Abstract

Objectives

To assess the effect of one-step temperature increase, from 35 to 55 °C, on the methane production of a mesophilic granular sludge (MGS) treating wine vinasses and the effluent of a hydrogenogenic upflow anaerobic sludge blanket (UASB) reactor.

Results

One-step temperature increase from mesophilic to thermophilic conditions improved methane production regardless of the substrate tested. The biomethane potentials obtained under thermophilic conditions were 1.8–2.9 times higher than those obtained under mesophilic conditions. The MGS also performed better than an acclimated thermophilic digestate, producing 2.2–2.5 times more methane than the digestate under thermophilic conditions. Increasing the temperature from 35 to 55 °C also improved the methane production rate of the MGS (up to 9.4 times faster) and reduced the lag time (up to 1.9 times). Although the temperature increase mediated a decrease in the size of the sludge granules, no negative effects on the performance of the MGS was observed under thermophilic conditions.

Conclusions

More methane is obtained from real agroindustrial effluents at thermophilic conditions than under mesophilic conditions. One-step temperature increase (instead of progressive sequential increases) can be used to implement the thermophilic anaerobic digestion processes with MGS.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The production of gas and liquid biofuels such as methane and bioalcohols from agroindustrial effluents is a hot topic worldwide due to its economic and environmental relevance (Kan et al. 2017; Lee et al. 2010; Zacharof 2017). Their abundance and high content of organic matter make agroindustrial effluents an attractive substrate to produce methane by means of anaerobic digestion processes (Díaz et al. 2016; Ferraz-Júnior et al. 2016). Moreover, biorefineries running on agroindustrial substrates also generate effluents highly loaded with organic matter that must be treated and valorized (Kaparaju et al. 2009). In this context, anaerobic digestion (AD) is a reliable, robust and highly implemented technology for the treatment and valorization of effluents rich in organic matter (Díaz et al. 2016; Ojeda et al., 2017). One of the main advantages of AD is the production of methane, a renewable biofuel that can be used to generate thermal and electrical power (Amani et al. 2010). AD is commonly performed under mesophilic conditions (30 – 40 °C); however, it has been consistently reported that carrying out AD under thermophilic conditions (45 – 60 °C) results in a higher specific methane yield and faster reaction rates (Amani et al. 2010; Lee et al. 2010). Sludge acclimation from mesophilic to thermophilic conditions is a sequential and time-consuming process that might take several months (de la Rubia et al. 2005; Tian et al. 2015). Nevertheless, there is a lack of systematic studies evaluating the direct temperature increase from mesophilic to thermophilic conditions on the performance of MGS for the treatment of agroindustrial effluents.

This work has investigated the effect of one-step temperature increase from 35 to 55 °C on methane production performance of a mesophilic granular sludge (MGS). Wine vinasses and the effluent of a hydrogenogenic UASB reactor were used as model agroindustrial substrates. Biomethane potential tests (BMP) were carried out with the MGS and also with a thermophilic digestate, which served as a reference inoculum already adapted to thermophilic conditions. The kinetics of the process and the impact of one-step temperature increase on the sludge granular structure were also studied. As far as the authors know, this is the first report on the systematic evaluation of one-step temperature increase (from mesophilic to thermophilic conditions) on the methane production from wine vinasses and hydrogenogenic upflow anaerobic sludge blanket effluent by AD.

Materials and methods

Inocula and substrates

The mesophilic granular sludge (MGS) was obtained from a brewery wastewater treatment plant (Guadalajara, Mexico). The thermophilic digestate was obtained from a thermophilic anaerobic digester (Querétaro, México). Two substrates were tested: white wine vinasses (referred to as “vinasses”) and the effluent of a hydrogenogenic upflow anaerobic sludge blanket (UASB) reactor treating the previously mentioned vinasses (referred to as “effluent”). The raw vinasses kindly provided by Freixenet (Ezequiel Montes, Querétaro, México) were allowed to settle for 1 h and the sediment fraction was used as substrate. Carboxymethylcellulose (CMC) at 50 g l−1 was used as a control substrate. The most significant characteristics of the inocula and substrates tested were determined according to standard methods (APHA 2005) (Table 1).

