Abstract

This paper incorporates consumers’ recycling behavior in remanufacturing decisions and strategies. We first empirically demonstrate that both firms’ monetary incentives and consumers’ environmental awareness positively influence consumers’ recycling behavior, then construct theoretical models to incorporate such consumers’ recycling behavior in two common remanufacturing strategies: remanufacturing by the manufacturer itself (self-remanufacturing) and by the authorized remanufacturer (authorization remanufacturing). We find that: first, when consumers are of high environmental awareness, the recycling amount driven by environmental awareness is enough to support the optimal production plan. Thus, there is no necessity for firms to implement monetary incentives. When consumers’ environmental awareness becomes lower, firms make a tradeoff between collection cost and profit improvement by increasing collection and finally decide to implement monetary incentives only when consumers’environmental awareness is low. Second, except for the new products’ price under the self-remanufacturing strategy, firms’ decisions under each strategy, such as the new products’ price, remanufactured products’ price, and the license fee, will change with consumers’ recycling behavior when consumers’ environmental awareness is not very high. As a result, the manufacturer’s profit increases with consumers’ environmental awareness no matter which remanufacturing strategy it adopts. However, the remanufacturer’s profit (under the authorization remanufacturing strategy) may decrease with consumers’ environmental awareness. Third, consumers’ recycling behavior is the determining factor for the manufacturer’s remanufacturing strategy selection. Our results reveal that ignoring consumers’ recycling behavior will lead to tremendous decision and strategy deviation in remanufacturing.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

With the increase of ecological footprint in society (Çetİn et al. , 2021) and the significant impact of human activity on the air quality (Şevİk et al. , 2017), the environmental problems and natural resource shortages have gradually attracted a lot of attention. To address these problems, sustainable development has become a major topic for production and manufacturing in both developed and developing countries. Many concepts have been put forward to ease environmental pollution, such as ecotourism (Çetİn & Şevİk 2016). In order to fundamentally solve these problems, the governments have introduced a series of legislations (e.g., green taxation and subsidies) to compel manufacturers to take more measures in their production activities (Sheu , 2011; Zou et al. , 2016).

Remanufacturing, which involves collecting end-of-life products, bringing them back to a brand new condition, and reselling them (Atasu et al. , 2010; Govindan et al. , 2015), is one of the most prevalent methods for manufacturers to express their concerns about the environment and support sustainable development (Webster & Mitra , 2007). In practice, recycling materials are widely used in various industries, such as the permeable pavements used in sustainable landscape architecture (Çetİn , 2015a, b). Besides environmental benefits, remanufacturing can also bring firms economic benefit by extracting value from used products (Galbreth et al. , 2013). For example, the remanufacturing program of Xerox help the firm reduce 40 to 65% of manufacturing costs (Savaskan et al. , 2004); the remanufacturing division of Caterpillar surpassed a total business volume of two billion dollars in 2007 (Ferguson & Souza , 2010).

In reality, manufacturers can either take the responsibility of remanufacturing operations themselves (self-remanufacturing strategy, strategy S for simiplify) or authorize a third party to take such a responsibility (authorization remanufacturing strategy, strategy A for simiplify). For example, Caterpillar established a remanufacturing division and set up remanufacturing factories all over the world (Ridley et al. , 2019); Apple signed an agreement with Foxconn to authorize it to remanufacture obsolete iPhones and put them back on the Chinese market as new phones (Feng et al. , 2021); Canon charged Recycle Assist companies for importing and selling its patented renewable cartridges (Hong et al. , 2017). Concerning this practice, a lot of researchers focus on exploring firms’ (e.g., manufacturers and remanufactures) operational decisions (e.g., pricing decisions, recycling rent) under the self-remanufacturing strategy (e.g., Choi et al., 2013; Ferrer & Swaminathan, 2010; Hong et al., 2015), or under the authorization remanufacturing strategy (e.g., Oraiopoulos et al., 2012, 2017). Some researchers also compare these two remanufacturing strategies and provide the optimal strategy choice for manufacturers (e.g., Feng et al., 2021).

With the green production and green marketing of manufacturers, consumers’ environmental awareness is gradually increasing (Zhang & Zheng , 2022). Since consumers’ environmental awareness will enhance their purchasing preference for the remanufactured products, some researchers begin to incorporate such impacts into manufacturers’ remanufacturing operations (e.g., Sabbaghi et al., 2016; Zhang & He, 2019; Feng et al., 2021). However, consumers’ environmental awareness is not only reflected in their preference for green products but also in their recycling behaviors of end-of-life products. Recently, there has been emerging empirical evidence that consumers’ environmental awareness will positively affect their willingness to recycle (Kumar , 2019; Dhir et al. , 2021). In this paper, we refer to consumers’ recycling behavior driven by their environmental awareness as green recycling behavior. This will drive consumers to participate in recycling spontaneously. As a result, the traditional way of monetary incentives used to motivate consumers to recycle may be less effective than before, and the structure of manufacturers’ recycling costs will be reshaped.

Considering consumers’ green recycling behavior, the performance of different remanufacturing strategies from the perspectives of multiple stakeholders (manufacturers and remanufacturers) remains questioned. Thus, our paper investigates the optimal recycling and pricing decisions under each remanufacturing strategy and the appropriate remanufacturing strategy for manufacturers to provide suggestions on remanufacturing operations. Although there is abundant research on remanufacturing operations (e.g., Oraiopoulos et al. 2012; Hong et al. 2015) and consumers’ green behavior (e.g., Feng et al., 2021; Zhang & Zheng, 2022), few researchers pay attention to consumers’ green recycling behavior and consider its impacts in the theoretical research about remanufacturing operations. Thus, this paper contributes to the literature by investigating such kind of consumers’ green behavior and revealing how it affects firms’ (manufacturers, remanufacturers) decisions and strategy selection. Besides, we also fill the gap between the research and the practice by incorporating consumers’ recycling behavior into firms’ remanufacturing decisions and theoretically showing when to choose different remanufacturing strategies when facing consumers with environmental awareness.

Inspired by the background above, we aim to answer the following four questions. First, in practice, how does consumers’ environmental awareness influence their recycling intentions? Second, under each remanufacturing strategy, how does consumers’ environmental awareness influence firms’ recycling decisions (including recycling prices and collection quantity)? Third, how do firms’ pricing decisions for new products and remanufactured products change with consumers’ environmental awareness? Fourth, considering consumers’ recycling behavior, what is the manufacturer’s optimal remanufacturing strategy under different landscapes?

To address these questions, we first conduct a questionnaire to investigate consumers’ recycling behavior. Through the questionnaire, we find that both environmental awareness and monetary incentives positively influence consumers’ recycling intentions, which reinforces the evidence of consumers’ green recycling behavior shown in the literature (Kumar , 2019; Dhir et al. , 2021). Then, based on the empirical results, we construct theoretical models to describe consumers’ recycling behavior and incorporate such behavior into manufacturers’ remanufacturing decisions and strategy selection. In detail, we consider a manufacturer who needs to choose a remanufacturing strategy (self-remanufacturing or authorization). If the manufacturer chooses the former, it needs to decide the prices of the new products and the remanufactured products, and the recycling price paid to consumers. If the manufacturer chooses the latter, the manufacturer first needs to decide the unit license fee charged to the remanufacturer. Then, it decides the price of the new products, and at the same time, the remanufacturer decides the price of the remanufactured products and the recycling price paid to consumers. After analyzing firms’ optimal decisions under each remanufacturing strategy, we move to compare these two strategies and show the manufacturer’s optimal strategy. The main results of the model are as follows.

First, consumers’ environmental awareness of recycling will impact firms’ recycling decisions (i.e., collection quantity and recycling price). Specifically, when consumers’ environmental awareness is high, no matter under which remanufacturing strategy, the recycling quantity driven by consumers’ environmental awareness is enough to support firms’ optimal production plan for remanufactured products. Thus, firms do not need to use monetary incentives to recycle. But when consumers’ environmental awareness decreases to a level that cannot support firms’ optimal production, firms face a tradeoff between the collection cost and profit improvement by increasing collection. As a result, firms decide (not) to use monetary incentives when consumers’ environmental awareness is low (moderate). This result reflects that when consumers’ environmental awareness comes into play in recycling, the recycling cost (paid to consumers) can be reduced or even completely erased, subverting firms’ original recycling and remanufacturing plans. Thus, both researchers and practitioners should pay more attention to the impact of consumers’ environmental awareness regarding recycling when making production and selling plans for remanufactured products.

Second, the new products’ price keeps constant under strategy S, but changes with consumers’ environmental awareness under strategy A. The relationship between the remanufactured products’ price and consumers’ environmental awareness under the two strategies is similar (non-increasing relationship). This implies that no matter under which remanufacturing strategy, consumers’ environmental awareness can reduce the remanufactured products’ price. Moreover, the license fee under strategy A first increases and then decreases with consumers’ environmental awareness. These results further demonstrate the important role of consumers’ recycling behavior in remanufacturing operations. If firms ignore such behavior, they may misprice products, resulting in a profit loss.

