Abstract

The Caulobacter crescentus (NA1000) xynB5 gene (CCNA_03149) encodes a predicted β-glucosidase-β-xylosidase enzyme that was amplified by polymerase chain reaction; the product was cloned into the blunt ends of the pJet1.2 plasmid. Analysis of the protein sequence indicated the presence of conserved glycosyl hydrolase 3 (GH3), β-glucosidase-related glycosidase (BglX) and fibronectin type III-like domains. After verifying its identity by DNA sequencing, the xynB5 gene was linked to an amino-terminal His-tag using the pTrcHisA vector. A recombinant protein (95 kDa) was successfully overexpressed from the xynB5 gene in E. coli Top 10 and purified using pre-packed nickel-Sepharose columns. The purified protein (BglX-V-Ara) demonstrated multifunctional activities in the presence of different substrates for β-glucosidase (pNPG: p-nitrophenyl-β-D-glucoside) β-xylosidase (pNPX: p-nitrophenyl-β-D-xyloside) and α-arabinosidase (pNPA: p-nitrophenyl-α-L-arabinosidase). BglX-V-Ara presented an optimal pH of 6 for all substrates and optimal temperature of 50 °C for β-glucosidase and α-l-arabinosidase and 60 °C for β-xylosidase. BglX-V-Ara predominantly presented β-glucosidase activity, with the highest affinity for its substrate and catalytic efficiency (Km 0.24 ± 0.0005 mM, Vmax 0.041 ± 0.002 µmol min−1 mg−1 and Kcat/Km 0.27 mM−1 s−1), followed by β-xylosidase (Km 0.64 ± 0.032 mM, Vmax 0.055 ± 0.002 µmol min−1 mg−1 and Kcat/Km 0.14 mM−1s−1) and finally α-l-arabinosidase (Km 1.45 ± 0.05 mM, Vmax 0.091 ± 0.0004 µmol min−1 mg−1 and Kcat/Km 0.1 mM−1 s−1). To date, this is the first report to demonstrate the characterization of a GH3-BglX family member in C. crescentus that may have applications in biotechnological processes (i.e., the simultaneous saccharification process) because the multifunctional enzyme could play an important role in bacterial hemicellulose degradation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Countries with extensive agricultural areas produce millions of tons of agro-industrial residues annually. These residues can often lead to environmental contamination, generating an excessive accumulation of organic materials in water bodies and soil. Agricultural residues comprise the most important sources of biomass and renewable energy in the world because they are found in abundance, have a low cost, and are composed of cellulose, hemicellulose, and lignin in variable proportions depending on the plant source. Hemicelluloses can be used as a carbon source for the growth of microorganisms, thereby leading to the production of compounds of commercial interest such as enzymes that can be applied to biotechnological processes, secondary metabolites, bio-pesticides, and biofuels (i.e., cellulosic ethanol and chemicals) (Goldbeck et al. 2014; Winger et al. 2014).

Xylan is a major component of hemicellulose. Different enzymes of the xylanolytic complex, work synergistically to degrade the xylan molecule including xylanases (EC 3.2.1.8) and β-xylosidases (EC 3.2.1.37). The endo-xylanases play a role in the depolymerization of xylan-hydrolyzing internal glycosidic linkages along the chain, thereby releasing xylo-oligosaccharides of various sizes and resulting in a lower degree of polymerization (Lara et al. 2014; Polizeli et al. 2005). The β-d-xylosidase enzymes hydrolyze xylo-oligosaccharides and lower xylobioses to produce xylose. Other enzymes are responsible for the removal of specific substituent residues of the xylan main chain, such as α-l-arabinosidase (EC 3.2.1.55), acetyl xylan esterase (EC 3.1.1.72), α-d-galactosidase (EC 3.2.1.22), α-d-glucuronidase (EC 3.2.1.139), ferulic acid esterase (EC 3.1.1.73) and esterase of p-coumaric acid (EC 3.1.1.-) (Collins et al. 2005).

The known enzymatic activities of glyco-hydrolase group 3 (GH3) include β-glucosidases (EC 3.2.1.21), β-d-xylosidases (EC 3.2.1.37), α-l-arabinosidase (EC 3.2.1.55), 1,3-β-glucosidases (EC 3.2.1.58), 1,4-β-glucosidases (EC3.2.1.74), β-glycosylceramidase (EC 3.2.1.45) and N-acetyl-β-d-glicohexosaminidases (EC3.2.1.52). The classification of these enzymes is based on similarities in the nucleotide and amino acid sequences of the corresponding genes. Few structures of β-glucosidases have been resolved, but β-glucosidases are known to use a nucleophile attack on aspartate and glutamate as proton donors during enzyme catalysis, as described in CAZy (http://www.cazy.org) (Lombard et al. 2014). The β-glucosidases (EC3.2.1.21) of the GH3 family may have different functions (i.e., the degradation of cellulosic biomass and cell wall remodeling in plants and bacteria and energy metabolism that may play a role in the defense against pathogens). Some of the enzymes have characterized to possess bi-functional activity and can present α-l-arabinosidase and/or β-d-xylosidase activities (Lee et al. 2003; Zhou et al. 2011; Gruninger et al. 2014).

Species from the genus Caulobacter are found in nature in various bodies of water, including fresh water, seawater, tap water and undisturbed water (where they form biofilms). The bacteria have been identified in neutral or slightly acidic soils with high moisture content and low organic content. Caulobacter strains present an easily adaptable survival mechanism in oligotrophic environments, where they participate in the recycling of carbon sources due to the decomposition of these elements at low concentrations (Randich and Brun 2015). Caulobacter crescentus is an interesting bacterium for biotechnological exploitation because it contains several enzymes involved in the metabolism of lignocellulose (Nierman et al. 2001; Marks et al. 2010).

In the present work, we performed cloning and heterologous expression of the C. crescentus xynB5 (CCNA03149) gene that encodes a predicted β-glucosidase-β-xylosidase based on the most recent genomic annotation of the NA1000 strain (Marks et al. 2010). Additionally, the recombinant enzyme was purified and characterized with respect to its biochemical and kinetic parameters in the presence of different chromogenic substrates.

Materials and methods

Bacterial strains, growth conditions, and plasmids

The Escherichia coli Top10 and DH10B strains were grown in Luria-Bertani broth at 37 °C (Sambrook et al. 1989). Ampicillin (10 mg mL−1) (Sigma®) was applied to select the pJET1.2 and pTrcHisA plasmids in E. coli. Cells of the C. crescentus strain were used to isolate the xynB5 gene and were grown at 30 °C in PYE complex medium (Poindexter 1964). The NA1000 C. crescentus strain is a holdfast mutant derivative of the wild-type strain CB15 (Evinger and Agabian 1977). More detailed features of the strains and tools used in this study are summarized in Table 1.

