Abstract

There is actually a need for efficient methods to clean waters and wastewaters from pollutants such as the bisphenol A endocrine disrupter. Advanced oxidation processes currently use persulfate or peroxymonosulfate to generate sulfate radicals. There are, however, few reports on the use of sulfite to generate sulfate radicals, instead of persulfate or peroxymonosulfate, except for dyes. Here we studied the degradation of the bisphenol A using iron(III) as catalyst and sulfite as precursor of oxysulfur radicals, at initial pH of 6, under UV irradiation at 395 nm. The occurrence of radicals was checked by quenching with tert-butyl alcohol and ethanol. Bisphenol A degradation products were analyzed by liquid chromatography coupled with mass spectrometry (LC–MS). Results reveal that iron(III) or iron(II) have a similar oxidation efficiency. Quenching experiments show that the oxidation rate of bisphenol A is 47.7 % for SO ·−4 , 37.3 % for SO ·−5 and 15 % for HO·. Bisphenol A degradation products include catechol and quinone derivatives. Overall, our findings show that the photo-iron(III)–sulfite system is efficient for the oxidation of bisphenol A at circumneutral pH.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Advanced oxidation processes involving hydroxyl radicals (HO·) and sulfate radicals (SO ·−4 ) have strong oxidation capacity for degrading pollutants in wastewater treatment (Shukla and Oturan 2015; Lee et al. 2015). At present, advanced oxidation processes based on sulfate radicals have received much attention since SO ·−4 has several advantages than HO·. For instance, the standard reduction potential of SO ·−4 (E 0 = 2.5–3.1 V, normal hydrogen electrode) (Neta et al. 1988; Minero et al. 2006) is higher than HO· (E 0 = 1.8–2.7 V, normal hydrogen electrode) (Buxton et al. 1988) at circumneutral pH. Moreover, SO ·−4 is more selective for oxidation than HO· (Anipsitakis and Dionysiou 2004). In advanced oxidation processes based on sulfate radicals, SO ·−4 is usually generated by using various means (e.g., transition metal catalysis, irradiation or pyrolysis) to stimulate persulfate or peroxymonosulfate (Zhou et al. 2015). While compared to persulfate or peroxymonosulfate, sulfite is usually cheaper and more environmentally friendly as well as iron which is abundant on earth (Chen et al. 2012; Yates et al. 2014). Currently, reports on the advanced oxidation processes based on sulfate radicals using sulfite to replace persulfate or peroxymonosulfate for the degradation of organic pollutants are much rare. Several works on iron(II)/(III)–sulfite system with or without irradiation have been explored by our group (Chen et al. 2012; Zhang et al. 2013; Zhou et al. 2014a, b, 2015).

However, previous studies mainly focused on the decolorization of azo dyes rather than oxidation of other organic pollutants, which limited the recognition of the new iron–sulfite system. Bisphenol A, an extensively used industrial chemical, usually behaves as an endocrine disruptor in living organisms (Zhu and Zuo 2013). In recent years, an increasing number of new technologies and methods have been studied for removal of bisphenol A since its high resistance to traditional wastewater treatment as a kind of phenolic organic pollutant (Huang et al. 2013; Rodriguez et al. 2010; Hammedi et al. 2015). In this work, bisphenol A was employed as the model pollutant to inspect the oxidation capability of photo-iron(III)–sulfite system. A comparison between iron(II) and iron(III) in this system was firstly studied. Then, effects of sulfite concentration, light intensity and initial concentrations of bisphenol A were investigated. Afterward, free radical quenching experiments were performed to determine the contributions of reactive free radicals in this system. In addition, the initial degradation products of bisphenol A were identified via liquid chromatography coupled with mass spectrometer (LC–MS). The results of this work can provide practical ideas and theoretical basis for new advanced oxidation processes based on sulfate radicals systems containing sulfite salts on the transformation and degradation of bisphenol A and its analog.

