Abstract

This research assessed the effects of pre-heating on the physical–mechanical–chemical properties of different resin composites. For this, resin composites were evaluated in 6 levels: Admira/ADM, Vitra/VIT, Filtek Supreme/FS, Filtek Supreme Flowable/FSF, Filtek One/FO, and Filtek Bulk Fill Flowable/FBF; temperature was evaluated in 4 levels using a composite heater: room temperature/22 ºC, 37 ºC, 54 ºC, and 68 ºC. Response variables were: degree of conversion/DC, flexural strength/FS and color stability/ΔE (immediately after light curing/LC, after 7 days of dark-dry-storage, and after 24 h and 3 days of artificial aging in water at 60 ºC). Data were subjected to 2-way ANOVA (DC and FR) and 3-way repeated measurements ANOVA (ΔE), all followed by Tukey’s test (α = 5%). DC were similar (FBF, FS, and FSF) or increased (ADM, FO, and VIT) as the temperature increased. Results of FR were unchanged or increased for all composites except VIT and ADM. High-viscosity composites (VIT and FS) showed higher FR values than low-viscosity composite (FSF). For bulk-fill composites, FBF and FO showed similar results, but lower than high-viscosity composites. Results of color stability showed acceptable values up to 3 days aging except for ADM and FSF. ΔE was not influenced by pre-heating and, overall, ΔE: FS < VIT < FO < FSF < ADM < FBF. Only VIT and FS showed ΔE ≤ 3.3 (clinical threshold). Therefore, the effects of pre-heating depend on the material. The tested materials generally showed similar or enhanced properties after pre-heating (except ADM and VIT).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Resin composites are the most versatile and widely used direct restorative materials. These materials are marketed with both low- and high-viscosities and there is constant research and development on ways to enhance their properties and clinical workflows. Some approaches can include changes proposed by the manufacturers (i.e., changes in organic and inorganic composition), while others can be introduced by the dentist (i.e., use of different light-curing units, use of different placement techniques, among others) [1, 2].

More recently introduced resin composites usually contain nanoparticles in their composition (nanofill and nanohybrid resins) [3], and are suitable for both anterior and posterior restorations due to their physico-mechanical properties, handling, and polishability [4]. The balance between strength and esthetics has made this group of resin composites widely used among clinicians in recent years.

Additionally, bulk-fill resin composites are becoming increasingly popular as the use of larger increments during direct restorative techniques reduces some limitations inherent in the incremental technique, such as technique sensitivity and time. The bulk-fill technique is also reported to be capable of improving marginal and internal adaptation [2, 5, 6].

One interesting use of high-viscosity resin composites is for cementation of indirect restorations, such as onlays, crowns, and veneers. To conduct such a procedure, the material is pre-heated to temperatures ranging from 37 to 70 ºC to reduce its viscosity [3, 7,8,9,10,11,12,13,14,15]. This procedure is becoming increasingly popular among clinicians not only due to the lower cost of resin composites when compared with resin cements, but mainly due to the greater shade availability, improved mechanical properties, lower polymerization shrinkage, higher color stability, and higher bond strength to ceramics [3, 7,8,9,10, 13,14,15].

The use of pre-heated resin composites has also been advocated for direct restorative procedures due to the enhancement of the above-mentioned physical and mechanical properties. Moreover, pre-heated resin composites are reported to be able to improve marginal and internal adaptation [9, 11, 12, 16, 17].

This technique was first proposed to facilitate insertion and adaptability of resin composites in deep preparations, reduce microleakage, increase the degree of conversion (DC), decrease polymerization shrinkage stress, and increase color stability [8, 9, 16,17,18,19].

While the use of pre-heated composites is interesting from a clinical point of view, there are still some doubts regarding the influence of different temperatures on the properties of high-viscosity materials of varying compositions, or even if higher temperatures could jeopardize a specific material. This issue becomes even more important due to controversial results in the literature associated with reports that some low-molecular-weight components of the material (i.e., components of the photoinitiator) can be volatilized [10, 20].

