is generally performed in the presence of relatively large amounts of palladium and copper in organic solvents which are cost-effective and environmentally inadmissible. However, this palladium-catalyzed reaction has been extensively investigated during the years to improve the reaction conditions, thus a wide variety of modifications has been reported so far, including the utilization of Pd-nanoparticles (Pd-NPs) as the catalyst.

Catalysts based on Pd-NPs often suffer from two main drawbacks. The first one is extensive leaching of the active metal species during reactions which eventually leads the less catalytic activity. Secondly, aggregation of the MNPs which leads to increase the size of MNPs and their relative surface area becomes smaller, thus, their activities are reduced significantly. Therefore, choosing an appropriate support to obtain suitable sized Pd-NPs in order to avoid their leaching is still in much demand. Graphene has been proven as one of the best support for different metals because of its large specified surface area, excellent electrical conductivity and high chemical and thermal stability [22,23,24]. Many ongoing attempts are focused on deposition of various MNPs, metal oxides, polymers and chalcogenides on graphene oxide (GO) sheets due to its superior functionality [25,26,27,28,29,30,31].

The recovery of expensive Pd based catalysts by magnetic nanoparticles (Mag) without losing their catalytic activity is a prominent feature in the maintainable catalytic processes and green chemistry [32, 33].

In addition to the advantages of GO and Mag in catalytic systems, development of a suitable stabilizer for uniformly distribution of nanoparticles sizes as well as capping agent gives nanoparticles a high desirable stability. Consequently, to this purpose a variety of stabilizers were examined. In 2000, the first Pd(0) species immobilized onto a polymer was reported by El-Sayed et al. [34]. They prepared and applied PVP as catalysts in the coupling of aryl iodides with phenylboronic acid in aqueous media via Suzuki reaction. Furthermore, other polymeric stabilizers such as poly(amido-amine) dendrimers [34,35,36,37,38], polyvinylpyrrolidone [39], poly(amino acetanilide) composite [40], polypyrrole [41], poly(p-phenyleneethynylene) [42], porous ionic copolymer [43] and biopolymer complex [44, 45] were also used in the Suzuki–Miyaura reaction. Despite these noticeable achievements obtained in the field of polymeric stabilizers, the development of hydrophilic polymeric networks with functional groups such as –SO3H, –COOH, –CONH2, –OH, and –NH2 for the protection of Pd-NPs has still remained a great challenge, especially in the case of Suzuki coupling reaction.

We are interested in Pd-catalyzed reactions [46,47,48]. We recently immobilized PdCl2 on modified poly(styrene-co-maleic anhydride) and used it as a highly active and recyclable catalyst for the Suzuki–Miyaura and Sonogashira reactions [49]. Very recently we disclosed the superiority of Pd(0) encapsulated nanocatalysts as an efficient catalytic systems for Pd-catalyzed organic transformations [50]. We also used the easily separable magnetic Fe3O4 as a component in our nano-catalytic systems [51,52,53].

Armed with these experiences, herein, we wish to reveal the design of a highly dispersed catalytic system in green environment which could be separated from the reaction mixture and recycled easily several times without appreciable loss of its catalytic activity.

In this line, we wish to introduce a novel catalytic system, denoted as Pd/GO/Fe3O4/PAMPS including, Pd-NPs immobilized onto the surface of graphene oxide (GO) modified by poly 2-acrylamido-2-methyl-1-propansulfonic acid (PAMPS), decorated with magnetic Fe3O4. This catalytic system was used successfully in Suzuki cross coupling reaction.

