Abstract

A new yet simple transformation is proposed to significantly improve the accuracy of computational fluid dynamics (CFD) modeling and simulations of free radical polymerization (FRP) reactions carried out especially in flow microreactors. The new transformation makes the kinetic rate coefficients dimensionless in terms of concentration. To that extent, the chemical data (chemical species concentration and kinetic rate coefficients values) can be fed in original molar form instead of usual mass form to CFD software package while simulating chemical species as passive scalars. The normalization of various variables (passive scalars) helps in reducing the numerical stiffness as well as numerical errors during simulations. Another advantage of this new transformation is that the expression for transformed reaction rate equations remains unchanged thus enabling an easy coding and debugging process. The new transformation was first validated through numerical simulation against theoretical analytical solution of FRP for homogeneous batch reactor. It was then validated through CFD simulation against published experimental data for FRP in coiled tube microreactor under steady-state flow condition. It has also been demonstrated that in CFD simulations of FRP in flow microreactors, significant error arises for the prediction of number-average chain length (and thus \({\text{MW}}_{n}\), number-average molecular weight) from the use of chemical data in mass form instead of original molar form. This new transformation is thus found to be more suitable for CFD simulations in flow reactors compared to previous Zhu’s transformation.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In today’s time, as the resources are becoming scarce, chemical industry needs to optimize its manufacturing processes, reactor design, operating conditions etc. This usually requires a lot of experiments and thorough analysis. This may consume a lot of physical resources and may be highly time consuming and costly especially for new emerging techniques. Even for well-established technologies, this may not be economical as not all desired conditions could be performed in limited time and budget.

This problem could partly be overcome by modeling the process mathematically and then simulating it with dedicated software. The increase in computational power with simultaneous decrease in its cost, along with past intensive research aimed at developing efficient and rapid numerical methods and algorithms, have increased the interest of industry toward modeling and simulation. Doing computer-based simulations instead of actual experiments offers several advantages as it is much cheaper, faster and flexible compared to physical experiments. However, computer simulations have their own limitations. They must be validated against physical experimental data under similar conditions. This is necessary to gain enough confidence before using the model to predict results for unknown conditions. To make the simulation match with the physical reality, a good mathematical model of the process is required. Many times, the complexity of the problem is lowered by applying several practical assumptions/transformations to make it solvable under the available computational power.

One of the most common areas for modeling is flow. Computational fluid dynamics (CFD) deals with it. The mathematical model for flow is based on three conservation laws, namely laws of conservation of mass, momentum and energy, in short Navier–Stokes equations. Various mathematical tools and software have been developed to successfully simulate flow under various conditions like in heat exchangers, mixers etc. Chemical reactions are also being modeled and simulated extensively in CFD to evaluate and optimize reactors. Various commercial CFD software offer special chemistry package to incorporate chemical reactions with flow, heat and mass transfer phenomena. Modeling chemical reactions in flow along with heat and mass transfer can offer formidable problems during simulation as these phenomena can be coupled to each other. Polymerization is one such area of chemical reactions.

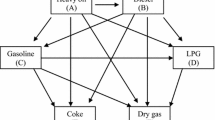

For the current work, free radical polymerization (FRP) is considered, and various elementary steps considered in this work are shown in Scheme 1. It has been modeled and simulated extensively for the study and optimization of different types of reactors under various conditions. Several researchers have modeled FRP for monomers such as for Methyl Methacrylate (MMA) under well mixed, isothermal batch reactor homopolymerization condition (Baillagou and Soong 1985a; Achilias and Kiparissides 1992a), copolymerization condition (Keramopoulos and Kiparissides 2002), flow reactor homopolymerization condition (Baillagou and Soong 1985b) or Styrene under well mixed, isothermal batch reactor copolymerization condition (Keramopoulos and Kiparissides 2002) and flow reactor condition (Cabral et al. 2003; Chen 1994, 2000; Costa et al. 2003).

The mathematical model for FRP consisting in ordinary differential equations (ODE) based on the moment method is given in Appendix-A of ESM and has been successfully used by several researchers (Baillagou and Soong 1985a; Achilias and Kiparissides 1992a; Keramopoulos and Kiparissides 2002). \(\lambda_{0}\), \(\lambda_{1}\) and \(\lambda_{2}\) are zeroth, first and second order moment of live polymer chain length distribution, whereas \(\mu_{0}\), \(\mu_{1}\) and \(\mu_{2}\) are zeroth, first and second order of moment of dead polymer chain length distribution. As can be seen in the mathematical model for FRP in Appendix-A of ESM, the form of equations does not give simple relationships between various chemical species and reaction rates. The various chemical species concentrations appearing in this model vary from each other by several orders of magnitude. This introduces a strong stiffness in the set of ODE during the gel effect and non-isothermal conditions thus making it difficult to solve. This also leads to numerical errors during solving such quantities, and much mathematical manipulations are required to keep the numerical errors low enough to let the simulations converge. So, it would be a good strategy to normalize all these variables so that they come to the same order. It is easier to normalize various chemical species like initiator, monomer, solvent and chain transfer agent (CTA) by dividing their concentration with their respective initial concentrations, i.e.,

