Abstract

This paper provides a comparative study on the fermentative production of lactic acid (LA) by the novel Pediococcus acidilactici KTU05-7, previously isolated from rye sourdough, and the common dairy Lactobacillus delbrüeckii spp. bulgaricus using dairy by-products as a substrate. Lactic acid bacteria growth in different fermentation medium, β-d-galactosidase activity, lactose consumption, distribution of l(+)/d(−)-lactic acid isomers and LA purification using a system of membranes were also examined. The highest LA yield (1.9 g/g) was obtained fermenting the whey permeate for 24 h with the novel P. acidilactici. This strain also showed a better growth in whey permeate, a higher tolerance to low pH conditions and tended to produce mainly l(+)-lactic acid, compared to the standard L. bulgaricus. Furthermore, the proteolytic action of P. acidilactici simplified the membrane filtration procedure, and hindered the formation of protein aggregate in fermented broth as compared to L. bulgaricus. The findings of this research suggest that the Pediococcus acidilactici strain has a potential to improve the biotechnological production of LA from dairy industry waste and its recovery by membrane processes.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Lactic acid (LA) or 2-hydroxypropionic acid exists as two optically active isomeric forms l(+)-lactic acid and d(−)-lactic acid and is widely used in food and chemical industries [1]. Nowadays, the demand of optically pure LA isomers is increasing, especially for the production of biodegradable poly LA (PLA). The chemical synthesis of LA always leads to a racemic mixture of both isomers. The optically pure lactic acid can be obtained by a biotechnological production route and the process involves the selection of lactic acid bacteria (LAB) strains that produce only one specific LA isomer [2]. Bio-based LA has been shown to be more sustainable than chemically synthesised LA, with an increase in energy efficiency by 47% and decrease in the total costs by 17% [3].

Cheese whey contains a high amount of fermentable lactose (44–52 g/L) [2, 4] and it is considered to be the most essential pollutant of dairy waste waters, not only because of its volume, but also for the high organic load [5]. Therefore, the usage of lactose rich dairy by-products for lactic acid production is relevant for the reduction of the environmental pollution. Most microorganisms producing lactic acid belong to the Lactobacillus, Lactococcus, or Rhizopus genera and have LA as the major end product from the fermentation of various sugars [6]. The effectiveness of the LA fermentation process is influenced by many parameters, such as LAB strain, substrate, nutrients, fermentation mode, temperature and pH [2]. The optimal pH for LA production varies between 5.0 and 7.0 [1]. The high acid tolerance of certain LAB strains is a significant advantage over many other bacterias for the efficient industrial production of LA. Due to the presence of specific NAD+—ependent lactate dehydrogenase and the specific activities of LAB, various strains produce only l(+)-lactic acid or d(−)-lactic acid or both forms in measurable amounts [7].

Once LA is produced, the next step is to recover it. Recently, membrane-based processes have been shown to efficiently separate valuable components in dairy waste [8,9,10]. It was shown that pressure-driven membrane processes, such as nanofiltration and reverse osmosis, can produce high purity and concentration lactic acid by skipping many of the steps and chemicals of other conventional processes [10, 11].

The Pediococcus acidilactici KTU05-7 strain was recently isolated from spontaneous rye sourdoughs and is able to maintain viability in very acidic conditions [12]. This low pH tolerance made it a good candidate for sour by-products fermentation and LA production. The main objective of this work was to evaluate the ability of of P. acidilactici KTU05-7 to produce LA isomers in comparison with the commonly used L. bulgaricus. Furthermore, two fermentation media, cheese whey and whey permeate, were tested in the study, together with lactic acid recovery by membrane processes in two steps: nanofiltration (NF) and reverse osmosis (RO).

Materials and Methods

Materials

Samples of cheese whey and whey permeate for the first part of experiment were obtained from SC “Rokiskio pienas” (Rokiskis, Lithuania). Ultrafiltrated whey permeate (WP) was obtained from the milk research plant “Aula de Productos Lácteos” (Spain, Lugo). WP was sterilized at 121 °C for 20 min and used as the substrate for lactic acid production. WP contained about 43 g/L of lactose and only traces in proteins and milk fats after ultrafiltration (0.34% and 0.25%, respectively).