2 Experimental

2.1 Characterization

All chemicals were purchased from international commercial suppliers. The solvents were purified and dried using standard procedures. X-ray photoelectron analysis (XPS) was performed using a VG multilab 2000 spectrometer (ThermoVG scientific) in an ultrahigh vacuum. A Shimadzu model AA-680 atomic absorption spectrometer equipped with deuterium background correction was employed for the determination of amount of Pd. The elemental evaluation was performed using Energy-dispersive X-ray spectroscopy (EDX) (Philips XL-30). Transmission electron microscope (TEM) image of GO/Fe3O4/PAMPS/Pd nanocomposite was taken using Philips CM-30 transmission electron microscope with an accelerating voltage of 150 kV. The crystalline phases of the nanoparticles were measured by X-ray powder diffraction (XRD) measurements (Siemens D5000 diffractometer). Fourier transform infrared (FT-IR) spectra were recorded using a BOMEM MB-series FT-IR spectrometer in the form of KBr pellets. Thermogravimetric analysis (TGA) was performed by a thermal analyzer instrument (TGA/DTA BAHR: STA 503) from 25 to 1000 °C at a heating rate of 10 °C/min under air. For investigation of the magnetic property, a vibrating sample magnetometer (VSM) from −10,000 to +10,000 Oe at room temperature was measured by Meghnatis Daghigh Kavir Company (MDK) Iran. 1H-NMR spectra were recorded on a BRUKERDRX-300 AVANCE spectrometer. CDCl3 and TMS were used as the solvent and internal standard, respectively. Melting points were measured on an Electrothermal 9100 apparatus and are uncorrected. Gas chromatography was performed on a Trace GC ultra from the Thermo Company equipped with FID detector and Rtx®-1 capillary column.

2.2 Preparation of the Catalyst System

2.2.1 Synthesis of GO

Graphene oxide was prepared via a modified Hummers’ method from graphite powder, in accordance with previously reported method [54]. In brief, graphite powder (5 g) was suspended in deionized water (100 mL) and dispersed for 3 h using an ultrasonic bath. Then, KMnO4 (1 g) was added to this suspension gradually under stirring for 15 min. This solution was stirred for 4 h then, diluted by addition of deionized water (250 mL) while the temperature kept below 50 °C. Then, H2O2 30% (10 mL) was added to this mixture till the color of the mixture changed into golden yellow. Finally, the obtained product was filtered and washed several times with HCl (0.1 M) for the removal metal ions, followed by addition of deionized water (250 mL) to decrease the acidity. The resulting GO solid was dried at 70 °C in a vacuum oven.

2.2.2 Synthesis of Magnetic GO

Magnetic GO was synthesized by dispersion of GO (1.5 g) and deionized water (150 mL) using an ultrasonic bath for 1 h. Then, the iron salt (1.2 g FeCl3·6H2O) was introduced to the mixture under vigorous stirring and purging of N2 gas for 30 min. Following, FeCl2·4H2O (1.8 g) was added under N2 atmosphere to the above mixture. Finally, to this mixture an ammonia solution (25%, 120 mL) was added, diluted by addition of 200 mL water and the suspension was refluxed for 2 h. The resultant GO/Fe3O4 as a black precipitate was separated by an external magnetic field and washed repeatedly with the water and ethanol, and then dried at 35 °C under vacuum overnight.

2.2.3 Synthesis of Magnetic GO Grafted by MAPTMS

In order to increase the stability and impeding the agglomeration of NPs, surface of GO/Fe3O4 sheets (1 g) was modified by 3-(trimethoxysilyl)propyl methacrylate (MAPTMS) (1.9 mL) as a silane coupling agent [55]. For this purpose, the above amounts of magnetic GO and MAPTMS was stirred in 20 mL toluene under a continuous flow of N2 gas at ambient temperature for 24 h. Finally, the prepared surface modified GO sheets were collected by an external magnet and repeatedly washed with toluene for the total elimination of the extra MAPTMS and then dried overnight in an oven under vacuum at 35 °C for 24 h.

2.2.4 Polymerization and Synthesis of GO/Fe3O4/PAMPS Nanocomposite

For the polymerization of the desired monomers on the surface of modified GO, in a typical experiment, 2-acrylamido-2-methyl-1-propansulfonic acid (AMPS) (1.0 g) and methylenbisacrylamide (MBA) (0.147 g) were added to a flask containing 1 g GO suspended in 12 mL deionized water. Then, the mixture was purged under N2 gas for 15 min to remove dissolved oxygen. Subsequently, 0.053 g azobisisobutyronitrile (AIBN) as an initiator was added to the reaction mixture, kept at 60 °C for 24 h to complete the polymerization. Finally, washing the synthesized polymer with ethanol and water (three times) and drying under a vacuum oven for 24 h at 50 °C afforded the GO/Fe3O4/PAMPS nanocomposite.

