Abstract

The main aim is to develop a simple, rugged, and sensitive method for determining the Montelukast Sodium-related impurities in a tablet dosage form using reverse-phase high-performance liquid chromatography (RP-HPLC) method. Chromatographic separation on the Agilent Eclipse XDB C18 (octadecylsilane) column of the dimension (100 mm × 4.6 mm, 5 µm) was carried out in the gradient mode with triethylamine and acetonitrile in various combinations and adjusted to a pH of 6.60 using phosphoric acid. The mobile phase was pumped at a flow rate of 1.0 mL min−1 and the analyte was monitored with a UV detector at a wavelength of 220 nm. The method was developed and validated under the stress conditions such as acidic, basic, peroxide, thermal, photolytic, and humidity degradation, respectively. Under the above conditions, oxidative degradation was performed which served as the system suitability solution providing a resolution of 2.5 between the Impurity 3 (retention time = 13.8 min) and Montelukast Sodium (retention time = 24.2 min). The method was validated with respect to specificity, linearity, precision, accuracy, limit of detection, and limit of quantification provided by the ICH guidelines. Results of linear regression analysis of the calibration plot revealed a good linear relationship between response and concentration with a correlation coefficient value of r2 = 0.9999. The accuracy of known impurities was obtained in the range of 94–108%. From the analysis, their LOD and LOQ values for impurities were measured and found to be 0.007 and 0.025 μg g−1, respectively. Chromatographic interference was not found during the degradation and excipients were detected from the tablet. The proposed method was successfully used to estimate the Montelukast Sodium-related impurities in a tablet dosage form.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Montelukast Sodium is a synthetic leukotriene receptor antagonist and an anti-asthmatic agent. Its chemical name is 2-[1-[[(1R)-1-[3-[(E)-2-(7-chloroquinolin-2-yl) ethenyl] phenyl]-3-[2-(2-hydroxypropan-2yl) phenyl] propyl] sulfanylmethyl] cyclopropyl] acetic acid, monosodium salt [1, 2] and is recommended for the treatment of asthma in children and adults. It is an exclusive leukotriene modifier approved by the US Food and Drug Administration (FDA) in 2008 to be used by young people from 2 to 12 years of age and adults [3, 4]. Montelukast Sodium’s empirical formula is C35H35ClNaO3S and it has a molecular weight of 608.18 g mol−1. It is readily soluble in ethanol, methanol, and water, and is virtually insoluble in acetonitrile [5]. It is a hygroscopic, optically active, white powder [6]. The value of its Log P is 7.9. The primary side effects include seizures, paraesthesia, angioedema, muscle cramps, liver disorders, and erythema multiforme [2].

Montelukast Sodium is sensitive to light, when exposed to light, it becomes unstable and cis-isomer (Impurity 4, Table 1) is formed as a result of photo-degradation. High levels of sulphoxide impurities were also observed when exposed to atmospheric oxygen. If the solution is in contact with the atmosphere for a long time, it chemically deteriorates [4].

Organic impurities might be produced during the storage and manufacturing of Active Pharmaceutical Ingredient (API) or pharmaceutical products. Its permissible limit is based on drug research or known safety data. If the content of such impurities in the drugs reaches the prescribed level, it may harm the patients and, in some cases, it may also jeopardize their life. These impurities play a vital role in the safety and effectiveness of drugs. As per the regulatory guidelines such as The International Council for Harmonisation (ICH), these impurities have to be controlled to specified limits.

Literature survey reveals that several methods are reported for the estimation of Montelukast sodium using high-performance liquid chromatography [7, 8], reverse phase high-performance liquid chromatography (RP-HPLC) with UV spectrophotometry [9, 10], Capillary electrophoresis [11] and cyclic voltammetry [12]. However, there are limited methods for the determination of Montelukast Sodium-related impurities by RP-HPLC. To the best of our knowledge, so far four potential impurities of Montelukast Sodium were already identified in the literature [13] and the relative response factor (RRF) of these impurities is unexplored. There is no method available to reach a satisfactory level to cover the process cum degradation impurities. USP method also has the limitation of poor column life, separation of sulfoxide impurities which are not adequately resolved and needs to be integrated together to determine conformance [14].

