Abstract

Microbial pretreatment of lignocellulosic biomass holds significant promise for environmentally friendly biofuel production, offering an alternative to fossil fuels. This study focused on the isolation and characterization of two novel delignifying bacteria, GIET1 and GIET2, to enhance cellulose accessibility by lignin degradation. Molecular characterization confirmed their genetic identities, providing valuable microbial resources for biofuel production. Our results revealed distinct preferences for temperature, pH, and incubation period for the two bacteria. Bacillus haynesii exhibited optimal performance under moderate conditions and shorter incubation period, making it suitable for rice straw and sugarcane bagasse pretreatment. In contrast, Paenibacillus alvei thrived at higher temperatures and slightly alkaline pH, requiring a longer incubation period ideal for corn stalk pretreatment. These strain-specific requirements highlight the importance of tailoring pretreatment conditions to specific feedstocks. Structural, chemical, and morphological analyses demonstrated that microbial pretreatment reduced the amorphous lignin, increasing cellulose crystallinity and accessibility. These findings underscore the potential of microbial pretreatment to enhance biofuel production by modifying the lignocellulosic biomass. Such environmentally friendly bioconversion processes offer sustainable and cleaner energy solutions. Further research to optimize these methods for scalability and broader application is necessary in the pursuit for more efficient and greener biofuel production.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The world’s increasing demand for sustainable and renewable sources of energy (Ritchie et al. 2020) necessitates innovative solutions to address the urgent challenges of climate change and the need for a reliable energy supply (Owusu and Asumadu-Sarkodie 2016). Lignocellulosic biomass (LCB), derived from a variety of plant sources, has emerged as a promising feedstock for bioenergy production due to its abundance and renewability (Himmel et al. 2007). However, the recalcitrant nature of biomass, primarily attributed to the presence of lignin, poses a formidable barrier to its efficient conversion into biofuels (Zoghlami and Paes 2019). Lignin, a complex aromatic polymer, acts as a natural defense mechanism in plants, safeguarding them against microbial and enzymatic degradation (Vanholme et al. 2010). This inherent recalcitrance necessitates a preprocessing step, delignification, to liberate the cellulose and hemicellulose fractions for subsequent conversion into biofuels (Tocco et al. 2021). Traditional delignification methods often involve harsh physical and chemical treatments, which not only consume considerable energy but also generate environmental issues (Ragauskas et al. 2014).

In response to these challenges, microbial pretreatment has emerged as an environmentally friendly and energy-efficient alternative for biomass delignification (Tsegaye et al. 2019). Microorganisms, including bacteria and fungi, possess the remarkable ability to produce an array of ligninolytic enzymes that can selectively degrade lignin and facilitate the release of fermentable sugars (Hatakka 2005). Moreover, they offer the advantage of high specificity, reducing the need for additional chemicals and minimizing undesirable by-products.

This work explores the dynamic landscape of microbial pretreatment in the context of biomass delignification and bioenergy production (Ferdes et al. 2020). We presented the optimized growth conditions of two bacterial isolates for the effective delignification of three selected lignocellulosic biomass samples that influence the effectiveness of this green and sustainable pretreatment approach (Yadav et al. 2022). Additionally, we discussed the importance of optimization of growth conditions that enhances the efficiency of microbial delignification, paving the way for a more economically viable and environmentally sustainable bioenergy production process (Baruah et al. 2018).

The objective of this piece of research is in-situ isolation of the delignifying bacteria Bacillus haynesii and Paenibacillus alvei from soil and optimization of their growth conditions for effective delignification of selected LCB. It provides a comprehensive overview of the current state of research in the field of microbial pretreatment for biomass delignification, emphasizing its potential to transform the bioenergy industry.

Materials and methods

Sample collection and isolation

To successfully isolate novel bacteria, we collected samples from the agricultural feed stock area in an Agri-farm of GIET University (latitude 19.05025° and longitude 83.83238°), Gunupur. These samples were carefully sealed in airtight zip-lock bags and subsequently transported to the laboratory for further experimentation. Upon arrival in the laboratory, 1g of each sample was suspended in 100 ml of sterile distilled water. From this suspension, 1ml of sample was utilized to perform serial dilutions. The serial dilution process includes the following dilutions such as 10−8, 10−9, and 10−10 for bacterial isolation purposes.

Preparation of selective media for screening of lignin degrading bacteria

The selective media was prepared by adding 2 g of hay powder of respective biomass (rice straw, sugarcane bagasse and wheat straw), 0.8 g of KH2PO4, 0.4 g of K2HPO4, 0.5 g of MgSO4⋅7H2O, 2 g of NH4 NO3, 2 g of yeast extract and 15 g of agar in 1000 ml of distilled water. The medium was autoclaved at 121 °C for 15 min. The medium was plated on sterile petri plates. In order to isolate lignin degrading bacteria, the bacteria isolated were sub-cultured on to the selective media (lignin agar) and incubated at 37 °C for 24 h (Umashankar et al. 2018).