Isolation and cloning of the C. crescentus xynB5 gene

Purification of the total DNA from C. crescentus was performed according to the method described by Chen and Kuo (1993). Isolation of the xynB5 (CCNA03149) gene was accomplished by PCR using 200 ng of C. crescenuts total DNA as the template in the reaction, 50 pmol of each primer (xynB5- Forward and xynB5-Reverse) (Table 1), 2.5 nM of dNTPs and the enzyme Platinum Taq DNA Polymerase (Invitrogen®) in a final volume of 50 μL in the buffer recommended by the manufacturer. The reaction was conducted in a Mastercycler gradient thermocycler (Eppendorf®). The primers were designed for the reaction according to the nucleotide sequence provided for the C. crescentus xynB5 gene (Marks et al. 2010). The PCR reaction was performed with an initial step of 3 min at 95 °C for complete DNA denaturation, followed by 35 cycles at 95 °C (denaturation) for 30 s, 55 °C for 30 s for annealing of primers and 2 min at 72 °C for polymerization from the template DNA strand. Subsequently, the PCR product obtained was analyzed by agarose gel electrophoresis in 1 % 1X TAE and quantified by spectrophotometry at 260 nm. Negative controls were carried out with Platinum Taq DNA Polymerase (Invitrogen®) and in the absence of C. crescentus DNA template to confirm that amplified products in the test tubes were not derived from a putative contaminant.

A total of 20 ng of DNA obtained by PCR was treated with the polynucleotide kinase from the CloneJET PCR Cloning Kit (Thermo®) to obtain blunt ends and ligated into the cloning vector pJET1.2 by incubation for 30 min at 22 °C. The reaction mixture was used to transform the chemically competent E. coli strain DH10B. The identity of the recombinant clones was confirmed by automated DNA sequencing. The pJet1.2 plasmid containing the xynB5 gene was subjected to digestion of the EcoRI/HindIII sites present in the xynB5-Forward and xynB5-Reverse primers, followed by subcloning (maintaining the correct reading frame) into the pTrcHisA vector digested with the same enzymes. This vector provides a recombinant protein fused to an amino-terminal histidine tail when overexpressed with 1 mM isopropyl β-D-thiogalactopyranoside (IPTG) in the E. coli TOP 10 strain. The identity of the gene and cloning orientation were confirmed by automated DNA sequencing. All sequencing reactions were performed by PCR using the Sanger method with the Big Dye Terminator v.2.2 kit (Life Technologies®), and the products generated were sequenced in the Chemical Institute of the University of São Paulo (IQ, USP, São Paulo, SP).

Gene and protein sequences analysis

The cloning and subcloning strategies were conducted after analysis of the nucleotide sequence of the xynB5 gene using the program Clone Manager. The identity of the nucleotide sequences as the C. crescentus xynB5 gene was confirmed using the BlastX algorithm (Basic Local Alignment Search Tool) of National Center for Biotechnology Information (NCBI). The alignment of the predicted protein from the xynB5 gene was performed with the Clustal W2 program from European Molecular Biology Laboratory (EMBL). Comparisons between only two protein sequences were performed with the aid of the algorithm BlastP (NCBI). Comparison of protein domains present in the product of the xynB5 gene of C. crescentus was performed using Conserved Domain Architecture Retrieval Tool (CDART), which is also available at NCBI.

Expression and purification of the xynB5 gene product

E. coli TOP 10 cells (50 mL) containing the pTriCHisA-xynB5 construct were grown in 250 mL flasks containing LB medium at 37 °C. Cell growing exponentially were induced with 1 mM IPTG for 0–4 h at 37 °C. The cells were centrifuged at 5000×g for 10 min at 4 °C, and the cells pellet were suspended in 4 mL of 1X FastBreak Cell Lysis Reagent (Promega®) to rupture the cells. This reagent was supplemented with 10 μL of 40 mg mL−1 lysozyme (Sigma®), 10 µL of the protease inhibitor pool (GE-Heathcare®) and 122 U of DNaseI (Invitrogen®). The mixture was incubated and shaken at 80 rpm for 30 min at 25 °C. The lysed cells were centrifuged, and the supernatant was added to a pre-packed nickel-Sepharose His Spin Trap Kit column (GE-Heathcare®), which allows the purification of the recombinant protein containing the His-tag by affinity chromatography. The columns were previously equilibrated with binding buffer (20 mM phosphate buffer, 500 mM NaCl, and 10 mM imidazole at pH 7.4). The cell lysate containing the recombinant protein of interest was transferred into four mini prepackaged columns and centrifuged at 1600×g at 4 °C for 1 min. Recombinant proteins containing the His-tag adhered to the nickel resin and were washed with 600 μL of Wash Buffer (20 mM phosphate buffer, 500 mM NaCl, and 10 mM imidazole at pH 7.4). Unlinked proteins were removed by centrifugation at 1600×g for 1 min at 4 °C. The recombinant protein was eluted with 500 μL of Elution Buffer (200 mM phosphate buffer, 500 mM NaCl, and 500 mM imidazole at pH 7.4) in four steps with centrifugation at 1600×g for 1 min at 4 °C. Aliquots of 5 μL of the recombinant purified protein were applied to a 9 % denaturing polyacrylamide gel (SDS-PAGE) to confirm the purification process. The remaining fractions were combined and dialyzed against 20 mM phosphate buffer with 50 mM NaCl at pH 7.4. The samples were stored under refrigeration at 4–8 °C for subsequent enzymatic characterizations.

Protein dosages and enzyme activities

The purified protein was measured using the Bradford colorimetric method. The determination of the different enzymatic activities was executed according to the adapted method of Corrêa et al. (2012) by estimating the amount of ρ-nitrophenol (ρNP) released from the ρ-nitrophenyl-β-d-glucopyranoside reagent (ρNPG) (Sigma®) for β-glucosidase, ρ-nitrophenyl-β-d-xylopyranoside (ρNPX) (Sigma®) for β-xylosidase and ρ-nitrophenyl-α-l-arabinofuranoside (ρNPA) (Sigma®) for α-l-arabinosidase. Briefly, a 25 μL aliquot of pure recombinant protein was added to 250 μL of each of the different substrates (35 mM) in 50 mM McIlvaine buffer at different pH values (3–9). The reactions were incubated at 50 °C for 30 min. Different enzymatic reactions were interrupted by adding 1 mL of a saturated solution of sodium tetraborate. The ρ-NP released was measured by spectrophotometry at 410 ηm. The enzyme activity was expressed in 1 μmol of ρ-nitro-phenol released per minute per mL of enzyme added. The specific activity was defined as the ratio of the obtained enzyme activity and the amount of protein added to each sample in U mg−1.