Experimental

Photochemical reaction

Light-emitting diode plates that emit ultraviolet A (λ max = 395 nm) was used as the light source. All experiments were performed in a 500-mL beaker and in an open environment. A 400 mL solution containing bisphenol A [chemically pure (higher than 95 %)] and iron(III)/iron(II) at the desired concentration were firstly added into the 500-mL beaker and constantly stirred with a polytetrafluoroethylene-coated magnetic stirrer. Then, the pH of the solution was adjusted to the desired value by using dilute NaOH or H2SO4. Subsequently, sulfite solution was added, and then, the pH was then quickly readjusted to the desired value (±0.05). Purified water with 18 MΩ cm resistivity was used throughout this work. At specific time intervals, a sample aliquot of 5 mL was removed, and then, 1.5 mL of ethanol was added to terminate the reaction.

Analysis

The analysis of bisphenol A concentration was performed using an LC-10A high-performance liquid chromatography (Shimadzu, Japan) equipped with a Shimadzu VP-ODS-C18 chromatographic column (25 cm × 4.6 mm, 5 μm) fixed at 28 °C for column temperature. Samples (20 μL) were injected using a mobile phase containing water–methanol (30/70, v/v) at a flow rate of 0.8 mL min−1. The detection wavelength of bisphenol A was set at 278 nm.

To understand the reaction mechanisms better, we determined the initial oxidation products of bisphenol A after 30 min of reaction. The pH value of the reaction solution was adjusted to pH 2 to stop the reaction since it is hard to form iron(III)–sulfite complex and the oxidation rate of S(IV) induced by iron(III) at pH 2 was about 100-fold lower as that at pH 3 (Seinfeld and Pandis 1998). Then, the sample was frozen for 12 h and lyophilized for the purpose of pre-concentration. The dried sample was dissolved in aqueous solution before analysis with an Agilent 1100 LC–MS. The separation was performed on a Supelco C18 reverse-phase column (4.6 mm × 250 mm, 5 μm) at an eluent flow of 1 mL min−1. A solution containing 40 % water with 0.01 % acetic acid and 60 % methanol was used as the mobile phase. Product ion scans were obtained in negative ion mode over a scan range of 50–500 m/z.

Results and discussion

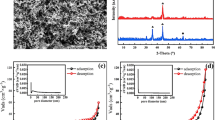

Comparison between iron(II) and iron(III) in photo-iron–sulfite system

The degradation curves in Fig. 1 suggest that the chain reactions are about the same under ultraviolet A irradiation when adding either iron(II) or iron(III), whereas without irradiation using iron(III) is more effective than using iron(II). This probably happens because decomposition of FeSO3 + complex [reaction (2)] is the rate-determining step in the whole reaction chain (1–8) (Zhou et al. 2014b; Chen et al. 2012). FeSO3 + complex as the radical precursor can be either formed from iron(II) through reactions (3) and (4) or from iron(III) via reaction (1).

Degradation of bisphenol A in different iron(III)/(II)–sulfite systems with or without light. Conditions: [bisphenol A]0 = 1 mg L−1, [Fe2(SO4)3]0 = 0.05 mmol L−1 or [FeSO4]0 = 0.1 mmol L−1, [Na2SO3]0 = 1 mmol L−1, initial pH = 6. Number of the light-emitting diode plates: 4. Kinetics curves show no significantly difference between photo-iron(II)–sulfite system and photo-iron(III)–sulfite system under ultraviolet A irradiation, whereas without irradiation using iron(III)–sulfite system shows a higher degradation efficiency than using iron(II)–sulfite system. Moreover, the curves also reveal a fast stage and a slow stage on the degradation process of bisphenol A

Compared with reaction (2) which is a slow reaction, iron(II) can be oxidized into iron(III) apace under UV irradiation. So, the slight difference between the formation time of FeSO3 + from iron(II) and from iron(III) can be ignored under irradiation. While without UV irradiation, the difference between from iron(II) and from iron(III) is more obvious.

