Abstract

A simple and sensitive stability indicating high performance liquid chromatography method was developed for quantification of Daclatasvir hydrochloride in bulk and tablet dosage forms. The analysis was performed on water symmetry analytical column (150 mm × 3.9 mm, 5 µm), packing octyl silica (Si-[CH2]7-CH3) C8. Mobile phase containing potassium phosphate buffer (pH 2.0) and acetonitrile (38: 62) v/v was used at flow rate 0.7 mL min−1 for isocratic elution. Detection was performed on 304 nm using UV detector. The method was validated appropriately according to the requirements of United State Pharmacopeia and International Conference on Harmonization guideline Q2 (R1). Recovery, precision, linearity and specificity of the method were assured. The correlation coefficient for linearity ranged from 2 to 24 µg mL−1 was (r > 0.9999). The limits of detection and quantification of Daclatasvir were 0.08 and 0.28 µg mL−1, respectively. Stability studies of Daclatasvir were performed under various stressed conditions, i.e., hydrolytic (acidic, basic and neutral), oxidation, photolytic and thermal conditions, according to International Conference on Harmonization Q1A (R2) and QIB Guidelines. The degradation products were resolved using proposed method and further characterized by MS, NMR and IR spectroscopic analyses. The proposed method was successfully applied to assay determination of bulk drugs and tablet dosage forms.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Hepatitis C virus (HCV) affects more than 3% of the world’s population and it is a significant public health concern [1, 2]. More than 70% of the patients infected with HCV proceed to a chronic state which can lead to serious liver diseases such as fibrosis, cirrhosis, hepatocellular carcinoma and liver-transplantation [3, 4].

Until the most recent developments of direct-acting antivirals (DAAs), the optimal treatment option for all genotypes was pegylated alpha interferon (PEG-IFN) in combination with Ribavirin. However, they were associated with potentially serious side effects such as risk of hepatic decompensation, septicaemia in patients with advanced liver disease and bone marrow suppression. PEG-IFN therapy was also associated with significant toxicities, poor tolerability, adverse reactions and limited efficacy against infected HCV genotype-1 cases [5, 6].

The recent availability of culture cell models provided valuable information for understanding the life cycle of HCV and non-structural HCV proteins involved in viral replication process. It completely revolutionized the treatment of HCV infection by providing new and highly effective direct-acting antivirals such as Telaprevir, Boceprevir, Simeprevir, Faldaprevir, Asunaprevir, Vaniprevir, Sofosbuvir, Ledipasvir and Daclatasvir [7,8,9,10,11,12,13].

Daclatasvir (DCV) also known as BMS-790052 is a novel, potent and selective non-structural protein (NS-5A) inhibitor, developed by Bristol–Myers Squibb (BMS) USA, and approved by FDA in July 2015. DCV is used for the treatment of HCV genotype-1 or genotype-3 infections in combination with Sofosbuvir and with or without Ribavirin with high SVR rates and greater tolerability [14,15,16,17].

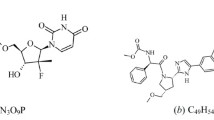

DCV being a carbamic acid dihydrochloride is a white to yellow crystalline solid having chemical formula C40H50N8O6·2HCl. Its structural formula is given in Fig. 1a. DCV has two polymorphic forms, i.e., N-1 and N-2. The N-2 form is thermodynamically the most stable polymorph that is used for the preparation of drug product [18].

A few bio-analytical methods are available for quantitative determination of DCV in plasma by LC–MS/MS [19,20,21], UHPLC-MS/MS [22, 23] and HPLC–UV [24]. These methods are specific for DCV determination in biological fluids and could not be suitable for routine analysis of assay determination of drug in tablet dosage forms. For analysis of tablet dosage forms and bulk drugs also some methods are recently published [25,26,27,28]. Only in few methods the stability of DCV is discussed which apparently discrepant with each other and with the European Medicines Agency (EMA) report of DCV. The EMA reported DCV is susceptible to degradation in solution at high-intensity UV and visible light [18] while Jiang H et al. [21], Rezk et al. [23], Chakravarthy et al. [26], showed DCV solution stable under light condition. Nannetti et al. [24] performed a detailed photo stability of DCV but not evaluated in different accelerated conditions and the photolytic degradation impurities are not further characterized. Similarly, the forced degradation results showed in different studies are discrepant with each other. Chakravarthy et al. [26] showed DCV stable in acidic, basic and oxidative condition and Saleh et al. [27] showed it is unstable in all conditions. Baker et al. [28] published a stability indicating HPLC–DAD method using Waters C8 column and mobile phase mixed phosphate buffer pH 2.5 and acetonitrile (75:25) at 1.2 mL/min.