Third, no matter under strategy S or A, the manufacturer’s profit will increase with consumers’ environmental awareness when it is not very high. That is, the manufacturer can always benefit from consumers’ environmental awareness of recycling. Thus, the manufacturer can use some publicity to appropriately enhance consumers’ environmental awareness of recycling, instead of wasting unnecessary funds to incentive consumers to recycle. However, under strategy A, the remanufacturer only can conditionally benefit from increased consumers’ environmental awareness, although its recycling cost will decrease due to consumers’ environmental awareness.

Fourth, consumers’ recycling behavior and the manufacturer’s recycling ability are determinant factors for the manufacturer’s remanufacturing strategy selection. Specially, when the manufacturer’s recycling ability is low and consumers are moderately influenced by monetary incentives, the manufacturer will adopt strategy A if firms ignore consumers’ environmental awareness. But in fact, the manufacturer should adopt strategy S when consumers’ environmental awareness is very high. This implies that ignoring consumers’ environmental awareness may lead the manufacturer to choose the wrong strategy and obtain suboptimal profit. Thus, our paper emphasizes the importance for manufacturers to consider consumers’ recycling behavior when choosing remanufacturing strategy.

The rest of this paper is organized as follows. Section 2 reviews the literature related to our work. Section 3 shows the empirical analysis of consumer recycling behavior. Section 4 describes the problem in detail and formulates the problem in two remanufacturing modes. Section 5 shows and analyzes the results. Section 6 summarizes the conclusions and discusses future directions.

2 Literature review

This paper relates to three important dimensions: pricing and collection decisions, remanufacturing strategy, and consumers’ environmental awareness in the remanufacturing operations.

2.1 Pricing and collection decisions

Pricing and collection decisions in the reverse supply chain have been investigated in various settings. For example, Savaskan et al. (2004) study the pricing and collection rate decisions under different recycling channels (such as recycling by the manufacturing itself, by the retailer, or by the third party); Wei et al. (2015) explore how the manufacturer and the retailer make their own decisions about the wholesale price, retail price, and collection rate decisions under symmetric and asymmetric information conditions. Liu and Xiao (2019) investigate the pricing and collection rate decisions under different reverse channel structures in a dyadic closed-loop supply chain with corporate social responsibility and consumers’ preference for green consumption. Chen et al. (2020) explore the optimal production and collection decisions of the remanufacturer who faces both mandatory carbon emission capacity and take-back regulations, and investigate the impacts of regulations from both economic and environmental perspectives. Han et al. (2020) study the optimal price and the recycling quantity of materials or products under different recovery strategies.

One common attribute of this stream of literature is that the collection decision is collection rate or quantity. However, a firm cannot completely decide its collection rate or quantity when consumers exhibit environmental awareness in the recycling process (Kumar , 2019; Dhir et al. , 2021). This paper empirically demonstrates that the collection quantity is determined by both the firms’ monetary incentives and consumers’ environmental awareness. Based on the empirical evidence, this paper focuses on the collection decision of the unit recycling price paid to consumers. The settings in our study are common sense in practice, therefore we believe our study has wide implications for practices and academia.

2.2 Remanufacturing strategy

Two kinds of remanufacturing strategies are relevant to our study. The first one is the self-remanufacturing strategy, referring to that manufacturers undertake the remanufacturing task itself. Some researchers study the manufacturer’s remanufacturing decisions (e.g., prices) under this strategy (Choi et al. , 2013; Ferrer & Swaminathan , 2010; Hong et al. , 2015). The second remanufacturing strategy related to our study is authorization remanufacturing in which manufacturers authorize a third party to undertake remanufacturing by charging patent license fees. The optimal license fee for manufacturers under the authorization remanufacturing strategy also has received much attention in the literature (Peng & Su , 2011; Abdulrahman et al. , 2015). Besides studying the optimal decisions under each remanufacturing strategy, some researchers carry out studies on the comparison of different remanufacturing strategies to provide suggestions on the optimal remanufacturing strategy (e.g., Zou et al., 2016; Hong et al., 2017; Feng et al., 2021).

Following this stream of literature, this paper also analyzes the most concerning issues in the literature, including the pricing decisions under each strategy, the optimal license fee under the authorization remanufacturing strategy, and the comparison of the two strategies. But different from the literature, this paper additionally considers the impact of consumers’ environmental awareness in the recycling process on firms’ decisions and strategy selection. Since the recycling process is an indispensable part of remanufacturing, firms should consider consumers’ environmental awareness into their remanufacturing operation plans.

2.3 Consumers’ environmental awareness

Consumers’ environmental awareness has been considered in operation management. Chitra (2007) points out that the consumers’ environmental awareness affects consumers’ willingness to pay higher prices for more eco-friendly products. Following this work, most literature in operations management has considered consumers’ environmental awareness as their preference for eco-friendly products such as remanufactured products (e.g., Gu et al., 2015; Liu et al., 2019), or the green innovative products (e.g., Iyer & Soberman, 2016; Li et al., 2021).

However, consumers’ environmental awareness not only influences their preference for purchasing but also has a positive influence on their recycling intentions (e.g., Kumar, 2019; Dhir et al., 2021). None of the existing studies in operation management has modeled such influence, let alone considering such influence in operations decisions and strategy selection. We fill this gap in this paper, by creatively modeling and exploring the impact of consumers’ environmental awareness in recycling on firms’ decisions and strategy selection.

The main contributions of this paper are threefold. Firstly, we regard the unit recycling price paid to consumers as firms’ collection decision, instead of the collection rate, based on our evidence that the collection quantity is determined by both the firms’ monetary incentives and consumers’ environmental awareness. Secondly, we construct theoretical models to describe remanufacturing strategies which consider consumers’ environmental awareness of recycling. At present, most studies only focus on investigating the impact of consumers behavior occurred in the forward channel, such as consumers’ environmental awareness in purchasing green products (e.g., Zhang & He, 2019), or the anticipated regret in purchasing (e.g., Yang et al., 2021). The impact of consumers’ behavior in the reverse channel has been ignored. The results show that consumers’ environmental awareness of recycling indeed has an essential influence on firms’ decisions and performance, and remind both practitioners and researchers to concern about consumers’ behavior in the reverse channel. Finally, we show the optimal pricing decisions for the manufacturer or/and the remanufacturer under different remanufacturing strategies considering consumers’ recycling behavior, and the optimal remanufacturing strategy under different conditions. It provides suggestions and theoretical support for firms to make remanufacturing decisions and strategy selection when considering consumers’ recycling behavior.

3 Empirical evidence of consumers’ recycling behavior

In this section, we design a questionnaire to investigate consumers’ recycling behavior related to the firms’ monetary incentives and consumers’ environmental awareness, enhancing the basis of our models.

We use nine items to capture consumers’ recycling intention, perceived economic benefit, and environmental awareness, as shown in Table 1. In each item, we adopt the 5-point Likert scoring method (1 \(=\) strongly agree; 5 \(=\) strongly disagree) (Likert , 1932). The measurement items of recycling intention i.e., items RI1–RI3, follow the work of Chen (2007) and Wang et al. (2013). Environmental awareness is measured by items EA1–EA3 in Table 1, which is consistent with the work of Chen (2007), Taylor and Todd (1995). Monetary incentives are measured by the scale proposed by Wang et al. (2013), i.e., items MI1–MI3 in Table 1. Besides recycling intention, environmental awareness, and monetary incentives, we also investigate some demographic variables such as age, education degree, and gender as the control variables. The detailed questionnaire is shown in “Appendix A”.

Following Dhir et al. (2021), we first examine the reliability of the study measures by using internal consistency reliability, as recommended in the existing literature (Henson , 2001). The results are shown in the third column of Table 1. Notably, we only report the factor load of items from the pre-designed dimension because all of the factor loads of items from the other dimensions are lower than 0.7. From Table 1, we can find that all of the items have a load larger than 0.7 from the pre-designed dimension. Moreover, Cronbach \(\alpha \) values of the three dimensions in this study are 0.808, 0.797, and 0.755, respectively. All Cronbach \(\alpha \) values are greater than 0.6. These results reflect that the scale has good reliability.

Then, we measure the validity of this study by using confirmatory factor analysis (CFA). The \(\chi ^2/df\) of this model is 1.11 and thus supports a good model fit (Hair et al. , 2010). The values of other important goodness of fit indicators are CFI \(=\) 0.995 and IFI \(=\) 0.995, all of which are larger than the minimum threshold values suggested by the prior literature (Hair et al. , 2010). Therefore, it can be considered that the structural validity of the scale is very good. Moreover, the RMSEA value is below the threshold value of 0.08, indicating that the study processes a good model fit.