But in this mathematical model, as mentioned above, there are some other mathematical variables (\(\lambda_{0} ,\lambda_{1} ,\lambda_{2} ,\mu_{0} ,\mu_{1} \,{\text{and}}\,\mu_{2}\)) also which individually do not represent any chemical species physically but still needed to be solved using ODE [Eqs. (A6) to (A11), respectively]. Thus, the question arises that the initial concentration of which chemical species should be used to normalize them? Should that be same for all or different for each of them? So offering any such normalization for them is not straightforward. Some of the trouble can be avoided by using a simple quasi-steady-state assumption (QSSA) for variables representing free radicals \((\lambda_{0} ,\lambda_{1} \,{\text{and}}\,\lambda_{2} )\) as used by several researchers (Hui and Hamielec 1972; Chen 1994; Serra et al. 2005a, b 2007; Mandal et al. 2011). In our previous work (Garg et al. 2014b, c), we have shown that QSSA for \(\lambda_{0} ,\lambda_{1} \,{\text{and}}\,\lambda_{2}\) is a good assumption even during gel effect and can give same results (compared to the one that is obtained without using QSSA) using proper algorithm. \(\mu_{0} ,\mu_{1} \,{\text{and}}\,\mu_{2}\) (variables representing dead polymer chains) are the three most important variables in this model as they are used to evaluate quite important properties of polymers given by Eqs. (A13) to (A16). Besides this, they are several orders apart from each other. Zhu (1999) have proposed a transformation to tackle these issues for homogeneous batch reactor:

In CFD software packages, chemical species are usually modeled as passive scalar, i.e., they do not affect the flow condition with their movement. One of the problems in modeling chemical reactions with flow is that chemical reaction rates (generation terms) and chemical data for chemical species are presented in terms of moles which is not a conserved quantity during reaction. Following the law of conservation of mass, all the computations in CFD code are performed in terms of mass. Hence, all quantities including passive scalars should be presented in terms of mass so that conservation of mass can be applied to such species. This requires all the chemical data to be converted from molar form to mass form before being fed in the CFD software. Chen (1994) has even reported the kinetic rate coefficients values, as used in simulations, in mass form. Several researchers (Baillagou and Soong 1985b; Cabral et al. 2003; Chen 1994, 2000; Costa et al. 2003) have modeled and simulated polymerization reaction in similar way but without mentioning anything about normalization.

But this strategy has some problems. First, all the chemical species are not normalized. So, good amount of computational power is required to handle the stiffness of the problem and numerical errors arising out of differences in the order of their values. Second is the problem of converting the values of various kinetic rate coefficients of different elementary reaction steps to be modeled, from molar form to mass form. For simple elementary reaction step where only one chemical species is present, the molecular weight of that chemical species can be used to convert the value of kinetic rate coefficient from molar to mass form [like in Eq. (A1)]. But if the reaction rate expression involves more than one chemical species, then it is difficult to choose any one chemical species or their combination for converting the kinetic rate coefficient data from molar to mass form [e.g., Eq. (A2)]. The third problem is slightly different as it is not that significant in the type of simulations already discussed. The flow reactors used are generally of macroreactor type i.e., large radial size (important for industrial scale). In such conditions, the effect of diffusion is quite negligible. Baillagou and Soong (1985b) have shown in their work that the results were unaffected despite varying the diffusion coefficient by two orders. They explained that this was because radial Peclet number was way higher than one hence, and the use of exact value of diffusion coefficient was not important.

But same is not true for microreactors where radial Peclet number can be near one (Serra et al. 2005b, 2007). As the polymerization reaction proceeds, the solution viscosity increases almost exponentially which lowers the value of diffusion coefficient of various chemical species in the solution. Different values of diffusion coefficient or continuous variation of diffusion coefficient can affect the simulation convergence and stability tremendously. So, the value of diffusion coefficient and its variation play an important role and offer a formidable task in case of simulation of FRP in microreactors unlike in macroreactors. Serra et al. (2005b, 2007) and Mandal et al. (2011) have simulated several geometries of flow microreactors for FRP but with constant fluid thermo-physical properties like density and viscosity to keep the problem manageable. Instead of continuously varying the diffusion coefficient during the simulations, they have conducted several simulations with discrete variation of diffusion coefficient to observe its effect on reaction as well as, to some extent, to mimic the effect of viscosity variation due to increase in monomer conversion. They have also used the transformation [Eqs. (1), (2), (5)–(7)] to model the respective variables as normalized and dimensionless passive scalars in CFD.

But the problem regarding the conversion of values of kinetic rate coefficients from molar to mass form remained. This conversion has not been clearly and logically defined and explained anywhere. We simply cannot feed the data in mass form in a kinetic rate expression which is obtained for molar form. For simpler expressions [Eq. (A1)], it might be fine, but for more complex expressions [e.g., Eq. (A2)], it is not straightforward. It may require several appropriate conversion factors to match the rate data in mass form with molar form. So, besides increasing its complexity, in absence of any such clear and logical method to convert the kinetic rate coefficient data from molar to mass form, simulation results using such values and expressions will always be seen with suspicion. Another problem is related to \(\mu_{0} ,\mu_{1} \,{\text{and}}\,\mu_{2}\). Since they are not physical quantities, so after the transformation, their range of variation is not limited to 0–1 as for the case of physical chemical species. They all are zero in the beginning, but with reaction they can increase beyond 1, especially \(\mu_{2}\). \(\mu_{0} \,{\text{and}}\,\mu_{1}\) can remain within 0-1 provided that transfer steps are limited to transfer to monomer only and do not include transfer to solvent and CTA (Scheme 1). Hence, it is very difficult to ascertain whether these quantities are actually conserved or not during CFD simulation.

In order to avoid all these problems and to bring more clarity and simplification in calculations, a new simple transformation for FRP is proposed in this work. Instead of applying the transformation to \(\mu_{0} ,\mu_{1} \,{\text{and}}\,\mu_{2}\), it is applied to kinetic rate coefficients, making them dimensionless in terms of concentration. It still retains all the desired purposes and properties of earlier Zhu’s transformation but it is more suitable for CFD. The new transformation is validated through numerical solution against analytical solution of FRP for homogeneous batch reactor. The use of this new transformation in CFD simulation of FRP is also validated against the experimental data under similar conditions. The CFD simulation results for FRP in microreactors are obtained using this new transformation and compared to published results and improvements are shown.