β-d-Galactosidase from Kluyveromyces lactis (Lactozyme 2600L) was obtained from Sigma Chem. Co. (St. Louis, MO, USA) and applied for the lactose hydrolysis in whey permeate (before fermentation). Lactic acid bacteria (LAB) Pediococcus acidilactici KTU05-7 (Pa) and Lactobacillus delbrüeckii spp. bulgaricus (DSM20081) (Lb) were used for the dairy by-products fermentation. Pediococcus acidilactici KTU05-7 was previously isolated from rye sourdoughs [12, 13]. Lactobacillus delbrüeckii spp. bulgaricus was obtained from the collection of Food Research Institute of Kaunas University of Technology (Lithuania) and used as a control for WP fermentation. Strains were activated in a MRS broth (CM 0359, Oxoid Ltd, Hampshire, UK) for 24 h at optimal temperatures (35 °C and 37 °C, respectively) until further use.

Methods

Selection of Dairy By-Products as a Fermentation Medium for Higher LA Production

Cheese whey and whey permeate were treated with β-d-galactosidase (104 AV/100 g, for 30 min at 50 °C) and inoculated with 2% (w/w) inoculum of the P. acidilactici (incubated for 48 h at 35 °C) and L. bulgaricus (incubated for 48 h at 37 °C). Samples for lactic and acetic acid content determinations were collected every 16 h.

Production of LA

According to the previous research results on highest LA amount producing dairy by-product substrate, a four-stage process for the conversion of whey permeate (WP) into LA was used, including: (1) WP pretreatment with enzyme lactase; (2) LAB fermentation of the WP with Pa or Lb, (3) separation of LA by nanofiltration and (4) LA concentration by reverse osmosis (Fig. 1).

Enzymatic treatment and fermentation of WP was performed in two feed tanks, surrounded by vapor heating and water cooling systems, which had a volume of 300 dm3 (Pierre Guerin, France). Each feed tank contained 150 L of WP. The tanks were pressurized with sterile air, and temperature was monitored and controlled. The enzymatic hydrolysis of WP lactose was performed using β-d-galactosidase 104 AV/100 g in batch process for 30 min at 50 °C temperature (Fig. 1, 1st stage). Then the WP media were inoculated with 2% (w/w) inoculum of the activated LAB strains and then incubated for 48 h at 35 °C for P. acidilactici and at 37 °C for L. bulgaricus (Fig. 1, 2nd stage). The equipment for the membrane filtration (APV, United Kingdom) with one/two organic industrial membranes in spiral configuration was used for LA purification by nanofiltration (NF) and concentration by reverse osmosis (RO) (Fig. 1, 3rd and 4th stages, respectively). Membrane modules of 3838/3840 dimensions were adjusted for NF and RO. NF was used to separate LA from lactose and other minerals, while RO produced the retentate containing LA in higher concentration. Samples were collected after the enzymatic treatment and fermentation to determine lactose and LA.

Microbiological Analysis

The growth of LAB in permeate medium was determined by the Plate count method. Ten milliliters of sample were homogenized with 90 mL of 0.9% NaCl solution. The suspension was diluted, and the solutions of 10−4–10−8 dilutions were inoculated on MRS agar (Liofilchem, REF 610024). The plates were incubated under anaerobic conditions at 30 °C for 48 h. The number of LAB was expressed as a decimal logarithmic value of colony forming units (CFU) per milliliter. The analysis was run in triplicate.

pH Determination

The pH of samples was measured using a pH meter (PP-15, Sartorius, Goettingen, Germany). 50 mL of sample was taken under aseptic conditions and pH values were measured directly.

Determination of Lactic Acid, Acetic Acid and Lactose Contents

The contents of lactic and acetic acids in the cheese whey and whey permeate samples were analysed with NMR. 900 µL of the sample were mixed with 100 µL of 1 mM 3-(trimethylsilyl)-propionic-2,2,3,3-d4 acid sodium salt (TSP) in 20 mM phosphate buffer, pH 7.0 in an Eppendorf tube and centrifuged at 20,000×g for 5 min. 600 µL of the centrifuged sample were transferred in a standard 5 mm NMR tube. 1D 1H, 2D 1H-1H TOCSY, 1H-13C HSQC and 1H-13C HMBC NMR spectra were acquired at 300 K with a Bruker Avance 600-MHz spectrometer equipped with 5-mm z-gradient TXI (H/C/N) cryoprobe. All the mentioned above NMR experiments were acquired using the standard Bruker pulse sequences noesygppr1d; mlevgpphprzf; hsqcetgpprsisp2.2 and hmbcgplpndprqf, correspondingly and using the standard settings. Each acquired spectrum was processed with TopSpin 3.2 (Bruker, Germany) software. NMR assignment was performed using both the registered experiments and the available NMR data bases (BMRB, HMDB). The spectra were calibrated against external standard assigning chemical shift of 0 ppm to TSP signal both in 1H and 13C dimensions. ERETIC2 (Electronic Reference To access In-vivo Concentrations, Bruker) quantification tool was used for the quantification of the acids.

