Abstract

Objective

The aim of the present study was to evaluate the efficiency of lactose derived from cheese whey and cheese whey permeate as inducer of recombinant Kluyveromyces sp. β-galactosidase enzyme produced in Escherichia coli. Two E. coli strains, BL21(DE3) and Rosetta (DE3), were used in order to produce the recombinant enzyme. Samples were evaluated for enzyme activity, total protein content, and sodium dodecyl sulfate–polyacrylamide gel electrophoresis (SDS-PAGE) analysis after induction with isopropyl-β-D-1-thiogalactoside (IPTG) (0.05 and 1 mM) and lactose, cheese whey, and cheese whey permeate solutions (1, 10, and 20 g/L lactose) at shake-flask cultivation, and whey permeate solution (10 g/L lactose) at bioreactor scale.

Results

The highest specific activities obtained with IPTG as inducer (0.05 mM) after 9 h of induction, were 23 and 33 U/mgprotein with BL21(DE3) and Rosetta(DE3) strains, respectively. Inductions performed with lactose and cheese whey permeate (10 and 20 g/L lactose) showed the highest specific activities at the evaluated hours, exhibiting better results than those obtained with IPTG. Specific activity of recombinant β-galactosidase using whey permeate (10 g/L lactose) showed values of approximately 46 U/mgprotein after 24-h induction at shake-flask study, and approximately 26 U/mgprotein after 16-h induction at bench bioreactor.

Conclusions

The induction with cheese whey permeate was more efficient for recombinant β-galactosidase expression than the other inducers tested, and thus, represents an alternative form to reduce costs in recombinant protein production.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The β-galactosidase (β-D-galactoside galactohydrolase, EC 3.2.1.23) catalyzes lactose hydrolysis into its constituent monosaccharides, glucose, and galactose (Ansari and Husain 2010; Panesar et al. 2010; Zou et al. 2014). This process is important in the dairy industry, as it prepares milk and dairy products with low lactose contents, as well as food supplements consumed by lactose-intolerant people (Kim et al. 2011; Pereira-Rodríguez et al. 2012; Erich et al. 2015). β-Galactosidases are widely distributed in biological systems, such as microorganisms, plants, and animals, and microorganisms are considered the most suitable sources for industrial applications due to their high yield, easy handling, and consequent reduced application costs. Additionally, enzymes obtained from microorganisms have higher stability under operational conditions (Gobinath and Prapulla 2014; Saqib et al. 2017). Although microbial enzymes already bring several advantages to industrial processes, they can be modified in order to enhance their major properties, such as: specific activity, stability, yield, and substrate specificity, in order to better fulfill industrial application requirements (Adrio and Demain 2014). The majority of recombinant enzymes produced for industrial purposes are microbial, due to their simple genome, which benefits production in different heterologous expression systems (Borrelli and Trono 2015). The most frequently used expression systems for the production of heterologous proteins in Escherichia coli are operon lac based; therefore, isopropyl-β-D-1-tiogalactoside (IPTG) or lactose can be used to induce the expression of the gene of interest. IPTG is a synthetic analogous of alloctase and an intermediary product of lactose metabolism. Since it is artificial, it is not metabolized in cultivation and it can induce operon lac expression in the long term without being consumed because it is not involved in any other metabolic pathway, and can thus be used in low concentrations. However, using IPTG as inducer is feasible in small-scale production of recombinant enzymes, as it is toxic to cells and costly (Donovan et al. 1996; Duan et al. 2017). Lactose, in turn, is a natural operon lac inducer, as it is low-priced and is non-toxic to cells. Its use is suitable for an industrial-scale production of recombinant proteins. Additionally, lactose can be used as both, inducer and source of carbon, for microbial growth (Duan et al. 2017).

Considering volume produced and pollutant potential, cheese whey is the major by-product of the dairy industry. It is generated in milk protein coagulation via addition of organic acids and/or proteolytic enzymes (Carvalho et al. 2013) during the manufacture of several types of cheese. In cheese production, approximately 85 to 95% of the milk volume used results in cheese whey, which retains approximately 55% of milk nutrients, comprised of lactose (4.5–5.0% w/v), soluble proteins (0.6–0.8% w/v), mineral salts (0.5–1.0% w/v), and lipids (0.4–0.5% w/v) (Guimarães et al. 2010; Dragone et al. 2011). Considering the increase in global cheese production, approximately 230 million tons of cheese whey are estimated to be produced in 2023 worldwide (Rama et al. 2019). This by-product can be employed in the production of cheese whey protein concentrates and isolates using membrane fractionation/filtration technology. However, this process generates another by-product called cheese whey permeate (Silveira et al. 2005). This permeate is primarily comprised of lactose (4–5% w/v) and mineral salts (~ 0.5% w/v) (Tetra Pak 1995; Cui et al. 2012). If these dairy by-products are inadequately discarded into the environment, they can cause environmental problems due to their high organic matter contents and high production volumes (Panesar et al. 2007; Prazeres et al. 2012). Considering nutritional composition of these dairy whey forms and high cost for their production (Mollea et al. 2013), technologies and new applications have been sought for the use of cheese whey and whey permeate. Due to their lactose concentrations, these whey forms rise as alternatives to induce the expression of recombinant proteins produced by microorganisms, thus helping to reduce environmental pollution, on one hand, and providing the dairy industry with the possibility to add value to these by-products, on the other (Júnior et al. 2001; Briand et al. 2016; Mesgari-Shadi and Sarrafzadeh 2017).

