Abstract

In the wake of an increased attention on the eco-friendly biopesticidal products and the rising market requirements for organic agents, lipopeptides compounds have been described as biological control agents which improve the overall health growth and development of plants. Nevertheless, their high production cost constitue the major flaw in their wide use to control plant diseases. The present article aims to formulate an economic media for lipopeptides production by Bacillus mojavensis A21 for application as natural fungicides for plant disease treatment. We herein demonstrated the suitability of the potato waste, as low cost substrate, for lipopeptides production. Moreover, sea water was found to be a good mineral salts sources. In the second part of this study, we investigate the inhibitory activity of A21 lipopeptides against the phtopathogenic Fusarium sp. The in vitro test showed a minimal inhibitory concentration of about 0.3 mg/ml. The microscopic examination, of the treated Fusarium revealed an excessive lysis of the mycelia ultrastructure with destructed spores. The in vivo antagonist activity was confirmed towards the infected potato tubers. A21 lipopeptides are effective in decreasing by about 78.26% and 60.68% when applied as preventive and curative treatments, respectively, as compared to the untreated tubers.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The annual crop losses of world as a result of diseases have been estimated at 25,000 million US dollars, of this a major part is due to fungal pathogens carried through seed (Chandler 2005). A variety species of fungi especially Fusarium sp and Aspergillus sp. are associated with critical vegetable products losses devouring harvesting, transport and keeping rendering them unqualified for human consuming by generating mycotoxins and touching their nutritive value (Miller 1995; Janardhana et al. 1999; Galvano et al. 2001). The plant diseases need to be controlled to maintain the level of yield both quantitatively and qualitatively. Farmers often rely heavily on the use of synthetic fungicides to control the plant diseases (Gupta 2011). Numerous substances with widely varying chemical constituents (benzimidazoles, aromatic hydrocarbons, and sterol biosynthesis inhibitors) have been used as antifungal agents to prevent, mitigate or control plant diseases. However, the uncontrollable use of synthetic fungicides have been correlated with the expansion of drug resistance mechanism (Cowen et al. 2015). So, unseemly treatments with synthetic fungicides have often been reported to bring an unpleasant side effects, particularly on soil, plants, environment, and eventually humans. Now, a rigorous rules have been made on chemical fungicides use and there is also a political pressure to dismiss the most dangerous chemicals from the market. Thus, there is an increasing demand to find new antifungal agents from new resources utilization of microbial antagonists is required in the biological control (Suprapta 2012).

It is well documented that many members of the genus Bacillus are well recognized as suppressing fungal disease (Ongena and Jacques 2008) and their derived bio-metabolites such as bacteriocins, antibiotics and lipopeptides were described as inhibitors of fungal spore germination (Leelasuphakul et al. 2008; Matar et al. 2009; Des Grades et al. 2012). Lipopeptides have been investigated as credible solution in preventing the spread of fungal infections, in both in vitro and in vivo, with low toxicity, high biodegradability and as being environmental friendly (Meena and Kanwar 2015). Nevertheless, their steep production cost mainly by the usage of commercial media composed of expensive substrate limited their industrial applications (Gurjar and Sengupta 2015). Thus, during the last decade, efforts have been deployed to reduce the final products cost by improving the yield and the use of either cost-free or low-cost feed stocks or agricultural by-products as substrate(s) for biosurfactant production by microbes either in submerged fermentation (SmF) or in solid-state fermentation (SSF) (Zouari et al. 2015). Several by-products of agro-industrial origin have been defined as low cost alternative substrate for biosurfactants production such as cassava, soybean (Abalos et al. 2001), sugar beet, potato (Noah et al. 2005; Thompson et al. 2000), etc. The aim of this study was to formulate low cost medium for lipopeptides production by B. mojavensis A21 for application as natural fungicides for plant disease treatment.

Experimental methods

Bacterial strain and phytopathogenic fungus

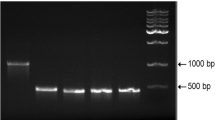

Bacillus mojavensis A21 (EU366229) was isolated from marine water in Sfax, Tunisia (Haddar et al. 2009).

The phtopathogenic fungus was isolated from infected potatoes. To this end, infected potatoes were rinsed with distilled water and disinfected for 10 min with sodium hypochlorite (2%). After washing with sterile distilled water, potatoes were cut into small morsels. Tissue pieces were then transferred to potato dextrose agar (PDA) medium in a Petri dish and cultured at 25 °C for 2 weeks. The isolate was checked morphologically with a light microscope to confirm it was Fusarium sp.

Plant material

The in vivo inhibitive power of A21 lipopeptides against infection by Fusarium sp. was proved on potato tubers. Potato tubers were selected according to homogeneous size, maturity, color, and absence of injuries from a local market in Sfax (Tunisia) and were stored at 4 °C for 2–4 days until use.