The results in Fig. 1 also indicated a two-staged kinetics curves, including a fast stage which could degrade about 60 % of bisphenol A in 2 min and a slow one afterward. This phenomenon was also observed during the decolorization of azo dye Orange II in photo-iron(II)–sulfite systems (Zhang et al. 2013), which is believed to be caused by the quick consumption of dissolved oxygen and sulfite (Brandt et al. 1999). In the fast stage, the concentration of dissolved oxygen and sulfite was relatively abundant which leads to produce more reactive sulfur species. Afterward, the dissolved oxygen and sulfite was dropped sharply, and the concentrations of reactive sulfur species decreased which retarded the degradation of bisphenol A.

Effect of initial concentration of sulfite

In fact, Fig. 2 reveals that the degradation efficiency of bisphenol A in photo-iron(III)–sulfite system with 0.2 or 3 mmol L−1 of sulfite ions was lower than that with 1.0 mmol L−1 sulfite ions. Small dosage of sulfite ions (e.g., 0.2 mmol L−1) cannot produce enough free radicals for bisphenol A degradation. Yet, when excessive sulfite ion was added, the reaction of HSO3 − with SO ·−4 or HSO5 − [reactions (9) and (10)] will reduce the concentrations of SO ·−4 . Hence, the optimal dosage ratio of iron(III) to sulfite ion is between 1:15 and 1:10. In subsequent experiments, the ratio of iron(III)/sulfite 1:10 was used when considering the degradation efficiency of bisphenol A.

(Wine et al. 1989)

(Zhang et al. 2000)

Effect of initial concentration of sulfite ion on the efficiency of bisphenol A degradation in the photo-iron(III)–sulfite system. Conditions: [bisphenol A]0 = 1 mg L−1, [Fe2(SO4)3]0 = 0.05 mmol L−1, [Na2SO3]0 = 0.2–3 mmol L−1, initial pH = 6. Number of light-emitting diode plates: 4. The curves show that the excess or lack of sulfite ion will reduce the degradation efficiency of bisphenol A. The optimal concentration of sulfite is 1 mmol L−1

Effect of light intensity

Results in Fig. 3 show that higher light intensities led to higher efficiencies of bisphenol A degradation, but bisphenol A degradation rates in slow stage under different numbers of light-emitting diode plate were similar. This enhancement on bisphenol A degradation can be attributed to the reinforced decomposition of FeSO +3 complex under light-emitting diode irradiation as shown in reaction (2), which leads to the higher concentration of oxysulfur radicals generated. Therefore, the effect of irradiation mainly occurs in the fast stage of the reaction. However, SO ·−4 generated involves dissolved oxygen, and the dissolved oxygen depleted sharply in the fast stage. Although the dissolved oxygen can recover slowly from the air with the reaction proceeding, the sulfite depletion still restrained the reaction. Therefore, due to the limitation of low concentrations of dissolved oxygen and sulfite, the effect of irradiation in the slow stage is not as significant as that in the fast stage of the reaction. But irradiation is still a simple method to enhance the efficiency of bisphenol A degradation by using more light-emitting diode irradiation, although the light-emitting diode light at the wavelength of 395 nm is very week compared with those lamps of higher energy like xenon lamp or high-pressure mercury lamp which have been used extensively. Furthermore, sunlight is believed to be effective in this photo-iron(III)–sulfite system as well.

Effect of different light intensities on the efficiency of bisphenol A degradation in the photo-iron(III)–sulfite system. Conditions: [bisphenol A]0 = 1 mg L−1, [Fe2(SO4)3]0 = 0.05 mmol L−1, [Na2SO3]0 = 1 mmol L−1, initial pH = 6. The number of light-emitting diode plates varied as 0, 1, 2 and 4. The efficiency of bisphenol A degradation increased as the light intensity ascended from 0 (dark) to 32 W (4 light-emitting diode plates)