2 Mathematical model for flow

CFD-ACE+, a proven and commercial CFD software, was used for steady-state CFD modeling and simulation. The fluid was considered to be incompressible with constant density [Eq. (A31)] and constant viscosity. The flow was considered like a Newtonian laminar flow. Since the flow in the coiled tube reactor (CTR) was 3D, as used in validation, a compact form of equations was considered for CFD modeling and is presented below. The transient part vanishes for steady-state simulations.

-

1.

The conservation of mass (incompressible fluid)

$$\nabla \cdot u = 0$$(8) -

2.

The conservation of momentum—Navier–Stokes equation was used

$$\rho \frac{\partial u}{\partial t} + \rho \left( {u \cdot {\nabla }} \right)u = - {\nabla }p + {\nabla } \cdot \left( {\eta \left[ {{\nabla }u + \left( {{\nabla }u} \right)^{T} } \right]} \right)$$(9) -

3.

The conservation of energy with heat generation Q

$$\rho C_{\text{p}} \frac{\partial T}{\partial t} + {\nabla }\left( { - K{\nabla }T} \right) = Q - \rho C_{\text{p}} u \cdot {\nabla }T$$(10)where

$$Q = -\Delta H_{p} K_{p} \lambda_{0} M$$(11) -

4.

The conservation of chemical species

$$\frac{{\partial C_{i} }}{\partial t} + \nabla \cdot \left( { - D_{i} \nabla C_{i} + C_{i} u} \right) = R_{i}$$(12)

As already mentioned, various chemical species were modeled as passive scalars. So, the generation term R i (Eq. (12)) for each passive scalar is same as their respective reaction rate term, which is presented in detailed mathematical model for FRP, given in Appendix-A of ESM. It is this equation by which polymerization reaction is integrated to CFD modeling.

3 New transformation

Two simple and well-proven assumptions are required before applying the new transformation to the mathematical model for FRP (Appendix-A of ESM) to be used in CFD modeling. These are as follows:

-

1.

QSSA for live polymer radical chain length distribution, i.e., \(\lambda_{0} ,\lambda_{1} ,\,{\text{and}}\,\lambda_{2}\).

This assumption is fully valid before the gel effect sets in. However, as already mentioned, our previous work (Garg et al. 2014a, b, c) have also shown that the models with or without using QSSA gave similar results when set properly. So, this assumption decreases modeling complexity without reducing its quality. This helps in reducing computational power required for simulation by reducing the number of variables by three which are supposed to be evaluated numerically by solving ODE. Other researchers (Serra et al. 2005b, 2007; Mandal et al. 2011) have also used this assumption in their work. Thus, application of QSSA leads to Eqs. (B7)–(B9) for \(\lambda_{0} ,\lambda_{1} \,{\text{and}}\,\lambda_{2}\), respectively, as given in Appendix-B of ESM.

-

2.

The above assumption leads to another simple and practical assumption i.e., \(\bar{L} \gg 1\).

This assumption has been used by other researchers also (Konstadinidis et al. 1992; Achilias and Kiparissides 1992b; Serra et al. 2005b, 2007; Mandal et al. 2011). This assumption is quite reasonable as the value of \(\bar{L}\) is quite large and thus, it does not introduce significant error in the model and its outcome. It further simplifies the relationships among \(\lambda_{0} , \lambda_{1} ,\,{\text{and}}\,\lambda_{2}\), which are as follows:

Now, the new transformation for kinetic rate coefficients is as follows:

So, Eqs. (15)–(17) constitutes the new transformations where all terms marked with (′) are dimensionless in terms of concentration. \(K_{\text{d}}\) does not require any transformation as it is already dimensionless in terms of concentration. All the transfer rate coefficients like transfer to monomer \(K_{\text{fm}}\), transfer to solvent \(K_{\text{fs}}\) and transfer to CTA \(K_{\text{fa}}\) are connected to \(K_{\text{p}}\) through Eqs. (A18) to (A21) and (A24) to (A28). Similarly, \(K_{\text{t}}\) is connected to \(K_{\text{tc}} \,{\text{and}}\,K_{\text{td}}\) through Eqs. (A17), (A22) and (A23).

Applying this transformation results into the following relationships between their dimensionless and dimensional forms:

As such, we have no theoretical basis to derive this new transformation for kinetic rate coefficients as suggested above. So, proving the correctness of new transformation in the absence of theoretical basis for its derivation is difficult. But we have used other means to prove its correctness. By applying this new transformation in the mathematical model of FRP (Appendix-A of ESM) along with the aforementioned assumptions, few things can easily be observed. First observation is that by applying the proposed transformation on the right hand side of the Eqs. (13) to (15) for the dead polymer chain length distribution and then taking out the common factor in each equation, we will obtain the same form of the transformation (Eqs. (5)–(7)) as proposed by Zhu (1999). The only difference is that the latter transformation was applied to the whole equation directly, whereas we have got that form indirectly by applying transformation to concentration terms [Eqs. (1)–(4)] and kinetic rate coefficients. This proves the correctness of our proposed new transformation with respect to the old one. This also proves the claim of our new transformation about bringing the various variables (\(\mu_{0} , \mu_{1} \& \mu_{2}\)) values at the same order and thus helping in reducing stiffness and numerical error. Second, the form of all the equations (Eqs. (A1)–(A5) and (A9)–(A11)) before and after applying the transformation remains the same except for the fact that now the transformed terms are dimensionless in terms of concentration. This is a very significant advantage as this transformation does not introduce any new factor in any equation of the model to account for the transformation as is the case with Zhu’s transformation. This helps in coding and debugging the equations as the same form of equation is retained.