Medium composition and culture condition

The basal liquid culture medium used for biosurfactant production by the B. mojavensis A21 strain was composed of (g/l) carbon source 20, MgSO4 (7 H2O) 0.5, K2HPO4 1, KH2PO4 1, and KCl 0.5. The initial pH was 8.0. Media were sterilized at 121 °C for 20 min. The strain was cultivated in 250 ml conical flasks containing 25 ml medium inoculated at initial OD of 0.02 and maintained for 72 h at 30 °C and 160 rpm. The cultures were centrifuged at 13,000 rpm for 15 min, and the cell-free supernatants were evaluated for their biosurfactant activity. The biosurfactants production was evaluated through the determination of surface tension according to the De Nouy methodology using a tensiometer TD1 (LaudaK onigshofen, Germany) and the emulsifying index values.

Optimization of biosurfactant production

Effects of different carbon sources

The effects of different carbon sources (potato waste, sesame waste and groats) on biosurfactant production by B. mojavensis A21 strain were assayed at a dose of 20 g/l, maintainig constant the other media compounds. The selected carbon sources was then optimized in the range of 10–40 g/l.

Effects of different nitrogen sources

To examinate the influence of various nitrogen sources on biosurfactant production, the basal medium, containing 30 g/l potato waste, was added with different organic compounds (yeast extract, and soya peptone) at a final concentration of 5 g/l, maintaining constant the other media compounds. The concentration of the selected nitrogen source was then optimized in the range of 0.1–1% (w/v).

Effects of salts source and temperature on bosurfactant production

To optomize the best incubation temperature on biosurfactant production, media was incubated for 72 h at 3 constant temperatures (25, 30, and 45 °C) in an automatic incubator.

To study the effects of mineral sources on biosurfactant production KH2PO4 (1 g/l), K2HPO4 (1 g/l), KCl (0.5 g/l) and MgSO4, (0.5 g/l) in the basal medium, containing 30 g/l potato waste and 5 g/l yeast extract were replaced with the diluted sea water (50%).

Determination of biosurfactants yield

At the end of the incubation period, the culure was centrifuged at 10.000 rpm and 4 °C for 20 min. The supernatant was acidified with 6 N HCl at pH 2.0. The obtained precipitate was then collected by centrifugation at 10,000 rpm and 4 °C for 20 min and washed two times with acid water to collect the biosurfactants preparation. The dry weight was determined after desiccation at 105 °C for 24 h. Culture without inoculation was used as negative control. The biosurfactants yield was calculated as the result of substracting the weight obtained with the negative control from that collected from the culture containing biosurfactants producing strain.

CMC determination

The critical micelle concentration (CMC) was measured by diluting the biosurfactant with distilled water to obtain a constant value of surface tension.

Lipopeptides detection by HPLC analysis

The crude supernatant was firstly applied to a C18 cartridge which retained biosurfactant molecules which are subsequently eluted with methanol (100%). After evaporation of the solvent, the obtained residue was dissolved in 300 µl methanol. Lipopeptides were then analyzed and quantified by reversed-phase high-performance liquid chromatography (600 s, Waters Corp.) using a C18 column (5 _m, 250 mm × 4.6 mm, 218 TP, VYDAC, Hes-peria, CA, USA) according to the method previously described by Coutte et al. (2010).

Lipopeptides extraction

The supernatant was ultrafiltered using a regenerated cellulose 10-kDa membrane (Millipore SA, Molsheim, France). The filtrate was collected, concentrated and lyophilized, resulting in partially purified A21 lipopeptides mixture which assist as preparation to prospect the anti-fusarium activity.

In vitro antifungal activity of A21 lipopeptides against Fusarium sp

The inhibitory potential of A21 lipopeptides against hyphal growth was examined by the agar well diffusion method as illustrated by Hammami et al. (2011). The fungal mycelium was removed in the center of PDA plates added with various concentrations of lipopeptides preparation (0.5, 1.0, 2.0 and 3.0 mg/ml). Plates are incubated at 25 °C for 5 days. The tachigazol (Bio Basic, Markham, Ontario, Canada) and water were added to PDA as positive and negative controls, respectively.

Radial growth was regularly controlled and the mycelial growth inhibition (MGI) was calculated as the percentage of the growth on the untreated medium using the subsequent formula.

where dc and dt represent mycelial growth diameter in control and treated Petri plates, respectively. All assays were repeated three time and the averages of the repeated experimental results were determined.

The minimal inhibitory concentration (MIC) defined as the smallest concentration that inhibits the fungal growth totally and the 50% inhibitory concentration of the lipopeptide (IC50) values were determined according to the method of Zu et al. (2010).

Effect of A21 lipopeptides treatment on mycelium morphology

In view to investigate the control of A21 lipopeptides on the mycelia growth and morphology, mycelium proximate the inhibition zone was taken after 5 days incubation with the desired lipopeptides concentration, examined by microscope and compared with an intact mycelium showing normal growth (without lipopeptides addition) serves as negative control.

Effect of A21 lipopeptides on spore germination of Fusarium sp.

Sporicidal activity of A21 lipopeptides were conducted using spore germination assay according to standard reference methods (Das et al. 2010). The test organism was grown on PDA medium for sporulation and spores were harvested when the cultures were fully sporulated and suspended in sterile distilled water. Spores were separated from the mycelium fragment by filtration, adjusted to 1 × 106 spores/ml and used for the germination test.

