Abstract

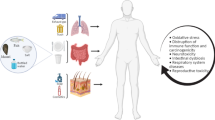

Microplastics have been recently detected in many environmental media and living organisms, yet their transfer and toxicity to humans are poorly known. Here, we review microplastic transfer in the food chain with focus on microplastic pollution sources, methods to analyze microplastics in food, health impact of food-related microplastic exposure, and remediation of microplastic pollution. Microplastic pollution sources include seafood, food additives, packaging materials, and agricultural and industrial products. Remediation techniques comprise the use of microbial enzymes and biofilms. Microplastic detection methods in food rely on separation and quantification by optical detection, scanning electron micrography, and Fourier-transform infrared spectroscopy. Human health impact following microplastic ingestion include cancers, organ and respiration damage, and reproductive impairments. Overall, microplastic toxicity is mainly due to their ability to enter the metabolism, adsorption into the circulatory system for translocation, and difficulty, if not impossibility, of excretion.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The plastic industries have recorded enormous growth in the last few decades, with global production of plastic above 367 million tons as of 2021. Consequently, plastic waste released into various environmental compartments has increased due to usage, and disposal (Huang et al. 2022; Anand et al. 2023; Osman et al. 2023; Ali et al. 2023; Sharma et al. 2023; Chia et al. 2023). Microplastics are generated when discarded plastic materials are exposed to external factors such as physical and chemical changes, mechanical force, and biological transformations (Novotna et al. 2019). Microplastics are plastic fragments less than 5 mm in size (Osman et al. 2023). Secondary microplastics are produced when raw plastic particles are degraded by chemical, biological, and physical processes in the environment, while primary microplastics are basic materials utilized in household and personal care goods (Padervand 2017; Padervand et al. 2020). Microplastics are of great concern and a challenge to environmentalists due to their long-term durability, their polymeric structure and ease of transfer between different environments (Chia et al. 2021). Microplastics are quite prevalent as a result of poor plastic waste management (Akan et al. 2021; Enechi et al. 2021; Deme et al. 2022; Okeke et al. , 2022a, b, 2023a; Okoye et al. 2022a). Microplastics' degradative mechanisms are not completely understood (Othman et al. 2021; Huang et al. 2022). For 3 years, under simulated realistic weather circumstances, the deteriorating changes of the chemical structure of two types of microplastics, including polypropylene and polyethylene, were evaluated (Brandon et al. 2016). They discovered some minor nonlinear variations in time in moieties like carbonyl, hydroxyl, and carbon–oxygen bonds using Fourier-transform infrared (FTIR) spectroscopy analysis (Huang et al. 2022; Chia et al. 2023), which suggests that microplastics degrade slowly (Brandon et al. 2016). Several methods have been employed in the removal of microplastics from different media including sorption and filtration methods (Adsorption on green algae, removal using membrane technology), advanced filtration technologies, chemical methods, biological removal and ingestion (using marine organisms, using bacteria, via ingestion (Padervand et al. 2020)).

A plethora of evidence from previous studies has demonstrated the retention of microplastics in various ecosystems, including those of the ocean, soil, freshwater, and the atmosphere (Akan et al. 2021; Deme et al. 2022; Okeke et al. 2022a, b, c, 2023a, b; Okoye, et al. 2022a, b). As a result, it is reasonable to assume that Microplastics will find their way into and accumulate in the food chain, which is based on above-ground ecosystems, before being consumed by man via diet. There are numerous studies on inner aquatic products at the moment because the majority of Microplastics detection and identification assessments are conducted on aquatic ecosystems (Zhao et al. 2022). However, foodborne Microplastics are not just found in aquatic foods; they are also found in some commonly ingested processed foods and terrestrial crops (Piyawardhana et al. 2022). Additional sources of Microplastics include fast food deliveries, foodstuffs packed and stored in plastic containers (Li et al. 2020b) and even indoor air (Zhang et al. 2022). Therefore, more effort is needed by researchers into both quantitative and qualitative research on different categories of food items, as this will serve as the foundation for determining the health risks associated with microplastics in humans. There are numerous documented detrimental consequences resulting from microplastics including reproductive toxicity (Liu et al. 2022b), inhibition of growth (Vickers 2017), impairment of nutrient absorption in plants as well as nervous system disorders (Lee et al. 2022). Results from previous study show that microplastics ingested through diet resulted in intestinal disorder in humans (Lu et al. 2019). The altered intestinal integrity could result to a concomitant anomaly in digestion and absorption of nutrients as well as altered mammalian homeostasis (Luissint et al. 2016), with resultants immune system dysfunction, metabolic disorders and pathogenesis of various diseases (Ganal-Vonarburg et al. 2020). In summary, it can be seen from these previous studies that microplastics have detrimental impacts on human health and the environment and could get into the human body via contaminated food or food packaging materials. Here, we review microplastics in food, effects on food security, and potential health risks.

Sources of microplastics in the food chain

Increasing incidence and consequent health risks of microplastics continue to raise concerns over entry into humans, by inhalation, ingestion and dermal contact (Asif et al. 2017). Microplastics incidence in the food chain is from the aquatic (Panel and Chain 2016; Du et al. 2020; Benson et al. 2022) and terrestrial (He et al. 2021a) environments (Fig. 1). Thus, both the aquatic and terrestrial ecosystems act as microplastics reservoirs. Extensive exposure via the food web involves seafood, drinking water, salt, honey, milk, sugar and meat (Panel and Chain 2016; He et al. 2021a; Jadhav et al. 2021; Benson et al. 2022; Alberghini et al. 2022; Vitali et al. 2023). We summarize some entry routes of microplastics to humans via the food web in the following sections and in Fig. 1 below. Overall, water sources and packing materials constitute the highest microplastics entrance route to the human food chain. For instance, salt retains and transmits microplastics through intake but terrestrial foods like cattle have a method for their elimination. We discuss below several pathways through which microplastics may migrate into food samples.

Microplastics can enter different environmental compartments and human food chain through various pathways. These include industrial operations, wastewater discharge, and the decomposition of larger plastic trash. Once in the environment, microplastics can spread through air, water, and soil, accumulating in different ecosystems, both aquatic and terrestrial. Animals residing in these habitats, such as fish, plankton, and bivalves, can ingest microplastics. Microplastics can enter the human body through the intake of tainted seafood, meat, or vegetables. They can also enter the body through drinking water and airborne particles

Water

Polyamide, polyethylene, polyester, polyvinyl chloride, polytetrafluoroethylene, etc. from food packaging, toys, personal care products and sewage have been reported in water (Muhib et al. 2023; Sewwandi et al. 2023). Microplastics including acrylonitrile, butadiene, polyethylene terephthalate, poly(ester amide) and styrene have been traced to production water sources including underground water, public water sources, surface water and rainwater (Schymanski et al. 2018; Makhdoumi et al. 2021; Samandra et al. 2022; Muhib et al. 2023; Sewwandi et al. 2023) with eventual incidence in the human food chain. For example, a study on comprehensive water chain reported epoxy resin, polyethylene, polyamide, polystyrene, and polyvinyl chloride at an average concentration of 700 particles/L (Pironti et al. 2021). Enormous microplastics are available to humans via treated water, with the World Health Organization reporting a concentration of 5 particles/L of tap water and worse for individuals drinking only bottled water (Pironti et al. 2021). Introduction of microplastics from water and drinks represents about the most important entry route considering the integral place of water in human nutrition (Miller and Young 2023) and the place of water as an important reservoir of microplastics (Sewwandi et al. 2023). In summary, water is critical to human nutrition and an important route of microplastics entry into humans.

Seafood

Seafood represents a preferred protein source in human diets (De-la-torre and De-la-torre 2020), but an important route of microplastics entry into the human food chain (Table 1) (Schymanski et al. 2018; Cverenkárová et al. 2021; Benson et al. 2022; Alberghini et al. 2022; Sewwandi et al. 2023). Microplastics incidence in fish is either direct via ingestion or passive via gill respiration and ingesting of contaminated prey (De-la-torre and De-la-torre 2020). Studies report the presence of microplastics in seafood including shellfish and fish (Cverenkárová et al. 2021; Alberghini et al. 2022; Sewwandi et al. 2023). The localization of microplastics in the usually discarded seafood gastrointestinal tract (Alberghini et al. 2022; Sewwandi et al. 2023) offers some respite, but they have been reported in some edible parts (Sridhar et al. 2022). Further, the presence of microplastics on the external intestinal linings of lower marine species suggests bioavailability to humans (Pironti et al. 2021; Benson et al. 2022). Similarly, shell fishes are sometimes eaten with the gastrointestinal tract, increasing entry to the food chain (De-la-torre and De-la-torre 2020; Cverenkárová et al. 2021). For example, Teng et al. (2019) reported microplastics present in 84% of the oyster samples studied in China (Table 1) (Teng et al. 2019).

