Abstract

Flubendiamide is a ryanodine insecticide that shows a strong insecticidal activity and is relatively safe for non-target organisms. Actually only flubendiamide and its product desiodo-flubendiamide have been studied during catalytic degradation using TiO2 and ZnO. Therefore, here we tested the photocatalytic removal of flubendiamide in the presence of nitrates or humic acids. Degradation kinetics were monitored using high-performance liquid chromatography ultraviolet–visible detector. Product identification was done using a high-resolution time-of-flight mass spectrometer coupled to a gas chromatograph (GC-HRMS). Results show that the addition of humic acids at 10 mg l−1 increased the removal of flubendiamide more than five times. The addition of nitrate ions at 10 mg l−1 had no influence. The removal of flubendiamide was more than ten times faster in experiments with oxygen purging. Fourteen degradation products were identified, which can be classified into three groups: phthalimide and related phthalic acid derivatives, fluorinated species related to the second amide moiety, and advanced transformation products.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Advanced oxidation processes (AOPs), although making use of different reacting systems (H2O2 and/or O3; Fenton system: addition of H2O2 to Fe2+ salts, semiconductors as TiO2, ozone chemistry O3/H2O2 and O3/UV and other combinations of oxidants and UV light), are all defined by the same chemical feature: production of ·OH radicals (Andreozzi et al. 1999).

Photocatalysis is an important AOP, making use of a semiconductor–metal oxides as a catalyst, because of their ability to create photogenerated conduction band electrons (e −cb ) and valence band holes (h vb+), which enable redox reactions with adsorbed aqueous species. Although several catalysts have been exploited so far, only TiO2 in the anatase form expressed sufficiently high stability, good performance and low cost. That is why it is one of the most important materials used in oxidation of organic molecules (Castellote and Bengtsson 2011). It is well known that photocatalytic activity of TiO2 depends on its electronic properties and structure, doping TiO2 with cationic and anionic metals, and coupling TiO2 with other semiconductors rises its capability of degrading pollutants (Daghrir et al. 2013).

Conventional photocatalytic processes have been exploited in large reactors of a wide variety of designs (e.g. parabolic trough, inclined plate, fixed/fluidised bed, packed bed, corrugated plate and falling film photoreactors). However, the commercial use of photocatalytic technologies implies still high efforts to promote the contact between solar irradiation and the surface of the photocatalyst in order to achieve an efficient photodegradation of organic pollutants (Braham and Harris 2009). However, it has been frequently observed in water purification systems (Barreiro and Pratt 1992) that some pollutants are not amenable to biological treatments and express a high chemical stability and/or a strong resistance to be completely mineralised. In these cases, it is necessary to define which degradation products are formed during the catalytic process.

Photocatalytic reactors used for water treatment can be classified not only regarding their designs, but also according to the catalysts’ application. There are designs with the photocatalyst suspended in the aqueous medium or with the photocatalyst immobilised on the surface. The most practical and frequently used immobilisation methods to produce thick highly active layers for air/water treatment are sol–gel, powder modified titania sol and sol–pray (Kete et al. 2014). In this study, we proved that the hybrid sol suspension method can be successfully used to prepare stable, thick and highly active photocatalytic layers used for flubendiamide degradation.

Flubendiamide is one of RI (ryanodine insecticides), developed by Nihon Nohyaku Co., Ltd. (Tokyo, Japan). Its mode of action involves activation of ryanodine-sensitive calcium release channels (ryanodine receptors; RyRs) in insects. The insect RyRs remain in an open state in a species-specific manner and affect the Ca2+ pump activity (Masaki et al. 2005; Masaki 2008). The chemical name of flubendiamide is N 2-[1,1-dimethyl-2-(methylsulphonyl)ethyl]-3-iodo-N 1-[2-methyl-4-[1,2,2,2-tetrafluoro-1-(trifluo-romethyl)ethyl]phenyl]-1,2-benzenedicarboxamide. The uniqueness of the structure results from three parts with novel substituents: heptafluoroisopropylgroup in the anilide moiety, a sulphonylalkyl group in the aliphatic amide moiety and an iodine atom at the 3-position of the phthalic acid moiety (Tohnishi et al. 2005). The compound shows an extremely strong insecticidal activity and relative safety for non-target organisms.