Molecular characterization

16S rDNA-based molecular analysis

DNA isolation

The isolated pure bacterial colonies were cultured in fresh medium after 48 h of incubation using InstaGene™ Matrix Genomic DNA isolation kit genomic DNA was isolated. Then the quality of the extracted DNA was assessed by running it on a 1.0% agarose gel. A single, high molecular-weight DNA band was observed under UV light, confirming the integrity of the DNA.

Polymerase Chain Reaction (PCR) Amplification of 16S rDNA: A specific fragment of the 16S rDNA gene was amplified using the 27F and 1492R primers. The PCR amplification process involved the following steps: A PCR reaction mixture was prepared, including template DNA, primers, and a suitable DNA polymerase. PCR amplification was performed under appropriate conditions. The resulting PCR products were analyzed by agarose gel electrophoresis. A single, discrete PCR amplicon band with an approximate size of 1500 base pairs (bp) was visualized (Johnson et al. 2019).

PCR amplicon purification

To eliminate any potential contaminants, the PCR amplicon was purified using a DNA purification kit.

DNA sequencing

Forward and reverse DNA sequencing reactions of the purified PCR amplicon were conducted using a sequencing kit, such as the BDT v3.1 Cycle sequencing kit, on an ABI 3730xl Genetic Analyzer.

Sequence analysis

Sequence data obtained from both forward and reverse reads were used to generate a consensus sequence of the 16S rDNA gene using Basic Local Alignment Search Tool (BLAST).

Bioinformatics analysis

The generated 16S rDNA gene sequence was subjected to the following bioinformatics analysis tools: BLAST was performed against the NCBI GenBank database to identify similar sequences. The top ten sequences with the highest identity scores were selected. The selected sequences were aligned using a multiple alignment software program, such as Clustal W, to identify conserved regions and variations. A distance matrix was generated to quantify the genetic distances between the sequences. Using software like MEGA 7, a phylogenetic tree was constructed based on the aligned sequences, allowing for the visualization of the evolutionary relationships between the sample sequence and other related sequences in the database.

Preparation of cellulose standard

Cellulose standard curve is required in order to determine the concentration of cellulose released after pretreatment. It was prepared using standard cellulose solutions by taking pure form of cellulose powder. Taken 0.01 g of cellulose in 10ml of distilled water with a final concentration of 1000 µg/ml as a stock solution. Then different concentrations of cellulose working standards such as 20, 40, 60, 80, 100, 120, 140, 160, 180, 200 µg/ml were prepared from the stock standard solution. Then 2 ml of each standard was mixed separately with 3 ml of freshly prepared anthrone reagent (2 g anthrone in 000 ml of sulphuric acid) (Viles and Silverman 1949). The solutions were subject to boiling at 100 °C in water bath for development of green-blue color. Further the solutions were brought into room temperature and optical density was measured at 630 nm using UV–Visible spectrophotometer (Systronics-119). The standard curve was plotted by taking concentrations of standard cellulose solutions in x-axis and optical density in y-axis. The concentration of cellulose released from each biomass sample after pretreatment was measured using standard curve by taking the given formula into account.

From standard curve, y = 0.0058 × x − 0.0027

Here, y is the dependent variable, which is typically your measured or observed values x is the independent variable, which represents the concentration of a standard solution, m is the slope of the linear regression line, which represents how much y changes for a unit change in x. In the context of a standard curve C is the y-intercept of the line.

Microbial pretreatment

Optimization of incubation period

The biological pretreatment of LCB samples were carried out at optimum pH (pH 7) and temperature 37 °C for 15 days of incubation. 5 g of each biomass samples was taken in 250 ml conical flasks and added 200 ml of distilled water into it. Then the samples were autoclaved at 121 °C for 15 min and further the biomass samples were cooled at room temperature. Each biomass sample was inoculated with a microbial load of 500 µl/10 ml, the pH was set to 7 and incubated at 37 °C for 15 days. Then the concentration of free cellulose at different days of incubation for both Bacillus haynesii and Paenibacillus alvei treated biomass sample were estimated for the following days of incubation 1 dpi, 3 dpi, 5 dpi, 7 dpi, 9 dpi, 11 dpi, 13 dpi and 15 dpi to determine the delignification. The free cellulose was estimated by following the cellulose standard curve as shown in Fig. 1.

Optimization of temperature

The biological pretreatment of LCB samples were carried out at optimum pH (pH 7) and microbial concentration (500 µl/10 ml). The pretreatment of LCB samples such as rice straw, sugarcane bagasse and corn stalk were performed by both GIET1 and GIET2 separately as like pH optimization. The pretreatment was carried out by taking 5 g of each powdered biomass samples in 200 ml distilled water in a 250 ml conical flask. Then the samples were autoclaved at 121 °C for 15 min and further the biomass samples were cooled at room temperature. The pH of each biomass sample was set to neutral and inoculated with 500 µl/10 ml of B. haynesii and P. alvei. Then the sample were incubated at different temperature like 32 °C, 37 °C and 42 °C for 15 days. Then the concentration of free cellulose at different temperature conditions of both B. haynesii and P. alvei treated biomass samples were estimated for the following days of incubation 1 dpi, 3 dpi, 5 dpi, 7 dpi, 9 dpi, 11 dpi, 13 dpi and 15 dpi to determine the delignification. The free cellulose was estimated by following the cellulose standard curve.