In this method, they not discussed the photolytic degradation of DCV and the impurities are not further characterized. Similarly, very recently, an RP-HPLC–UV method for analysis of degradation behavior is also published by Hassib et al. [29]. In this study, C18 column is used in combination of phosphate buffer pH 2.0 and acetonitrile (60:40) as mobile phase at flow rate 2.0 mL min−1. The forced degradation studies are performed in different conditions but the method is not properly validated using impurity standard to properly resolve the degradation impurities. The DCV solution is showed stable during photolytic degradation studies and the degradation products are not further characterized by IR and NMR analysis. In the context of large scale product development studies, alternative stability indicating analytical methods which describe the forced degradation studies of DCV in all accelerated condition and complete identification and characterization of degradation impurities is needed.

For the purpose, a simple and efficient isocratic HPLC–UV method was developed for the determination of DCV and its degradation products in bulk and tablet dosage forms. This method was validated using reference materials of degradation impurities according the requirement of United State Pharmacopeia (USP) and International Conference on Harmonization (ICH) Guideline. Moreover, the forced degradation studies were performed to assessed the stability of DCV under different accelerated conditions and the degradation products were further characterized by MS, NMR and IR spectroscopy analyses.

Experimental

Materials and Chemicals

Generic product tablet dosage forms of DCV-30 mg, DCV-60 mg and excipients, i.e., anhydrous lactose (BP), microcrystalline cellulose (USP, magnesium stearate (BP), croscarmellose sodium (BP), silicon dioxide (E551), titanium dioxide (E171), macrogol 400 (EP), hydroxypropyl methylcellulose (BP), yellow iron oxide (E172) were provided by Genome Pharmaceuticals (Pvt.) Ltd Pak. DCV drug substance purity 99.4%, reference standards purity 98.9% and impurities reference standards of impurity-A (Imp-A) having purity 91.5%, impurity-B (Imp-B) having purity 93.8% and impurity-C (Imp-C) having purity 92.4% were provided by (Ruyuan HEC Pharm Co. Ltd., China). Methanol HPLC, acetonitrile HPLC, sodium hydroxide, hydrochloric acid (37% w/v) and hydrogen peroxide (30% w/v) were purchased from Sigma-Aldrich (Germany).

Instrumentation

Gradient HPLC system comprised a Cecil low pressure quaternary gradient pump Adept CE-4104, UV detector Adept CE 4200 (Cecil Instruments Limited UK). The system was controlled by power stream chromatography manager version 4.2. Symmetry analytical column 150 mm × 3.9 mm, 5 µm, packing octyl silica (Si-[CH2]7-CH3) C8 (Waters USA) was used for analysis. Other equipments also used in this work included Nicolet iS5 N FT-NIR spectrometer (Thermo fisher scientific, USA), Agilent 6320 Iron Trap MS (USA), Bruker AVANCE III HD 600 NMR (USA) and photostability chamber with florescent light of 1.2 milli lux hm2 and UV light of 200 W hm2 (China).

Solution Preparation

Mobile Phase and Dilution Medium

Potassium phosphate buffer pH 2.0 was prepared by dissolving 1.36 g of anhydrous potassium dihydrogen phosphate and 7.02 g of sodium perchlorate monohydrate in 400 mL of purified water using a 500-mL volumetric flask. The pH was adjusted to pH 2.0 ± 0.5 with phosphoric acid solution. Mobile phase was prepared by mixing potassium phosphate buffer pH 2.0 and acetonitrile having ratio 38:62 v/v, and filtered through a 0.2-µm nylon membrane filter. A homogeneous mixture of acetonitrile and water ratio (1:1) was prepared to use as dilution medium.

Reference and Sample Stock Solutions

Stock solution of DCV 0.6 mg mL−1 was prepared by dissolving equivalent to 30.0 mg DCV reference standard in 50 mL of dilution medium. Impurity reference solution 0.1 mg mL−1 was prepared by dissolving 5.0 mg reference standards of each impurity separately in 50 mL of dilution medium.