However, there was a need of additional peer review for flubendiamide carried out by the competent authority of the rapporteur Member State Greece 3 years ago. The European Food Safety Authority (EFSA) concluded that flubendiamide is appropriate for use in regulatory risk. In a laboratory sterile aqueous photolysis experiment, flubendiamide formed two major transformation products named desiodo-flubendiamide (NNI-0001-desiodo (A1)) and hydroxy-perfluoroalkyl-flubendiamide [NNI-0001-3-OH-hydroxy-perfluoroalkyl (A10)]. EFSA concluded that the risk assessment for aquatic invertebrates from metabolite A10 could not be finalised (EFSA 2013).

Flubendiamide and its major transformation product desiodo-flubendiamide have been studied in different plants (Buddidathia et al. 2016; Mohapatra et al. 2010, 2011) and soils. The calculated half-life values for flubendiamide (t 1/2) ranged from 37.62 to 50.17, 43–50.17 to 50.17–60.21 days for new alluvial, red/laterite and coastal soil (Paramasivam and Banerjee 2012) to 155.1 and 130.8 days in field capacity and submerged soils. In the later case, 2.5% of organic manure was added (Das and Mukherjee 2012).

In aqueous solutions (tap, leaching and watercourse), the photocatalytical degradation of flubendiamide using ZnO and TiO2 was enhanced by the addition of an electron acceptor, such as Na2S2O8. In addition, the main phototransformation product desiodo-flubendiamide was also successfully photodegraded under the same conditions (Fenoll et al. 2015). To our knowledge, there is a lack of information regarding photocatalytic removal of ryanodine insecticides, in the presence of nitrates or dissolved organic matter in general as naturally the most widespread oxidisers. Many examples summarised by Remucal (2014) show that dissolved organic matter, nitrites and nitrates can be an important source of ·OH radicals and therefore may play a significant role in the elimination of pollutants. On the other side, it is known that nitrate ions undergo photocatalytical degradation during photocatalytic processes using different photocatalytic materials (Remucal 2014).

Within this research, we have studied the photocatalytical degradation of flubendiamide using TiO2 films in order to identify its transformation products and propose its degradation pathway. Additionally, we have investigated how the addition of nitrates or humic acids influences the photocatalytical degradation of flubendiamide.

Experimental

Materials

The analytical standard of flubendiamide (98.8% purity) and organic solvents: acetone, acetonitrile, salt NaNO3 and humic substances, were all from Sigma-Aldrich (St. Louis, Missouri, USA).

Photocatalytic experiment

The reactor cell consisted of a Durand glass tube (280 mm, inner diameter 80 mm) with the effective volume of 1.5 L. The reactor cell was then placed in the photoreactor chamber equipped with ultraviolet A (UVA) lamps (15 W, 265 mm × 16 mm, Philips Cleo; broad maximum at 355 nm) mounted on the reflective surface of polished aluminium which was placed behind the lamps. Twelve glass sheets with immobilised catalyst TiO2 (Kete et al. 2014) were fastened around the axis of a special Teflon holder immersed in the centre of the reactor cell.

For the photocatalytic experiments, 5 mg of flubendiamide in 50 mL of acetone (100 mg l−1) was diluted with distilled water up to 1000 mL. The solution was then filtrated and transferred into the reactor cell. The Teflon holder with 12 glass sheets with immobilised TiO2 was immersed in the centre of the cell. A gentle purging of oxygen (1–2 mL min−1) allowed the mixing of the solution and the contact of the pesticide with the catalysts. The reaction time was set to 3 h. At different time intervals (5, 15, 30, 45, 60, 90, 120 and 180 min), the samples of 1 mL were taken for HPLC analyses. After 3 h of photocatalytic irradiation, the final solution was extracted with solid-phase extraction (SPE) C18 cartridges (Supelco, Discovery DSC-18), washed with 5 mL of acetonitrile, dried to dryness, redissolved in dichloromethane and analysed by gas chromatography–mass spectrometry (GC–MS).