Optimization of pH

After identification of bacterial strains, the biological pretreatment of LCB samples such as rice straw, sugarcane bagasse and corn stalk were performed by both B. haynesii and P. alvei separately. The pretreatment was carried out by taking 5 g of each powdered biomass samples in 200 ml distilled water taken in a 250 ml conical flask. Then the samples were autoclaved at 121 °C for 15 min and further the biomass samples were cooled at room temperature. The pH of each biomass sample is adjusted to 6.0, 6.5, 7.0, 7.5, and 8.0 respectively. Each biomass sample with varying pH was inoculated with bacterial culture of 500 µl/10 ml of both B. haynesii and P. alvei separately and incubated at 37 °C for 15 days. Then the concentration of free cellulose at different pH conditions of both B. haynesii and P. alvei treated biomass sample were estimated for the following days of incubation 1 dpi, 3 dpi, 5 dpi, 7 dpi, 9 dpi, 11 dpi, 13 dpi and 15 dpi to determine the delignification. The free cellulose was estimated by following the cellulose standard curve.

Optimization of microbial load

The biological pretreatment of LCB samples were carried out at optimum pH (pH 7) and temperature 37 °C for 15 days of incubation. Taken 5 g of each biomass samples in 250 ml conical flasks and added 200 ml of distilled water into it. Then the samples were autoclaved at 121 °C for 15 min and further the biomass samples were cooled at room temperature. Each biomass sample was inoculated with a microbial load of 500 µl/10 ml, the pH was set to 7 and incubated at 37 °C for 15 days. Then the concentration of free cellulose at different days of incubation for both B. haynesii and P. alvei treated biomass sample were estimated for the following days of incubation 1 dpi, 3 dpi, 5 dpi, 7 dpi, 9 dpi, 11 dpi, 13 dpi and 15 dpi to determine the delignification. The free cellulose was estimated by following the cellulose standard curve.

Fourier transform infrared (FTIR) analysis

Monitoring changes in the FTIR spectra that are indicative of lignin removal or alteration is necessary to determine the delignification of LCB using FTIR data. The effects of microbial pretreatment on the biomass components (cellulose, hemicelluloses, and lignin) of LCB such as rice straw, sugarcane bagasse and corn stalk were investigated using FTIR spectroscopy (Mothe and De Miranda 2009). The FTIR spectra of untreated and microbial pretreated biomass samples were obtained by using FTIR 3000-Bruker. The fiber powder sample (10 mg) of each LCB of untreated and pretreated mixed with (200 mg) KBr salt separately followed by compression to form a homogenous disc for analysis. The FTIR data for all the LCB samples was obtained in the range of 4000–400 cm-1 at a resolution of 0.2 cm−1 with the rapid scan of 65 spectra/sec at 16 cm−1.

Powder-X-ray diffraction (XRD) analysis

The structure and crystallinity of LCB can be evaluated in relation to the effect of pretreatment using XRD analysis. It offers vital details for improving pretreatment procedures and creating more effective techniques for converting biomass into biofuels. The PXRD was performed to determine the crystallinity of cellulose of untreated and microbial pretreated biomass samples using Rigaku Miniflex instrument operated at 30 kV and 15 mA with λ (Cu Kα radiation) = 1.54 Å. The crystallinity index of cellulose in LCB samples of both untreated and pretreated was determined using the following peak intensity method (Segal et al. 1959).

where, CI is the crystallinity index, I002 is the maximum intensity at 2° = 22.17° (cellulose) and Iam is the minimum intensity corresponding to the amorphous content at 2° = 18.0° (cellulose, hemicellulose and lignin), (Harris et al. 2008; Naik et al. 2010; Kuila et al. 2011; Xiao et al. 2011).

Scanning electron microscope (SEM) analysis

SEM offers detailed information on surface and microstructural changes in LCB after pretreatment. The changes in surface morphology and structure of native rice straw, sugarcane bagasse, corn stalk and that with GIET1, GIET2 microbial pretreated samples were investigated. Prior to analysis, the biomass samples were fixed onto copper stubs using carbon tape. After fixation, gradual dehydration of all the samples was done by increasing the concentration of ethanol solution. Then the samples were incubated at 50 °C for 24 h in hot air oven for complete drying. Further, the samples were coated with gold particles and the surface morphology images of untreated and microbially pretreated LCB samples were taken at magnification of 2500× using FESEM JEOL, JSM-7610F scanning electron microscope with acceleration voltage between 10 and 20 kV. In order to provide a clear observation, thorough investigation was conducted for each sample and at least 5 photographs per sample were acquired from various locations.

Results and discussion

The utilization of microorganisms including both bacteria and fungi for delignification of lignocellulosic biomass holds an immense potential because the process is eco-friendly and effective in biofuel production. However, the inherent recalcitrance of lignocellulosic materials necessitates effective pretreatment methods to enhance the bioconversion process. One promising strategy involves screening bacterial cultures from diverse environmental sources to identify novel microorganisms capable of efficiently degrading lignocellulosic materials for biofuel production (Pena-Castro et al. 2023).