So, in a way, one can say that this proposed new transformation is a new way of achieving Zhu’s transformation but with an additional advantage of having kinetic rate coefficients dimensionless in terms of concentration and thus moles. Thus, this new transformation is more suitable for CFD modeling and simulation for FRP.

4 Validation

After applying QSSA to Eqs. (A6)–(A8), we obtained another mathematical model called as FRP_QSSA introduced firstly in our previous work (Garg et al. 2014a). An analytical solution (AS) was thus developed against FRP_QSSA for the MMA homogeneous isothermal batch reactor. The new transformation was first validated against this analytical solution (AS). For this, the new transformation was applied to both AS and FRP_QSSA and both were solved against time in Matlab R2008a. For FRP_QSSA, ODE solver ode15s was used. For MMA data used in this validation, please refer to Garg et al. (2014a). The results are presented later.

In the absence of validation against physical experimental data, the accuracy of simulation results cannot be ascertained. So, in this work, CFD simulation was performed using the new transformation and compared with experimental data (Serra et al. 2005a) obtained for the benzoyl peroxide (BPO) initiated polymerization of styrene with 30 % dilution in a coiled tube reactor (CTR). The details of the operating conditions and reactor are given in Table 1.

5 Meshing and boundary conditions

To observe any improvement using the new transformation in CFD simulation, it was applied to the numerical simulation of FRP of styrene in straight tube reactor (STR) with unmixed feed condition. This was done to compare the results using new transformation with published results (Serra et al. 2007) under similar conditions except for the fact that in the reference work, the chemical data were fed to simulations in mass form. The details of the operating conditions, physical and kinetic data can be found in Mandal et al. (2011).

A well-established and proven commercial CFD software package based on the finite volume method, CFD-ACE+ (Liu et al. 2002; Senn and Poulikakos 2004; Stutz and Poulikakos 2005; Dreher et al. 2010), was used for this purpose. CFD-GEOM was utilized to generate the geometry grid, while CFD-ACE and CFD-VIEW were used to process the problem and for the post-processing of the simulation results, respectively. CFD-ACE+ can accommodate structured and unstructured grid as well as simulate steady state as well as transient simulations.

The CFD geometry grid for STR was same as used by Mandal et al. (2011), so no additional separate mesh independency analysis was performed in this case. An unstructured grid was used for straight tube as shown in Fig. 1a, b. The geometry of CTR (required for validation with experimental work) was generated using CFD-GEOM with a structured square grid. A mesh independency analysis for fully mixed feed condition with constant density and viscosity was done for similar geometry and dimensions but with higher curvature and same chemical kinetic model. It was done at two levels—radial and axial. We took several radial meshing densities varying from very coarse meshing of 20 × 20 to very fine meshing of 100 × 100 for different values of axial meshing points. For all the different axial mesh densities investigated, we found that the results were independent of the radial mesh density. This was understandable as radial concentration gradients would be expected quite less under above stated conditions. So, we have chosen a 20 × 20 radial mesh for further studies. We also observed that the results were more dependent on axial (flow) direction mesh density. This was understandable due to inherent curvature of the geometry. For the given dimensions of the CTR investigated, the lesser curvature led to a limitation on the minimum number of points in each coil turn to maintain its circular geometry otherwise a polygon-like geometry is obtained. So, we worked with some higher numbers of mesh point per turn of coil with radial mesh density of 20 × 20 whose results are presented in Table 2. As no significant changes in the monomer conversion (\(X_{\text{M}}\)), number-average molecular weight (DP n ) and polydispersity index (PDI) were observed when the axial mesh point per coil turn was increased from 150 to 200, we selected for further studies 150 axial mesh point per coil turn. The final mesh of the CTR inlet (20 × 20) and volume grid are shown in Fig. 1c, d.

a Unstructured mesh for STR (Mandal et al. 2011) inlet, b volume grid of STR, c CTR inlet structured mesh, d structured volume grid of CTR

The flow, heat and scalar modules of CFD-ACE were used to model, respectively, the flow, heat effects due to chemical reaction and heat transfer through the fluid as well as across the reactor wall and the modeling of all the various chemical species as passive scalars with their respective reaction rates as generation terms. There were five passive scalars used for simulation: initiator, monomer, \(\mu_{0} ,\mu_{1} \,{\text{and}}\,\mu_{2}\). To reduce the numerical diffusion, a third order space discretization scheme was used for all variables like velocity, enthalpy and passive scalars. SIMPLEC was used for pressure–velocity coupling. Conjugated gradient squared (CGS)+ preconditioning solver was used for the velocity, enthalpy and all passive scalars. Algebraic multigrid (AMG) solver was used for pressure. All CFD simulations were taken to be steady state. Various relaxation parameters related to velocity, pressure and all passive scalars were adjusted in order to have simulations converge faster. All post-processing was done using CFD-VIEW.

The no-slip boundary conditions for the velocities, i.e., u i = 0, and the zero first derivative conditions for the passive scalars concentration were imposed on the solid wall implying zero diffusion flux of passive scalars through the wall. Flat concentration and velocity profiles were imposed at rector inlet. The value of average velocity at inlet was chosen to have a residence time of 12 h in STR and 2.5 h in CTR. The fluids considered in the study were assumed to be completely miscible in each other and to have similar and constant thermo-physical and chemical properties as given in Table 1 for CTR. The flow was modeled as Newtonian in nature. The wall of the pipe was maintained at a constant temperature of 70 °C (isothermal condition). The numerical computation was found to be converged when the error residual added over all the computational nodes is \({\le} 10^{ - 6}\) for pressure p, velocity u i and all passive scalars.

