Abstract

High Weber number drops are found to undergo a Cassie-to-Wenzel transition on hydrophobic textured surfaces. Previous studies with many-body dissipative particle dynamics (MDPD) method were based on an absolute Cassie state, with no splash. Hence, an MDPD method was developed in this paper, which could simulate drop splashes in a hybrid state. Millimeter-sized drops on hydrophobic substrates were simulated with different solid fraction, and results were compared to experimental results using high-speed photography. The numerical spread diameter, contact time, and splash amount are matched with experiments. Results showed that hydrophobic substrates with lower solid fraction possess better water repellency as compared to those with similar apparent contact angle. However, the influence of the microstructure on superhydrophobic surfaces is much less than that on hydrophobic ones, and surfaces with lower solid fraction did not have better water repellency capabilities. It is believed that the MDPD method proposed in this study can effectively predict relationship between surface topography and water repellency of a material.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Droplet impact on a solid surface is one of the most common physical phenomena in nature and has been widely utilized in numerous industrial fields, such as ink-jet printing, surface coating, crop dusting, aircraft anti-icing, and forensic science. In particular in aircraft design, it is desirable to manufacture materials with self-cleaning, anti-icing, enhanced heat transfer, and reduced passive fluid drag properties. These properties mainly depend on water repellency of the surface (Checco et al. 2014), and a traditional way to examine this is through the apparent contact angle and contact angle hysteresis. However, these two properties are mainly measured in a low Weber number, i.e., \((We = \rho DU^{2} /\sigma )\) situation, where droplets usually remain in a Cassie state on hydrophobic textured surfaces (Cassie and Baxter 1944). However, in most engineering applications, droplet impact usually occurs in high Weber number conditions (high impact velocity), and impacting droplet may be in a Wenzel state (Wenzel 1936), instead of an absolute Cassie state. Hence, the apparent contact angle and its hysteresis may be insufficient to represent water repellency. In high Weber number conditions, a simple way to examine water repellency of the contact surface is the droplet impact test.

Significant advancements have been made through experiments. Impact velocity, surface tension, wettability, and surface structure are usually recorded to investigate impact process (Brunet et al. 2008; Lagubeau et al. 2012; Ukiwe and Kwok 2005; Bartolo et al. 2005; Yarin 2006). With high-resolution video technology being widely employed in recent years, imaging of these parameters has been studied in detail (Deng et al. 2012; Pernites et al. 2011; Mertaniemi et al. 2011). Additionally, equipping surfaces with microstructures is a useful way to raise water repellency of the contact surface (Tsai et al. 2009; Zhang et al. 2016; Shen et al. 2015).

However, unlike experimental studies, so far there is no effective numerical method to simulate droplet impact process. Droplet impact is a complex physical process, which contains three-phase direct-contact, and some small-scale parameters (e.g., splash) that are far smaller than the characteristic scale. Thus, it is very difficult to simulate impact using traditional fluid mechanics (Pan et al. 2014). Moreover, it is impossible to simulate a certain splash amount using a lattice-based method like LBM (Lattice Boltzmann method, Wang et al. 2011). Therefore, a particle-based method with the capability to simulate multiphase fluid flow with relatively reasonable computational efforts is required.