2.2.5 Synthesis of GO/Fe3O4/PAMPS/Pd Nanocomposite

For decoration of Pd-NPs, the mixture of GO/Fe3O4/PAMPS (0.5 g) and PdCl2 (0.1 g) was dispersed in H2O (50 mL) using ultrasonic bath. After being sonicated about 30 min, the reaction left to stir for 12 h at room temperature. Then, excess amount of sodium borohydride (NaBH4) solution as reducing agent was added dropwise to convert Pd(ΙΙ) ions to Pd(0). Ultimately, GO/Fe3O4/PAMPS/Pd nanocomposite was obtained by an external magnet and washed several times with distilled water, ethanol and acetonitrile to remove unanchored Pd-NPs and finally dried in vacuum oven at 60 °C for 24 h. The content of Pd was estimated to be 1.1150 mmol/g based on atomic absorption spectroscopy (AAS).

2.3 Investigations on the Catalytic Activity

2.3.1 GO/Fe3O4/PAMPS/Pd Catalyzed Suzuki–Miyaura Reaction: General Procedure

To a 10 mL flask an appropriate aryl halide (1 mmol), suitable arylboronic acid (1.2 mmol), K2CO3 (3 mmol), the above-mentioned catalyst (0.2–1 mol% Pd based on aryl halide) and 5 mL EtOH/water (1:1 V/V) were added. The mixture was stirred at reflux temperature (80 °C) for appropriate time. Upon completion of the reaction, the reaction mixture was cooled down to room temperature. Then, the solution was diluted with deionized water, and the catalyst was separated by using an external permanent magnet. The reaction solution was extracted with ethyl acetate and the organic phase was dried over MgSO4, filtered and then the solvent was evaporated off under reduced pressure. The resulting residual was purified by column chromatography on silica gel (n-hexane/ethyl acetate) to give the corresponding pure products. All products were known and identified by FT-IR and 1H NMR spectra with those of authentic samples which were found identical.

2.3.2 The Reusability Test

In order to investigate the reusability of desired nanocatalyst, the separated catalyst was washed with ethanol and water and reused in a model reaction involving 4-bromotoluene and phenyl boronic acid under already secured optimal optimized conditions.

3 Results and Discussion

Unsupported Pd-NPs have been extensively employed in various Pd catalyzed name reactions such as Suzuki [13], Heck [41], Sonogashira [56] and Negishi [57]. However, the utilization of supported Pd-NPs scarcely can be found in the chemical literature, although, the inherent tendency toward particle agglomeration makes the use of stabilizing agents or solid supports mandatory in most cases.

The purpose of this study is developing a new Pd-NPs immobilized onto a suitable support which is decorated with magnetic Fe3O4 for the ease of its separation by just an external magnet. In this line, we decided to design a novel magnetic Pd-NPs using GO and stabilizing it by the polymer.

Initially, water dispersed GO was performed from graphite, according to Hummer’s method [54]. Then, magnetic GO was prepared by introducing iron salts as illustrated in Scheme 1. The surface of magnetic GO was modified using MAPTMS to provide the reactive C=C bonds. Subsequently, AMPS as monomer and MBA as cross–linker were polymerized onto the modified magnetic GO using AIBN as initiator for radical polymerization to produce the desired polymeric network. Finally, to this polymeric segment, Pd(ΙΙ) salt was added with subsequent addition of NaBH4 as reducing agent to obtain the expected GO/Fe3O4/PAMPS/Pd catalyst.

The characterization was started by measuring the Pd content of GO/Fe3O4/PAMPS/Pd nanocomposite based on AAS analysis which found being 1.1150 mmol/g. The full characterization for proving the structure of the nano-size particles were achieved using FT-IR, XRD, XPS, TGA, TEM, VSM and EDX analysis.