6 Results

First of all, the result is presented for theoretical validation of the new transformation. As shown in Fig. 2, the plots are obtained for all five passive scalars which are transformed variables as well. Since the new transformation is applied to both FRP_QSSA and AS, so both the results should match if it is correct. Furthermore, since the reactor studied is a batch reactor and so working in transient regime, results were plotted against time. As can be seen in Fig. 2, results of AS matched exactly with that of FRP_QSSA, hence, only one color is prominently visible in the graphs for all the variables shown for isothermal homogeneous batch reactor. Another thing that can be observed is that all the variables (passive scalars) are of the same order as desired and expected except for \(\lambda_{0}\) which is not modeled as passive scalar. This validates that the new transformation is theoretically correct and also works for the AS under batch reactor condition (dynamic condition).

It is now extended to flow reactor steady-state conditions. For this, CFD simulation of FRP of styrene under flow in STR microreactor is modeled with new transformation. The results are compared with published results (Serra et al. 2007) under similar conditions in Figs. 3, 4 and 5 on semi-log plots with diffusion coefficient on x-axis (log-scale). This enables to view the effect of variation of diffusion coefficient on various polymer properties in STR microreactor.

Comparison for \(X_{\text{M}}\) (monomer conversion) between present work and Serra et al. (2007)

Comparison for \({\text{PDI}}\) (polydispersity index) between present work and Serra et al. (2007)

Comparison for \({\text{DP}}_{n}\) (number-average molecular weight) between present work and Serra et al. (2007)

As can be seen, Fig. 3 shows slight differences for \(X_{\text{M}}\) and Fig. 4 shows a very good match for \({\text{PDI}}\). But the most significant differences between the results of two works can be observed for \({\text{DP}}_{n}\) in Fig. 5. This large difference in \({\text{DP}}_{n}\) values requires some theoretical explanation as well as validation against experimental data. This is necessary so as to prove that these new results using the new transformation are indeed correct, and significant deviations from the earlier published results are not due to either numerical or modeling error. Detailed explanation of all these results under flow condition in STR is presented in discussion section.

For this, FRP with mixed feed condition in CTR microreactor is modeled using new transformation and simulated using CFD. Its results are compared with experimental data (Serra et al. 2005a) under similar conditions. The Table 3 shows the results for both the CFD simulation and the experimental data. As can be seen, the simulation results matches satisfactorily with the experimental data under the simplified assumptions using the new transformation. It also shows that the new transformation improves the \({\text{DP}}_{n}\) prediction as the value predicted for \({\text{DP}}_{n}\) using CFD is quite near to experimental value. So, we can easily conclude that the higher values shown in Fig. 5 for \({\text{DP}}_{n}\) are actually an improvement in modeling of FRP due to the new transformation and not a numerical or modeling error.

7 Discussion

In this work, a new transformation is proposed which is applied to various kinetic rate coefficients of FRP, making them dimensionless in terms of concentration. This indirectly helps in making three non-physical mathematical variables \(\mu_{0} ,\mu_{1} \,{\text{and}}\,\mu_{2}\) dimensionless in terms of concentration besides normalizing them with the form similar to the one given by Zhu (1999) [Eqs. (5)–(7)]. So, it partly proves the correctness of this new transformation. The claim of normalization of \(\mu_{0} ,\mu_{1} \,{\text{and}}\,\mu_{2}\) is clearly validated by the results shown in Fig. 2 where the order of the magnitude of their values is same. Only molar form of data is used for the results shown in Fig. 2 where AS is compared with FRP_QSSA after applying the new transformation for both. Another interesting thing that can be noticed in the plot of \(\mu_{1} \,{\text{and}}\,\mu_{2}\) in Fig. 2 is that their values go beyond 1 after certain time as predicted in introduction earlier. As mentioned, \(\mu_{0} \,{\text{and}}\,\mu_{1}\) values can be limited within 0–1 for the case of transfer steps limited to transfer to monomer only. This can be checked from Eqs. (B10) and (B11) (Appendix-B of ESM) where \(\mu_{0} \,{\text{and}}\,\mu_{1}\) can be found to be function of \(I\,{\text{and}}\,M\), respectively, under this condition, which is same as Zhu’s transformation. This not only shows the importance of the new transformation in CFD but also validates the results using this transformation. This can be claimed because AS results, against which validation is made, are without any numerical error and absolute in value.

As we can see from Eqs. (18) to (21), various terms like \(\lambda_{0}^{{\prime }}\), \(L^{'}\) and \({\text{DP}}_{n}\) are not completely independent of initial values of initiator, \(I_{0}\) and monomer, \(M_{0}\) except for \({\text{PDI}}\). Since the final form of transformation for \(\mu_{0} ,\mu_{1} \,{\text{and}}\,\mu_{2}\) is same in both Zhu (1999) and new transformation, \({\text{PDI}}\) and \({\text{DP}}_{n}\) will have same expression using \(\mu_{0} ,\mu_{1} \,{\text{and}}\,\mu_{2}\). So, one can wonder as to what is the importance of the initial concentration values on the final values of conversion, \({\text{PDI}}\) and \({\text{DP}}_{n}\) as visible in the Figs. 3, 4 and 5.

It can be seen that AS (Garg et al. 2014a) for initiator concentration, i.e.,

is of first order with respect to \(I\), initiator concentration and only one concentration term is present. So, applying the transformation of Eq. (1), \(I\) will become dimensionless in terms of concentration and units (mass or molar), and value of concentration term will have no effect on the solution of this \(I^{{\prime }}\) (passive scalar1). Final value of \(I\) can simply be obtained by multiplying it by \(I_{0}\).