Food packaging

With 40% of the total plastic production, food packaging (cans, bottles, wrappings, cups) uses the highest volume of plastics (Sridhar et al. 2022; Muhib et al. 2023), accounting for appreciable levels of microplastics migration into the human food chain (Al Mamun et al. 2023). In fact, food packaging and water may represent the most important route of microplastics in food explained by atmospheric fallout, surface leaching due to loose/rough structure, mechanical degradation and stress (opening methods) (Mason et al. 2018; Winkler et al. 2019; Du et al. 2020; Sobhani et al. 2020; Muhib et al. 2023). These mechanisms account for ingestion of about 2.98 × 103 microplastics person−1 year−1 and may increase based on ingestion frequency. For example, bottled water and drinks are severally reported with high incidence of microplastics that end up in human food (Table 2) (Panel and Chain 2016; Jadhav et al. 2021; Cverenkárová et al. 2021; Sridhar et al. 2022; Sewwandi et al. 2023; Vitali et al. 2023). The global bottle water consumption is above 22 billion liters annually (Luo et al. 2018), with microplastics in approximately 93% of bottle water samples studied in different countries (Pironti et al. 2021). Microplastics in bottled water are about twice the quantity reported in tap water (Table 2) (Mason et al. 2018; Jadhav et al. 2021). Other studies also report the presence of microplastics in bottled water examining, single use, beverage cartons (Table 2) (Schymanski et al. 2018; Muhib et al. 2023).

Further, the replacement of traditional paper wrapper to plastic materials for teabags also presents an important route of microplastics entry into human food chain. Irrespective of quality, plastic materials degrade from 40 °C over time. Therefore, tea bags that may be brewed almost 100 ° release billions of microplastics in a single teacup (Jadhav et al. 2021; Carr Kinnear et al. 2021; Sewwandi et al. 2023), with high toxicity index. Further disposable paper cups with hydrophobic inner linings release substantial microplastics when used to serve hot drinks (Liu et al. 2022a). This presents another synergy for high microplastics contamination from water and packing material, in addition to the high microplastics contaminations present in water sources, including treated tap water.

Microplastics incidence in milk and dairy products due to hygiene and corrosion from the milk processing and packaging materials have been reported. Thermoplastic sulfone polymers used in the ultrafiltration of milk have been reported due to high pressure-induced peel-off and chemical stress on the membranes (Benson et al. 2022; Vitali et al. 2023). Further, about 16 million microplastics/L are released due to shaking and preparation temperature in feeding bottles, representing a worrisome position as milk is mostly consumed by infants (Li et al. 2021b; Sewwandi et al. 2023). Microplastic intake from feeding bottles is 3000 times adults exposure from air, food and water at 1,580,000 per child (Li et al. 2020c; Jadhav et al. 2021). Obviously, the recent preference of plastic materials for food package is a critical route of entry for microplastics into the human food chain, form plastic tea bags, to feeding bottles and plastic bottles for water and other drinks, all account for appreciable levels of microplastics in human food.

Agricultural products

Soil is an important sink for microplastics, with 4–23 times the volume of microplastics in water, distributed in agricultural soils, industrial and remote areas (He et al. 2021a). Agriculture uses 38% of all global land (Zabel et al. 2019) and soil microplastics contamination results from anthropogenic activities and degradation (He et al. 2021a). The soil–plant pathway contributes 99% of human calories but represents an important microplastics entry route to the human food chain (Abbasi et al. 2020). Studies have shown the size-dependent root intake of microplastics from contaminated soils related to a crack-entry route in the root and subsequent translocation to the stem and then to other edible plant parts (He et al. 2021a; Wen et al. 2022). Also, another study has described the vertical migration of microplastics entry into plants aided by infiltration, fauna activities and root growth (Li et al. 2021b).

Important food plants and vegetable including apple, broccoli, carrot, corn, cucumber, lettuce, onions, pears, wheat crops are able to take up microplastics of between 50 and 700 nm from the soil via the root (Table 3) (Sewwandi et al. 2023; Wen et al. 2022; Li et al. 2021a, b, c; Oliveri Conti et al. 2020). These contaminants are incident in livestock (cow, pig and poultry), but don’t have a direct entry into the food chain, due to an elimination mechanism in animals (Wu et al. 2021; Wen et al. 2022). Ingested microplastics do not get absorbed from the gastrointestinal tract and are not present in edible parts (Wen et al. 2022). However, consumption of the animal intestine is a relished cuisine in parts of Africa, such as eastern Nigeria. Further, chopping boards and packaging materials such as trays and films have been implicated for microplastics in meat products (Wu et al. 2021; Habib et al. 2022). Seafood is also a source of introduction of microplastics into the poultry and livestock industry with eventual transfer to human food chain explained by trophic level food transfer mechanism (Panel and Chain 2016). Incidence of microplastics in poultry has been demonstrated to pose significant risk of introduction to the human food web (Pironti et al. 2021; Sewwandi et al. 2023). Studies showed route of entry into chicken and increasing concentration traced from soil to chicken feces to gizzard (Habib et al. 2022) and more recently polyvinyl chloride and polystyrene have been reported in chicken flesh (Pironti et al. 2021). Agriculture is at the very bottom of human food chain, supplying all needed nutrients from both plant and animal produce. As expected, agriculture is an important source of microplastics in human food, worse from plants but also from animal sources.

Food additives

Salt is a carrier of microplastics, with a maximum human exposure of 6110 microplastic/year, presenting an important ingestion route based on the World Health Organization recommended daily consumption of 5 g daily (Pironti et al. 2021; Benson et al. 2022; Sewwandi et al. 2023). Global incidence of microplastics has been reported in edible salt, with least contamination in China and highest in Croatia at 2000 particles/kg of salt (Pironti et al. 2021; Kuttykattil et al. 2023). Mostly, the plastic particles found in salt consist of cellophane, cellulose, paraffin wax, polyvinyl chloride, etc. The highest Microplastics contamination is reported in sea salt, suggesting industrial effluents or the degradation of larger plastics as main sources of microplastics (Kim et al. 2018). Specifically, Kim and others reported microplastic contents of 0–1674 n/kg in sea salt, 0–148 n/kg in rock salt and 28–462 n/kg in lake salt showing salt as an important source of microplastics in food. The high incidence of microplastics in salt indicates that evaporation is unable to remove contaminant, exposure humans to microplastics. Further, the primary source of salt contributes to microplastics load in salt such that sea salt was most contaminated, explain by the disposal of contaminated industrial wastes into the sea. Microplastics are present in other food additives (Table 3) (Sewwandi et al. 2023). For example, the presence of microplastics in honey is traced beekeepers and atmospheric contamination during production (Sewwandi et al. 2023). Similarly, microplastics contamination has been reported in sugar, though likely below acceptable safe limits (Vitali et al. 2023). Appreciable levels of microplastics end up in food from salt, honey, sugar and other additives traced to production sources and staff.

Industrial products

Many industries are implicated for the incidence of microplastics in food and eventual entry into the food chain. Earlier in this section, we highlighted the routes of microplastics incidence to include air, water and soil environments and here, we elucidate the role of industries in the introduction of microplastics. Globally, personal care products from wastewater treatment plants contribute about 1500 tons/year of microplastics to the aquatic environment alone with a global emission of 1.2 × 104 tons/year and an average microplastics of 2162 particles/g (Sun et al. 2020a). These microplastics in the aquatic environment could contaminate seafood and public water sources and end up in the human food chain as already discussed in this review. Further, the textile industry is reputed for the release of fiber from industries into the aquatic environment (Periyasamy and Tehrani-Bagha 2022). These fiber materials have been traced to seafood and eventually the human food chain (Table 3). Research has demonstrated the incidence of Microplastics resulting from industrial emissions via ingestion, inhalation and dermal absorption with enormous health implication (Auguet et al. 2022). Industrial release of microplastics into the atmosphere with subsequent settling on plants, soils and food materials is also implicated for the incidence of microplastics in the human food chain (Pironti et al. 2021). These industrial releases actually represent a primary source of microplastics for the various routes of entry into the human food chain.