The rapid d-/l-Lactic acid (d-/l-Lactate) assay kit (Megazyme Int. Ireland, Wicklow, Ireland) was used to measure total LA and l- and d-lactic acid contents in fermented WP samples before and after membrane filtration. The Lactose/Galactose (Rapid) test kit (Megazyme Int. Ireland, Wicklow, Ireland) was used for the determination of lactose content before and after enzymatic treatment of WP and during the fermentation process in order to monitor the consumption of lactose. Samples (1 mL) were diluted with distilled water, filtered through a Whatman’s filter paper No. 1 and used for lactose/galactose and LA analysis. Different dilution factors were used for sample preparation depending on lactic acid/lactose concentration in WP samples.

LAB Protease Activity Assay

Protease activity of LAB was estimated with the Sigma Aldrich (SSCASE01.001, 1999) enzymatic assay of protease using tyrosine as a standard. A casein solution (0.65%) was used as a substrate. The reaction mixture contained 5 mL of casein in a potassium phosphate buffer (pH 7.5), and 1 mL of the fermented WP sample. After 30 min of incubation at 37 °C, 5 mL of 110 mM trichloroacetic acid was added to the mixture to stop the reaction. The Folin & Ciocalteu’s phenol reagent was used for colour development, and the absorbance was measured at 660 nm. The tyrosine calibration curve was used to calculate the protease activity. One unit (PU) of protease activity was defined as the micromoles of tyrosine equivalents released from casein per minute under the assay conditions.

LAB β-d-Galactosidase Activity Assay

The LAB incubation in the whey permeate (“Rokiskio pienas”) for 48 h was performed for the assessment of LAB β-d-galactosidase activity with o-nitrophenyl β-d-galactopyranoside (ONPG) as a substrate [14]. The WP sample (10 mL) was filtered and, after adjusting the pH to 4.5, the supernatant was used as the enzyme solution. The reaction was carried out with continuous shaking in an assay volume of 2.0 Ml, containing 1.7 mL of 100 mM sodium acetate buffer (pH 4.5), 0.2 mL enzyme solution, and 0.1 mL of 20 mM ONPG. The reaction was stopped by adding 2.0 mL sodium carbonate solution (1.0 M) and the formation of o-nitrophenol was measured spectrophotometrically at 405 nm. One unit (1.0 AU) of β-d-galactosidase activity is defined as the amount of enzyme that liberates 1.0 μmole of o-nitrophenol per minute under standard assay conditions.

Statistical Analysis

All analyses were performed in triplicate and the mean values and standard deviations are reported. Statistical analyses were carried out using a Microsoft Excel spreadsheetfor Windows XP V15.0 (SPSS Inc., Chicago, IL, USA, 2007). The means were compared by a one-way analysis of variance at 5% significance level.

Results and Discussion

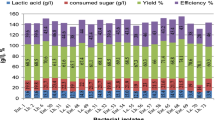

Selection of Dairy By-Products as a Medium for Lactic Acid Production

The first aim of the study was to determine which of the selected dairy by-products is more suitable for the production of lactic acid. The concentrations of total lactic acid and acetic acid using different dairy by-product medium are summarised in Table 1. A significant increase (P < 0.05) in lactic acid content was noticed when whey permeate was used as fermentation medium. Production of this organic acid after 48 h of fermentation was 88.7 and 73.3% higher in whey permeate with P. acidilactici and L. bulgaricus, respectively, compared with cheese whey medium. Also, P. acidilactici was more active in producing LA during the first 16 h of fermentation in whey permeate medium compared to L. bulgaricus.

Acetic acid production was also measured and the results demonstrate that a higher amount of acetic acid was obtained during whey permeate fermentation. However, P.acidilactici tended to form a higher content of this acid compared to L.bulgaricus. The measurement of pH showed that its values (data not shown) from the beginning of the fermentation decreased by 40.8 and 41.4% till the final stage of fermentation (48 h) in cheese whey and whey permeate mediums, respectively.

Due to these results, whey permeate was chosen as fermentation medium for the subsequent experiments: lactic acid production and separation with membrane technologies.

Production of β-d-Galactosidase by Tested LAB in Whey Permeate Medium

To better understand the lactase production as well as to identify particular properties of LAB that may be relevant to the acceleration of lactose hydrolysis during the LAB fermentation process, lactase activity of both tested strains was assessed. The β-d-galactosidase activity of the tested LAB, as a function of fermentation time is presented in Fig. 2.