Optimal pH and temperature of the recombinant enzyme

The optimal pH and temperature effect on enzyme activity of the recombinant product of the C. crescentus xynB5 gene was verified by incubation of 5 μL of the purified enzyme in 20 μL of McIlvaine buffer (pH 3–9) in the presence of 250 μL of the substrates ρNPG, ρNPX or ρNPA at 35 mM for 30 min at 50 °C. The same procedure was performed to determine the optimum temperature; however, the obtained optimum temperature varied in the range of 30–70 °C. The enzymatic reaction was stopped adding 1 mL of a saturated solution of sodium tetraborate and a subsequent spectrophotometric reading at 410 ηm. The results were expressed in relative specific activity (%), with the maximum value obtained as 100 %. All biological assays were performed in experimental duplicates and the enzymatic assays in triplicate.

Determination of kinetic parameters

The kinetic properties of the purified recombinant protein were determined performing the enzymatic activity assay under the pH and temperature conditions previously obtained and varying the concentrations of the ρNPG, ρNPX and ρNPA substrates at intervals from 0.125 to 35 mM. The assays were performed in duplicate, and the kinetic parameters (Vmax and Km) were calculated based on the construction of double-reciprocal plots. The catalytic efficiency of each enzyme was defined by the ratio of Kcat (catalytic constant) calculated based on the experimental molecular weight obtained in the SDS-PAGE and the Km observed for each specific chromogenic substrate under the optimal conditions of enzymatic assay.

Statistical analysis

Characterization of the activities of the purified recombinant enzymes to different substrates was performed in experimental biological duplicate and triplicate assays with repetitions for inconsistent results. The data were plotted using the program Excel (Office pack) and Origin 6.0 and analyzed by dispersing the means.

Results

Isolation, cloning, and analysis of the xynB5 gene product

The xynB5 gene (Marks et al. 2010) from C. crescentus encodes a probable β-glucosidase/β-xylosidase with 806 amino acids and a predicted molecular mass of about 90 kDa. To clone the gene, bacterial genomic DNA was used as the template for a polymerase chain reaction with the xynB5-forward and reverse primers (Table 1). A single PCR product of about 2.4 kb was obtained and resolved on a 1 % 1X TAE agarose gel (data not shown). The fragment was cloned into the pJet1.2/blunt cloning vector (Table 1) in non-cohesive sites of the linearized plasmid provided by the manufacturer (Thermo®). After confirmation of the identity of the C. crescentus xynB5 gene by DNA sequencing, the gene was subcloned (maintaining the reading frame) in the EcoRI/HindIII sites of the pTrcHisA expression vector, which provided an amino terminal His-tag fusion.

The DNA sequence obtained for these clones was compared with other sequences deposited in GenBank using the Blast-x algorithm. The identity of the gene was confirmed based on the high similarity of xynB5 (100 % identity) with the β-glucosidase-β-xylosidase sequence from the C. crescentus NA1000 strain and the counterpart gene xynB5 (CC_03054) from the CB15 strain of C. crescentus. Based on the annotation of Nierman et al. (2001), this sequence encodes a predicted protein with the enzymatic function of β-xylosidase-α-arabinosidase. The NA1000 strain of C. crescentus studied in this work was derived from the CB15 strain (Evinger and Agabian, 1977). However, the NA1000 strain has other adaptations in its genome in addition to possessing conjugative functions (Marks et al. 2010). Thus, the purified recombinant enzyme was initially tested against different specific protein substrates to confirm the possible activities mentioned above (i.e., ρNPG for β-glucosidase, ρNPX for β-xylosidase and ρNPA for α-arabinosidase) to confirm any of the predicted annotation activities of both C. crescentus genomes (Nierman et al. 2001; Marks et al. 2010).

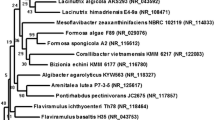

The local alignment provided by the BLAST algorithm for proteins revealed the presence of a conserved domain characteristic of the BglX of β-Glucosidases-β-xylosidases that in general acts in the periplasmic region in Gram-negative bacteria (Yang et al. 1996; Varghese et al. 1999). The BglX domain was verified to be a conserved domain in GH3 family proteins (Fig. 1). Additionally, a protein domain was found at the carboxyl-end portion of the recombinant protein and named fibronectin type III-like; the function of this domain is not yet well defined, but has been found in the extremely thermophilic bacteria Thermotoga neapolitana. Thus, the domain may be involved in protein thermostability and the anchoring of the enzyme on large polymeric substrates (Pozzo et al. 2010).

Schematic representation of the predicted C. crescentus BglX-V-Ara protein encoded by the xynB5 gene containing 806 amino acids. BglX represents a typical β-glucosidase-β-xylosidase domain associated with function in the periplasmic region in Gram-negative bacteria. GH3 corresponds to glycoside hydrolase family 3 according CAZy. The Fn3-like domain has no defined function, but is probably associated with the thermal stability of the enzyme

Gene expression and protein purification

The recombinant protein with putative β-glucosidase-β-xylosidase activity obtained by cloning the C. crescentus xynB5 gene into vector pTrcHisA was induced with 1 mM IPTG for 0–4 h. IPTG is a non-metabolizable synthetic inducer that positively regulates the E. coli lacZ gene promoter present in vector pTriCHisA, leading to the overexpression of the fusion protein cloned in frame with the His-tag in this vector in E. coli cells. Numerous clones were obtained from the subcloning steps in the expression vector, but only three were tested for enzyme induction efficiency (Fig. 2a). Induction with IPTG was initiated during the growth exponential phase under constant stirring at 120 rpm and 37 °C (λ600 nm = 0.4–0.6). Although induction of recombinant protein expression after 4 h in the presence of IPTG was more efficient (Fig. 2a), further experiments showed that this condition did not improve the purification of the soluble protein (data not shown). Some heterologous recombinant proteins present a toxic effect in E. coli when expressed at high levels, and therefore are expressed and organized into so-called inclusion bodies composed of insoluble aggregates of the expressed protein. Purification of a recombinant enzyme from inclusion bodies in most cases requires protein-denaturing processes that compromise the structure and activity tests for the biochemical characterization of the purified enzyme (Sambrook et al. 1989). All purification steps performed with E. coli cells induced with IPTG for 4 h (i.e., clone 5 shown in Fig. 2a) failed to result in the purification of a functional protein (i.e., with enzymatic activity that could be biochemically characterized) (data not shown).