Analysis of microplastics in food

The process of microplastic analysis in food generally involves sample digestion (food matrix destruction), sample extraction/separation, and sample identification, measurement, and characterization. The pretreatment of the sample is essential for a successful spectroscopic analysis of microplastics in food because it maximizes extraction efficiency, protects polymers, and yields reliable results. The kind of food matrices and targeted microplastics determines the suitable sample pretreatment to use. Because there are many different types of microplastics in samples, it is frequently challenging to recover all of them using a single technique. Understanding the advantages and disadvantages of each sample pretreatment technique are crucial.

Separation techniques

Physical treatments

Membrane-based filtration

One of the effective techniques for isolating microplastics from food matrices is membrane-based separation. To recover microplastics and conduct additional analysis, various liquids, such as drinking water samples and certain beverages, can be filtered onto filter membranes. To retain the microplastics in other liquid or solid samples, filtering digestants are typically used after chemical or enzymatic digestion. The simple method uses a pressure difference to cause the liquid to pass through the membrane and does not require a complicated setup. Applying pressure enables the solution to keep the microplastics on the surface of various membrane filters with a distinct size separation. The membrane filtration technique for microplastic separation after treatment is depicted in Fig. 2. The potential to replace traditional methods that are energy-intensive and need sophisticated maintenance and operation has attracted interest in the technology (Sridhar et al. 2021). The size of the filtered particles can also be used to categorize the separation process; these include nanofiltration, ultrafiltration, reverse osmosis, and microfiltration.

Microplastic separation using membrane filtration for liquid and solid foods. The microplastic in solid food samples undergoes chemical digestion using the appropriate chemical, and the solvent is subsequently extracted. Similarly, microplastic-contaminated liquid food samples undergo microfiltration to extract the media containing microplastics. The solvent extracts are then passed through the membrane filtration apparatus with the appropriate membrane filters. The extracted microplastics are then characterized, and the digestion media is removed

Microplastics on filters could either be transferred to slides or used directly for spectroscopic analysis. Mesh, glass fiber, cellulose acetate membranes, cellulose nitrate, and metal-coated filters are a few of the frequently recommended filtering materials. Aluminum/gold-coated filters typically have a clear background, simplifying spectroscopic identification (Oßmann et al. 2018). Metal surfaces are more expensive than other filters, and they are also more prone to distortion. Concentrating microplastics within a particular size range is possible by using a number of filters with various pore sizes. In addition, the chemical compatibility of various filters varies. As a result, another crucial factor to take into account is the compatibility of filter materials with digesting solvents. The potential of membrane separation technology in the water sector has been thoroughly investigated. For instance, a study done in drinking water treatment plants to separate soluble microbial products (a mixture containing proteins, fulvic acids, polymers, organic matter, and polysaccharides) using ultrafiltration revealed a 20% enhancement in removal efficiency after biodegradation (Wu et al. 2019). The method has been explored for the separation of microplastics as a result of these encouraging results in the removal of particles, suspended solids and particular ions. A South Korean-based study examined the use of a membrane disk filter in conjunction with sand filtration and ozone treatment to separate microplastics (Hidayaturrahman and Lee 2019). Filtration technique was used for the isolation of microplastics from organic matter in tap water samples (Li et al. 2022). According to the results, wastewater removal effectiveness ranged from 75 to 91.9%. Another independent study carried out in the United States of America examined the impact of sewage released into the San Francisco Bay and other broad geographic regions (Mason et al. 2016). According to the study, 0.05 to 0.024 particles/L of wastewater were discovered in the 90 samples taken from 17 different facilities using a mix of chemical and microfiltration techniques with a mesh size of 125 m. When compared to industrial effluents, the microplastic observed in these WWTPs was lower between 50 thousand to 15 million particles/L (Mason et al. 2016). Conclusively, these studies using filtration based on membrane technology recorded promising results in separation of microplastics.

Recently, microplastics in food have also been detected using membrane separation technology. One intriguing study, for instance, looked at the presence of microplastics in branded milk (23 samples) from both foreign and local brands (Kutralam-Muniasamy et al. 2020). The samples were handled at 0.5 bar pressure and slightly warmed before filtering because casein and fat could clog the filters. Microfilters with pore diameters of 0.22, 0.45, 11, and 5 μm were selected, with 11 μm being the ideal size for separation. The findings revealed a total of 2.5% granules and 97.5% fibers, with polyethersulfone and polysulfone polymers making up the majority. The lowest concentration was 32 particles/L while the highest was recorded as 11 ± 3.54 particles/L. The average microplastic count was 6.5 ± 2.3 particles/L. One of the intriguing conclusions was that none of the milk samples included any of the typical polymers like polyester, polypropylene, polyethylene, or PET. Furthermore, it was found that thermoplastic sulfone polymers could be readily extracted from milk samples using membrane filters. Similar investigations were carried out to find microplastic in takeaway food packages. The microplastics were extracted using membrane filters with a 5 μm pore size. According to the findings, microplastics ranged from 3 to 29 particles per container across all of the containers, with polystyrene flakes making up roughly 77% of those particles. Further analysis revealed that those who order meals 4–7 times per week may consume 12–203 microplastics via food packaging material (Du et al. 2020). Based on the positive results recorded in the above studies, it can be concluded that membrane technology is a technique for separating microplastics from foods samples. Outlined below are other examples of studies where membrane technology was used for isolation of microplastics from various food samples (Table 4). The primary drawback of filtration techniques is that if the pore size is too small, the filter can become easily clogged; hence, great care should be taken to use the appropriate equipment to retain all target particles.

Flotation

In order to extract microplastics from materials with nearly full separation, floatation is a widely used, quick, and easy approach (Nguyen et al. 2019). Compared to higher-density plastics like styrene, polyvinyl chloride, plasticizers and additives with a density of 1.40 g/cm3, microplastics like polyethylene and polypropylene have lower densities of 1.10 g/cm3. Although there are various varieties of the floatation technique, each has advantages and disadvantages of its own. To optimize the extraction of plastics, the sample matrix is first pre-digested typically using an H2O2 solution. To create a homogenized solution, the solution is then combined with the floatation medium (Wang et al. 2018). The floating medium is selected based on the plastic's density. For instance, sodium iodide (NaI) (1.6–1.8 g/cm3) can extract lesser-density plastics, while zinc chloride (ZnCl2), which has a greater density of 1.5–1.7 g/cm3, is capable of extracting microplastics (Liebezeit and Dubaish 2012). After a short period of time during which phase separation takes place, the slurry is kept undisturbed, and the supernatant fraction is collected for further investigation (Van Cauwenberghe et al. 2015). For the purpose of understanding floatation experiments in freshwater systems, several studies have been carried out. For example, an average of 66 particles were found per 100 g of the sample after conducting floatation studies in the river Thames, United Kingdom (UK). Plastic pieces made up 91% of these particles (Horton et al. 2017). Similar studies were carried out to determine whether microplastics were present in groundwater samples from 8 water treatment facilities in England, UK. According to the findings, potable water contained 0.00011 microplastic/L, and raw water contained 4.9 microplastic/L (Johnson et al. 2020). Numerous food items have also been the subject of research into the possibility of the flotation technique with diverse media. For instance, in a study conducted in East China, the flotation medium was a solution of potassium hydroxide (20% w/v), sodium iodide (4.4 M), and hydrogen peroxide (30% v/v) for the detection of microplastics in wild fish and crustaceans. According to the findings, 57.5% of the fishes had average microplastic counts of 0.77 to 1.25 in the gills and 0.52 to 0.90 in the digestive system (Zhang et al. 2019a). Similar investigations were made to assess the health of sardines and mussels. With 1.7–2 items per mussel and 1.5–1.9 items for fish using NaCl as floating media, microplastics occurred 47.2% of the time (Dekiff et al. 2014). To comprehend the existence of polyethylene terephthalate (PET) in table sea salts, another study was examined (Zhang et al. 2018). Further evidence of its effectiveness came from floatation investigations conducted after vacuum filtration, which revealed a concentration of 16–63 particles per 50 g of material. The overall process of floatation is often has a high recovery rate (up to 99%), is inexpensive, and is simple to regulate (Tirkey and Upadhyay 2021). The fundamental disadvantage of these materials is that the plastic particles must first be separated from the matrix materials.

