Abstract

Objective

To avoid lipase deactivation by methanol in the enzymatic transesterification process, a two-step biocatalytic process for biodiesel production from unrefined jatropha oil was developed.

Results

Unrefined jatropha oil was first hydrolyzed to free fatty acids (FFAs) by the commercial enzyme Candida rugosa lipase. The maximum yield achieved of FFAs 90.3 % at 40 °C, water/oil ratio 0.75:1 (v/v), lipase content 2 % (w/w) after 8 h reaction. After hydrolysis, the FFAs were separated and converted to biodiesel by using Rhizopus oryzae IFO4697 cells immobilized within biomass support particles as a whole-cell biocatalyst. Molecular sieves (3 Å) were added to the esterification reaction mixture to remove the byproduct water. The maximum fatty acid methyl ester yield reached 88.6 % at 35 °C, molar ratio of methanol to FFAs 1.2:1, molecular sieves (3 Å) content 60 % (w/w) after 42 h. In addition, both C. rugosa lipase and R. oryzae whole cell catalyst in the process showed excellent reusability, retaining 89 and 79 % yields, respectively, even after six batches of reactions.

Conclusion

This novel process, combining the advantages of enzyme and whole cell catalysts, saved the consumption of commercial enzyme and avoid enzyme deactivation by methanol.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Biodiesel, which is produced through transesterification of vegetable oils, animal fats or waste oils, has become increasingly important as an alternative fuel due to diminishing petroleum reserves and strict environmental regulations (Wardle 2003). Transesterification, the central reaction in biodiesel production, can be catalyzed either chemically or enzymatically. Increasing attention have been paid to the enzymatic production of biodiesel since no complex operations are required for the recovery of glycerol and the elimination of the catalyst and salt in comparison with chemical methods (Du et al. 2007; Fukuda et al. 2001). However, most enzymatic methods using extracellular lipases require a procedure for purifying the enzymes, that poses an obstacle to practical applications (Iso et al. 2001; Bajaj et al. Bajaj et al. 2001). Moreover, during the preparation of biodiesel by enzyme catalysis, the lipase will become inactivated due to the poisoning by one of the substrates, methanol (Shimada et al. 1999).

Using an intracellular lipase directly as a whole-cell biocatalyst to replace the extracellular lipase for biodiesel production can avoid complex procedures such as isolation, purification and immobilization of traditional extracellular lipase and, therefore, is an effective way to reduce production costs (Oda et al. 2005). Lipase-producing microorganisms, including bacteria, yeast and fungi, can catalyze methanolysis of edible or inedible oils for biodiesel production (Fukuda et al. 2008; Ban et al. 2001). In particular, filamentous fungi can be spontaneously immobilized within porous biomass support particles during batch cultivation which greatly reduces the cost of catalyst preparation (Sun et al. 2010). Compared with conventional extracellular lipases, whole-cell catalysts have better operating stability due to their complete cellular structure and also can be easily separated from products and then reused. However, the preparation of biodiesel using whole-cell catalysts is generally characterized by low conversion efficiency and long reaction periods due to the mass transfer resistance (Matsumoto et al. 2001).

The present study uses two-step biological catalysis to produce biodiesel from unrefined jatropha oil (UJO). First, the commercial enzyme Candida rugosa lipase is used to hydrolyze the UJO to free fatty acids (FFAs) in the absence of methanol, and then whole cells of Rhizopus oryzae IFO4697 are used to catalyze the FFAs to prepare biodiesel through esterification with the addition of methanol. Several process parameters are optimized, and the stability of the biocatalysts in batch reactions is evaluated.

Materials and methods

Microorganism and materials

Candida rugosa lipase (Type VII) was purchased from Sigma. The lipase-producing fungal strain R. oryzae IFO 4697 was obtained from China General Microbiological Culture Collection Center (CGMCC). Biomass support particles (BSP) used for immobilization of R. oryzae IFO 4697were 6 mm × 6 mm × 3 mm cuboids of reticulated polyurethane foam with a particle voidage beyond 97 % and a pore size of about 20 pores per linear centimeter. Samples of UJO with an acid value of 26 ± 0.5 mg/KOH were provided by a local company.