Induction, expression and purification steps of C. crescenus BglX-V-Ara. a SDS-PAGE (0.9 %) containing total Top10 E. coli protein extracts expressing different pTricHisA-xynB5 gene constructs (clones 1, 3 and 5) at different time points of incubation with 1 mM IPTG. b SDS-PAGE (0.9 %) showing total protein extracts obtained in different steps of BglX-V-Ara purification from nickel-Sepharose pre-packed columns. T time (h), W1 and W2 corresponds to the first and second washing of pre-packed nickel-Sepharose columns. E1–E4 represents total protein purified in different steps of elution with buffer containing different concentrations of imidazole. The data presented are representative of three independent biological experiments

Although it was evident that a greater induction of the xynB5 gene occurred after 4 h of incubation, expression of the recombinant proteins was evident in all three clones tested at different time points following incubation with IPTG (Fig. 2a). Thus, a purification test was standardized from clone 3 after 3 h of IPTG induction at 37 °C. The recombinant protein was purified by affinity chromatography using pre-packed column nickel-Sepharose (GE Healthcare®) according to the manufacturer’s specifications (for details see “Materials and methods” section), using increasing concentrations of Imidazole (100–500 mM). An efficient purification that was not dependent on increases in the concentration of imidazole was demonstrated by electrophoresis on 9 % SDS-PAGE (Laemmli 1970) after various purification steps (Fig. 2b). The obtained pure enzyme was dialyzed and subjected to enzymatic assays in the presence of different chromogenic substrates for the characterization of their catalytic abilities. Under these conditions, recombinant protein expression occurred at lower levels than was observed after 4 h, but a functional enzyme was obtained in this assay and a more accurate measurement of its catalytic activity was achieved using different substrates.

According to the information present the in the genomic annotation provided by Marks et al. (2010) and Nierman et al. (2001), the recombinant protein was preliminarily and individually incubated in the presence of the chromogenic substrate ρNPG to measure the β-glucosidase activity, followed by ρNPX and ρNPA to determine the β-xylosidase and α-arabinosidase activities, respectively. Pure recombinant protein was shown to be active in the presence of the three different substrates in a pH range from 4 to 7 (Table 2). The highest enzymatic activity was verified for the protein at pH 6 for the specific β-glucosidase substrate; for comparison purposes, it was regarded as a relative enzyme activity equivalent to 100 % (Table 2). The second highest activity was observed at the same pH for the specific substrate for β-xylosidase (ρNPX), with 4.3 U mL−1 (relative enzyme activity of 57 %), followed by further reduced α-l-arabinosidase activity, with 3 U mL−1 (relative enzymatic activity of 38 %) (Table 2).

Despite the observation that the enzymatic activity for the recombinant protein in the presence of ρNPA was low compared to the activity obtained for β-glucosidase and β-xylosidase (Table 2), we conducted an enzymatic characterization of the C. crescentus BglX-V-Ara protein to determine the optimal pH, temperature and kinetic parameters in the presence of 3 different chromogenic substrates (ρNPG, ρNPX and ρNPA). The enzyme failed to hydrolyze other common substrates such as o-nitrophenyl-β-d-galactopyranoside (data not shown), indicating that the enzyme specificity was limited to the chromogenic substrates cited above. Regardless, our data strongly indicated that the C. crescentus xynB5 gene from the NA1000 strain encodes a multifunctional enzyme. Thus, from this point the xynB5 gene product will be referred to as a β-glucosidase-β-xylosidase V-arabinosidase, or BglX-V-Ara. The protein was named β-xylosidase-V because the xynB1 and xynB2 genes encoding for C. crescentus β-xylosidase I (Graciano et al. 2012) and β-xylosidase II (Corrêa et al. 2012; Santos et al. 2012 and Corrêa et al. 2014) have been previously studied. Additionally, the xynB3 and xynB4 genes are still under investigation in our laboratory. Thus, the gene overexpressed in this work was the fifth of five probable β-xylosidases present in the C. crescentus genome.

Optimal pH and temperature determination

The results presented in Table 2 suggest that the preferential pH for the enzymatic activities of the 3 tested BglX-V-Ara substrates was pH 6. However, the enzyme was re-characterized using a broader range of pH values to obtain a more accurate definition of the optimum pH for the different chromogenic substrates. The relative specific enzymatic activities of β-glucosidase, β-xylosidase and α-arabinosidase were maintained in the pH range 3–9, which was concordant with the fact that the optimum pH 6 was associated with the best relative activity for the multifunctional enzyme BglX-V-Ara in the presence of the three different substrates (Fig. 3a). However, the β-xylosidase activity and α-arabinosidase were somewhat variable at different pH values compared to the outstanding increase of β-glucosidase activity of C. crescentus BglX-V-Ara at pH 6.

Optimal pH (a) and temperature (b) obtained for C. crescentus BglX-V-Ara with substrates specific for β-glucosidase-β-xylosidase-α-arabinosidase. Filled circles represent data relative to the enzyme activity (%) obtained for β-glucosidase; Open circles correspond to data relative to the enzyme activity (%) obtained for β-xylosidase and filled squares represent the data relative to the enzyme activity (%) obtained for α-arabinosidase. The highest value obtained for β-glucosidase activity was considered 100 %, and the other values were calculated based on this value. The experiments were conducted in biological duplicates and triplicate measurements and standard deviations are shown as vertical bars

To define the optimal temperature for the activity of the C. crescentus BglX-V-Ara enzyme, the protein was incubated in individual tubes with different chromogenic substrates at pH 6 and at temperatures ranging from 30 to 70 °C. An optimal temperature of 50 °C was observed for the β-glucosidase and α-arabinosidase activities of the multifunctional enzyme. In contrast, a higher optimal activity at 60 °C was observed for the β-xylosidase catalytic function of C. crescentus BglX-V-Ara (Fig. 3b).