Biomethane potential (BMP) tests

The BMP tests were performed in 1-l glass bottles according to Angelidaki et al. (2009). Inoculum sludge was degassed for 48 h at 35 °C or 55 °C prior the beginning of the tests. A ratio of 0.5 g CODsubstrate/g VSinoculum was used. After headspace deoxygenation with N2, the bottles were gas-tight closed and incubated at 35 °C or 55 °C for 6 days (Fig. 1). The tests were carried out in duplicate. Blanks without substrate (to evaluate the endogenous CH4 production of the inoculum) and controls with CMC (to confirm the hydrolytic activity of the inoculum) were also performed.

Schematic of the experimental BMP setup and quantification of methane production. The anaerobic digestion process took place in the glass bottles under controlled temperature, while the biogas was collected in Tedlar® bags for periodical volume quantification and characterization of biogas composition

Assessment of biokinetic parameters

The impact of the one-step temperature increase on the biomethane potential was evaluated in terms of changes in the biokinetic parameters of the process. The modified Gompertz equation was fitted to the experimental methane production from the BMP tests according to:

where, H is the cumulative methane production at time t (mlCH4 g COD−1), Hmax is the maximum volume of methane produced (mlCH4 g COD−1); Rmax is the maximum methane production rate (mlCH4 g COD−1 h−1); t is the experimental time; e is the exponential 1 which is 2.71828 and λ represent the lag–phase time (h).

Parameter fitting was done using Microsoft Solver.

Effect of temperature on granular sludge structure

The effect of temperature on the size of the sludge granules was evaluated from liquid samples containing granular sludge taken before and at the end of BMP tests under complete mixing. The structure of the MGS was observed microscopically and LAS-EZ software (version, Leica, 3.0, Switzerland) was used to determine the diameter of the granules. The average diameter of the granules was determined by analyzing at least 100 granules randomly selected. Significant differences among average diameters were determined by means of Tukey-Kramer tests performed after ANOVA tests (α = 0.05) using the NCSS software.

Analytical methods

The biogas composition was determined according to Cardeña et al. (2017) using GC (SRI Instruments, California, USA) equipped with thermal conductivity detector and a Carboxen 1010 Plot column (30 m × 0.53 mm × 30 µm). The injector, column and detector were at 200, 100 and 230 °C, respectively. N2 was used as the carrier gas at 20 ml min−1.

Results and discussion

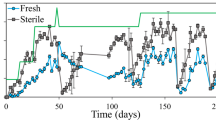

Impact of one-step temperature increase on the biomethane potential

With vinasses as substrate, a maximum methane production of 154 ± 3 ml CH4 g COD−1 was achieved under mesophilic conditions, while a maximum production of 282 ± 9 ml CH4 g COD−1 was recorded under thermophilic conditions (Fig 2a). This represents a 1.8-fold increase on the maximum methane produced driven by the one-step temperature increase. When effluent was used as substrate a similar trend was observed. A maximum methane production of 104 ± 1 ml CH4 g COD−1 was achieved under mesophilic conditions, while 302 ± 7 ml CH4 g COD−1 were produced under thermophilic conditions (Fig. 2b). This enhancement represented a 2.9-fold increase in the maximum methane produced.

Methane production curves of: (a) MGS with vinasses as substrate at 35 °C (closed circles) and 55 °C (open circles); (b) MGS with effluent as substrate at 35 °C (closed circles) and 55 °C (open circles); (c) thermophilic digestate at 55 °C with vinasses (closed triangle) and effluent (open triangle) as substrates. Typical fitting of the modified Gompertz model is represented by the continuous line