Literature is controversial regarding the effect of pre-heating resin composites, which may be explained by the widely variable organic and inorganic composition between the various resin composites [5, 9, 11, 12, 16, 17, 21]. Nevertheless, information about the effects of pre-heating on the physical and mechanical properties of nanoparticulated and bulk-fill resin composites is lacking. Moreover, studies evaluating the effects of different heating temperatures on contemporary resin composites are still necessary.

Therefore, the present study assessed the effects of different pre-heating temperatures on the physical, mechanical, and chemical properties of different resin composites with nanoparticles, including different viscosities (high and low viscosity) and types (conventional and bulk-fill). The null hypotheses evaluated were: different pre-heating temperatures would not improve the properties of the resin composites; and there would be no differences between the evaluated resin composites.

Materials and methods

Study design

The study evaluated the factors: resin composites in 6 levels (6 different resins); and temperatures at 4 levels using a composite heater (room temperature/22 ºC; 37 ºC; 54 ºC and 68 ºC). Response variables were: flexural strength, degree of conversion, and color stability (after 7 days of dark-dry-storage, and after 24 h and 3 days of artificial aging in water at 60 ºC) [22, 23]. The compositions of the resin composites evaluated are described in Table 1. All resin specimens were obtained at four different temperatures: 22 ºC/room temperature, or 37 ºC, 54 ºC, and 68 ºC obtained by pre-heating the resin compules on a composite warmer (Calset Warmer, AdDent Inc., Danbury, CT, EUA) for 15 min prior to polymerization.

Degree of conversion (DC)

A Fourier Transformed Infrared Spectroscope (FTIR—Shimadzu Corporation, Model IR Prestige 21, Kyoto, Japan) with an attenuated total reflectance (ATR—Smart Miracle TM) accessory was used for DC measurements. Three specimens for each group were pre-heated, when applicable, and prepared using a polyvinyl siloxane (PVS) mold (2.5 mm diameter × 1 mm height). An initial reading (uncured) was performed, followed by a 20 s light curing using a 1000mW/cm2 light polymerization unit (Valo Grand, Ultradent, South Jordan, UT) and a second reading (cured) immediately after. For all groups, the base of the resin composite heater was positioned covering the sample and FTIR crystal to ensure the same test conditions for all samples and to maintain the temperature for the pre-heated groups. Both readings were performed with a resolution of 4 cm−1 and 32 scans ranging from 4000 to 800 cm−1, and the absorption peaks of aromatic double bonds at 1608 cm−1 and aliphatic double bonds (1636 cm−1) were recorded. Degree of conversion was calculated based on the following formula:

Flexural strength

Eight samples were obtained for each group (n = 8) using a stainless-steel matrix (8 × 2 × 2 mm). The different resin composites were pre-heated (when applicable) and inserted into the matrix. A transparent Mylar strip and a glass slab were used to standardize the samples’ dimensions and surfaces. For the pre-heated groups, the stainless-steel matrix was positioned over the resin composite heater and the samples were left over the heater during 1 min prior to light curing [24]. All samples were cured for 20 s using a 1000 mW/cm2 LED light-curing unit (VALO Grand Cordless, Ultradent), confirmed with a radiometer after every 10 polymerization cycles (LM-1, Guilin Woodpecker Medical Instrument Co., Guangxi, China). The dimensions of the specimens were established based on the diameter of the tip of the LED device (VALO Grand Cordless), which is 12 mm in diameter, ensuring uniform light exposure during photoactivation without requiring additional light activation cycles. The resin composite specimens were stored in distilled water at 37 ºC, in the absence of light, for 24 h. The 3-point bending test was performed using a 3-point bending test device with a 6 mm-span, adapted to a Universal Testing Machine, with a crosshead speed of 0.5 mm/min, in a downward movement until specimen’s fracture. The maximum load, in Newtons (N), was recorded and converted to MPa using the formula

where F represents the axial load (N) at the fracture point, L represents the length of the support span, and b and d represent the width and thickness, respectively, of the transverse section of the specimen.