Analysis of the kinetic parameters and catalytic efficiency

Once the optimal conditions of pH and temperature were defined for C. crescentus BglX-V-Ara, the kinetic parameters were evaluated using the ρNPG, ρNPX and ρNPA substrates under the optimal pH conditions defined for each enzymatic activity. The concentration of the substrates varied in the range of 0.125–35 mM for the determination of the kinetic parameters Km and Vmax, which were calculated based on double reciprocal plots. BglX-V-Ara showed activity to β-glucosidase with a Km equal to 0.24 ± 0.0005 mM and Vmax equivalent to 0.041 ± 0.002 μmol mL−1 for the substrate ρNPG. The recombinant enzyme once more confirmed its multifunctionality to β-xylosidase activity in the presence of ρNPX, showing a Km of 0.64 ± 0.032 mM and Vmax of 0.055 ± 0.002 μmol mL−1, and to α-l-arabinosidase with a Km 1.45 ± 0.05 mM and Vmax 0.091 ± 0.0004 μmol min−1 in the presence of the ρNPA substrate (Table 3).

Moreover, C. crescentus BgxlV-Ara showed an obvious major functionality for β-glucosidase enzymatic activity not only in terms of the level (Table 2) or relative specific activity (Fig. 3a, b) but also by presenting the lowest Km value for the ρNPG substrate compared to the Km obtained for the other two substrates (ρNPX and ρNPA) (Table 3). This result suggests that although C. crescentus BglX-V-Ara is multifunctional, it possesses not only a key activity for β-glucosidase but also increased affinity for the ρNPG substrate compared to ρNPX and ρNPA because a lower concentration of the substrate is required for the enzyme to reach half of its maximum speed under optimum assay conditions (Table 3).

Discussion

The genetic manipulation of microorganisms has provided great advancements in the production of enzymes involved in the conversion of biomass to different compounds of commercial value (Liu et al. 2006). The genetic manipulation of bacteria is made possible by the development a set of tools to enable their molecular genetic modification and functional genomics studies based on gene knockouts (Corrêa et al. 2014). This process is aided when the microorganism genome has already been completely defined and made available in databases in the public domain. The bacterium C. crescentus is a typical example of a genetically manipulated microorganism because it can be easily transformed by bacterial conjugation events (NA1000 strain) and different plasmids have been developed for the bacteria that allow the construction of genetically modified strains. Additionally, the genome of C. crescentus has been completely sequenced (Nierman et al. 2001; Marks et al. 2010). C. crescentus is a fast growing bacteria; thus, the growth cycle, although asymmetrical, is completed in just 3 h at 30 °C in defined medium (McAdams and Shapiro 2009).

Comparison of the predicted protein sequence from the C. crescentus xynB5 gene using the ClustalW2 algorithm provided at NCBI demonstrated that C. crescentus β-glucosidase-β-xylosidase showed about 92 % identity with the β-xylosidase of the related bacteria Caulobacter segnis. Moreover, it showed a high similarity to other species of Gram-negative bacteria that belong to family Caulobacteraceae, such as Asticcacaulis excentricus (77 %) and Asticcacaulis benevestitus (76 %). This analysis suggests high structural conservation for the xynB5 gene in family Caulobacteraceae of alpha-Proteobacteria. In contrast, when BglX-V-Ara was compared with the predicted structure of the xynB1 (Marks et al. 2010; Graciano et al. 2012) and xynB2 genes from C. crescentus (Marks et al. 2010; Corrêa et al. 2012), low sequence similarity was observed (less than 39 % identity). This low similarity was also observed for the bifunctional protein RuBX1 (30 %) (Zhou et al. 2012) from an uncultured bacteria belonging to the same CAZy family as C. crescentus BglX-V-Ara (Table 3).

According to the Conserved Domain Architecture Retrieval Tool (CDART) also available from NCBI (Geer et al. 2002), the distribution of the BglX and Fn3-like domains in the GH3 family is typical of β-glucosidase-β-xylosidase enzymes (Fig. 1). According to CAZy (Lombard et al. 2014), these domains also occur in 93 other bacterial sugar hydrolases and 78 bacterial glucosidases that probably act in the periplasmic region. These data suggest a synteny in the distribution of these domains in different bacteria, indicating that the proteins involved in the metabolism of sugars probably perform a conserved function in Gram-negative bacteria. Experiments involving immune-localization with a specific antibody against the protein studied here are needed to confirm that C. crescentus β-glucosidase-β-xylosidase exerts its catalytic function in the periplasmic region.

The functional data presented in the present report corroborate the predicted annotation that the C. crescentus xynB5 gene encodes an enzyme with predominant β-glucosidase activity and β-xylosidase activity, as suggested by Marks et al. (2010) for the NA1000 strain. Moreover, the enzyme was also confirmed to possess α-arabinosidase activity, as suggested for the homologous xynB5 gene of the C. crescentus CB15 strain annotated by Nierman et al. (2001).

C. crescentus is a very interesting bacterium because it demonstrates a highly adaptive versatility. It is able to degrade a variety of aromatic (Chatterjee and Chatterjee 1987) and toxic compounds, such as policlorofenol (Mannisto et al. 1999). The bacterium is also tolerant to uranium by a mechanism of action that leads to the formation of calcium-phosphate-uranium precipitates in the extracellular medium (Hu et al. 2005) and has been shown to be able to remove high concentrations of cadmium from contaminated water (Patel et al. 2010). In addition to these properties, C. crescentus has the ability to form high-density biofilms and a very efficient bio-adhesive with great potential for application in the medical field (Smit et al. 2000).

Similar results were observed for the recombinant xylan-degrading proteins C. crescentus GH43 β-xylosidase I (Graciano et al. 2012), β-xylosidase II GH39 (Corrêa et al. 2012) and xylanase A GH10 (Graciano et al. 2015) encoded by the genes xynB1, xynB2 and xynA1, respectively. These proteins also showed maximum activity at pH 6, suggesting that all of the enzymes of the C. crescentus xylanolytic complex may efficiently use similar biochemical requirements. Thus, these enzymes probably act in synergy for the deconstruction of hemicellulose (Table 3).

The optimal temperature found for the β-xylosidase activity of C. crescentus BglX-V-Ara at 60 °C was higher than the other optimal temperatures observed to date for this bacterium. Perhaps this thermostability occurs in response to the presence of the fibronectin type III-like domain in the protein structure, as suggested for the bacterium T. neapolitana (Pozzo et al. 2010), but this speculation requires further analysis.

Interestingly, about 78 % of the enzyme activity detected at 30 °C was still present for the ρNPG and ρNPX substrates tested at 60 °C, and about 69 and 78 % of the specific enzyme activity was still present in the presence of the substrates ρNPX and ρNPG, respectively; thus, more than 50 % of the BglX-V-Ara activity was retained under moderately hot and cold temperatures (Fig. 3b). However, the relative activity for α-arabinosidase remained between 30 and 40 % at the different pH ranges and temperatures tested (Fig. 3a, b). Thus, the optimal conditions of pH and temperature for α-arabinosidase were 6 and 50 °C, respectively. This suggests that the C. crescentus BglX-V-Ara could maintain its active α-arabinosidase catalytic ability when the xynB5 gene is expressed. The low levels or low catalytic efficiency (Table 3) probably act as a disbranching enzyme that assists the other enzymatic activities of the same multifunctional protein in the degradation process of hemicellulose. However, this hypothesis requires further testing in in vitro assays.