R. oryzae whole cell biocatalyst preparation

R. oryzae IFO 4697was immobilized on the BSPs by cross-linking with glutaraldehyde according to the method of Sun et al. (2010).

Hydrolysis of UJO

The hydrolysis reaction was carried out in a 50 ml screw-cap bottle on a reciprocal shaker (150 rpm) at 40 °C. The reaction system consisted of 10 g UJO, 0.2 g C. rugosa lipase and an appropriate amount of 0.1 M phosphate buffer (pH 6.8, used to adjust water to UJO ratio). At the end of the reaction, the product [primarily free fatty acids (FFAs)] was extracted with hexane and concentrated in a rotary evaporator, and then used as feedstock for the whole cell-catalyzed esterification. For investigating the recyclability of C. rugosa lipase,hexane was added to the reaction mixture after each batch reaction and then centrifuged. The organic phase was analyzed for FFAs concentration, and the aqueous phase containing lipase was subsequently used without further treatment.

Esterification of FFAs

The esterification reaction was carried out at 35 °C in a 100 ml screw-cap bottle with incubation on a reciprocal shaker (150 rpm).The reaction system contained 40 BSPs retaining dry immobilized R. oryzae cells, 9.65 g FFAs and 1.26 g methanol (a total molar ratio of methanol to FFAs is about 1.2:1). 50 % 3 Å molecular sieve (w/w, based on FFAs weight) was added to the reaction system to adsorb byproduct water. Methanol was added separately in three equal amounts at 0, 12 and 24 h. Samples (150 μl) were taken from the reaction mixture at specified times and held at 110 °C for 5 min to eliminate the residual methanol and water formed, and then the fatty acid methyl ester (FAME) content in the treated sample (mainly containing FAME and the unconverted FFAs) was analyzed by GC. After a reaction, the whole-cell biocatalyst was separated from the reaction mixture by filtration and then added to the fresh reaction mixture for the next cycle.

Analytical method

The FFAs were also analyzed by HPLC (see Ting et al. 2006). The biodiesel was analyzed by GC (see Chen et al. 2006). The FAME content was defined as the percentage of the actual amount of methyl ester detected in the aforementioned treated sample.

Results and discussion

Candida rugosa lipase-catalyzed hydrolysis of unrefined jatropha oil (UJO)

The time course of the hydrolysis of UJO at different water: UJO ratios is shown in Fig. 1. The highest FFAs content (90.3 %, w/w) was obtained after 8 h when water/UJO was 0.75:1(v/v).When the water/UJO ratio was below 0.75:1(v/v), both the FFA yield and the reaction rate increased with the increasing water to UJO ratio. This was possibly because lipase, which is a surface-active enzyme, bound with the substrates at the oil–water interface and, with the increased addition of water, the amount of water available for oil to form oil–water droplets increased, thereby increasing the available interfacial area. Another explanation might be that lipase-catalyzed hydrolysis of oil was an equilibrium reaction and the higher water content shifted the reaction equilibrium to the right. When the water/UJO ratio was >0.75:1(v/v), a further increase in the water/UJO ratio did not have much effect on the FFA yield but did slow down the hydrolysis, which might be due to the dilution effect of the too much water in the system on the substrate.

Time courses of UJO hydrolysis at different water to UJO ratios. Reaction conditions: UJO, 10 g; lipase 0.2 g; temperature, 40 °C and shaking speed, 150 rpm. Figure indicates the average corresponding to at least three independent experiments. Error bars represent SD and differences are considered significant at P < 0.05

Rhizopus oryzae IFO4697 whole cell-catalyzed esterification of FFAs

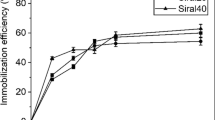

After the hydrolysis of UJO with C. rugosa lipase, the esterification of FFAs with methanol was carried out, catalyzed by the BSPs-immobilized R. oryzae IFO4697 whole cells. Figure 2 shows the time course of R. oryzae IFO4697 whole cell-catalyzed esterification of FFAs and transesterification of unhydrolyzed UJO. Both the reaction rate and the FAME yield for the esterification of the FFAs were significantly higher than those for the transesterification of the unhydrolyzed UJO. These results indicated that the FFAs were more easily converted into biodiesel compared to triacylglycerides when the R. oryzae IFO4697 whole cells were used as a catalyst, which might be explained as follows. The lipase in whole cells of R. oryzae has a 1,3-positional specificity; thus, biodiesel production from triacylglycerols of UJO is restrained to some extent. When being used as the substrate, triacylglycerols were first hydrolyzed into FFAs. Then, FFAs were further esterified with methanol to form biodiesel. By contrast, when FFAs are used as the substrate, only the second step occurred.