Color stability (ΔE)

Eight composite disks (6 × 1 mm) were obtained for each group using a polyvinyl siloxane (PVS) matrix. The samples were pre-heated, when applicable, and inserted into the matrix. Their surfaces were standardized using a Mylar strip and a glass slab. For the pre-heated samples, the PVS matrix was positioned over the resin composite heater, and each sample was left in place for 1 min before curing. All samples were cured during 20 s, followed by an initial color reading and dry storage in dark containers at 37 ºC. Color measurements were obtained after curing (baseline) and after 7 days of dark-dry-storage. The samples were also evaluated after 24 h and 3 days of artificial aging in water at 60 ºC [22, 23]. The same samples were evaluated at each timepoint to assess the degree of color change (n = 8 per group).

All color readings were performed using a CIE-Lab-based spectrophotometer (Easyshade V, Vita-Zanhnfabrik, Bad Säckingen, Germany). For this, samples were positioned on a standardized white background, dried with absorbent papers if needed, followed by the color readings. After the spectrophotometer was calibrated, 2 consecutive measurements were taken in the center of the specimen until uniformity of values was observed. The degree of color change (∆E) was calculated using the following formula:

All data were evaluated for homogeneity using Levene’s test and for normality using the Shapiro–Wilk test. For flexural strength (FS) and degree of conversion (DC), a two-way ANOVA analysis was performed (resin composites and temperatures), followed by Tukey’s HSD test. For ΔE, a three-way ANOVA with repeated measurements was performed, followed by Tukey HSD test. All tests adopted a significance level of 5% (α = 0.05).

Results

Results for DC can be observed in Table 2. Significant differences were observed for resin, temperature, and the interaction between both factors (p < 0.001). Overall, the results showed 68 ºC ≈ 56 ºC > 37 ºC ≈ 22 ºC, and FSF > FBF > VIT > ADM > FS > FO. DC increased after pre-heating for ADM, FO, and VIT. FBF, FS, and FSF showed similar results in DC regardless of the temperature. Among bulk-fill composites, the low-viscosity FBF showed higher DC at all temperatures. Among high-viscosity materials, VIT showed higher DC when pre-heated at 68 ºC. Among low-viscosity materials, FSF showed higher overall DC.

Results for flexural strength are presented in Table 3. Significant differences were observed for resin, temperature, and the interaction between both factors (p < 0.001). The highest FS was observed for VIT a 22 ºC [111.93 (13.81)]. Considering high-viscosity resins, VIT and FS showed higher overall values compared to ADM and FO. All high-viscosity resin composites showed lower values after pre-heating compared to room temperature, except FO, which showed increased flexural strength after pre-heating (especially at 37 ºC and 68 ºC), and FS, which showed similar results except when pre-heated at 54 ºC. Considering low-viscosity resin composites, FBF showed an increase in flexural strength, especially at 54 ºC, while FSF did not show any differences.

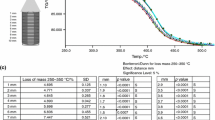

Results for ΔE can be observed in Figs. 1, 2, 3. Significant differences were observed for resin, temperature, time, and for all interaction between factors (p < 0.001). Overall results showed differences for resin: FS ≈ VIT < FO < ADM ≈ FSF < FBF, temperature: 68 ºC ≈ 54ºC < 37 ºC ≈ 22 ºC, and time: 7d < 24 h aging < 3d aging. All composites showed ΔE values lower than 3.3 after up to 1 day of artificial aging except ADM and FBF. Most resin composites showed increased color alteration after 3 days of artificial aging. The increase in temperature showed a tendency to decrease ΔE.

Considering low-viscosity resin composites, FBF showed a high-color alteration between baseline and 7 days of dark-dry-storage, which remained stable after artificial aging (Fig. 2). FSF showed color stability up to 24 h artificial aging with ΔE < than 3.3, but a significant color alteration on the 3rd day of artificial aging. Higher temperatures seemed to show a tendency of higher color stability (lower ΔE), although not statistically significant.

