Abstract

The rising water pollution by pesticides, pharmaceuticals and dyes is a major health issue calling for advanced remediation methods such as photocatalysis with titanium dioxide (TiO2), yet the use of TiO2 displays issues of aggregation, mass loss, recovery, and reusability. These issues have been recently solved by synthesizing biopolymer-supported photocatalysts using cheap, biodegradable and safe biopolymers such as chitosan, alginate, cellulose, cyclodextrin, guar gum and starch. Here we review biopolymer-supported TiO2 photocatalysts for the removal of organic compounds, with focus on preparation methods, photo and chemical stability, reusability, and adsorptive capacity. We discuss applications of immobilized photocatalysts at the industrial scale.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Water is a necessity for all humans living on the globe. Freshwater availability has been seriously reduced in recent decades as a result of population increase, industrialization, and growing demand (Gusain et al. 2019). Water contamination is the most serious threat to the growth and survival of flora and animals, causing enormous socioeconomic difficulties (Ponnuchamy et al. 2021). Water contamination increased owing to the presence of both man-made and natural pollutants in water resources. The organic pollutants (pesticides, pharmaceuticals, chlorinated solvents, dyes), inorganic pollutants (nitrates, phosphate, and heavy metals), and pathogens (coliform bacteria) have been identified as major pollutants in water (Dong et al. 2020; Laws 2017; Yang et al. 2017). Due to the rapid usage of these products, organic pollutants are detected in the different environmental spheres (Dhaka et al. 2019; Jaafarzadeh et al. 2017). These organic pollutants persist in nature, resist biodegradation, and eventually accumulate in the food chain (Gui et al. 2014; Qiu et al. 2019). Therefore, the removal of organic pollutants and their metabolites from water resources are necessary to provide safe drinking water and ensure safety.

The ultimate requirement for adequate water treatment technology is critical for the mineralization of organic pollutants. In recent times, advanced oxidation processes have emerged as powerful technologies in mineralizing the organic contaminants in liquid streams. Among different photocatalysts, TiO2 is the most widely employed photocatalyst because of non-toxicity, greater photostability, chemical inertness, and better oxidation efficiency (Kanan et al. 2020). TiO2 is capable of eliminating both organic and inorganic pollutants but they are not commercialized due to different technical barriers. Firstly, the wide band gap (3.2 eV for anatase phase) of the TiO2 needs ultraviolet light for the activation of photocatalyst and results in minimum utilization of solar light. In the solar spectrum, only 5% of the sun’s energy belongs to the UV range, while it is 45% for the visible range (Balakrishnan et al. 2021). Thus, shifting the bandgap of the TiO2 from the ultraviolet region to the visible region is necessary for real-life applications (Dong et al. 2015). Other associated problems with TiO2 based photocatalysis are (i) low adsorption of organic pollutants, (ii) difficulty in the recovery of photocatalyst, (iii) aggregation of nano-sized catalysts and, (iv) difficulty in uniform distribution of catalyst (Balakrishnan et al. 2020a). The development of new photocatalysts is evident to extend the absorption wavelength to the visible range region and minimize the effects of recombination of electron/hole pairs. In addition, a special focus must be given to the reusability and recoverability of the photocatalyst.

Different strategies have been proposed to overcome the drawbacks of TiO2 are doping with metals and non-metals (Juan et al. 2021), co-doping (Al-Mamun et al. 2019), heterojunction construction (He et al. 2021), surface organic modifications (Park et al. 2013), and immobilization of support structures (Shi et al. 2019). Where immobilization of support structures is considered as an effective strategy to minimize the cost associated with recovery and separation of photocatalyst from aqueous solution (Sraw et al. 2018). Many studies reported the utilization of different supports (polymers, clay, silica, and perlite) for the photocatalyst to enhance recovery, reusability, and degradation efficiency to a greater extent (Sraw et al. 2018). One of the prominent methods to enhance the reuse of the photocatalyst is the utilization of biopolymers as a support material for TiO2. The key features of biopolymers include low-cost, durability, environmentally friendly, higher adsorption property, availability and biodegradable (Balakrishnan and Chinthala 2022). This paper reviews the different biopolymers and their performance as support materials for TiO2 based photocatalyst. The important biopolymers reviewed in this paper are chitosan, cellulose, alginate, cyclodextrin, gum, starch and collagen.

The manuscript is divided into different sections. Firstly, the photocatalytic degradation mechanism of TiO2 based materials is described. The next sections discuss the photocatalytic supports with potent advantages and disadvantages. The succeeding section briefs the role of biopolymer as a support material for TiO2. Finally, a comprehensive review is conducted on the removal of organic pollutants using different biopolymer supported photocatalysts. An approach for the scale-up of photocatalytic studies from batch mode to continuous mode is illustrated in the section industrial perspectives. The strategies to overcome the challenges faced by biopolymer supported TiO2 is also emphasized in the conclusion. It is also believed that this review helps the researchers to scale up the photocatalytic technology.

Photocatalytic degradation mechanism

Heterogeneous photocatalysis is conducted in five stages:

-

1.

Diffusion of organic pollutants from the bulk liquid phase to the photocatalyst surface,

-

2.

Adsorption of organic pollutants onto the surface of photocatalyst,

-

3.

Photochemical reaction due to the interaction between light and catalyst producing highly reactive species (for example oxygen radicals),

-

4.

Desorption of products from the surface of photocatalyst,

-

5.

Removal of products from the bulk of the solution (Paumo et al. 2020).

Among these five steps, the slowest step determines the reaction rate for any process. So, the mass transfer steps I and V are speeded than the reaction steps 2, 3, and 5. Steps 2 and 3 do not interfere with the overall rate of any chemical reaction. In photocatalytic remediation, highly powerful hydroxyl radicals are involved as the oxidizing agents for removing pollutants (Al-Mamun et al. 2019).

Upon the illumination by a suitable light source, the electrons are transferred from the valence band to the conduction band with simultaneous generation of holes in the valence band (Fig. 1). These photo-induced holes are easily trapped by hydroxyl ions and are partially converted to hydroxyl radicals quickly (Chinthala et al. 2021). The produced hydroxyl radicals are extremely strong oxidants responsible for the mineralization of organic pollutants (Aanchal and Basu 2020). The highly efficient trapped oxygen may suppress the recombination of photo-induced holes. Moreover, the limited oxygen supply may cause faster recombination of electrons and holes (Dong et al. 2015; Meenakshi & Farzana, 2013; Paumo et al. 2020).

Photocatalytic degradation mechanism using TiO2 as a photocatalyst. The formation of holes in the valence band and the electrons in the conduction band end up in the oxidation of water molecules and consequently, oxygen molecules are reduced. These redox products undergo a reaction with pollutant molecules and give carbon dioxide and water molecules as end products. Where Eg is the band gap of the photocatalyst, h+ is hole and e− is electron

Photocatalyst supports

Photocatalysts take part in a chemical reaction only upon light source irradiation (Shan et al. 2010). Various materials are explored to modify the TiO2 or other photocatalysts to redeem organic pollutants (Chen et al. 2020a, b). Polymers were incorporated with photocatalysts through immobilization, surface coating, chemical or blending processes (Bet-Moushoul et al. 2016). Any ideal supports for the photocatalyst must exhibit a strong affinity between the photocatalyst and support for anchoring the base material (Singh et al. 2013). The inorganic carbon fabrics, synthetic fabrics, plastics, fly ash, fiberglass, silica gel, wool, glass beads, quartz optical fibers, alumina clays, cellulose, zeolites, chitosan, glass plates, Raschig rings, chitosan, and alginate have been used as support materials for photocatalyst (Adnan et al. 2019; Singh et al. 2013). The different types of support materials and their advantages and disadvantages are mentioned in Table 1.

Biopolymer as a support material

The development of appropriate and effective ways for hybrid matrices to function as envelopes for dopants of large solid particles (Sirajudheen et al. 2021). Biopolymers, activated carbon, silica, and clays were the most commonly utilized support materials in developing hybrid composite materials (Balakrishnan et al. 2021). The removal of organic pollutants depends on the form and morphology of the produced photocatalyst. The support materials may also affect the specific surface area of the photocatalyst that could influence the degradation rate of the pollutant.

Apart from improving the specific surface area, biopolymers possess functional groups in their structure that may interact with the organic pollutants and result in their higher removal rate (Nithya et al. 2014; Shukla et al. 2013). The key reasons for the selection of biopolymers as a suitable support for TiO2 based materials are (Puls et al. 2010; Singh et al. 2013; Shan et al. 2010):

-

Biopolymers are relatively cheap and abundantly available on earth.

-

Biopolymers are safe, chemically inert, and mechanically stable with greater durability.

-

The majority of the polymers are resistant to ultraviolet and do not participate in the oxidation reaction.

-

Bio-polymers as support materials improve adsorption and subsequent oxidation due to the preconcentration of organic contaminants on the catalyst surface.