For the better understanding how Pd-NPs immobilized on the surface of catalyst, another schematic was illustrated in Scheme 2. As one can see, modification the surface of GO with cross linked PAMPS carrying CONH2 and SO3H functional groups could immobilize Pd-NPs. PAMPS are believed to work as ligands, through nitrogen and oxygen atoms, thereby avoiding the need of additional ligand. In addition, hydrophilicity of this polymer was another important character for choosing PAMPS as polymeric segment.

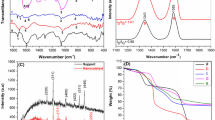

Figure 1 shows the FT-IR spectra of the GO (a), GO/Fe3O4 (b), GO/Fe3O4/MAPTMS (c), GO/Fe3O4/PAMPS (d) and GO/Fe3O4/PAMPS/Pd (e) nanocomposite. The spectra of GO (Fig. 1a) demonstrates a broad band around 3400 cm−1, which results from –OH groups of GO. Also, C–O stretching group of alkoxy and C=O stretching vibration of carbonyl were assigned at 1093 and 1623 cm−1 respectively. In the magnetic GO (Fig. 1b), the band at 570 cm−1 is attributed to Fe–O stretching vibration. The spectra of modified GO using MAPTMS (Fig. 1c) showed a broad peak between 1060 and 1110 cm−1, which was assigned to Si–O–Si. The bands at 1144 cm−1 (C–O), 1645 cm−1 (C=C), and 1725 cm−1 (C–O) are characteristic of MAPTMS, and indicated the successful linkage of MAPTMS to the surface of GO sheet. After polymerization process, the presence of bands at 1644 cm−1 and 3250–3400 cm−1 is due to CONH2 and NH, respectively (Fig. 1d). In addition, the peak around 1109–1120 cm−1 is attributed to S=O stretching of sulfonic acid. In Fig. 1e, the intensity of the peak at about 1644 cm−1 is weaker than that of GO/Fe3O4/PAMPS (Fig. 1d) due to the formation of a metal–ligand bond.

The crystalline structures of GO/Fe3O4 (a), GO/Fe3O4/PAMPS (b) and GO/Fe3O4/PAMPS/Pd (c) were characterized by powder X-ray diffraction (XRD) (Fig. 2). All these species have six strong diffraction peaks at 2θ = 30.37, 35.71, 43.42, 53.79, 57.41, 63.05 corresponding to the crystal face (220), (311), (400), (422), (511) and (440) of Fe3O4 lattice [58]. The appearance of diffraction peaks at 2θ = 40.12, 46.52 and 68.27 (weak peak) are due to the Pd (111), Pd (200) and Pd (220) lattice planes, respectively.

The XPS survey scan spectra of the GO/Fe3O4/PAMPS/Pd catalyst, Fe and Pd 3d region is shown in Fig. 3. As displayed in Fig. 3a, the peaks corresponding to C 1s, N 1s, O 1s, Fe 2p and Pd 3p & 3d was clearly observed in the XPS survey spectrum. Figure 3b, c present the curve fitted Fe 2p and Pd 3d respectively. As shown in Fig. 3b, two peaks at 711.75 and 725.42 eV, related to Fe 2p3/2 and Fe 2p1/2 respectively, which reveals the presence of Fe2+ in Fe3O4 [59]. The high-resolution XPS spectra of Pd 3d was collected and peaks at 335.48 and 340.94 eV were ascribed to Pd0 3d5/2 and 3d3/2 respectively (Fig. 3c).

The magnetic property of the GO/Fe3O4/PAMPS/Pd catalyst was measured with a vibrating sample magnetometer (VSM) from −10,000 to +10,000 Oe at room temperature (Fig. 4). As expected, the saturation magnetization value (Ms) of resultant nanocomposite is 50 emu/g, which is lower than that of pure Fe3O4 NPs because the presence of GO and polymeric moieties. In addition, VSM measured by homemade instrument (Meghnatis Daghigh Kavir Company, Iran), does not show any hysteresis loop and perfect Langevin behavior which indicates its superparamagnetic characteristics. The magnetic character of GO/Fe3O4/PAMPS/Pd catalyst also facilitates the removal of the catalyst by a simple permanent magnet (See the photo in Fig. 4).