The objective of the research work reported in this paper is to develop a suitable stability-indicating method to estimate the process and degradation impurities of Montelukast Sodium (Impurity 1–8) in dosage form to prevail over the published researches. The method was validated with required parameters such as precision, specificity, linearity, accuracy, LOD, LOQ, and robustness following the ICH guidelines to check whether the developed method meets the regulatory requirements.

Experimental Section

Chemicals and Reagents

Montelukast Sodium standard and its impurities standards were obtained from Orchid Pharma Ltd. Montelukast Sodium tablets (Singulair) were purchased from a pharmacy. Each 10-mg film-coated (Singulair) tablet contains 10.4 mg Montelukast Sodium, which is equivalent to 10 mg of Montelukast containing the following inactive ingredients (placebo) microcrystalline cellulose, lactose monohydrate, croscarmellose sodium, hydroxypropyl cellulose, and magnesium stearate. The film coating consists of hydroxypropyl methylcellulose, hydroxypropyl cellulose, titanium dioxide, red ferric oxide, yellow ferric oxide, and carnauba wax, respectively. Analytical grade reagents (such as potassium dihydrogen phosphate, ammonium acetate, triethylamine, phosphoric acid, hydrochloric acid, sodium hydroxide, and sodium peroxide) were acquired from Merck's specialties private limited, Mumbai. HPLC-grade solvents (such as water, methanol, and acetonitrile) were acquired from Rankem Private Limited, Mumbai.

Instrumentation

The development and validation activities were accomplished using Agilent 1200 (Agilent Technologies, California, the United States) high-performance liquid chromatography (HPLC) system equipped with a low-pressure quaternary gradient pump along with a PDA detector, column oven, auto-sampler, and Waters Empower 3 software. The weighing of the mobile phase reagents, standard and impurities were measured using the Sartorius E2 analytical balance. The pH of the mobile phase was adjusted using a Metrohm printable pH meter. The mobile phase was filtered through a 0.22 mm filter paper using a glass vacuum-filtration apparatus. The dissolved gas and the air bubbles ensnared in the mobile phase were removed using an ultrasonic bath. The samples were centrifuged using Beckman Coulter Life Sciences, Allegra 64R, with a thermostatic cooler system. Thermo Fisher heating oven was used for stress studies.

Operating Conditions

HPLC method development, validation, and analysis of solutions from forced degradation studies were performed with an Agilent 1200 series HPLC system with photo diode-array detection. Chromatographic separations were achieved on a 150 mm, 4.6 mm i.d., 5-µm particle size, Agilent Eclipse XDB C18 column with a mobile phase gradient prepared from 0.1% aqueous Triethylamine and adjusted to pH 6.6 with orthophosphoric acid, in the composition of 70:30 (v/v) pH 6.6 buffer–acetonitrile (mobile phase A) and 15:85 (v/v) pH 6.6 buffer–acetonitrile (mobile phase B). The gradient programme (time (min)/percentage B) was 0/4, 4/4, 20/40, 40/90, 50/90 and 55/4, with a post-run time of 10 min with a constant flow rate 1.0 mL min−1. The column temperature was maintained at 30 °C and detection was performed at 220 nm. The test concentration was approximately 500 µg mL−1 and the injection volume was 20 µL. Data were collected and Montelukast peak purity was checked using Empower 2 software. Calculate the percentage of each impurity in the portion of Montelukast Sodium taken:

rU = peak area from the sample solution, rS = peak area from the standard solution, CS = concentration of Montelukast Sodium in the standard solution (mg mL−1), CU = concentration of Montelukast Sodium in the sample solution (mg mL−1) and F = relative response factor.