Several studies have shown the use of cheese whey and whey permeate for biotechnological purposes e.g. as carbon sources and expression inducers (Lata et al. 2018; Mano et al. 2019; Zhou et al. 2019). Koller et al. (2008) and Alonso et al. (2013) showed the feasibility, scalability, and cost-effectiveness of using cheese whey as a source of carbon for the production of polyhydroxyalkanoate and lactobionic acid, respectively. The use of these dairy whey forms as inducers of recombinant enzyme expression in E. coli was evaluated by synthesizing Lactobacillus phage muramidase and Lactobacillus alcohol dehydrogenase (Viitanen et al. 2003) to obtain penicillin acylase (De León-Rodríguez et al. 2006), and to produce flavanone 3-hydroxilase and chalcone 3-hydroxilase (Hausjell et al. 2019). However, no studies have been found in literature using cheese whey and whey permeate as inducers of recombinant β-galactosidase expression. Therefore, the aim of the present study was to evaluate the efficiency of lactose derived from cheese whey and cheese whey permeate as inducer of recombinant Kluyveromyces sp. β-galactosidase produced in E. coli. Enzyme production was studied with two E. coli strains, BL21(DE3) and Rosetta (DE3). IPTG (0.05 and 1 mM), lactose, whey permeate, and cheese whey (1, 10, and 20 g/L lactose) were used as inducers at shake-flask cultivation, and whey permeate (10 g/L lactose) was used in batch cultivations at bench bioreactor.

Material and methods

Materials

Powdered sweet cheese whey was purchased from Brazil Foods S.A. (Rio Grande do Sul, Brazil). Powdered whey permeate was provided by Arla Foods (Córdoba, Argentina). Ortho-nitrophenyl-β-D-galactopyranoside (ONPG), Isopropyl β-D-thiogalactoside (IPTG), lactose, and other chemicals were purchased from Sigma Aldrich Co. (St. Louis, USA). All other reagents were of analytical grade.

Methods

Cultivation of E. coli strains: BL21(DE3) and Rosetta(DE3)

The pET-30a( +):β-galactosidase construction was obtained according to De Andrade et al. (2019). Different E. coli electrocompetent cells (BL21(DE3) and Rosetta (DE3)) were transformed by electroporation (2.45 kV, 200 Ω, 25 µF) (BioRad®, Gene Pulser II, US) and the transformed cells were selected on LB agar plates containing the appropriate antibiotics for each strain (50 µg/mL of kanamycin for BL21(DE3), and 30 µg/mL of kanamycin and 34 µg/mL of chloramphenicol for Rosetta(DE3)). Pre-inoculum with recombinant strains were prepared in Luria–Bertani (LB) medium (10 g/L tryptone, 10 g/L NaCl, and 5 g/L yeast extract) containing specific antibiotics and were incubated overnight on an orbital shaker (Marconi®, MA830, Brazil) at 37 °C and 180 rpm. For expressions assays, each of these cultures were used to inoculate, separately, 50 mL of LB medium in unbaffled 250 mL Erlenmeyer flasks at optical density at 600 nm (OD600nm) of 0.1, and were incubated on an orbital shaker (Marconi®, MA830, Brazil) (30 °C, 180 rpm). The expression induction was done when the cultures reached OD600nm between 0.4 and 0.6.

Characterization and preparation of inducers

Powdered cheese whey and powdered cheese whey permeate were characterized according to the methods described by the Association of Official Analytical Chemists regarding moisture (990.20), protein (991.20), lipid (2000.18), ash (968.08), carbohydrate (986.25), and lactose contents (984.15) (AOAC 2016). Cheese whey, cheese whey permeate, and lactose induction solutions were prepared dissolving each material in deionized water, in order to obtain stock solutions with a 200 g/L lactose concentration. The concentrated solutions of dairy whey inducers were heat-treated at 100 °C for 20 min, and the lactose solution was sterilized at 121 °C for 15 min.