Photocatalytical degradation of flubendiamide in the presence of humic acids and nitrate

To study the influence of nitrates and humic acids on flubendiamide photodegradation, 10 mg of NO3 − and 10 mg of humic acids were added to the solution of flubendiamide (10 mg l−1 in 5% acetone solution). The solutions were then placed in the reactor cell and photocatalytically degraded as described in the paragraph above (photocatalytic experiments).

Analytical methods

Kinetic studies with high-performance liquid chromatography with ultraviolet–visible detector (HPLC–UV–Vis)

Solutions of flubendiamide were analysed by Agilent 1100 HPLC–UV–Vis chromatograph (Agilent Technologies, Palo Alto, CA, USA). The separation was done using Supelco Ascentis® Express 5 μm C18 column (5 μm, 150 mm × 4.6 mm). The temperature was set at 25 °C, the injection volume was 20 μL, the mobile phase consisted of 60% acetonitrile and 40% distilled water with the flow rate of 1.0 mL min−1 and the wavelength was set at 230 nm. For the quantification purposes, the calibration curve ranged from 0.04 to 50.0 mg l−1 with seven different concentrations in triplicates. The correlation coefficient (r 2) was above 0.99.

Product identification with gas chromatography–mass spectrometry (GC–MS)

All data were obtained using high resolution Folded Flight Path (FFP™) multiple reflecting geometry time-of-flight (TOF) mass spectrometer Pegasus® GC-HRT (LECO Corporation, Saint Joseph, MI, USA) coupled to an Agilent 7890A gas chromatograph (Agilent Technologies, Palo Alto, CA, USA). The system was controlled by the ChromaTOF-HRT® software (Version 1.91, LECO Corporation), which was also used for spectra collection and data processing. The data were acquired using ten full (10–800 m/z range) spectra per second in high-resolution mode (25,000 or above at m/z 218.9851), with high mass accuracy (< 1 ppm), reliably determining elemental composition of all ions of interest in mass spectra. The multi-point mass calibration of mass spectra with FC-43 (perfluorotributylamine) was performed before running the samples as a part of the automated tuning routine. The mass spectrometer’s hardware and acquisition software allows minimising mass drift during data collection. The electron ionisation source temperature was kept at 270 °C, while the electron energy was 70 eV. Chromatographic separation of the samples was performed using an Rxi-5SilMS 30 m × 0.25 mm (id) × 0.25 µm (df) (Restek Corporation, Bellefonte, PA) column with a constant helium flow of 1 mL min−1. All injection volumes were 1 µL, splitless for 60 s, and thereafter purged with 20 mL min−1 flow. The septum purge flow was 3 mL min−1. The injector and the transfer line temperature were set at 270 and 320 °C, respectively. The oven program was as follows: 0.5 min isothermal at 50 °C, then 10 °C min−1 ramping to 320 °C and 8 min isothermal hold at 320 °C.

Results and discussion

The photocatalytic experiments with flubendiamide were carried out by applying gas purging with oxygen and without gas purging. Besides, the influence of nitrates and humic acids on the process was studied.

Generally, the application of gas enables a better mixing of solution and a better contact between the catalyst and the compound that should be degraded. The role of nitrate in the photodegradation of organic pesticides involves the absorption of solar light between 290 and 400 nm and the generation of highly reactive hydroxyl radicals (Méallier 1999). Many examples (benzoylcyclohexanedione herbicides and phenyl urea herbicides), summarised by Remucal (2014), showed that nitrates, besides the dissolved organic matter, can play an important role in the pesticides’ removal in nitrate rich natural waters. Our results indicate that the degradation of flubendiamide is more than ten times faster in experiments which included the gas purging, compared to those when the gas purging was turned off (Table 1).

Table 1 shows the first-order reaction rate constants ([k] = min−1) describing the photocatalysis of flubendiamide without and with oxygen purging in solutions with addition of nitrates and humic acids (both 10 mg l−1). The correlation coefficients (second column) indicate good correlation between experimental results and fitted curves of the first-order reaction.