The lactase activities of P. acidilactici and L. bulgaricus in whey permeate fermentation medium after 12 h were found to be relatively similar, 30.4 U/mL and 40.2 U/mL, respectively. The increase in LAB lactase activity during whey permeate fermentation was noted. L. bulgaricus was found to produce lactase more actively than P. acidilactici. After 24 h of fermentation, lactase activity increased to 130.3 U/mL (Lb) and 93.6 U/mL (Pa). The longer incubation (48 h) induced a decrease by 22.3% (Lb) and 32.6% (Pa) in the production of lactase. The results showed a significant difference in the excreted lactase levels depending on the LAB strain. At the end of the fermentation, L. bulgaricus had a 1.6-fold higher lactase activity compared to P. acidilactici.

The use of measuring the enzymatic activity of starter cultures as a selection criterion is of great interest, since lactobacilli could affect the hydrolysis of disaccharides such as lactose. Our study indicates that L. bulgaricus possesses the highest lactase activity, compared to P. acidilactici, and therefore could be a more suitable strain for WP lactose degradation during fermentation. Most studies have focused on the enzymatic activities of Lactobacillus delbrueckii subsp. bulgaricus [15, 16], meanwhile Pescuma et al. [17] analysed the enzymatic profiles of other important LAB genera strains such as Lactobacillus acidophilus CRL 636 and Lactobacillus thermophilus, as well as Streptococcus thermophilus CRL 804 and Leuconostoc citrovorum. These studies suggest that the enzymatic activities of various LAB strains might exceed the one of Lb and thus have a positive effect on the LAB fermentation process and milk sugar degradation.

l(+)-Lactic Acid and d(−)-Lactic Acid Production and Recovery

Growth of Tested LAB in Whey Permeate (WP)

The results of the growth of tested LAB in WP medium are presented in Table 2. The two LAB strains were found to have significantly different (P < 0.05) growth patters in the tested medium. At the beginning of the fermentation, P. acidilactici and L. bulgaricus counts were 7.25 and 7.20 log CFU/ml, respectively. A considerable distinction in growth was detected after 36 h of fermentation when P. acidilactici cell count was higher by 4.8% compared to L. bulgaricus. At the end of the fermentation, the cell counts of both LAB strains were almost similar.

In this study, most of the samples had a LAB count within the range reported by other authors [2, 18]. Nutritionally rich medium and process parameters such as temperature are important for the efficient growth of LAB strains [19]. However, another significant factor affecting their viability during lactic acid production is the pH of the fermentation media. During this research, P. acidilactici KTU05-7 has demonstrated a higher acid tolerance than L. bulgaricus and kept its viability till the end of the 48 h lacto-fermentation. Therefore, the direct control of selected starter cultures is the highlight of the bio-based lactic acid production, helping to control the overall standardization of the fermentation process and yield of the end product [18].

Production of Organic Acids During WP Fermentation

In all samples, the pH values decreased with increased fermentation time (Table 2). The application of P. acidilactici for the WP fermentation influenced the rapid decrease in pH values during the first 24 h of fermentation by an average of 32% as compared to the acidity of the medium with L. bulgaricus. However, after 24 h of fermentation, a slower decrease in pH value in both cases (Pa and Lb) was observed. At the end of the fermentation, the pH values reached 3.7 (Pa) and 3.9 (Lb), respectively.

As reported by other authors, the type of LAB strain, the fermentation time and preferably the enrichment of the fermentation medium with nutrients enhance the production of acids in the dairy by-products [1, 19]. The main factor regulating acidification is the amount of fermentable carbohydrates [20], although the production of acids depends also on other parameters such as fermentation inhibitors. Das et al. [21] reported the significant interaction of pH and carbohydrates hydrolysis degree due to fact that activity of β-d-galactosidase is reduced in acid pH (< 5) values and hydrolysis of lactose could be diminished. The results obtained in the microbiological study confirmed that WP is a suitable medium for P. acidilactici cultivation, which increases the acidity level in whey permeate.

Lactose Consumption During WP Fermentation

The efficiency of the hydrolysis of lactose could be increased by the addition of industrial enzymes. The efficiency of the saccharification process was analysed by qualitative evaluation of lactose after 30 min treatment with β-d-galactosidase and after every 8 h during the fermentation with different LAB (Pa, Lb) (Fig. 3). The results showed that after treatment with β-d-galactosidase, the content of lactose decreased from 42.6 to 12.6 g/L using P. acidilactici, and from 42.3 to 10.9 g/L in the case of L. bulgaricus, after 48 h of fermentation. A rapid decrease in the lactose content by 56.1% was noticed during 24 h of fermentation with P. acidilactici with the lower changes of milk sugar on the following period (32.9%). Meanwhile using L. bulgaricus the changes in lactose were similar: a lower decrease of lactose (50.2%) was obtained during the first 24 h of fermentation, and a rapid decrease of lactose content followed in the remaining time of fermentation (48.4%). At the end of the fermentation, lactose hydrolysis rate reached 70.5% (Pa) and 74.2% (Lb).