In recent years, a many-body dissipative particle dynamics (MDPD) method has been used to explore droplet impact mechanism. Dissipative particle dynamics (DPD)—a particle-based simulation method—is thought to be a coarse-grained version of molecular dynamics (MD) (Wörner 2012). DPD method has the ability to reduce computational efforts by using each DPD particle to represent a cluster of actual molecules. Warren (2003) introduced a van der Waals loop into the equation of state, making the DPD method more suitable to simulate liquid or vapor interface, and the MDPD method has been widely employed since then. Ghoufi (2011) demonstrated that MDPD method can be used to explore a planar water liquid–vapor interface and the interfacial properties of a water droplet. Pan et al. (2014) optimized this method and simulated droplet–droplet impact. Wang and Chen (2015b) provided three linear weight functions to simulate interactions between solid, liquid and vapor states, which made it possible to investigate interactions between droplets and solid substrates. Arienti et al. (2011) provided a fitting method for surface tension coefficient, which enabled quantifying droplet surface tension in simulation. Wang and Chen (2015a) introduced a method describing in detail, the simulation of droplet impact on a textured surface, in a total Cassie state with no splashing. However, it is insufficient to investigate droplet impact phenomenon without a Cassie–Wenzel transition, as splash amount has a significant effect on droplet impact. In order to make apparent contact angle agree with Cassie–Baxter theory, the parameters for dynamic interaction of the surface involved were changed in their study. Thus, surface wettability changed because of the dynamic interaction parameters, instead of the substrate structure. Moreover, the effect of surface topography is sensitive to surface contact angle and Wang and Chen (2015a) applied a method that cannot discern influence of the surface structure, from dynamic parameters.

The MDPD method was used in this paper, to forecast relationship between the water repellency of the substrate and surface topography, keeping in mind Cassie–Wenzel transition. Based on the methods mentioned in previous references (Warren 2003; Ghoufi 2011; Pan et al. 2014; Wang and Chen 2015a, b; Arienti 2011), this method was developed from the absolute Cassie state with no splash, to a hybrid state with splashing. In this study, 2.4 mm diameter droplets impacting surfaces with different pillar spacing were tested and simulated. All surfaces in the experiment had a similar contact angle, and all drop–surface interaction parameters in the simulation remained the same. The droplet impact process was recorded with high-speed photography. Spread diameter, contact time, rebound height, and splash amount were investigated. Results on hydrophobic and superhydrophobic surfaces, as well as simulation and experimental results were compared. Comparing simulation results with results of other researchers may help bring greater clarity to the influence of Cassie–Wenzel transition. Keeping in mind several related research studies such as Wang and Chen (2015a, b) and Arienti et al. (2011) that chose 2D simulation, this paper also used a 2D model to simulate the drop collision process.

2 Method

2.1 Numerical method

2.1.1 DPD and MDPD method

In DPD method, each DPD particle represents a cluster of actual molecules moving in a Lagrangian fashion (Espanol and Warren 1995; Groot and Warren 1997), and this method has already been applied in a wide range of mesoscopic simulations (Yamada et al. 2015). As a mesh-free particle-based method, both fluids and solids are modeled as a group of DPD particles. The basic rule of the DPD method is based on Newton’s second law. For more details on this method, refer to Liu et al. (2015).

MDPD is a modified version of the classic DPD method and was proposed by Warren (2003). In an MDPD approach, a conservative force is composed of an attractive force and a repulsive force:

where \(A_{ij}\) and \(B_{ij}\) are amplitudes of attractive and repulsive forces, respectively. Moreover, \(r_{\text{d}} = 0.75\,r_{\text{c}}\) is the cutoff range of the attractive force; repulsive force is dependent on density function \(\bar{\rho }_{i}\), while \(\omega_{\text{c}}\) and \(\omega_{\text{d}}\) are weight functions.