Time course of R. oryzae IFO4697 whole cell-catalyzed esterification of FFAs and transesterification of unhydrolyzed UJO. Reaction conditions: FFAs, 9.65 g; methanol, 1.26 g; BSPs with immobilized R.oryzae IFO 4697 cells 40 pieces (see "Methods" section); temperature, 35 °C; 3 Å molecular sieve content, 50 % (w/w, based on FFAs weight) and shaking speed, 150 rpm. Methanol was added three times at the times indicated by the arrows. Figure indicates the average corresponding to at least three independent experiments. Error bars represent SD and differences are considered significant at P < 0.05

Effect of 3 Å molecular sieves on the esterification of FFAs

When FFAs are used as raw material for biodiesel production, water is produced as a by-product. Because excess water would limit the yield of FAME, 3 Å molecular sieves were used as an adsorbent to remove the excess water produced during the reaction process. As shown in Fig. 3, the reaction carried out using 3 Å molecular sieves to remove the water produced finally achieved a FAME content of more than 88 %, while FAME content of lower than 81 % was observed for the system without adsorption. These results were obtained as expected because the esterification reaction was an equilibrium reaction and reducing one of the products would shift the equilibrium toward FAME production.

Time course of R. oryzae IFO4697 whole cell-catalyzed esterification of FFAs with and without water adsorbents. Methanol was added three times at the times indicated by the arrows. Figure indicates the average corresponding to at least three independent experiments. Error bars represent SD and differences are considered significant at P < 0.05

The effect of different amounts of the adsorbent on the esterification of FFAs was further studied. Figure 4 shows that the FAME contents first increased and then decreased slightly as the amount of 3 Å molecular sieves increased. When 60 % of 3 Å molecular sieves (w/w, based on FFAs weight) were used as the adsorbent, the highest biodiesel content reached 88.6 %. When the amount of the 3 Å molecular sieves was less than 60 % (w/w), the FAME content increased as the amount of the adsorbent amount increased. This phenomenon may be explained by the excess water produced during the esterification process of FFAs, which affected the reaction equilibrium. When more than 60 % (w/w) of 3 Å molecular sieves were added, the FAME content decreased slightly as the amount of the adsorbent increased, indicating that an insufficient amount of water (too much water was absorbed by excess amount of the adsorbent) probably resulted in the inactivation of the lipase by methanol.

Effect of the adsorbent amount on the esterification of FFAs. Reaction conditions: FFAs, 9.65 g; methanol, 1.26 g; BSPs with immobilized R.oryzae IFO 4697 cell, 40 pieces (see "Methods" section); temperature, 35 °C; 3 Å molecular sieve content, 0–80 % (w/w, based on FFAs weight) and shaking speed, 150 rpm. Molecular sieve (3 Å) was added at 12 h. Methanol was added three times at the times indicated by the arrows. Figure indicates the average corresponding to at least three independent experiments. Error bars represent SD and differences are considered significant at P < 0.05

Recycling of C. rugosa lipase and R. oryzae IFO4697 whole-cell catalysts

Figure 5 shows that C. rugosa lipase and R. oryzae IFO4697 whole-cell catalysts were repeatedly used for six cycles, both resulting in no significant loss of their activity. Over 89 % (w/w) of the initial activity of C. rugosa lipase was observed after six repeated cycles. C. rugosa lipase was more stable when being used as the catalyst for hydrolysis than when being directly used as the catalyst for transesterification, possibly because C. rugosa lipase was not deactivated in the process of catalyzing the hydrolysis in the absence of methanol. The catalytic activity of the R. oryzae IFO4697 whole-cell catalyst decreased gradually as the number of cycles increased but it was still high at ~79 % even in the sixth cycle. The R. oryzae IFO4697 whole-cell catalyst was more stable when being used to catalyze the FFAs to prepare biodiesel than when being directly used to catalyze triacylglycerols to prepare biodiesel. This was possibly because the reaction time required by the R. oryzae IFO4697 whole-cell catalysts to catalyze the FFAs to prepare biodiesel was much shorter than to catalyze triglycerides to prepare biodiesel, and the time for the contact of R. oryzae IFO4697 whole-cell catalysts with methanol in the reaction process also shortened.