Chemical treatment

Chemical treatments have been used to attain the goal of quicker sampling methods for better detection. Physical separation investigations have been beneficial, but they take time and require more accurate detection. Chemical processing is one method for removing microplastics from food systems in an efficient manner. Acid and alkaline treatments can be broadly categorized into two groups when it comes to the chemical digestion of microplastics. Without damaging the plastics, both treatments were able to break down the organic material in foods and tissue samples (Lusher et al. 2020). However, concentration is important for digestion when using alkaline solutions. Other substances have also undergone testing in recent years to determine their benefits and drawbacks. For instance, microscopy was used to investigate the Nile Red dye's potential for quantifying microplastics in bottled water. The results demonstrated Nile Red's ability to adsorb the microplastics from water selectively; propylene was found to be the most common type of polymer (54%) followed by copolymers and lubricants. In addition, 95% of the microplastics ranged in size from 6.5 to 100 µm (Mason et al. 2018). Much research has been done on fish and seafood. A laboratory examination found microplastics in oyster and mussel tissues after 69% HNO3 treatment (mussels: 0.36 ± 0.07 particles/g, oysters: 0.047 ± 0.16 particles/g) (Van Cauwenberghe and Janssen 2014). Similar experiments used 1 M NaOH 35% HNO3 to separate microplastics from mussel soft tissues (Catarino et al. 2017). While the recovery rate was good (93%), extreme responses occurred during HNO3 treatment. Sample pretreatment with H2O2 caused froth and poor tissue digestion. It was found that alkaline digestion (10 M NaOH) resulted in a better efficiency of 91.3 ± 0.4% compared to acidic digestion with HCl (1 M: 82.6 ± 3.7% and 2 M: 72.1 ± 9.2%) (Hidalgo-Ruz et al. 2012). However, excessive amounts may block plant cell walls. To remove plastics from vegetal-rich samples (plant leaves, seagrasses, and seeds), a novel, efficient, and economical digesting process has been suggested six protocols were examined: four acid/alkaline, one with H2O2, and another with ethanol (Herrera et al. 2018). Acid and alkaline treatment with NaOH, KOH, and HCl yielded 9–40% separation efficiency. H2O2 treatment showed an average effectiveness of 64.6 ± 7.1%. The maximum efficiency was 97% with 100 ml of 96% ethanol mixture (Herrera et al. 2018). Alkaline and acid digestion are good for decomposing organic materials and recognizing microplastics, but microplastic treatment needs a systematic approach. High concentrations of chemicals such as concentrated HNO3 (22.5 M) can damage pH-sensitive polystyrene polymers, making microplastic counting and measurement difficult. Moreover, H2O2 treatment causes foaming. However, enzymatic digestion efficiency testing does not damage the food matrix (Primpke et al. 2020a). Conclusively, this technique is suitable for animal tissues and organs; however, it must be tailored to digest all organic debris and could damage or break down plastic particles.

Enzymatic treatment

Enzymatic treatment uses biologically active enzymes to separate better than chemical treatment and is less harmful to the environment. Mild enzymatic digestions take longer and are less effective than chemical digestions. The plastic structure remains after digestion (De Boer et al. 2011). Cellulase, protease, lipase, and chitinase are commonly utilized enzymes (Löder and Gerdts 2015). Because of their selectivity, several enzymes are used to digest a food sample (e.g., proteinase only digests protein). A study recovered PP from marine invertebrates and fish using enzymes and H2O2. With 97% plastic particle recovery, plastic degradation was not observed (Karlsson et al. 2017). As ocean plastic waste increases, plasticizers like bisphenol-A and chemical colors harm aquatic biodiversity. These degraded plastics reach fish guts that humans eat. The growing issue of aquatic life contamination has prompted investigations on sea foods and marine ecosystems. Seawater biota-rich samples were used in early enzyme therapy research (Cole et al. 2014). Proteinase-K was used to separate microplastics in acid, alkaline, and enzymatic methods. Enzymatic digestion achieved > 97% (by weight) digestion efficiency in 2 h at 50 °C for particles over 300 μm. Similar research was done with mussel tissues using papain, collagenase, and trypsin. Trypsin was the most cost-effective and fastest, yielding 88% efficiency in 30 min at 40 °C (Courtene-Jones et al. 2017). An intriguing plant-soil ecosystem study examined how polystyrene microplastics affected broad beans using two enzymes. Using biomass and catalase enzyme activity on plant roots resulted in smaller polystyrene particles (< 5 μm) compared to superoxide dismutase and peroxide enzyme mixture. Microplastics may also clog pores and cell walls during nutrient transport, causing toxicity (Jiang et al. 2019). Conclusively, enzymatic digestion causes less harm to polymers than alkaline or acidic treatments. Although suitable for various biological matrices, it is costly and unpredictable, as enzymatic activity is greatly dependent on the matrix.

Extraction techniques

3.1.1.5.1 Ultrasound extraction Extraction has also been investigated in addition to enzymatic, chemical, and floatation techniques for microplastic separation. For instance, pulse ultrasonic extraction was used in a novel laboratory-scale extraction method to separate microplastics from the intestines of freshwater fish (Wagner et al. 2017). A bath sonicator was used to separate microplastics smaller than 50–100 m containing significant levels of polyethylene, styrene, plasticizers, and fibers from the gut sample for 15 min at 39–41 kHz. As they are less toxic to the sample and more effective, the same novel technique was later suggested for treating microplastics in different marine settings (Wagner et al. 2019). The ultrasound extraction method provides advantages over enzymatic and chemical treatment, such as cost-effectiveness and little sample loss without the need for intricate chemical processes. Improved solvent penetration is another benefit of the ultrasonic technique. In addition, investigations on the processing of vegetables and the treatment of industrial wastewater using ultrasonic extraction techniques, were conducted (Simon et al. 2018; Yu et al. 2021). To comprehend the existence of microplastic pollutants, comparable tests were done with milk, beer, honey, and soft beverages (Diaz-Basantes et al. 2020). The filtered drinks were given a one-hour treatment in an ultrasonic bath. According to the FTIR data, the average microplastic/L for craft honey, industrial honey, milk, industrial beer, and soft drinks, was 67, 54, 40, 47, and 32 microplastic/L, respectively. In summary, it can be observed that these techniques achieved appreciable success for extraction of microplastics based on the previous studies discussed above.

3.1.1.5.2 Solid phase microextraction The Solid-phase microextraction approach has also been investigated for the extraction of microplastics. The methodology has lately received interest for microplastic separation even though it is more frequently used for food product analysis since it combines four phases namely sampling, extraction, concentration, and sample introduction into a single solvent-free step (Kusch and Knupp 2004). In addition to these benefits, the process reduces waste disposal expenses and time. Due to its effectiveness in degrading both polymers and monomers, microextraction in headspace mode has drawn interest as a sample approach. For instance, expanded polystyrene fibers, a polymer typically used for food packaging, were degraded at various temperatures using headspace solid-phase microextraction (Kusch and Knupp 2004). The results showed that when sonication at 60 °C and 15 min of sample collection was coupled, there was strong repeatability with few mistakes (3.2–3.6%). The treatment and identification of polymers and volatile organic compounds from PS contained in soil mixtures comprising of alluvial soil, algae biomass, and organic compost were carried out utilizing HS-SPME in conjunction with gas chromatography-mass spectrometry (GC–MS). The findings demonstrated that the method is particularly effective for identifying both coarser fractions (0.1–1 mm) and larger particles (1–5 mm) (Šunta et al. 2021).