Finally, we test the proposed hypotheses by estimating and assessing the significance of path coefficients. The regression results are shown in Table 2. In model (1), we include all the control variables. Models (2) and (3) test the impact of monetary incentives and environmental awareness on recycling intention, respectively. The results show that monetary incentives and environmental awareness are positively associated with recycling intentions. Comparing the adjusted-\(R^2\) of models (2) and (3), we can find that environmental awareness can explain the recycling intention better than monetary incentives does. In model (4), we further consider the influence of monetary incentives and environmental awareness simultaneously. We can find that both environmental awareness and monetary incentives significantly positively influence recycling intention. It further proves that both monetary incentives and environmental awareness are positively associated with recycling intentions. Moreover, the adjusted-\(R^2\) in model (4) is larger than that in other models. This indicates that it is more reasonable to simultaneously consider the influence of monetary incentives and environmental awareness on recycling intention.

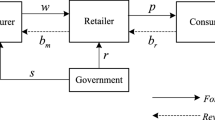

4 Model setup

This section develops game theoretical models to incorporate consumers’ recycling behavior into the manufacturer’s remanufacturing decisions and strategies. We consider that a manufacturer needs to choose from two remanufacturing strategies: (a) collecting the end-of-life products, producing and selling the remanufactured products itself (strategy S); (b) authorizing a third-party remanufacturer (remanufacturer for short) to collect the end-of-life products, and produce and sell the remanufactured products (strategy A). If the manufacturer chooses strategy S, it needs to decide the new products’ price \(p_n\), the remanufactured products’ price \(p_r\), and the unit recycling price paid to consumers \(p_{cr}\). If the manufacturer chooses strategy A, it is the Stackelberg leader and the remanufacturer is the Stackelberg follower: The manufacturer first needs to determine the unit patent license fee \(t^A\); Then, the remanufacturer decides the remanufactured products’ price \(p_{r}\) and the recycling price \(p_{cr}\), and the manufacturer decides the new products’ price \(p_n\) simultaneously. Figure 1 summarizes the product and cash flows under two remanufacturing strategies.

Consumers are involved in firms’ decisions via their purchasing behavior and recycling behavior, which determine the demands of the new products and the remanufactured products, and the recycling quantity.

4.1 Demands

We consider that consumers are heterogeneous when evaluating the functional attributes of new and remanufactured products. Let V denote the utility from the functional attribute of the new product, and \(\alpha \) (\(0<\alpha <1\)) be the discount rate when customers evaluate the remanufactured products (Ferrer & Swaminathan , 2010). The higher the discount rate, the higher the customers’ preference for remanufactured products. Furthermore, V is uniformly distributed in [0, 1], as discussed extensively in the literature (e.g., Atasu et al., 2008; Wu, 2012; Yenipazarli, 2016).

Let \(p_n\) and \(p_r\) be the prices of new products and remanufactured products, respectively. Without loss of generality, we assume that the costs for new and remanufactured products are less than 1 (Vorasayan & Ryan , 2006; Mitra & Webster , 2008). Then, consumers’ utilities from the new and remanufactured products are \(u_n=V-p_n\) and \( u_r=\alpha V-p_r\), respectively. Customers buy new product if \(u_n>0\) and \(u_n>u_r\), and purchase remanufactured product if \(u_r>0\) and \(u_r>u_n\).

Let \(d_n\), and \(d_r\) be the demands for the new and remanufactured products, respectively. Then the demand functions are formulated by:

To ensure \(d_r>0\) and \(d_n>0\), we assume the unit production cost of remanufactured products satisfies: \(c_n-(1-\alpha )<c_r<\alpha c_n\), which means that the unit production cost should neither be too high nor too low. It is because when the unit production costs of remanufactured products are too high, the manufacturer would not produce remanufactured products; when the unit production costs of the remanufactured products are very low, the manufacturer would like to produce remanufactured products only. Thus, we omit other cases in our model as discussed in the existing literature (Ferguson & Toktay , 2006; Atasu et al. , 2008).

4.2 Recycling quantity and costs

Consumers’ recycling behavior will influence the recycling quantity and recycling cost. As shown in Sect. 3, consumers’ recycling behaviors are driven by two parts: the firms’ monetary incentives and their environmental awareness. Let \(\beta \) be the degree of consumers’ economic benefit awareness (i.e., the impact of firms’ monetary incentives), k be the degree of consumers’ environmental awareness, and \(e_r\) be consumers’ perceived environmental benefit from recycling. Then, the ideal recycling quantity of the end-of-life products is

However, the actual quantity recycled is usually less than the ideal recycling quantity due to the constraint on recycling ability. Savaskan et al. (2004) show that the agent closest to customers is the most ideal undertaker of the manufacturer’s product recycling activities. Thus, we assume that the remanufacturer has a perfect recycling ability, i.e., it can recycle \(q_{r}\) units of end-of-life products, while the manufacturer’s recycling amount has a discount \(\lambda \) (\(\lambda <1\)) in the ideal recycling amount \(q_{r}\). That is, the total recycling amount of the remanufacturer is \(q_{r}\) and that of the manufacturer is \(\lambda q_r\).

The manufacturer’s total recycling cost paid to consumers for purchasing the end-of-life products under strategy S is \(C_{r}^S=p_{cr} \lambda q_r=\lambda ^2 q_r^2/\beta -\lambda k e_r q_r/\beta \). Similarly, under strategy A, the remanufacturer’s recycling cost is \(C_{r}^A=p_{cr} q_r=q_r^2/\beta -k e_r q_r/\beta \). Both the manufacturer’s and remanufacturer’s recycling costs are convex functions of their recycling amounts, sharing a similar structure with that of the recycling cost in the literature. However, compared with the literature (e.g., Feng et al., 2021), the cost function is shifted \(k e_r\) units to the left due to consumers’ green recycling awareness (i.e., \(k>0\)). This indicates that a firm can spend less or even no effort in recycling, as consumers’ environmental awareness comes to play. Moreover, the firm can control its recycling quantity and recycling cost by adjusting the unit recycling price to cooperate with its remanufacturing production plan.

4.3 Profit functions

Under strategy S, the manufacturer enjoys the profit of producing and selling the remanufactured products, but needs to bear the recycling cost, since the manufacturer undertakes the collection, production, and selling tasks by itself. Thus, the manufacturer’s profit is

where \((p_n-c_n)d_n\) is the manufacturer’s profit from new products (denoted as \(\pi _{Mn}\)), \((p_r-c_r)d_r\) is the manufacturer’s profit from remanufactured product (denoted as \(\pi _{Mr}\)). Because remanufactured products are made based on recycled end-of-life products, the recycling amount is no less than the demand for the remanufactured products, i.e., \(\lambda q_r \ge d_r\). Considering the large stock of end-of-life products in the market, we do not restrict the amount of \(q_r\) in this paper.

Under strategy A, the manufacturer authorizes the remanufacturer to recycle and remanufacture. Thus, the manufacturer’s profit includes two parts: The first part is the profit from the new product, and the second part is the authorization fee charged to the remanufacturer. The manufacturer’s profit under strategy A is

The remanufacturer profits from the remanufactured products, but needs to pay the recycling costs to consumers and the authorization fees paid to the manufacturer. Thus, the remanufacturer’s profit is

where \((p_r-c_r)d_r\) is the remanufacturer’s profit from remanufactured products (denoted as \(\pi _{Rr}\)), \(t d_r \) is the total authorization fees paid to the manufacturer. Similar to that under strategy S, the recycling amount should be no less than the demand for remanufactured products, i.e., \(q_{r} \ge d_r\).

Using backward induction, we can first obtain the optimal decisions under each strategy and then find the manufacturer’s optimal remanufacturing strategy by comparing its profits under two strategies.

5 Analysis

In this section, we first show the optimal decisions and the impact of consumers’ environmental awareness on the manufacturer/remanufacturer’s decisions and outcomes under each remanufacturing strategy and then move to compare these two strategies.

5.1 Self-remanufacturing strategy

Under strategy S, the manufacturer collects the end-of-life products, and produces and sells both remanufactured products and new products. Maximizing Eq. (3) with the constraints of \(d_r \le \lambda q_r\) and \(p_{cr} \ge 0\), the manufacturer’s pricing decisions and outcomes under strategy S can be obtained in the following Table 4.

Table 4 shows that consumers’ environmental awareness can be divided into three levels: low (\(k<\widehat{k_2}\)), moderate (\(\widehat{k_2}\le k<\widehat{k_1}\)), and high (\(k>\widehat{k_1}\)). The manufacturer will formulate three different price plans (i.e., SI, SII, and SIII) when consumers’ environmental awareness is at a different level. Correspondingly, the manufacturer can achieve different recycling and remanufacturing plans, as shown in Proposition 1.