Sample solution of tablet with known concentration of DCV 0.6 mg mL−1 was prepared by dissolving ten tablets of each brand in 1 L of dilution medium. This solution was filtered through a 0.45-µm nylon filter (Millipore).

The possible degradation of DCV under high-intensity light conditions was previously reported [18]. All solutions of DCV were protected from daylight during preparation, storage, and analysis. The above solutions were stored at 2–8 °C and further diluted to 20 μg mL−1 for assay, method development and validation studies.

Method Validation

Accuracy and Recovery

Six concentration levels (20–120% of assay concentration) with known amount of DCV ranging from 4 to 24 µg mL−1 were prepared. To check the recovery of impurities based on ICH guidelines Q3B (R2), the reporting threshold of impurities should be as low as 0.05%. The solutions were spiked with 0.1–0.5% of Imp-A, Imp-B and Imp-C each (0.02–0.12 µg mL−1) and analyzed replicates (n = 3). The recovery of DCV from dosage form was determined by spiking of excipients with DCV drug. Excipient solutions were spiked with known amount of DCV drug and analyzed for recovery. The recovery of each sample was calculated by comparing the peak response with individual reference solution. The values of relative error (RE) and RSD were evaluated against acceptance limits ± 2% for DCV and ± 10% for impurities.

Precision and Intermediate Precision

The precision was assured by analyzing replicates (n = 6) of three samples (high, medium and low concentration levels (20, 60 and 120% of assay concentration). The samples containing known amounts of DCV (4, 12, and 24 µg mL−1) were spiked with 0.1–0.5% of each impurity (0.02, 0.06 and 0.12 µg mL−1). For precision and intermediate precision, the values of overall relative standard deviation (RSD %) of peak response at different days were checked against the acceptable limits (± 2% for DCV and ± 10 for impurities).

Robustness

Robustness of the method was assured by small changes (± 2%) in the given values of dilution medium column temperature, detection wavelength and mobile phase ratio. Replicates (n = 6) of DCV solutions (4, 12, and 24 µg mL−1) spiked with 0.1–0.5% of each impurity (0.02, 0.06 and 0.12 µg mL−1) were analyzed using given mobile phase. The influence of the changes on results was determined by evaluating the value of (RSD %) against acceptable limits acceptable ± 2% of peak response and retention times.

Linearity and Range

For linearity assessment, replicates (n = 3) of seven concentrations were analyzed ranging from 10 to 120% of the assay having known amount of DCV (2–24 µg mL−1) spiked with 0.05–0.5% each impurity (0.01–0.12 µg mL−1), respectively. The values of peak response were plotted on X-axis against concentration on Y-axis, and based on least-square linear regression equation (A = slope C + Y intercept), the relation of peak response with concentration was evaluated. The LOD and LOQ were calculated from slope using expression (3.3δ/slope) and (10δ/slope), respectively.

Specificity and Placebo Interference

Composite solution of placebo was prepared in dilution medium using all excipients of tablet except active ingredients. This solution was analyzed on the same chromatographic condition and the baseline was evaluated for peak response. Placebo interference was also assured by spiking of reference solution with appropriate level of excipients and the baseline was evaluated for any interference or additional peak other than known peaks of DCV.

Stability Studies of Solution

Stress stability studies are essential to evaluate the drug substance in product under various stress conditions such as alkaline, acidic hydrolytic, photolytic, thermal and oxidative conditions. It provides insight into the potential degradation products that can pose risks to stability and efficacy of product and patient safety [30, 31].

Stressed condition studies were performed for the evaluation of degradation products using 500 µg mL−1 DCV solutions. The solutions were refluxed in acidic (5 M HCl), alkaline (1 M NaOH) and neutral (in diluents) for 4 and 8 h. The oxidative stress testing was performed using 10% H2O2 for 4 and 8 h. A composite solution of drug product (tablets) containing all excipients was refluxed in neutral medium (diluents) for 4 and 8 h to check the compatibility of excipients. The effect of heat and light on drug product was studied by exposing the drug substance and drug product in solid and solution to 80 ± 5 °C and 75 ± 5% relative humidity, 200 W/m2 UV light and 1.2 million lux hours visible light at 40 °C using photostability chamber. The drug product in solid and solutions was also exposed to direct sunlight for 6 h to evaluate the effect maximum light on product and solution.