Experiments were exanimated in 96-well plates containing 100 μl of a 1:100 dilution of spore suspension and 100 μl of different A21 lipopeptide concentrations in each well. Lipopeptides were assayed at various concentrations: 0 (control), 0.5, 1.0, 2.0 and 3.0 mg/ml. Distilled water was used as control treatment. After incubation at 25 °C for 1 h, spores were diluted and used to inoculate PDA medium. Lipopeptide samples were added by spreding the spores on PDA and incubated for 72 h at 25 °C. The results of the inhibitory activity were expressed in terms of the percentage of germinated spores as compared to the control. The spore germination inhibition percentage was determined according to the present formula (Rebib et al. 2012)

where G0, Number of spores germinated in control set; G, Number of spores germinated in the test set.

In vivo antifungal activity of A21 lipopeptides against Fusarium sp. infection

The method of Yangui et al. (2013) was used to investigate the influence of A21 lipopeptides on the rot maturity. Latterly picked healthy tubers were washed with water, surface was then disinfected with sodium hypochlorite solution (1%) and cleaned in five changes of sterile water. Then discs (5 mm depth, 6 mm diameter) were detached from tubers by a sterile cork borer and replaced with disc of a 5 days old culture of the isolated fungi.

The susceptibility of A21 lipopeptides in the control of tubers rot was evaluated in two ways: a preventive treatment applied 24 h before tuber infection by Fusarium sp. and a curative one executed 24 h after tuber inoculation by the pathogen. Treatments were achieved by injecting 100 µl (2 mg/ml) of A21 extracts in the provoked wounds. Positive control was prepared at the same manner using sterile distilled water rather than A21 lipopeptides solution. Non-inoculated and non-treated tubers corresponding to negative control was also realized. In order to estimate the penetration percentages of the pathogen, tubers were longitudinally cleaved via sites of inoculation after 6 days at 25 °C. The necrosis width (w) and the necrosis depth (d) were then calculated according the formula of Yangui et al. (2013).

where w width of soft rot (mm); d depth of the soft rot (mm); p depth of the inoculation well (mm).

The inhibition of the rot extension was calculated according to the presented formula:

where Ti positive control: inoculated and not treated tuber and Tr inoculated and treated tuber.

Statistical analyses

Statistical analyses were performed with SPSS version 5.0 (Professional Edition) using ANOVA analysis. Differences were con-sidered significant at p < 0.05. All analyses were performed intriplicate.

Results and discussion

Biosurfactants production by B. mojavensis A21

Effects of different carbon sources on biosurfactants production

The limited use of biosurfactants in the various biotechnological fields is due to their production in high cost culture media while using expensive substrates such as pure sugar forms. The large-scale economic production for new applications of biosurfactants remains a challenge.

In recent years, there has been considerable interest in the use of agro-industrial residues and agricultural wastes as substrates for a more economical production of biosurfactants. In the course of this work, attempts have been made to formulate new culture media composed of agricultural by-products as economic carbon. B. mojavensis A21 was cultivated in the basal medium added with various natural sources (potato waste, sesame waste, and gruau) (Fig. 1a).

The maximum reduction in surface tension and the highest emulsifing index were 37 mNm−1 and 80%, respectively, which were simultaneously achieved when the A21 strain was grown on potato waste (20 g/l), as sole substrate. The experimental results showed that the potato waste was proved to be potentially useful as substrate for biosurfactants production followed by gruau. However, biosurfactants production was significantly low when the strain was grown on sesame waste. Many researchers have attempted to produce biosurfactants by using agricultural waste in culture medium (Sharma et al. 2015a, b; Surekha et al. 2017; Barros et al. 2007). The potato waste presents one of the greatest attraction for many studies. In fact, this solid effluent is composed of 80% water, 17% carbohydrates, 2% protein, 0.1% fat and 0.9% vitamins, inorganic minerals and trace elements and therefore, can support growth and production of metabolites (Makkar and Cameotra 2002). In this context, Thompson et al. (2000) suggested the use of potato waste for production of surfactin from Bacillus spp. Fox and Bala (2000) tested the impact of a potato based mineral salts medium on biosurfactants production by B. subtilis ATCC 21332 and the results showed a significant reduction in surface tension (from 71.3 to 28.3 mN/m).

Since potato waste was the most effective carbon source for biosurfactants synthesis, the influence of its concentration (10–40 g/l) was studied (Fig. 1b). The increase of potato waste concentration exhibited a significant increases in biosurfactants production. Infact, the maximum reduction in surface tension (35 mNm−1) and the highest emulsifing index (87%) were simultaneously achieved when the A21 strain was grown in the presence of 30 g/l potato waste. However, further increase of potato waste concentration resulted in rapid decrease of biosurfactants production.

Effects of various nitrogen sources on biosurfactants production

Various nitrogen sources at a concentration of 5 g/l were assayed using an optimum potato waste concentration of 30 g/l (Fig. 2). Addition of yeast extract exhibited a significant icreases in biosurfactants activity (emulsifying activity 95% and surface tension reduction 33 mN/m). However, no positive effect was observed with soya pepton addition in the medium growth.