Proposition 1

Under strategy S, there is: (i) \(p_{cr}^{S*}>0\) and \(d_{r}^{S*}>\lambda k e_r\) when \(k \le \widehat{k_2}\); (ii) \(p_{cr}^{S*}=0\) and \(d_{r}^{S*}=\lambda k e_r\) when \(\widehat{k_2}<k<\widehat{k_1}\); (iii) \(p_{cr}^{S*}=0\) and \(d_{r}^{S*}<\lambda k e_r\) when \(k \ge \widehat{k_1}\).

Proposition 1 indicates that when consumers’ environmental awareness is high (\(k>\widehat{k_1}\)), the recycling amount driven by consumers’ green recycling behavior is higher than the demand for remanufactured products, i.e., \(\lambda k e_r > d_{r}^{S*}\). Thus, there is no need for the manufacturer to spend money on recycling. But when consumers’ environmental awareness is lower than \(\widehat{k_1}\), the manufacturer needs to evaluate whether it is worth spending money on recycling to increase the production of remanufactured products. When consumers’ environmental awareness is moderate, monetary incentives cannot render an effective increase in recycling amount, but the cost is relatively large. Thus, the manufacturer will not choose to pay consumers money for recycling when facing moderate environmental awareness consumers. Only when consumers’ environmental awareness is low, the monetary incentives can work well and the manufacturer should provide monetary incentives to stimulate consumers to return the end-of-life products.

In particular, if consumers do not have environmental awareness of recycling, i.e., \(k=0\), the manufacturer always needs to pay for recycling. This is a common assumption in the literature (e.g., Hong et al., 2017; Feng et al., 2021). Compared with this stream of literature, this paper shows that the recycling quantity (return rate called in the literature) is not just subjectively determined by the manufacturer itself, but partly driven by consumers. When consumers’ environmental awareness comes into play in recycling, the recycling cost (paid to consumers) can be reduced or even completely erased. Thus, we remind both researchers and practitioners to pay more attention to the impact of consumers’ environmental awareness regarding recycling when making production and selling plans for remanufactured products.

In the rest of this section, we will further show the impact of consumers’ recycling behavior on firms’ pricing decisions and profits. Notably, when consumers’ environmental awareness is high, the manufacturer’s pricing decisions will not be affected by consumers’ environmental awareness because the recycling amount driven by consumers’ green recycling behavior is higher than the demand for remanufactured products. Thus, we focus on the situation where consumers’ environmental awareness is not high (\(k<\widehat{k_1}\)).

Proposition 2

When \(k<\widehat{k_1}\), as k increases, (i) \(p_{n}^{S*}\) keeps unchanged, \(p_{r}^{S*}\) always decreases, and \(p_{cr}^{S*}\) decreases until it is zero;

(ii) \(d_{n}^{S*}\) always decreases, and \(d_{r}^{S*}\) always increases.

Proposition 2 shows how the manufacturer’s pricing decisions and product demands change with consumers’ environmental awareness when consumers’ environmental awareness is not high (i.e., \(k<\widehat{k_1}\)). We find that the manufacturer will set a lower recycling price (until zero) as consumers’ environmental awareness increases. It is intuitive since the monetary incentives become less influential on consumers’ recycling intention as environmental benefit impacts more. The manufacturer will cut down the expenditure on recycling when the monetary incentives become less efficient.

The manufacturer will also decrease the price of the remanufactured products. It is because the total recycling amount (i.e., \(\lambda q_r\)) increases with consumers’ environmental awareness. Thus, the manufacturer decreases the remanufactured products’ price to increase the demand for the remanufactured products. As shown in Fig. 3b, the manufacturer can keep a good balance between the recycling amounts and the demand for remanufactured products, i.e., \(\lambda q_r=d_r^{S*}\). Thus, the manufacturer can avoid any wasted recycling costs or missing profit margins, achieving the highest profit. Furthermore, the decrease rate of the remanufactured products becomes faster when consumers’ environmental awareness arrives at a moderate level from a low level because the manufacturer no longer needs to pay consumers money for recycling when consumers’ environmental awareness is at a moderate level. Responding to the price changes, the demand for remanufactured products increases, and the increase rate becomes faster as consumers’ environmental awareness arrives at a moderate level.

As the remanufactured products become more competitive, the new products’ demand will decrease. An interesting finding is that the manufacturer does not decrease the new product’s price to react to the intense competition from the remanufactured products. It is because the increase in profits from selling more remanufactured products is higher, even though the profits from selling new products decline. To ensure the sales of the remanufactured products, the manufacturer has to sacrifice part of the sales of the new products. Thus, the new products’ price will not change with consumers’ environmental awareness under strategy S.

Moreover, if the manufacturer ignores consumers’ environmental awareness, i.e., the manufacturer believes \(k=0\), the manufacturer will overprice the remanufactured products and the unit recycling price, as shown in Fig. 3a. As a result, the manufacturer makes unnecessary expenditures on recycling, leading to excessive recycling of end-of-life products and inventory pressure. The demand for remanufactured products also decreases, resulting in a profit loss. Thus, the manufacturer will spend more but gain less due to its ignorance of consumers’ environmental awareness of recycling. These results highlight the importance for the manufacturer to incorporate consumers’ green recycling behavior into its pricing decisions in remanufacturing operations.

Proposition 3

When \(k<\widehat{k_1}\), as k increases, (i) \(\pi _{Mn}^S\) decreases and \(\pi _{Mr}^S\) increases; (ii) \(C^S_r\) decreases until it is zero, and \(\pi _{Mr}^S-C^S_r\) increases; (iii) \(\pi _{M}^S\) increases.

Proposition 3 (i) shows that when consumers’ environmental awareness is not high (\(k<\widehat{k_1}\)), as consumers become more environmentally aware, the manufacturer will earn a lower profit from new products but a higher profit from remanufactured products. The result is easy to understand since the remanufactured products become more competitive because of the price advantage, as proved in Proposition 2. Similarly, the recycling cost will decrease to zero gradually because the unit recycling price paid to consumers decreases with k. As a result, the net profits from remanufactured products, i.e., \(\pi _{Mr}^S-C_r^S\) increase with consumers’ environmental awareness. The total profits of the manufacturer will increase with k because the profit improvement from remanufactured products is larger than the profit decrease from the new products.

Proposition 3 exhibits the important role of consumers’ recycling behavior in improving the manufacturer’s profits. This result suggests that the manufacturer can use some publicity to appropriately enhance consumers’ environmental awareness of recycling. Such publicity may also require some cost, thus the manufacturer may trade off the cost and the benefit from making such publicity. Moreover, the initial state of consumers’ environmental awareness will also affect the effectiveness of the manufacturer’s publicity. For example, it is less effectiveness when consumers’ environmental awareness is low (\(k<\widehat{k_2}\)) than when consumers is moderately environmental aware (\(\widehat{k_2}<k<\widehat{k_1}\)). When consumers’ environmental awareness is high (\(k>\widehat{k_1}\)), there is no need for the manufacturer to make such publicity to enhance consumers’ environmental awareness. Moreover, if the manufacturer makes such publicity under this condition, it may face losses because of excessive recycling and inventory pressure.

5.2 Authorization strategy

Under strategy A, the manufacturer authorizes a third-party remanufacturer to collect end-of-life products, produce, and sell remanufactured products. The manufacturer earns money from remanufactured products by charging remanufacturers license fees. As illustrated in Section 3, the manufacturer first decides the unit license fee. Then, in the second stage, the manufacturer decides the new products’ price, and at the same time, the remanufacturer decides the remanufactured products’ price and the unit recycling price paid to consumers.

According to backward induction, we first calculate the equilibrium pricing decisions of the manufacturer and the remanufacturer with a given \(t^A\), as shown in Table 5.

From Table 5, we can obtain the following results.

Lemma 1

With \(t^A\) increases, there is:

-

(i)

\(\partial p_n^{A}/ \partial t^{A} >0\), \(\partial p_r^{A}/ \partial t^{A} >0\), \(\partial p_{cr}^{A}/ \partial t^{A} \le 0\);

-

(ii)

\(\partial d_n^{A}/ \partial t^{A} <0\), \(\partial d_r^{A}/ \partial t^{A} \le 0\).

Lemma 1 (i) shows the prices of the new and remanufactured products are positively related to the license fee, but the unit recycling price is negatively related to the license fee. It is because when the manufacturer charges more license fee per remanufactured product, the remanufacturer needs to price the remanufactured product higher to extract more benefit from consumers and decrease the unit recycling price to reduce the recycling cost. As the remanufactured product becomes less competitive for its increased price, the manufacturer prices the new products higher to improve the marginal profit per product and achieve a higher overall profit. As a result, the demands for the remanufactured and the new products decrease due to the increased price of the products, as shown in Lemma 1 (ii). Lemma 1 suggests that raising the license fee has both positive and negative effects on the manufacturer’s profit: the positive side is that it can help increase the marginal profit of the new products, and lead to more authorization incomes for it can improve the sales of the remanufactured products (except under the condition of \(\widehat{t_2}<t^A<\widehat{t_1}\)); the negative impact is that it decreases the demand for the new product.