Thermogravimetric analysis (TGA) of GO/Fe3O4 (a) and GO/Fe3O4/PAMPS/Pd nanocomposite (b) was further used to study the composition of the resultant nanocomposite.

The TGA of both materials show three main weights loss. The first weight loss was occurred under 100 °C which attributed to desorption of water. The second weight loss from 200 to 300 °C is due to the dehydration process of surface oxygen and hydroxyl groups in GO. The final weight loss around 400–450 °C is related to the decomposition of graphene structure as well as decomposition of immobilized organic moieties on the surface of nanocomposite. Interestingly, the total mass loss of catalyst (Fig. 5b) was only 6.8% at temperatures below 200 °C and 20% at 650 °C which shows good thermal stability of the nanocomposite. The percentage of the remaining mass of GO/Fe3O4/PAMPS/Pd was also compared with GO/Fe3O4. It was found about 17% which revealed the amount of loaded Pd and polymeric moieties in the structure of catalyst.

Transmission electron microscopy (TEM) images (Fig. 6) of GO (Fig. 6a, b) and GO/Fe3O4/PAMPS/Pd nanocomposite (Fig. 6c, d) were illustrated. The TEM images of GO sheets (Fig. 6a, b) demonstrated the flake-like shapes of graphene oxide. The high transparency of GO showed a few layers proved thin film of GO. As shown in figure (Fig. 6c, d), GO was successfully exfoliated in water and also show that the Fe3O4 nanoparticles are quasi-spherical, with average diameters of 16 nm. The Pd-NPs with mean size of 5 nm were dispersed in close contact with the surface of GO sheet. As shown in TEM images, Pd-NPs are not found outside the modified GO because of polymer network prevents the aggregation or agglomeration of Pd-NPs on the GO sheets. Owing to the high density of polymeric network and the presence of spherical Fe3O4 NPs, it is difficult to recognize Pd-NPs. In this regard, we tried to illustrate a closer sight of Pd-NPs at the bottom of the Fig. 6. In addition, EDX image (Fig. 7), also indicates the successful incorporation and presence of all the elements (O, C, N, Fe, Si and Pd) onto the GO sheets.

3.1 Catalytic Performance of GO/Fe3O4/PAMPS/Pd Nanocomposite

Heterogeneous palladium catalysts stabilized by polymers are extensively studied for the Suzuki–Miyaura cross-coupling reaction [60, 61]. However, to the best of our knowledge there are only a few reports on the application of magnetically separable Pd stabilized by hydrophilic polymers which catalyze the Suzuki reaction under green conditions [62,63,64,65,66].

To study the effects of solvent, optimal amount of catalyst and required time, we selected a model reaction. To the purpose, 4-bromotoluene was reacted with phenyl boronic acid in the presence our new catalytic system, using different amounts of catalysts, the required base and solvents diversel, finding the required times for each runs under examination (Table 1). As shown in Table 1, the best result was obtained in a mixture of H2O and EtOH as solvent. This mixture of solvent provides a good interaction of hydrophilic polymer stabilized Pd-NPs with water soluble boronic acid and hydrophobic aryl halides which leads to an improvement in Suzuki reaction. With the previous experiments in hand, K2CO3 was selected as the most efficient base for the present catalytic system. Amount of catalyst and time of the reaction are two prominent parameters which investigated precisely in this work. The better conversion of 4-bromotoluene to the corresponding biphenyl was occurred with 0.4 mol% of catalyst in 2 h.