Effects of salts source and temperature on biosurfactants production

In an attempt to increase the biosurfactants production by B. mojavensis A21, the effect of minerals salts source was investigated. KH2PO4 (1 g/l), K2HPO4 (1 g/l), KCl (0.5 g/l) and MgSO4, (0.5 g/l) in the basal medium, containing 30 g/l potato waste and 5 g/l yeast extract were replaced with the diluted sea water. As shown in Fig. 3, The dilluted sea water could perfectly replace the individual supply of all the minerals into the basal culture medium.

The effect of temperature (25, 30 and to 45 °C) on biosurfactants production by B. mojavensis A21 was studied in optimized medium containing 30 g/l potato waste, 5 g/l yeast extract and water sea (50%). Optimum level of biosurfactants production was achieved at 30 °C (based on their ability to reduce surface tension) (data not shown). This result is in accordance with previous studies on Bacillus biosurfactant, (Gancel et al. 2009; Agarry et al. 2015). Indeed, at 45 °C, the production was 40% lower than that at 30 °C.

The present optimization let to formulate an economic medium composed of 30 g/l potato waste and 5 g/l yeast extract dissolved in 50% diluted sea water that supports a high production yield of about 3 g/l of crude biosurfactants. This contributes significantly to the decrease of B. mojavensis A21 production cost for large scale application and to the valorization of by- products and wastes.

Lipopeptides detection by HPLC analysis

In our previous study, the strain A21 was found to produce lipopeptides when grown in landy medium. The use of the molecular approach suggests the existence of genes coding for nonribosomal peptide synthetases implied in the biosynthesis of fengycin and surfactin (Ben Ayed et al. 2014).

In this study, RP-HPLC was used to check the expression of these genes when the strain was grown in the tested renewable media. After centrifugation, the supernatant was subjected to solid phase extraction and analyzed by reversed-phase HPLC analysis. The eluted molecules were identified by comparing their retention times with those of reference substances. Figure 4 presents the pattern of lipopeptides detected by the RP-HPLC analysis of the concentrated supernatant. Result revealed the presence of surfactin (between 5 and 20 min of elution) and fengycin isoforms (between 40 and 60 min of elution).

RP-HPLC peak areas were also used for quantification, on the basis of obtained values for the standards. The total amounts of fengycins and surfactins produced by the strain A21 were found to be 194.27 and 85.12 mg/l, respectively.

Pattern of lipopeptides production by B. mojavensis A21

Bacillus mojavenis A21 was grown aerobically in the optimized medium [potato waste 30 g/l, yeast extract 5 g/l and sea water (50%)] for 72 h at 30 °C. The lipopeptides production kinetics and the bacterial growth were followed with time (Fig. 5).

The RP-HPLC results exhibit a higher amount of fengycin compared to surfactin. Indeed, after 72 h of fermentation, the fengycin level was approximately 2.3 fold higher than surfactin. The surfactin production was growth-associated and starts at the beginning of the exponential phase up to the stationary phase. Nevertheless, the fengycin synthesis initiate after 12 h till the end of the cultivation. The growth-associated relationship in surfactin production was observed when the strain was grown in Landy medium (Ben Ayed et al. 2014) and also signaled in some other B. subtilis strains Deleu et al. (1999).

CMC determination

CMC is the lowest biosurfactant concentration needful to reduce the surface tension to its minimal value. In this study, A21 biosurfactants reduced the surface tension of water to 29 mN/m with a CMC of about 120 mg/l.

In vitro antifungal activity of A21 lipopeptides

Effect of A21 lipopeptides treatment on mycelium morphology

In this part, we investigated the in vitro antagonistic activity of A21 lipopeptides versus the phytopathogenic fungus, Fusarium sp. The estimation of antifungal activity was carried out in terms of radial growth percentage on solid medium (potatoes dextrose agar PDA). Four different concentrations of lipopeptides A21 (0, 0.5, 1.0, 2.0 and 3.0 mg/ml) were used throughout the experiment. Findings demonstrate that, comparatively to the negative control for which lipopeptides preparation was substituted by sterile distilled water, the radial growth of the Fusarium sp. was strongly inhibited at all the tested concentrations. As presented in Fig. 6, a dose dependent reduction in radial growth was observed. In fact, a gradual reduction of fungi diameter was registered with increasing A21 lipopeptides concentration. A21 lipopeptides exhibited higher inhibitory activity than the positive control at a concentration of 3 mg/ml.

The minimum inhibitory concentration (MIC) and the median inhibitory concentration (IC50%) were estimated to be 0.3 mg/ml and 0.9 mg/ml, respectively. According to literature, the MIC value of A21 lipopeptides against Fusarium sp was less than that recorded for the Bacillus subtilis SPB1 lipopeptides versus F. solani (3 mg/ml) (Mnif et al. 2015). However, this value was much higher than that registered for the antifungal lipopeptide produced by FK463 strain (Tawara et al. 2000) and for the cyclic lipopeptide antibiotics produced by B. subtilis C2 against F. solani (20 μg/ml) (Li et al. 2012).