Lemma 2

Given \(t^A\), with k increases, there is:

-

(i)

\(\partial p_n^{A}/ \partial k \le 0\), \(\partial p_r^{A}/ \partial k \le 0\), \(\partial p_{cr}^{A}/ \partial k \le 0\).

-

(ii)

\(\partial d_n^{A}/ \partial k < 0\), \(\partial d_r^{A}/ \partial k >0\).

Lemma 2 (i) shows that the prices of the new and remanufactured products, and the unit recycling price are non-positively related to consumers’ environmental awareness. It is because when consumers become more environmentally aware, the remanufacturer will spend less money on recycling. As the cost is cut down, the remanufacturer decreases the price of remanufactured products to motivate consumers to buy its products. Thus, the demand for the remanufactured products increases, as shown in Lemma 2. Since the competitiveness of the remanufactured products increases, the manufacturer decides to decrease the price of the new products to mitigate the decreases in its market share, i.e., the demand for the new products. According to the results in Table 5, the optimal prices of the new products and the remanufactured products, and the unit recycling price are piecewise linear functions of the unit license fee. Therefore, the manufacturer’s profit, i.e., Eq. (4), is a piecewise function of the unit license fee. By calculating the highest point of the piecewise function, we can obtain the manufacturer’s optimal license fees under different conditions. Substituting the optimal license fee decisions into the price functions in Table 5, we can get the final equilibrium pricing decisions. All the results are summarized in Table 6.

The results in Table 6 show that when the manufacturer adopts strategy A, the manufacturer will formulate different license fee plans (i.e., AI, AII, AIII, and AIV) when consumers’ environmental awareness is at a different level. As a result, the remanufacturer’s recycling and remanufacturing plans, and the manufacturer’s pricing plan for new products vary on the levels of consumers’ environmental awareness. In the rest of this section, we will analyze the impact of consumers’ environmental awareness under strategy A.

Proposition 4

When the manufacturer adopts strategy A, there is:

-

(i)

\(p_{cr}^{A*}>0\) and \(d_{r}^{A*}> k e_r\) when \(\beta \le \widehat{\beta _1}\) and \(k < \widehat{k_5}\) or when \(\beta > \widehat{\beta _1}\) and \(k < \widehat{k_6}\).

-

(ii)

\(p_{cr}^{A*}=0\) and \(d_{r}^{A*}=k e_r\) when \(\beta \le \widehat{\beta _1}\) and \(\widehat{k_5}\le k \le \widehat{k_3}\) or when \(\beta > \widehat{\beta _1}\) and \(\widehat{k_6} \le k \le \widehat{k_3}\);

-

(iii)

\(p_{cr}^{A*}=0\) and \(d_{r}^{A*}<k e_r\) when \(k > \widehat{k_3}\).

The remanufacturer’s recycling plans are similar to that of the manufacturer under strategy S (as shown in Proposition 1). To express more concisely, we define a piecewise function of \(\beta \) as \(\widehat{k_7}\), which equals to \(\widehat{k_5}\) and \(\widehat{k_6}\) when \(\beta \le \widehat{\beta _1}\) and \(\beta > \widehat{\beta _1}\) respectively. Then, under strategy A, consumers’ environmental awareness can also be divided into three levels: low (\(k>\widehat{k_7}\)), moderate (\(\widehat{k_7}<k<\widehat{k_3}\)), and high (\(k>\widehat{k_3}\)). Similar to the manufacturer’s recycling plan under strategy S, the remanufacturer will pay consumers money for recycling only when consumers’ environmental awareness is low. When consumers’ environmental awareness is at a high level, the recycling quantity driven by consumers’ behavior is enough to support the optimal remanufacturing plans. Thus, there is no need for the remanufacturer to use monetary incentives. When consumers are of moderate environmental awareness, the remanufacturer will not pay consumers money for recycling either since the monetary incentives are not cost-effective to increase the recycling amount. These results further prove the importance of considering consumers’ environmental awareness when operating the remanufacturing supply chain, as consumers’ environmental awareness can help reduce or even completely erase the recycling cost.

Compared to the results under strategy S, the threshold of whether to pay consumers for recycling is lower, i.e., \(\widehat{k_7}<\widehat{k_2}\). It indicates that when the manufacturer authorizes the remanufacturer to undertake the remanufacturing task, the remanufacturer will take less effort than the manufacturer to recycle in person. For example, when \(\widehat{k_7}<k<\widehat{k_2}\), the remanufacturer will not use monetary incentives but the manufacturer will use them. It is reasonable since the manufacturer extracts a part of the remanufacturer’s profit through the authorization fee. The threshold of whether the recycling amount driven by consumers’ green recycling behavior is enough for remanufacturing is also lower under strategy A, i.e., \(\widehat{k_3}<\widehat{k_1}\), suggesting that it is easier for the remanufacturer to arrive at ideal recycling amount. For example, when \(\widehat{k_3}<k<\widehat{k_1}\), consumers’ environmental awareness will cause the remanufacturer to recycle excessively, while the recycling quantity for the manufacturer is insufficient under this scenario. The first reason is that the manufacturer’s ability in recycling is lower than the remanufacturer’s (i.e., \(\lambda <1\)). Another potential reason is that the ideal amount of remanufactured products for the remanufacturer is lower than that of the manufacturer, due to the authorization fee.

Proposition 5

When \(k \le \widehat{k_3}\), \(\partial t^{A*}/ \partial k >0\) if \(\beta \le \widehat{\beta _1}\) and k \(\in \) (0, \(\widehat{k_5}\)) \(\cup \) (\(\widehat{k_5}\), \(\widehat{k_4}\)) or if \(\beta > \widehat{\beta _1}\) and k \(\in \) (0, \(\widehat{k_6}\)). Otherwise, \(\partial t^{A*}/ \partial k <0\).

Proposition 5 and Fig. 6 show that when consumers’ environmental awareness is low (i.e., \(k<\widehat{k_7}\)), the manufacturer’s license fee increases with consumers’ environmental awareness because it can enhance the manufacturer’s benefit from the remanufactured products and increase its marginal benefit from the new products, as suggested in Lemma 1. However, a strange phenomenon happens when consumers’ environmental awareness begins to reach a moderate level: a jumping point in \(\widehat{k_7}\) occurs. It is because when k becomes higher than \(\widehat{k_7}\), the remanufacturer no longer uses monetary incentives, leading the recycling amount to plummet. Thus, the manufacturer renders a sudden increase in the license fee to ensure its profit.

As consumers’ environmental awareness continues to increase, the license fee continues to increase only when the impact of monetary incentives is low (i.e., \(\beta \le \widehat{\beta _1}\)) and consumers’ environmental awareness is at the primary stage in the moderate level (i.e., \(\widehat{k_5}<k<\widehat{k_4}\)). It is because under this condition, calling off the monetary incentives has little influence on the recycling amount. There is still an obvious advantage in the demand for the remanufactured products. Thus, the manufacturer increases the unit licensing fee to improve its profit from the authorization channel. But as consumers’ environmental awareness becomes larger (i.e., \(\widehat{k_4}<k<\widehat{k_3}\)) or the monetary incentives become more influential (i.e., \(\beta > \widehat{\beta _1}\)), the manufacturer will suffer a higher profit decrease from the new product or enjoy a little profit improvement from the authorization channel if it raises the license fee. Thus, the manufacturer turns to pay more attention to improving the profit from the new products by decreasing the unit license fee.

Proposition 6

When \(k \le \widehat{k_3}\),

-

(i)

\(\partial p^{A*}_n/ \partial k >0\) if \(\beta \le \widehat{\beta _1}\) and k \(\in \) (0, \(\widehat{k_5}\)) \(\cup \) (\(\widehat{k_5}\), \(\widehat{k_4}\)) or if \(\beta > \widehat{\beta _1}\) and k \(\in \) (0, \(\widehat{k_6}\)). Otherwise, \(\partial p^{A*}_n/ \partial k <0\).

-

(ii)

\(\partial p^{A*}_r/ \partial k <0\) if \(\beta \le \widehat{\beta _1}\) and k \(\in \) (0, \(\widehat{k_5}\)) \(\cup \) (\(\widehat{k_4}\), \(\widehat{k_3}\)) or if \(\beta > \widehat{\beta _1}\) and k \(\in \) (0, \(\widehat{k_6}\)) \(\cup \) (\(\widehat{k_6}\), \(\widehat{k_3}\)). Otherwise, \(\partial p^{A*}_r/ \partial k =0\).

-

(iii)

\(\partial p^{A*}_{cr}/ \partial k <0\) if k \(\in \) (0, \(\widehat{k_7}\)). Otherwise, \(\partial p^{A*}_{cr}/ \partial k =0\).