Preparation of Chromatographic Solutions

Preparation of Standard Solution

The standard solution was prepared following the Montelukast Sodium standard. An accurately weighed quantity of Montelukast Sodium standard was dissolved in 15:85 (v/v) water–methanol (diluent) to obtain a solution having a known concentration of about 2.5 (µg mL−1).

Preparation of Sample Solution

The sample solution was prepared from Montelukast Sodium tablets. Using a mortar and pestle, the tablets (around 20) were pulverized into a fine powder. Accurately weighed quantity of Montelukast Sodium tablets was dissolved in 15:85 (v/v) water–methanol to obtain a solution having a known concentration of about 500 µg mL−1 equivalent to Montelukast.

Preparation of System Stability

The system stability solution was carefully prepared by the oxidative degradation process. Accurately weighed 50 mg of Montelukast Sodium standard was transferred to a 100 mL volumetric flask and 20 mL of 15:85 (v/v) water–methanol was added. Then 5 mL of 3% v/v of peroxide solution was added. Finally, the volumetric flask is prepared with the further addition of the 15:85 (v/v) water–methanol.

Preparation of Placebo Solution

An accurately weighed placebo powder, equivalent to 25 mg of Montelukast Sodium (Weight of placebo to be taken (mg) = Weight of powdered tablets equivalent to 25 mg of Montelukast Sodium (mg)–26 mg), was transferred into a 50 ml volumetric flask. Then about 30 mL of 15: 85 (v/v) water–methanol was added. The solution was sonicated for about 20 min with intense shaking and then diluted to volume with 15:85 (v/v) water–methanol. A part of the solution is then taken in a 10 mL centrifuge tube and centrifuged at 2500 rpm for 5 min. The topmost layer is then filtered using a 0.45 μm PVDE.

Stress Degradation Studies of Montelukast Sodium

For stress degradation study, the solutions were prepared using tablets of Montelukast Sodium. Using a mortar and pestle, around 10 tablets were pulverized into a fine powder and mixed rigorously to produce a homogeneous powder. Accurately weighed Montelukast Sodium powdered tablets equivalent to 25 mg of Montelukast Sodium was transferred into a 50 mL volumetric flask and 20 mL of 15:85 (v/v) water–methanol was added. Then it was treated with 5 mL of 5 N HCl solution (for acid degradation), 5 mL of 5 N NaOH solution (for base degradation) and 5 mL of 3%v/v of H2O2 solution (for peroxide degradation). In case of thermal degradation, 25 mg of Montelukast Sodium was kept in an oven in powdered form at 100 °C for 16 h and then added into a 50 mL volumetric flask. Then 20 mL of 15:85 (v/v) water–methanol was added. The solution was then sonicated for about 20 min with vigorous shaking and then mixed with 15:85 (v/v) water–methanol. Further, a part of each solution is taken in a 10 mL centrifuge tube and rotated at 2500 rpm for 5 min. The topmost layer is then filtered a using sample filter of 0.45 µm PVDE. In case of photolytic degradation study, an accurately weighed quantity of powdered Montelukast Sodium tablets equivalent to 25 mg of Montelukast Sodium was exposed to 200 W-hours/square meter and 1.2 Million lux hours and added into a 50 mL volumetric flask. Then 20 mL of 15:85 (v/v) water–methanol was added. The solution was sonicated for about 20 min with vigorous shaking and the volumetric flask was kept on the top of a bench for about ten minutes adding 15:85 (v/v) water. The topmost layer is then filtered using a sample filter of 0.45 µm PVDE. In case of humidity study, accurately weighed quantity of powdered Montelukast Sodium tablets equivalent to 25 mg was exposed to humidity at 25 °C; 97% RH for 74 h; and was transferred into a 50 mL volumetric flask. Then, 20 mL of 15:85 (v/v) water–methanol was added. The solution was sonicated for about 20 min with vigorous shaking and the volumetric flask was prepared with the further addition of the 15:85 (v/v) water–methanol. The topmost layer is then filtered using a sample filter of 0.45 µm PVDE.

