A comparative analysis of the intensity of mixing processes and losses due to hydraulic resistance in variously designed mixers used in electrical desalting plants of oil refineries was made. The effect of the working fluid feed rate was studied to analyze the flow structure in the working space of the apparatuses and to determine the hydrodynamic conditions that are favorable for execution of the flow mixing process and that excludes formation of stagnant areas in the equipment. The obtained results of numerical simulation of velocity and pressure fields can be used at the initial stage of design of new mixers (to justify choice of the shape, size of the working area, etc.) and to determine the optimum technological conditions of the operating apparatuses for crude oil desalting and dehydration (to reduce energy and fresh water consumption).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

For determining the optimum conditions for crude oil desalting and dehydration processes and reducing energy and freshwater consumption, it is essential to choose the shape and size of the working area of the mixers (or their designs) justifiably at the initial stage. This is essential also for preventing formation of stagnant areas and reducing losses due to hydraulic resistance of the mixer. Of late, numerical methods of investigation of flow hydrodynamics in the working space of the apparatuses are being used for these purposes [1,2,3,4].

A generalized calculation procedure developed by us and investigations of electrohydrodynamic mixers and dehydrators [5,6,7,8,9] make it possible to optimize by numerical methods (using Salome, Code Saturne, Paraview, Elmer FEM, and COMSOL Metaphysics software) construction of and/or conditions of operation of the mixers and dehydrators using the developed models of flow of incompressible fluids.

In this paper, we report the results of comparative analysis of the intensity of the processes of mixing and losses due to hydraulic resistance in mixers of various designs used in electrical desalting plants of oil refineries.

We studied the effect of change in velocity field on the presence or absence of stagnant and eddy areas in the working fluid to analyze the structure in the working space of the apparatuses and to determine the hydrodynamic conditions that are optimum for the flow mixing process without formation of stagnant areas in the equipment.

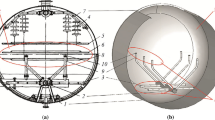

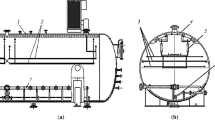

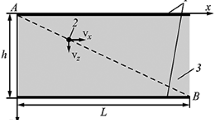

Three-dimensional simulation was carried out for the mixing valve (Fig. 1), SPV (FWM) freshwater mixer (Fig. 2), PR-1 mixer (Fig. 3), and SNV (OWM)-150-1-25 oil−water mixer (Fig. 4).

The velocity, pressure, and kinetic turbulence energy fields of these mixers (Figs. 1–4) were calculated by the procedure presented by us earlier [5,6,7,8,9].

To compare the intensity of the mixing processes in these mixers, the pressure difference between the primary flow entrance cross-section and the mixer outlet cross-section was determined. The dependence of pressure losses Δp in the mixers on the Reynolds number Re is illustrated in Fig. 5.

The parameter Zp = Δpmixer/Δptu (ratio of pressure loss due to hydraulic resistance in the electrohydrodynamic apparatus Δpmixer to the pressure loss in the empty tube Δptu) is estimated from the results of numerical simulation and the energy consumption for the process of mixing in these apparatuses (mixers) is compared.

Results of Analysis of Obtained Data

Pressure losses are maximum in the mixing valve and minimum in the SNV-150-1-25 oil−water mixer; in terms of magnitude, pressure losses in PR-1 mixer, KS-02n coalescenter-mixer, and KS-02v coalescenter-mixer are comparable; pressure losses in SPV oil−freshwater mixer and in MTA small tube apparatus are less.

Maximum losses are observed in the three-way mixing valve (Fig. 5). Its energy utilization efficiency is disputable.

Flow structure analysis (Fig. 1) shows that there are circulation and stagnant areas in the working space. A large amount of energy is consumed for formation of secondary eddies, but not always does it facilitate the mixing process.