In this study, we isolated and identified delignifying bacterial strains with the capacity to break down lignin and improve the accessibility of free cellulose for enzymatic hydrolysis (Tian et al. 2016). Out of 15 different isolates, two bacterial isolates labelled as GIET1 and GIET2, demonstrated significant delignification potential (Wang et al. 2016).

The isolated bacteria were identified through both traditional techniques, following Bergey’s Manual, and molecular characterization, employing PCR and 16S rRNA gene sequences (Kitahara et al. 2023). The results of the molecular characterization, which are presented in Table 1, confirmed the identities of the two bacteria (Olatunji et al. 2021).

The molecular characterization of GIET1 identified it as Bacillus sp., closely related to Bacillus haynesii, with a high similarity of 99.57, GIET2 was identified as Paenibacillus sp., specifically Paenibacillus alvei, with a similarity of 99.46%. These findings indicated that both bacterial cultures belong to their respective genera with high genetic similarity to the identified species and their forward and reverse sequence data are shown below:

16S rDNA gene sequence of Bacillus haynesii

16S rDNA sequence of Paenibacillus alvei

The isolation of these delignifying bacteria, B. haynesii and P. alvei, showcases the potential for leveraging novel microbial resources in lignocellulosic biomass degradation. These bacterial cultures can be valuable in the development of eco-friendly and efficient biofuel production processes by enhancing the breakdown of lignin, a significant barrier in the bioconversion of biomass. The results of this study contribute to the growing body of knowledge on lignocellulose degradation and biofuel production, emphasizing the importance of microbial screening and isolation for sustainable and renewable energy solutions.

Cellulose standard curve

The optical density of all the cellulose standard solutions were measured at 630 nm against anthrone reagent as reference. The optical densities were recorded and a standard curve was plotted as shown in Fig. 1.

Microbial pretreatment

Bacillus haynesii treated biomass

The impact of B. haynesii pretreatment on rice straw was characterized by examining cellulose concentrations over the incubation period. Initially, there was a substantial increase in cellulose concentration from day 1 to day 7, indicating that B. haynesii effectively initiated lignin breakdown, leading to an enhanced release of cellulose. However, beyond day 7, there was a slight decline in cellulose concentration, suggesting a potential plateau in the pretreatment process. Notably, the highest cellulose concentration was achieved on the 7th day, suggesting that this timeframe is optimal for rice straw pretreatment with B. haynesii.

In contrast, B. haynesii-treated sugarcane bagasse displayed consistent increases in cellulose concentration throughout the incubation period. The most substantial increase occurred from day 1 to day 5, after which cellulose concentration stabilized. This steady rise in cellulose concentration suggests that B. haynesii is efficient in continuously delignifying sugarcane bagasse. The data implies that the optimal incubation period for achieving maximum cellulose concentration is approximately 5 days.

B. haynesii-treated corn stalk exhibited fluctuating cellulose concentrations during the incubation period. An initial increase was observed from day 1 to day 5, followed by fluctuations and a gradual decline. These fluctuations may be attributed to the complex lignocellulosic structure of corn stalk, suggesting that B. haynesii’s performance on corn stalk is less consistent compared to rice straw and sugarcane bagasse. Achieving optimal results with corn stalk may require further investigation and optimization of pretreatment conditions.

These results underscore the diverse effects of B. haynesii pretreatment on different lignocellulosic biomasses. Understanding the variations in cellulose concentration over time is crucial for optimizing the pretreatment process and enhancing biofuel production. Further research should delve into the mechanisms underlying these observations and fine-tune the process conditions for maximum efficiency.

Paenibacillus alvei treated biomass

For P. alvei treated rice straw, the incubation period exhibited distinct patterns in cellulose concentration. There was a steady increase from day 1 to day 9, with the highest concentration observed on day 9. This suggests that P. alvei effectively initiates lignin degradation, leading to a substantial increase in free cellulose content. Beyond day 9, cellulose concentration remained relatively stable, with minor fluctuations.

In the case of P. alvei-treated sugarcane bagasse, cellulose concentrations consistently rose throughout the incubation period. The most substantial increase occurred from day 1 to day 5, after which cellulose concentration remained stable. This pattern suggests that P. alvei efficiently delignifies sugarcane bagasse. The optimal incubation period for achieving the highest cellulose concentration appears to be around the 5th day.

P. alvei-treated corn stalk displayed variations in cellulose concentration during the incubation period. A significant increase was observed from day 1 to day 7, with the highest concentration on day 7, followed by a period of fluctuation and gradual decline.

These outcomes highlight the distinct effects of P. alvei pretreatment on different lignocellulosic biomasses. Understanding these variations in cellulose concentration changes over time is essential for refining the pretreatment process and ultimately enhancing biofuel production. Further investigations could delve into the underlying mechanisms behind these observations and fine-tune the process conditions for maximum efficiency.

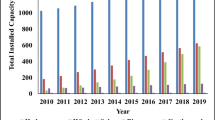

Effect of temperature

The temperature was a critical factor influencing the efficiency of microbial pretreatment for both B. haynesii and P. alvei. For B. haynesii, the optimal temperature conditions for cellulose recovery were identified as 37 °C for rice straw, sugarcane bagasse and corn stalk. In contrast, P. alvei showed remarkable cellulose recovery at 42 °C for rice straw, sugarcane bagasse and corn stalk, as shown Fig. 2.