Method Validation

Specificity

The specificity of the RP-HPLC method was evaluated to ensure that there is not any interference in the excipients present in the formulations. The specificity was studied by injecting impurities, through degradation products and excipients. The test was performed by adding known Impurities individually, about 0.20% of Impurities 1, 2, 5, 6 and 8 (unspecified impurity which is limited but not more than 0.20%) whereas 0.5% of Impurities 3, 4 and 7 (specified impurity which is controlled but not more than 0.5%) with Montelukast Sodium concentration [14,15,16].

Linearity

Linearity is the ability to obtain the test results that are directly proportional to the analyte concentration. Linearity was determined by five different concentrations (0.1, 1.3, 2.6, 3.9 and 5.2 µg mL−1) of Montelukast Sodium and its known impurities (LOQ level to 200% of specification limit). Impurities 3, 4 and 7 are the potential impurities (Specified impurity) which are limited by not more than 0.5% and the remaining Impurities 1, 2, 5, 6 and 8 are unspecified impurities, which are present in the sample that is lesser than the reporting threshold. As per the European pharmacopeia general chapter (5.10) [16,17,18,19,20], three specified impurities were taken for the linearity study and the values of their peak area versus concentration were plotted. To calculate the coefficient of correlation, slope, and intercept using linearity curve extrapolation.

Precision

The precision of an analytical method is the degree of agreement amongst individual test results when the method is applied repeatedly to multiple sampling of a homogeneous sample. The precision of the analytical method is usually expressed as the standard deviation or relative standard deviation (coefficient of variation) of series of measurements. The system precision, method precision (Repeatability) and intermediate precision (Reproducibility or Ruggedness) of the proposed methods were determined by several measurements of known Impurities 3, 4 and 7, respectively [14,15,16].

System precision was established by performing six different measurements of the known standard Montelukast Sodium at 2.5 (µg mL−1). Method precision was determined by six individual preparation of Montelukast Sodium spiked with (2.5 µg mL−1) of Impurities 3, 4, and 7, respectively. Intermediate precision was performed with different instruments and different columns by different analysts on different days. The percentage RSD of each impurity and total impurities were calculated and recorded in the table.

Accuracy

The accuracy of an analytical method is the nearness between the expected value and the value found. It is obtained by calculating the percent recovery (% R) of the analyte recovered. A study of recovery was performed on LOQ (0.1 µg mL−1), 50% (1.25 µg mL−1), 100% (2.5 µg mL−1), 150% (3.75 µg mL−1) and 200% (5 µg mL−1) of the target concentration of each impurity (2.5 µg mL−1) by spiking (n = 3) with 500 µg mL−1 of Montelukast Sodium. Spiked samples were extracted and analyzed. Then the % recovery and its relative standard deviation were calculated [14,15,16].

Limit of Detection (LOD) and Limit of Quantification (LOQ)

The limit of detection (LOD) of an analytical method is the lowest amount of analyte in a sample that can be detected but not necessarily quantitated as an exact value. The limit of quantification (LOQ) of an analytical procedure is the lowest amount of analyte in a sample that can be quantitatively determined with suitable precision and accuracy.

The limit of detection (LOD) and the limit of quantification (LOQ) of the known Impurities 3, 4, 7 and Montelukast Sodium were calculated using the signal-to-noise ratio method as per ICH. A typical signal-to-noise ratio is 10:1 for Limit of Quantification (LOQ) and a signal-to-noise ratio between 3 and 2:1 is generally considered acceptable for estimating the detection limit (LOD). Further, the % RSD of six preparations at LOQ was calculated [14,15,16].

Robustness

The robustness of the developed method was investigated. The experimental conditions were deliberately changing the composition of the mobile phase A, B ± 10%, there is also a slight change in the pH value ± 0.2 units, flow rate ± 1 min mL−1 and column temperature ± 5 °C [17,18,19].