Identification of radicals

The photo-iron–sulfite system involves free oxysulfur radicals including SO ·−4 , SO ·−3 and SO ·−5 described via reactions (1–8). HO· could be generated from SO ·−4 via reactions (11) and (12), which might have contributed to the degradation of bisphenol A. To better understand the reaction mechanisms, we identified the main reactive free radicals. Ethanol and tert-butyl alcohol were employed as the radical scavenger. The rate constant for the reaction between ethanol and HO· is (1.2–2.8) × 109 L mol−1 s−1, which is about 50 times higher than that for the reaction between ethanol and SO ·−4 , which is (1.6–7.7) × 107 L mol−1 s−1 (McLachlan et al. 1996). Thus, ethanol in sufficient amount can capture both HO· and SO ·−4 . While the rate constant for the reaction between tert-butyl alcohol and HO· is in fact (3.8−7.6) × 108 L mol−1 s−1, which is 1000 times higher than that for reaction between tert-butyl alcohol and SO ·−4 , which is (4–9.1) × 105 L mol−1 s−1 (Anipsitakis and Dionysiou 2004). The scavenger experiments were undergoing with 500 mmol L−1 of ethanol or tert-butyl alcohol. In the absence of scavenger, bisphenol A degradation efficiency reached 89.9 %, while in the presence of 500 mmol L−1 ethanol, bisphenol A degradation efficiency decreased to 33.5 %, which means that this 33.5 % degradation was contributed to the SO ·−5 or SO ·−3 since the rate constant between SO ·−5 /SO ·−3 and ethanol are very low (k ≤ 103 L mol−1 s−1) (Hayon et al. 1972). In addition, SO ·−3 tends to be oxidized by dissolved oxygen to SO ·−5 very fast. Therefore, SO ·−5 caused the 33.5 % of bisphenol A degradation when the concentration of dissolved oxygen was higher than bisphenol A. Moreover, 76.4 % of bisphenol A were degraded with 500 mmol L−1 of tert-butyl alcohol added in the mixture showing that about 42.9 % of the degradation were attributed to SO ·−4 and that HO· was responsible for about 13.5 % of the degradation.

So, in such system we can estimate that three radicals, SO ·−4 , SO ·−5 and HO·, are involved in the organic compounds oxidation, contributed to about 47.7, 37.3 and 15 %, respectively, to the total degradation efficiency of bisphenol A (89.9 %). pH higher than 7:

(Liang and Su 2009)

All pH values:

(Neta et al. 1988)

Initial products

Through LC–MS, three chemicals were identified including bisphenol A, bisphenol A-o-catechol and bisphenol A-o-quinone as shown in Table 1, in which the latter two were considered as the initial degradation products of bisphenol A. Both products of catechol and quinone derivatives could be formed by either HO· or SO ·−4 . For HO·, bisphenol A molecule was attacked through hydroxyl addition which is subsequently oxidized by O2 to generate bisphenol A-o-catechol. Thereafter, H atoms on the hydroxyl group of catechol are extracted by HO· and produce bisphenol A-o-quinone (Sajiki and Yonekubo 2003; Zhou et al. 2004). While the pathway of SO ·−4 oxidation is different from HO·, SO ·−4 acted as an electrophile abstracts an electron from one of the aromatic rings and forms positively charged aromatic intermediates. Then, the latter intermediate can transform to catechol derivatives (bisphenol A-o-catechol), via nucleophilic addition of HO·, or via nucleophilic addition of H2O and subsequent substitution and deprotonation. Afterward, the bisphenol A-o-catechol can be oxidized to the corresponding quinone (bisphenol A-o-quinone) (Jiang et al. 2013). Although very few reaction of SO ·−5 with organic compounds have been reported, SO ·−5 has a comparatively higher standard reduction potential E 0 = 0.95 V (normal hydrogen electrode, pH 7) or E 0 = 1.12 V (normal hydrogen electrode, pH 4) for SO ·−5 /HSO5 − (Das et al. 1999), which may act as oxidant for bisphenol A like SO ·−4 through hydrogen abstraction and electron transfer (Neta and Huie 1985).

Conclusions

Photo-iron–sulfite system can degrade bisphenol A effectively. Under the same conditions, the iron(III)–sulfite system and iron(II)–sulfite system almost have the same capability of bisphenol A degradation under irradiation. The optimal dosage ratio of iron(III) to sodium sulfite ranged from 1:10 to 1:15, with the degradation efficiency under both ratios being very similar. At specific concentrations of iron(III) and sodium sulfite, the efficiency of bisphenol A degradation was higher at higher light intensity. Radical scavenging tests confirmed that transformation of bisphenol A was caused by SO ·−4 (47.7 %), SO ·−5 (37.3 %) and HO· (15 %). The initial degradation products were identified as bisphenol A-o-catechol and bisphenol A-o-quinone. Current work extends the application of photo-iron–sulfite system as a new advanced oxidation processes based on sulfate radicals and can provide practical basis to treat wastewater containing bisphenol A or its analogs.