To compare the performance of the MGS with an inoculum already acclimated to thermophilic conditions, BMP tests inoculated with a thermophilic digestate were also carried out. The digestate supported maximum methane productions of 113 ± 9 ml CH4 g COD−1 and 136 ± 21 ml CH4 g COD−1 with vinasses and effluent, respectively, under thermophilic conditions. These maximum methane productions were 2.5- and 2.2-times lower than the values obtained with the MGS for the same substrates. Such differences in the performance of both inocula was attributed to their sources. While MGS was obtained from a WWTP treating brewery effluents where lignocellulosic compounds are found, the thermophilic digestate was obtained from a digester treating WWTP sludge with a minimum load in lignocellulosic compounds. These results confirmed that the one-step temperature indeed increased the performance of the MGS in terms of the maximum volume of methane produced. A previous study applying one-step temperature increases from 46 to 55 and 64 °C to a UASB reactor operated with MGS showed that methane production decreased just after the one-step temperature increase (van Lier et al., 1992). However, stable thermophilic methanogenesis was achieved after a relatively short acclimation period. Although a synthetic wastewater loaded with volatile fatty acids (acetate, propionate, and butyrate) rather than a real effluent was used, these authors confirmed that one-step temperature increase can be applied to implement a thermophilic AD process using MGS. Furthermore, in the present study the performance of the methane production by the MGS was evaluated via BMP tests, which granted that no limitation/inhibition of bioreaction occurred in the AD process.

Biokinetic parameters

The effect of the one-step temperature increase on the biomethane potential was also quantified in terms of changes in the biokinetic parameters, mainly on the methane production rate (Rmax). Table 2 summarizes the biokinetic parameters retrieved from the modified Gompertz model. The goodness of fit between the model and the experimental data, quantified through the R2 correlation coefficient, ranged between 90 and 99%, which confirmed the accuracy of the model and the biokinetic parameters retrieved. As shown in Table 2, the temperature increase modified all the kinetic parameters regardless of the substrate tested. With vinasses as substrate, Rmax increased from 8.84 ± 0.53 to 27.52 ± 3.66 ml CH4 g COD−1 h−1 (a 3.1-fold increase), while λ decreased from 1.11 ± 0.07 to 0.64 ± 0.05 h (a 1.7-fold reduction). Likewise, with effluent as substrate, Rmax increased from 4.79 ± 0.52 to 45.32 ± 3.17 ml CH4 g COD−1 h−1 (a 9.4-fold increase), while λ decreased from 4.01 ± 0.39 to 2.12 ± 0.14 h (a 1.9-fold reduction). These results clearly showed that the one-step temperature increase indeed promoted faster reaction rates. This is in agreement with Tian et al. (2015) who reported that thermophilic digestion processes can be implemented from mesophilic sludge without requiring long periods of sequential acclimation.

Effect of one-step temperature increase on the granular sludge structure

The activated sludge granules were observed microscopically before and after performing the BMP tests to evaluate the impact of temperature increase on the size of the granules. As shown in Fig. 3, it was clear that the temperature increase mediated an important reduction in the size of the granules. Before starting the BMP tests, an average granule size of 0.43 ± 0.18 mm was determined (Fig. 3a). After performing the mesophilic tests, average granule sizes of 0.4 ± 0.18 mm and 0.42 ± 0.23 mm were determined when using vinasses and effluent as substrates, respectively (Fig. 3b). No significant differences were observed among these average granule sizes (α=0.05), which was quite expected since the granular sludge was already acclimated to mesophilic conditions. On the contrary, increasing the temperature to 55 °C led to a decrease in the average granule sizes. The average granule size at the end of the thermophilic test with vinasses was 0.15 ± 0.06 mm and with effluent was 0.13 ± 0.08 mm, which represents a ~3-fold reduction in the granule size relative to mesophilic conditions (Fig. 3c).

It is important to stress that the substrates did not mediate significant differences in the granule sizes and the only significant variable was the temperature increase. Methanogenic bacteria are indeed able to produce extracellular polymeric substances (EPS), which contribute to the adhesion among microbial groups to form granules (Veiga et al. 1997). Nevertheless, above ~ 42 °C the production of EPS was significantly reduced (Veiga et al. 1997; Liu and Tay 2004). Moreover, Appels et al. (2010) reported that key components of EPS such as proteins and carbohydrates can be solubilized at temperatures as low as 60–70 °C. Therefore, the hindered EPS production and the higher solubility of EPS components as a result of temperature increase likely determined the granule size reduction observed at thermophilic conditions. Finally, it must be stressed that the size reduction observed did not decrease the methane production under the thermophilic conditions.

