Biodiesel fuel is attracting interest as an alternative fuel as environmental pollution increases and fossil fuel supplies diminish. Biodiesel is not only cleaner than petro-diesel, but also has high degradability and excellent lubricity. Since biodiesel has very low sulfur content (0.002 wt. %), it is environmentally friendly. The effect of a biodiesel additive in a diesel engine fuel system for reducing pollutant emission and wear characteristics was studied experimentally. Analysis was performed in two steps. First, the injection of biodiesel into the diesel engine channel was simulated. Second, tribological experiments were performed using the ball-on-ring contact method. The wear scar diameters and wear surfaces of the tribopairs were then analyzed. Wear experiments showed that a small addition of biodiesel to pure petrodiesel reduced friction and wear under boundary lubrication considerably.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

The energy industry is essential for economic growth and a high standard of living. Globally, the transportation sector is the second largest energy consumption sector after the industrial sector and accounts for 30% of the energy delivered globally. This sector has experienced a steady growth in the past 30 years. Nearly all (97%) fossil fuel energy consumption in the transportation sector corresponds to oil consumption. However, the use of fossil fuels is associated with environmental problems including depletion of carbon energy sources and subsidence of the ground surface after the extraction of said carbon sources and minerals. The use of biodiesel may provide solutions to these problems.

Biodiesel is a clean-burning monoalkyl ester-based oxygenated fuel derived from natural, renewable and sustainable sources such as soybean oil, palm oil, and waste edible oils. The physical and chemical properties of biodiesel are similar to and compatible with those of pure petrodiesel. The most important advantage of using biodiesel is the reduction of greenhouse gas emissions [1]. Due to well-developed lubricating properties, biodiesel is an effective lubricity additive to petroleum diesel fuel (DF). Stricter requirements for the sulfur content in diesel fuel oil lead to a decrease of lubricating properties [2], which, in turn, can cause damage to the engine and fuel system. The use of biodiesel can solve this problem as it increases lubricity and fulfills cetane number requirements particularly of ultra-low sulfur diesel fuels [3].

Oil production rate of palm trees is about 13 times higher than that of soybean plants. Life cycle analysis performed in various biodiesel fuels showed that the production and use of biodiesel based on palm oil reduces emissions of greenhouse gases (due to CO2 recovery) by 62% – more than soybean oil (40%), rapeseed oil (45%), and sunflower oil (58%) [4].

In [5] testing of biodiesel produced from sunflower oil showed no significant reduction in power, fuel consumption, or balancing force. In [6] biodiesel produced from rapeseed oil was tested; methyl ester emissions tests showed a 55.6% reduction in emissions of unburned hydrocarbons, a 50.6% reduction in carbon monoxide, an 11.8% reduction in nitrogen oxide, and a simultaneous increase in emissions of carbon dioxide (by 1.1%) and particulate matter (by 0.3%). The composition of emitted particulate matter did not differ significantly from that from petrodiesel fuel [7]. Demirbas [8] reported significantly better lubricity characteristics of biodiesel compared to petrodiesel and markedly improved lubricity of petrodiesel after addition of biodiesel. It has been shown that addition of less than 1% biodiesel to petrodiesel improves lubricity by as much as 30% [1].

While many studies have confirmed acceptable performance results for engines operating with biodiesel, very few have performed long-term wear analysis. Wear resistance and tribological properties of the fuel supply system of a diesel engine operating on biodiesel are still poorly understood. In this paper, tribological properties of biodiesel as additive to pure petrodiesel were investigated using the ball-on-ring wear tester to determine its optimal concentration in petrodiesel. The mechanism of the reduction of wear and friction was investigated by optical microscopy (OM) and scanning electron microscopy (SEM).

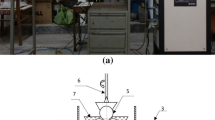

Mixtures of petrodiesel and biodiesel were prepared by stirring for 30 min at 3000 rpm using a mechanical homogenizer. The blends did not contain water and showed no separation of phases. Palm oil methyl esters (POME) were selected for the study as the representative biodiesel. Lubricity of mixtures containing from 0 to 20% POME was analyzed by the ball-on-ring contact method. The objective of the study was to establish the correlation between measured wear characteristics and the content of biodiesel in diesel fuel mixtures. Tribological properties were determined from motion resistance and wear [9]. The wear scar diameter on the ball was measured with an optical microscope while the wear profile and surface roughness of the disc were analyzed using a profilometer. A steel ball 12.5 mm in diameter of and a ring 70 mm in diameter and 17 mm thick made of ball-bearing steel were used. Test conditions were regulated in accord with the PN-EN ISO 12156 standard: fuel temperature – 60 °C, volume – 300 mL. Relative humidity was maintained around 50-55%, and the temperature of air in the laboratory – around 23 °C. During the test the ball and ring were completely immersed in fuel. Speed of rotation of the ring was 500 rpm, and test duration was 2 hours [10].

The fuel supply system supplies fuel from the tank to the injectors. The fuel supply system model used in this study includes a tank, preliminary filter, pump, filter, injector pump, injectors, and connecting lines. The injector pump feeds the high-pressure connecting lines leading to the injectors that inject fuel into the cylinders. In-line pumps and injectors do not rely on fuel for lubrication. However, the fuel itself lubricates some of the moving parts [11]. The system simulates injector motion and operates at a frequency of 50 Hz. The amplitude of reciprocation is 4 mm, and test duration is 5 million cycles.