2.1.2 Numerical model

The numerical model that was used in this paper was the MDPD method, as shown below (Fig. 1; Table 1). In previous studies (Arienti et al. 2011; Wang and Chen 2015a), the droplet particle never penetrated into structures (absolute Cassie state); however, in the present study, and in order to simulate Cassie–Wenzel transition process, the droplet particle interspace must be much smaller than pillar structure spacing. Thus, droplet particle number density in this study was much larger than those in previous studies, and this is the reason parameters from previous studies could not be directly utilized. The droplet was composed of 90,000 DPD particles. The droplet mod diameter was 120 \(l_{\text{DPD}}\), which was 2.4 mm. When choosing particle number, it is necessary to ensure that there are enough drop particles between surface structures during droplet impact process. Using the drop particle number above, the drop particle interspace (diameter divided by the square root of particle number) was approximately one fifth of structure spacing. Hence, it was considered that the particle number selection was reasonable. In every simulation group, the droplet’s initial seat and shape were the same. When the simulation commenced, the lowest droplet particle was 2 \(l_{\text{DPD}}\) higher, than highest solid surface wall particle. The solid surface wall with pillared structures was also composed of DPD particles. The solid surface was meshed by Ansys with an element length of 0.1. Every particle was at the location of solid wall meshed nodes. The wall particles were frozen so that the wall would not move. All solid surface geometric parameters are shown in Fig. 1. Every DPD particle had a mass of 1 \(M_{\text{DPD}}\). In the experiment, the droplet fell from a specific height (h), with an approximate impact velocity of \(v = \sqrt {2gh}\). The interaction cutoffs (\(r_{\text{c}}\), \(r_{\text{d}}\)) were default parameters in most references (Warren 2003; Ghoufi 2011; Pan et al. 2014; Wang and Chen 2015a, b; Arienti et al. 2011). The force parameters (A, B) were chosen to obtain a reasonable fitting droplet surface tension \(\sigma_{\text{fit}}\) (Table 1), indicated by the following formula (Arienti et al. 2011):

2.1.3 Solid–fluid interaction

In the simulation, wall particles and droplet particles interact through a conservative force, as follows:

This conservative force function is a modified version of Wang and Chen’s (2015b) three linear weight functions. The repulsive force with a nonlinear formation can significantly prevent droplet particles from passing through a solid wall. The solid–fluid force parameters that were chosen in this paper are as follows (in Table 2).

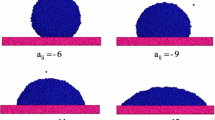

When the cutoff was set with solid–fluid interaction at 0.3 \(l_{\text{DPD}}\), the contact angle was approximately 165° (±5°). When the cutoff was set with solid–fluid interaction at 0.4 \(l_{\text{DPD}}\), the contact angle was approximately 140° (± 5°) (as shown in Fig. 2b). In the simulation, all solid surface pillars had a width of 1 \(l_{\text{DPD}}\), a height of 2 \(l_{\text{DPD}}\), and different spacing. Pillar spacing and surface solid fractions are displayed in Table 3. The solid fraction is defined as pillar width, divided by sum of pillar width and pillar spacing. After the parameters were set, simulation results remained the same with good repeatability.

2.1.4 Nondimensionalization

The weakness in DPD lies in the lack of a direct link between simulation parameters and physical parameters (Arienti et al. 2011). Different research groups have used different scaling methods for primary units. In this study, the main nondimensional formulas are as follows:

where \(R_{\text{drop}}\) and \(d_{\text{drop}}\) are droplet radius and diameter, respectively; \(\rho_{\text{drop}}\) is density; \(\sigma_{\text{drop}}\) is droplet surface tension coefficient (0.073 N/m); and d (d = 120) and n (n = 90,000) are droplet model diameter and particle number, respectively. The remaining parameters can be deduced based on the above four parameters.

All deduced nondimensional parameters are shown in Table 4.

Using above parameters, gravity of acceleration g = 3.5e−4 \(a_{\text{DPD}}\) can be deduced. In the simulation, 0.001 \(t_{\text{DPD}}\) was chosen as the simulation time step. If Weber number is defined as \(We = \frac{{\rho v^{2} d}}{{\sigma_{\text{fit}} }}\), then We = 256, 320, and 384, when droplets fall from heights of 40, 50, and 60, respectively.