To screen the efficiency and limitation of our novel nanocatalyst, different substituted aryl halides and aryl boronic acids, bearing either electron- donating or electron withdrawing groups were reacted under secure optimal reaction conditions. These reactions all, proceeded smoothly, resulted in the desired corresponding cross coupled products in high to excellent yields. The results are summarized in Table 2. As it can be seen, when iodobenzene, 4-iodoanisole and 4-iodotoluene were used as reactants, desired coupling products were obtained in only 2 h with excellent yields (95–98%) in the presence of 0.2 mol% catalyst (Table 1, entries 1–3). Aryl bromides with electron-donating and electron-withdrawing groups such as 4-nitro, 4-methyl as well as bromobenzene, gave the coupling products in excellent yields (up to 95%) (entries 4–6). It is noteworthy to mention that the Suzuki reaction of aryl chlorides is more difficult than aryl bromides and aryl iodides because of strong C–Cl bond than that of C–Br and C–I and longer reaction time is required. However, by increasing the amount of catalyst loading to 1 mol% and extending the reaction time, the Suzuki reaction of aryl chlorides was completed in good yields (52–68%) within 24 h (entries 7–10). Furthermore, 4-tolylboronic acid as a coupling partner was subjected to various aryl halides and the results were mentioned in entries 11–16. Surprisingly, compare with phenyl boronic acid, 4-tolylboronic acid showed less efficient result with aryl bromides (Table 2, entries 8–9) and superior result with aryl chloride (entry 10) in term of yield (75%) without using harmful solvents such as DMF or tetra butyl ammonium bromide (TBAB) or excess amount of catalyst. After completion of each reaction, all products were analyzed by 1H NMR and FT-IR techniques and the corresponding peaks were observed.

3.2 Leaching

Another catalytic experiment was further conducted to estimate the impact of palladium leaching. For the purpose, a certain amount of catalyst was dispersed in the presence of K2CO3 and solvents (EtOH:H2O). The mixture was stirred and then filtered to obtain a transparent solution. In the next step, the Suzuki coupling substrates such as phenyl boronic acid and bromobenzene were introduced to the above clean supernatant and the solution was heated to 80 °C and stirred. It was found that no biphenyl was detected even after 5 h, indicating that the coupling reaction catalyzed by heterogeneous catalyst not homogeneous leaching Pd.

3.3 Comparison

To evaluate the efficiency of the GO/Fe3O4/PAMPS/Pd catalyst, its catalytic activity was compared with some other Pd supported catalysts reported, previously. The results revealed that PAMPS cross linked by MAPTMS is a superior ligand to some of the previously reported catalysts in terms of using green solvent, less reaction times, ease of separation, recyclability, less Pd leaching and also better isolated yields (Table 3).

3.4 Recycles

The reusability of the GO/Fe3O4/PAMPS/Pd catalyst was evaluated by using it in the coupling of 4-bromotoluene with phenyl boronic acid as the model reaction under optimized reaction conditions. After completion of each cycle, the catalyst was separated easily by an external magnetic field and the residue was analyzed by GC. Next, fresh starting materials were then introduced to the flask containing magnetic catalyst and a new Suzuki coupling was started. The catalyst was recovered and reused for seven consecutive runs without any significant loss of its activity (Fig. 8).

4 Conclusion

In summary, we have developed a novel Pd NPs composite as denoted by GO/Fe3O4/PAMPS/Pd. It was efficiently used in Suzuki reaction of aryl halides with boronic acid in green media to give the cross-coupled products in high to excellent yields in relatively short reaction times. Worthy to mention, this novel catalytic system worked equally well with less reactive aryl chlorides compared with the corresponding aryl bromides and aryl iodides. Furthermore, GO sheet provided a high surface area for uniform distribution of Fe3O4 NPs and magnetic character led to easy separation of the catalyst from the reaction mixture by using a simple external magnet. The catalyst was reused at least seven times without appreciable loss in its catalytic activity. Lack of metal leaching is a promising advantage for our novel catalyst proved by leaching test.

References

Johansson Seechurn CCC, Kitching MO, Colacot TJ, Snieckus V (2012) Angew Chem Int Ed 51:5062–5085

Balanta A, Godard C, Claver C (2011) Chem Soc Rev 40:4973–4985

Farina V (2004) Adv Synth Catal 346:1553–1582

Li H, Johansson Seechurn CC, Colacot TJ (2012) ACS Catal 2:1147–1164

Kohler K, Prockl S, Kleist W (2006) Curr Org Chem 10:1585–1601

Colacot TJ (2011) Platin Met Rev 55:84–90

Heravi MM, Hashemi E, Nazari N (2014) Mol Divers 18:441–472

M. Heravi M, Hashemi E, Ghobadi N (2013) Curr Org Chem 17:2192–2224

Heravi MM, Hashemi E, Azimian F (2014) Tetrahedron 70:7–21

Nicolaou KC, Chen JS (2011) Classics in total synthesis III, vol 3. Wiley, Weinheim