3.1.1.5.3 Magnetic extraction Microplastics in drinking water and environmental samples have been subject to magnetic separation. The straightforward method uses iron nanoparticles, which bind to the plastic in the sample to produce a hydrophobic tail. With recoveries of 92%, the attached iron particles magnetize the polymers, attracting microplastics with particle sizes 10–20 m (Grbic et al. 2019). The isolation of microplastics from food matrices can be accomplished using similar techniques. Although the structural integrity of the sample is not affected by magnetic separation techniques, many gaps are seen when the sample is being separated. Therefore, rather than employing a single separation technique, the bulk of researchers have concentrated on using this method of extraction as a pretreatment step (Zhu and Wang 2020). Furthermore, using extraction techniques like pulse ultrasound or ultrasound only promoted the breakdown of brittle plastic components into smaller microplastic pieces, making it difficult to estimate the total count (Simon et al. 2018). Therefore, additional research is needed to assess microplastic separation.

Microplastics identification techniques

Following the separation using the proper procedure, microplastics in the target component of the food sample are identified and quantified. These identification methods are vital for risk evaluations and sample quality control. The techniques range from low-cost, simple techniques to expensive, complex-equipment procedures that yield reliable outcomes. We present some techniques available in literature in the following subsections.

Optical detection

Due to its simplicity and ease of usage, the naked eye approach has been widely employed to characterize microplastics. According to color, size, and plastic-type, including beads, granules, or fragments, visible-to-the-unaided eye particle sizes (larger than 500 μm) are manually separated before being counted (Renner et al. 2018). Optically observing microplastics has also been done in recent years using microscopy. Although the procedure is cheap and straightforward, it cannot be advised as a routine identification method because microscopic or manual counting may lead to errors and incorrect calculations. Additionally, counting the split microplastics could be difficult because of potential debris in the microplastics.

Scanning electron microscopy

Scanning electron microscopy (SEM) is a visual characterization technique frequently used in the field of study for detecting microplastics. The microplastics' morphology is examined using a scanning electron microscope. An electron beam is focused and utilized to scan the microplastics' surface. These electrons contact the atoms on the microplastics' surface and give the right signals, which, when paired with the beam's position, yield an image showing the sample's size and morphological details (Henini 2000). Several research has been done on the use of SEM for microplastic identification. For instance, the search pattern was divided into five groups in a study to determine the microplastics in freshwater fish, with the primary categories being fragments, micro-pellets, fibers, films, and foams. The SEM results employed an elimination-based methodology and were able to distinguish 23% of the particles from plastic (Anderson et al. 2017).

Another study examined the shape, size distribution, and polymer composition of marine ecosystems using a combination of SEM, infrared spectroscopy, and X-ray tomography. The analysis of the SEM data revealed small fractures 30–40 μm deep, few microplastics (mostly copolymers and polyethylene) of approximately 2 mm, and flat cubical-shaped debris of around 2 mm (Ter Halle et al. 2016). Additionally, 92% of the microplastics were polyethylene, with detritus and polypropylene making up the other 8%. Similar tests were done on commercial Malaysian fish dinners, canned sardines, and sprats (Karbalaei et al. 2020). The research used SEM and energy-dispersive X-ray Analysis (EDX) to combine higher picture resolutions with microplastic elemental compositions. SEM has recently been used to identify microplastics in liquids like milk. To determine the properties of the microplastics present, 23 different milk samples were investigated using SEM (Kutralam-Muniasamy et al. 2020). About 72% of the microplastics (fragments and fibers) were blue in color, and 42% of them were small (< 0.5 mm). Micro-holes and cracks on the surface of microplastics were also noted to have a slight form variation. Similar research was done to comprehend the properties of polystyrene buildup and breakdown in honey (Wang et al. 2021b). However, SEM is always used in accordance with protocols to determine if the separated fragments and granules can be classified as microplastics (Renner et al. 2018). As a result, a more quantitative approach is needed to estimate the concentration of microplastics in food samples.

Fourier-transform infrared spectroscopy

For many years, it has been standard practice to investigate the surface properties of materials using Fourier-transform infrared spectroscopy (FTIR) (Huang et al. 2022). The sample absorbs infrared light at a certain wavelength, which causes a vibration (or disturbances) that can be used to analyze the molecular properties and makeup of the sample. The following stages can be used to describe how FTIR works briefly: The microplastic sample is first placed on a mechanically stable, water-resistant filter substrate. The sample is put in an FTIR setup after drying. The next step in the polymer identification process is to use the system database to quantitatively determine the highest composition of plastics and non-plastics. With spatial resolutions of 5 m, the system can detect samples with a minimum thickness of 150 nm (Nguyen et al. 2019). Transmission, reflection, and attenuated total reflectance (ATR) are the three operational modes of FTIR. ATR-FTIR is typically used to identify larger plastic samples, while micro-FTIR is typically used to identify smaller plastic samples (Li et al. 2018b). A sequential measurement of infrared spectra at various locations on the sample's surface is known as micro-FTIR mapping. To create a chemical image of the sample, thousands of spectra are captured inside the measuring area (Levin and Bhargava 2004). This technique has been used to identify microplastics with success.

Numerous studies have been done recently to assess the microplastics in the food chain. For example, a study was done to assess the microplastics in samples of drinking water (Mintenig et al. 2019). Averaging 7 particles/m3 of water with diameters between 5 and 150 μm, the micro-FTIR analysis with a spectral resolution of 8 cm−1 and polymer determination range between 1430 and 1480 cm−1 came to this conclusion. The capability of FTIR has also been used to identify microplastics in a variety of foods and drinks, including milk, honey, soft drinks, and beer. According to recent study, there were 13.45–6742.48 μm fibers and 2.48–247.54 μm fragments with an overall microplastics concentration of 12% (Diaz-Basantes et al. 2020). The detection of microplastics in bottled drinking water has also been successfully accomplished in an intriguing work that combined FTIR with Nile Red stain (Mason et al. 2018). Nile Red binds to the microplastics' surface, creating a stain that emits fluorescence at a certain wavelength. Therefore, while taking into account things like results precision and time constraints, FTIR is a viable approach. Water in the sample, it should be emphasized, prevents the approach from being used because it can cover up the target spectrum (Primpke et al. 2020a).

Raman spectroscopy

Raman spectroscopy is a particularly popular technique for microplastic identification. The method uses a scattering method to excite the target molecules with a laser of a specific wavelength. The sample's elemental makeup can be determined by measuring the frequency of scattered radiation from the sample. Due to the scattered frequencies produced by the sample, the analytical technique can analyze particles of much smaller sizes with spatial resolutions below 1 μm compared to other techniques like FTIR (Imhof et al. 2016). The possibility of Raman spectroscopy for identifying microplastics in food samples has been examined in a number of studies. For instance, a study was carried out using micro-Raman spectroscopy to comprehend the microplastic concentration in 17 distinct commercial table salts (Karami et al. 2017b). Samples contained 41.6% polymers, 23.6% pigments, and 5.5% amorphous carbon with a laser wavelength of 785 nm and power below 3 mW. Using a combination of microscopic and micro-Raman techniques, similar studies were carried out on Turkish-origin table salts (Gündoğdu 2018). According to the composition tests, polypropylene (19.2%) was followed by polyethylene (22.9%). With particle sizes ranging from 20 to 5 mm (wavelength: 785 nm), the MP concentration in sea, lake, and rock salt was 16–84, 8–102, and 9–16 items/kg, respectively. Micro-Raman spectroscopy was used in another experiment with beach waters (Erni-Cassola et al. 2017). Raman spectroscopy has reportedly been used to analyze microplastics in drinks like wine (Prata et al. 2020). The micro-Raman spectroscopy used to identify polyethylene particles of various sizes (20 m) and colors in white wine had a wavelength of 633 nm and a resolution of 100 cm−1. Crystals of minerals, trash, and fragments of wood were also seen. One of the groundbreaking research was also shown to be true for soft drinks, cold tea, and energy drinks, which after Raman analysis revealed considerable levels of blue pigments and polyamide content (Shruti et al. 2020). Raman spectroscopy was not, however, used as the only approach for identification in the majority of these studies because of the high background fluorescence, sample photodegradation, and weathering-related spectral fluctuation. Many investigations have found success using a Raman and FTIR or Raman and electron microscopy combo. Additionally, only a very tiny number of studies have used Raman spectroscopy to identify microplastics with particle sizes of 1 µm visually. This is such that the scanning filters cannot be handled with tweezers directly (Xu et al. 2019a). Small filter regions are therefore checked, making the entire procedure labor- and time-intensive. The spectral interference that developed during the examination was another roadblock. For instance, it was observed the presence of several additives, colors, and compounds in bottled mineral water that produced higher background signals in opposition to the weak Raman signals (Oßmann et al. 2018). These components included calcium chloride, magnesium fluoride, and silica. Additionally, for encouraging outcomes during MP identification from samples, a more extensive library for polymer identification should be accessible (Xu et al. 2019a).