To define clearly the action of A21 lipopeptides on the mycelium morphology, mycelium around the inhibition zone was removed and observed by microscope. Compared to the negative control which showed typical mycelium aspect and smooth surfaces, the microscopic analysis, of the treated Fusarium revealed that an obvious alteration in mycelial shape was appeared accompanied with moderate lysis in fungal hyphae (Fig. 7). An excessive lysis of mycelia ultrastructure with destructed spores was also observed when high levels of A21 lipopeptides were applied. These results revealed the fungicidal effect of A21 lipopeptides. This fungitoxicity almost certainly relies on their membrane permeabilization properties (Bonmatin et al. 2003). The present result corroborates the results by Mnif et al. (2015) confirming that F. solani treated with B. subtilis SPB–derived lipopeptide showed an excessive lysis of the mycelium with polynucleated and destructed spores. Lin et al. (2010) demonstrated that the treatment with the iturin A of B. subtilis BS-99-H caused a net deformation of fungus hyphae of P. eugeniae.

Effect of A21 lipopeptides treatment on mycelium morphology: representative microscopic pictures (10 × 40 magnifications) of mycelium and spores of Fusarium grown in medium with a negative control without A21 lipopeptides treatment; b–eFusarium mycelia treated with 0.5, 1, 2 and 3 mg/ml A21 lipopeptides, respectively

Effect of A21 lipopeptides on Fusarium sp. spore production and germination

The effect of increasing concentrations of A21 lipopeptides on the fungal sporulation was also conducted. A21 lipopeptides were found to be effective at reducing fungal sporulation. The obtained results showed that treatment using a sub-inhibitory dose of A21 compounds caused a considerable inhibition of fungal spore formation. In fact, the number of spores was about 4 × 106 spores/ml in the presence of 1 mg/ml A21 lipopeptides consisting towards 12 × 106 spores/ml in their absence. However, the sporulation was absolutely inhibited at 2 mg/ml.

Fungus spores were treated with varous lipopeptides concentrations and then tested for their germination capacity. The germination rates of fungal spores with sterile water (control) was approximately 100% after incubation. However, A21 lipopeptides significantly inhibited spore germination. Of particular note, A21 lipopeptides generally caused a dose-dependent response. An increase of inhibition potency was observed when increasing lipopeptide concentration (Fig. 8).

Therefore, we confirmed that A21 lipopeptides were effective also in inhibiting spore formation and germination. Results are in accordance to those published by Ruangwong et al. (2012) reporting that fengycin produced by B. subtilis LB5 inhibit Colletotrichum gloeosporioides conidia germination. Lipopeptides from B. amyloliquefaciens TF28 were able to inhibit Fusarium. moniliforme spore germination (Zhang et al. 2012). Chitarra et al. (2003) suggesting that iturin by B. subtilis YM 10–20 causes Penicillium roqueforti conidiospore permeabilization preventing therefore their germination. The antifungal lipopeptides of B. subtilis K1 prevented the germination of spores of Magnaporthe oryzae.

In vivo antifungal activity of A21 lipopeptides

It’s true that utilizing synthetic pesticides can improve economic potential in terms of increased the yield production of food and fibre, but they cause a real health problems to human and his environment. Thus, advanced methods with greater trustworthiness are required to divine the virtual risk of pesticides and thus reducing their side impacts. Many studies have revealed that biological control constitue an interesting approach that might be applied in the management of plant diseases (Fravel 2005). In fact, using antagonistic microorganisms to control phytopathogens, is an alternate, safe approach for checking plant diseases. Recently, biological control has been focused on microorganisms producing lipopeptides which are widely popular for their broad-spectrum fungicidal activities that certainly relies on their membrane permeabilization action (Ongena and Jacques 2008).

In this study, we investigate also the inhibitory potential of A21 lipopeptides against the phtopathogenic Fusarium sp. in vivo. Experiments were performed using infected potato tubers. The obtained results showed that all the treatments with A21 lipopeptides were significantly efficient in controlling rot infection when tubers were treated 24 h before and after their inoculation for preventive and curative treatments, respectively (Fig. 9). Compared to the untreated and inoculated tubers, when a total rot was observed, significant reduction of the rot lesion diameter was obtained with A21 lipopeptides treatments. The penetration percentages for negative and the treated tubers are showed in Fig. 10. Data analysis showed that A21 lipopeptides are effective in decreasing tuber rot severity by about 78.26% and 60.68% when applied as preventive and curative treatments, respectively, as compared to the untreated control tubers. B. mojavensis A21–derived lipopeptides are promising candidates for the treatment of potato diseases.