Stability of solutions exposed to room temperature (15–25 °C) for 7 days, and cool temperature (02–08 °C) for 14 days were also assessed. The results obtained were evaluated by comparing with assay results of reference standards.

Results and Discussion

Method Development and Optimization

Due to the presence of conjugated group at belt K and aromatic ring at belt E, DCV is UV active compound. DCV shows maximum absorbance at λ = 304 ± 2 nm in methanol and the specific absorbance (A = 1%) is 636.1 ± 6. To optimize wavelength for simultaneous detection, the reference solutions DCV, Imp-A, Imp-B Imp-C each 20 µg mL−1 were scanned from 200 to 400 nm (Fig. 2). DCV and all impurities showed maximum absorbance at 304 ± 5 nm; hence 304 nm was selected as detection wavelength.

After systematic elution of different mobile phases at different flow rates over different stationary phases, a set of suitable conditions for better resolution of each analyte was selected. The composite reference solution of all analytes was analyzed using mobile phase with different organic and ionic ratios, i.e., acetonitrile with 0.1% phosphoric acid (60:40 v/v), methanol with ammonium acetate buffer solution pH 3.0 (55: 35) and acetonitrile with potassium phosphate buffer solution pH 2.0 (62:38 v/v). The results of acidic mobile phase were more favorable than neutral or basic mobile phase. It is important to note that sodium perchlorate is an effective anionic ion-pairing reagent in acidic condition. For this purpose, sodium perchlorate was added to potassium phosphate buffer solution and better results were achieved as compared to other mobile phases. Mobile phase containing potassium phosphate buffer (pH 2.0) with acetonitrile (38: 62 v/v) at flow rate 0.7 mL min−1 over C8 (Waters) column showed better resolution and symmetrical peaks for each analyte as compared to ODS C18 (Promosil). Symmetry analytical column 5 µm (150 mm × 3.9 mm) packing C8 was selected for analysis. The retention time of each analyte was quite different (Fig. 3). This may help in identification and quantification of each analyte by comparing it with individual reference solution.

The selected chromatographic conditions were further validated for accuracy, precision and linearity. Specificity, limit of detection (LOD) and limit of quantification (LOQ) were determined as per USP and ICH guidelines [32, 33].

System suitability was checked by replicate analysis (n = 6) of 20 µg mL−1 DCV reference solution spiked with 0.02 µg mL−1 (0.1%) impurities. To check the sensitivity of method, a composite standard solution at very low concentration, i.e., DCV 4 µg mL−1, spiked with impurity each 0.02 µg mL−1 was analyzed (Fig. 3a). Furthermore, statistical data of peak response were calculated for theoretical plates (N), symmetry factor (As) and retention factor (Ko) using power stream chromatography manager. The resolution and relative retention time of DCV and each impurity were calculated. The relative standard deviations (% RSD) of peak area of each analyte were calculated and the results were evaluated against acceptable limits ± 2.0, ± 10.0%, for DCV and each impurity, respectively.

System Suitability

The results in Table 1 showed that all performance parameters comply with the USP requirements for system suitability. The value of RSD % of peak response was less than 2.0% for DCV and less than 10% for Imp-A and Imp-B. The resolution of Imp-A and Imp-B was 3.5 as compared to DCV and theoretical plates were more than 10,000. The method was suitable and capable to isolate and quantify DCV and all impurities simultaneously.

Accuracy and Recovery

The results of recovery studies in Table 2 showed that overall recovery of DCV was 100 ± 1% and each impurity was 100 ± 10%. The value of RSD % and RE % for was less than 2.0% and each impurity was less than 10%.

Precision and Intermediate Precision

Results in Table 3 for precision and intermediate precision studies showed that the RSD % for peak response is less than 2.0% for DCV and less than 10% for each impurity. The results indicate that the given method is precise and reproducible within the acceptable limits and criteria.

Robustness

The minor changes ± 2% of the given values in chromatographic condition does not affect the results of DCV and each impurity. The values of RSD % shown in Table 4 indicate that there is no influence of minor changes on resulted values. The method is robust and suitable for routine analysis of assay determination of DCV tablet dosage forms and degradation impurities.