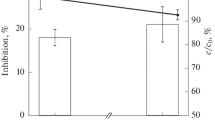

Surprisingly, the photocatalysis of flubendiamide under oxygen flow in the presence of nitrates was the same as without added nitrates. During the experiment, the concentration of added nitrates remained the same (± 5%). No difference in degradation kinetics was observed (Fig. 1). The same observation was found in the research of Rabindranathan et al. (2003), who studied the photocatalytic degradation of phosphamidon, where in the presence of 1.5 × 10−4 M NO3 −, no significant effect under the examined conditions was observed. Authors reported the decrease in degradation rate which was attributed to the competition of ions for active sites on the TiO2 surface (Rabindranathan et al. 2003).

On the other hand, the addition of humic acids in photodegradation processes induced more than five times faster transformation of flubendiamide. The irradiation of dissolved organic matter results in arising of different reactive species including hydroxyl, hydroperoxyl and superoxide radical anions, singlet oxygen, excited triplet states of dissolved organic matter, hydrated electrons, carbonate radicals and other radicals (Richard and Canonica 2005). In fact, dissolved organic matter enhanced the photodegradation of the fungicides carboxin and oxycarboxin (Hustert et al. 1999). On the other hand, there are also examples where dissolved organic matter had no effect (antracene; Bertilsson and Widenfalk 2002) or even an inhibition effect in case of carbofuran (Bachman and Patterson 1999).

Photochemical study, performed by Chen et al. (2010), examined the effect of humic acids (0–25 mg l−1) as possible photosensitiser on the photocatalytic mineralisation of dimethoate. Upon 60 min irradiation, the mineralisation efficiency is shown to increase from 63.73 to 78.88% as the humic acids concentration increases from 0 to 5 mg/L. A further increase in humic acids led to a decrease in photocatalytic efficiency. This was attributed to the reduced light transmittance due to the presence of excessive humic acids in reactive solution and the competitive adsorption of humic acids for the active sites on the catalyst surface (Chen et al. 2010).

The degradation pathway in flubendiamide photocatalysis suggested the amide moiety being the most susceptible part in the molecule for the hydroxyl attack. The most abundant degradation products are listed in Table 2. Although the majority of the identified compounds were not present in the available mass spectrometry library (MS library, National Institute of Standards and Technology, NIST14), the identification was rather straightforward, simple and reliable using the accurate mass measurements feature of the Pegasus-HRT instrument (Lebedev et al. 2013) and the known pathways of the transformation of organic compounds under electron ionisation (Lebedev 2015; McLafferty and Turecek 1993).

Table 2 shows the identified flubendiamide photocatalytic products. Consecutive numbers of identified compounds in the chromatogram are presented in the first column, the molecular formulas of identified compounds are represented in the second column, the retention times of identified compounds are mentioned in the third column, while the peak areas expressed in the arbitrary units (a.u.) are shown in the last column.

The transformation products may be roughly divided into three groups (Fig. 2). The first one consists of the phthalimide and related phthalic acid derivatives (9, 11, 12, 13, 14) (Kushwaha and Kaushik 2016). Fluorinated species related to the second amide moiety represent the second group (1–6). The third one involves advanced transformation products (7, 8, 10). It is worth mentioning that dialkylsulphonyl chain appears to be unstable in reaction conditions, and the corresponding products are not detected in the reaction mixture, possibly degrading rapidly to polar or volatile small molecules.

Proposed degradation pathway of flubendiamide under photocatalytic conditions. Identified products are divided into three groups: Group 1: phthalimide and related phthalic acid derivatives, Group 2: fluorinated species and Group 3: advanced transformation products marked in brackets by numbers of each compound found in Table 2

The process then involves the cleavage of the phthalimide cycle with the formation of aldehydes 13 and 14 or anchimeric assistance of the second nitrogen atom and the formation of phthalimide derivatives. It is worth mentioning a secondary process dealing with deiodination, i.e. substitution of iodine atom in the aromatic ring for a hydrogen atom (compounds 9 and 13). The loss of the second amide moiety (or its part) results in the formation of the advanced transformation products 7, 8, 10. A group of fluorinated alkylbenzene derivatives (1–6) includes iodocyanate, amines, nitroso-derivative, aldehyde and compounds with a shortened heptafluoroisopropyl group.