Similar to the optimal pH values for BglX-V-Ara, β-xylosidase I, and β-xylosidase II of C. crescentus, β-glucosidase-β-xylosidase (Zhou et al. 2012) and β-d-glucosidase-β-xylosidase-α-d-arabinonosidase (Gruninger et al. 2014) from a non-cultured bacterium also showed optimum activity at pH 6 (Table 3). The bgxA1 gene encoding the multifunctional enzyme β-glucosidase-β-xylosidase-α-d-arabinosidase in the non-cultured bacteria, which was isolated using a metagenomic approach from the rumen contents of a grass- and hay-fed dairy cow (Gruninger et al. 2014), also showed optimum pH values of 8.5 and 6.5 to the ρNPX and ρNPA substrates, respectively. Among the enzymes included in Table 3, only E. coli BglX operates more efficiently at physiological pH 7. Indeed, most of the proteins reported in Table 3, including other enzymes such as the multifunctional β-glucosidase isolated from a thermophilic anaerobic bacterium (Patchett et al. 1987) and β-glucosidase from Streptomyces sp. (ATCC 11238) (Pérez-Pons et al. 1995), showed higher activity at pH 6.2 and in the pH range 6–6.5, respectively. These data suggest that some multifunctional bacterial glyco-hydrolases adapt to optimal pH values that are slightly acidic or closer to physiological pH for the efficient performance of their multiple catalytic functions.

C. crescentus BglX-V-Ara presented an optimum temperature ranging from 50 to 60 °C depending on the different activities characterized for the multifunctional protein (Fig. 3b; Table 3). β-xylosidase I (Graciano et al. 2012), and β-xylosidase II (Corrêa et al. 2012) from the bacterium showed an optimum temperature of 45 and 55° C, respectively (Table 3). More recently, one of the three xylanases encoded by the bacterium (GH10 xylanase A) showed an optimum pH of 6 and a larger relative specific activity at an optimum temperature of 50 °C (Graciano et al. 2015), suggesting that the biochemical parameters for the different xylan-degrading enzymes of C. crescentus are very close. It is possible that the development of the variety of genes present in C. crescentus encoding different xylan-degrading enzymes would be associated with the structural diversity of hemicellulose found in nature or could even be associated with differential gene expression encoded not only to respond to variations in the availability of nutrients in the environment but also to variations in the life cycle of the bacteria. During C. crescentus development, the bacterium generates morphologically and physiologically distinct cells that include motile, pre-divisional and swarmer cells (for review see Skerker and Laub 2004). However, experiments that more clearly interrelate the role of each of these xylanase and β-xylosidases genes in the degradation of hemicellulose and studies of their regulators are required to test this hypothesis.

Similarly, the β-xylosidase and α-arabinosidase activities of the C. crescentus BglX-V-Ara protein, the β-glucosidase-β-xylosidase encoded by the rubGX gene (Zhou et al. 2012) and the β-glucosidase of Streptomyces sp. (Pérez-Pons et al. 1995) had an optimum temperature of 50 °C. The β-glucosidase-β-xylosidase-α-d-arabinosidase encoded by the gene bgxa1 (Gruninger et al. 2014) showed a lower optimum temperature at 45 °C using ρNPG as the chromogenic substrate and at 40 °C for the ρNPX substrate (Table 3).

An even lower relative similarity was observed with multifunctional bacterial proteins studied by multiple strategies that performed similar functions and were grouped into the same protein GH3 family (Table 3). This finding suggested a certain structural uniqueness for C. crescentus BglX-V-Ara that could be better exploited with more in-depth knowledge of the molecular structure of the protein.

The Km and Vmax of the C. crescentus β-xylosidase I were 2.89 ± 0.13 mM and 1.4 ± 0.04 µM min−1, respectively (Graciano et al. 2012), while the Km was 9.3 ± 0.45 mM and Vmax was 402 ± 19 mM min−1 for the C. crescentus β-xylosidase II (Corrêa et al. 2012). A Km value of 0.164 mM to ρNPG and 0.03 mM to ρNPX was observed for the β-glucosidase-β-xylosidase product of the bacterial rubGX gene (Zhou et al. 2012) (Table 3).

The catalytic potential of a high renewal value can only be achieved at high substrate concentrations, which are defined as saturating concentrations. However, this situation rarely occurs under cellular conditions. Thus, a constant alternative, called the specificity constant and defined as Kcat/Km, is a more accurate measure of the catalytic efficiency of the enzymatic conversion a substrate to a product under conditions of low substrate concentrations or in multi-enzymatic reactions where the product of an enzyme that becomes the substrate for another is produced gradually (Wyman 1999). The catalytic efficiency of C. crescentus BglX-V-Ara is comparable to the efficiencies obtained for other xylanolytic proteins from other bacteria and C. crescentus. Considering the Kcat/Km of different enzymes, the higher numerical order of magnitude of Kcat/Km, the higher enzyme catalytic efficiency was observed (Table 3).

The β-glucosidase-β-xylosidase-α-arabinosidase encoded by the bglA1 gene showed a 100× higher catalytic efficiency for β-glucosidase than β-xylosidase and α-arabinosidase (Gruninger et al. 2014) (Table 3). The characterization of the bglA1 gene isolated using metagenomic approaches showed the great advantage of using this technology for the identification of new biocatalysts from bacteria that are not cultivated, and certainly may represent a treasure of unknown proteins (Shestakov 2012; Gruninger et al. 2014).

The catalytic efficiency for β-xylosidase of BglX-V-Ara (0.14 mM−1 s−1) was 300-fold lower than the efficiency of β-xylosidase II (43.3 mM−1 s−1) (Table 3) from the same bacterium. This comparison indicates that despite the fact that BglX-V-Ara shows a low catalytic efficiency for different substrates, the protein offers an interesting multifunctionality profile and may confer some adaptive advantage to the microorganism to enable survival during the evolutionary process. For instance, the multifunctional nature of the enzyme conferred the ability to degrade structurally different hemicellulosic compounds in the environment and even more complex branching structures such as xylan and its substituent groups; as a consequence, the xynB5 gene was maintained in the C. crescentus genome.