Considering high-viscosity resin composites, FS and VIT showed the best color stability, with ΔE ≤ 3.3 after all timepoints. ADM showed a significant increase in color alteration between the 1st and the 3rd days of artificial aging.

Discussion

Pre-heating resin composites has been used with the premise of improving cavity adaptation, possibility of cementation of indirect restorations, and increased physical and mechanical properties, among other benefits [3, 7,8,9,10,11,12,13,14,15,16,17, 25,26,27]. Nevertheless, literature results are often limited and controversial. Differences are associated with the widely variable organic and inorganic composition of resin composites [5, 8, 9, 11, 12, 16, 17, 21]. Therefore, not all resin composites may be suitable for pre-heating and cementation of veneers without significant interference in their properties.

Literature reports that DC can increase after pre-heating resin composites, since thermal energy increases the mobility of free radicals and monomers, resulting in an improved polymerization rate and polymeric chain [6, 9, 18, 21, 24]. An increased DC typically results in enhanced mechanical and physical properties, thereby increasing the stability and strength of the resin composite in the oral cavity [6, 21]. It is noteworthy that DC can be influenced by many factors, such as the composition and amount of organic matrix and filler content, the light-curing unit, and temperature, among others [6, 28].

In the present study, only the high-viscosity bulk-fill resin composites (ADM and FO) and VIT showed an increase in DC after pre-heating. ADM is a high-viscosity bulk-fill resin composite based on an organically modified ceramic as the organic matrix, which seems to have increased reaction when pre-heated. FO is a high-viscosity bulk-fill resin composite, and VIT is a high-viscosity conventional resin composite. Both present lower filler content compared to FS, which may explain the present results regarding the increase in DC at higher temperatures. Previous studies have reported that high-viscosity resin composites containing lower filler content (i.e., micro-filled composites) are more prone to exhibit a higher DC after pre-heating, which may not be observed for composites with higher filler content [8]. Nanofilled resin composites vary greatly in their filler content, which may explain the wide range of results reported in the literature [16, 17, 21, 24, 29]. In addition, FBF, FSF, and FS showed similar DC regardless of the temperature, which may be explained by the higher filler content (FS) or by the naturally lower viscosity (FBF and FSF).

Flexural strength is one of the main studied mechanical properties and is associated with the long-term maintenance of resin restorations in the oral cavity without fracturing. Generally, resins with higher filler content present the highest values of flexural strength, although the composition of the organic matrix also plays an important role [2, 16, 17, 21, 24, 25, 29]. Some studies have reported an increase in flexural strength for pre-heated bulk-fill resin composites [25]. In the present study, both bulk-fill resin composites FO and FBF showed an increase in flexural strength after being pre-heated. For the other resin composites, the flexural strength was either similar regardless of the temperature (FSF), or showed a tendency to be reduced (ADM, FS, and VIT). Interestingly, there was a pronounced reduction in flexural strength for VIT and ADM after pre-heating. For VIT, despite the decrease in flexural strength after pre-heating, the results were still similar to FS and higher than all other tested groups. Although the viscosity before and after pre-heating and properties of veneer resin cements were not addressed in the present study, it is known that pre-heating is widely employed for cementation purposes. When pre-heated at 68 ºC, VIT showed flexural strength values significantly higher than the flowable resin composites evaluated. For ADM, the ormocer organic matrix may have been degraded by the heat, which could explain the observed results of flexural strength, as well as the increase in DC. The reduced flexural strength in some resin composites after pre-heating was also observed by other authors [30], who showed a tendency for a decrease in flexural strength for FS after pre-heating at 68 ºC, similar to the present study. Although not statistically significant, those authors reported a handling time of 40 s before curing, which may have diminished the temperature effects due to rapid cooling of the material, even after less than 1 min [17, 20, 24].