Thermo-analytical technique

It has been discovered that the thermal degradation of microplastics is advantageous because it can serve the dual purposes of determining the kind of polymer and locating organic substances, gases, and additives in the intricate formulation. To eliminate the problem of background contamination, such approaches can be completed in a single run without the use of solvents like ethanol or water (La Nasa et al. 2020). The method typically makes use of pyrolysis byproducts at a specific temperature and oxygen-free environment. For molecular measurement of polymers, these products are combined with mass spectrometry (MS) and gas chromatography (GC) setups (Fries et al., 2013). GC–MS investigations have proved crucial for examining non-polar components, fatty acids, lipids, and polymers. Due to its dependability, accuracy, and low cost, the technique has proved helpful in the food business in detecting adulteration, pesticides, or other contaminants (Fauzi et al. 2017). The method has been effectively used in a number of food matrices in recent years. As an illustration, a study on fish meal revealed the use of a pyrolysis GC–MS setup with a mass accuracy of 1 ppm and spiked levels of 2.7 g and 2.5 g of polystyrene and polymethylmethacrylate in the sample, respectively (Logemann et al. 2018). The GC–MS equipment also produced a good linear response when recognizing 0.05 g to 50 g of plastic by weight. Another study used pyrolysis GC–MS and transmission electron microscopy (TEM) to show the presence of microplastics in soils grown with wheat (Watteau et al. 2018). The results showed that after pyrolysis treatment at 650 °C with 30 s holding time, microplastics of sizes less than 200 m combined with organic materials were present.

Other than polymers, organo-mineral particles such as titanium, barium, and others were also found. Similar research was done to investigate the possibility of pyrolysis GC–MS and the presence of polystyrene microparticles in mussel tissues at 500 °C (Fabbri et al. 2020). The sensitivity examination revealed bioaccumulation of polystyrene particles in the digestive glands as well as traces of chitin and proteins. A combination of high-performance liquid chromatography (HPLC) and MS has also been used to develop methods for evaluating microplastics in cat and dog food (Zhang et al. 2019b). The study aimed to comprehend the potential hazards of cats and dogs ingesting microplastics. The research found that the range of cat and dog food with the maximum PET detection was 1500 ng/g to 12,000 ng/g after examining 58 pet food samples. According to conclusive correlations, other monomers such as bisphenol-A, polycarbonate, and terephthalic acid were successfully detected using HPLC–MS. The authors of the aforementioned research noted a significant difficulty in quantifying microplastics with regard to particle size, color, and shape. The detection is also in the millimeter range, which results in low efficiencies and resolutions (Primpke et al. 2020b). Although the method is affordable and capable of analyzing complicated matrices, it might be an alternative for quantifying microplastic fragments because it may react with complex sample tissues at a specific temperature, making microplastic identification difficult.

Health impact of microplastic-contaminated foods

The proliferation and adoption of plastics for various uses in daily human endeavors have resulted in a significant increase in microplasticss in the environment (Çıtar Dazıroğlu and Bilici 2023). As already discussed, these microplastics are highly incident and has entered the human food chain through various routes including food packaging, seafood, agricultural produce and food additives (Benson et al. 2022; Alberghini et al. 2022; Çıtar Dazıroğlu and Bilici 2023). The health implication of microplastics pollution may not be limited to food intake, but also from colonizing microorganisms and sorbed contaminants (Udovicki et al. 2022). Although the presence of microplastics in the human food chain has been established, the health implications is understudied, although health risks are enormous (He et al. 2021a, b). Studies show that the ubiquity of microplastics ensure steady inundation of food materials from source to the final consumption (Fig. 3) (He et al. 2021a, b); suggesting a steady increase in the microplastics content in food. This continued contamination of food materials has resulted in variable microplastics content, thus different contributions to the microplastics burden in humans. For example, the microplastics content of salt and the average daily intake suggests a burden range between 0 and 7.3 × 104 MP/person/year (Renzi and Blašković 2018; Wu et al. 2022).

Microplastic ingestion by humans induces severe health implications mainly due to bioavailability and biopersistence. Metabolism is followed by adsorption into the circulatory system and subsequent translocation to various parts. It is the properties of the microplastics that lead to persistence as they are not very degradable, leading to various health implications. Necessary steps need to be taken to remediate this occurrence

Similarly, risk assessment on the microplastics load from seafood shows a global average intake ranging between 11 to 3.5 × 104 MP/year (Hantoro et al. 2019) and about 11,000 microplastics/year in countries of low consumption (Van Cauwenberghe and Janssen 2014). The presence of microplastics in edible parts including muscles at concentrations higher than found in the gut (Karami et al. 2017a; Hantoro et al. 2019) totally cancel this respite. This suggests high bioavailability of microplastics which is an underlying factor to contaminant toxicity (Wu et al. 2022; Okeke et al. 2023b). Further, upon entry into humans, by ingestion, dermal contact or inhalation, these contaminants enter the metabolic pathways, are distributed to other parts and are excreted via urine and stool. Microplastics was detected in the muscles of all sampled fish, with higher concentrations in the benthic compared to pelagic species, posing a serious health risk to consumers (Akhbarizadeh et al. 2018). Similarly, various microplastics have been detected in the gastrointestinal tracts of fish (Cyprinus carpio) with impact on scale morphology and genetics, presenting health implications to the fish and human consumers (Saad et al. 2022). Microplastics have been detected in the liver, blood cells and brain of Oryzias latipes, with the detection in brain proving that microplastics can cross the tough, protective blood–brain barrier; posing significant danger. Overall, seafood including fish and shellfish from oceans has been identified as the most important microplastic source humans (Çıtar Dazıroğlu and Bilici 2023).

There is a lot of premium on increased water intake, drinking up to 2 L of water/day presents many health benefits (Nakamura et al. 2020). But juxtaposed with the health risks due to microplastic contamination, increased water intake may pose a greater health risk. With about 103 microplastics/year available from tap water and more in bottle water, increase water intake appears to present severe health concerns (He et al. 2021b). An average human may drink up to 4.1 × 104 microplastics from drinking water yearly (Wu et al. 2022). Although these risk assessment figures offer an idea of the possible risk faced by humans due to consumption of food contaminated with microplastics, there is need for more reliable and detailed methods of analysis. These methods will go beyond estimation and could capture more microplastics to offer the true information of health impacts of microplastics. Further, information on the availability, metabolism and egestion of microplastics will enable the elucidation of the public health risks.

Obviously, microplastics are incident in food at appreciable levels and present respiratory, reproductive, neurotoxic diseases as well as cancer and disruptions to microbiota (Çıtar Dazıroğlu and Bilici 2023). (Kashiwada 2006). The effects of microplastics on human health remain poorly elucidated, although the presence of this toxicant has been reported in liver, spleen, lungs, heart, kidneys and brain of lower animals with evidence of vector functions from lower animals into humans (Çıtar Dazıroğlu and Bilici 2023; Ziani et al. 2023). The toxic impacts of microplastics in humans have been linked to the translocation and accumulation of microplastics in humans (He et al. 2021b). Ecotoxicity studies on fish has shown that microplastics can enter the blood circulation following adsorption from the gut and can then be translocated to other sites of toxic actions (Guerrera et al. 2021). This translocation made worse by biopersistence of microplastics, cause apoptosis, necrosis, oxidative stress, genotoxicity and inflammation, which could be made worse due to their surface area to volume ratio leading to carcinogenesis (Çıtar Dazıroğlu and Bilici 2023). The contributions of microplastics to immune disruption, neurotoxicity, neoplasm are due to inflammation, particle toxicity and oxidative stress (Prata et al. 2020).