Linearity

Statistical data derived from linearity studies indicate a good correlation between concentration and peak response. The main linear regression equation for linearity of DCV, Imp-A, Imp-B and Imp-C was found as (A = 117.05C − 6.90), (A = 1357.68C − 235), (A = 1272.11C − 4.55) and (A = 1318.16C − 5.62), respectively. The correlation coefficient (r) was 0.9999, 0.9997, 0.9996 and 0.9985, respectively. The value of LOD for DCV was 0.08 and each impurity was 0.02 µg mL−1. The values of LOQ were 0.28, 0.05, 0.06 and 0.07 µg mL−1 for DCV, Imp-A, Imp-B and Imp-C, respectively.

Specificity and Placebo Interference

Results of placebo intemperance studies showed that there is no significant peak of any excipient at given retention time of DCV. The influence of tablets excipients on peak of DCV and all impurities at given chromatographic condition is negligible. The results show that proposed method is specific for quantification of DCV and degradation impurities bulk and tablet dosage form.

Stability of Solution

Stability of DCV drug substance and drug product in solid and solution were investigated for normal and stressed conditions, summarized in Table 5 (Fig. 4). Due to possible degradation of DCV in light condition, all the solutions were stored protected from light during studies. Our results of normal studies showed that solutions in dilution medium were stable for 7 days at room temperature (15–25 °C) and for 14 days at cool temperature (02–08 °C). Solutions of tablet dosage forms, stored at cool temperature and at 80 ± 5 °C and 75 ± 5% RH were also stable and no degradations were noted.

Chromatogram of a composite sample of reference standards DCV 20 µg mL−1, Imp-A, Imp-B and Imp C each 0.05 µg mL−1 b DCV degradation in alkaline (1 M NaOH) refluxed for 4 h c DCV degradation in acidic medium (5 M HCl) refluxed for 8 h, d DCV degradation in oxidative condition (10% H2O2) refluxed for 8 h e DCV degradation in light exposed to sunlight for 6 h

The results of stress stability studies showed that the solutions in acidic conditions (5 M HCl) were stable for 7 days at room temperature. The solutions in acidic medium (5 M HCl) were also stable when refluxed for 4 and 8 h (Fig. 4c). Similarly, the drug substance DCV and drug product in solid form exposed to heat and moisture (80 ± 5 °C and 75 ± 5% RH) were also stable for 7 days. However, the solution in basic medium (1 M NaOH in methanol), oxidative condition (10% H2O2) and solutions exposed to light were unstable.

Solutions in basic medium were degraded to Imp-A and Imp-C. These solutions stored at room temperature were degraded more than 10% to Imp-A in 8 h and it was degraded very rapidly up to 51% (39% to Imp-A and 12% to Imp-C) when it was refluxed for 8 h (Fig. 4b). This solution was further refluxed for 12 h and it was noted that Imp-A was also converted to Imp-C.

The solutions in oxidative condition showed slight degradation to Imp-A and Imp-C (Fig. 4d). The DCV solutions at oxidative condition stored at room temperature were almost stable and no degradation was noted. However, slight degradation about 4% (3% Imp-C and 1% Imp-A) was noted after refluxed for 8 h.

The results of photo stability showed that solution exposed to light was unstable and degraded to Imp-A. The solution exposed to UV and fluorescence for 7 days was degraded around 8% to Imp-A. In the same vein, solutions exposed to sun light were rapidly degraded up to 24% (Imp-A) (Fig. 4e).

In overall stress studies, Imp-A was the major degradation impurity of DCV, Imp-C was only detected in alkaline and oxidative conditions and Imp-B was not detected at any stress condition. All possible degradation impurities were resolved using the same HPLC method and it was proved that the method is stability indicating and capable to isolate and quantify the possible degradation products. To the best of our knowledge, there are no details available in the literature for degradation products of DCV. Therefore, the impurities were further characterized and confirmed by NMR, MS, and IR spectroscopy analyses. The NMR analysis was performed using DMSO-d6 as solvent. Mass spectrum was obtained using both ESI and Auto MS mode. The drying gas temperature was 350 ± 10 °C at flow rate 11 L−min, Nebulizer gas pressure was 45 psi and Capillary voltage was 3.5 kV.