Stability of Solution

The stability of Montelukast Sodium and its known Impurities solution is determined. The working standard solution of Montelukast Sodium and its known Impurities to be tested was kept on the bench at a temperature of 25 °C and analyzed in a chromatographic time interval of 48 h for Montelukast Sodium and 36 h for its known impurities.

Results and Discussion

Method Development

The RP-HPLC method was developed to separate Montelukast Sodium from its impurities. During initial development, potassium dihydrogen phosphate buffer was used for acidic pH and ammonium acetate buffer for basic pH. An octadecylsilane (C18-stationary phase) column was used for method development. During the pH study, it was observed that there are not any distinct effects in the elution of retention times on either value of the pH. However, the elution of all impurities was found during the higher percentage of organic modification mixed with mobile phases. To prevent precipitation, non-volatile buffers of salt have been used, out of which, the method was optimized using a triethylamine buffer with a pH of 6.60 mixed with acetonitrile in gradient mode using the Agilent column.

Montelukast Sodium shows a very high logP value of about 8.49 and is also associated with inherent lipophilicity. Since there are no other alternatives, the reversed-phase chromatographic analysis is the only option available. As a result of the high logP value, it is evident that Montelukast Sodium should undergo partition primarily into the stationary phase of the reversed-phase column. Due to this, the coefficient of mass transfer in the Van Deemter equation plays a significant role, which additionally contributes to the poor chromatographic separation and long retention times.

There are two ways to counteract the problem caused due to the coefficient of mass transfer: one is to decrease the velocity of the mobile phase which gives plenty of time for the drug to undergo partition into the stationary phase; and second is to increase the elution power of the mobile phase using higher percentage of organic solvents with good elution property.

Taking practicality into account, the first option does not seem feasible; as it would eventually lead to broader peaks and long retention times the second option is better as it is one of the components in the mobile phase with significantly higher proportions. The method developed using the other option exhibited the best resolution between known impurities, and degradation peaks of Montelukast Sodium. The wavelength (220 nm) used in the method exhibited best separation and absorption measurements, provided its optimal values [19,20,21].

The method was developed for the separation of impurities (1–8), which comprises process and degradation. Further, the method specificity was confirmed by spiking the impurities (1–8) and by implementing degradation procedures against the sample. Based on the degradation studies, Impurities 3 (Sulfoxide), 4 (cis-isomer) and 7 (dehydrated) were identified as degradation impurities. These three impurities are the potential (Specified) impurities which are controlled by acceptance criteria not more than 0.5% and the rest of the Impurities 1, 2, 5, 6 and 8 are considered as unspecified impurities, controlled under any other individual impurities not more than 0.2%. Hence, the potential impurities were taken for the present validation study.

The blank solution that was injected exhibited a very little interference at the initial stage and no interference was observed throughout the entire chromatogram as shown in Fig. 1a. The resolution solution chromatogram, which is considered as the system suitability solution (performed by the peroxide degradation) shows one major degradation peak (sulphoxide peak) other than Montelukast Sodium with system suitability parameter like-resolution of about 26.2 as shown in Fig. 1b.

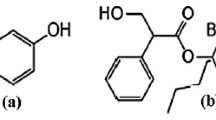

As shown in Fig. 2a, the standard solution was injected in six replicates and the average of the injections was used for calculation. The first injection is considered for the system suitability of the standard solution with parameters such as tailing factor is about 1.15, USP plate count about 85,300 and the % RSD of the six injections about 0.23. The placebo solution as shown in Fig. 2b was injected after this and had no interference when compared to other charts. Finally, the spike solution containing all the impurities spiked at known concentrations was injected to check the specificity of the method as shown in Fig. 2c. From this, the retention time, relative retention time for Montelukast sodium and the known impurities were obtained. The minimum linearity studies provided the relative response factor values for the impurities obtained which are tabulated as shown in Table 2. The Montelukast Sodium-related impurities labeled in the chromatograms are as follows: acid impurity (Impurity 1), bis-sulfanyl diastereomer (Impurity 2), sulphoxide impurity (Impurity 3), cis-isomer (Impurity 4), keto impurity (Impurity 5), ester impurity (Impurity 6), dehydrated impurity (Impurity 7) and chloro-alcohol impurity (Impurity 8).