Various mechanisms are involved in the impacts of microplastics to health. For example, the disruption of immune function and carcinogenicity could involve the upregulation of immunity related genes or reduced expression of immune factors (Çıtar Dazıroğlu and Bilici 2023). Specifically, polyethylene toxicity has been linked to decreased levels of CD4-, T helper- and regulatory T- cells, worsened by intestinal inflammation (Li et al. 2020a). Further, Li and others (Li et al. 2020a) highlight that this PE-induced inflammation led to dysbiosis, with marked increase in abundance of Staphylococcus and decrease in Parabacteroides species plus a corresponding increase in interleukin. Immune cytokines, such as interleukin, was previously reported in response to inflammations even in humans (Nishimoto et al. 2008). In a study on the effect of polystyrene on the epithelial A549 epithelial cells of the human lungs, the easy internalization of microplastics was confirmed to influence apoptosis and cell cycle to eventually disrupt gene transcription and protein expression (Xu et al. 2019b). Further, the consistent exposure to microplastics has been implicated for carcinogenesis due to the increased expression of oncogenes, like asialoglycoprotein receptor 2 (Çıtar Dazıroğlu and Bilici 2023). Neurotoxicity due to exposure to microplastics is the result of their access to the systemic circulation and ability to cross the blood brain barrier to induce oxidative stress (Çıtar Dazıroğlu and Bilici 2023). As the brain is most sensitive to oxidative stress (Dutta and Bandopadhyay 2022), this affects inflammations and consequent diseases. Apart from inflammation due to oxidative stress, microplastics may inhibit acetylcholinesterase expression and change neurotransmitter levels to cause behavioral changes (Prüst et al. 2020). In the long run, the proliferation of plastic materials needs to be downregulated considering the enormous public health consequences. Human exposure to microplastic may cause various diseases including inflammatory, liver, neuro, lung diseases and metabolic imbalance (Prata 2018; Prata et al. 2020; Yan et al. 2022). Further, microplastics release different harmful chemicals such as bisphenol-A, poly aromatic hydrocarbons, chlorinated pesticides, could lead to dysbiosis and other physiological alterations leading to mutation and cancer (De-la-Torre 2020). The need for more studies on these health impacts may need to be more accurate and human-based to provide details on the actual risk.

Impact of microplastic contamination on the global food security

Microplastics particles originating from different sources and having various chemical compositions, shapes and sizes (macro, meso, micro- and nanoparticles) are abundant in the environment (Duis and Coors 2016; Crossman et al. 2020; Wahl et al. 2021; Kuttykattil et al. 2023; Métais et al. 2023; Jiang et al. 2023; Myszka et al. 2023; Chandrakanthan et al. 2023; Rasmussen et al. 2023). In the year 2018, global plastic pollution reached around 380 million tons per year which is predicted to triple by 2050. Mostly these plastic particles originate from various inland sources including domestic and industrial sewage, storm sewers, and runoff from agricultural fields having plastic mulching or treated with sewage sludge and wastewater treatment effluents. The use of polystyrene and polyurethane compost to increase crop productivity and subsequently add to the Microplastics pollution was recently reviewed (Hurley and Nizzetto 2018). This rapidly increasing use of plastic along with paucity proper disposal strategies has resulted in huge waste generation in oceans and land. Microplastic particles are generated by the slow fragmentation of plastic waste as well as from beads and pellets present in personal care products (Wang et al. 2020). These minute particles easily diffuse into different food sources and enter the food chain.

Microplastics are reported to extensively widespread in seafood, fishes such as tuna, sardines, mackerel, haddock, and plaice as well as oysters, mussels, cockles, squids, clams, urchins, cockles, periwinkles, prawns, shrimps and crabs (Markic et al. 2018; Walkinshaw et al. 2020; Ma et al. 2020; Neto et al. 2020; Wootton et al. 2021; Diaz-Basantes et al. 2022; Zitouni et al. 2022; Vitali et al. 2023). These mussels have an ability to thrive under diverse environmental parameters and being filter-feeding organisms, they can concentrate microplastic (Li et al. 2019). Microplastic particles ranging from 200 to 1500 µm were detected from tissue samples of commercially cultivated mussels such as Mytilus galloprovincialis and Mytilus edulis obtained from Belgian supermarkets (De Witte et al. 2014) where the quantity of total microplastics varied from 0.26 to 0.51 fibers/g of soft tissue. The existence of nearly 0.36 and 0.47 microplastic particles/g from Mytilus edulis and Pacific oysters produced in Atlantic Ocean and North Sea was reported (Van Cauwenberghe and Janssen 2014). Similarly, oysters and clams before depuration have also been reported to accumulate a wide amount of microplastics. The presence of microplastic particles in shrimps and crabs was recently demonstrated, these food items which are widely consumed seafood (Daniel et al. 2021). Similar reports of existence of microplastics in the size range of 19.97 to 4976.22 μm from crabs were reported by (Zhang et al. 2021).

The presence of 73 microplastics (48 fibers and 25 fragments) in 26 commercial fish species which consists of particle sizes ranging from 217 to 4810 µm from stomach contents of the commercial fishes available in Portugal (Neves et al. 2015). Another study by Phillips and Bonner (2015) showed the extensive presence of microplastic particles in fish from the Gulf of Mexico. The presence of microplastic particles, mostly polyethylene of size range around < 5 mm in both pelagic fish species such as mackerel, herring and also from demersal fish species such as cod, flounder and dab from Baltic and North Sea was studied (Rummel et al. 2017). In most cases, plastic contamination was more dominant in pelagic species than demersal species. Microplastics were reported in gastrointestinal tracks and dorsal muscles and gills of mackerel and seabass; these microplastics particle sizes ranged from 151 to 5000 μm (Barboza et al. 2020). Several experiments have also been conducted to focus on the transfer of microplastic from one trophic to another trophic level. A study conducted by Farrell and Nelson (2013) highlighted the transfer of microplastic between mussels and crabs. Moreover, fish meals are extensively used as poultry and pig feed which may result in the transfer of microplastic particles in non-marine food sources (Bouwmeester et al. 2015). The presence of microplastics is also reported in poultry products and eggs. In a study made by Huerta Lwanga et al. (2017), it was reported that chicken gizzards, intestinal mucosa and chicken-organs, digestive system showed presence of microplastics. The particle size was reported to vary from 1.5 to 150 μm (EFSA Panel on Contaminants in the Food Chain 2016). Apart from the animal source, microplastic of varying sizes has also been reported in apples, pears, broccoli, lettuce, wax, honey, larvae, corn flour, and carrots (Oliveri Conti et al. 2020; Alma et al. 2023; Shi et al. 2023; Pham et al. 2023). Microplastic contamination in vegetables occurs due to irrigation, plastic items present in covers which are degraded under ultraviolet light, polymers used in the microencapsulation of agrochemicals and the use of sewage as soil fertilizer (Milojevic and Cydzik-Kwiatkowska 2021; Kallenbach et al. 2022; Lwanga et al. 2022). In most cases, the exact mechanism associated with absorption, transportation and accumulation of microplastics from the soil to the aerial part of crop plants is still considered crucial and needs further research.

According to the studies by Li et al. (2021a) and Azeem et al. (2021), it was reported that microplastic of less than 100 nm was able to infiltrate roots and reach stems and leaves of crop plants; on the other hand, the bigger particles fail to penetrate cell wall and remains on the root’s surface. Microplastic of different surface charges and having a diameter of around 100 nm size can accumulate within the crop plants like lettuce and wheat mainly through cracks in the lateral roots (Sun et al. 2020b). In another study by Giorgetti et al. (2020), it was shown that microplastics of size 50 nm were present in the root cells of Allium cepa. A similar accumulation of 100–700 nm polystyrene microplastics was also reported in the cucumber plant by Li et al. (2021c). These accumulations of microplastic and microplastic in plants significantly alter porosity, hydraulic conductivity, bulk density, field capacity, soil water repellency and rhizospheric bacterial communities of crop plants (Qi et al. 2020). The presence of microplastic contamination in nori seaweed widely cultivated in ocean was reported (Li et al. 2020c). A detailed account of microplastic in the food items is enlisted in Table 5.

Remediation of microplastic pollution

The issue of microplastic pollution has caused numerous environmental and human health hazards resulting to global threat to the society. A set of biobased and technologically driven ecofriendly strategies are necessary to address the possible effects of microplastics on global food security.