Recombinant β-galactosidase expression at shake-flask

Induction of recombinant β-galactosidase expression was evaluated using IPTG (0.05 and 1 mM), lactose, cheese whey, and whey permeate (1, 10, and 20 g/L lactose), at a temperature of 30 °C (De Andrade et al. 2019). Nine and 24 h after induction, 1-mL aliquots were collected from the cultures, centrifuged (Thermo Fischer Scientific®, Heraeus Fresco 17, Germany) (2790*g, 4 °C, 2 min), and microbial cells were separated and stored at −20 °C. Control cultures were performed with recombinant strains (E. coli BL21(DE3) and Rosetta (DE3)) without adding inducers and under the same cultivation conditions.

Recombinant cells were resuspended in 500 µL of Tris–HCl buffer solution (50 mM, pH 8.0), and disrupted in an ultrasonicator (VCX 750, Sonics, USA) at an amplitude of 21%, with three 9.9-s pulses. The disrupted cells were centrifuged (Thermo Fischer Scientific®, Heraeus Fresco 17, Germany) (16,200*g, 4 °C, 30 min) and recombinant β-galactosidase expression was analyzed by sodium dodecyl sulfate–polyacrylamide gel electrophoresis (SDS-PAGE, 12% w/v) in soluble and insoluble fractions.

Bioreactor cultivations

In order to evaluate the scaling up of the production process, batch cultivations were performed using a 2-L bench bioreactor (Sartorius®, Biostat B, Germany) with automatic control of pH and dissolved oxygen measured by electrodes (Hamilton®, Switzerland), with automatic temperature control (Pt-100 sensor), equipped with two Rushton turbines (2.5 cm apart from each other) with six blades. Cultivations were performed using E. coli BL21(DE3) and Rosetta (DE3) strains at 30 ºC, 1 L LB cultivation medium, containing the specific antibiotics for each strain, as described previously, with controlled dissolved oxygen at 30% using constant aeration rate of 1 L/min and stirring cascade (400–800 rpm); pH was maintained at 7.0, using 12.5% NH4OH (v/v) and 10% phosphoric acid (v/v). Pre-inoculum were prepared as described for orbital shaker cultivations, and were incubated overnight on an orbital shaker (Marconi®, MA830, Brazil) at 37 °C and 180 rpm. These cultivations were used to inoculate the bioreactor medium in order to reach an initial OD600nm of 0.1. Induction of recombinant β-galactosidase expression was performed after 8 h growth using whey permeate (10 g/L of lactose) and cultivation was performed for 24 h. Aliquots of 1 mL were collected from cultivations, standardized at OD600nm 5.0, and centrifuged (2790*g, 4 °C, 2 min). Recombinant cells were resuspended in 500 µL of Tris–HCl (50 mM, pH 8.0) buffer solution, and disrupted by ultrasonication (VCX 750, Sonics, USA) at 21% amplitude, with three 9.9-s pulses. The disrupted cells were centrifuged (16,200*g, 4 °C, 30 min) and the recombinant β-galactosidase expression was analyzed using SDS-PAGE (12% w/v) (soluble and insoluble fractions). The enzymatic activity was analyzed by a colorimetric assay (soluble fraction). Additionally, aliquots were collected from the cultivation to determine microbial growth, using optical density (OD600nm) and biomass (g/L), and lactose concentration (g/L). All experiments and analyses were performed in duplicates.

Analytical determinations

Volumetric enzyme activity (U/mL) was determined in soluble fractions using ONPG substrate, following the methodology proposed by Rech et al. (1999). One activity unit (U) was defined as the amount of enzymes capable of hydrolyzing 1 µmol of substrate per minute under reactional conditions. The Bradford (1976) method was employed for protein analysis using a standard curve of bovine serum albumin (BSA). The specific activity of β-galactosidase was calculated using the ratio between volumetric activity and total protein values. Biomass (g/L) produced in bioreactor cultivations was determined by drying the cell pellets at 60 °C (EthikTechnology, 403-3D, Brazil) until constant weight.

Statistical analysis

All data were submitted to an Analysis of Variance (ANOVA) and the significance of the model was tested using the F-test. In significant models, mean values were compared using Tukey’s test at a significance level of 95% (p < 0.05). Statistical calculations were performed using the statistical program BioEstat 5.3.

Results and discussion

Characterization of dairy whey

Cheese whey and cheese whey permeate, used as inducers in β-galactosidase expression, were characterized regarding their percent composition, and the results of these evaluations are shown in Table 1. The highest difference observed between the two dairy by-products is related to protein concentration, with cheese whey having values approximately tenfold higher. Additionally, ash contents are also high, which shows that most minerals present in milk remain in the whey during cheese processing. This by-product also has a high lactose concentration (75.66%). As whey permeate is obtained from cheese whey using ultra-filtration, in which macromolecules such as proteins and lipids are retained, it has high concentration of carbohydrates, especially in the form of lactose (85.98%). Concerning the effect of these by-products as inducers, compared with lactose solution, also used in induction processes, it is observable that aside from inducing β-galactosidase expression, cheese whey might work as a source of amino acids and lipids for the cells, thus favoring their metabolism (Hausjell et al. 2019). On the other hand, cheese whey permeate provides bacterial cells with some minerals, which are also important for microbial metabolism (Girard et al. 2014).