Magano J, Dunetz JR (2011) Chem Rev 111:2177–2250

Corbet J-P, Mignani G (2006) Chem Rev 106:2651–2710

Miyaura N, Yamada K, Suzuki A (1979) Tetrahedron Lett 20:3437–3440

Heravi MM, Hashemi E (2012) Tetrahedron 68:9145–9178

Heravi MM, Hashemi E (2012) Monatshefte für Chemie 143:861–880

Suzuki A (2011) Angew Chem Int Ed 50:6722–6737

Suzuki A (2002) J Organomet Chem 653:83–90

Kim J, Swager TM (2001) Nature 411:1030–1034

Fang Y-Q, Karisch R, Lautens M (2007) J Org Chem 72:1341–1346

Bringmann G, Rüdenauer S, Bruhn T, Benson L, Brun R (2008) Tetrahedron 64:5563–5568

Hassan J, Sevignon M, Gozzi C, Schulz E, Lemaire M (2002) Chem Rev 102:1359–1470

Wu J, Pisula W, Müllen K (2007) Chem Rev 107:718–747

Moussa S, Siamaki AR, Gupton BF, El-Shall MS (2011) ACS Catal 2:145–154

Qu K, Wu L, Ren J, Qu X (2012) ACS Appl Mater Interfaces 4:5001–5009

Takamura T, Endo K, Fu L, Wu Y, Lee KJ, Matsumoto T (2007) Electrochim Acta 53:1055–1061

Zhu C, Dong S (2013) Nanoscale 5:1753–1767

Zhang N, Zhang Y, Pan X, Yang M-Q, Xu Y-J (2012) J Phys Chem C 116:18023–18031

Scherer F, Anton M, Schillinger U, Henke J, Bergemann C, Kruger A, Gansbacher B, Plank C (2002) Gene Ther 9:102–109

Gersting SW, Schillinger U, Lausier J, Nicklaus P, Rudolph C, Plank C, Reinhardt D, Rosenecker J (2004) J Gene Med 6:913–922

Muthana M, Scott S, Farrow N, Morrow F, Murdoch C, Grubb S, Brown N, Dobson J, Lewis C (2008) Gene Ther 15:902–910

Yang X, Wang Y, Huang X, Ma Y, Huang Y, Yang R, Duan H, Chen Y (2011) J Mater Chem 21:3448–3454

Baig RN, Varma RS (2013) Chem Commun 49:752–770

Cheng T, Zhang D, Li H, Liu G (2014) Green Chem 16:3401–3427

Li Y, Hong XM, Collard DM, El-Sayed MA (2000) Org Lett 2:2385–2388

Li Y, El-Sayed MA (2001) J Phys Chem B 105:8938–8943

Narayanan R, El-Sayed MA (2004) J Phys Chem B 108:8572–8580

Narayanan R, El-Sayed MA (2005) Langmuir 21:2027–2033

Narayanan R, El-Sayed MA (2005) J Catal 234:348–355

de Luna Martins D, Alvarez HM, Aguiar LC (2010) Tetrahedron Lett 51:6814–6817

Islam RU, Witcomb MJ, Scurrell MS, Van Der Lingen E, Van Otterlo W, Mallick K (2011) Catal Sci Technol 1:308–315

Heck RF (2004) Palladium-Catalyzed Vinylation of Organic Halides. In: Organic Reactions. John Wiley & Sons, Inc. doi:10.1002/0471264180.or027.02

Daves GD Jr, Hallberg A (1989) Chem Rev 89:1433–1445

Bedford RB, Cazin CS, Coles SJ, Gelbrich T, Horton PN, Hursthouse MB, Light ME (2003) Organometallics 22:987–999