2.2 Experimental method

Silicon surfaces with micro-pillar structures were fabricated to test droplet impact, in this study. The Weber number in the experiment was defined as \(We = \frac{{2\rho_{\text{drop}} ghd_{\text{drop}} }}{{\sigma_{\text{drop}} }}\). \(\rho_{\text{drop}}\) and \(d_{\text{drop}}\) were experimental droplet density (1000 kg/m3) and diameter (2.4 mm), respectively. All droplets had the same diameter of 2.4 mm and fell from different heights of 40 and 60 cm, representing a Weber number of We = 257 (40 cm) and We = 386 (60 cm), respectively. The surface was prepared with three kinds of solid fractions: 0.133, 0.174, and 0.256. The aspect ratio was defined as pillar width divided by sum of pillar width and pillar spacing. The microscopic structure of the tested surface is displayed in Fig. 2a.

The micro-pillar structured substrates were fabricated using standard photolithography technology and etching of inductively coupled plasma (ICP). Then OTS (octadecyl trichloro silane) self-assembled membrane technology was used for long-lasting hydrophobic treatment. For details on the OTS method, refer to Cho et al. (2012), and Zhang et al. (2016). Lastly, surface contact angle was measured with a standard contact angle goniometer, to verify wettability.

The experimental procedures are as follows. Deionized water droplets with a diameter of 2.4 mm were generated from a fine capillary tube and dropped from heights of 40 or 60 cm, onto a sample surface. The dynamic process of droplet impact was recorded using a high-speed camera (FASTCAM Mini UX100, Photron) at a frame rate of 8000 fps, with a shutter speed of 1/40,000 s. All experiments were performed at least three times under each condition. The substrate was dried after every experiment. For details on the experimental method, refer to Zhang et al. (2016).

Contact angle of each experimental surface in this study was approximately 140° (±5°). The hydrophobic surface in the simulation had a contact angle of approximately 140° (±5°), and the superhydrophobic surface had a contact angle of approximately 165° (±5°).

3 Results

Temporal evolution of spread diameter, contact time, and splash amount were measured to investigate relationship between surface structure and water repellency. The temporal evolution of the spread diameter in the simulation was compared to experiments, to verify simulation accuracy. The microstructure of the surface was then changed to test whether this method could forecast relationship between water repellency of the substrate and surface structure. Finally, droplet impact on a superhydrophobic surface was simulated to verify the theoretical concept of this paper, and this included surface impact at different contact angles. However, influence of surface structure on droplet impact may differ.

3.1 Temporal evolution of spread diameter

In this study, the dynamic process of droplet impact and temporal evolution of spread diameter were measured. The experimental result of a droplet impacting a surface with solid fraction of 0.256 was compared with simulation results of a surface with a solid fraction of 0.250. The comparison of spread diameter as a function of time is plotted in Fig. 3. Figure 4 displays selected snapshots of impact patterns from the simulation, and corresponding high-speed images captured during the experiment.

In the experiment, the droplets fell from a height of 60 cm and 40 cm, respectively. As displayed in Figs. 3 and 4, the simulation and experiment trends showed good similarity, and droplet splash occurred during impact, in both the simulation and the experiment. However, droplet mass and impact velocity in the experiment were lower than those in the simulation (air-resistance, instrument friction). Thus, droplet spread is larger but slower in the simulation; unlike 2D simulation, it is hard to determine whether splash had spread off the droplet in the experiment. Hence, the maximum spread diameter in the experiment (2 ms) was larger than in the simulation. Furthermore, it is normal for some of the experiment results to not perfectly match the 2D simulation.

3.2 Rebound

Contact time is defined as the time when lowest droplet particle rebounded to a height of 2 \(l_{\text{DPD}}\) (40 μm) in the simulation. Simulation results matched the experiment. Similar phenomenon can be found in Wang and Chen (2015a).