Recombinant β-galactosidase expression at shake-flask

In the search for alternative inducers other than IPTG, two dairy by-products aside from pure lactose were tested (whey permeate and cheese whey) for the production of recombinant β-galactosidase. In the assays in which expression was performed using IPTG as inducer, the highest specific activities of recombinant E. coli strains, BL21(DE3) and Rosetta(DE3), were approximately 23 and 33 U/mgprotein, respectively, at 9 h after induction, using 0.05 mM IPTG.

In cultivations with induction with lactose, whey permeate, and cheese whey using recombinant strain E. coli BL21(DE3) (Fig. 1a, b), the highest specific activities (> 35 U/mgprotein) were obtained in inductions with lactose and whey permeate at the concentrations of 10 and 20 g/L, regardless of time after induction. Maximum specific activity of β-galactosidase was attained 9 h after induction (Fig. 1a) and remained practically constant in samples collected 24 h after induction (Fig. 1b).

Effect of different inducers and concentrations on specific activity of recombinant β-galactosidase expressed in E. coli BL21(DE3) 9 h a and 24 h after induction b and in Rosetta(DE3) 9 h c and 24 h after induction d with lactose (open square), whey permeate (grey filled square), and cheese whey (black filled square). Bars with different letters have significant difference (p < 0.05) according to Tukey's test

Recombinant β-galactosidase expression assays were performed under the same conditions with E. coli Rosetta(DE3) (Fig. 1c, d). This strain was observed to have lower levels of enzyme expression at the lowest inducer concentration (1 g/L lactose) compared to BL21(DE3). There was no significant difference (p < 0.05) in the specific activities of Rosetta (DE3) obtained with lactose and whey permeate as inducers at the two highest concentrations tested, either. The highest specific activities (~ 45 U/mgprotein) were obtained with these inducers at the concentration of 20 g/L after 9 h (Fig. 1c). In addition, values obtained with the concentration of 10 g/L increased approximately 2.2-fold while the concentration of enzyme expressed with the concentration of 20 g/L of lactose remained constant at the periods of 9 and 24 h after induction.

In the inductions using E. coli BL21(DE3) (Fig. 1a, b), cheese whey resulted in lower specific activity values (10–18 U/mgprotein) than in inductions obtained with IPTG (23 U/mgprotein), while lactose solution and whey permeate resulted in higher levels of enzyme expression, approximately 26–45 U/mgprotein with both inducers. The effect of induction using either IPTG or lactose was also studied by Duan et al. (2017) in the extracellular expression of Bacillus circulans β-galactosidase in E. coli BL21(DE3). The authors evaluated both inducers at different concentrations (0.05 to 0.60 mM IPTG and 1 to 20 g/L lactose). Overall, lactose showed higher efficiency of inducing β-galactosidase expression than IPTG. The highest activity (21 U/mL) was obtained using the lactose concentration of 15 g/L as inducer, 48 h after induction. According to the findings of the authors, cell growth might have been negatively affected by the highest inducer concentrations, resulting in decreased β-galactosidase activity. Results of enzyme activity in both strains were higher in our study than those reported by Duan et al. (2017). With E. coli BL21(DE3), the highest volumetric activities were approximately 38, 58, and 35 U/mL with inducers lactose, whey permeate, and cheese whey, respectively, 24 h after induction with 10 g/L of lactose. On the other hand, differences in volumetric activities were more significant with Rosetta (DE3), as the maximum values of lactose, permeate, and cheese whey were 6.8-, 5.4-, and 2.4-fold higher, respectively, than those observed by Duan et al. (2017).

Khani and Bagheri (2020) also reported the use of lactose to induce recombinant protein expression. However, these authors used skimmed milk as source of lactose for the expression of FliC proteins of Salmonella enterica serovar Typhimurium (S. Typhimurium) (ATCC 14,028) in E. coli BL21(DE3). Aside from 1% (w/v) skimmed milk, induction was also performed with 1 mM IPTG. Production yields ranged from 55 to 70 and from 30 to 45 mgprotein/Lmedium in cultivations induced with lactose derived from skimmed milk and IPTG, respectively. Based on their findings, the authors suggested that skimmed milk might be a suitable alternative to induce recombinant protein expression. Although it is considered an alternative material, skimmed milk is a nutritiously rich product with high added value in the food industry. The present study attained similar increases (1.1- to 2.0-fold) in enzyme expressions using inducers other than IPTG, particularly whey permeate, and thus, we have shown this application, which adds value to a material that is considered a by-product in the dairy chain.