But this is not the case for \(M\), monomer concentration. AS (Garg et al. 2014a) for monomer concentration is

Eq. (B3) is first order in \(M\) but of complex order in \(I\). So, after applying Zhu’s transformation (Zhu 1999) for monomer concentration (Eq. 2), the dimensionless monomer concentration is injected into Eq. (B3). It can be seen that the result is still dependent on \(I_{0}\). So, the value of \(I_{0}\), depending on the units chosen (mass or molar), will have impact on evaluation of \(M^{{\prime }}\) and ultimately on \(M\). So, this could be the possible reason for the discrepancy observed between monomer conversions as shown in Fig. 3.

In case of \({\text{PDI}}\), as can be seen in Eq. (21), it is totally independent of initial values of initiator and monomer concentrations. So, whatever may be the individual values of \(\mu_{0} , \mu_{1} \,{\text{and}}\, \mu_{2}\), their ratio as given in Eq. (21) will still give the same result for diffusive flow in the absence of any convective mixing in straight tube microreactor. In our case, the main source of radial mixing is due to diffusion which is not affected by transformation. This is clearly visible in Fig. 4.

As for \({\text{DP}}_{n}\), as can be seen in Eq. (20), it is strongly dependent on the ratio of initial concentration values of both initiator and monomer. Besides this, the value of \(\mu_{1}\) is dependent on the calculation of \(M\) also. So, the choice of units (mass or molar) and thus the values will definitely affect the final value of \({\text{DP}}_{n}\). This is the most probable theoretical reason for the large discrepancy observed in Fig. 5 and this requires further validation especially with physical experimental data. Now, the CFD simulation results using the new transformation match quite well with the experimental data as shown in Table 3 and this validates our reasoning. It is noteworthy that \({\text{DP}}_{n}\) simulated values are quite near to the experimental one (Serra et al. 2005a). So, there should not be any doubt about the validity of the new transformation proposed in this work.

In our opinion, the discrepancy between our current results and Serra et al. (2007) is not because of any modeling error or numerical error in simulation. The discrepancy probably arises because compared to us, they have used different transformation in modeling which requires the data to be fed in mass form. Their modeling is affected by the units as well as by the numerical value of the initial concentrations of initiator and monomer and this has affected their subsequent results. The new results, thus, should be seen as the outcome of improvement in the modeling by use of the new transformation rather than due to incorrect data or as error.

8 Conclusion

A new transformation is proposed in this work for the mathematical model of FRP with two simple and reasonable assumptions. The new transformation makes the kinetic rate coefficients dimensionless in terms of concentration. This has three distinct benefits. First, kinetic rate coefficient data can now be fed in molar form in CFD simulations instead of mass form. Second, \(\mu_{0} ,\mu_{1} \,{\text{and}}\,\mu_{2}\) are indirectly normalized, without introducing any new normalizing factor, in the same way, it was first proposed by Zhu (1999) to reduce stiffness and numerical error. And lastly, the form of equations of all the variables, that need to be transformed, remains unchanged hence enable easy coding and debugging. This new transformation is basically a different way of implementing Zhu’s transformation but in a more suitable and adoptable way with added advantages for CFD modeling and simulation of FRP. This is important especially in microreactors where diffusion is important and can have significant impact on simulation convergence and stability. Validation of this new transformation was necessary so it was first validated against the AS (Garg et al. 2014a) for homogeneous batch reactor. Then, the CFD results were compared for FRP in STR with published results (Serra et al. 2007). Slight difference in \(X_{\text{M}}\), no difference for \({\text{PDI}}\) and most significant differences for \({\text{DP}}_{n}\) values were observed. Results for \(X_{\text{M}}\) could easily be explained through AS for initiator and monomer, whereas results for \({\text{PDI}}\,{\text{and}}\,{\text{DP}}_{n}\) could easily be explained from their transformed expressions. To check the correctness of predictions for \({\text{DP}}_{n}\) values using the new transformation, it was validated against the physical experimental data for FRP in CTR microreactor (Serra et al. 2005a). The results were in good agreement. The main contribution of this new transformation is the improved CFD simulation prediction of \({\text{DP}}_{n}\) in microreactors compared to the use of Zhu’s transformation. Hence, the new transformation can be accepted as an improvement in the modeling of FRP in CFD problems.

Abbreviations

- \(A\) :

-

Chain transfer agent concentration at any time \(t\) (mol/l)

- \(A_{\text{H}}\) :

-

Area for heat transfer (m2)

- \(C_{\text{A}}\) :

-

\({=} \frac{{K_{fa} }}{{K_{p} }}\) (dimensionless)

- \(C_{\text{b}}\) :

-

Bulk monomer concentration (mol/l)

- \(C_{\text{M}}\) :

-

\({=} \frac{{K_{{\text{fm}}} }}{{K_{\text{p}} }}\) (dimensionless)

- \(C_{\text{p}}\) :

-

Specific heat capacity of mixture [cal/(g °C)]

- \(C_{\text{S}}\) :

-

\({=} \frac{{K_{{\text{fs}}} }}{{K_{\text{p}} }}\) (dimensionless)

- \(C_{\text{T}}\) :

-

\({=} \frac{{K_{{\text{td}}} }}{{K_{{\text{tc}}} }}\) (dimensionless)

- \({\text{DP}}_{n}\) :

-

Number-average degree of polymerization

- \(I\) :

-

Initiator concentration (mol/l)

- \(K_{d}\) :

-

Dissociation rate coefficient (min−1)

- \(K_{{\text{fa}}}\) :

-

Transfer to CTA rate coefficient [l/(mol min)]

- \(K_{{\text{fm}}}\) :

-

Transfer to monomer rate coefficient [l/(mol min)]