According to literature reviews and studies, many microbial derived compounds were described as inhibitors of in vivo fungi rot development (Leelasuphakul et al. 2008). Mnif et al. (2015) reported that the lipopeptides from B. subtilus SPB1 were more effective in controlling F. solani potato tuber rot infection when applied as preventive treatment than the curative one. Kita et al. (2005) described the suppressive ability of iturin A derived from B. subtilis RB14 against damping-off of tomato seedlings caused by R. solani and Phomopsis root rot of cucumber. Cao et al. (2012) evaluated the in vivo efficiency of fengycin from B. subtilis SQR 9 for suppressing Fusarium wilt of cucumber. Also, Rebib et al. (2012) reviewed the biological control of Fusarium foot rot of wheat using fengycin-producing B. subtilis isolated from salty soil. A mycosubtilin from a B. subtilis BBG100 was effective for reducing a Pythium infection of tomato seedlings (Leclère et al. 2005). In the same context, Yokota and Hayakawa (2015) demonstrated direct disease suppression by the purified lipopeptides iturin A and surfactin from Bacillus sp against a soil-borne disease caused by Fusarium oxysporumon tatsoi. Zeriouh et al. (2011) reported the effect of UMAF6639 lipopeptides on the suppression of disease symptoms caused by Xanthomonas campestris pv. cucurbitae and Pectobacterium carotovorum subsp. carotovorum on melon leaves.

Prior efforts to understand lipopeptides mechanisms of action highlighted that micelles formation significantly induce their interference with the cell membranes. Lipopeptides have been shown to proceed mainly by antagonistic interactions with the plasma membranes of the mark fungus (Etchegaray et al. 2008; Romero et al. 2007; Straus and Hancock 2006). In fact, their amphiphilic nature may allow them to ingress many diverse biological membranes. This ability to target fungal and bacterial pathogens makes lipopeptides one of the most attractive candidate compounds among the next generation of plant health products (Joshi and McSpadden Gardener 2006).

However, other additional mechanisms were proposed for some of them. In fact, fengycin- and surfactin-type lipopeptides can stimule the plant immune system through their interaction with plant cells as a bacterial determinant. In this context, Ongena et al. (2007) reported an excesive accretion of plant phenolics compounds after treatment of potato tuber cells with purified fengycins. This path is also well recognized to be stimulated concomitantly with the activation of plant defence reactions. So lipopeptides could act not only as ‘antagonists’ by inhibiting phytopathogen growth but also as ‘immuno-stimulators’ by enhancing host resistance potential.

Conclusion

In conclusion, B. mojavensis A21 was a worthy biocontrol microorganism against Fusarium sp. in vitro and inhibited potato tuber rot severity. In exploring the mechanisms of this inhibition, the strain A21 was found to produce different isoforms of lipopeptides belonging to surfactin and fengycin families. The potato waste was proved to be potentially useful as sole substrate to improve lipopeptides production efficiency. These produced compounds would play a role in simultaneously offering better and more efficient disease control. Thus, lipopeptides A21 could be defined as a novel potential products to explore for use as biocontrol agents against plant disease.

References

Abalos A, Pinazo A, Infante MR, Casals M, García F, Manresa A (2001) Physicochemical and antimicrobial properties of new rhamnolipids produced by Pseudomonas aeruginosa AT10 from soybean oil refinery wastes. Langmuir 17:1367–1371

Agarry SE, Salam KK, Arinkoola A, Aremu MO (2015) biosurfactant production by indigenous Pseudomonas and Bacillus species isolated from auto mechanic sol environment towards microbial enhanced oil recovery. Eur J Eng Technol 3(6)

Barros FFC, Quadros CP, Maróstica MR, Pastore GM (2007) Surfactina: Propriedades químicas, tecnológicas e funcionais para aplicações em alimentos. Quim Nova 30:01–14

Ben Ayed H, Hmidet N, Béchet M, Chollet M, Chataigné G, Leclère V, Jacques P, Nasri M (2014) Identification and biochemical characteristics of lipopeptides from Bacillus mojavensis A21. Process Biochem 49:1699–1707

Bonmatin JM, Laprévote O, Peypoux F (2003) Diversity among microbial cyclic lipopeptides: iturins and surfactins. Activity-structure relationships to design new bioactive agents. Comb Chem High Throughput Screen. 6:541–556

Cao Y, Xu Z, Ling N, Yuan Y, Yang X, Chen L, Shen B, Shen Q (2012) Isolation and identification of lipopeptides produced by B. subtilis SQR 9 for suppressing Fusarium wilt of cucumber. Sci Hortic 135:32–39

Chandler J (2005) Cost reduction in SIT programmes using exosect auto-dissemination as part of area wide integrated pest management. Int Jof Pest Control 47:257–260

Chitarra GS, Breeuwer P, Nout MJR, van Aelst AC, Rombouts FM, Abee T (2003) An antifungal compound produced by Bacillus subtilis YM 10–20 inhibits germination of Penicillium roqueforti conidiospores. J Appl Microbiol 94:159–166

Coutte F, Lecouturier D, Yahia SA, Leclère V, Béchet M, Jacques P et al (2010) Production of surfactin and fengycin by Bacillus subtilis in a bubbleless membrane bioreactor. Appl Microbiol Biotechnol 87:499–507

Cowen LE, Sanglard D, Howard SJ, Rogers PD, Perlin DS (2015) Mechanisms of antifungal drug resistance. Cold Spring Harb Perspect Med 5:a019752