Cheese whey, another inducer used in the present study, has lipids, proteins, and mineral salts, as well as lactose in its composition. Lactose solution, on the other hand, is only composed of this sugar, and permeate is composed of minerals along with carbohydrates (Lehn et al. 2018). Based on the results obtained, it was possible to observe that cheese whey was not efficient to induce the recombinant β-galactosidase expression. These lower expression levels observed might be related to the composition of this by-product, regarding whey permeate and lactose solution. The highest concentration of macro-components of cheese whey, proteins and lipids (Table 1), probably affected cell metabolism, leading to changes in the production of recombinant proteins, as observed by other authors (Viitanen et al. 2003; De León-Rodríguez et al. 2006; Hausjell et al. 2019).

Viitanen et al. (2003) used cheese whey and a solution of lactose as alternative inducers to IPTG for the heterologous expression of Lactobacillus delbrueckii subsp. lactis alcohol dehydrogenase in E. coli BL21(DE3). The enzyme activity obtained with induction with lactose and cheese whey had a different behavior than that of the present study. While we obtained higher enzyme activity with lactose and lower values with cheese whey compared to IPTG, Viitanen et al. (2003) found no difference between IPTG, lactose, or cheese whey (535, 520, and 518 U/mL, respectively).

Other authors have used cheese whey not only as alternative inducer but also as carbon source (De León-Rodríguez et al. 2006; Hausjell et al. 2019). De León-Rodríguez et al. (2006) studied the production of penicillin acylase (PA) in E. coli W3110. For that purpose, a complete factorial planning 32 was used to evaluate the influence of independent variables, dissolved oxygen (3 to 15%) and cheese whey concentration (5 to 15 g/L lactose), on the production of PA by E. coli W3110. The highest specific activity was obtained with addition of 5 g/L of cheese whey lactose and 3% of dissolved oxygen. Using this same approach, Hausjell et al. (2019) aimed to maximize the production of recombinant proteins, flavanone 3-hydroxylase (FHT) and chalcone 3-hydroxylase (CH3H). The authors observed increases of 39% in growth rate and of 24% in biomass yield in processes using concentrated cheese whey (200 g/L lactose) as cultivation medium, compared to a lactose-only process. Regarding protein expression, cheese whey also allowed higher protein concentrations (1.6 mgprotein/Lmedium of FHT and 30 mgprotein/Lmedium of CH3H) compared to lactose. In both studies, the authors emphasized the potential of cheese whey as carbon source for cell growth and as inducer of expression of operon lac-based recombinant proteins.

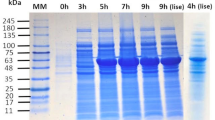

The results obtained (Fig. 1) using cheese whey as inducer (up to 25 U/mgprotein) were lower than those observed using whey permeate. Enzyme activities had statistically similar results (p < 0.05) between pure lactose and whey permeate (~ 42 U/mgprotein), one of the major by-products generated in whey processing. Therefore, we observed that a dairy industry by-product, with high treatment cost due to its composition, can be efficient as inducer of recombinant protein expression. Recombinant β-galactosidase expression (~ 120 kDa), produced via this induction with whey permeate, and using both E. coli strains evaluated, is shown in Fig. 2.

Expression of recombinant β-galactosidase in the E. coli strains BL21(DE3) a and Rosetta(DE3) b, after 16 h induction (24 h cultivation) using whey permeate at different concentrations. M: Page Ruler molecular weight marker; 1, 2, and 3: soluble fraction, induction with 1, 10, and 20 g/L lactose, respectively; 4, 5, and 6: insoluble fraction, induction with 1, 10, and 20 g/L lactose, respectively; NI-1: control, non-induced soluble fraction; NI-2: control, non-induced insoluble fraction. Recombinant β-galactosidase shows a molecular weight of 120 kDa

The profiles of proteins expressed after 24 h induction with whey permeate in the assays with E. coli BL21(DE3) and Rosetta(DE3) were analysed by SDS-PAGE (Fig. 2a, b). An apparent band of 120 kDa was observed at soluble and insoluble fractions, which corresponds to the molecular weight of β-galactosidase, for both strains and at all inducer concentrations tested (1, 10, and 20 g/L lactose). No expression of β-galactosidase was observed in non-induced controls.

Bioreactor cultivations

Based on expression assays at shake-flask, there was no significant difference (p < 0.05) in the specific activity of lactose- and whey permeate-induced β-galactosidase (both inducers containing 10 g/L lactose) (Fig. 1). Therefore, considering that whey permeate has mineral salts in its composition, as well as carbohydrates, which might help microbial metabolism, it was selected for the analysis of enzyme expression in batch cultivations at bench bioreactor with the strains BL21(DE3) and Rosetta (DE3). Moreover, as whey permeate is a by-product of the dairy industry, its use as inducer enables the costs reduction of the recombinant enzyme production bioprocess. Figure 3 shows the results of volumetric and specific enzyme activity and microbial growth using BL21(DE3) (Fig. 3a) and Rosetta(DE3) (Fig. 3b) strains.