The results highlight the strain-specific nature of the temperature requirement for effective lignin degradation and cellulose recovery. B. haynesii displayed better performance at a moderate temperature, whereas P. alvei required higher temperatures for maximum efficiency. These findings underscore the significance of tailoring temperature conditions to the specific microbial strain used for pretreatment.

Effect of pH

pH optimization played a crucial role in enhancing cellulose recovery during microbial pretreatment. B. haynesii demonstrated its optimal pH at 6.5 for rice straw and sugarcane bagasse, while corn stalk required a slightly lower pH of 6. P. alvei, on the other hand, exhibited maximum cellulose recovery at a pH of 7.5 for all three biomass types, as shown in Fig. 3.

The differences in pH requirements between the two bacteria emphasize their distinct enzymatic activities and lignin degradation capabilities. B. haynesii’s preference for a slightly acidic to neutral pH range suggests its proficiency in breaking down lignin under these conditions, whereas P. alvei’s alkaline pH requirement indicates its ability to effectively degrade lignin at higher pH levels.

Effect of microbial load

The microbial load is another critical factor influencing the microbial pretreatment process. Both B. haynesii and P. alvei exhibited different microbial load requirements for optimal cellulose recovery. Bacillus haynesii achieved the best results with a microbial load of 500 µl for all three biomass types. In contrast, P. alvei also performed optimally with a microbial load of 500 µl, as shown in Fig. 4.

The consistency in microbial load requirements for P. alvei across all three feedstocks suggests its resilience and adaptability to various biomass types. In contrast, B. haynesii’s specific microbial load requirement may be attributed to its unique enzymatic capabilities and microbial activity.

Comparative analysis

Comparing the performance of B. haynesii and P. alvei, it is evident that both strains display distinct temperature, pH, and microbial load preferences (Qiu et al. 2022; Tan et al. 2022). Bacillus haynesii exhibits efficiency under moderate conditions, particularly at 37 °C and pH 6.5, facilitating a faster cellulose recovery (Johnson et al. 2019). In contrast, P. alvei demonstrates optimal performance under elevated temperature and slightly more alkaline pH conditions, notably at 42 °C and pH 7.5, albeit with a slightly extended incubation period (Liao et al. 2006; Mei et al. 2014). These findings emphasize the adaptability of different microbial strains to specific pretreatment conditions, underscoring the importance of customizing these parameters for optimal lignin degradation and cellulose release (Zeng et al. 2013; Lynd et al. 2022).

FTIR spectroscopy played a pivotal role in investigating alterations in functional groups and chemical structures within various lignocellulosic biomass samples, including rice straw, sugarcane bagasse, and corn stalk, both before and after pretreatment (Sills and Gossett 2012; Ma et al. 2022). The results unveiled substantial changes in the FTIR spectral peaks, elucidating the structural and chemical transformations induced by the pretreatment procedures. Notably, the pretreated biomass samples exhibited heightened peak intensities within the 3429–3447 cm−1 range, corresponding to O–H stretching vibrations as shown in Figs. 5, 6 and 7. This increase strongly implied an enhanced accessibility of cellulose, particularly post-pretreatment (Podgorbunskikh et al. 2019).

Furthermore, an increase in the intensity of C–H stretching vibrations at 2916–2919 cm−1 suggested the breakdown of acetyl and ester linkages in lignin, providing clear evidence of lignin degradation (Moosavinejad et al. 2019). This removal of lignin was further substantiated by the absence of peaks around 1720–1733 cm−1, signifying the cleavage of ester bonds (Lou et al. 2023). The augmented signals at 1636–1642 cm−1, associated with C=O stretching vibrations, indicated delignification and the release of free hemicellulose. Additionally, the intensified signals at 1037–1061 cm−1 for C–O–C and C–O stretching vibrations pointed to increased accessibility of cellulose and hemicellulose (Zhuang et al. 2020). The discernible downward peaks in the fingerprint region (1508.57–442.45 cm−1) further revealed reduced crystallinity within the samples, potentially contributing to improved digestibility and enzymatic degradation.

The assessment of crystallinity index (CI) in untreated and pretreated lignocellulosic biomass samples was performed using X-ray diffraction (XRD) analysis (Melesse et al. 2022; Montoya-Escobar et al. 2022; Karthika et al. 2012). The results of this analysis unveiled a clear and direct association between CI and cellulose content. Specifically, the pretreated biomass samples exhibited a notably higher CI, a phenomenon attributed to the increased presence of crystalline cellulose following the removal of amorphous lignin (Baruah et al. 2018) as shown in Figs. 8, 9 and 10.

Significantly, both chemical and microbial pretreatments were found to result in the removal of a substantial proportion of amorphous lignin, leading to a remarkable boost in CI. This heightened CI serves as a robust indicator of the augmented crystalline cellulose content within the pretreated lignocellulosic biomass (Montoya-Escobar et al. 2022). These findings are consistent with prior research demonstrating a similar increase in CI following alkali pretreatment, thereby further emphasizing the potential for enhanced enzymatic digestibility and biofuel production (Gong et al. 2023).