Das K, Tiwari RK, Shrivastava DK (2010) Techniques for evaluation of medicinal plant products as antimicrobial agent: current methods and future trends. J Med Plants Res 4:104–111

Deleu M, Razafindralambo H, Popineau Y, Jacques P, Thonart P, Paquot M (1999) Inter-facial and emulsifying properties of lipopeptides from Bacillus subtilis. Colloid Surf A 152:3–10

Des Grades ZE, der Agrarwissenschaften D, Fakultät HL, Wilhelms RF (2012) Biological control of leaf pathogens of tomato plants by Bacillus subtilis (strain FZB24): antagonistic effects and induced plant resistance. Inaugural-Dissertation, Institute of Crop Science and Resource Conservation—Phytomedicine, vorgelegt am 06.06.201

Etchegaray A, de Castro Bueno C, de Melo IS, Tsai SM, de Fátima Fiore MF, Silva-Stenico ME, de Moraes LAB, Teschke O (2008) Effect of a highly concentrated lipopeptide extract of Bacillus subtilis on fungal and bacterial cells. Arch Microbiol 190:611–622

Fox SL, Bala G (2000) Production of surfactant from Bacillus subtilis ATCC 21332 using potato substrates. Biores Technol 75:235–240

Fravel DR (2005) Commercialization and implementation of biocontrol. Annu Rev Phytopathol 43:337–359

Galvano F, Piva A, Ritienei A, Galvano G (2001) Dietary strategies to counteract the effect of mycotoxins: a review. J Food Prot 64:120–131

Gancel F, Montastruc L, Liu T, Zhao L, Nikov I (2009) Lipopeptide overproduction by cell immobilization on iron-enriched light polymer particles. Process Biochem 44:975–978

Gupta PK (2011) Herbicides and fungicides in reproductive and developmental toxicology

Gurjar J, Sengupta B (2015) Production of surfactin from rice mill polishing residue by submerged fermentation using Bacillus subtilis MTCC 2423. Bioresour Technol 189:243–249

Haddar A, Bougatef A, Agrebi R, Sellami-Kamoun A, Nasri M (2009) A novel surfactant stable alkaline-serine from a newly isolated Bacillus mojavensis A21: purification and characterization. Process Biochem 44:29–35

Hammami I, Triki MA, Rebai A (2011) Purification and characterization of the novel bacteriocin Back IH7 with antifungal and antibacterial properties. J Plant Pathol 93:443–454

Janardhana GR, Raveesha KA, Shetty HS (1999) Mycotoxin contamination of maize grains grown in Karnataka (India). Food Chem Toxicol 37:863–868

Joshi R, McSpadden Gardener BB (2006) Identification and characterization of novel genetic markers associated with biological control activities in Bacillus subtilis. Phytopathology 96:145–154

Kita N, Ohya T, Uekusa H, Nomura K, Manago M, Shoda M (2005) Biological control of damping-off of tomato seedlings and cucumber Phomopsis root rot by Bacillus subtilis RB14-C. Jpn Agric Res Q 39:109–114

Leclère V, Béchet M, Adam A, Guez JS, Wathelet B, Ongena M, Thonart P, Gancel F, Chollet-Imbert M, Jacques P (2005) Mycosubtilin overproduction by Bacillus subtilis BBG100 enhances the organism’s antagonistic and biocontrol activities. Appl Environ Microbiol 71:4577–4584

Leelasuphakul W, Hemmanee P, Chuenchitt S (2008) Growth inhibitory properties of Bacillus subtilis strains and their metabolites against the green mold pathogen (Penicillium digitatum Sacc.) of citrus fruit Postharvest. Biol Technol 48:113–121

Li L, Ma MC, Huang R, Qu Q, Li GH, Zhou JW, Zhang KQ, Lu KP, Niu XM, Luo J (2012) Induction of chlamydospore formation in fusarium by cyclic lipopeptide antibiotics from Bacillus subtilis C2. J Chem Ecol 38:966–974

Lin HF, Chen TH, Liu SD (2010) Bioactivity of antifungal substance iturin A produced by Bacillus subtilis strain BS-99-H against Pestalotiopsis eugeniae, a causal pathogen of wax apple fruit rot. Plant Pathol Bull 19:225–233

Makkar RS, Cameotra SS (2002) An update on the use of unconventional substrates for biosurfactant production and their new applications. Appl Microbiol Biotechnol 58:428–434

Matar SM, Kazzaz SAE, Wagih EE, El-Diwany AI, Moustafa HE (2009) Bioprocessing and scaling-up cultivation of Bacillus subtilis as a potential antagonist to certain plant pathogenic fungi. Biotech 8:138–143

Meena KR, Kanwar SS (2015) Lipopeptides as the antifungal and antibacterial agents: applications in food safety and therapeutics. Biomed Res Int. https://doi.org/10.1155/2015/473050

Miller JD (1995) Fungi and mycotoxins in grain: implications for stored product research. J Stored Prod Res 31:1–16