Characterization of DCV, Imp-A, Imp-B and Imp-C

DCV and its impurities, i.e., Imp-A, Imp-B and Imp-C were confirmed by MS, IR, NMR spectroscopy. The data of MS, IR and NMR spectrum showed that the given values comply with the reported structure of DCV shown in Fig. 1a. The positive ion MS spectrum of DCV exhibits a parent ion peak [M+H]+ of 739 (m/z) which is corresponded to the theoretical value of molecular mass of DCV, i.e., (738.89 g/mol). The IR spectrum showed characteristic absorptions corresponding to the (−CO–NH–), (–CH3, –CH2), (–NH–) (C = O), aromatic ring, (C–N, C–O) stretching mode, and (–CH3, –CH2), aromatic ring bending mode, respectively. Similarly, the number of protons and carbons in 1H NMR, 13C NMR analysis showed completely consistent with the structure of DCV reported in the literature [18].

Characterization Imp-A

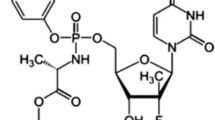

The ESI–MS spectrum full scan of Imp-A showed that the parent ion peak [M+H]+ of m/z 582 suggests a molecular mass of 582 for Imp-A. The spectrum with auto MS mode showed that the parent ion at m/z 582 produced five significant ions at m/z 565, 513, 408, 356 and 287, respectively, corresponding to the fragmentation pattern shown in Fig. 5. The IR absorption peaks of Imp-A also support that the stretching and bending vibrations are according to the given functional groups, i.e., –CO–NH–, CH3, –CH2, –NH– C = O, C–N, C–O, and aromatic rings. The proposed structure (Fig. 1b) is further supported by the 1H NMR and 13C NMR spectra. The numbers of proton and carbon for Imp-A are concordant with the proposed chemical structure (C33H39N7O) of Imp-A.

Characterization Imp-B

The ESI–MS full spectrum of Imp-B exhibits a parent ion peak [M+H]+ at m/z 624, which supports the proposed structure of Imp-B (Fig. 1c) with molecular mass of 623. The auto MS mode spectrum showed that the parent ion at m/z 624 produced five significant ions at m/z 592, 450, 398, 339 and 287, respectively. This spectrum also corresponds to the [M+H]+ ion fragmentation pattern of Imp-B shown in Fig. 6. The IR spectrum of Imp-B showed that the absorption peaks are corresponding the functional groups –CO–NH–, CH3, –CH2, –NH– C = O, C–N, C–O and aromatic rings. The data of NMR for numbers of proton and carbon in Imp-B allow unambiguous assignment of given structure as shown in Fig. 1c. The correlation of 1H NMR and 13C NMR in 2D NMR also supports the proposed structure.

Characterization Imp-C

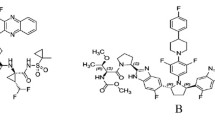

The mass balance studies of Imp-C at auto MS mode showed that the parent ion at m/z 513 produced four significant ions at m/z 481, 356, 339 and 287, respectively, corresponding to the fragmentation pattern shown in Fig. 7. Similarly, the ESI–MS full spectrum showed a parent ion peak [M+H]+ at m/z 513, suggests a molecular weight of 512 that corresponds to the proposed chemical structure of DCV Imp-C (Fig. 1d). The chemical characteristics of Imp-C on IR showed that all absorbance bands observed in IR spectrum from the sample agreed with the functional groups –CO–NH–, CH3, –CH2, –NH– C = O, C–N, C–O and aromatic rings of Imp-C. 1H and 13C spectra show that the numbers of proton and carbon in the sample are concordant with the structure of Imp-C. 1H–1H and 1H–13C correlations detected in the 2D NMR experiments further confirm the structure and allow for unambiguous assignment of all the signals in the proton and carbon-13 NMR spectra of Imp-C. Furthermore, to our knowledge, there are no details available in the literature, and it is the first report about the chemical characterization of degradation impurities of DCV.

Conclusions

A new RP-HPLC method was developed and validated according to the requirements of USP and ICH guidelines. Stress stability testing of DCV was performed, and four degradation products of DCV were efficiently isolated using same validated HPLC method. Furthermore, all degradation products were characterized by means of MS, 1H NMR, 13C NMR, and FT-IR spectroscopy analyses. The same HPLC method was successfully applied to assay determination of DCV bulk drug and tablet dosage forms. It was concluded that the developed method is stability indicating and can be applied to analysis of tablet dosage form and quantification of degradation products of DCV.