Of the compared designs, energy losses are minimum in the SNV oil−water mixer (Fig. 5, curve 7). It can therefore be concluded by analogy that pressure losses will be minimal in a smooth tube of a similar size, but the mixing process in this case will be least efficient. So, the efficiency parameter Zp used in the literature is incorrect for comparative appraisal of mixing devices. A criterion that takes account of the level of attainment of the goal, i.e., uniformity of the obtained emulsion, is required.

It is evident from the plots in Fig. 6 that with increase of Reynolds number the hydraulic friction coefficients λ for the studied devices deviate from the theoretical relationships for a straight tube, which are calculated from the Poiseuille, Blasius, and Nikuradse analytical correlations. The obtained deviations can be explained by the influence of secondary flow arriving in this case at a constant rate and by the transition from the injection mode to the ejection mode. Up to a certain rate of the primary flow the pressure difference in the device corresponds to the injection mode, i.e., the secondary flow enters the primary flow with a high pressure and ‘pushes” the primary flow; with increase of the rate of primary flow the injection mode passes to the ejection mode (when the primary flow “entrains” the secondary flow).

The obtained results of numerical simulation of velocity and pressure fields can be used at the initial stage of mixer designing for justifying the selection of the shape and size of the working area and for determining the optimum technological conditions of functioning of mixers for crude oil desalting and dehydration processes and for reducing energy and freshwater consumption.

References

A. G. Mukhametzyanova, Intensification of Hydromechanical and Heat and Mass Transfer Processes in Small-sized Tube Apparatuses [in Russian], Doctoral Dissertation, Kazan (2012), p. 356.

E. A. Petrovicheva, Turbulent Flow of Mixing Fluids in Small-sized Tube Apparatuses of Chemical Plants: Numerical Simulation [in Russian], Candidate’s Dissertation, Kazan (2006), p. 130.

K. A. Alekseev, Hydrodynamics of Flow in Static Packed-Type Mixers [in Russian], Candidate’s Dissertation, Kazan (2016), p. 170.

A. G. Mukhametzyanova, G. S. D’yakonov, and E. I. Kul’ment’eva, “Modern computer-aided technologies in investigation of flows in channels with various geometry,” Vestn. Kazan. Tekhnol. Univ., No. 2, 164–172 (2005).

K. V. Tarantsev, E. G. Krasnaya, V. A. Chirkov, and I. A. Ashikhmin, “Optimization of designs of electrical dehydrators by computer simulation,” Khim. Neftegaz. Mashinostr., No. 6, 12–14 (2013).

K. V. Tarantsev and I. A. Proshin, “Development of a design for a mixer-electrocoalescing unit for production of water-in-oil emulsions by numerical methods,” No. 4, 10–12 (2015).

K. V. Tarantsev, A. V. Korosteleva, and I. A. Proshin, “Development of design of electrodehydrator for dewatering water-oil emulsions by numerical methods using Salome software,” Khim. Neftegaz. Mashinostr., No. 5, 3–6 (2015).

K. V. Tarantsev, S. I. Ponikarov, and K. R. Tarantseva, “Analysis of feasibility of using modern computer technologies to investigate hydrodynamics of an incompressible fluid in the working space of the apparatus,” Khim. Neftegaz. Mashinostr., No. 5, 40–42 (2019).

K. V. Tarantsev, S. I. Ponikarov, and K. R. Tarantseva, “Development of mixer design taking account of hydrodynamics of flows in the working space using numerical methods,” Khim. Neftegaz. Mashinostr., No. 6, 14–16 (2019).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimicheskoe i Neftegazovoe Mashinostroenie, Vol. 55, No. 9, pp. 8–11, September, 2019.

Rights and permissions

About this article

Cite this article

Tarantsev, K.V., Ponikarov, S.I. & Tarantseva, K.R. Comparative Analysis of Mixing Intensity and Losses Due to Hydraulic Resistance in Mixers of Electrical Desalting Plants. Chem Petrol Eng 55, 706–712 (2020). https://doi.org/10.1007/s10556-020-00683-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10556-020-00683-1