Stress Studies of Montelukast Sodium

Stress studies were performed on Montelukast Sodium tablets to provide a stability-indicating property and also the specificity of the developed method. The degradation was performed on the Montelukast Sodium tablets intentionally by various conditions which are mentioned in the experiment part to evaluate that the proposed chromatographic method is suitable to separate the main moiety from its impurities. Also, the peak purity checked through the photodiode array detector gets passed, and the determined purity angle was lower than the calculated purity threshold which is a part of the development activity. As shown in Fig. 3a–f, the representative degradation chromatograms starting from acid, base, peroxide, thermal, photolytic, and humidity are represented and the percentage of degradation for each stress condition is recorded in Table 3

In the acid stress study, the major degradation product observed was dehydrated impurity (Impurity 7), which was about 5.8%. In the base stress study, the major degradation was about 1.2% of cis-isomer (Impurity 4). In peroxide and thermal stress studies, the major degradation product observed was sulphoxide impurity (Impurity 3) which was observed about 2.8% and 3.7%, respectively.

The organic impurities to be controlled in drug substances (API) are the process of impurities and degradation products. The organic impurities to be controlled in the drug product (dosage) are those resulting from the degradation of the drug substance or the interaction of the drug substance with excipients and/or the primary container closure. Drug substance process impurities need not be controlled in the drug product unless they are also degradation products as per USP General Chapter Impurities in Drug Substances and Drug Products (USP 1086) [22]. Based on the degradation studies by the newly developed method, the degradation products that are most likely to form were identified as Impurities 3, 4 and 7; these are the specified impurities for the tablet formulation and limited with acceptance criteria and these impurities shall be considered for the analytical method validation.

Method Validation

Specificity

The study is performed by spiking the individual impurities at a known concentration with Montelukast Sodium checking its separation. The impurities were found to be separated from each other and also from Montelukast Sodium and also the peak purity of the injection was checked. Further, the individual injection of the impurities was injected at the same concentration as injected above to confirm the retention time (Table 2). Also, the placebo injected did not have any interference in any of the impurities and Montelukast Sodium itself.

Linearity

A series of solutions of Montelukast Sodium and its known impurities were injected from LOQ to 200% as discussed, and the obtained peak area versus concentration was plotted to provide the linearity graph from which the slope, intercept and correlation coefficient values are obtained. These values are tabulated in Fig. 4 and Table 4.

Precision

We have studied three precision parameters namely the system precision which tells about the % RSD of the six replicate standard solutions injected which is about 0.23. The % RSD values are obtained for the Impurities 3, 4 and 7, through method precision where six individual spiked sample preparations were done and the values were within 2.0%. This is in compliance with the method and the intermediate precision performed with different HPLC system and different column by a different analyst on a different day provided % RSD values less than 2.0%. The % RSD value for the combined precision was less than 5.0% and the respective values are shown in Tables 5 and 6.

Accuracy

The study was performed to find the recovery of the impurities spiking it with Montelukast Sodium from LOQ, 50, 100, 150 and 200% of target concentration and it has provided satisfactory results. The percentage of recovery for each impurity was calculated, and it was found to be around 90.0 to 110.0% and the % RSD for each impurity at each level ranged from 0.2 to 4.1% and the corresponding results are tabulated in Table 7.

Limit of Detection and Quantification (LOD and LOQ)

The linearity study was used to determine the limit of detection (LOD) and limit of quantification (LOQ) for the impurities using the signal-to-noise ratio concept. Further, the precision studies performed at the LOQ level were found to provide good results and the % RSD calculated for each impurity was found to be less than 3%. The obtained values for the LOD, LOQ, and LOQ precision are tabulated in Table 8.