For LA production, the substrate hydrolysis into fermentable carbohydrates is performed simultaneously with the fermentation or already pre-hydrolysed substrate can be used [1, 22]. In the latter case commercial enzymes preparations are employed. The combination of enzymatic treatment and fermentation with β-d-galactosidase activity possessing LAB strains can give the most efficient rate of sugars hydrolysis, increased process productivity and decrease fermentation time [23, 24].

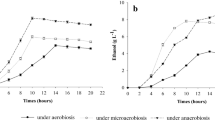

l(+)-Lactic Acid and d(−)-Lactic Acid Production by P. acidilactici and L. bulgaricus

The results showed that the total LA amount as well as the amounts of l(+)-lactic acid (LLA) and d(−)-lactic acid (DLA) increased with fermentation time (Fig. 4). P. acidilactici increased the LA content on average by 17.4% during the first 24 h, as compared to L. bulgaricus. P. acidilactici tended to produce higher amount of LLA (average d/l ratio 0.4) compared to L. bulgaricus (average d/l ratio 4.4) during the whole fermentation time. The production of DLA by L. bulgaricus was on average fourfold higher than the production of LLA after 48 h of fermentation. The total LA content in both fermented products after 32 h of fermentation was the same (29 g/L for Pa and Lb). However, during the next 16 h of fermentation, LA was produced more intensively by L. bulgaricus compared to P. acidilactici. After 48 h of fermentation, the LA yield and productivity of 1.03 g/g and 0.83 g/(L h) for P. acidilactici and 1.05 g/g and 0.88 g/(L h) for L. bulgaricus, respectively, were achieved in fermented WP. The final d/l ratios were of 0.3 (Pa) and 5.7 (Lb).

Total lactic acid (LA) a content in with P. acidilactici and L. bulgaricus fermented whey permeate. l(+) and d(−) isomer ( d/l) contents b in with P. acidilactici and L. bulgaricus fermented whey permeate. Note for the same fermentation time interval, values followed by different letters are significantly different (P < 0.05)

LAB can produce one isomeric form of LA or a racemic mixture. The form of the enzyme lactate dehydrogenase determines the production of LA isomers [7, 25]. Several Lactobacilli produce l(+)-isomers, which on accumulation induce a racemase, that converts them into d(−)-lactic acid until an equilibrium is obtained and a racemic mixture is formed [25]. Furthermore, the changes of pH, nutrients, substrate, temperature, aeration or usage of batch or continues cultures have the significant impact on the composition of the racemic mixture and the predominant LA isomer content [26, 27]. According to other research studies, Lb. delbrueckii produces a mixture of l(+)-lactic acid and d(−)-lactic acid, where the latter isomer is predominant, or exclusively just one form of isomer, depending on the substrate and fermentation mode [1]. Our study showed that P. acidilacticiproduced both LA isomers in dairy medium but the mixture was formed by 76% of the LLA isomer. This strain can also produce a high content of LLA in fermented plant materials [28].

The acidification activity of LAB and the pH of the medium contribute to the production of LA, because it affects the microbial growth [29]. The most suitable pH range for fermentation is 5.0–7.0, in some cases 6.0–6.5, depending upon the culture used [2]. For Lb strains, a pH value below 5.7 is optimal [30]. P. acidilactici proved its ability to survive in pH lower than 4 and produce lactic acid in similar amounts as L. bulgaricus. The LA production results, obtained in this study, correspond to the other authors results [1, 31].

LA Recovery Peculiarities After WP Fermentation with P. acidilactici and L. bulgaricus

Lactic acid purification is one of the most costly steps of the production process [32, 33]. A combined process of NF and RO was applied to separate and concentrate lactic acid after fermentation. The concentrations of LA isomers obtained in the final products (permeate after NF and retentate after RO) are presented in Table 3.

The higher lactose retention (89 ± 1%) was obtained by the NF of the broth fermented with Pa compared to Lb (lactose retention was 85 ± 1%). The LA content in the permeate after the NF reached 55.5 g/L for P. acidilactici with total volume of 94 liters and 54.9 g/L for L. bulgaricus with a total volume of 105 liters. A fourfold (Pa) and threefold (Lb) increase in LA concentration was obtained in the retentate after the concentration by the RO. After the membrane filtration, the same tendency of LA isomers distribution was observed as it was after 48 h of LAB fermentation: a higher content of LLA were obtained in WP fermented by P. acidilactici (d/l ratio 0.3). In the case of L. bulgaricus fermented WP, a greater content of DLA was determined in NF permeate and RO retentate with d/l ratios 5.8 and 5.6, respectively.