An interesting finding was the reduction in flexural strength for VIT and ADM, despite the increase in DC. A DSC test was performed in 3 samples of VIT and ADM resin composites for both room temperature and pre-heating at 68 ºC to better understand the phenomenon. For VIT at 22 ºC, the tests showed that the glass transition occurred at approximately 65 ºC. Considering VIT pre-heated at 68 ºC, the test showed a transition at 300 ºC, which suggests a possible melting at 300 ºC. A high degree of crystallinity is desirable in a resin composite as it increases material strength. However, it is important to keep in mind that increase in strength might lead to reduction in material toughness which should be avoided [31]. For ADM, the DSC test suggests that the interface between the Ormocer and the filler content is degraded at relatively low temperatures, which corroborates the present study results, where the polymer still achieves similar DC, but the mechanical properties are significantly reduced. Literature reports that some low-molecular-weight components of the material (i.e., components of the photoinitiator) can be volatilized at relatively low temperatures [10, 20].

Another important property evaluated in the present study was color stability, which can be correlated with degree of conversion and other physico-mechanical properties. Hence, a better cured resin composite should be more resistant to color alterations [6, 8, 14, 21, 22]. The color stability is reported to be also dependent on the material composition and to be influenced by pre-heating [6, 8, 9, 14, 21, 22, 32]. In the present study, both flowable composites (FSF and FBF), as well as ADM, showed the highest degree of color change, especially after artificial aging in water at 60 ºC. For the low-viscosity resin composites, the higher degree of color alteration is expected as there is a higher amount of organic matrix compared to high-viscosity materials. The lower color stability for ADM agrees with previous literature reports and may have occurred due to its composition [29]. FS and Vitra showed adequate color stability (ΔE lower than the 3.3 clinical threshold for unacceptable color change) [22, 23, 33], except Vitra at 54 ºC. FO showed good color stability at the different timepoints, being statistically similar to FS and VIT groups for most timepoints, although higher than the clinical threshold. ADM showed the highest color alteration among the high-viscosity composites evaluated, especially for the non-pre-heated groups.

Considering the tested temperatures, there is a tendency for higher degree of conversion and color stability as the temperature increases up to 68 ºC, the maximum temperature tested in the present study. For flexural strength, the results were widely variable among the different materials, pointing to a need for careful selection of temperature during different clinical procedures. It is noteworthy that, although there was a decrease in mechanical properties for some materials, it can be suggested that pre-heated composites may still be preferable for cementing indirect restorations, as their mechanical properties are higher than the results observed for resin cements [23]. Moreover, in the present study, the experiments were conducted to maintain the resin composites as close as possible to the pre-heated temperature, which may not occur in the clinical setting, as the resin material cools by about 40% in 1 min [17, 20, 24]. Therefore, it should be emphasized that not all resin composites may be indicated for pre-heating without significant interference in their physical and mechanical properties. However, the clinical significance of pre-heating needs to be further studied.

Based on the limitations of the present study, pre-heating of resin composites showed either similar or improved physical, mechanical, and chemical properties. An increase in DC was observed only for ADM, FO, and VIT after pre-heating, while FBF, FS, and FSF did not show alteration. Flexural strength results after pre-heating increased for FO and FBF, remained similar for FSF, and decreased for ADM, FS, and VIT. Color tended to be more stable as the pre-heating temperature increased. Therefore, pre-heating of resin composites is material dependent, and its clinical impact may depend on the desired application.

Data availability

Data available on request from the authors.

References

Furuse AY, Mondelli J, Watts DC. Network structures of Bis-GMA/TEGDMA resins differ in DC, shrinkage-strain, hardness and optical properties as a function of reducing agent. Dent Mater. 2011;27(5):497–506.

Rizzante FAP, Duque JA, Duarte MAH, Mondelli RFL, Mendonça G, Ishikiriama SK. Polymerization shrinkage, microhardness and depth of cure of bulk fill resin composites. Dent Mater J. 2019;38(3):403–10.