Blend stability. For each blend, stability tests were performed to determine whether phase separation occurred. Blends containing 1, 2, 5, 10, and 20 vol. % POME in petrodiesel were prepared. The blends were maintained at 30 °C, and stability was tested every 2 hrs for the first 24 hrs and every day thereafter for one month. During that time no precipitate or turbidity was observed indicating full miscibility of petrodiesel and biodiesel [12].

Simulation of the injection system. Visual inspection of the injectors at the end of each trial with different fuels showed no significant carbon deposits on the nozzle tips (Fig. 1). Test conditions: 400 hrs at a speed of 500 rpm. The high-pressure fuel pump acts as an effective mechanical stirring device effectively blending the suspensions [13]. Injector plunger surface roughness was analyzed to determine wear after the test in the same conditions. The surface exposed to pure petrodiesel after the lubricity test revealed a residue at the wear scar periphery and had a surface roughness of 0.412 microns. The surfaces of injectors working in fuel mixtures containing biodiesel showed less surface roughness indicating better lubricating properties and a reduction of friction. Average roughness determined with a surface profiler decreased from 0.347 microns to 0.289 microns when biodiesel was used.

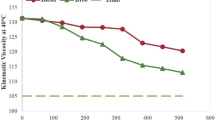

Wear characteristics. Fig. 2 displays the effect of the content of POME in mixed fuel on wear scar diameter. In the case of pure petrodiesel the wear scar was the largest (1.39 mm in diameter). The smallest wear scar diameter (1.04 mm) was observed when the fuel mixture containing 10 vol. % POME was used. With increasing POME concentration above 10 vol. % wear scar diameter increased slightly, grasp of metal surfaces was observed that can be attributed to oxidation or corrosion due to friction and wear [14]. Reduction of the wear scar diameter observed as a result of adding biodiesel to petrodiesel may be due to the presence of fatty acids, which form a lubricating film and reduce the friction and wear of the contact surfaces [15].

Fig. 3 shows the dependence of the friction force on PEMO concentration in the mixed fuel. As can be seen, the minimum friction force is achieved with a 10% content of biodiesel. The greatest decrease in frictional force is observed in the concentration range of 1-5%. Percent fraction of the surface under friction covered by the lubricant film is increased with increasing concentration of biodiesel. Protective films can reduce thermal energy in sliding contact and thereby improve lubricity. In all likelihood, the lubricating film is formed by functional groups of fatty acids. In another opinion [16], lubricity of biodiesel is due to the traces of free fatty acids and mono- and diglycerides.

Thus, friction and wear are reduced with increasing content of biodiesel in mixed diesel fuel. A solid monolayer that substantially reduces wear forms between moving metal surfaces.

References

I. M. Atadashi, M. K. Arou, and A. A. Aziz, Renew. Sust. Energ. Rev., 14, 1999–2008 (2010).

D. P. Geller and J. W. Goodrum, Fuel, 83, 2351–2356 (2004).

S. Kaul, R. C. Saxena, A. Kumar, et al., Fuel Process. Technol., 88, 303–307 (2007).

H. C. Ong, T. M. I. Mahlia, H. H. Masjuki, et al., Renew. Sust. Energ. Rev., 15, 3501–3515 (2011).

F. Karaosmanoglu, G. Kurt, and T. Ozaktas, Renew. Energ., 19, 219–221 (2000).

R. K. Pandey, A. Rehman, and R. M. Sarviya, Renew. Sust. Energ. Rev., 16, 1762–1778 (2012).

L. P. Charles, R. L. Daryl, T. C. Joseph, et al., Biomass Bioenerg., 10, 331–340 (1996).

A. Demirbas, Fuel, 87, 1743–1748 (2008).

E. Sukjit and K. D. Dearn, Wear, 271, 1772–1777 (2011).

M. W. Sulek, A. Kulczycki, and A. Malys, Wear, 268, 104–108 (2010).

A. S. M. A. Haseeb, M. A. Fazal, M. I. Jahirul, et al., Fuel, 90, 922–931 (2011).

H. H. Masjuki and M. A. Maleque, Wear, 206, 179–186 (1997).

A. S. M. A. Haseeb, S. Y. Sia, M. A. Fazal, et al., Energy, 35, 1460–1464 (2010).

M. Munoz, F. Moreno, C. Monne, et al., Renew. Energ., 36, 2918–2924 (2011).

B. P. Anand, C. G. Saravanan, and C. A. Srinivasan, Renew. Energ., 35, 1179–1184 (2010).

P. R. Wander, C. R. Altafini, A. L. Colombo, et al., Energy, 36, 3917–3923 (2011).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Khimiya i Tekhnologiya Topliv i Masel, No. 6, pp. 48 – 50, November – December, 2016.

Rights and permissions

About this article

Cite this article

Peng, DX. Biodiesel Improves Lubricity of Low-Sulfur Petro-Diesels. Chem Technol Fuels Oils 52, 699–703 (2017). https://doi.org/10.1007/s10553-017-0762-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10553-017-0762-1