Biopolymers have gained increased scientific relevance because of their non-toxicity, compatibility, flexibility, pore size, surface morphology, and mechanical strength. As a result, biopolymers are favored over chemical polymers since they are more ecologically friendly and contribute to a more sustainable environment (Karimi-Maleh et al. 2021; Qamar et al. 2020). Due to these unique properties, biopolymers found prominent applications in packaging, biofuels, water treatment, energy storage (George et al. 2020). Majority of the biopolymers are extracted from different biological species as shown in Fig. 2, and Table 2 discusses the properties of the commonly used biopolymer supports.

Preparation methods

The photocatalytic remediation of wastewater has been thoroughly researched by utilizing various biopolymers. The presence of different or unique functional groups indicates the reactivity and flexibility of the polymeric chains for varying applications (Balakrishnan et al. 2020a, b). Different forms of structures can be developed for photocatalytic application. Some of them are beads, films, aerogels, hydrogels, composites, and membranes. Different preparation routes of TiO2/biopolymer supported photocatalyst are illustrated as follows:

Hydrothermal method

The photocatalyst is synthesized in a steel autoclave at 130 to 250 °C by distinctively crystallizing the substances at an elevated vapor pressure of 0.3 to 4 MPa (da Silva et al. 2020; Denkbaş et al. 2016; Sirajudheen et al. 2021). The crystallization leads to particles agglomeration as the vapors pressure gets saturated. However, the usage of stabilizing agents avoids the problems related to agglomeration (Broujeni et al. 2021; Shao et al. 2019). The hydrothermal method can control both the size and shape of the particles through the use of suitable reagents. Furthermore, this eco-friendly approach requires a one-step preparation route (Jadoun et al. 2021).

Sol–gel method

The sol–gel method comprises the condensation of precursors (metal chlorides, nitrates, or alkoxides) in to a solid material upon the evaporation of the respective solutions (Grossin 2021). This is followed by cross-linking reaction and dehydration. Either hydrolysis or condensation of respective precursors yields a sol and coverts to gel upon thermal treatment. Finally, gel is calcined to yield the final products (D’Arienzo et al. 2017). The main advantages of this method are tunable or controllable composition and morphology, low-temperature synthesis, larger surface area, and smaller particle size (D’Arienzo et al. 2017; Yilmaz & Soylak, 2020).

Co-precipitation method

In this strategy, the nanoparticles (metals) are prepared under the presence of biopolymer through precipitation of the catalyst from their precursors (Ashik et al. 2018). The hindered release of anions and cations is beneficial in controlling the nucleation and particle growth. Researchers reported the utilization of this strategy in the preparation of chitosan-based nanocomposites or other structures due to the presence of different functional groups present in their structure (Sirajudheen et al. 2021). The advantages are the ability to control particle size, low-temperature requirements, greater energy efficiency, and the ability to change the surface of particle state (Cruz et al. 2018; Huang et al. 2019). However, this method faces problems due to larger time requirements, and chances of precipitation of impurities present with products (Nawaz et al. 2019).

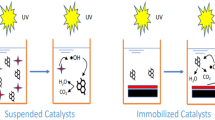

Immobilization

In this method, the nanoparticles are immobilized onto the surface of polymeric networks. Different strategies used for immobilizingTiO2 on biopolymers are crosslinking, entrapment, encapsulation, and covalent bonds (Kumar et al. 2020). All the naturally derived biopolymers can act as supports for immobilizing TiO2 photocatalyst. The immobilized photocatalyst always displayed phenomenal catalytic stability and high dispersion. This method minimizes the catalyst loss and improves the reusability of the material to a greater extent (Satoh et al. 2016). Even though immobilized photocatalysts are more expensive than homogeneous materials, the cost is reduced via recycling or reusing.

Electrospinning

Electrospinning is a well-adopted technology for preparing fibers or one-dimensional materials through the utilization of polymers and their respective precursors. This method employs the synthesis of a non-woven web of micro or nanofibers (Kumar et al. 2020). High voltage requirement is necessary to apply on the liquid stream and a collector, which gradually allows solution passage through a nozzle. Later, the formed jet-shaped fibers are passed through the drying stage and eventually deposits fibers at the collector (Reddy et al. 2016). The nanofibers prepared through this method have a tunable morphology, porosity, higher surface area to volume ratio, low-cost setup, simplicity, high efficiency. The usage of organic solvents and hindered control of porous structures are drawbacks of the electrospinning synthesis process (Kumar et al. 2020; Sirajudheen et al. 2021).

Phase inversion

The phase inversion is a demixing process, where homogeneous polymer solution is transferred from liquid to solid state in a controlled manner (Zare and Kargari 2018). The conversion is attained through the casting of the polymeric solution on a suitable support, followed by dipping or coating in a non-aqueous solvent medium (Sirajudheen et al. 2021). Phase inversion is widely used to prepare the polymeric porous membranes with a bulky form of structure (Figoli et al. 2016). The properties and chemical interactions of the synthesized membranes are dependent on the choice of polymers and the type of additives employed in the casting solution (Purkait et al. 2018).

Biopolymer-supported TiO2 photocatalysts

Chitosan

Chitosan is the second most abundant natural biopolymer in the world (Divya and Jisha 2018). Chitosan is produced from the deacetylation of chitin, which is found in abundance in the exoskeletons of crustaceans (For example shrimp, crab, prawns, and shellfish) (Morin-Crini et al. 2019). The primary benefits of choosing chitosan in wastewater treatment are its low cost and environmental friendliness, high chemical and thermal stability, nontoxicity, biodegradability, simple physical and chemical modification, biocompatibility, and good adsorption properties (Lee et al. 2015). Due to these unique characteristics, chitosan is employed as possible catalyst support. The literature reported that chitosan could be easily modified physically or chemically into different shapes. Because of the hydroxyl and amine groups in the chitosan structure, chitosan is significantly insoluble in certain solvents, making chitosan suitable for the redemption of organic pollutants (Balakrishnan et al. 2020a, b). Additionally, chitosan finds versatile applications in water treatment, biomedical applications, pharmaceuticals, cosmetics, food industry, packaging’s and drug delivery (Parhi 2020; Nasrollahzadeh et al. 2021; Sirajudheen et al. 2021).

Additionally, chitosan is used as an adsorbent to remove organic pollutants from aqueous streams. So, incorporating chitosan to TiO2 integrates both adsorption and photocatalysis. Many studies emphasized the exploration of TiO2/chitosan-based macroporous materials for different advanced oxidation processes in wastewater technology. Hasmath Farzana and Meenakshi, 2014, described the utilization of chitosan/TiO2 nano-composites for the destruction of dyes. The Ti–O–C bond enhanced the polarity of the chitosan-TiO2 mixture benefitting in the efficient separation of electron/hole pairs in the excited state (Hasmath Farzana and Meenakshi 2015). However, a significant catalyst loss was associated with the recovery. Saravanan et al. (2018) emphasized the preparation of TiO2/chitosan via the sol–gel method at different weight ratios. With increase in the chitosan loading in the nano-composites, a reduction in the bandgap of the photocatalyst was observed. For instance, the amphoteric chitosan/TiO2 was prepared by grafting the acrylic acid on the chitosan surface under the presence of potassium persulfate through a free radical polymerization reaction for the elimination of dyes. The obtained chitosan/TiO2 could remove 99.5% of malachite green within 240 min (15 Watts white light). The higher efficiency of the photocatalyst is attributed to the minimized electron–hole recombination. The functional groups of chitosan also contributed to the degradation of malachite green (Bahal et al. 2019).

For instance, Jbeli et al. (2018) synthesized highly active chitosan-TiO2/ZnS via immobilization method followed by hydrothermal treatment. Initially, the chitosan was coated over a glass substrate followed by the deposition of titanium precursor and immersed in Zn(O2CCH3)2 and Na2S. The chitosan, hydroxyl and amino groups and the absence of water molecules accelerated the chemical coordination of titanium precursor, resulting in a small nano-metric amorphous oxo-titanate. Later, Shao et al. (2019) emphasized the development of polydimethylsiloxane-SiO2-chitosan@TiO2 composites on pumice through the immobilization method. The polydimethylsiloxane-SiO2-chitosan@TiO2 was used to remove methylene blue under the illumination of simulated sunlight. This catalyst also exhibited a reusability of five cycles. Moreover, this immobilization approach has increased photostability, reusability, and minimized filtration costs.

Afzal et al. (2019) focused on the magnetically separable TiO2/chitosan assisted visible-light mediated photocatalytic degradation of o-nitrophenol. Response surface methodology analysis estimated 92% of nitrophenol removal within 180 min. Moreover, studies proved that the pH of the medium had played an essential role in the elimination of nitrophenol. The ternary chitosan-based catalyst exhibited greater interactions between each component and resulted in higher absorption capacity. However, studies on the reusability of the photocatalysts are not explored. Later, Afzal et al. (2021) highlighted the preparation of TiO2/chitosan/Fe3O4 to eliminate nitrophenol. The studies also proved the reduction in bandgap from 2.85 eV and minimized charge carrier separation. Under the illumination of the solar light, more than 90% of nitrophenol was degraded within 180 min. After four consecutive cycles, the reusability studies showed 1% nitrophenol reduction.