Robustness

This study was performed by varied chromatographic conditions as mentioned above such as flow rate, column temperature, pH, and composition of an organic ratio in mobile phases. It was found that the resolution between Montelukast Sodium and the Impurity 3 was greater than 25.0 which illustrated that the method was robust. This was one of the parameters for the method to be robust and another parameter is the change in the RRT values of the individual impurities on performing the varied parameters systematically. The RRT values for the impurities are compared with the original RRT value obtained initially during the specificity studies. The obtained data are provided in Table 9.

Stability

The standard solution containing Montelukast Sodium was very stable which is understood from the similarity factor value which is about 1.0 for the initial injection and the solution kept on the benchtop for 48 h. Next is the stability of the impurities studied by injecting the spike solution in which the difference is less than 1% between the initial one and the one injected after 36 h. Finally, the stability of the mobile phases was checked by injecting the system suitability solutions and the spike solution which showed that the system suitability parameters provided good repeatability even after 3 days. The only thing is that a decrease was observed in the plate count each day. Then on studying the RRTs of the impurities from the spike solution it was found that the RRT values varied by ± 0.01 units as per the study (Tables 10 and 11).

Conclusion

The existing USP methodology of Montelukast Sodium tablets utilizes phenyl column as the stationary phase along with guard whereas the in-house developed method uses C18 column. The lifetime performance of the phenyl column deteriorates over time and it is quite expensive, while the XDB C18 phase is cost-effective along with an extended lifetime and excellent performance. USP method adopts volatile buffer as mobile phase with a detection wavelength of 255 nm, while in-house developed method adopts triethylamine as mobile phase with detection at 220 nm.

The advantage of lower wavelengths is that it detects those impurities that are having lower absorbance in turn to ensure consistency of the product quality and elimination of response factor. The sulphoxide impurities (isomers) are not resolved by the USP method, whereas the in-house developed method resolves the isomeric peaks which lead to accurate quantification of individual isomer and a separate limit shall be proposed. The in-house developed method identifies eight impurities (process and degradation), whereas the published one covers four process impurities.

An RP-HPLC in-house method was developed and validated as per the current ICH guidelines for the quantitative determination of related substances of Montelukast Sodium in pharmaceutical dosage forms. The result of the study indicates a very well separation between all the process and degradation impurities, and shows the suitability of the method as stability-indicating. The developed method is simple, robust, specific, rugged and accurate, and is very much suitable for its intended purpose.

References

Saeed-Ul-Hassan S, Ahsan-Ul-Haq Athe R, Ansari MT, Tariq I, Karim S (2013) Determination of Montelukast Sodium in raw material and solid dosage form using reverse phase HPLC. Asian J Chem 25(13):7481–7484

C. N. Nalini, Vinoth Kumar (2020) A Review of Different Analytical Techniques for Fexofenadine Hydrochloride and Montelukast Sodium in Different Matrices. Critical Reviews in Analytical Chemistry

Revathi R, Ethiraj T, Thenmozhi P, Saravanan VS, Ganesan V (2011) High performance liquid chromatographic method development for simultaneous analysis of doxofylline and montelukast sodium in a combined form. Pharma Methods 2(4):223–238

Badulla W, Arli G (2017) Comparative study for direct evaluation of montelukast sodium in tablet dosage form by multiple analytical methodologies. Rev Roum Chim 62(2):173–179

Garg LK, Reddy VS, Sait SS, Krishnamurthy T, Jafer Vali S, Malleswara Reddy A (2013) Quality by design: design of experiments approach prior to the validation of a stability-indicating HPLC method for montelukast. Chromatographia 2013(76):1697–1706

Ali S, Gupta M (2019) Method development and validation for the simultaneous estimation of montelukast sodium and levocetirizine hydrochloride tablet using RP-HPLC. J Pharm Sci Res 11(8):2998–3000

Shakya AK, Arafat TA, Hakooz NM, Abuawwad AN, Al-Hroub H, Melhim M (2014) High-performance liquid chromatographic determination of montelukast sodium in human plasma: application to bioequivalence study. Acta Chromatogr 26(3):457–472