Mnif I, Hammami I, Triki MA, Cheffi Azabou M, Ellouze-Chaabouni S, Ghribi D (2015) Antifungal efficiency of a lipopeptide biosurfactant derived from Bacillus subtilis SPB1 versus the phytopathogenic fungus, Fusarium solani. Environ Sci Pollut Res 22:18137–18147

Noah KS, Bruhn DF, Bala GA (2005) Surfactin production from potato process efluent by Bacillus subtilis in a chemostat. App biochem biotechnol 122:465–474

Ongena M, Jacques P (2008) Bacillus lipopeptides: versatile weapons for plant disease biocontrol. Trends Microbiol 16:115–125

Ongena M, Jourdan E, Adam A, Paquot M, Brans A, Joris B, Arpigny JL, Thonart P (2007) Surfactin and fengycin lipopeptides of Bacillus subtilis as elicitors of induced systemic resistance in plants. Environ Microbiol 9:1084–1090

Rebib H, Hedi A, Rousset M, Boudabous A, Limam F, Sadfi-Zouaoui N (2012) Biological control of Fusarium foot rot of wheat using fengycin-producing Bacillus subtilis isolated from salty soil. Afr J Biotechnol 11:8464–8475

Romero D, de Vicente A, Rakotoalay RH, Dufour SE, Veening JW, Arrebola A, Cazorla FM, Kuipers OP, Paquot M, Pérez García A (2007) The iturin and fengycin families of lipopeptides are key factors in antagonism of Bacillus subtilis toward Podosphaera fusca. Mol Plant-Microbe Interact 20:430–440

Ruangwong OU, Chang CI, Lamine SA, Liang WJ (2012) Identification of antifungal compound produced by Bacillus subtilis LB5 with ability to control anthracnose disease caused by Colletotrichum gloeosporioides. Afr J Microbiol Res 6:3732–3738

Sharma D, Ansari MJ, Gupta S, Al Ghamdi A, Pruthi P, Pruthi V (2015a) Structural characterization and antimicrobial activity of a biosurfactant obtained from Bacillus pumilus DSVP18 grown on potato peels Jundishapur. J Microbiol. https://doi.org/10.5812/jjm.21257

Sharma R, Rani D, Jain N, Katwa SM, Jaitawat A (2015b) Healthy pregnancy with potato: a review. Int J Curr Res Biosci Plant Biol 2:35–46

Straus SK, Hancock REW (2006) Mode of action of the new antibiotic for Gram-positive pathogens daptomycin: comparison with cationic antimicrobial peptides and lipopeptides. Biochim Biophys Acta Biomembr 1758:215–1223

Suprapta DN (2012) Potential of microbial antagonists as biocontrol agents against plant fungal pathogens. J ISSAAS 18:1–8

Surekha K, Satpute Grażyna A, Płaza Arun GB (2017) Biosurfactants’ production from renewable natural resources: example of innovative and smart technology in circular bioeconomy. Manag Syst Prod Eng 25:46–54

Tawara S, Ikeda F, Maki K, Morishita Y et al (2000) In vitro activities of a new lipopeptide antifungal agent, FK463, against a variety of clinically important fungi. Antimicrob Agents Chemother 44:57–62

Thompson DN, Fox SL, Bala GA (2000) Biosurfactants from potato process effluents. Appl Biochem Biotechnol 84–86:917–930

Yangui T, Sayadi S, Dhouib A (2013) Sensitivity of Pectobacteriu mcarotovorum to hydroxytyrosol-rich extracts and their effect on the development of soft rot in potato tubers during storage. Crop Prot 53:52–57

Yokota K, Hayakawa H (2015) Impact of antimicrobial lipopeptides from Bacillus sp. on suppression of Fusarium yellows of tatsoi. Microbes Environ 30:281–283

Zeriouh H, Romero D, García-Gutiérrez L, Cazorla FM, de Vicente A, García A (2011) The iturin-like lipopeptides are essential components in the biological control arsenal of Bacillus subtilis against bacterial diseases of cucurbits. Am Phytopathol Soc 24:1540–1552

Zhang SM, Wang YX, Meng LQ, Li J et al (2012) Isolation and characterization of antifungal lipopeptides produced by endophytic Bacillus amyloliquefaciens TF28. Afr J Microbiol Res 6:1747–1755

Zouari R, Ellouze-Chaabouni S, Ghribi-Aydi D (2015) Optimization of Bacillus subtilis SPB1 biosurfactant production under solid-state fermentation using by-products of a traditional olive mill factory Ach. Life Sci 8:162–169

Zu W, Yu H, Liang L, Fu Y, Efferth T, Liu X, Wu N (2010) Activities of ten essential oils towards Propionibacterium acnes and PC-3, A-549 and MCF-7 cancer cells. Molecules 15:3200–3210

Funding

This work has been supported by grants from the Tunisian Ministry of Higher Education, Scientific Research and Technology and the Tunisian Ministry of Agriculture.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ayed, H.B., Azabou, M.C., Hmidet, N. et al. Economic production and biocontrol efficiency of lipopeptide biosurfactants from Bacillus mojavenis A21. Biodegradation 30, 273–286 (2019). https://doi.org/10.1007/s10532-018-9864-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10532-018-9864-7