The immobilized TiO2 on chitosan beads through the phase inversion method was reported by Balakrishnan et al. (2020a, b). With the addition of chitosan to the mixture, the bandgap was reduced from 3.2 to 2.79 eV. Under ultraviolet light, the obtained beads degraded 92% of the 2,4-dichlorophenoxyacetic acid. The studies also answered the concerns of catalyst loss and recovery, as the catalyst demonstrated reusability for ten consecutive cycles with a mass loss of less than 5%, as shown in Fig. 3a. Fourier transform infrared spectra confirmed that the catalyst offered the same stability even after ten cycles (Fig. 3b). They also stated that TiO2/chitosan beads could be adopted for the continuous mode of operation with a potent scope of commercialization. Later, Balakrishnan et al. (2021) also studied the feasibility of 2,4-dichlorophenoxyacetic acid removal (86%) in a recirculating type photocatalytic reactor under ultraviolet light. Recently developed TiO2/chitosan/glycerol beads which removed 93.3% of acid blue 193 at optimized conditions of 90 min, pH 4.5, and an initial concentration of 10 ppm (Hoang et al. 2021).

a Reusability of chitosan/TiO2 beads. A decline in degradation efficiency is observed from 92 to 80% at the end of 11 cycles, b FTIR spectra of fresh and reused catalysts confirm the stability of the photocatalyst. Reprinted from Balakrishnan et al. (2020a, b) with permission from Elsevier. Where TCB is TiO2/chitosan beads

Xu et al. (2021) reported a simple and highly reusable visible-light-driven chitosan/TiO2@g-C3N4 nanocomposite membrane. The membrane removed methyl orange, rhodamine-B, and chromium (VI) with efficiency greater than 90%. The catalyst also displayed reusability up to 10 consecutive cycles. The membranes hydrophilic nature enhanced the reusability of the photocatalyst without any loss in degradation efficiency. This catalyst was also extended to a continuous flow-photocatalytic system and showed removal of 90% for rhodamine-B. Saleh et al. (2021) developed a bentonite/Chitosan/TiO2 heterostructure to reduce arsenic (III) present in the water. Upon the illumination of ultraviolet light, the prepared material reduced 97% of arsenic (III) to arsenic (V). The hydroxyl radicals present in the TiO2 structure were responsible for the pollutant elimination. Moreover, the existence of different co-ions did not interface with the degradation process.

Fused modeling three dimensional deposition, an easily scalable technology is also adopted for the immobilization of TiO2 nanoparticles. Along with that, three dimensional printing technology also plays a vital role in water technology. Bergamonti et al. (2019) highlighted the utilization of three dimensionally printed TiO2/chitosan scaffolds to eliminate amoxicillin under ultraviolet light irradiation. The three dimensionally printed TiO2/chitosan scaffolds showcased the possibilities to modulate the shape and size of the photocatalyst. This, in turn, increases the surface area to volume ratio, which imparted the photocatalytic degradation of amoxicillin. The literature also proved that the scaffolds are elastic, durable, and robust and can be easily recovered and reused from large quantities of polluted water. Table 3 summarizes the different chitosan-supported TiO2 photocatalysts for removing organic pollutants from wastewater.

The photocatalytic effectiveness of chitosan-based materials was higher under both visible and ultraviolet light sources. Furthermore, chitosan present in the chitosan-TiO2 can (i) control the bandgap, (ii) make recovery easier, (iii) decrease mass loss, (iv) enhance stability, and (v) can form any shape or structure (Zhao et al., 2018). Despite the advantages, chitosan possesses several limitations concerning the protonation of NH2 groups of chitosan. The mutual interaction of the chitosan/TiO2 photocatalyst through chelation, coordination of NH2 groups, electrostatic interaction hinders the adsorption of organic pollutants on the catalyst surface. Along with that, most of the studies reported its reusability up to 10 cycles only.

Several steps must be adopted to overcome the problems associated with chitosan/TiO2 materials in wastewater treatment. Firstly, physical and chemical modification of chitosan is desirable to enhance the physicochemical properties and influence the adsorption capacity of the prepared material. Secondly, the doping of metals onto the chitosan/TiO2 may also improve the activity of the photocatalyst via shifting to the visible light activity, which may also suppress the recombination rate. Finally, the development of magnetic chitosan/TiO2 materials may also resolve problems related to catalyst recovery.

Alginate

Alginate is an anionic poly-3-saccharide that may be found in the outer shells of certain algae (brown algae, kelps) (Ibrahim et al. 2017). Alginic acid is the main component for alginate, and sodium alginate is the sodium salt of alginate rich in free hydroxyl and carboxyl groups found in the polymer chain (Wang et al. 2019). The alginate is a copolymer comprised of both α-l-gluronic acid and β-d-mannuronic acid with homopolymeric regions of G block and M-blocks which are connected alternatively with the polymeric structure (Hasnain et al. 2020). Alginate is derived from different sources and exhibits different chemical structures with varying concentrations of G and M-blocks resulting in higher and lower rigidity (Jahandideh et al. 2021).

Sodium alginate is non-toxic and ecologically safe, with high stability due to its strong gelation, film-forming, and complexing properties (Wang et al. 2019). Alginate is biocompatible, biodegradable, non-toxic, and non-immunogenic. Alginate can crosslink with cations due to its intrinsic properties. As a result, alginate is used in various applications in the field of agriculture, food technology, cosmetics, chemical engineering, environmental engineering, medicine, and others (Subekti and Helmiyati 2018; Szekalska et al. 2016). The environmental remediation employing alginate highlighted the rich functional groups that may improve the uptake of metallic ions through ion exchange between the target pollutant and crosslinking cations. Alginate-based polymers are being used to remove dyes, heavy metals, pesticides, and other emerging contaminants found in water. Due to high rigidity and poor elasticity, surface modifications were carried out through metal doping and organic coatings to overcome the concerns (Wang et al. 2019).

In recent years, different studies explained the usage of alginate as a support for the development of semiconductor-based photocatalyst targeting wastewater treatment (Cheng Keong et al. 2017; Reveendran and Ong 2018). Albarelli et al. (2009) explained the usage of calcium alginate as a supporting substrate for TiO2 to eliminate methylene blue. The calcium alginate/TiO2 beads were prepared through the immobilization method. A fixed proportion of the reactor was filled with the catalyst for efficient mass transfer. Moreover, alginate beads act as a semipermeable membrane that permits the passage of low molecular weight water-soluble molecules. Albarelli et al. (2009) also explained that methylene blue degradation follows initial adsorption followed by photocatalytic degradation. The alginate beads also exhibited very good reusability property up to 20 cycles because of enhanced superficial area. In another study, laccases were used along with alginate due to their high oxidizing ability. The spore laccase/TiO2 nanoparticles entrapped alginate beads were reported to eliminate the 25 mg/L of indigo carmine. The studies confirmed 69% indigo carmine removal under the illumination of a light source within 60 min (Khakshoor et al. 2021).

Wei et al. (2016) described the preparation of polyacrylamide/calcium Alginate/TiO2 composite hydrogel film of specific thickness 0.3 mm under UV irradiation and Ca-crosslinking. The prepared film demonstrated superior mechanical strength and toughness. The photocatalytic studies revealed that 81% methyl orange was removed within a contact time of 120 min under ultraviolet illumination with reusability of 5 cycles. Gjipalaj & Alessandri, (2017) prepared alginate-based TiO2 beads through ionotropic gelation for the removal of both anionic (Methyl orange) and cationic dye (Methylene blue). The beads morphology of alginate-based TiO2 adsorbed a higher amount of dyes than in powder form. However, beads took more time than powder for methylene blue removal due to the porous catalysts reduced surface area. The beads also exhibited reusability up to five consecutive cycles under ultraviolet light irradiation. So, the key advantages of preparing beads are their reusability and ease of recoverability.

Kanakaraju et al. (2017), described the dual usage of TiO2/ZnO-calcium alginate beads to remove copper through adsorption and photocatalysis, respectively. The immobilized beads were prepared with three different mass ratios of TiO2 and Zinc (1:1, 1:2, 2:1) to redeem pollutants under direct ultraviolet light. The photocatalytic studies revealed that these beads (1:1) could remove 7.14 to 62.0 mg/L of copper (initial concentration of 10 to 80 mg/L). The better efficiency of this catalyst may be due to the enhanced adsorption of the metal cations on the surface of beads. Later, magnetic TiO2/Alginate/Fe nanoparticles triads were developed via facile non-thermal method. The unique property of alginate in this prepared catalyst is their ability to act as an obstacle between the direct contact of magnetic core and TiO2. This magnetic catalyst also displayed 97.6% of methylene blue removal within 120 min under the illumination of ultraviolet light (254 nm). The efficiency of the prepared catalyst was reduced to 88.5% after three consecutive cycles (Kanakaraju et al. 2018).