The complexity of the medium, affecting the NF separation conditions, has been observed by comparing visually the fermentation broth, obtained after fermentations using different LAB strains. Protein aggregates were formed in broth fermented with Lb, while protein aggregation did not occur in broth fermented with Pa. Therefore, due to the biomass and other non-dissolved compounds in the fermented broth, a covering layer was formed on the membrane surface, or even in some cases inside the membrane pores. This causes an attenuation of the membrane flux shortly after the filtration starts and needed to be filtered before being transferred to the NF.

A study on the proteolytic action of LAB allowed to provide useful information on the relationship between the flocculation process in the fermented broth and enzymatic activity of LAB strains. Proteins can be broken down by enzyme hydrolysis into small peptide molecules and amino acids. This positive effect of Pa, possessing the proteolytic activity (0.3 PU/mL), might be due to the solubilization of the precipitated proteins during the long fermentation leading to the anti-fouling effect in fermented broth, while Lb did not show these activities. The undenaturated protein content could decrease with the increase in acidity of medium (pH 4.6–4.8) indicating the effect of P. acidilactici strain in a more intensive denaturation of whey proteins during fermentation.

Current research was focused on the evaluation of performance criteria of membrane filtration (permeate flux, trans membrane pressure and volumetric concentration factor) using different LAB strains for l(+)-lactic acid and d(−)-lactic acid production (Table 4). After the separation and concentration operations had begun, the flux strongly decreases within 60–70 min (NF) and 15–20 min (RO). The following changes have been noted within the application of the different LAB strains for WP fermentation: the lower decrease (by 66.7%) in the permeate flux during the NF was reached in the Pa sample; during concentration stage (RO), the decrease in permeate flux was lower (by 41.4%) in the Lb sample.

Permeate flux can decrease with time due to membrane fouling and concentration polarization [9, 34]. Membrane surface and pore clogging by small molecules is one of the reasons for fouling [35]. Cake layer formation by sludge particle deposition is the most common reason for the flux decline. When the equilibrium between the formation and the washing away of the covering layer was established, the permeability settled at a steady state. Trans membrane pressure (TMP) varied during NF within the range of 12.75–20.25 bar and during RO from 9.25 to 16.25 bar. When filtration and concentration of with Pa and Lb fermented WP is carried out at the same TMP [12.75 bar (NF); 14.25 (RO)], a permeate flux of 37.33 Lm−2h (NF, Lb); 38.67 Lm−2h (RO, Pa) was obtained with a higher permeate flow 0.28 m3h−1 (NF, Lb); 0.29 m3h−1 (RO, Pa), because the covering layer is reduced by a better flush effect and is not as thick as by a lower flow velocity.

The development of an effective method of lactic acid separation and purification from a fermentation broth is essential for economic viability. Membrane based processes have a broad application in dairy industry and are used for dairy wastewater treatment and production of high purity lactic acid [36,37,38,39]. Several membrane separation steps are combined together to design specific schemes of LA production for industrial use. Furthermore, membrane based processes allow to eliminate many stages and chemicals used in traditional LA production [40].

Conclusions

This study provides significant information on the effect of a novel LAB strain Pediococcus acidilactici KTU05-7, for the amelioration of eco-friendly lactic acid production from harmful to the environment dairy industry by-products. The obtained results revealed that, compared to L. bulgaricus, the higher content of LA as well as l(+)-lactic acid during the first 24 h of whey permeate fermentation can be achieved using P. acidilactici, which also has an advantage in facilitating the LA recovery using nanofiltration and reverse osmosis.