Figure 5 indicates that the droplet rebounds faster on substrates with larger pillar spacing (lower solid fraction). It is important to note that dynamic parameters of each simulation group and apparent contact angle of all tested surfaces are the same. Thus, this paper proposes that surfaces with similar wettability (contact angle) and different microstructure may have distinct water repellency. The method described in this paper predicts that hydrophobic surfaces with larger pillar spacing (lower solid fraction) possess greater water repellency. Similar results were obtained by Wang and Chen (2015a, Fig. 7), which showed that droplets rebounded faster off surfaces with low solid fraction; however with reference to Wang and Chen (2015a), the drop–solid interaction was modified to represent change in solid surface fraction, in an absolute Cassie state. Hence, the phenomenon of droplet splash in a Cassie state as descried by Wang and Chen could not be observed. When droplet impacted surfaces with a similar drop-contact-angle and different morphology, the splash amount played an important role, due to which surface water repellency differed. Hence, it is important to develop MDPD drop simulation, from a totally Cassie state to a hybrid state.

3.3 Spread and splash

A droplet falling from a height of 40 cm and 60 cm, respectively, was simulated to compare maximum spread diameter and splash amount. The spread diameter at 120 \(t_{\text{DPD}}\) (3.216 ms) and splash droplet particles at 800 \(t_{\text{DPD}}\) (21.44 ms) were recorded to investigate impact dynamics of different structures. When droplet impacted on a hydrophobic or superhydrophobic surface, some parts of the droplet splashed and moved away from the original droplet. It is believed that droplets splash more severely on surfaces with good water repellency (Yarin 2006). Most parts of the droplets were close to reaching their maximum spread diameter at 3.216 ms, in the simulation; hence, spread diameter at 3.216 ms can be estimated to be maximum spread diameter; and at 21.44 ms most of the droplet had already departed from the surface. Thus, total splash amount was taken into consideration.

Figure 6 indicates that MDPD method has the ability to simulate a droplet splash. In many research studies such as Wang and Chen (2015a, b), and Arienti et al. (2011), the splash amount of the droplet was neglected. However, references from work published by Zhang et al. (2016) show that splash amount did influence water repellency of the surface, especially when impact Weber number was high. In the simulation, splash amount increases with increase in pillar spacing. Based on the theory of KH instability, difference in velocity between drop film and air determines splashing; however, in the MDPD method, influence of air is ignored. On a surface with large pillar spacing, drop spread velocity extensively changed due to different drop–solid interactions, and this led to an increase in splash amount. When impact velocity is high, an air bubble (empty area with no drop particle) may be captured at the center of the impact. The air cushion reduces drop–solid interaction area, thereby weakening the influence of the structure. This may explain why there is no obvious splash amount increase with increase in pillar spacing, when initial drop height is 60 cm. In addition, splash amount in the simulation was much less than that in the experiment. The largest splash amount in the simulation appeared when the droplet was spreading. Moreover, when droplet was shrinking, the splash amount increased as well, in the experiment. Simulating a droplet splash during shrinking process remains a challenge for MDPD method, and this may also lead to deviation in contact time between the simulation and the experiment.

Figure 7 indicates that droplet spread diameter was mainly controlled by impact velocity, instead of surface structure. Similar results were observed in the experiment (as shown in Fig. 8), and similar phenomenon can be found in work done by Wang and Chen (2015a). This phenomenon is explained as a dynamic process that is inertia-dominated at the very beginning of the impact, due to the large kinetic energy of the droplet (Wang and Chen 2015a).

3.4 Superhydrophobic surface

By setting the cutoff range for solid–fluid interaction from 0.4 \(l_{\text{DPD}}\) to 0.3 \(l_{\text{DPD}}\), a superhydrophobic surface with an apparent contact angle of 160°–170° can be obtained. Just like the above simulations, droplet impact from a height of 50 cm on to a superhydrophobic surface with different pillar spacing was simulated.