SEM analysis was conducted to examine the microstructural and morphological changes in rice straw, sugarcane bagasse, and corn stalk after microbial pretreatment with B. haynesii and P. alvei (Marzouk et al. 2023). The images revealed striking transformations in the surface structures of the biomass. Untreated biomass samples exhibited smooth, compact, and rigid surfaces due to lignin lamination on the fibers (Ma et al. 2022). In contrast, pretreated biomass samples displayed cracks and substantial disruption in well-ordered cellulose microfibril structures. This structural perturbation, induced by pretreatment, increased the enzymatic accessibility of cellulose (Nakagame et al. 2011). Moreover, pretreated biomass exhibited greater porosity and internal surface area, resulting from the fragmentation and cleavage of cellulose microfibrils (Meng et al. 2016). The structural changes confirmed the separation of structural linkages between lignin and cellulose and disruptions in the lignin structure. The results of SEM analysis showed in Figs. 11, 12 and 13 were in line with the findings from FTIR and XRD analyses, collectively pointing to the effectiveness of microbial pretreatment in modifying the morphology and structure of lignocellulosic biomass (Ahmed et al. 2022; Sunkar and Bhukya 2022).

These analyses collectively demonstrate the efficacy of pretreatment processes in altering the structural, chemical, and morphological attributes of lignocellulosic biomass, making it more amenable to enzymatic digestion and biofuel production.

Conclusions

This study explored the potential of microbial pretreatment as a crucial step in the bioconversion of lignocellulosic materials into biofuels. The isolation and identification of two delignifying bacteria Bacillus haynesii and Paenibacillus alvei, provided the foundation for investigating their effectiveness in enhancing the accessibility of free cellulose through enzymatic degradation of lignin. The molecular characterization of these strains confirmed their genetic identities and highlighted their potential for biofuel production.

Our findings revealed that the two strains exhibited distinctive preferences for pretreating different lignocellulosic biomasses. B. haynesii displayed optimal performance at moderate temperature and pH conditions, with a shorter incubation period, making it a promising candidate for the pretreatment of rice straw and sugarcane bagasse. In contrast, P. alvei thrived under higher temperature and slightly alkaline pH conditions, and it demonstrated an extended incubation period that is well-suited for corn stalk pretreatment. These strain-specific variations underscore the importance of customizing pretreatment conditions for different feedstocks, thereby maximizing lignin degradation and cellulose release.

The combination of FTIR, XRD, and SEM analyses provided valuable insights into the structural, chemical, and morphological transformations of pretreated lignocellulosic biomass. Our results demonstrated that both chemical and microbial pretreatments led to a considerable reduction in amorphous lignin, increasing the crystallinity index of cellulose. The enhanced accessibility of cellulose was evident in the FTIR spectra, with increased intensities of O–H and C–H stretching vibrations, indicating the effectiveness of lignin degradation. SEM imaging revealed the disruption of lignin structures, increased porosity, and greater enzymatic accessibility of cellulose.

In conclusion, this study underscores the potential of microbial pretreatment for improving the efficiency of biofuel production from lignocellulosic biomass. The isolation of novel bacterial B. haynesii and P. alvei, with distinct pretreatment preferences, offers a promising avenue for tailoring pretreatment strategies to different feedstocks. This approach not only contributes to sustainable biofuel production but also aligns with the broader goal of transitioning to eco-friendly energy sources and reducing the dependence on fossil fuels. Further research can delve deeper into the optimization of pretreatment parameters and scaling up these processes, bringing us closer to a cleaner and more sustainable energy future.

Data availability

The authors are committed to making the data and materials associated with this research available upon request for the purpose of transparency and scientific inquiry.

References

Ahmed E et al (2022) Lignocellulosic biomasses from agricultural wastes improved the quality and physicochemical properties of frying oils. Foods 11(19):3149. https://doi.org/10.3390/foods11193149

Baruah J et al (2018) Recent trends in the pretreatment of lignocellulosic biomass for value-added products. Front Energy Res. https://doi.org/10.3389/fenrg.2018.00141

Ferdeș M et al (2020) Microorganisms and enzymes used in the biological pretreatment of the substrate to enhance biogas production: a review. Sustainability 12(17):7205. https://doi.org/10.3390/su12177205

Gong JSQ et al (2023) Enhanced enzymolysis and bioethanol yield from tobacco stem waste based on mild synergistic pretreatment. Front Energy Res. https://doi.org/10.3389/fenrg.2022.989393

Harris D, DeBolt S (2008) Relative crystallinity of plant biomass: studies on assembly, adaptation and acclimation. PLoS ONE 3(8):e2897. https://doi.org/10.1371/journal.pone.0002897

Hatakka A (2005) Biodegradation of lignin. Environmental and microbial relationships. Springer, Cham, pp 85–115

Himmel ME, Ding SY, Johnson DK, Adney WS, Nimlos MR, Brady JW, Foust TD (2007) Biomass recalcitrance: Engineering plants and enzymes for biofuels production. Science 315(5813):804–807