- \(K_{{\text{fs}}}\) :

-

Transfer to solvent rate coefficient [l/(mol min)]

- \(K_{\text{i}}\) :

-

Kinetic rate constant for initiation (s−1)

- \(K_{\text{p}}\) :

-

Propagation rate coefficient [l/(mol min)]

- \(K_{{\text{pr}}}\) :

-

\({=} K_{\text{p}} + K_{{\text{fm}}} = (1 + C_{\text{M}} )K_{\text{p}}\) [l/(mol min)]

- \(K_{\text{t}}\) :

-

\({=} K_{{\text{tc}}} + K_{{\text{td}}}\) [l/(mol min)]

- \(K_{{\text{tc}}}\) :

-

Termination by combination rate coefficient [l/(mol min)]

- \(K_{{\text{td}}}\) :

-

Termination by disproportionation rate coefficient [l/(mol min)]

- \(L\) :

-

Kinetic chain length, \({=} \frac{{K_{{\text{pr}}} M\lambda_{0} }}{{2fK_{\text{d}} I}}\)

- \(\bar{L}\) :

-

\({=} L\left( {\frac{{1 - R_{{\text{MM}}} }}{{1 + R_{\text{P}} L}}} \right) = L\left( {\frac{{1 - R_{\text{M}} }}{{1 + R_{\text{P}} L}}} \right)\)

- \(M\) :

-

Monomer concentration (mol/l)

- \({\text{MW}}\) :

-

Molecular weight (g/mol)

- \({\text{MW}}_{n}\) :

-

Number-average chain length of polymer (g/mol)

- \({\text{MW}}_{\text{w}}\) :

-

Weight averaged chain length of polymer (g/mol)

- \({\text{PDI}}\) :

-

Polydispersity index (dimensionless)

- \(P_{n}\) :

-

Dead polymer chain length of n no. of monomer units

- \(R\) :

-

Universal gas constant (1.986 cal/mol/K)

- \(R_{0}\) :

-

Zero order radical obtained from initiator dissociation

- \(R_{\text{A}}\) :

-

\({=} \frac{{C_{\text{A}} }}{{1 + C_{\text{M}} }} = \frac{{K_{\text{fa}} }}{{K_{\text{pr}} }}\)

- \(R_{\text{AM}}\) :

-

\({=} \frac{{C_{\text{A}} }}{{1 + C_{\text{M}} }} \frac{A}{M} \approx \frac{{C_{\text{A}} }}{{1 + C_{\text{M}} }} \frac{{A_{0} }}{{M_{0} }}\)

- \(R_{\text{M}}\) :

-

\({=} \frac{{K_{\text{fm}} }}{{K_{\text{p}} + K_{\text{fm}} }} = \frac{{K_{\text{fm}} }}{{K_{\text{pr}} }} = \frac{{C_{\text{M}} }}{{1 + C_{\text{M}} }}\)

- \(R_{\text{MM}}\) :

-

\({=} R_{\text{M}}\)

- \(R_{n}\) :

-

Live polymer chain length of n no. of monomer units

- \(R_{\text{P}}\) :

-

\({=} R_{\text{MM}} + R_{\text{SM}} + R_{\text{AM}} = R_{\text{MM}} + R_{\text{SA}}\)

- \(R_{\text{S}}\) :

-

\({=} \frac{{C_{\text{S}} }}{{1 + C_{\text{M}} }} = \frac{{K_{\text{fs}} }}{{K_{\text{pr}} }}\)

- \(R_{\text{SA}}\) :

-

\({=} R_{\text{SM}} + R_{\text{AM}}\)

- \(R_{\text{SM}}\) :

-

\({=} \frac{{C_{\text{S}} }}{{1 + C_{\text{M}} }} \frac{S}{M} \approx \frac{{C_{\text{S}} }}{{1 + C_{\text{M}} }} \frac{{S_{0} }}{{M_{0} }}\)

- \(R_{\text{T}}\) :

-

\({=} \frac{{K_{\text{tc}} }}{{K_{\text{tc}} + K_{\text{td}} }} = \frac{{K_{\text{tc}} }}{{K_{\text{t}} }} = \frac{1}{{1 + C_{\text{T}} }}\) (dimensionless)

- \(S\) :

-

Solvent concentration any time \(t\) (mol/l)

- \(T\) :

-

Temperature (K)

- \(T_{\text{bath}}\) :

-

Temperature of heat sink (K)

- \(U\) :

-

Overall heat transfer coefficient (W/m2/K)

- \(V_{\text{R}}\) :

-

Volume of solution at any time t (l)

- \(V_{{{\text{R}}_{0} }}\) :

-

Initial volume of solution at t 0 (l)

- \(f\) :

-

Initiator efficiency (dimensionless)

- \(f_{\text{s}}\) :

-

Solvent volume fraction (dimensionless)

- \(t\) :

-

Time (min)

- u :

-

Velocity (m/s)

- \(x_{\text{M}}\) :

-

Monomer conversion (dimensionless)

- \(y\) :

-

\({=} {\text{e}}^{{\frac{{ - K_{\text{d}} \cdot t}}{2}}}\), variable evaluated in the analytical solution

- \(\Delta H_{\text{P}}\) :

-

Heat of reaction (cal/mol)

- \(\beta\) :

-

Ratio of solvent volume to non-solvent volume (dimensionless)

- \(\varepsilon\) :

-

Volume contraction factor corrected for solvent volume fraction (dimensionless)

- \(\varepsilon_{0}\) :

-

Volume contraction factor without solvent volume fraction (dimensionless)

- \(\lambda_{0}\) :

-

Zeroth order moment for live polymer chain concentration (mol/l)

- \(\lambda_{1}\) :