Reveendran and Ong (2018) focused on removing dyes through the development of sodium alginate-TiO2 films. The catalyst demonstrated more than 50% removal of Congo red. Similarly, the sodium alginate-TiO2-bentonite nanocomposite was prepared through in-situ method for the reclamation of methylene blue from wastewater. The degradation studies showed 90.5% removal of methylene blue at the optimized condition (pH 8, time 30 min, and catalyst dosage of 30 mg/L) (Subekti and Helmiyati 2018). In the highly stable and porous polysulfone-alginate/TiO2 photocatalyst, the polysulfone matrix resembled as a sponge-macro-void structure; alginate anchored the sites of TiO2 nanoparticles and restricted the surface porosity. TiO2 enhanced the thermal and mechanical properties of the beads. The polysulfone-alginate/TiO2 displayed complete removal of methylene blue, triclosan, diclofenac within 50, 40, and 120 min. Figure 4A shows the photocatalytic redemption of diclofenac and triclosan by utilizing the polysulfone-alginate/TiO2. The appearance and disappearance of the colored by-products of diclofenac at different time intervals are shown in Fig. 4B. The stability of the beads is also observed in Fig. 4C. The enhanced removal rate is attributed to the catalysts higher surface area and greater adsorption properties. The catalyst ensured reusability for 25 consecutive cycles with a 99% removal rate (Mehmood et al. 2020). Floating TiO2/polyvinyl alcohol/alginate composite exhibited a 28.5% and 29.3% ammonia degradation under visible and ultraviolet light, respectively. The floatable catalyst displayed reusability up to 5 cycles (Zendehzaban 2019).

A Photocatalytic degradation of diclofenac and triclosan using polysulfone-alginate/TiO2, B Photographs of diclofenac sample yielded at different time intervals showing the formation of different colored by-products, C The photograph images of polysulfone-alginate/TiO2 beads before and after use. The stability of the photocatalyst is also understood from the figure in detail. Reprinted from Mehmood et al. (2020) with permission from Elsevier

Dalponte Dallabona et al. (2021) prepared floating catalyst with Brazilian bentonite/TiO2/alginate beads by adopting the gelation method. Prepared beads exhibited spherical shape, and the addition of bentonite does not influence the size. However, the addition of gas-forming agents (calcium carbonate) increased the average diameter of floating catalyst from 3 to 4.9 mm. The significant enhancement in size was also attributed to the release of carbon dioxide with carbonate decomposition in an acidic-acetic base. Moreover, the surface area of the beads was 4.447 m2/g, greater than that of sodium bentonite (3.562 m2/g). Photocatalytic studies of bentonite/TiO2/alginate beads demonstrated a 99% dye removal with a total organic carbon removal of 34% and 53% for tartrazine and methylene blue, respectively. Floating catalyst also exhibited a reusability up to 7 cycles and yielded a degradation of > 80%.

Mallakpour et al. (2019) reported the sono-assisted synthesis of the alginate/carbon nanotube/carbon dot/fluoroapatite/TiO2 beads for the elimination of methylene blue from wastewater. Figure 5 shows the schematic representation of different stages during the preparation of alginate/carbon nanotube/carbon dot/fluoroapatite/TiO2 beads. Studies reported the higher efficiency of the prepared photocatalyst under the illumination of ultraviolet light. The presence of the carbon nanotubes, carbon dot, and fluoroapatite not enhanced the removal efficiency but also minimized the recombination of photo-induced electron–hole pairs. The hydroxyl radical’s superoxide radicals and holes played a phenomenal role in degradation of dyes. Recently, Chkirida et al. (2021) prepared alginate/bentonite impregnated TiO2 beads to degrade methylene blue present in the wastewater by utilizing a green and simple impregnation method. The obtained photocatalyst showed 98% methylene blue and 93% chemical oxygen demand reduction within one hour of light irradiation. Table 4 summarizes different alginate-supported TiO2 photocatalysts for removing organic pollutants.

Preparation mechanism of floatable with alginate/carbon nanotube/carbon dot/fluoroapatite/TiO2 beads. The key steps involved in the preparation are (i) Mixing of carbon nanotube/carbon dot/fluoroapatite/TiO2 with sodium alginate solution via sonication. (ii) Drop the mixture into a calcium chloride bath using a syringe to yield beads. Finally wash the prepared beads to eliminate the excess calcium chloride on the bead surface. Reprinted from Mallakpour et al. (2019) with permission from Elsevier. Where FA is fluoroapatite, Cdot is carbon dot, and CNT is carbon nanotube

Alginate-based materials are widely used in developing multifunctional systems, particularly for photocatalytic applications. The uniqueness of alginate is ascribed to biocompatibility, stability, changeable porosity, and low cost. Even after continuous research, the following points must be addressed as earliest to attain a sustainable solution.

(i) Sodium alginates mechanical strength and stability are determined to be relatively poor. As a result, additional attention must be paid to the development of alginate-based polymers with increased surface area and active sites.

(ii) Developing a low-cost, effective synthesis process is essential for the catalyst's enhanced structure.

(iii) Most studies reported the reusability of the alginate-based materials up to 5 cycles only. Thus, developing a highly stable alginate-based photocatalyst is mandatory for large-scale applications.

Cellulose

Cellulose is the most abundant natural polymer obtained from cotton, rice husks, banana, acetobacter, rhizobium, aerobacter, pseudomonas, and sarcina. Cellulose is a tough and insoluble fiber due to strong inter and intramolecular hydrogen bonds that always benefit the maintenance of plants cell walls (Mohamed et al. 2017). The unique properties of cellulose are high flexibility, biodegradability, and protecting capability (Li et al. 2014). Different materials including cellulose acetate, cellulose nanofibers, and nanocrystalline cellulose was produced from cellulose sources (Mohamed et al. 2017).

Cellulose acetate is an ester of cellulose derived through the chemical reaction between cellulose with the anhydride of acetic acid in the presence of sulfuric acid. Cellulose acetate can be drawn into beads, sheets, films, membranes, and nanocomposites. The cellulose acetate is preferred due to high electrospinning ability, ease of dilution, porosity, better surface area, and good hydrolytic stability (Jatoi et al. 2019). The potent usage of cellulose acetate is extended to textile industries, water treatment, adsorption, pharmaceuticals, and membranes.

Mohamed et al. (2015) emphasized the development of nitrogen-doped TiO2 nanorods in regenerated cellulose thin film through the phase inversion method. The recycled newspaper was used as a sustainable cellulose source throughout this study. The prepared catalyst exhibited a remarkable property between the cellulose and TiO2 nanorods anchored on the thin film, which also resolved the problems related to aggregation of TiO2 photocatalyst. The optical studies confirmed the introduction of localized N 2p states just above the valence band due to nitrogen doping resulting in the enhancement of visible light absorption. Moreover, the bandgap of the thin film was reduced from 3.09 to 2.95 eV for the prepared thin film. The prepared catalyst demonstrated 96% and 78.8% methylene blue removal under ultraviolet and visible light illumination.

Differently, Marinho et al. (2017) prepared the cellulose acetate monoliths coated with TiO2 utilizing the dip-coating method. Here, cellulose acetate monoliths were employed due to their higher irradiated surface area inside the reactor, increasing light utilization. The prepared structure exhibited a better-illuminated surface area of 212 m2/m3. Experimental investigations reported only 10% chromium (VI) removal within 210 min under the absence of citric acid. Even though studies reported the chromium (VI) reduction by single-electron steps, gradual reduction and re-oxidation of chromium species occurred due to the conduction band electrons and valence band holes or hydroxyl radicals. The cellulose acetate monoliths coated with TiO2 exhibited reusability up to 10 consecutive cycles.

The elimination of the hydrophobic compounds using cellulose-based materials is restricted due to cellulose's hydrophilic characteristics. This particular limitation is improved by a team of researchers led by Ríos-Gómez et al. (2018) through chemical modification. This resulted in the enhancement of the interaction between catalyst and pollutant. Ríos-Gómez et al. (2018) also explored cellulose as a base substrate for the development of TiO2 based nanocomposite film for removal of methyl orange. The cellulose paper was coated with polyamide/TiO2 photocatalyst through the simple dipping method. Under the illumination of ultraviolet light, the photocatalyst degraded methyl orange completely within 20 min. The presence of cellulose improved the mechanical stability and acted as an efficient sorptive phase against the pollutants. The polymeric nature of the photocatalyst attributed to the stabilization of TiO2 nanoparticles and exhibited higher ability towards the retention of the pollutant, which favors photocatalytic degradation of methyl orange. In the same year, Li et al. (2018) focused on overcoming the poor mechanical stability of cellulose nanofibers via chemical crosslinking. Cellulose nanofiber/TiO2 aerogel photocatalyst was chemically cross-linked via hydrothermal method. The TiO2 particles have adhered to the surface of cellulose nanofibers as scaffold through a hydrogen bond. Photocatalytic studies proved the potential viability of catalysts in the redemption of methylene blue under irradiation of ultraviolet light. The catalyst also extended the reusability to five cycles and exhibited 72% at the end.