Johnson JS, Spakowicz DJ, Hong BY, Petersen LM, Demkowicz P, Chen L, Leopold SR, Hanson BM, Agresta HO, Gerstein M, Sodergren E, Weinstock GM (2019) Evaluation of 16S rRNA gene sequencing for species and strain-level microbiome analysis. Nat Commun. https://doi.org/10.1038/s41467-019-13036-1

Karthika K, Arun AB, Rekha PD (2012) Enzymatic hydrolysis and characterization of lignocellulosic biomass exposed to electron beam irradiation. Carbohyd Polym 90(2):1038–1045. https://doi.org/10.1016/j.carbpol.2012.06.040

Kitahara K et al (2023) Flavobacterium okayamense sp. Nov. isolated from surface seawater. Arch Microbiol. https://doi.org/10.1007/s00203-023-03682-x

Kuila A et al (2011) Production of ethanol from lignocellulosics: an enzyme venture. EXCLI J 10:85–96

Liao CC, Liu SL, Wang WL (2006) Effects of temperature and pH on growth and photosynthesis of the thermophilic cyanobacterium Synechococcus lividus as measured by pulse-amplitude modulated fluorometry. Phycol Res 54(4):260–268. https://doi.org/10.1111/j.1440-1835.2006.00432.x

Lou Y et al (2023) One-pot protolignin extraction by targeted unlocking lignin–carbohydrate esters via nucleophilic addition–elimination strategy. Research 6:0069. https://doi.org/10.34133/research.0069

Lynd LR et al (2022) Toward low-cost biological and hybrid biological/catalytic conversion of cellulosic biomass to fuels. Energy Environ Sci 15(3):938–990. https://doi.org/10.1039/d1ee02540f

Ma Y et al (2022) A combination of novel microecological agents and molasses role in digestibility and fermentation of rice straw by facilitating the ruminal microbial colonization. Front Microbiol. https://doi.org/10.3389/fmicb.2022.948049

Ma S et al (2022) Structural changes in lignin during different pretreatment ways of bamboo biomass and the effect on enzymatic hydrolysis. SSRN Electron J. https://doi.org/10.2139/ssrn.4020952

Marzouk HA et al (2023) Effect of agricultural phragmites, rice straw, rice husk, and sugarcane bagasse ashes on the properties and microstructure of high-strength self-compacted self-curing concrete. Buildings 13(9):2394. https://doi.org/10.3390/buildings13092394

Mei N et al (2014) Fermentative hydrogen production by a new alkaliphilic Clostridium sp. (strain PROH2) isolated from a shallow submarine hydrothermal chimney in Prony Bay, New Caledonia. Int J Hydrogen Energy 39(34):19465–19473. https://doi.org/10.1016/j.ijhydene.2014.09.111

Melesse GT, Hone FG, Mekonnen MA (2022) Extraction of cellulose from sugarcane bagasse optimization and characterization. Adv Mater Sci Eng 2022:1–10. https://doi.org/10.1155/2022/1712207

Meng X et al (2016) Physicochemical structural changes of poplar and Switchgrass during biomass pretreatment and enzymatic hydrolysis. ACS Sustain Chem Eng 4(9):4563–4572. https://doi.org/10.1021/acssuschemeng.6b00603

Montoya-Escobar N et al (2022) Use of fourier series in X-ray diffraction (XRD) analysis and fourier-transform infrared spectroscopy (FTIR) for estimation of crystallinity in cellulose from different sources. Polymers 14(23):5199. https://doi.org/10.3390/polym14235199

Moosavinejad SM et al (2019) Evaluation of degradation in chemical compounds of wood in historical buildings using FT-IR and FT-Raman vibrational spectroscopy. Maderas Ciencia y Tecnol. https://doi.org/10.4067/s0718-221x2019005000310

Mothe CG, De Miranda IC (2009) Characterization of sugarcane and coconut fibers by thermal 580 analysis and FTIR. J Therm Anal Calorim 97:661–665

Naik S et al (2010) Characterization of Canadian biomass for alternative renewable biofuel. Renew Energy 35(8):1624–1631. https://doi.org/10.1016/j.renene.2009.08.033

Nakagame S et al (2011) Enhancing the enzymatic hydrolysis of lignocellulosic biomass by increasing the carboxylic acid content of the associated lignin. Biotechnol Bioeng 108(3):538–548. https://doi.org/10.1002/bit.22981

Owusu PA, Asumadu-Sarkodie S (2016) A review of renewable energy sources, sustainability issues and climate change mitigation. Cogent Eng 3(1):1167990. https://doi.org/10.1080/23311916.2016.1167990

Peña-Castro JM et al (2023) Engineering the metabolic landscape of microorganisms for lignocellulosic conversion. Microorganisms 11(9):2197. https://doi.org/10.3390/microorganisms11092197

Podgorbunskikh EM, Bychkov AL, Lomovsky OI (2019) Determination of surface accessibility of the cellulose substrate according to enzyme sorption. Polymers 11(7):1201. https://doi.org/10.3390/polym11071201