Conclusion

A two-step biocatalytic process consisting of C. rugosa lipase-catalyzed hydrolysis and whole-cell R. oryzae IFO4697-catalyzed esterification was employed for the production of biodiesel from UJO. The results indicated that the application of this two-step biocatalytic process could improve the conversion rate and the stability of both biocatalysts, especially the commercial enzyme C. rugosa lipase. This novel process, which combined the advantages of enzyme and whole cell catalysts, saved the consumption of commercial enzyme and avoid enzyme deactivation by methanol, showing broad prospects as an alternative to the traditional process of biodiesel production by enzymatic transesterification.

References

Bajaj A, Lohan P, Jha PN, Mehrotra R (2001) Biodiesel production through lipase catalyzed transesterification: an overview. J Mol Catal B 62:9–14

Ban K, Kaieda M, Matsumoto T, Kondo A, Fukuda H (2001) Whole cell biocatalyst for biodiesel fuel production utilizing Rhizopus oryzae cells immobilized within biomass support particles. Biochem Eng J 8:39–43

Chen GY, Ying M, Li WZ (2006) Enzymatic conversion of waste cooking oils into alternative fuel-biodiesel. Appl Biochem Biotechnol 132:911–921

Du W, Wang L, Liu DH (2007) Improved methanol tolerance during Novozym435-mediated methanolysis of SODD for biodiesel production. Green Chem 9:173–176

Fukuda H, Kondo A, Noda H (2001) Biodiesel fuel production by transesterification of oils. J Biosci Bioeng 92:405–416

Fukuda H, Hama S, Tamalampudi S, Noda H (2008) Whole-cell biocatalysts for biodiesel fuel production. Trend Biotechnol 26:668–673

Iso M, Chen BX, Eguchi M, Kudo T, Shrestha S (2001) Production of biodiesel fuel from triglycerides and alcohol using immobilized lipase. J Mol Catal B 16:53–58

Matsumoto T, Takahashi S, Kaieda M, Ueda M, Tanaka A, Fukuda H, Kondo A (2001) Yeast whole-cell biocatalyst constructed by intracellular overproduction of Rhizopus oryzae lipase is applicable to biodiesel fuel production. Appl Microbiol Biotechnol 57:515–520

Oda M, Kaieda M, Hama S, Yamaji H, Kondo A, Izumoto E, Fukuda H (2005) Facilitatory effect of immobilized lipase-producing Rhizopus oryzae cells on acyl migration in biodiesel-fuel production. Biochem Eng J 23:45–51

Shimada Y, Watanabe Y, Samukawa T, Sugibara A, Noda IL, Fukuda H, Tominaga Y (1999) Conversion of vegetable oil to biodiesel using immobilized Candida antarctica lipase. J Am Oil Chem Soc 76:789–793

Sun T, Du W, Liu DH, Dai LM (2010) Improved catalytic performance of GA cross-linking treated Rhizopus oryzae IFO 4697 whole cell for biodiesel production. Process Biochem 45:1192–1195

Ting WJ, Tung KY, Giridhar R, Wu WT (2006) Application of binary immobilized Candida rugosa lipase for hydrolysis of soybean oil. J Mol Catal B 42:32–38

Wardle DA (2003) Global sale of green air travel supported using biodiesel. Renew Sustain Energy Rev 7:1–64

Acknowledgments

This paper is financially supported by the National High-tech R&D Program (863 program) of China through Project (2012AA051801) and the National Natural Science Foundation of China through Project (51036006).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, Gx., Chen, Gy. & Yan, Bb. Two-step biocatalytic process using lipase and whole cell catalysts for biodiesel production from unrefined jatropha oil. Biotechnol Lett 37, 1959–1963 (2015). https://doi.org/10.1007/s10529-015-1883-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10529-015-1883-4