References

Shepard CW, Finelli L, Alter MJ (2005) Global epidemiology of hepatitis C virus infection. Lancet Infect Dis 5:558–567

Lavanchy D (2011) Evolving epidemiology of hepatitis C virus. Clin Microbiol Infect 17:107–115

Maasoumy B, Wedemeyer H (2012) Natural history of acute and chronic hepatitis C. Best Pract Res Clin Gastroenterol 26:401–412

Terrault N (2012) Liver transplantation in the setting of chronic HCV. Best Pract Res Clin Gastroenterol 26:531–548

Ghany MG, Nelson DR, Strader DB, Thomas DL, Seeff LB (2011) An update on treatment of genotype 1 chronic hepatitis C virus infection: 2011 practice guideline by the American association for the study of liver diseases. Hepatology 54:1433–1444

Magiorkinis G, Sypsa V, Magiorkinis E, Paraskevis D, Katsoulidou A, Belshaw R et al (2013) Integrating phylodynamics and epidemiology to estimate transmission diversity in viral epidemics. PLoS Comput Biol 9:e1002876

Naggie S, Patel K, McHutchison J (2010) Hepatitis C virus directly acting antivirals: current developments with NS3/4A HCV serine protease inhibitors. J Antimicrob Chemother 65:2063–2069

Jacobson IM, McHutchison JG, Dusheiko G, Di Bisceglie AM, Reddy KR, Bzowej NH et al (2011) Telaprevir for previously untreated chronic hepatitis C virus infection. N Engl J Med 364:2405–2416

Poordad F, McCone J Jr, Bacon BR, Bruno S, Manns MP, Sulkowski MS et al (2011) Boceprevir for untreated chronic HCV genotype 1 infection. N Engl J Med 364:1195–1206

McPhee F, Sheaffer AK, Friborg J, Hernandez D, Falk P, Zhai G et al (2012) Preclinical profile and characterization of the hepatitis C virus NS3 protease inhibitor asunaprevir (BMS-650032). Antimicrob Agents Chemother 56:5387–5396

Lemm JA, Liu M, Gentles RG, Ding M, Voss S, Pelosi LA et al (2014) Preclinical characterization of BMS-791325, an allosteric inhibitor of hepatitis C virus NS5B polymerase. Antimicrob Agents Chemother 58:3485–3495

Rose L, Bias TE, Mathias CB, Trooskin SB, Fong JJ (2014) Sofosbuvir: a nucleotide NS5B inhibitor for the treatment of chronic hepatitis C infection. Ann Pharmacother 48:1019–1029

Afdhal N, Zeuzem S, Kwo P, Chojkier M, Gitlin N, Puoti M et al (2014) Ledipasvir and sofosbuvir for untreated HCV genotype 1 infection. N Engl J Med 370:1889–1898

Smith MA, Regal RE, Mohammad RA (2016) Daclatasvir: a NS5A replication complex inhibitor for hepatitis C infection. Ann Pharmacother 50:39–46

Fridell RA, Wang C, Sun JH, O’boyle DR, Nower P, Valera L et al (2011) Genotypic and phenotypic analysis of variants resistant to hepatitis C virus nonstructural protein 5A replication complex inhibitor BMS-790052 in humans. In vitro and in vivo correlations. Hepatology 54:1924–1935

Burgess S, Partovi N, Yoshida EM, Erb SR, Azalgara VM, Hussaini T (2015) Drug interactions with direct-acting antivirals for hepatitis C: implications for HIV and transplant patients. Ann Pharmacother 49:674–687

Bifano M, Hwang C, Oosterhuis B, Hartstra J, Grasela D, Tiessen R et al (2013) Assessment of pharmacokinetic interactions of the HCV NS5A replication complex inhibitor daclatasvir with antiretroviral agents: ritonavir-boosted atazanavir, efavirenz and tenofovir. Antivir Ther 18:931–940

Assessment Report EMEA/H/C/003768/0000 (2014) Committee for medicinal products for human use (CHMP) (http://www.ema.europa.eu/docs/enGB/documentlibrary/EPAR-Publicassessmentreport/human/003768/WC500172849.pdf. Accessed Nov 2016

Yuan L, Jiang H, Ouyang Z, Xia Y-Q, Zeng J, Peng Q et al (2013) A rugged and accurate liquid chromatography–tandem mass spectrometry method for the determination of asunaprevir, an NS3 protease inhibitor, in plasma. J Chromatogr B 921:81–86