Proposition 6 (i) shows that as consumers’ environmental awareness increases, the new product’s price will occur a sudden increase at \(k=\widehat{k_7}\), and overall, it first increases and then decreases with consumers’ environmental awareness. Although the increase in consumers’ environmental awareness directly renders the new product’s price decrease (as shown in Lemma 2), it can also implicitly influences the price of the new products via influencing the license fee. Since the license fee positively influences the new product’s price (as shown in Lemma 1), it is reasonable that the price of the new product shares the same trend as the license fee. Compared to the result under strategy S where the manufacturer will keep the new products’ price unchanged, the manufacturer must adjust the new product’s price to cope with consumers’ different green recycling behavior under strategy A. Moreover, this result reflects that the new products’ price does not always increase with the collection rate, which is different from that in Feng et al. (2021). The reason for this difference is that when consumers’ environmental awareness of recycling is high, the remanufacturer can achieve a high level of collection rate without any recycling cost. Then, the remanufacturer will decrease the remanufactured products’ price to increase its competitiveness. Consequently, the manufacturer also decreases the new products’ price.

Proposition 6 (ii) and (iii) show that the remanufactured products’ price and the recycling price have sudden decreases at \(k=\widehat{k_7}\), due to the sudden increase of the license fee. Overall, the manufacturer will either reduce or fix the remanufactured products’ price, as consumers’ environmental awareness increases. Even though the manufacturer charging a higher license fee motivates the remanufacturer to price higher on the remanufactured product, the increase in consumers’ environmental awareness will increase the recycling quantity as well as the supply of the remanufactured products. Thus, the remanufacturer finally reduces or fixes the remanufactured products’ prices to seize more demands. Especially, when the impact of monetary incentives is low (i.e., \(\beta \le \widehat{\beta _1}\)) and consumers’ environmental awareness is at the primary stage in the moderate level (i.e., \(\widehat{k_5}<k<\widehat{k_4}\)), the positive impact of the license fee and the negative impact of consumers’ environmental awareness cancel each other out, so that the remanufactured products’ price keeps stable. Furthermore, the recycling price displays a decreasing trend with consumers’ environmental awareness since the monetary incentives become less influential on consumers’ recycling behavior. Echoing the results in Proposition 2, we can find that the influences of consumers’ environmental awareness on the remanufactured products’ price and the recycling price are robust.

Corollary 1

When \(k\le \widehat{k_3}\),

-

(i)

\(\partial d^{A*}_n / \partial k<0 \) if \(\beta \le \widehat{\beta _1}\) and k \(\in \) (0, \(\widehat{k_5}\)) \(\cup \) (\(\widehat{k_5}\), \(\widehat{k_4}\)) or if \(\beta > \widehat{\beta _1}\) and k \(\in \) (0, \(\widehat{k_6}\)); Otherwise, \(\partial d^{A*}_n / \partial k>0\).

-

(ii)

\(\partial d^{A*}_r / \partial k>0 \) if \(\beta \le \widehat{\beta _1}\) and k \(\in \) (0, \(\widehat{k_5}\)) \(\cup \) (\(\widehat{k_5}\), \(\widehat{k_3}\)) or if \(\beta > \widehat{\beta _1}\) and k \(\in \) (0, \(\widehat{k_6}\)) \(\cup \) (\(\widehat{k_6}\), \(\widehat{k_3}\)).

Corollary 1 (i) shows that as consumers’ environmental awareness increases, the new products’ demand will occur a sudden decrease at \(k=\widehat{k_7}\), and overall, it first decreases and then increases with consumers’ environmental awareness. Echoing Proposition 6, the trends of the new products’ demand and price are contrary. It is because that the price of the new products dominantly influences the competitiveness of the new product. Thus, the increased (decreased) price of the new products will render the new product less (more) competitive and less (more) consumers buy the new product.

The remanufactured products’ demand increases with consumers’ environmental awareness when consumers’ environmental awareness is low. But as consumers’ environmental awareness arrives at a moderate level, it will suffer a sudden decrease at \(k=\widehat{k_7}\) due to the sudden increase of the remanufactured products’ price. After that, the demand for remanufactured products increases again, attributing to the decreased/fixed price of the remanufactured products and the increased recycled amount caused by the increased consumers’ environmental awareness.

Echoing the result in Proposition 2 (ii), we find that the increase of consumers’ environmental awareness no longer always hurt the demand for the new product when the manufacturer adopts strategy A. Specifically, when consumers are of moderate environmental awareness, increasing consumers’ environmental awareness may not only increase the demand for the remanufactured product, but also increase the demand for the new product.

Proposition 7

When \(k\le \widehat{k_3}\), (i) \(\partial \pi ^{A}_M / \partial k>0\) always holds; (ii) \(\partial \pi ^{A}_R / \partial k>0\) if \(\beta \le \widehat{\beta _1}\) and k \(\in \) (0,\(\widehat{k_5}\)) \(\cup \) (\(\widehat{k_5}\),\(\widehat{k_8}\)) \(\cup \) (\(\widehat{k_4}\),\(\widehat{k_3}\)) or if \(\beta > \widehat{\beta _1}\) and k \(\in \) (0,\(\widehat{k_6}\)) \(\cup \) (\(\widehat{k_6}\),\(\widehat{k_3}\)); Otherwise, \(\partial \pi ^{A}_R / \partial k <0\). Where \(\widehat{k_8}=\frac{\alpha c_n-c_r}{4 e_r (1-\alpha )}\).

Proposition 7 (i) shows that under strategy A, the manufacturer’s profit continuously increases with consumers’ environmental awareness. It is because as consumers’ environmental awareness increase, the amount of the remanufactured products increases. The manufacturer can make full use of the quantitative advantage of the remanufactured products by adjusting the unit licensing fee to increase its profits from the authorization channel. Although consumers’ environmental awareness will hurt the profit from the new product, the manufacturer’s total profit still increase because of the dominant increased profit from the authorization channel. Echoing Proposition 3, the positive influence of consumers’ environmental awareness on the manufacturer’s profit is robust. A little difference is that under strategy A, the manufacturer benefits from the remanufactured product through charging license fees, rather than producing and selling remanufactured products by itself.

Compared to the manufacturer, the remanufacturer seems to be less fortunate. It can only conditionally benefit from consumers’ increased environmental awareness. As shown in Proposition 7 (ii) and Fig. 9 (b), the remanufacturer’s profit will plummet when consumers’ environmental awareness begins to reach a moderate level, due to the sudden increase of the license fee from the manufacturer. Moreover, when the impact of monetary incentives is low (i.e., \(\beta \le \widehat{\beta _1}\)) and consumers’ environmental awareness is at the primary stage in the moderate level (i.e., \(\widehat{k_5}<k<\widehat{k_4}\)), the remanufacturer’ profit first increases and then decreases with consumers’ environmental awareness. It is because as consumers’ environmental awareness increases, the remanufacturer can earn more profits from selling more remanufactured products to consumers, but at the same time it needs to bear license fees. When the increased profit from selling remanufactured products covers the loss, the remanufacturer will benefit from consumers’ environmental awareness. Otherwise, it will suffer a loss. The results suggest that as a follower in the Stackelberg game, the remanufacturer cannot always reap the rewards from consumers’ environmental awareness increase, due to the manufacturer’s power over the license fee.

5.3 Strategy comparison

This section first compares the equilibrium decisions under two remanufacturing strategies and then analyzes the impacts of green recycling behavior on the manufacturer’s strategy choices. According to Tables 4 and 6, the following is derived.

Proposition 8

-

(i)

No matter the value of k, \(p_n^{S*}<p_n^{A*}\) and \(p_{cr}^{S*}\ge p_{cr}^{A*}\) always hold.

-

(ii)

When \(k \le \widehat{k_7}\), \(p_r^{S*}>p_r^{A*}\) holds if \(\lambda <\widehat{\lambda }_1\) and \(\widehat{\beta }_2<\beta <\widehat{\beta }_3\); When \(k > \widehat{k_7}\), \(p_r^{S*}>p_r^{A*}\) holds if \(\lambda <\frac{2}{2+\alpha }\) and \(\underline{K}_1(\beta )<k<\overline{K}_1(\beta )\) and \(\beta \le \frac{\alpha \lambda +2 \lambda -4}{\alpha ^3 \lambda +3 \alpha ^2 \lambda -4 \alpha \lambda }\).