Recombinant β-galactosidase volumetric (U/mL) (grey filled triangle) and specific (U/mg) (open diamond) activity, cell growth in optical density (OD600nm) (black filled square) and biomass (g/L) (open circle) in E. coli BL21(DE3) a and Rosetta(DE3) b after induction with cheese whey permeate (10 g/L lactose) in batch cultivations at bench bioreactor. Dotted lines represent the induction moment

Cultivation induction was performed in the early stationary growth phase (8 h of cultivation) (Fig. 3). BL21(DE3) strain (Fig. 3a) showed higher growth rate, reaching an OD600nm higher than 4.0 after 4 h cultivation, while Rosetta(DE3) reached an OD600nm of approximately 3.0 over the same period (Fig. 3b). Regarding biomass, BL21(DE3) attained values approximately 1.6-fold than those obtained with Rosetta (DE3). Both strains had similar behaviors in the production of recombinant β-galactosidase, with volumetric activities higher than 40 U/mL and specific activities higher than 26 U/mgprotein after 16 h induction (24 h cultivation). Lactose concentration (10 g/L) remained constant after cultivation induction of both strains. Recombinant β-galactosidase production in bioreactor was also evaluated by Domingues et al. (2004), who studied the extracellular production of this Aspergillus niger enzyme in Saccharomyces cerevisiae cells, and observed a more than tenfold increase in the extracellular activity of β-galactosidase produced in bioreactor compared to cultivations at shake-flask.

Figure 4 shows the proteins expressed in bioreactor cultivations with the two studied strains, 16 h after the induction of expression using whey permeate (10 g/L lactose). Using SDS-PAGE, we observed that the profile of proteins expressed in bioreactor cultivations is similar to that observed in studies with shake-flasks. Furthermore, there is generally a reduction in the expression of all proteins, which corroborates the reduction in enzyme activity comparing the two process scales evaluated, shaker and bioreactor. In spite of that, β-galactosidase (120 kDa) stands out among other proteins, showing higher levels of expression.

Expression of recombinant β-galactosidase in batch cultivations performed at bench bioreactor with both E. coli strains, after 16 h induction (24 h cultivation) with whey permeate (10 g/L lactose). M: Page Ruler molecular weight marker; 1 and 2: soluble fraction of BL21(DE3) and Rosetta(DE3) strains, respectively; 3 and 4: insoluble fraction of BL21(DE3) and Rosetta(DE3) strains, respectively

Conclusion

Considering that the industrial use of cheese whey and whey permeate is relatively lower than the volumes produced by the dairy industry, it is important to develop new technologies for their adequate reuse, thus reducing environmental impacts and adding value to these by-products. Therefore, the present study reported the use of IPTG, lactose, whey permeate, and cheese whey for the production of recombinant β-galactosidase from Kluyveromyces sp. in E. coli strains, BL21(DE3) and Rosetta(DE3). Inductions using solutions of lactose and cheese whey permeate (10 and 20 g/L lactose), 9 and 24 h after induction, had the highest specific activity in both strains. The use of these inducers resulted in an enzyme activity 1.7 and 1.4 times higher than when induced by IPTG in the strains BL21(DE3) and Rosetta(DE3), respectively. Aiming at the industrial production of recombinant β-galactosidase, cultivations were performed in bioreactor using both strains and cheese whey permeate (10 g/L lactose) as inducer, reaching maximum activity values of 1.93 and 2.12 U/mL.h for BL21(DE3) and Rosetta(DE3) strains, respectively. Therefore, both solutions were efficient and can be used in biotechnological processes for that purpose. However, the use of cheese whey permeate becomes a viable and innovative alternative if we consider reduction of bioprocess costs. Hence, it is important to highlight the possibility of using other dairy by-products with similar characteristics, such as ricotta cheese whey, composed basically of lactose and mineral salts, and also known as second cheese whey.

References

Adrio JL, Demain AL (2014) Microbial enzymes: tools for biotechnological processes. Biomolecules 4:117–139. https://doi.org/10.3390/biom4010117

Alonso S, Rendueles M, Díaz M (2013) Feeding strategies for enhanced lactobionic acid production from whey by Pseudomonas taetrolens. Bioresour Technol 134:134–142. https://doi.org/10.1016/j.biortech.2013.01.145

Ansari SA, Husain Q (2010) Lactose hydrolysis by β galactosidase immobilized on concanavalin A-cellulose in batch and continuous mode. J Mol Catal B Enzym 63:68–74. https://doi.org/10.1016/j.molcatb.2009.12.010

AOAC G, (2016) Official methods of analysis of AOAC International. AOAC International, Rockville, MD

Borrelli GM, Trono D (2015) Recombinant lipases and phospholipases and their use as biocatalysts for industrial applications. Int J Mol Sci 16:20774–20840. https://doi.org/10.3390/ijms160920774

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254. https://doi.org/10.1016/0003-2697(76)90527-3