Conclusion

It is the first report on the photocatalytic degradation of flubendiamide, novel registered ryanodine insecticide. Flubendiamide transforms into several degradation products. GC–MS proved to be an optimal tool for the identification of the products formed under photocatalytic conditions in oxygen flow, with the addition of nitrates or humic acids. Fourteen novel compounds were identified, and the degradation pathways were proposed. One group of identified products belong to the phthalimide and related phthalic acid derivatives, which are known to express pharmacological activities, and should not be released uncontrolled to the environment.

References

Andreozzi R, Caprio V, Insola A, Marotta R (1999) Advanced oxidation processes (AOP) for water purification and recovery. Catal Today 53(1):51–59. https://doi.org/10.1016/s0920-5861(99)00102-9

Bachman J, Patterson HH (1999) Photodecomposition of the carbamate pesticide carbofuran: kinetics and the influence of dissolved organic matter. Environ Sci Technol 33(6):874–881. https://doi.org/10.1021/es9802652

Barreiro R, Pratt JR (1992) Toxic effects of chemicals on microorganisms. Water Environ Res 64(4):632–641 (ISSN 1061–4303)

Bertilsson S, Widenfalk A (2002) Photochemical degradation of PAHs in freshwaters and their impact on bacterial growth: influence of water chemistry. Hydrobiologia 469:23–32. https://doi.org/10.1023/A:1015579628189

Braham RJ, Harris AT (2009) Review of major design and scale-up considerations for solar hotocatalytic reactors. Ind Eng Chem Res 48(19):8890–8905. https://doi.org/10.1021/ie900859z

Buddidathia R, Mohapatra S, Siddamallaiah L, Manikrao G, Shankara Hebbar S (2016) Dissipation pattern of flubendiamide residues on capsicum fruit (Capsicum annuum L.) under field and controlled environmental conditions. J Environ Sci Health B 51(1):44–51. https://doi.org/10.1080/03601234.2015.1080496

Castellote M, Bengtsson N (2011) Principles of TiO2 photocatalysis. In: Ohama Y, Van Gemert D (eds) Application of titanium dioxide photocatalysis to construction materials, 1st edn. Springer, Berlin, pp 5–9

Chen J, Hub Z, Wang D, Gao C, Ji R (2010) Photocatalytic mineralization of dimethoate in aqueous solutions using TiO2: parameters and by-products analysis. Desalination 258(1–3):28–33. https://doi.org/10.1016/j.desal.2010.03.053

Daghrir R, Drogui P, Didier R (2013) Modified TiO2 for environmental photocatalytic applications: a review. Ind Eng Chem Res 52(10):3581–3599. https://doi.org/10.1021/ie303468t

Das SK, Mukherjee I (2012) Effect of moisture and organic manure on persistence of flubendiamide in soil. Bull Environ Contam Toxicol 88:515–520. https://doi.org/10.1007/s00128-012-0551-9

European Food Safety Authority (2013) Conclusion on the peer review of the pesticide risk assessment of the active substance flubendiamide. EFSA J 11(9):3298–3360. https://doi.org/10.2903/j.efsa.2013.3298

Fenoll J, Vela N, Garrido I, Navarro G, Perez-Lucas G, Navarro S (2015) Reclamation of water polluted with flubendiamide residues by photocatalytic treatment with semiconductor oxides. Photochem Photobiol 91:1088–1094. https://doi.org/10.1111/php.12479

Hustert K, Moza PN, Kettrup A (1999) Photochemical degradation of carboxin and oxycarboxin in the presence of humic substances and soil. Chemosphere 38(14):3423–3429. https://doi.org/10.1016/S0045-6535(98)00555-4

Kete M, Pavlica E, Fresno F, Bratina G, Lavrenčič Štangar U (2014) Highly active photocatalytic coatings prepared by a low-temperature method. Environ Sci Pollut Res 21:11238–11249. https://doi.org/10.1007/s11356-014-3077-3

Kushwaha N, Kaushik D (2016) Recent advances and future prospects of phthalimide derivatives. J Appl Pharm Sci 6(03):159–171. https://doi.org/10.7324/JAPS.2016.60330