The product of the xynB5 gene is able to act on different substrates and differs not only in structural and functionally characteristics compared to the xynB1 and xynB2 genes but also because can act on a greater range of compounds that are not broken down by the products of the xynB1 and xynB2 genes. Interestingly, the ability to metabolize a variety of complex compound, (i.e., multifunctionality) in a manner that is independent of the catalytic efficiency of a particular enzyme it is extremely relevant.

As shown with C. crescentus BglX-V-Ara, the BglX protein was originally purified from the periplasmic region in E. coli (Yang et al. 1996) and presents a preponderant β-glucosidase activity; however, the β-xylosidase activity is completely absent in E. coli (Table 3). In contrast, the product of the gene rubGX1 (Zhou et al. 2011) maintains not only the β-xylosidase function but also the β-glucosidase activity because it is able to degrade both specific substrates of the enzyme. Nevertheless, contrary to the observations for C. crescentus BglX-V-Ara, the predominant activity of RubGX1 was β-xylosidase and not β-glucosidase.

The search for enzymes with multifunctional characteristics for biotechnological applications for the use of residual biomass is of constant interest to researchers worldwide, regardless of whether these enzymes are generated using genetic engineering strategies, screening untapped biomass or even metagenomic approaches. Thus, the fact that the C. crescentus BglX-V-Ara protein probable presents natural versatility for applications to the degradation of complex hemicellulolytic substrates is very relevant for the study of enzymes with potential applications in industrial processes involving the simultaneous saccharification of cellulose and xylan to their fermentable products, many of which rely on the production of biofuels and chemicals by microorganisms. Moreover, the use of nucleic acid-based techniques emphasizes the relevance of these methods to find and improve applied enzyme catalytic functions of biotechnological interest (Elleuche 2014).

In conclusion, in the present study the C. crescentus xynB5 gene was successfully overexpressed in E. coli, and a recombinant soluble protein was efficiently purified by affinity chromatography. The purified protein BglX-V-Ara presented β-glucosidase-β-xylosidase and α-l-arabinosidase activity, thereby proving to be multifunctional for the three different chromogenic substrates tested (ρNPG, ρNPX and ρNPA). A more specific enzyme activity was observed for β-glucosidase, with higher affinity for the substrate ρNPG (Km) and a higher catalytic efficiency (Kcat/Km) for β-glucosidase, followed by β-xylosidase and α-l-arabinosidase. The trifunctional C. crescentus Bglx-V-Ara showed optimal activity for the three substrates at pH 6, but the optimum temperature ranged from 50 °C for β-glucosidase and α-l-arabinosidase to 60 °C for β-xylosidase. To date, this is the first C. crescentus xylanolytic enzyme characterized that presented a high optimum temperature. The data in the present report may be of relevance for exploitation in future biotechnological processes. BglX-V-Ara may be tested for industrial applications (i.e., in enzyme cocktails combined with other well-characterized proteins to increase the efficiency of the deconstruction of hemicellulose, resulting in the release of 5 and 6 carbon sugars that can be used for the production of compounds with high economic value using residual biomass). A multifunctional enzyme is likely more valuable and efficient than a single enzyme. Consequently, the future application of C. crescentus BglX-V-Ara could be to decrease the wastes in environments with contaminated soils and/or water bodies (Wyman 1999).

References

Chatterjee DK, Chatterjee P (1987) Expression of degradative genes of Pseudomonas putida in C. crescentus. J Bacteriol 69:2962–2966

Chen WP, Kuo TTA (1993) Simple and rapid method for the preparation of gram-negative bacterial genomic DNA. Nucleic Acids Res 21:22–60

Collins T, Gerday C, Feller G (2005) Xylanases, xylanases families and extremophilic xylanases. FEMS Microbiol Rev 29:3–23

Corrêa JM, Graciano L, Abrahão J, Loth EA, Gandra RF, Kadowaki MK, Henn C, Simão RCG (2012) Expression and characterization of a GH39 β-xylosidase II from Caulobacter crescentus. Appl Biochem Biotechnol 168:2218–2229

Corrêa JM, Mingori MR, Gandra RF, Loth EA, Seixas FAV, Simão RCG (2014) Depletion of the xynB2 gene upregulates β-xylosidase expression in C crescentus. Appl Biochem Biotechnol 172:1085–1097

Elleuche S (2014) Bringing functions together with fusion enzymes-from nature’s inventions to biotechnological applications. Appl Microbiol Biotechnol 99:1545–1556

Evinger M, Agabian N (1977) Envelope-associated nucleoid from Caulobacter crescentus stalked and swarmer cells. J Bacteriol 132:294–300

Geer LY, Domrachev M, Lipmam DJ, Bryant SH (2002) CDART: protein homology by domain architecture. Genome Res 12(10):1619–1623

Goldbeck R, Damásio ARL, Gonçalves TA, Machado CB, Paixão DAA, Wolf LD, Mandelli F, Rocha GM, Ruller R, Squina FM (2014) Development of hemi cellulolytic enzyme mixtures for plant biomass deconstruction on target biotechnological applications. Appl Microbiol Biotechnol 98:8513–8525

Graciano L, Corrêa JM, Gandra RF, Seixas FAV, Kadowaki MK, Sampaio SC, Silva JLC, Osaku CA, Simão RCG (2012) The cloning, expression, purification, characterization and modeled structure of Caulobacter crescentus β-Xylosidase I. World J Microbiol Biotechnol 28:2879–2888

Graciano L, Corrêa JL, Vieira FGN, Bosetto A, Loth EA, Kadowaki MK, Gandra RF, Simão RCG (2015) Cloning and expression of the xynA1 gene encoding a xylanase of the GH10 group in Caulobacter crescentus. Appl Biochem Biotechnol 175:3915–3929

Gruninger RJ, Gong X, Forster RJ, Mcallister TA (2014) Biochemical and kinetic characterization of the multifunctional β-glucosidase/β-xylosidase/α-arabinosidase, Bgxa1. Appl Microbiol Biotechnol 98:3003–3012

Hu P, Brodie EL, Suzuki Y, Mcadams HH, Andersen GL (2005) Whole-genome transcriptional analysis of heavy metal stresses in Caulobacter crescentus. J Bacteriol 187:8437–8449

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head bacteriophage T4. Nature 226:680–685

Lara CA, Santos RO, Cadete RM, Marques CFS, Gírio F, Oliveira ES, Rosa CA, Fonseca C (2014) Identification and characterisation of xylanolytic yeasts isolated from decaying wood and sugarcane bagasse in Brazil. Antonie Van Leeuwenhoek 105:1107–1119