Simulation results indicate that the influence of the structure on the superhydrophobic surface was much less than that on the hydrophobic ones. For example, contact time variation range on superhydrophobic surface was 0.7 ms, while the range on hydrophobic surface was 3 ms. Contact time on superhydrophobic surface changed only slightly, as did average rebound height. The reason for this phenomenon is due to the fact that the droplet was not in a total Wenzel state all the time (Fig. 9c), when the droplet impacted onto a superhydrophobic surface. Most of the time, the droplet was in a Cassie–Wenzel transition state. At first, the droplet was in a total Wenzel state that lasted for a few milliseconds. A Wenzel–Cassie transition occurred after a specific number of milliseconds, and the droplet was then in a total Cassie state on the superhydrophobic surface; it is important to note that the droplet stayed in a hybrid state for a longer period of time on a hydrophobic surface. If the droplet was in a Cassie state as it was on the superhydrophobic surface, the effect of the microstructure was minimal. Although spread diameter was mainly controlled by impact velocity, the hybrid state process involves a longer drop–solid interface on small pillar spacing surface. This may lead to a decrease in contact time on the hydrophobic surface, with increased spacing. However, the effect was small on a superhydrophobic surface interface. The splash amount also slightly increased the contact time, as pillar spacing increased on the superhydrophobic surface. In addition, this effect reduced when the interspace was too large.

Hence, it is concluded that, although microstructures with low solid fraction significantly improved water repellency of the hydrophobic surfaces, it had limited influence on water repellency of superhydrophobic surfaces. In addition, it can also be found that when surface wettability differed, the influence of the structure on droplet impact was quite distinct.

4 Conclusions

In this study, the MDPD method was used to investigate the dynamics of droplet impact on textured surfaces. This method was developed from an absolute Cassie state with no splash, to a hybrid state with a certain splash amount. The DPD parameters were nondimensionalized to compare simulation results with experimental results. Temporal evolution of spread diameter was recorded, and it was found that the simulation matched the experiment, as well as studies conducted by Wang and Chen (2015a). Surfaces with same wettability (same dynamic parameter), but different solid fraction (different pillar spacing), were then investigated. Results indicated that droplets rebounded faster and splashed more severely on surfaces with larger pillar spacing (low solid fraction). This phenomenon matched the experiment. It is proposed that surfaces with similar apparent contact angle and different microstructures may have different water repellency. Furthermore, although a low solid fraction microstructure significantly improved water repellency of hydrophobic surfaces, it had limited effect on superhydrophobic surfaces. Hence, it is assumed that when surface wettability differs, the influence of the structure on droplet impact also differs. A 2D simulation was conducted in order to compare simulation results with results of other studies; however, a 3D simulation can be conducted in a similar way, as mentioned in this paper. In order to prevent droplet particle from moving through the solid surface wall, the numerical density of the solid surface must be larger than the droplet. Thus, a 3D simulation requires a lot of computational effort for solid surface particles. Results indicate that droplet splash simulation during shrinking remains a challenge using the MDPD method. Hence, simulating splash amount through reasonable computational efforts shall be the future developmental direction for the MDPD method.

References

Arienti M, Pan W, Li X, Karniadakis G (2011) Many-body dissipative particle dynamics simulation of liquid/vapor and liquid/solid Interactions. J Chem Phys 134(20):204114

Bartolo D, Josserand C, Bonn, D (2005) Retraction dynamics of aquous drops upon impact on nonwetting surfaces. https://arxiv.org/abs/physics/0509133

Brunet P, Lapierre F, Thomy V, Coffinier Y, Boukherroub R (2008) Extreme resistance of superhydrophobic surfaces to impalement: reversible electrowetting related to the impacting/bouncing drop test. Langmuir 24(19):11203–11208

Cassie ABD, Baxter S (1944) Wettability of porous surfaces. Trans Faraday Soc 40:546–551

Checco A, Ocko BM, Rahman A, Black CT, Tasinkevych M, Giacomello A, Dietrich S (2014) Collapse and reversibility of the superhydrophobic state on nanotextured surfaces. Phys Rev Lett 112(21):216101

Cho EC, Kong H, Oh TB, Cho K (2012) Protein adhesion regulated by the nanoscale surface conformation. Soft Matter 8(47):11801–11808

Deng X, Mammen L, Butt HJ, Vollmer D (2012) Candle soot as a template for a transparent robust superamphiphobic coating. Science 335(6064):67–70