Coelho NF, Barbon FJ, Machado RG, Boscato N, Moraes RR. Response of composite resins to preheating and the resulting strengthening of luted feldspar ceramic. Dent Mater. 2019;35(10):1430–8.

Mundim FM, Garcia Lda F, Cruvinel DR, Lima FA, Bachmann L, Pires-de-Souza FC. Color stability, opacity and degree of conversion of pre-heated composites. J Dent. 2011;39(Suppl 1):e25–9.

Hordones Ribeiro MT, Felipe de Bragança G, Sales Oliveira LR, Lourenço Braga SS, Quirino de Oliveira HL, Price RB, et al. Effect of pre-heating methods and devices on the mechanical properties, post-gel shrinkage, and shrinkage stress of bulk-fill materials. J Mech Behav Biomed Mater. 2023;2023(138):105605.

Theobaldo JD, Aguiar FHB, Pini NIP, Lima D, Liporoni PCS, Catelan A. Effect of preheating and light-curing unit on physicochemical properties of a bulk fill composite. Clin Cosmet Investig Dent. 2017;9:39–43.

Almeida JR, Schmitt GU, Kaizer MR, Boscato N, Moraes RR. Resin-based luting agents and color stability of bonded ceramic veneers. J Prosthet Dent. 2015;114(2):272–7.

Gugelmin BP, Miguel LCM, Baratto Filho F, Cunha LFD, Correr GM, Gonzaga CC. Color stability of ceramic veneers luted with resin cements and pre-heated composites: 12 months follow-up. Braz Dent J. 2020;31(1):69–77.

Lopes LCP, Terada RSS, Tsuzuki FM, Giannini M, Hirata R. Heating and preheating of dental restorative materials-a systematic review. Clin Oral Investig. 2020;24(12):4225–35.

Lousan do Nascimento Poubel D, Ghanem Zanon AE, Franco Almeida JC, Vicente Melo de Lucas Rezende L, Pimentel Garcia FC 2022 Composite Resin Preheating Techniques for Cementation of Indirect Restorations. Int J Biomater. 2022 2022-5935668.

Bhopatkar J, Ikhar A, Chandak M, Patel A, Agrawal P. Examining the impact of preheating on the fracture toughness and microhardness of composite resin: a systematic review. Cureus. 2023;15(10): e47117.

Bhopatkar J, Ikhar A, Chandak M, Mankar N, Sedani S. Composite pre-heating: a novel approach in restorative dentistry. Cureus. 2022;14(7): e27151.

Ferreira MC, Alessandretti R, Pereira GKR, Bacchi A, Maroli A, Gomes ÉA, et al. Do preheated composite resin or adhesive resin layer strengthen the feldspar ceramic? J Prosthet Dent. 2022. https://doi.org/10.1016/j.prosdent.2022.08.014.

Raposo CC, Nery LMS, Carvalho EM, Ferreira PVC, Ardenghi DM, Bauer J, et al. Effect of preheating on the physicochemical properties and bond strength of composite resins utilized as dental cements: An in vitro study. J Prosthet Dent. 2023;129(1):299.e1-299.e7.

Souza TJS, Freitas ADS, Ferreira D, Maia LC, Rabello TB. Does the use of preheated restorative resin composite as a luting agent influence the adaptation of fixed dental prostheses? A systematic review J Prosthet Dent. 2024;131(3):384–91.

Kimyai S, Mashayekhi Z, Mohammadi N, Bahari M, Abed Kahnamouei M, Ebrahimi Chaharom ME. Comparison of the effect of preheating on the flexural strength of giomer and nanohybrid composite resin. J Dent Res Dent Clin Dent Prospects. 2022;16(3):159–63.

Silva M, Batista JMN, Fraga MAA, Correr AB, Campos EA, Geraldeli S, et al. Surface analysis of a universal resin composite and effect of preheating on its physicochemical properties. Braz Dent J. 2023;34(4):115–26.