Lebedev AT (2015) Mass spectrometry in organic chemistry. Technosfera, Moscow

Lebedev AT, Polyakova OV, Mazur DM, Artaev VB (2013) The benefits of high resolution mass spectrometry in environmental analysis. Analyst 138:6946–6953. https://doi.org/10.1039/C3AN01237A

Linsebigler AL, Lu G, Yates JT (1995) Photocatalysis on TiO2 surfaces: principles, mechanisms, and selected results. Chem Rev 95(3):735–758. https://doi.org/10.1021/cr00035a013

Masaki T (2008) Study on the mechanism of insecticidal activity through disruption of intracellular calcium homeostasis. J Pestic Sci 33(3):271–272. https://doi.org/10.1584/jpestics.a330301

Masaki T, Tohnishi M, Nishimatsu T, Tsubata K, Inoue K, Motoba K, Hirooka T (2005) Flubendiamide, a novel Ca2+ channel modulator, reveals evidence for functional cooperation between Ca2+ pumps and Ca2+ release. Mol Pharmacol 69(5):1733–1739. https://doi.org/10.1124/mol.105.020339

McLafferty FW, Turecek F (1993) Interpretation of mass spectra. University Science Books, Mill Valley

Méallier P (1999) Phototransformation of pesticides in aqueous solution. In: Boule P (ed) The handbook of environmental chemistry, Part L: environmental photochemistry, vol 2, 1st edn. Springer, Berlin, pp 241–261

Mohapatra S, Ahuja AK, Deepa M, Sharma D, Jagadish GK, Rashmi N (2010) Persistence and dissipation of flubendiamide and des-iodo flubendiamide in cabbage (Brassica oleracea Linne) and soil. Bull Environ Contam Toxicol 85(3):352–356. https://doi.org/10.1007/s00128-010-0063-4

Mohapatra S, Ahuja AK, Deepa M, Jagadish GK, Rashmi N, Sharma D (2011) Development of an analytical method for analysis of flubendiamide, des-iodo flubendiamide and study of their residue persistence in tomato and soil. Environ Sci Health B 46(1):264–271. https://doi.org/10.1080/03601234.2011.540536

Paramasivam M, Banerjee H (2012) Degradation dynamics of flubendiamide in different types of soils. Bull Environ Contam Toxicol 88:511–514. https://doi.org/10.1007/s00128-012-0552-8

Rabindranathan S, Devipriya S, Yesodharan S (2003) Photocatalytic degradation of phosphamidon on semiconductor oxides. J Hazard Mater 102(2):217–229. https://doi.org/10.1016/S0304-3894(03)00167-5

Remucal CK (2014) The role of indirect photochemical degradation in the environmental fate of pesticides: a review. Environ Sci Process Impacts 16:628–653. https://doi.org/10.1039/c3em00549f

Richard C, Canonica S (2005) Aquatic phototransformation of organic contaminants induced by coloured dissolved organic matter. In: Boule P, Bahnemann DW, Robertson PKJ (eds) Environmental photochemistry part II, the handbook of environmental chemistry, 2nd edn. Springer, Berlin, pp 299–323

Tohnishi M, Nakao H, Furuya T, Seo A, Odama H, Tsubata K, Fujioka S, Kodama S, Hirooka T, Nishimatsu T (2005) Flubendiamide, a novel insecticide highly active against Lepidopterous insect. Pests J Pestic Sci 30(4):354–360. https://doi.org/10.1584/jpestics.30.354

Acknowledgements

The authors acknowledge the financial support from the Slovenian Research Agency [research core funding No. P3-0388, Mechanisms of health protection (Mehanizmi varovanja zdravja)]. We acknowledge financial support from Scholarship of the Republic of Slovenia scheme Mobility Grant (CMEPIUS).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bavcon Kralj, M., Divanović, H., Košenina, S. et al. Effect of humic acids, nitrate and oxygen on the photodegradation of the flubendiamide insecticide: identification of products. Environ Chem Lett 16, 591–597 (2018). https://doi.org/10.1007/s10311-017-0691-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10311-017-0691-6