Note: \(\widehat{\lambda }_1=\frac{2+\alpha -\sqrt{4+\alpha ^2}}{4}\), \(\widehat{\beta }_2=\frac{2 (\alpha \lambda +2 \lambda -1)}{(\alpha -1) \alpha (\alpha +4) \lambda }-2 \sqrt{-\frac{2 \alpha \lambda -4 \lambda ^2+4 \lambda -1}{(\alpha -1)^2 \alpha ^2 (\alpha +4)^2 \lambda ^2}}\), \(\widehat{\beta }_3=2 \sqrt{-\frac{2 \alpha \lambda -4 \lambda ^2+4 \lambda -1}{(\alpha -1)^2 \alpha ^2 (\alpha +4)^2 \lambda ^2}}+\frac{2 (\alpha \lambda +2 \lambda -1)}{(\alpha -1) \alpha (\alpha +4) \lambda } \),

and

Proposition 8 (i) shows that the unit recycling price under strategy S is no less than that under strategy A. Echoing Proposition 4, it is reasonable since the manufacturer’s recycling ability is lower and the remanufacturer is less motivated to remanufacture the remanufactured products due to the authorization fee. Proposition 8 (i) also shows that the new products’ price under strategy S is always lower than that under strategy A. Under strategy S, the manufacturer faces internal competition between its new products and remanufactured products. Thus, it can achieve the highest profit by adjusting the production plan of remanufactured products. But under strategy A, the manufacturer faces external competition from the remanufacturer. Thus, the manufacturer prices the new product higher compared to that under strategy S, to soften the external competition and ensure the profit from authorization.

Proposition 8 (ii) shows that the remanufactured products’ price under strategy S is sometimes higher than that under strategy A. It seems to be counter-intuitive because the double marginalization effect should compel the remanufacturer to charge a higher price for the remanufactured products than the manufacturer does. The reason is that the manufacturer’s recycling ability is limited and the recycling amount has a discount. When consumers’ environmental awareness is low (\(k<\widehat{k_7}\)), both the manufacturer and the remanufacturer will pay for recycling. If consumers are slightly influenced by monetary incentives, there is no need for the manufacturer to spend significantly higher money to recycle; if consumers are highly influenced by monetary incentives, only a slightly higher recycling price can greatly compensate for the discount on the recycling amount. Thus, only when consumers are moderately influenced by the monetary incentives (\(\widehat{\beta }_2<\beta <\widehat{\beta }_3\)), the manufacturer’s recycling price is significantly higher than the remanufacturer’s. As the recycling cost is significantly higher, the price set by the manufacturer for the remanufactured product will be higher than that set by the remanufacturer.

Proposition 9

-

(i)

when \(\lambda <\widehat{\lambda }_1\), \(\pi _M^{A}>\pi _M^{S}\) holds if \(k<\widehat{k}_7\) and \(\widehat{\beta }_2<\beta <\widehat{\beta }_3\) or if \(\underline{K}_2(\lambda , \beta )<k<\overline{K}_2(\lambda , \beta )\) and \(0<\beta <\widehat{\beta }_4\);

-

(ii)

when \(\widehat{\lambda }_1<\lambda <\widehat{\lambda }_2\), \(\pi _M^{A}>\pi _M^{S}\) holds if \(\underline{K}_2(\lambda , \beta )<k<\overline{K}_2(\lambda , \beta )\) and \(0<\beta <\widehat{\beta }_4\);

-

(iii)

when \(\lambda >\widehat{\lambda }_2\), \(\pi _M^{A}<\pi _M^{S}\) always hold.

Note: \(\widehat{\lambda }_2=\left( 2+\alpha -\sqrt{4 \alpha +\alpha ^2} \right) /2\), \(\widehat{\beta _4}=2 \sqrt{-\frac{\alpha \lambda -\lambda ^2+2 \lambda -1}{(\alpha -1)^2 \alpha ^2 (\alpha +4)^2 \lambda ^2}}+\frac{\alpha \lambda +2 \lambda -2}{(\alpha -1) \alpha (\alpha +4) \lambda }\), \(\overline{K}_2(\lambda , \beta )\) and \(\underline{K}_2(\lambda , \beta )\) are piecewise functions of \(\lambda \) and \(\beta \), the detailed expressions are shown in “Appendix”.

Proposition 9 shows the conditions when the manufacturer should choose strategy A. Since the functions of the thresholds \(\underline{K}_2(\lambda , \beta )\) and \(\overline{K}_2(\lambda , \beta )\) vary from the value of \(\lambda \), Fig. 10a–f plots all the potential scenarios where \(\lambda \) is in different ranges. The shadow regions in each subfigure are when the manufacturer should adopt strategy A.

Figure 10a–c corresponds to the result in Proposition 9 (i). It shows that as long as the manufacturer’s recycling ability is low (\(\lambda <\widehat{\lambda }_1\)), regardless of the degree, the manufacturer should authorize the remanufacturer to recycle and remanufacture products when consumers are slightly/moderately environmental aware and moderately/slightly self-benefit aware. Echoing Proposition 8 (ii), it indicates that the conditions of using strategy A share a similar pattern with that ensuring the price of the remanufactured products under strategy S is higher than that under strategy A. It is intuitive since when the manufacturer is limited in recycling ability, its increased cost on recycling will decrease its profit under strategy S. Moreover, the remanufactured products’ price under strategy A is lower than that under strategy S, then the manufacturer can obtain more profits through the authorization channel because the remanufacturer produces and sells more remanufactured products.

As the manufacturer’s recycling ability becomes moderate (\(\widehat{\lambda }_1<\lambda <\widehat{\lambda }_2\)), the manufacturer no more uses strategy A when consumers are of slightly environmental awareness (\(k<\widehat{k_7}\)) because the manufacturer’s recycling cost under strategy S is no longer significantly higher. Thus, Proposition 9 (ii) suggests that when the manufacturer’s recycling ability becomes moderate, the manufacturer adopts strategy A only if consumers are of moderately environmental awareness and slightly self-benefit awareness. Moreover, the detailed degree of the manufacturer’s recycling ability also influences the probability that the manufacturer chooses strategy A, as shown in Fig. 10d–f, the probability of the manufacturer choosing strategy A decreases as \(\lambda \) increases.

Proposition 9 (iii) indicates that when the discount rate of the manufacturer’s recycling ability is small (or \(\lambda \) is large), the manufacturer should always choose strategy S. It is easily understood because the manufacturer is no more troubled with recycling. This result suggests that recycling ability is also one of the key issues that should be considered when the manufacturer chooses its remanufacturing strategy.

Different from the results in Feng et al. (2021) which shows that the discount rate of purchasing remanufactured products significantly influences the manufacturer’s remanufacturing strategy, our results demonstrate that the manufacturer’s recycling ability and consumers’ recycling behavior are the determinant factors of the manufacturer’s remanufacturing strategy. The reason for this difference is that consumers’ recycling behavior will essentially affect firms’ recycling decisions (e.g., recycling price). Our results emphasize the importance for manufacturers to consider consumers’ recycling behavior when choosing remanufacturing strategy. In Corollary 2, we further show the aftermath of ignoring consumers’ green recycling behavior.

Corollary 2

When consumers are not environmental awareness, i.e., \(k=0\), \(\pi _M^{A}>\pi _M^{S}\) holds only if \(\lambda < \widehat{\lambda }_1\) and \(\widehat{\beta }_2<\beta <\widehat{\beta }_3\).

Corollary 2 shows that if consumers do not have environmental awareness, the manufacturer will choose strategy A when the manufacturer’s recycling ability is low (\(\lambda <\widehat{\lambda }_1\)) and consumers are moderately influenced by monetary incentives (\(\widehat{\beta }_2<\beta <\widehat{\beta }_3\)). Otherwise, the manufacturer will always choose strategy S.

Echoing to Proposition 9, Corollary 2 suggests that when the manufacturer’s recycling ability is low (\(\lambda <\widehat{\lambda }_1\)) and consumers are moderately influenced by monetary incentives (\(\widehat{\beta }_2<\beta <\widehat{\beta }_3\)), ignoring consumers’ environmental awareness will not lead the manufacturer to adopt the wrong strategy if consumers’ environmental awareness is not very high (\(k<\overline{K}_2(\lambda , \beta )\)). Otherwise if consumers’ environmental awareness is very high (\(k>\overline{K}_2(\lambda , \beta )\)), the manufacturer will mischoose strategy S. When the manufacturer’s recycling ability is moderate (\(\widehat{\lambda }_1<\lambda <\widehat{\lambda }_2\)), ignoring consumers’ environmental awareness will render the manufacturer to choose strategy S. However, when consumers are moderate environmental awareness (\(\overline{K}_2(\lambda , \beta )<k<\overline{K}_2(\lambda , \beta )\)), the manufacturer should choose strategy A. Therefore, ignoring consumers’ environmental awareness leads the manufacturer to the wrong strategy and obtain suboptimal profit.

6 Conclusions

In this paper, we first develop a questionnaire to investigate consumers’ recycling behavior. The empirical analysis demonstrates that both firms’ monetary incentives and consumers’ environmental awareness positively influence consumers’ recycling intention. Then, we construct two theoretical models to describe the self-remanufacturing and authorization remanufacturing strategies incorporated into consumers’ recycling behavior. Through theoretical analysis, we obtain the optimal pricing and collection decisions for firms under each remanufacturing strategy and show the impact of consumers’ recycling behavior on firms’decisions and strategy selection.