Lee RC, Hrmova M, Burton RA, Lahnstein J, Fincher GB (2003) Bifunctional family 3 glycoside hydrolases from barley with alpha-L-arabinofuranosidase and β-d-xylosidase activity characterization, primary structures, and COOH-terminal processing. J Biol Chem 278:5377–5387

Liu CF, Sun RC, Qin M, Hang AP, Ren JL, Xub F, Wu SB (2006) Chemical modification of ultrasound-pretreated sugarcane bagasse with maleic anhydride. Ind Crops Prod 26:212–219

Lombard V, Golaconda Ramulu H, Drula E, Coutinho PM, Henrissat B (2014) The carbohydrate-active enzymes database (CAZy) in 2013. Nucleic Acids Res 42:490–495

Mannisto MK, Tiirola MA, Salkinoja-Salonen MS, Kulomaa MS, Puhakka JA (1999) Diversity of chlorophenol-degrading bacteria isolated from contaminated boreal groundwater. Arch Microbiol 171:189–197

Marks ME, Castro-Rojas CM, Teiling C, Du L, Kapatral V, Walunas TL, Crosson S (2010) The genetic basis of laboratory adaptation in Caulobacter crescentus. J Bacteriol 192:3678–3688

McAdams HH, Shapiro L (2009) System-level design of bacterial cell cycle control. FEBS Lett 583:3984–3991

Nierman WC, Feldblyum TV, Laub MT, Paulsen IT, Nelson KE, Eisen J, Heidelberg JF, Alley MRK, Ohta N, Maddock JR, Potocka I, Nelson WC, Newton A, Stephens C, Phadke ND, Ely B, Deboy RT, Dodson RJ, Durkin AS, Gwinn ML, Haft DH, Kolonay JF, Smit J, Craven MB, Khouri H, Shetty J, Berry K, Utterback T, Tran K, Wolf A, Vamathevan J, Ermolaeva M, White O, Salzberg SL, Craig Venter J, Shapiro L, Fraser CM (2001) Complete genome sequence of Caulobacter crescentus. PNAS 98:4136–4141

Patchett ML, Daniel RM, Morgan HW (1987) Purification and properties of a stable beta-glucosidase from an extremely thermophilic anaerobic bacterium. Biochem J 243:779–787

Patel J, Wilson G, Mckay RML, Vicent R, Xu Z (2010) Self-immobilization of recombinant Caulobacter crescentus and its application in removal of cadmium from water. Appl Biochem Biotechnol 162(4):1160–1173

Pérez-Pons JA, Rebordosa X, Querol E (1995) Properties of a novel glucose-enhanced beta-glucosidase purified from Streptomyces sp (ATCC 11238). Biochim Biophys Acta 6:145–153

Poindexter JS (1964) Biological properties and classification of the Caulobacter group. Bacteriol Rev 28:231–295

Polizeli MLTM, Rizzati ACS, Monti R, Terenzi HF, Jorge JA, Amorin DS (2005) Xylanases from fungi: properties and industrial applications. Appl Microbiol Biotechnol 67:577–591

Pozzo T, Pasten JL, Karsson EN, Logan DT (2010) Structural and functional analyses of β-glucosidase 3B from Thermotoga neapolitana: a thermostable three-domain representative of glycoside hydrolase. Mol Biol 397:724–739

Randich AM, Brun YV (2015) Molecular mechanisms for the evolution of bacterial morphologies and growth modes. Front Microbiol 6(580):1–13

Sambrook J, Fritsch EF, Maniatis T (1989) Molecular cloning: a laboratory manual, 2nd edn. Cold Spring Harbor Laboratory Press, Cold Spring Harbor

Santos CR, Polo CC, Corrêa JM, Simão RCG, Seixas FAV, Murakami MT (2012) Accessory domain changes accessibility and molecular topography of the catalytic interface in monomeric GH39 & β-xylosidases. Acta Crystallogr D 68:1339–1345

Shestakov SV (2012) Impact of metagenomics on biotechnological development. Appl Biochem Microbiol 48:705–715

Skerker JM, Laub MT (2004) Cell-cycle progression and the generation of asymmetry in Caulobacter crescentus. Nat Rev Microbiol 2:325–337

Smit J, Sherwood CS, Turner RF (2000) Characterization of high-density monolayers of the biofilm bacterium C. crescentus: evaluating products for developing immobilized cell bioreactors. Can J Microbiol 46:339–349

Varghese JN, Hrmova M, Fincher GB (1999) Three-dimensional structure of a barley beta-d-glucan exohydrolase, a family 3 glycosyl hydrolase. Structure 7:179–190

Winger AM, Heazlewood JL, Chan LJG, Petzold CJ, Permaul K, Singh S (2014) Secretome analysis of the thermophilic xylanase hyper-producer thermomyces lanuginosus SSBP cultivated on corn cobs. J Ind Microbiol Biotechnol 41:1687–1696

Wyman CE (1999) Biomass ethanol: technical progress, opportunities, and commercial challenges. Annu Rev Energy Environ 24:189–226

Yang M, Luoh SM, Goddard A, Reilly D, Henzel W, Bass S (1996) The bglX gene located at 47.8 min on the Escherichia coli chromosome encodes a periplasmic β-glucosidase. Microbiology 7:1659–1665

Zhou J, Copeland B, Zhang C, Liu Z, Bhatti S, Sauve R, Zhou S (2011) Identification of prokaryotic organisms in goat rumen based on metagenomic DNA sequences. J Res Biol 6:451–455

Zhou J, Bao L, Chang L, Liu Z, You C, Lu H (2012) Beta-xylosidase activity of a GH3 glucosidase/xylosidase from yak rumen metagenome promotes the enzymatic degradation of hemicellulosic xylans. Lett Appl Microbiol 54:79–87

Acknowledgments

J. M. Corrêa is a post-doctoral fellow of the Coordination of Improvement of Higher Education Personnel (CAPES, Brazil). P.I. Justo is a professional funded by Diagnostics of America SA (DASA). R.C.G. Simão (process 630/2014) was partially supported by the Araucaria Foundation (Research Fellow, Brazil).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that the research was performed in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Rights and permissions

About this article

Cite this article

Justo, P.I., Corrêa, J.M., Maller, A. et al. Analysis of the xynB5 gene encoding a multifunctional GH3-BglX β-glucosidase-β-xylosidase-α-arabinosidase member in Caulobacter crescentus . Antonie van Leeuwenhoek 108, 993–1007 (2015). https://doi.org/10.1007/s10482-015-0552-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10482-015-0552-x