Elkaffas AA, Eltoukhy RI, Elnegoly SA, Mahmoud SH. The effect of preheating resin composites on surface hardness: a systematic review and meta-analysis. Restor Dent Endod. 2019;44(4): e41.

Nascimento Batista JM, Sinhoreti MAC, AlvesFraga MA, Manoel da Silva MV, Correr AB, Roulet JF, et al. Effect of preheating on mechanical properties of a resin-based composite containing elastomeric urethane monomer. J Mech Behav Biomed Mater. 2023;141:105758.

Daronch M, Rueggeberg FA, Moss L, de Goes MF. Clinically relevant issues related to preheating composites. J Esthet Restor Dent. 2006;18(6):340–50.

Elkaffass AA, Eltoukhy RI, Elnegoly SA, Mahmoud SH. Influence of preheating on mechanical and surface properties of nanofilled resin composites. J Clin Exp Dent. 2020;12(5):e494–500.

Furuse AY, Santana LOC, Rizzante FAP, Ishikiriama SK, Bombonatti JF, Correr GM, et al. Delayed light activation improves color stability of dual-cured resin cements. J Prosthodont. 2018;27(5):449–55.

Rizzante FAP, Locatelli PM, Porto TS, Borges AFS, Mondelli RFL, Ishikiriama SK. Physico-mechanical properties of resin cement light cured through different ceramic spacers. J Mech Behav Biomed Mater. 2018;85:170–4.

Daronch M, Rueggeberg FA, De Goes MF. Monomer conversion of pre-heated composite. J Dent Res. 2005;84(7):663–7.

Uctasli MB, Arisu HD, Lasilla LV, Valittu PK. Effect of preheating on the mechanical properties of resin composites. Eur J Dent. 2008;2(4):263–8.

Wagner WC, Aksu MN, Neme AM, Linger JB, Pink FE, Walker S. Effect of pre-heating resin composite on restoration microleakage. Oper Dent. 2008;33(1):72–8.

Tomaselli LO, Oliveira D, Favarão J, Silva AFD, Pires-de-Souza FCP, Geraldeli S, et al. Influence of pre-heating regular resin composites and flowable composites on luting ceramic veneers with different thicknesses. Braz Dent J. 2019;30(5):459–66.

da Silva EM, Poskus LT, Guimarães JG, de Araújo Lima Barcellos A, Fellows CE. Influence of light polymerization modes on degree of conversion and crosslink density of dental composites. J Mater Sci Mater Med. 2008;19(3):1027–32.

Llena C, Fernández S, Forner L. Color stability of nanohybrid resin-based composites, ormocers and compomers. Clin Oral Investig. 2017;21(4):1071–7.

Fróes-Salgado NR, Silva LM, Kawano Y, Francci C, Reis A, Loguercio AD. Composite pre-heating: effects on marginal adaptation, degree of conversion and mechanical properties. Dent Mater. 2010;26(9):908–14.

Zweben CH, Beaumont P. Comprehensive Composite Materials II: Elsevier Science; 2017.

Abed Kahnamouei M, Gholizadeh S, Rikhtegaran S, Daneshpooy M, Kimyai S, Alizadeh Oskoee P, et al. Effect of preheat repetition on color stability of methacrylate- and silorane-based composite resins. J Dent Res Dent Clin Dent Prospects. 2017;11(4):222–8.

Mondelli R, Rizzante F, Rosa ER, Borges A, Furuse AY, Bombonatti J. Effectiveness of LED/Laser irradiation on in-office dental bleaching after three years. Oper Dent. 2018;43(1):31–7.

Acknowledgements

The authors would like to thank FGM, 3M ESPE, Voco GmbH, Ultradent, and Addent for the donation of the resin composites and heater used in the present study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors report no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bueno, T., Masoud, N., Akkus, A. et al. Effects of pre-heating on physical–mechanical–chemical properties of contemporary resin composites. Odontology (2024). https://doi.org/10.1007/s10266-024-00953-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10266-024-00953-x