Jiang H, Zeng J, Kandoussi H, Liu Y, Wang X, Bifano M et al (2012) A sensitive and accurate liquid chromatography–tandem mass spectrometry method for quantitative determination of the novel hepatitis C NS5A inhibitor BMS-790052 (daclastasvir) in human plasma and urine. J Chromatogr A 1245:117–121

Jiang H, Kandoussi H, Zeng J, Wang J, Demers R, Eley T et al (2015) Multiplexed LC-MS/MS method for the simultaneous quantitation of three novel hepatitis C antivirals, daclatasvir, asunaprevir, and beclabuvir in human plasma. J Pharm Biomed Anal 107:409–418

Ariaudo A, Favata F, De Nicolò A, Simiele M, Paglietti L, Boglione L et al (2016) A UHPLC–MS/MS method for the quantification of direct antiviral agents simeprevir, daclatasvir, ledipasvir, sofosbuvir/GS-331007, dasabuvir, ombitasvir and paritaprevir, together with ritonavir, in human plasma. J Pharm Biomed Anal 125:369–375

Rezk MR, Bendas ER, Basalious EB, Karim IA (2016) Development and validation of sensitive and rapid UPLC–MS/MS method for quantitative determination of daclatasvir in human plasma: application to a bioequivalence study. J Pharm Biomed Anal 128:61–66

Nannetti G, Messa L, Celegato M, Pagni S, Basso M, Parisi SG et al (2017) Development and validation of a simple and robust HPLC method with UV detection for quantification of the hepatitis C virus inhibitor daclatasvir in human plasma. J Pharm Biomed Anal 134:275–281

Srinivasu G, Kumar KN, Thirupathi C, Narayana CL, Murthy CP (2016) Development and validation of the chiral HPLC method for daclatasvir in gradient elution mode on amylose-based immobilized chiral stationary phase. Chromatographia 79:1457–1467

Chakravarthy VA, Sailaja B (2016) Method development and validation of assay and dissolution methods for the estimation of daclatasvir in tablet dosage forms by reverse phase HPLC. Eur J Pharm Med Res 3:356–364

Saleh H, Ragab GH, Othman MA (2016) Stability indicating HPLC method development and validation for determination of daclatasvir in pure and tablets dosage forms. Indo Am J Pharm Sci 3(12):1565–1572

Baker M, El-Kafrawy D, Mahrous M, Belal T (2017) Validated stability-indicating HPLC-DAD method for determination of the recently approved hepatitis C antiviral agent daclatasvir. Ann Pharm Fr 75(3):176–184

Hassib ST, Taha EA, Elkady EF, Barakat GH (2017) Reversed-phase liquid chromatographic method for determination of daclatasvir dihydrochloride and study of its degradation behavior. Chromatographia 80(7):1101–1107

ICH (2003) ICH harmonised tripartite guideline Q1A(R2): Stability testing of new drug substances and products. ICH, Geneva. https://www.ich.org/fileadmin/Public_Web_Site/ICH_Products/Guidelines/Quality/Q1A_R2/Step4/Q1A_R2__Guideline.pdf. Accessed Nov 2016

ICH (1996) ICH harmonised tripartite guideline Q1B: photo stability testing of new drug substances and products, ICH, Geneva. https://www.ich.org/fileadmin/Public_Web_Site/ICHProducts/Guidelines/Quality/Q1B/Step4/Q1B_Guideline.pdf Accessed Nov 2016

USP (2014) The United States Pharmacopeia, 37th revision. United States Pharmacopeial Convention, Rockville, pp 1157–1162

ICH (2005) ICH harmonised tripartite guideline Q2(R1): validation of analytical procedures. ICH, Geneva. http://www.ich.org/fileadmin/Public_Web_Site/ICH_Products/Guidelines/Quality/Q2_R1/Step4/Q2_R1__Guideline.pdf. Accessed Nov 2016

Acknowledgments

The authors are thankful to Genome Pharmaceuticals for providing generic products, reference standards and for their support in this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zaman, B., Hassan, W. Development of Stability Indicating HPLC–UV Method for Determination of Daclatasvir and Characterization of Forced Degradation Products. Chromatographia 81, 785–797 (2018). https://doi.org/10.1007/s10337-018-3503-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10337-018-3503-7