-

First order moment for live polymer chain concentration (mol/l)

- \(\lambda_{2}\) :

-

Second order moment for live polymer chain concentration (mol/l)

- \(\mu_{0}\) :

-

Zeroth order moment for dead polymer chain concentration (mol/l)

- \(\mu_{1}\) :

-

First order moment for dead polymer chain concentration (mol/l)

- \(\mu_{2}\) :

-

Second order moment for dead polymer chain concentration (mol/l)

- \(\rho\) :

-

Mixture density (g/cm3)

- \(\varPhi\) :

-

Volume fraction (dimensionless)

- \(\eta\) :

-

Dynamic viscosity (cP)

- \(\left[ \eta \right]\) :

-

Intrinsic viscosity of the polymer (dl/g)

- M :

-

Monomer

- P :

-

Polymer

- S :

-

Solvent

- I :

-

Initiator

- 0:

-

At time t = 0

References

Achilias DS, Kiparissides C (1992a) Development of a general mathematical framework for modeling diffusion-controlled free-radical polymerization reactions. Macromolecules 25(14):3739–3750

Achilias DS, Kiparissides C (1992b) Toward the development of a general framework for modeling molecular weight and compositional changes in free-radical copolymerization reactions. J Macromol Sci Part C Polym Rev 32(2):183–234

Baillagou PE, Soong DS (1985a) Major factors contributing to the nonlinear kinetics of free-radical polymerization. Chem Eng Sci 40(1):75–86

Baillagou PE, Soong DS (1985b) Free-radical polymerization of methyl-methacrylate in tubular reactors. Polym Eng Sci 25(4):212–231

Cabral PA, Melo PA, Biscaia EC, Lima EL, Pinto JC (2003) Free-radical solution polymerization of styrene in a tubular reactor—effects of recycling. Polym Eng Sci 43(6):1163–1179

Chen CC (1994) A continuous bulk-polymerization process for crystal polystyrene. Polym Plast Technol 33(1):55–81

Chen CC (2000) Continuous production of solid polystyrene in back-mixed and linear-flow reactors. Polym Eng Sci 40(2):441–464

Costa EF, Lage PLC, Biscaia EC (2003) On the numerical solution and optimization of styrene polymerization in tubular reactors. Comput Chem Eng 27(11):1591–1604

Dreher S, Engler M, Kockmann N, Woias P (2010) Theoretical and experimental investigations of convective micromixers and microreactors for chemical reactions. In: Bockhorn H, Mewes D, Peukert W, Peukert H-J (eds) Micro and macro mixing, heat and mass transfer. Springer, Berlin, pp 325–346

Garg DK, Serra CA, Hoarau Y, Parida D, Bouquey M, Muller R (2014a) Analytical solution of free radical polymerization: derivation and validation. Macromolecules 47(14):4567–4586

Garg DK, Serra CA, Hoarau Y, Parida D, Bouquey M, Muller R (2014b) Analytical solution of free radical polymerization: applications-implementing gel effect using CCS model. Macromolecules. doi:10.1021/ma501251j

Garg DK, Serra CA, Hoarau Y, Parida D, Bouquey M, Muller R (2014c) Analytical solution of free radical polymerization: applications-implementing gel effect using AK model. Macromolecules 47(21):7370–7377

Hui AW, Hamielec AE (1972) Thermal polymerization of styrene at high conversions and temperatures. An experimental study. J Appl Polym Sci 16:749–769

Keramopoulos A, Kiparissides C (2002) Development of a comprehensive model for diffusion-controlled free-radical copolymerization reactions. Macromolecules 35(10):4155–4166

Konstadinidis K, Achilias DS, Kiparissides C (1992) Development of a unified mathematical framework for modelling molecular and structural changes in free-radical homopolymerization reactions. Polymer 33(23):5019–5031

Liu RH, Yang J, Grodzinski P, Pindera MJ, Athavale M (2002) Bubble-induced acoustic micromixing. Lab Chip 2(3):151–157

Mandal MM, Serra C, Hoarau Y, Nigam KDP (2011) Numerical modeling of polystyrene synthesis in coiled flow inverter. Microfluid Nanofluidics 10(2):415–423

Senn SM, Poulikakos D (2004) Laminar mixing, heat transfer and pressure drop in tree-like microchannel nets and their application for thermal management in polymer electrolyte fuel cells. J Power Sources 130(1–2):178–191

Serra C, Sary N, Schlatter G (2005a) A multiphysics approach of the styrene free radical polymerization modeling performed in different microreactors. In: Proceedings of conference FemLab, Paris (France), 15 Nov

Serra C, Sary N, Schlatter G, Hadziioannou G, Hessel V (2005b) Numerical simulation of polymerization in interdigital multilamination micromixers. Lab Chip 5(9):966–973

Serra C, Schlatter G, Sary N, Schonfeld F, Hadziioannou G (2007) Free radical polymerization in multilaminated microreactors: 2D and 3D multiphysics CFD modeling. Microfluid Nanofluidics 3(4):451–461

Stutz MJ, Poulikakos D (2005) Effects of microreactor wall heat conduction on the reforming process of methane. Chem Eng Sci 60(24):6983–6997

Zhu S (1999) Modeling of molecular weight development in atom transfer radical polymerization. Macromol Theor Simul 8(1):29–37

Acknowledgments

The financial support by ANR Grant No. 09-CP2D-DIP2 is greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Garg, D.K., Serra, C.A., Hoarau, Y. et al. New transformation proposed for improving CFD simulation of free radical polymerization reactions in microreactors. Microfluid Nanofluid 18, 1287–1297 (2015). https://doi.org/10.1007/s10404-014-1527-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10404-014-1527-3