Abbreviations

- LA:

-

Lactic acid

- LAB:

-

Lactic acid bacteria

- Pa :

-

Pediococcus acidilactici

- Lb :

-

Lactobacillus bulgaricus

- WP:

-

Whey permeate

- LLA:

-

l(+)-lactic acid

- DLA:

-

d(−)-lactic acid

- NF:

-

Nanofiltration

- RO:

-

Reverse osmosis

References

Hofvendahl, K., Hahn–Hägerdal, B.: Factors affecting the fermentative lactic acid production from renewable resources 1. Enzyme Microb. Technol. 26(2), 87–107 (2000)

Panesar, P.S., Kennedy, J.F., Gandhi, D.N., Bunko, K.: Bioutilisation of whey for lactic acid production. Food Chem. 105(1), 1–14 (2007)

Juodeikiene, G., Vidmantiene, D., Basinskiene, L., Cernauskas, D., Bartkiene, E., Cizeikiene, D.: Green metrics for sustainability of biobased lactic acid from starchy biomass vs chemical synthesis. Catal. Today. 239, 11–16 (2015)

Suárez, E., Lobo, A., Alvarez, S., Riera, F., Álvarez, R.: Demineralization of whey and milk ultrafiltration permeate by means of nanofiltration. Desalination. 241(1), 272–280 (2009)

Carvalho, F., Prazeres, A.R., Rivas, J.: Cheese whey wastewater: characterization and treatment. Sci. Total Environ. 445, 385–396 (2013)

Wang, C., Li, Q., Wang, D., Xing, J.: Improving the lactic acid production of actinobacillus succinogenes by using a novel fermentation and separation integration system. Process Biochem. 49(8), 1245–1250 (2014)

Garvie, E.I.: Bacterial lactate dehydrogenases. Microbiol. Rev. 44(1), 106–139 (1980)

Akoum, O., Jaffrin, M.Y., Ding, L.H., Frappart, M.: Treatment of dairy process waters using a vibrating filtration system and NF and RO membranes. J. Membr. Sci. 235(1), 111–122 (2004)

Wojtyniak, B., Szaniawska, D.: Separation of lactic acid solutions from whey fermentation broth using zirconium (IV) hydrous oxide dynamically formed membranes. Pol. J. Environ. Stud. 24(3) (2015)

Atra, R., Vatai, G., Bekassy-Molnar, E., Balint, A.: Investigation of ultra-and nanofiltration for utilization of whey protein and lactose. J. Food Eng. 67(3), 325–332 (2005)

Dey, P., Linnanen, L., Pal, P.: Separation of lactic acid from fermentation broth by cross flow nanofiltration: membrane characterization and transport modelling. Desalination. 288, 47–57 (2012)

Digaitiene, A., Hansen, ÅS., Juodeikiene, G., Eidukonyte, D., Josephsen, J.: Lactic acid bacteria isolated from rye sourdoughs produce bacteriocin-like inhibitory substances active against bacillus subtilis and fungi. J. Appl. Microbiol. 112(4), 732–742 (2012)

Digaitiene, A., Hansen, A., Juodeikiene, G., Josephsen, J.: Microbial population in lithuanian spontaneous rye sourdoughs. Ekologia i Technika. 13(5), 193–198 (2005)

Ansari, S.A., Husain, Q.: Lactose hydrolysis from milk/whey in batch and continuous processes by concanavalin A-celite 545 immobilized Aspergillus oryzae β galactosidase. Food Bioprod. Process. 90(2), 351–359 (2012)

Vasiljevic, T., Jelen, P.: Production of β-galactosidase for lactose hydrolysis in milk and dairy products using thermophilic lactic acid bacteria. Innov. Food Sci. Emerg. Technol. 2(2), 75–85 (2001)

Gassem, M., Schmidt, K., Frank, J.: Exopolysaccharide production from whey lactose by fermentation with Lactobacillus delbrueckii ssp. bulgaricus. J. Food Sci. 62(1), 171–173 (1997)

Pescuma, M., Hébert, E.M., Mozzi, F., De Valdez, G.F.: Functional fermented whey-based beverage using lactic acid bacteria. Int. J. Food Microbiol. 141(1), 73–81 (2010)

Sanni, A., Morlon-Guyot, J., Guyot, J.: New efficient amylase-producing strains of Lactobacillus plantarum and L. fermentum isolated from different nigerian traditional fermented foods. Int. J. Food Microbiol. 72(1), 53–62 (2002)

Komesu, A., de Oliveira, J.A.R., da Silva Martins, L.H., Maciel, M.R.W., Maciel Filho, R.: Lactic acid production to purification: a review. BioResources. 12(2), 4364–4383 (2017)

Rogers, L.A., Whittier, E.O.: Limiting factors in the lactic fermentation. J. Bacteriol. 16(4), 211–229 (1928)

Das, B., Roy, A.P., Bhattacharjee, S., Chakraborty, S., Bhattacharjee, C.: Lactose hydrolysis by β-galactosidase enzyme: optimization using response surface methodology. Ecotoxicol. Environ. Saf. 121, 244–252 (2015)

Øyaas, J., Storrø, I., Levine, D.: Uptake of lactose and continuous lactic acid fermentation by entrapped non-growing Lactobacillus helveticus in whey permeate. Appl. Microbiol. Biotechnol. 46(3), 240–249 (1996)