Shi et al. (2019) also used TiO2 doped chitosan microspheres supported cellulose acetate fibers to remove methyl orange. The cellulose acetate material was used as base material to increase the water flux of the membrane. Moreover, the chitosan hemisphere gradually dispersed TiO2 nanoparticles and helped to enhance the catalyst surface. At optimum conditions of pH 4, and initial concentration = 40 mg/L, about 98% methyl orange removal was observed. Even at the end of the fifth cycle, the membrane exhibited 98% degradation efficiency due to the presence of chitosan in the membrane, which made the intermolecular hydrogen bonds stronger among chitosan, cellulose acetate and TiO2. In the same year, ZabihiSahebi et al. (2019) synthesized cellulose acetate/chitosan/single walled carbon nanotube/Fe3O4/TiO2 composite nanofibers using the electrospinning method. The presence of single walled carbon nanotubes increases the removal efficiency due to their ability to disperse at a very low concentration. Catalyst also displayed a phenomenal activity towards the reduction of chromium (VI), arsenic (V), methylene blue, and congo red from wastewater.

For instance, Chen et al. (2020a, b) emphasized the eco-friendly cellulose/graphene oxide/TiO2 hydrogel photocatalyst synthesized through one-step green and simple method for removing methylene blue. The catalyst exhibited 93% methylene blue removal within 120 min with reusability up to ten consecutive cycles. The enhanced degradation efficiency was attributed to the stronger interaction between TiO2 and graphene oxide, facilitating interfacial charge transfer and minimizing the electron–hole recombination. Moreover, the higher surface area of the cellulose hydrogel provided a large number of active sites and enhanced the surface adsorption of methylene blue. These hydrogels composed of graphene oxide and TiO2 maintained the hydrogel structure and did not cause secondary pollution.

Yang et al. (2020) focused on the preparation of three-dimensional bacterial cellulose/polydopamine/TiO2 membrane adopting a facile strategy. Figure 6a–d describes the surface morphology of the bacterial cellulose/polydopamine/TiO2 membrane. Studies indicated that the uniform dispersion of TiO2 nanoparticles on the bacterial cellulose/polydopamine matrix. This also played a critical role in enhancing the surface area of 170 m2/g. The prepared composite membrane could remove 100% of rhodamine B, 99.5% of methylene blue, and 95.1% of methyl orange within 60, 20, and 30 min under the illumination of a 500 Watts Hg lamp. The prepared composites demonstrated reusability up to five consecutive cycles with a reduction in 5% removal efficiency as observed in Fig. 6e. Thus, incorporating cellulose has improved the adsorption stability, reusability, and photocatalytic performance of the photocatalyst. Moreover, the polydopamine acted as a secondary reaction route by forming a non-covalent bond with TiO2 particles. The polydopamine also boosted the catalytic efficiency through promoting photo-induced charge-carrier species at the interface between polydopamine and TiO2.

Surface morphology a Interwoven three dimensional nanofibrous structure of the pristine bacterial cellulose membrane of 40 nm in diameter, b In polydopamine/bacterial cellulose, the diameter of nanofibers increased to 50 nm, c The increment of size of nanofibers is enhanced to 200 nm for the bacterial cellulose/polydopamine/TiO2, d The spherical TiO2 particles are evidently seen in the bacterial cellulose/TiO2 matrix. e Reusability of the photocatalysts. A decline of 5.5%, and 23.8% in the removal efficiency is seen for bacterial cellulose/polydopamine/TiO2 and bacterial cellulose/TiO2, respectively. Reprinted from Yang et al. (2020) with permission from Elsevier. Where BC is bacterial cellulose, and PDA is polydopamine

Recently, Lin and Huang (2021) synthesized the H3PW12O40/TiO2 with cellulose as a scaffold, which acted as a template with a porous structure. The H3PW12O40 has served as an effective electron acceptor and improved the separation of electron–hole pairs in eliminating methylene blue and rhodamine B under sunlight. Experimental studies proved that the photocatalyst developed through impregnation method was better than the layer-by-layer method due to the closer contact between the TiO2 and H3PW12O40 in cellulose matrix. Additionally, the catalyst prepared through the impregnation method can act as an effective photocatalyst towards the elimination of pollutants under direct sunlight. In the same year, Wafiroh et al. (2021) reported the preparation of cellulose acetate hollow fiber membrane from banana stems coated with TiO2. The highly porous structure of the prepared hollow fiber membrane showed the presence of rigid pores with enhanced mechanical properties. The photocatalytic studies showed a removal efficiency of 94.96% for congo red and 94% for textile wastewater. The studies on reusability are necessary to showcase the stability of the material.

Table 5 summarizes different cellulose-supported TiO2 photocatalysts for the removal of organic pollutants. The TiO2/cellulose-based structures always lead the path for the preparation of novel photocatalytic materials. The following benefits are observed with the usage of cellulose as a support material (Hamad et al. 2020).

-

Control the hydrolysis, polycondensation, and growth of cellulose/metal oxides

-

Provides strong mechanical support by acting as an attractive material for the suspension of the photocatalyst.

-

Tune the optical properties of photocatalyst, shifts the absorption from ultraviolet to visible light region.

-

Improves electron distribution and electron transfer to the catalyst surface and restricts the recombination of electron and hole pairs.

-

Improves the thermal stability of the photocatalyst and enhance adsorption in the absence of light

-

The cellulose-supported membrane sheets also make the recovery and reusability easier.

The stability and mechanical properties of cellulose-based TiO2 materials can be increased by altering their proportions. The development of different morphologies of cellulose-based materials is important to overcome the issues related to separation and recovery. The detailed study on the degradation mechanism and the photocatalytic process for various pollutants are beneficial in designing suitable materials. In addition, the detailed analysis on pollutant removal and recycling of materials is necessary for large-scale wastewater treatment plants. The development of cellulose-based composites with high performance and selectivity is a great barrier to practical applications.

Cyclodextrin

Antoine Villiers firstly reported cyclodextrin in the nineteenth century (Liu et al. 2019). Cyclodextrin was initially used in pharmaceuticals, food industries, and chromatography and later conquered different areas in the field of drug delivery, and water treatment (Adeoye & Cabral-marques, 2017; Liu et al. 2019; Preethi et al. 2020; Tian & Liu, 2020). Cyclodextrin is a cyclic low molecular oligo polymer yielded from the starch via enzymatic action (Crini et al. 2018; Sherje et al. 2017). Cyclodextrin are composed of six to eight units of α-d-glucose represented as denoted α-, β-, and γ-cyclodextrin (Rajalakshmi et al. 2019; Sherje et al. 2017; Tian & Liu, 2020). Literature reported that cyclodextrin forms an inclusion complex with different molecules of appropriate polarity and dimension with hydrophobic interior and hydrophilic external surface (Rajalakshmi et al. 2019; Tian and Liu, 2020). The cyclodextrin are hollow, truncated cone-shaped molecules with a large number of glucose units connected with oxygen covalently through hydrogen bonds (Crini et al. 2018). Cyclodextrin are frequently used because of the low cost, availability, complex formation towards large complexes (Crini et al. 2018).

The cyclodextrin-supported polymers, semiconductor-based materials, metals, carbon nanomaterials have been reported as sustainable and efficient materials for wastewater remediation through photocatalysis and adsorption (Kumari 2020). The cyclodextrin showed an extremely good adsorption property for organic contaminants, bringing them close to the photocatalyst surface and enhancing the removal efficiency. Further, the catalysts offer very high catalytic efficiency, durability, and stability and are used as an alternative towards commercial TiO2. Finally, cyclodextrin-supported materials have a promising future in the field of wastewater treatment because of low energy requirements and trap and zap treatment methods (García-díaz et al. 2020).

Zhang et al. (2020) emphasized the utilization of Ag/β-cyclodextrin co-doped TiO2 floating photocatalytic membrane synthesized via modified electrospinning process coupled with the low-temperature in-situ hydrothermal method. The Brunauer–Emmett–Teller results revealed that the surface area of the catalyst increased from 0.0192 to 0.0652 cm3/g. The existence of mesopores is the key factor in enhancing the adsorption behavior of the photocatalyst. The incorporation of Ag, cyclodextrin with TiO2 altered the bandgap to 1.9 eV and was active under visible light. The Ag/β-cyclodextrin co-doped TiO2 degraded N,N-dimethylformamide under visible light (150 Xenon lamp). The photocatalytic degradation mechanism of the prepared catalyst is illustrated in Fig. 7. The floating photocatalyst combine with the visible light and oxygen directly. Because of the surface plasmon resonance effect, the Ag nanoparticles near their plasmon frequency exhibit a trend of being excited by visible light and generate electron field and produce the electron–hole pairs. The transfer of electrons to the conduction band of TiO2 and were trapped by the oxygen molecules in the mesopores to form superoxide radicals. The hole scavenging properties of the C, photo-induced holes transfer from valence band of TiO2 to cyclodextrin and minimize the recombination of electron–hole pairs. The floating photocatalytic membrane has potential significance in wastewater treatment because of extended reusability, durability, mechanical strength, hydraulic permeability.