Vilar R, Mingos DMP, Cardin CJ (1996) J Chem Soc Dalton Trans 23:4313–4314

Durà-Vilà V, Mingos DMP, Vilar R, White AJ, Williams DJ (2000) J Organomet Chem 600:198–205

Heravi MM, Kivanloo A, Rahimzadeh M, Bakavoli M, Ghassemzadeh M, Neumüller B (2005) Tetrahedron Lett 46:1607–1610

Oskooie H, Heravi MM, Behbahani F (2007) Molecules 12:1438

Heravi MM, Keivanloo A, Rahimizadeh M, Bakavoli M, Ghassemzadeh M (2004) Tetrahedron Lett 45:5747–5749

Heravi MM, Hashemi E, Beheshtiha YS, Ahmadi S, Hosseinnejad T (2014) J Mol Catal A 394:74–82

Sadjadi S, Heravi MM (2016) RSC Adv 6:88588–88624

Nemati F, Heravi MM, Saeedi Rad R (2012) Chin. J Catal 33:1825–1831

Nemati F, Heravi MM, Elhampour A (2015) RSC Adv 5:45775–45784

Ayati A, Heravi MM, Daraie M, Tanhaei B, Bamoharram FF, Sillanpaa M (2016) J Iran Chem Soc 13:2301–2308

Hummers WS, Offeman RE (1958) J Am Chem Soc 80:1339–1339

Gao P, Ng K, Sun DD (2013) J Hazard Mater 262:826–835

Sonogashira K (2002) J Organomet Chem 653:46–49

Negishi E-i, Hu Q, Huang Z, Qian M, Wang G, Brown H (2005) Aldrichim Acta 38:71–87

Wan J, Cai W, Feng J, Meng X, Liu E (2007) J Mater Chem 17:1188–1192

Zhang X, Niu Y, Meng X, Li Y, Zhao J (2013) CrystEngComm 15:8166–8172

Paul S, Islam MM, Islam SM (2015) RSC Adv 5:42193–42221

Yin, Liebscher J (2007) Chem Rev 107:133–173

Sakai T, Matsunaga T, Yamamoto Y, Ito C, Yoshida R, Suzuki S, Sasaki N, Shibayama M, Chung U-i (2008) Macromolecules 41:5379–5384

Lee Y, Hong MC, Ahn H, Yu J, Rhee H (2014) J Organomet Chem 769:80–93

Sivudu KS, Reddy NM, Prasad MN, Raju KM, Mohan YM, Yadav J, Sabitha G, Shailaja D (2008) J Mol Catal A 295:10–17

Song H-q, Zhu Q, Zheng X-j, Chen X-g (2015) J Mater Chem A 3:10368–10377

Sheldon RA, Wallau M, Arends IW, Schuchardt U (1998) Acc Chem Res 31:485–493

Hong MC, Ahn H, Choi MC, Lee Y, Kim J, Rhee H (2014) Appl Organomet Chem 28:156–161

Park JH, Raza F, Jeon S-J, Kim H-I, Kang TW, Yim D, Kim J-H (2014) Tetrahedron Lett 55:3426–3430

Bai C, Zhao Q, Li Y, Zhang G, Zhang F, Fan X (2014) Catal Lett 144:1617–1623

Shang N, Feng C, Zhang H, Gao S, Tang R, Wang C, Wang Z (2013) Catal Commun 40:111–115

Shang N, Gao S, Feng C, Zhang H, Wang C, Wang Z (2013) RSC Adv 3:21863–21868

Zhang Y, Yang J, Zhang X, Bian F, Yu W (2012) React Funct Polym 72:233–241

Acknowledgements

Sh. Asadi and M. M. Heravi are grateful to Iran National Science Foundation (INSF) for financial support provided by the post-doctoral project (94026040). We also appreciate Alzahra University and Shahid Beheshti University Research Council for their help and supports.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Asadi, S., Sedghi, R. & Heravi, M.M. Pd Nanoparticles Immobilized on Supported Magnetic GO@PAMPS as an Auspicious Catalyst for Suzuki–Miyaura Coupling Reaction. Catal Lett 147, 2045–2056 (2017). https://doi.org/10.1007/s10562-017-2089-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-017-2089-2