Briand L, Marcion G, Kriznik A et al (2016) A self-inducible heterologous protein expression system in Escherichia coli. Sci Rep 6:1–11. https://doi.org/10.1038/srep33037

Carvalho F, Prazeres AR, Rivas J (2013) Cheese whey wastewater: characterization and treatment. Sci Total Environ 445–446:385–396. https://doi.org/10.1016/j.scitotenv.2012.12.038

Cui F, Wan C, Li Y et al (2012) Co-production of lactic acid and Lactobacillus rhamnosus cells from whey permeate with nutrient supplements. Food Bioprocess Technol 5:1278–1286. https://doi.org/10.1007/s11947-010-0426-1

De Andrade BC, Migliavacca VF, Okano FY et al (2019) Production of recombinant β-galactosidase in bioreactors by fed-batch culture using DO-stat and linear control. Biocatal Biotransformation 37:3–9. https://doi.org/10.1080/10242422.2018.1493105

De Júnior CG, S, Macdonald Ledingham W, Antônio De Morais Júnior M, (2001) Utilisation of cheese whey as an alternative growth medium for recombinant strains of Kluyveromyces marxianus. Biotechnol Lett 23:1413–1416. https://doi.org/10.1023/A:1011617914709

De León-Rodríguez A, Rivera-Pastrana D, Medina-Rivero E et al (2006) Production of penicillin acylase by a recombinant Escherichia coli using cheese whey as substrate and inducer. Biomol Eng 23:299–305. https://doi.org/10.1016/j.bioeng.2006.09.003

Domingues L, Oliveira C, Castro I et al (2004) Production of β-galactosidase from recombinant Saccharomyces cerevisiae grown on lactose. J ofChemical Technol Biotechnol 79:809–815. https://doi.org/10.1002/jctb.1025

Donovan RS, Robinson CW, Click BR (1996) Review: Optimizing inducer and culture conditions for expression of foreign proteins under the control of the lac promoter. J Ind Microbiol 16:145–154. https://doi.org/10.1007/BF01569997

Dragone G, Mussatto SI, Almeida e Silva JB, Teixeira JA (2011) Optimal fermentation conditions for maximizing the ethanol production by Kluyveromyces fragilis from cheese whey powder. Biomass Bioenerg 35:1977–1982. https://doi.org/10.1016/j.biombioe.2011.01.045

Duan X, Hu S, Qi X et al (2017) Optimal extracellular production of recombinant Bacillus circulans β-galactosidase in Escherichia coli BL21(DE3). Process Biochem 53:17–24. https://doi.org/10.1016/j.procbio.2016.11.008

Erich S, Kuschel B, Schwarz T et al (2015) Novel high-performance metagenome β-galactosidases for lactose hydrolysis in the dairy industry. J Biotechnol 210:27–37. https://doi.org/10.1016/j.jbiotec.2015.06.411

Garcia-ochoa F, Gomez E (2009) Bioreactor scale-up and oxygen transfer rate in microbial processes: an overview. Biotechnol Adv 27:153–176. https://doi.org/10.1016/j.biotechadv.2008.10.006

Girard J, Roy M, Ben M et al (2014) Mixotrophic cultivation of green microalgae Scenedesmus obliquus on cheese whey permeate for biodiesel production. Algal Res 5:241–248. https://doi.org/10.1016/j.algal.2014.03.002

Gobinath D, Prapulla SG (2014) Permeabilized probiotic Lactobacillus plantarum as a source of β-galactosidase for the synthesis of prebiotic galactooligosaccharides. Biotechnol Lett 36:153–157. https://doi.org/10.1007/s10529-013-1345-9

Guimarães PMR, Teixeira JA, Domingues L (2010) Fermentation of lactose to bio-ethanol by yeasts as part of integrated solutions for the valorisation of cheese whey. Biotechnol Adv 28:375–384. https://doi.org/10.1016/j.biotechadv.2010.02.002

Hausjell J, Miltner M, Herzig C et al (2019) Valorisation of cheese whey as substrate and inducer for recombinant protein production in E coli HMS174(DE3). Bioresour Technol Reports 8:100340. https://doi.org/10.1016/j.biteb.2019.100340

Hewitt CJ, Nienow AW (2007) The scale-up of microbial batch and fed-batch fermentation processes. Adv Appl Microbiol. 62:105–135

Khani MH, Bagheri M (2020) Skimmed milk as an alternative for IPTG in induction of recombinant protein expression. Protein Expr Purif 170:105593. https://doi.org/10.1016/j.pep.2020.105593

Kim YS, Yeom SJ, Oh DK (2011) Reduction of galactose inhibition via the mutation of β-galactosidase from Caldicellulosiruptor saccharolyticus for lactose hydrolysis. Biotechnol Lett 33:353–358. https://doi.org/10.1007/s10529-010-0445-z