Degradation mechanism of Ag/β-cyclodextrin co-doped TiO2 floating photocatalytic membrane. The photocatalytic membrane float in the surface of water and combine with the incident visible light and oxygen directly. Because of the surface plasmon resonance, Ag nanoparticles are excited by visible light and produce an electric field and results in generation of hot electron–hole pairs. These electrons are transferred to conduction band of TiO2 and trapped by absorbed O2 in the mesopores to form superoxide radicals. The hole scavenging effect of cyclodextrin resulted in the transfer of holes from valence band of TiO2 to cyclodextrin. This also leads to minimized recombination of electron hole pairs. Reprinted from Y. Zhang et al. (2020) with permission from Elsevier. Where β-CD is β-cyclodextrin, Ag is silver, PAN is polyacrylonitrile, SPR surface plasmon resonance, PM is photocatalytic membrane, e is electron, h is hole, CB is conduction band, and VB is valence band

The cyclodextrin-directed synthesis of Au/TiO2 materials was prepared through the colloidal self-assembly approach under visible light illumination. Moreover, the catalyst removed the phenoxyacetic acid from aqueous streams. Reusability studies demonstrated a decline in catalytic activity from 85 to 52% during the third run. The decline in the catalytic activity is ascribed to the competitive adsorption and agglomeration of the phenoxyacetic acid on the catalyst surface through the hydrogen bond formation between surface hydroxyls and carboxylic acid groups of phenoxyacetic acid reduce the photonic efficiency (Lannoy et al. 2017). In the same year, Zhu et al. (2017) reported the deposition of cyclodextrin/gold nanoclusters on TiO2 nanoparticles. The prepared material could remove 98% of methyl orange in 10 min. The high removal efficiency is attributed to the unique cavity of the prepared catalyst improved the adsorption through ghost-guest interaction. The Au in the core helped in accepting the electrons and minimized the recombination rate of electron/hole pairs.

Recently, Zhang et al. (2021) focused on preparing TiO2/graphene oxide on polyacrylonitrile/β-cyclodextrin nano-fibrous membrane by ultrasonic-assisted electrospray method. Experimental investigations found that the prepared material exhibited 93% and 90% removal efficiency for methylene blue and methyl orange, respectively. Moreover, this membrane displayed good antibacterial properties and extended reusability up to 3 cycles. The inclusion of polyacrylonitrile and cyclodextrin into the structure of the desired photocatalyst (i) impart low density and hydrophobicity to the catalyst, which could enhance the light penetration, (ii) minimize the problems due to the secondary pollution caused by the leaching of the TiO2 and graphene-oxide from the surface of the photocatalyst, (c) enhance porosity and specific surface area of the nanofiber.

Similarly, Wang et al. (2021) focused on removing bisphenol-A from aquatic streams by utilizing the TiO2@aspartic acid-β-cyclodextrin@ reduced graphene oxide developed through photochemical method as highlighted in Fig. 8a. The surface morphology showed uniform distribution of TiO2 nanoparticles on the catalyst surface due to the inclusion of aspartic acid (enhancing water solubility). The prepared catalyst displayed high degradation efficiency towards eliminating 5 mg/L of bisphenol-A under the illumination of the ultraviolet light (250 Watts metal halide lamp). Moreover, O2− and holes were responsible for the elimination of bisphenol-A (see Fig. 8b). The possibility of recombining photogenerated electron–hole pairs on catalyst surfaces may lead to low quantum yield. The higher charge separation and electron transfer are necessary to benefit greater efficiency. The catalyst exhibited higher stability and reusability up to 5 consecutive cycles. The presence of the cyclodextrin enhanced the mass transfer process at the interface and enhanced the photocatalytic activity. At the same time, graphene triggered the electron transfer during the degradation process.

a Preparation of TiO2@aspartic acid-β-cyclodextrin@ reduced graphene oxide. The aspartic acid-β-cyclodextrin@ reduced graphene oxide was dispersed in water followed by the ultrasonic treatment. To this solution TiO2 was added with continuous stirring and exposed to simulated sunlight for 15 h and dried in vacuum at 65 °C. b Photocatalytic degradation mechanism. The introduction of reduced graphene oxide to the photocatalytic system, caused the electron transfer from semiconductor to reduced graphene oxide. This suppress the recombination of electron–hole pairs. The inclusion of aspartic acid-β-cyclodextrin can form an inclusion complex with bisphenol-A and enhance the mass transfer of bisphenol-A at the photocatalyst surface and enhance the catalytic activity. Reproduced with permission from Wang et al. (2021) with permission from Elsevier. Where GO is graphene oxide, RGO is reduced graphene oxide, e is electron, h is hole, CB is conduction band, VB is valence band, UV is ultraviolet, and ACD is aspartic acid-β-cyclodextrin

Table 6 summarizes different cyclodextrin-supported TiO2 photocatalysts for the removal of organic pollutants. Cyclodextrin is a versatile material for sustainable treatment technologies and can remove various pollutants. Even though cyclodextrin-based materials exhibit higher efficiency, further studies are required to overcome the hindrances or the application towards large-scale treatment plants. The eco-friendly routes need to be identified to synthesize cyclodextrin/TiO2 based materials.

Other biopolymer-supported TiO2 catalysts

Starch

Starch is a bio-polymer abundantly available from wheat, paddy, potatoes, corn (Sarmah and Karak 2020). Starch is a three-dimensional structure with better crystallinity (15 to 45%) and possesses D-glucose units with macromolecules similar to amylopectin, amylose, and glucan. The nanocrystal starch and microcrystalline starch are yielded through the hydrolysis (Bahrami et al. 2019). The popularity of the starch derivatives increased due to the higher surface area, abundance, low cost, non-toxicity, and renewability. For example, Guo et al. (2019) also focused on preparation of synthesizing TiO2 cross-linked carboxymethyl starch composites by utilziing corn as a natural source through sol–gel method for eliminating cationic golden yellow X-GL/dye from wastewater. The prepared material degradation efficiency dropped from 80 to 50% at the end of the fourth cycle. The spent catalysts can be directly mixed with wall coatings and cement due to their non-toxicity.

Gum

Guar gum is a biodegradable polysaccharide produced by endosperms of guar beans composed of D-mannopyransoyl with D-galactopyransoyl units (Balachandramohan et al. 2020). Guar gum is employed as a supporting agent due to the ability to tune rheological properties. Guar gum can also act as a potential stabilizer for different catalysts. However, few studies have been reported guar gum/TiO2 photocatalyst for wastewater treatment (Nasrollahzadeh et al. 2021). For instance, Rahimdokht et al. (2019) et al. employed TiO2/gum tragacanth nano-hydrogel to redeem MB from textile wastewater. The catalyst exhibited 88.86% methylene blue removal at optimized pH 9.02, time 124.34 min, and an initial dye concentration of 9.37 mg/L.

Xanthan Gum is composed of repeating pentasaccharide units of two glucose units and two mannose units and one glucuronic acid. The structure also resembles cellulose. The important properties are non-toxicity, water-solubility, thermal stability, high viscosity. The Xanthan gum/TiO2 was prepared through a simple mixing method followed by calcination. Experimental studies were conducted in the presence and absence of hydrogen peroxide (74%) and the studies under the influence of hydrogen peroxide exhibited greater catalytic activity. About 89% of methyl orange was removed in the presence of solar light. The higher adsorption ability and improved photo-response boosts-up the catalytic activity of the composite. The higher visible light absorption of the catalyst was confirmed through the narrowing the band gap to 2.8 eV (Inamuddin 2019).

Collagen

Similar to the biopolymers mentioned above, few studies are conducted on collagen-supported TiO2 photocatalyst. Collagen is an abundant protein seen in mammals and solid wastes of tanning industries (Bazrafshan and Stylios 2019). The utilization of these collagens as catalyst support is highly effective and sustainable. Nagaraj et al. (2021) reported that the collagen nano-biosponge exhibited 95% degradation of rhodamine B under the illumination of natural sunlight. The bandgap of the prepared catalyst is 2.5 eV, whereas TiO2 exhibits 3.35 eV. The amine functionalization on the TiO2 surface is responsible for the bandgap reduction. Lower bandgap contributes to higher charge separation, extended lifetime electrons, and generated holes. Overall, these materials act as a cost-effective and sustainable engineering materials for real life applications.

The N doped TiO2/Acid soluble collagen-polyvinyl pyrrolidone hybrid composite was developed by sol–gel method. The oxygen vacant sites and nitrogen interstitial type doping in N doped TiO2 was confirmed with the x-ray photoelectron spectroscopy. Photocatalytic studies reported an 86% of naphthalene removal within 100 min under the visible light irradiation. The catalyst also extended the reusability for four cycles and the degradation efficiency is declined to 81.4%. The proposed degradation mechanism of naphthalene is reported in the Fig. 9. The possible mechanism of the photocatalyst is that the aromatic rings of the naphthalene is readily adsorbed on the surface of the photocatalyst due to the π-π stacking adsorption between the benzene rings of naphthalene and pyrrole rings of the photocatalyst. So, under the illumination of light, electrons reacts with oxygen to produce superoxide radicals. These superoxide radicals and holes plays a major role in elimination of pollutants (Doabi et al. 2022).