Microbial enzymes-mediated bioremediation

The circular economy for plastic waste could be achieved via microbial enzyme technology. Because they can produce enzymes for using plastic as a source of energy, making microbes the most ideal for reducing environmental plastic pollution. Till date, potential microbial degraders of plastics have been reported in seven out of the twelve microbial phyla (Gambarini et al. 2022). Further, synthetic plastics can be degraded by microbial enzymes, including lipases, hydrolases, laccases, and peroxidases. Most fungal enzymes present a machinery integrated for depolymerizing and mineralizing plastic (Zhu et al. 2016). The use of microbial enzymes for plastic degradation is preferred for improve stability when compared to their equivalents from animals and plants. For example, Ideonella sakaiensis 201-F6 is a well-known illustration of a bacterial strain that can degrade polyethylene terephthalate (PET). The most widely produced synthetic polymer, PET, is produced annually in excess of 50 million tonnes worldwide (Bornscheuer 2016). Strain 201-F6 produced the serine hydrolases known as IsPETase and IsMHETase, which resemble cutinases (da Costa et al. 2021).

PET breakdown proceeds in two steps; in the first step, an IsPETase causes a nick to form in the PET polymer chain, producing PET chains with hydroxyethyl (HE)- and terephthalic acid (TPA) ends. Later, bis- and mono-(2-hydroxyethyl) terephthalic acid (BHET) and mono-(2-hydroxyethyl) terephthalic acid (MHET) are produced from the two PET chains with those termini (da Costa et al. 2021). Terephthalic acid (TPA) and ethylene glycol (EG) were produced as a result of the subsequent digestion of these compounds (Knott et al. 2020). EG and TPA are converted into water and carbon dioxide through absorption and mineralization, respectively (da Costa et al. 2021). Further, modified/hydrolase fold with a hydrophobic active domain and a lid site was visible in the 3D structure of MGS0156. However, due to its exceptional enzymatic activity against PET, IsPETase has undergone structural changes using a number of biotechnological techniques. It has also been demonstrated that a number of cutinases degrade PET. Cutinases have been discovered in fungus like Fusarium solani pisi and bacteria like Thermobifida fusca (Stavila et al. 2013). Cutinases from both groups belong to the ß-hydrolase superfamily and have comparable spatial configurations. As PET degraders, Thermomonospora and Thermobifida genera have been identified (Ru et al. 2020). PET can be effectively broken down by the catalytic trio of MHETase, tannase, and PET hydrolase (Taniguchi et al. 2019; Bhatt et al. 2021). According to structural studies, these enzymes feature disulfide linkages and/or folds that give them thermal stability. The fungi phyla Humicola and Fusarium have been studied for their cutinases, which degrade PET. The role of PET hydrolases in degradation was investigated in a bioinformatics-based work. The study reported over 800 PET hydrolases from bacteria and archaea from both marine and terrestrial habitats (Danso et al. 2018).

Specific enzymes from different strains have been reported to degrade PETs. For instance, cutinase from Pseudomonas pelagia (De Jesus and Alkendi 2022) and P. pertucinogena (Bollinger et al. 2020) degrades polyester. The genome-based esterases MGS0156 and GEN0105 hydrolyzes polycaprolactone, bis(benzoyloxyethyl)-terephthalate and polylactic acid (Bhatt et al. 2021). Some listed PET-degrading enzymes include TfH from Thermobifida fusca, HiC from Humicola insolens, lsPETase from Ideonell asakaiensis, Tfcut2 from Thermobifida fusca, Cut190 from Saccharomonospora viridis, PsC from Pseudomonas mendocina, PmC, and LC-cutinase from Fusarium solani (Wei et al. 2019). Polyisocyanates and polyols are condensed to produce polyurethane (PU), which is then linked to urethane linkages (Bhatt et al. 2021).

Recent research has shown that biotechnological methods improve the structural stability of enzymes. Protein engineering usually uses a structural-based modeling approach to create enzyme variations with improved enzyme performance and properties that are thermally stable. An IsPETaseS121E/D186H/S242T/N246D strain with improved thermostability and substrate binding efficiency (Son et al. 2020; Meng et al. 2021). When compared to wild-type TfCut2, the mutant T. fusca thermally stable cutinase (TfCut2) had a hydrolyzing action that was 12.7 times better (Furukawa et al. 2019). Therefore, MP bioremediation may be made more effective by the development of a better and more effective microbial strain by site-directed mutagenesis. To create biofuels from microalgae, significant biotechnological research is now being conducted. Additionally, the microalgae's potential for bioremediation has been mentioned in a number of studies. On a diatom and a green alga, numerous functional expression studies have been carried out (Moog et al. 2019; Furukawa et al. 2019; Meng et al. 2021). The ability to clone and express intracellular lipases was discovered by Mohanan et al. in a study (Mohanan et al. 2022). These lipases effectively degraded short- and medium-chain polymers, suggesting a viable bioremediation approach for the biodegradation of microplastics. Nanotechnology and other cutting-edge techniques, such as enzyme immobilization, have begun to spark attention for potential uses to stop microplastics in the near future. The site-directed immobilization method of PETase on magnetic nanoparticles has suggested a potential method for decreasing microplastic (Schwaminger et al. 2021). It is important to pay close attention to how various microbial networks produce enzymes and how microbial associations cooperate with one another. It is expected that further research in this area will quickly reveal useful techniques for biodegradation that can be employed on a bigger scale because microorganisms have almost endless potential and are continually adapting to their surroundings. A detailed account of a few microbes associated with Microplastics particle degradation is enlisted in Table 6. All these bacteria and associated enzymes can be used as a suitable biotechnological approach for the degrade of microplastics particles.

Biofilm-mediated remediation

When microorganisms are introduced to an aqueous environment, they quickly colonize the surface to create a permanent biofilm (Okeke et al. 2022c). Certain bacteria in biofilms have the ability to degrade organic pollutants and promote the adhesion of pollutants by microplastics (Rummel et al. 2017). The biological breakdown of the microplastics may be caused by the interaction of microplastics with biofilms, which may alter the chemical and physical properties of the polymer surface. The sorption of heavy metals onto plastic surfaces, the relationship between biofilms and toxins and the impact of biofilm establishment on microplastics were the main topics of early research into microplastics and biofilms (Wu et al. 2021). Research on how biofilms affect the ecologically friendly biodegradation of microplastics has just recently started. On polyethylene (PE) surfaces, Rhodococcus ruber has been demonstrated to colonize and create biofilms (Hadad et al. 2005). The usual molecular mass of the PE samples was reduced to 14% and 21%, respectively (Hadad et al. 2005). Thus, research into whether biofilms' development could alter the microplastics' physicochemical characteristics started (Ganesan et al. 2022) considerable surface degradation of microplastics treated with biofilms has also been observed in an environment with a considerable amount of methane gas; this can support the rise in bacterial aggregation (Faheem et al. 2020). The only byproducts of microplastic degradation that are still present are water and carbon dioxide, neither of which harm the ecosystem (Faheem et al. 2020). In an environment with high levels of methane gas, which may promote the establishment of bacterial aggregation, significant surface degradation of microplastics treated with biofilms has also been observed (Faheem et al. 2020).

Biofilms are abundant and easily accessible in the natural world (Faheem et al. 2020). Scientists have also predicted that biofilms, which act as transporters and may increase the adsorption of microplastics to pollutants in the ecosystem, will amplify the ecological danger posed by microplastics in the environment (Richard et al. 2019; Wang et al. 2021a; Stabnikova et al. 2022). Microplastics are discovered to break down more quickly than natural biofilms when glucose is employed as an external carbon source (Shabbir et al. 2020). While acting as carriers and increasing the ecological risk of microplastics in the ecosystem, other studies have proposed that biofilms can promote the adsorption of microplastics to environmental pollutants (Wang et al. 2021a). In one study, it was discovered that as soon as microplastics are introduced to an aqueous environment, bacteria immediately colonize their surfaces and create biofilms that promote the adsorption of the microplastics to environmental pollutants (Chen et al. 2020). However, the issue can be largely resolved if the biofilm is produced and formed previously under controlled conditions before being treated with microplastics. It is possible to adsorb additional environmental pollutants in addition to breaking down microplastics in the aqueous environment by integrating the technology of biofilm degradation of microplastics into the source treatment of microplastics or applying it to in situ cleanup of microplastics in freshwater sources. Using biofilms to break down microplastics could represent a comparatively environmentally friendly strategy (Faheem et al. 2020).