Koller M, Bona R, Chiellini E et al (2008) Polyhydroxyalkanoate production from whey by Pseudomonas hydrogenovora. Bioresour Technol 99:4854–4863. https://doi.org/10.1016/j.biortech.2007.09.049

Lata K, Sharma M, Patel SN et al (2018) An integrated bio-process for production of functional biomolecules utilizing raw and by-products from dairy and sugarcane industries. Bioprocess Biosyst Eng 41:1121–1131. https://doi.org/10.1007/s00449-018-1941-0

Lehn DN, Esquerdo VM, Dahlem Júnior MA et al (2018) Microencapsulation of different oils rich in unsaturated fatty acids using dairy industry waste. J Clean Prod 196:665–673. https://doi.org/10.1016/j.jclepro.2018.06.127

Mano MCR, Paulino BN, Pastore GM (2019) Whey permeate as the raw material in galacto-oligosaccharide synthesis using commercial enzymes. Food Res Int 124:78–85. https://doi.org/10.1016/j.foodres.2018.09.019

Mesgari-Shadi A, Sarrafzadeh MH (2017) Osmotic conditions could promote scFv antibody production in the Escherichia coli HB2151. BioImpacts 7:199–206. https://doi.org/10.15171/bi.2017.23

Mollea C, Marmo L, Bosco F (2013) Valorisation of cheese whey, a by-product from the dairy industry. Food Ind. https://doi.org/10.5772/53159

Panesar PS, Kennedy JF, Gandhi DN, Bunko K (2007) Bioutilisation of whey for lactic acid production. Food Chem 105:1–14. https://doi.org/10.1016/j.foodchem.2007.03.035

Panesar PS, Kumari S, Panesar R (2010) Potential applications of immobilized β-galactosidase in food processing industries. Enzyme Res. https://doi.org/10.4061/2010/473137

Pereira-Rodríguez Á, Fernández-Leiro R, González-Siso MI et al (2012) Structural basis of specificity in tetrameric Kluyveromyces lactis β-galactosidase. J Struct Biol 177:392–401. https://doi.org/10.1016/j.jsb.2011.11.031

Prazeres AR, Carvalho F, Rivas J (2012) Cheese whey management: a review. J Environ Manage 110:48–68. https://doi.org/10.1016/j.jenvman.2012.05.018

Rama GR, Kuhn D, Beux S et al (2019) Potential applications of dairy whey for the production of lactic acid bacteria cultures. Int Dairy J 98:25–37. https://doi.org/10.1016/j.idairyj.2019.06.012

Rech R, Cassini CF, Secchi A, Ayub MAZ (1999) Utilization of protein-hydrolyzed cheese whey for production of β-galactosidase by Kluyveromyces marxianus. J Ind Microbiol Biotechnol 23:91–96. https://doi.org/10.1038/sj.jim.2900692

Saqib S, Akram A, Halim SA, Tassaduq R (2017) Sources of β-galactosidase and its applications in food industry. Biotech 7:1–7. https://doi.org/10.1007/s13205-017-0645-5

Silveira WB, Passos FJV, Mantovani HC, Passos FML (2005) Ethanol production from cheese whey permeate by Kluyveromyces marxianus UFV-3: a flux analysis of oxido-reductive metabolism as a function of lactose concentration and oxygen levels. Enzyme Microb Technol 36:930–936. https://doi.org/10.1016/j.enzmictec.2005.01.018

Tetra Pak (1995) Whey Processing: Different Whey Processes. In: Dairy Processing Handbook

Viitanen MI, Vasala A, Neubauer P, Alatossava T (2003) Cheese whey-induced high-cell-density production of recombinant proteins in Escherichia coli. Microb Cell Fact 2:1–10

Zhou X, Hua X, Huang L, Xu Y (2019) Bio-utilization of cheese manufacturing wastes (cheese whey powder) for bioethanol and specific product (galactonic acid) production via a two-step bioprocess. Bioresour Technol 272:70–76. https://doi.org/10.1016/j.biortech.2018.10.001

Zou S, He X, Liu Y et al (2014) Toxicological evaluation of lactase derived from recombinant Pichia pastoris. PLoS ONE 9(9):e106470. https://doi.org/10.1371/journal.pone.0106470

Aknowledgements

We would like to thank Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) (Grant no. 311655/2017-3, no. 315225/2018-1, no. 420506/2016-0) and Fundação de Amparo à Pesquisa do Estado do Rio Grande do Sul (FAPERGS) for the scholarships, and Universidade do Vale do Taquari—Univates for the financial support granted for this research paper. We also thank Quatro G Pesquisa & Desenvolvimento Ltda for their support in the experiment.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare they do not have any conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mobayed, F.H., Nunes, J.C., Gennari, A. et al. Effect of by-products from the dairy industry as alternative inducers of recombinant β-galactosidase expression. Biotechnol Lett 43, 589–599 (2021). https://doi.org/10.1007/s10529-020-03028-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-020-03028-3