Preparation mechanism of Nitrogen doped TiO2/Acid soluble collagen-polyvinyl pyrrolidone hybrid composite toward the removal of naphthalene. The illumination of visible light cause the electrons to move from valence band to conduction band. This leads to the simultaneous production of holes in the valence band and excess electrons in the conduction band. The holes hold a positive potential to generate hydroxyl radicals and oxidize naphthalene. Reproduced from Doabi et al. (2022) with permission from Elsevier. Where N-TiO2/ASC-PVP is the nitrogen doped TiO2/acid soluble collagen-polyvinyl pyrrolidone composite, e is electrons, h is holes, CB is conduction band, VB is valence band and Eg is the band gap energy of the photocatalyst

Industrial perspectives

The promotion of photocatalysis on an industrial scale is necessary. For that, the adaptations of structural changes of the photocatalyst are important to alter the band gap of photocatalyst and to utilize the visible light irradiation efficiently. The main problem that restricts photocatalysis at a larger scale is the recovery of the photocatalyst after each cycle. For example, the photocatalysts in powder form easily get precipitated at the bottom of the tank. So, the complete recovery of these photocatalysts is impossible. In addition to this, the low absorbance of light and poor contact between powdered photocatalyst and pollutant. Thus, the adaptation of immobilization of the photocatalyst is the acceptable solution. As the aim of this manuscript, biopolymers can be employed as sustainable low-cost immobilizing agents. However, the complexity of the reactor design is a major problem. The need of maximizing the contact between the illuminated catalyst surface area and reactor volume reduces the path length of wastewater above the surface from a suitable light source. Despite these disadvantages, the pilot-scale studies using the immobilized catalysts were reported. The adaptation of biopolymers for the immobilized system also exhibits several advantages: biocompatibility, low cost, environmental friendliness and ease in preparation.

Conclusion

This review paper summarizes the utilization of different biopolymer-supported TiO2 for the reclamation of organic pollutants seen in aquatic steams. The TiO2 based photocatalyst is still considered one of the most prominent routes for the redemption of organic pollutants. Even after continuous research, TiO2 suffers from several problems due to the aggregation of nano-sized TiO2, mass loss during catalyst recovery, and poor reusability. Numerous efforts have been put by the scientific community to address the challenges of TiO2 as a photocatalyst. This study reviewed the different biopolymers as the supporting agents for TiO2. The natural polymers were selected due to their abundance, biodegradability, biocompatibility, non-toxicity. Several preparation routes are immobilization, hydrothermal, and sol–gel methods are well discussed. The utilization of different biopolymers as a supporting medium to TiO2 has gathered high efficiency and enhanced the reusability of the photocatalyst to larger extent. However, various challenges and further research recommendations must be addressed as earlier as possible to develop a sustainable wastewater treatment technology.

-

The large-scale preparation of biopolymer-supported TiO2 photocatalyst at minimum investments.

-

Further research is mandatory in selecting suitable catalyst support based on selectivity and stability. Moreover, enhancing the active surface area to volume ratio and greater mass transfer is necessary for a photocatalytic process.

-

Development of the metal-doped TiO2 supported biopolymers to enhance the visible light activity of the photocatalyst. Moreover, metal doping is also beneficial in narrowing the bandgap to visible light. This may also increase the chances of complete utilization of natural sunlight as a light source.

-

The development of magnetic TiO2 supported biopolymer-based photocatalyst leads to a revolution in wastewater remediation, minimizing the problems related to catalyst loss and reusability.

-

Application of different bio-waste materials as a renewable feedstocks for the development of biopolymers for wastewater remediation.

-

The need of greener biological processes are necessary to bring down the production cost of biopolymer based materials under mild conditions and to improve the catalytic performance.

-

In photocatalytic membranes, the impact of fouling is severe and leads to the deposition of organic pollutants on membrane surface that may deteriorate the degradation efficiency. Thus, the development of cost-effective fouling photocatalytic membranes is necessary to meet real-life applications.

-

Moreover, the reduction in bandgap due to biopolymer incorporation needs further investigation. Overall, the role of biopolymer as a supporting agent for TiO2 needs a detailed study to understand the mechanism in photodegradation.

-

Most current photocatalytic studies have only been conducted at the laboratory scale. The performance of the photocatalytic studies in the pilot plants will help us know the process feasibility.

References

Aanchal BS, Basu S (2020) Complete removal of endocrine disrupting compound and toxic dye by visible light active porous g-C3N4/H-ZSM-5 nanocomposite. Chemosphere. https://doi.org/10.1016/j.chemosphere.2019.124981

Abdelwahab NA, Helaly FM (2017) Simulated visible light photocatalytic degradation of Congo red by TiO2 coated magnetic polyacrylamide grafted carboxymethylated chitosan. J Ind Eng Chem 50:162–171. https://doi.org/10.1016/j.jiec.2017.02.010

Adeoye O, Cabral-marques H (2017) Cyclodextrin nanosystems in oral drug delivery: a mini review. Int J Pharm 531:521–531. https://doi.org/10.1016/j.ijpharm.2017.04.050

Afzal S, Julkapli NM, Mun LK (2019) Response surface approach for visible light assisted photocatalytic degradation of ortho nitrophenol by magnetically separable TiO2/CS nanocomposite. Mater Sci Semicond Process 99:34–43. https://doi.org/10.1016/j.mssp.2019.04.022

Afzal S, Julkapli NM, Mun LK (2021) Visible light active TiO2/CS/Fe3O4 for nitrophenol degradation: studying impact of TiO2, CS and Fe3O4 loading on the optical and photocatalytic performance of nanocomposite. Mater Sci Semicond Process 131:105891. https://doi.org/10.1016/j.mssp.2021.105891

Albarelli JQ, Santos DT, Murphy S, Oelgemöller M (2009) Use of Ca-alginate as a novel support for TiO2 immobilization in methylene blue decolorisation. Water Sci Technol. https://doi.org/10.2166/wst.2009.459

Al-Mamun MR, Kader S, Islam MS, Khan MZH (2019) Photocatalytic activity improvement and application of UV-TiO2 photocatalysis in textile wastewater treatment: a review. J Environ Chem Eng. https://doi.org/10.1016/j.jece.2019.103248

Amir MNI, Muhd Julkapli N, Hamid SBA (2017) Effective adsorption and photodegradation of methyl orange by TiO2-chitosan supported glass plate photocatalysis. Mater Technol 32:256–264. https://doi.org/10.1080/10667857.2016.1201635

Arikal D, Kallingal A (2019) Photocatalytic degradation of azo and anthraquinone dye using TiO2/MgO nanocomposite immobilized chitosan hydrogels. Environ Technol (united Kingdom). https://doi.org/10.1080/09593330.2019.1701094

Ashik UPM, Kudo S, Hayashi J (2018) An overview of metal oxide nanostructures. Synth Inorg Nanomater. https://doi.org/10.1016/B978-0-08-101975-7.00002-6

Babul Reddy A, Siva Mohan Reddy G, Sivanjineyulu V et al (2016) Hydrophobic/hydrophilic nanostructured polymer blends. Des Appl Nanostruct Polym Blends Nanocompos Syst. https://doi.org/10.1016/B978-0-323-39408-6.00016-9

Bahal M, Kaur N, Sharotri N, Sud D (2019) Investigations on amphoteric chitosan/TiO2 bionanocomposites for application in visible light induced photocatalytic degradation. Adv Polym Technol. https://doi.org/10.1155/2019/2345631

Bahmani E, Seyyed Zonouzi H, Koushkbaghi S et al (2020) Electrospun polyacrylonitrile/cellulose acetate/MIL-125/TiO2 composite nanofibers as an efficient photocatalyst and anticancer drug delivery system. Cellulose. https://doi.org/10.1007/s10570-020-03459-1

Bahrami M, Amiri MJ, Bagheri F (2019) Optimization of the lead removal from aqueous solution using two starch based adsorbents: Design of experiments using response surface methodology (RSM). J Environ Chem Eng 7:102793. https://doi.org/10.1016/J.JECE.2018.11.038

Bahrudin NN, Nawi MA (2019) Effects of montmorillonite on the enhancement of physicochemical, optical and photocatalytic properties of TiO2/chitosan bilayer photocatalyst. Korean J Chem Eng 36:478–488. https://doi.org/10.1007/s11814-018-0221-7

Balachandramohan J, Sivasankar T, Sivakumar M (2020) Facile sonochemical synthesis of Ag2O-guar gum nanocomposite as a visible light photocatalyst for the organic transformation reactions. J Hazard Mater 385:121621. https://doi.org/10.1016/J.JHAZMAT.2019.121621

Balakrishnan A, Chinthala M (2022) Comprehensive review on advanced reusability of g-C3N4 based photocatalysts for the removal of organic pollutants. Chemosphere. https://doi.org/10.1016/J.CHEMOSPHERE.2022.134190

Balakrishnan A, Appunni S, Gopalram K (2020a) Immobilized TiO2/chitosan beads for photocatalytic degradation of 2,4-dichlorophenoxyacetic acid. Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2020.05.204

Balakrishnan A, Appunni S, Gopalram K (2020b) Immobilized TiO2/chitosan beads for photocatalytic degradation of 2,4-dichlorophenoxyacetic acid. Int J Biol Macromol 161:282–291. https://doi.org/10.1016/j.ijbiomac.2020.05.204