Roman J, Breier AR, Steppe M (2011) Stability indicating LC method to determination of sodium montelukast in pharmaceutical dosage form and its photodegradation kinetics. J Chromatogr Sci 49:540–546

Bhagade SR (2013) Spectrophotometric estimation of montelukast from bulk drug and tablet dosage form. IJPSR 4(11):4432–4434

Singh RM, Saini PK, Mathur SC, Singh GN, Lal B (2010) Development and validation of a RP-HPLC method for estimation of montelukast sodium in bulk and in tablet dosage form. Indian J Pharm Sci 72(2):235–237

Flor S, Juan MH, Tripodi V, Lucangioli S (2016) Development of an enantioselective capillary electrophoretic method for the simultaneous determination of montelukast enantiomeric and diastereoisomeric forms and its main degradation product. Electrophoresis 37:2420–2428

Çölkesen B, Öztürk F, Erden PE (2016) Electroanalytical characterization of montelukast sodium and its voltammetric determination in pharmaceutical dosage form and biological fluids. J Braz Chem Soc 27(5):849–856

Saravanan M, Siva Kumari K, Pratap Reddy P, Naidu MN, Moses Babu J, Srivastava AK, Lakshmi Kumar T, Chandra Sekhar BVVN, Satyanarayana B (2008) Identification, synthesis, isolation and spectral characterization of potential impurities of montelukast sodium. J Pharm Biomed Anal 48(2008):708–715

USP Pharmacopeia Monograph for Montelukast Sodium Tablets May 2020

ICH Harmonised Tripartite Guideline (1994) Validation of Analytical Procedures: Text and Methodology Q2 (R1). International Conference on Harmonisation of Technical Requirements for Registration of Pharmaceuticals for Human use

ICH Harmonised Tripartite Guideline (2006) Impurities in new drug substances Q3A (R2). International Conference on Harmonisation of Technical Requirements for Registration of Pharmaceuticals for Human use

ICH Harmonised Tripartite Guideline (2006) Impurities in new drug products Q3B (R2). International Conference on Harmonisation of Technical Requirements for registration of Pharmaceuticals for Human use

European pharmacopoeia 5.0 5.10. Impurities in Substances for Pharmaceutical use

Narin I, Sarioglan S, Anilanmert B, Sari H (2010) pK a determinations for montelukast sodium and levodropropizine. J Sol Chem 39(10):1582–1588

Van Deemter J, Zuiderweg F, Klinkenberg AV (1956) Longitudinal diffusion and resistance to mass transfer as causes of nonideality in chromatography. Chem Eng Sci 5(6):271–289

Ranjan OP, Nayak UY, Reddy MS, Dengale SJ, Musmade PB, Udupa N (2013) Development and validation of RP-HPLC method with ultraviolet detection for estimation of montelukast in rabbit plasma: application to preclinical pharmacokinetics. J Young Pharm 5(4):133–138

⟨1086⟩ Impurities in Drug Substances and Drug Products, USP 40 page 1270; and PF 41(3) [May–June 2015]

Funding

The author, Dr. K. Venkatachalam is extremely thankful for the financial help for the DST-SERB project of the Department of Science and Technology, India (Ref. No EEQ/2016/000559, Date: 06.02.2017).

Author information

Authors and Affiliations

Contributions

KSB—conceptualization, methodology, writing—original draft preparation, and writing—reviewing and editing. SPS—investigation, reviewing and editing. GD—data curation. KV—writing-review, visualization, supervision and project administration.

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Barnabas, K.S., Suvaitha, S.P., Dhinagaran, G. et al. A Novel Stability-Indicating Method for Determination of Related Substances of Montelukast Sodium in a Pharmaceutical Dosage Form Using RP-HPLC. Chromatographia 84, 645–662 (2021). https://doi.org/10.1007/s10337-021-04045-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10337-021-04045-8