Espanol P, Warren P (1995) Statistical mechanics of dissipative particle dynamics. Europhys Lett 30(4):191

Ghoufi A, Malfreyt P (2011) Mesoscale modeling of the water liquid-vapor interface: a surface tension calculation. Phys Rev E 83(5):051601

Groot RD, Warren PB (1997) Dissipative particle dynamics: Bridging the gap between atomistic and mesoscopic simulation. J Chem Phys 107(11):4423–4435

Lagubeau G, Fontelos MA, Josserand C, Maurel A, Pagneux V, Petitjeans P (2012) Spreading dynamics of drop impacts. J Fluid Mech 713:50–60

Liu MB, Liu GR, Zhou LW, Chang JZ (2015) Dissipative particle dynamics (DPD): an overview and recent developments. Arch Comput Methods Eng 22(4):529–556

Mertaniemi H, Jokinen V, Sainiemi L, Franssila S, Marmur A, Ikkala O, Ras RH (2011) Superhydrophobic tracks for low-friction, guided transport of water droplets. Adv Mater 23(26):2911–2914

Pan D, Phan-Thien N, Khoo, BC (2014) Dissipative particle dynamics simulation of droplet suspension in shear flow at low capillary number. J Nonnewton Fluid Mech 212:63–72

Pernites RB, Santos CM, Maldonado M, Ponnapati RR, Rodrigues DF, Advincula, RC (2011) Tunable protein and bacterial cell adsorption on colloidally templated superhydrophobic polythiophene films. Chem Mater 24(5):870–880

Shen Y, Tao J, Tao H, Chen S, Pan L, Wang T (2015) Approaching the theoretical contact time of a bouncing droplet on the rational macrostructured superhydrophobic surfaces. Appl Phys Lett 107(11):111604

Tsai P, Pacheco S, Pirat C, Lefferts L, Lohse D (2009) Drop Impact upon micro- and nanostructured superhydrophobic surfaces. Langmuir 25(20):12293–12298

Ukiwe C, Kwok DY (2005) On the maximum spreading diameter of impacting droplets on well-prepared solid surfaces. Langmuir 21(2):666–673

Wang Y, Chen S (2015a) Droplets impact on textured surfaces: mesoscopic simulation of spreading dynamics. Appl Surf Sci 327:159–167

Wang Y, Chen S (2015b) Numerical study on droplet sliding across micropillars. Langmuir 31(16):4673–4677

Warren PB (2003) Vapor-liquid coexistence in many-body dissipative particle dynamics. Phys Rev E 68(6):066702

Wang W, Liu Z, Jin Y, Cheng Y (2011) LBM simulation of droplet formation in micro-channels. Chem Eng J 173(3):828–836

Wenzel RN (1936) Resistance of solid surfaces to wetting by water. Ind Eng Chem 28(8):988–994

Wörner M (2012) Numerical modeling of multiphase flows in microfluidics and micro process engineering: a review of methods and applications. Microfluid Nanofluid 12(6):841–886

Yamada T, Yuan J, Sunden BA (2015) Application of many-body dissipative particle dynamics to determine liquid characteristics. Int J Numer Meth Heat Fluid Flow 25(7):1619–1637

Yarin AL (2006) Drop impact dynamics: splashing, spreading, receding, bouncing. Annu Rev Fluid Mech 38:159–192

Zhang R, Hao P, Zhang X, He F (2016) Dynamics of high Weber number drops impacting on hydrophobic surfaces with closed micro-cells. Soft Matter 12(26):5808-5817

Acknowledgements

The study was supported by the State Key Project of Research and Development (Grant No. 2016YFC1100300) and the National Key Technology R&D Program (2014BAI11B06).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wang, L., Zhang, R., Zhang, X. et al. Numerical simulation of droplet impact on textured surfaces in a hybrid state. Microfluid Nanofluid 21, 61 (2017). https://doi.org/10.1007/s10404-017-1900-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10404-017-1900-0