Balakrishnan A, Gopalram K, Appunni S (2021) Photocatalytic degradation of 2,4-dicholorophenoxyacetic acid by TiO2 modified catalyst: kinetics and operating cost analysis. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-021-12928-4

Bazrafshan Z, Stylios GK (2019) Spinnability of collagen as a biomimetic material: a review. Int J Biol Macromol 129:693–705. https://doi.org/10.1016/J.IJBIOMAC.2019.02.024

Bel Hadjltaief H, Omri A, Ben Zina M et al (2015) Titanium dioxide supported on different porous materials as photocatalyst for the degradation of methyl green in wastewaters. Adv Mater Sci Eng. https://doi.org/10.1155/2015/759853

Bergamonti L, Bergonzi C, Graiff C et al (2019) 3D printed chitosan scaffolds: a new TiO2 support for the photocatalytic degradation of amoxicillin in water. Water Res 163:114841. https://doi.org/10.1016/j.watres.2019.07.008

Bet-Moushoul E, Mansourpanah Y, Farhadi K, Tabatabaei M (2016) TiO2 nanocomposite based polymeric membranes: a review on performance improvement for various applications in chemical engineering processes. Chem Eng J 283:29–46. https://doi.org/10.1016/j.cej.2015.06.124

Chalasani R, Vasudevan S (2013) Nanoparticles for photocatalytic degradation of endocrine-disrupting chemicals in water supplies, pp 4093–4104. https://doi.org/10.1021/nn400287k

Chen C, Zhang Y, Zeng J et al (2017a) Aligned macroporous TiO2/chitosan/reduced graphene oxide (rGO) composites for photocatalytic applications. Appl Surf Sci 424:170–176. https://doi.org/10.1016/j.apsusc.2017.02.137

Chen X, Liu D, Wu Z et al (2017b) Microwave-assisted rapid synthesis of Ag-β-cyclodextrin/TiO2/AC with exposed 001 facets for highly efficient naphthalene degradation under visible light. Catal Commun. https://doi.org/10.1016/j.catcom.2017.10.026

Chen D, Cheng Y, Zhou N et al (2020a) Photocatalytic degradation of organic pollutants using TiO2-based photocatalysts: a review. J Clean Prod 268:121725. https://doi.org/10.1016/j.jclepro.2020.121725

Chen Y, Xiang Z, Wang D, et al (2020b) Effective photocatalytic degradation and physical adsorption of methylene blue using cellulose/GO/TiO2 hydrogels †. https://doi.org/10.1039/d0ra04509h

Cheng Keong C, Sunitha Vivek Y, Salamatinia B, Amini Horri B (2017) Green Synthesis of ZnO Nanoparticles by an Alginate Mediated Ion-Exchange Process and a case study for Photocatalysis of Methylene Blue Dye. J Phys Conf Ser

Chinthala M, Balakrishnan A, Venkataraman P et al (2021) Synthesis and applications of nano-MgO and composites for medicine, energy, and environmental remediation: a review. Springer International Publishing, Cham

Chkirida S, Zari N, Achour R et al (2021) Highly synergic adsorption/photocatalytic efficiency of Alginate/Bentonite impregnated TiO2 beads for wastewater treatment. J Photochem Photobiol A Chem 412:113215. https://doi.org/10.1016/J.JPHOTOCHEM.2021.113215

Colpani GL, Zanetti JT, Cecchin F et al (2018) Carboxymethyl-β-cyclodextrin functionalization of TiO2 doped with lanthanum: characterization and photocatalytic activity enhance. Catal Sci Technol. https://doi.org/10.1039/C7CY02115A

Crini G, Fourmentin S, Fenyvesi É et al (2018) Cyclodextrins, from molecules to applications. Environ Chem Lett. https://doi.org/10.1007/s10311-018-0763-2

Cruz IF, Freire C, Araújo JP et al (2018) Multifunctional ferrite nanoparticles: from current trends toward the future. Magn Nanostruct Mater Lab Fab. https://doi.org/10.1016/B978-0-12-813904-2.00003-6

D’Arienzo M, Scotti R, Di Credico B, Redaelli M (2017) Synthesis and characterization of morphology-controlled TiO2 nanocrystals: opportunities and challenges for their application in photocatalytic materials. Stud Surf Sci Catal 177:477–540. https://doi.org/10.1016/B978-0-12-805090-3.00013-9

da Silva AK, Ricci TG, de Toffoli AL et al (2020) The role of magnetic nanomaterials in miniaturized sample preparation techniques. Handb Miniaturization Anal Chem. https://doi.org/10.1016/B978-0-12-819763-9.00004-0

Dalponte I, de Sousa BC, Mathias AL, Jorge RMM (2019) Formulation and optimization of a novel TiO2/calcium alginate floating photocatalyst. Int J Biol Macromol 137:992–1001. https://doi.org/10.1016/j.ijbiomac.2019.07.020

Dalponte Dallabona I, Mathias ÁL, Jorge RMM (2021) A new green floating photocatalyst with Brazilian bentonite into TiO2/alginate beads for dye removal. Colloids Surfaces A Physicochem Eng Asp 627:127159. https://doi.org/10.1016/J.COLSURFA.2021.127159

Danfá S, Martins RC, Quina MJ, Gomes J (2021) molecules supported TiO2 in ceramic materials for the photocatalytic degradation of contaminants of emerging concern in liquid effluents: a review. https://doi.org/10.3390/molecules26175363

Denkbaş EB, Çelik E, Erdal E et al (2016) Magnetically based nanocarriers in drug delivery. Nanobiomater Drug Deliv Appl Nanobiomater. https://doi.org/10.1016/B978-0-323-42866-8.00009-5

Dhaka S, Kumar R, Deep A et al (2019) Metal–organic frameworks (MOFs) for the removal of emerging contaminants from aquatic environments. Coord Chem Rev 380:330–352. https://doi.org/10.1016/j.ccr.2018.10.003

Ding C, Sun Y, Lin Y, et al (2017) PT SC. J Photochem Photobiol A Chem. https://doi.org/10.1016/j.jphotochem.2017.12.031

Divya K, Jisha MS (2018) Chitosan nanoparticles preparation and applications. Environ Chem Lett 16:101–112. https://doi.org/10.1007/s10311-017-0670-y

Doabi EH, Elmi F, Elmi MM (2022) Facile and novel synthesis of nitrogen doped TiO2/Acid soluble collagen-polyvinyl pyrrolidone (ASC-PVP) hybrid nanocomposite for rapid and effective photodegradation of naphthalene from water under visible light irradiation. J Photochem Photobiol A Chem 425:113677. https://doi.org/10.1016/J.JPHOTOCHEM.2021.113677

Dong H, Zeng G, Tang L et al (2015) An overview on limitations of TiO2-based particles for photocatalytic degradation of organic pollutants and the corresponding countermeasures. Water Res 79:128–146

Dong H, Zeng G, Tang L, Fan C (2020) An overview on limitations of TiO2-based particles for photocatalytic degradation of organic pollutants and the corresponding countermeasures. Water Res. https://doi.org/10.1016/j.watres.2015.04.038

Farhadian N, Akbarzadeh R, Pirsaheb M et al (2019) Chitosan modified N, S-doped TiO2 and N, S-doped ZnO for visible light photocatalytic degradation of tetracycline. Int J Biol Macromol 132:360–373. https://doi.org/10.1016/j.ijbiomac.2019.03.217

Figoli A, Marino T, Galiano F (2016) Polymeric membranes in biorefinery. Membr Technol Biorefin. https://doi.org/10.1016/B978-0-08-100451-7.00002-5

García-díaz E, Zhang D, Li Y et al (2020) TiO 2 microspheres with cross-linked cyclodextrin coating exhibit improved stability and sustained photocatalytic degradation of bisphenol A in secondary ef fl uent. Water Res 183:116095. https://doi.org/10.1016/j.watres.2020.116095

Garusinghe UM, Raghuwanshi VS, Batchelor W, Garnier G (2018) Water resistant cellulose-titanium dioxide composites for photocatalysis. Sci Rep 8:1–13. https://doi.org/10.1038/s41598-018-20569-w

George A, Sanjay MR, Srisuk R et al (2020) A comprehensive review on chemical properties and applications of biopolymers and their composites. Int J Biol Macromol 154:329–338. https://doi.org/10.1016/J.IJBIOMAC.2020.03.120

Gjipalaj J, Alessandri I (2017) Easy recovery, mechanical stability, enhanced adsorption capacity and recyclability of alginate-based TiO2 macrobead photocatalysts for water treatment. J Environ Chem Eng 5:1763–1770. https://doi.org/10.1016/j.jece.2017.03.017

Grossin D (2021) Phosphates. Encycl Mater Tech Ceram Glas. https://doi.org/10.1016/B978-0-12-803581-8.12089-2

Gui D, Yu R, He X et al (2014) Bioaccumulation and biomagnification of persistent organic pollutants in Indo-Pacific humpback dolphins (Sousa chinensis) from the Pearl River Estuary, China. Chemosphere 114:106–113. https://doi.org/10.1016/j.chemosphere.2014.04.028