Juodeikiene, G., Zadeike, D., Bartkiene, E., Klupsaite, D.: Application of acid tolerant pedioccocus strains for increasing the sustainability of lactic acid production from cheese whey. LWT-Food Sci. Technol. 72, 399–406 (2016)

Matijević, B., Lisak, K., Božanić, R., Tratnik, L.: Impact of enzymatic hydrolyzed lactose on fermentation and growth of probiotic bacteria in whey. Mljekarstvo. 61(2), 154 (2011)

Narayanan, N., Roychoudhury, P.K., Srivastava, A.: l(+) lactic acid fermentation and its product polymerization. EJB. 7(2), 167–178 (2004)

Severson, D.K., Barrett, C.L.: Lactobacillus delbrueckii ssp. bulgaricus strain and fermentation process for producing l-(+)-lactic acid. Biotechnol. Adv. 3(14), 382 (1996)

Hofvendahl, K., Hahn-Hägerdal, B.: L-lactic acid production from whole wheat flour hydrolysate using strains of lactobacilli and lactococci. Enzyme Microb. Technol. 20(4), 301–307 (1997)

Bartkiene, E., Krungleviciute, V., Juodeikiene, G., Vidmantiene, D., Maknickiene, Z.: Solid state fermentation with lactic acid bacteria to improve the nutritional quality of lupin and soya bean. J. Sci. Food Agric. 95(6), 1336–1342 (2015)

Panesar, P.S., Kennedy, J.F., Knill, C.J., Kosseva, M.: Production of l(+) lactic acid using Lactobacillus casei from whey. Braz. Arch. Biol. Technol. 53(1), 219–226 (2010)

Kashket, E.R.: Bioenergetics of lactic acid bacteria: cytoplasmic pH and osmotolerance. FEMS Microbiol. Lett. 46(3), 233–244 (1987)

Zorn, H., Czermak, P., Lipinski, GvR.: Biotechnology of Food and Feed Additives, vol. 143. Springer, Heidelberg (2014). https://doi.org/10.1007/978-3-662-43761-2

Abdel-Rahman, M.A., Tashiro, Y., Sonomoto, K.: Lactic acid production from lignocellulose-derived sugars using lactic acid bacteria: overview and limits. J. Biotechnol. 156(4), 286–301 (2011)

Datta, R., Henry, M.: Lactic acid: recent advances in products, processes and technologies—a review. J. Chem. Technol. Biotechnol. 81(7), 1119–1129 (2006)

Silalahi, S.H., Leiknes, T.: High frequency back-pulsing for fouling development control in ceramic microfiltration for treatment of produced water. Desalin. Water Treat. 28(1–3), 137–152 (2011)

Sondhi, R., Bhave, R.: Role of backpulsing in fouling minimization in crossflow filtration with ceramic membranes. J. Membr. Sci. 186(1), 41–52 (2001)

Yorgun, M., Balcioglu, I.A., Saygin, O.: Performance comparison of ultrafiltration, nanofiltration and reverse osmosis on whey treatment. Desalination. 229(1–3), 204–216 (2008)

Vourch, M., Balannec, B., Chaufer, B., Dorange, G.: Nanofiltration and reverse osmosis of model process waters fromthe dairy industry to produce water for reuse. Desalination. 172(3), 245–256 (2005)

Giorno, L., Chojnacka, K., Donato, L., Drioli, E.: Study of a cell-recycle membrane fermentor for the production of lactic acid by Lactobacillus bulgaricus. Ind. Eng. Chem. Res. 41(3), 433–440 (2002)

Gonzalez, M.I., Alvarez, S., Riera, F.A., Alvarez, R.: Lactic acid recovery from whey ultrafiltrate fermentation broths and artificial solutions by nanofiltration. Desalination. 228(1–3), 84–96 (2008)

Pal, P., Sikder, J., Roy, S., Giorno, L.: Process intensification in lactic acid production: a review of membrane based processes. Chem. Eng. Process. 48(11), 1549–1559 (2009)

Acknowledgements

This work was funded by the European Union’s Seventh Framework Programme for research, technological development and demonstration (Grant Agreement Number 613589, SUSMILK).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Klupsaite, D., Juodeikiene, G., Arbones, E. et al. A Comparison Study on the Production and Recovery of Lactic Acid by Fermenting Dairy By-Products with P. acidilactici and Lb. delbrüeckii spp. bulgaricus. Waste Biomass Valor 10, 1519–1528 (2019). https://doi.org/10.1007/s12649-017-0171-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-017-0171-z