Analytical results reveal that no matter which remanufacturing strategy the manufacturer adopts, the recycling amount driven by consumers’ environmental awareness is enough to support the optimal production plan when consumers are of high environmental awareness. Thus, there is no need to implement monetary incentives for recycling under this condition. When consumers’ environmental awareness is not at a high level, the original optimal production plan cannot preserve. Firms should make a trade-off between the recycling cost and the profit improvement from additional paid recycling. As a result, firms decide (not) to implement monetary incentives when consumers are of low (moderate) environmental awareness. The results indicate that firms’ efforts in recycling may be in vain if not considering consumers’ environmental awareness in the recycling process.

The impact of consumers’ recycling behavior is also reflected in firms’ optimal decisions. Under the self-remanufacturing strategy, the new products’ price keeps stable, but the remanufactured products’ price decreases with consumers’ environmental awareness. Correspondingly, the demand for new/remanufactured products decreases/increases. As a result, the manufacturer’s profit increases with consumers’ environmental awareness; Under authorization remanufacturing strategy, the new products’ price no more keeps a stable status but exhibits complex trends. Although the remanufacturers’ price for the remanufactured product still displays a decreased trend, an interval of stable price occurs. An interesting finding is that the demand for the new/remanufactured products may increase simultaneously. The manufacturer’s profit still increases with consumers’ environmental awareness, indicating that the positive impact of consumers’ environmental awareness on the manufacturer’s profit is robust. However, the remanufacturer’s profit may decrease with consumers’ environmental awareness.

As for the comparison of the two strategies, the impact of consumers’ recycling behavior is concentrated on the price of remanufactured products and the profits of the manufacturer. The new products’ price (recycling price) under self-remanufacturing strategy is always lower (larger) than that under authorization remanufacturing strategy. But the relative prices of remanufactured products under two strategies depend on the degree of consumers’ environmental awareness and the influence of monetary incentives. Thus, consumers’ recycling behavior becomes one of the determining factors for the manufacturer’s remanufacturing strategy selection.

Future research can extend our line of inquiry in several directions. First, consumers’ recycling intentions are also influenced by other factors, such as knowledge about recycling. It may involve some marketing strategies, such as advertisement. Although some researchers have incorporated such kinds of strategies in remanufacturing research (e.g., Hong et al., 2015), what they focus on is how consumers’ purchasing preference changes but not their recycling intentions. Thus, it is still interesting and important to incorporate other operations related to recycling with remanufacturing operations. Second, generally, the production and collection tasks can be assigned to two firms for competition. Thus, we believe that more detailed recycling and production structures in our setting are topics worthy of further exploration; Third, we consider the game when there are already enough used products in the market and there is no limit to the number of products that can be recycled. It would be interesting to relax this assumption and study a multi-period game or an infinitely repeated game.

References

Abdulrahman, M. D. A., Subramanian, N., Liu, C., & Shu, C. (2015). Viability of remanufacturing practice: A strategic decision making framework for Chinese auto-parts companies. Journal of Cleaner Production, 105, 311–323.

Atasu, A., Guide, V. D. R., Jr., & Van Wassenhove, L. N. (2010). So what if remanufacturing cannibalizes my new product sales? California Management Review, 52(2), 56–76.

Atasu, A., Sarvary, M., & Van Wassenhove, L. N. (2008). Remanufacturing as a marketing strategy. Management Science, 54(10), 1731–1746.

Çetİn, M. (2015a). Using recycling materials for sustainable landscape planning. In Environment and ecology at the beginning of 21st century (pp. 783–788).

Çetİn, M. (2015b). Consideration of permeable pavement in landscape architecture. Journal of Environmental Protection and Ecology, 16(1), 385–392.

Çetİn, M., & Şevİk, H. (2016). Assessing potential areas of ecotourism through a case study in Ilgaz Mountain National Park. In Tourism-from empirical research towards practical application (pp. 81–110).

Çetİn, M., Agacsapan, B., Cabuk, S. N., Senyel Kurkcuoglu, M. A., Isik Pekkan, O., Baran Argun, E., & Cabuk, A. (2021). Assessment of the ecological footprint of Eskisehir technical University-Iki Eylul Campus. Journal of the Indian Society of Remote Sensing, 49(10), 2311–2327.

Chen, C. F. (2007). Applying the stochastic frontier approach to measure hotel managerial efficiency in Taiwan. Tourism Management, 28(3), 696–702.

Chen, Y., Li, B., Zhang, G., & Bai, Q. (2020). Quantity and collection decisions of the remanufacturing enterprise under both the take-back and carbon emission capacity regulations. Transportation Research Part E: Logistics and Transportation Review, 141, 102032.

Chitra, K. (2007). In search of the green consumers: A perceptual study. Journal of Services Research, 7(1), 173–191.

Choi, T. M., Li, Y., & Xu, L. (2013). Channel leadership, performance and coordination in closed loop supply chains. International Journal of Production Economics, 146(1), 371–380.

Dhir, A., Malodia, S., Awan, U., Sakashita, M., & Kaur, P. (2021). Extended valence theory perspective on consumers’ e-waste recycling intentions in Japan. Journal of Cleaner Production, 312, 127443.

Feng, Z., Xiao, T., & Robb, D. J. (2021). Environmentally responsible closed-loop supply chain models with outsourcing and authorization options. Journal of Cleaner Production, 278, 123791.

Ferguson, M. E., & Souza, G. C. (2010). Closed-loop supply chains: New developments to improve the sustainability of business practices. Auerbach Publications.

Ferguson, M. E., & Toktay, L. B. (2006). The effect of competition on recovery strategies. Production and Operations Management, 15(3), 351–368.

Ferrer, G., & Swaminathan, J. M. (2010). Managing new and differentiated remanufactured products. European Journal of Operational Research, 203(2), 370–379.

Galbreth, M. R., Boyacı, T., & Verter, V. (2013). Product reuse in innovative industries. Production and Operations Management, 22(4), 1011–1033.

Govindan, K., Soleimani, H., & Kannan, D. (2015). Reverse logistics and closed-loop supply chain: A comprehensive review to explore the future. European Journal of Operational Research, 240(3), 603–626.

Gu, W., Chhajed, D., Petruzzi, N. C., & Yalabik, B. (2015). Quality design and environmental implications of green consumerism in remanufacturing. International Journal of Production Economics, 162, 55–69.

Hair, J. F., Celsi, M., Ortinau, D. J., & Bush, R. P. (2010). Essentials of marketing research (Vol. 2). New York, NY: McGraw-Hill/Irwin.

Han, X., Shen, Y., & Bian, Y. (2020). Optimal recovery strategy of manufacturers: Remanufacturing products or recycling materials? Annals of Operations Research, 290(1), 463–489.

Henson, R. K. (2001). Understanding internal consistency reliability estimates: A conceptual primer on coefficient alpha. Measurement and Evaluation in Counseling and Development, 34(3), 177–189.

Hong, X., Govindan, K., Xu, L., & Du, P. (2017). Quantity and collection decisions in a closed-loop supply chain with technology licensing. European Journal of Operational Research, 256(3), 820–829.

Hong, X., Xu, L., Du, P., & Wang, W. (2015). Joint advertising, pricing and collection decisions in a closed-loop supply chain. International Journal of Production Economics, 167, 12–22.

Iyer, G., & Soberman, D. A. (2016). Social responsibility and product innovation. Marketing Science, 35(5), 727–742.

Kumar, A. (2019). Exploring young adults’ e-waste recycling behaviour using an extended theory of planned behaviour model: A cross-cultural study. Resources, Conservation and Recycling, 141, 378–389.

Li, J., Liang, J., Shi, V., & Zhu, J. (2021). The benefit of manufacturer encroachment considering consumer’s environmental awareness and product competition. Annals of Operations Research, 1–21. https://doi.org/10.1007/s10479-021-04185-y.

Likert, R. (1932). A technique for the measurement of attitudes. Archives of Psychology, 140, 5–55.

Liu, Y., & Xiao, T. (2019). Pricing and collection rate decisions and reverse channel choice in a socially responsible supply chain with green consumers. IEEE Transactions on Engineering Management, 67(2), 483–495.

Mitra, S., & Webster, S. (2008). Competition in remanufacturing and the effects of government subsidies. International Journal of Production Economics, 111(2), 287–298.

Oraiopoulos, N., Ferguson, M. E., & Toktay, L. B. (2012). Relicensing as a secondary market strategy. Management Science, 58(5), 1022–1037.

Peng, Z. Q., & Su, P. (2011). On the licensing strategy of remanufacturing patented product under compulsory licensing. In 2011 international conference on E-business and E-government (ICEE).