References

Anipsitakis GP, Dionysiou DD (2004) Radical generation by the interaction of transition metals with common oxidants. Environ Sci Technol 38:3705–3712. doi:10.1021/es035121o

Brandt C, Fabian I, van Eldik R (1999) Kinetics and mechanism of the iron(III)-catalyzed autoxidation of sulfur(IV) oxides in aqueous solution: evidence for the redox cycling of iron in the presence of oxygen and modeling of the overall reaction mechanism. Inorg Chem 33:687–701. doi:10.1021/ic00082a012

Buxton GV, Greenstock CL, Helman WP, Ross AB (1988) Critical review of rate constants for reactions of hydrated electrons, hydrogen atoms and hydroxyl radicals (·OH/·O−) in aqueous solution. J Phys Chem Ref Data 17:513–886. doi:10.1063/1.555805

Chen L, Peng X, Liu J, Li J, Wu F (2012) Decolorization of orange II in aqueous solution by an Fe(II)/sulfite system: replacement of persulfate. Ind Eng Chem Res 51:13632–13638. doi:10.1021/ie3020389

Das NT, Huie ER, Neta P (1999) Reduction potentials of SO3 −, SO5 − and S4O6 3− radicals in aqueous solution. J Phys Chem A 103:3581–3588. doi:10.1021/jp9900234

Hammedi T, Triki M, Alvarez MG, Chimentao RJ, Ksibi Z, Ghorbel A, Llorca J, Medina F (2015) Total degradation of p-hydroxybenzoic acid by Ru-catalysed wet air oxidation: a model for wastewater treatment. Environ Chem Lett 13:481–486. doi:10.1007/s10311-015-0529-z

Hayon E, Treinin A, Wilf J (1972) Electronic spectra, photochemistry, and autoxidation mechanism of the sulfite–bisulfite–pyrosulfite systems. J Am Chem Soc 94:47–57. doi:10.1021/ja00756a009

Huang W, Brigante M, Wu F, Mousty C, Hanna K, Mailhot G (2013) Assessment of the Fe(III)–EDDS complex in Fenton-like processes: from the radical formation to the degradation of bisphenol A. Environ Sci Technol 47:1952–1959. doi:10.1021/es304502y

Jiang X, Wu Y, Wang P, Li H, Dong W (2013) Degradation of bisphenol A in aqueous solution by persulfate activated with ferrous ion. Environ Sci Pollut Res 20:4947–4953. doi:10.1007/s11356-013-1468-5

Lee HJ, Kim HH, Lee H, Lee C (2015) Reaction of aqueous iodide at high concentration with O3 and O3/H2O2 in the presence of natural organic matter: implications for drinking water treatment. Environ Chem Lett 13:453–458. doi:10.1007/s10311-015-0519-1

Liang C, Su HW (2009) Identification of sulfate and hydroxyl radicals in thermally activated persulfate. Ind Eng Chem Res 48:5558–5562. doi:10.1021/ie9002848

McLachlan GA, Muller JG, Rokita SE, Burrows CJ (1996) Metal-mediated oxidation of guanines in DNA and RNA: a comparison of cobalt(II), nickel(II) and copper(II) complexes. Inorg Chim Acta 251:193–199. doi:10.1016/s0020-1693(96)05272-3

Minero C, Maurino V, Pelizzetti E, Vione D (2006) An empirical, quantitative approach to predict the reactivity of some substituted aromatic compounds towards reactive radical species (Cl −·2 , Br −·2 , ·NO2, SO −·3 , SO −·4 ) in aqueous solution. Environ Sci Pollut Res 13:212–214. doi:10.1065/espr2006.06.318