Qiu Y et al (2022) The effects of ventilation, humidity, and temperature on bacterial growth and bacterial genera distribution. Int J Environ Res Public Health 19(22):15345. https://doi.org/10.3390/ijerph192215345

Ragauskas AJ, Beckham GT, Biddy MJ, Chandra R, Chen F, Davis MF, Wyman CE (2014) Lignin valorization: improving lignin processing in the biorefinery. Science 344(6185):1246843

Ritchie H, Rosado P, Roser M (2020) Energy Production and Consumption. Published online at OurWorldInData.org. Retrieved from: ‘https://ourworldindata.org/energy-production-consumption’ [Online Resource]

Segal L et al (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29(10):786–794. https://doi.org/10.1177/004051755902901003

Sills DL, Gossett JM (2012) Using FTIR spectroscopy to model alkaline pretreatment and enzymatic saccharification of six lignocellulosic biomasses. Biotechnol Bioeng 109(4):894–903. https://doi.org/10.1002/bit.24376

Sunkar B, Bhukya B (2022) An approach to correlate chemical pretreatment to digestibility through biomass characterization by SEM, FTIR and XRD. Front Energy Res. https://doi.org/10.3389/fenrg.2022.802522

Tan YS et al (2022) Microbial adaptation to enhance stress tolerance. Front Microbiol. https://doi.org/10.3389/fmicb.2022.888746

Tian JH, Pourcher AM, Peu P (2016) Isolation of bacterial strains able to metabolize lignin and lignin-related compounds. Lett Appl Microbiol 63(1):30–37. https://doi.org/10.1111/lam.12581

Tocco D et al (2021) Recent developments in the delignification and exploitation of grass lignocellulosic biomass. ACS Sustain Chem Eng 9(6):2412–2432. https://doi.org/10.1021/acssuschemeng.0c07266

Tsegaye B, Balomajumder C, Roy P (2019) Microbial delignification and hydrolysis of lignocellulosic biomass to enhance biofuel production: an overview and future prospect. Bull Natl Res Centre. https://doi.org/10.1186/s42269-019-0094-x

Umashankar N, Meghashree HM, Benherlal PS, Chavan M (2018) Isolation and screening of lignin degrading bacteria from different natural and organic sources. Int J Curr Microbiol Appl Sci 7(12):609–617. https://doi.org/10.20546/ijcmas.2018.712.075

Vanholme R, Demedts B, Morreel K, Ralph J, Boerjan W (2010) Lignin biosynthesis and structure. Plant Physiol 153(3):895–905

Viles FJ Jr, Silverman L (1949) Determination of starch and cellulose with anthrone. Anal Chem 21(8):950–953. https://doi.org/10.1021/ac60032a019

Wang L et al (2016) Diverse bacteria with lignin degrading potentials isolated from two ranks of coal. Front Microbiol. https://doi.org/10.3389/fmicb.2016.01428

Xiao LP et al (2011) Impact of hot compressed water pre-treatment on the structural changes of woody biomass for bioethanol production. BioResources 6:1576–1598

Yadav VK et al (2022) Recent advances in synthesis and degradation of lignin and lignin nanoparticles and their emerging applications in nanotechnology. Materials 15(3):953. https://doi.org/10.3390/ma15030953

Zeng J et al (2013) Degradation of native wheat straw lignin by Streptomyces viridosporus T7A. Int J Environ Sci Technol: IJEST 10(1):165–174. https://doi.org/10.1007/s13762-012-0085-z

Zhuang J et al (2020) Observation of potential contaminants in processed biomass using Fourier transform infrared spectroscopy. Appl Sci 10(12):4345. https://doi.org/10.3390/app10124345

Zoghlami A, Paes G (2019) Lignocellulosic biomass: understanding recalcitrance and predicting hydrolysis. Front Chem 7:874. https://doi.org/10.3389/fchem.2019.00874

Acknowledgements

The authors are thankful to the authorities of Department of Biotechnology, School of Engineering and Technology, GIET University, for providing research facilities. Authors also thankful to the Director, Saif Office, IIT Mumbai for support in terms technical analysis of FTIR, SEM, XRD.

Funding

No financial support received for this study. By signing this author statement, we affirm our commitment to the accuracy and integrity of the research presented in this manuscript and our adherence to the ethical standards and guidelines of Environmental Pollution and the scientific community at large.

Author information

Authors and Affiliations

Contributions

The authors declared that we have no financial conflict of interest in this current study. And the authors also undersigned following: RP and SP Conceived, designed and conducted experiments, analyzed data, and wrote the manuscript. RP, SP and RK also contributed to data interpretation, and revised the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest related to this research, including financial, personal, or professional relationships that could influence the interpretation of results or bias the content of the manuscript.

Ethical approval

This research was conducted following GIET University ethical guidelines, and all necessary permissions and approvals were obtained for the collection and experimentation on biomass and microbial isolation.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rabi Prasad, B., Polaki, S. & Padhi, R.K. Isolation of delignifying bacteria and optimization of microbial pretreatment of biomass for bioenergy. Biotechnol Lett 46, 183–199 (2024). https://doi.org/10.1007/s10529-023-03463-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-023-03463-y