Conclusions

The methanogenic potential of agroindustrial effluents was improved by the one-step temperature increase from mesophilic to thermophilic conditions. Although the temperature increase reduced significantly the average size of the sludge granules, the reaction kinetics and the maximum amount of methane produced were boosted. Therefore, this study demonstrates that a mesophilic granular sludge might be successfully used to implement a thermophilic digestion process with a one-step temperature increase.

References

Amani T, Nosrati M, Sreekrishnan TR (2010) Anaerobic digestion from the viewpoint of microbiological, chemical, and operational aspects - a review. Environ Rev 18:255–278

Angelidaki I, Alves M, Bolzonella D et al (2009) Defining the biomethane potential (BMP) of solid organic wastes and energy crops: a proposed protocol for batch assays. Water Sci Technol 59:927–934

APHA (2005) Standard methods for examination of water and wastewater, 21st edn. APHA, AWWA, WPCR, New York

Appels L, Degreve J, Van der Bruggen B et al (2010) Influence of low temperature thermal pre-treatment on sludge solubilisation, heavy metal release and anaerobic digestion. Bioresour Technol 101:5743–5748

Cardeña R, Moreno G, Bakonyi P et al (2017) Enhancement of methane production from various microalgae cultures via novel ozonation pretreatment. Chem Eng J 307:948–954

de la Rubia MA, Romero LI, Sales D et al (2005) Temperature Conversion (Mesophilic to Thermophilic) of Municipal Sludge Digestion. AIChE J 51:2581–2586

Díaz I, Figueroa-González I, Miguel JA et al (2016) Enhancing the biomethane potential of liquid dairy cow manure by addition of solid manure fractions. Biotechnol Lett 38:2097–2102

Ferraz-Júnior ADN, Koyama MH, Araújo-Júnior MM et al (2016) Thermophilic anaerobic digestion of raw sugarcane vinasse. Renew Energy 89:245–252

Kan X, Yao Z, Zhang J et al (2017) Energy performance of an integrated bio-and-thermal hybrid system for lignocellulosic biomass waste treatment. Bioresour Technol 228:77–88

Kaparaju P, Serrano M, Thomsen AB et al (2009) Bioethanol, biohydrogen and biogas production from wheat straw in a biorefinery concept. Bioresour Technol 100:2562–2568

Lee DY, Ebie Y, Xu KQ et al (2010) Continuous H2 and CH4 production from high-solid food waste in the two-stage thermophilic fermentation process with the recirculation of digester sludge. Bioresour Technol 101:S42–S47

Liu Y, Tay JH (2004) State of the art of biogranulation technology for wastewater treatment. Biotechnol Adv 22:533–563

Ojeda F, Bakonyi P, Buitrón G (2017) Improvement of methane content in a hydrogenotrophic anaerobic digester via the proper operation of membrane module integrated into an external loop. Bioresour Technol 245:1294–1298

Tian Z, Zhang Y, Li Y et al (2015) Rapid establishment of thermophilic anaerobic microbial community during the one-step start up of thermophilic anaerobic digestion from a mesophilic digester. Water Res 69:9–19

van Lier JB, Grolle KCF, Stams AJM et al (1992) Start-up of a thermophilic upflow anaerobic sludge bed (UASB) reactor with mesophilic granular sludge. Appl Microbiol Biotechnol 37:130–135

Veiga MC, Jain MK, Wu WM et al (1997) Composition and role of extracellular polymers in methanogenic granules. Appl Environ Microbiol 63:403–407

Zacharof MP (2017) Grape winery waste as feedstock for bioconversions: applying the biorefinery concept. Waste Biomass Valori 8:1011–1025

Acknowledgements

This work was supported by “Fondo de Sustentabilidad Energética CONACYT – SENER (Mexico)”, through the project Mexican Bioenergy Innovation Centre, Bioalcohols Cluster (249564). The authors thank the technical support of Jaime Pérez. G. Quijano acknowledges the support from CONACYT through the CÁTEDRAS program (Researcher ID 1535, Project 265).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Figueroa-González, I., Moreno, G., Carrillo-Reyes, J. et al. From mesophilic to thermophilic conditions: one-step temperature increase improves the methane production of a granular sludge treating agroindustrial effluents. Biotechnol Lett 40, 569–575 (2018). https://doi.org/10.1007/s10529-017-2490-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-017-2490-3