Neta P, Huie RE (1985) One-electron redox reactions involving sulfite ions and aromatic amines. J Phys Chem 89:1783–1787. doi:10.1021/j100255a049

Neta P, Huie RE, Ross AB (1988) Rate constants for reactions of inorganic radicals in aqueous solution. J Phys Chem Ref Data 17:1027–1284. doi:10.1063/1.555808

Rodriguez EM, Fernandez G, Klamerth N, Maldonado MI, Alvarez PM, Malato S (2010) Efficiency of different solar advanced oxidation processes on the oxidation of bisphenol A in water. Appl Catal B Environ 95:228–237. doi:10.1016/j.apcatb.2009.12.027

Sajiki J, Yonekubo J (2003) Leaching of bisphenol A (BPA) to seawater from polycarbonate plastic and its degradation by reactive oxygen species. Chemosphere 51:55–62. doi:10.1016/s0045-6535(02)00789-0

Seinfeld JH, Pandis SN (1998) Atmospheric chemistry and physics: from air pollution to climate change. Wiley, New York

Shukla S, Oturan MA (2015) Dye removal using electrochemistry and semiconductor oxide nanotubes. Environ Chem Lett 13:157–172. doi:10.1007/s10311-015-0501-y

Wine PH, Tang Y, Thorn RP, Wells JR, Davis DD (1989) Kinetics of aqueous phase reactions of the SO −·4 radical with potential importance in cloud chemistry. J Geophys Res 94:1085–1094. doi:10.1029/jd094id01p01085

Yates BJ, Darlington R, Zboril R, Sharma VK (2014) High-valent iron-based oxidants to treat perfluorooctanesulfonate and perfluorooctanoic acid in water. Environ Chem Lett 12:413–417. doi:10.1007/s10311-014-0463-5

Zhang W, Singh P, Muir D (2000) Iron(II) oxidation by SO2/O2 in acidic media: Part I. Kinetics and mechanism. Hydrometallurgy 55:229–245. doi:10.1016/s0304-386x(99)00082-1

Zhang L, Chen L, Xiao M, Zhang L, Wu F, Ge L (2013) Enhanced decolorization of orange II solutions by the Fe(II)–sulfite system under xenon lamp irradiation. Ind Eng Chem Res 52:10089–10094. doi:10.1021/ie400469u

Zhou D, Wu F, Deng N, Xiang W (2004) Photooxidation of bisphenol A (BPA) in water in the presence of ferric and carboxylate salts. Water Res 38:4107–4116. doi:10.1016/j.watres.2004.07.021

Zhou D, Chen L, Zhang C, Yu Y, Zhang L, Wu F (2014a) A novel photochemical system of ferrous sulfite complex: kinetics and mechanisms of rapid decolorization of acid orange 7 in aqueous solutions. Water Res 57:87–95. doi:10.1016/j.watres.2014.03.016

Zhou D, Zhang H, Chen L (2014b) Sulfur-replaced Fenton systems: can sulfate radical substitute hydroxyl radical for advanced oxidation technologies? J Chem Technol Biotechnol 90:775–779. doi:10.1002/jctb.4525

Zhou D, Yuan Y, Yang S, Gao H, Chen L (2015) Roles of oxysulfur radicals in the oxidation of acid orange 7 in the Fe(III)–sulfite system. J Sulfur Chem 36:373–384. doi:10.1080/17415993.2015.1028939

Zhu Z, Zuo Y (2013) Bisphenol A and other alkylphenols in the environment—occurrence, fate, health effects and analytical techniques. Adv Environ Res 2:179–202. doi:10.12989/aer.2013.2.3.179

Acknowledgments

This work was supported by the Natural Science Foundation of China (No. 21477090). Comments from anonymous reviewers are also appreciated.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Yu, Y., Li, S., Peng, X. et al. Efficient oxidation of bisphenol A with oxysulfur radicals generated by iron-catalyzed autoxidation of sulfite at circumneutral pH under UV irradiation. Environ Chem Lett 14, 527–532 (2016). https://doi.org/10.1007/s10311-016-0573-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10311-016-0573-3