Abstract

Research on the height of the water-flowing fractured zone (HWFFZ) is important for mine safety and regional eco-environmental conservation in the Jurassic coal field of northwestern China. Using the Cuimu coal mine as a case study, on-site measurement, mechanical theory calculation, and numerical simulation were used to analyze the regularity of the HWFFZ in this area. A television borehole wall imaging system with a light source allowed us to examine the size and shape of fissures intuitively, allowing the top boundary of the HWFFZ to be determined. Per mechanical theory, the overlying strata in the decreasing stress zone was simplified as a clamped rectangular plate and the formula for calculating HWFFZ was obtained by comparing the value of the ultimate deflection of the thin plate and the height of the free space in the lower part of the stratum. In addition, the dynamic development of the HWFFZ was simulated using realistic failure process analysis software. The unusual characteristics of the HWFFZ were analyzed from two aspects: the inapplicability of the traditional empirical formula and the difference of the overlying strata structure of the Jurassic and the Carboniferous Permian coalfields. These strata can be divided into layered and integrated strata in the Jurassic coalfield.

导水裂隙带高度(HWFFZ) 研究对西北侏罗系煤田煤矿安全开采和生态环境保护具有重要意义。以催木煤矿为例,利用现场监测、力学计算和数值模拟方法研究了该区导水裂隙带发育规律。带光源的钻孔孔壁电视有助于观察初始裂隙大小、形状和判定导水裂隙带顶部位置。经力学分析,将应变衰减区上覆岩层简化为固支矩形板,通过比较薄板挠曲和下部地层自由空间高度获得导水裂隙带高度计算公式。利用真实破裂过程分析软件(RFPA)模拟了导水裂隙带发育的动力学过程。从两个方面分析了导水裂隙异常特征:经验公式的不适用性和侏罗系与石炭二叠系地层结构的差异。侏罗系煤田地层可被分为层状和整体两种。

Zusammenfassung

Die Erforschung der Höhe der wasserführenden Bruchzone (HWFFZ) ist bedeutsam im Hinblick auf Grubensicherheit und Umweltschutz im jurassischen Kohlerevier von Nordwestchina. Am Beispiel der Kohlegrube Cuimu wurde anhand von Feldmessungen, gebirgsmechanischen Berechnungen und numerischen Simulationen die Regelmäßigkeit der HWFFZ in diesem Gebiet untersucht. Ein Bohrlochkamerasystem mit Lichtquelle ermöglichte die direkte Untersuchung von Spaltengröße und -form und damit der Bestimmung der Oberkante der HWFFZ. Mittels mechanischer Theorie wurden die Deckschichten in der Stressabbauzone vereinfacht als eingespannte rechteckige Platte betrachtet, die Berechnungsformel für die HWFFZ ließ sich durch Vergleich des Werts der maximalen Durchbiegung der dünnen Platte und einem entsprechenden Abstandsmaß im unteren Schichtbereich berechnen. Zudem wurde die dynamische Entwicklung der HWFFZ mittels realistischer Versagensprozessanalyse (RFPA) simuliert. Die ungewöhnlichen Eigenschaften der HWFFZ wurden unter zweierlei Aspekten analysiert, nämlich der Nichtanwendbarkeit der herkömmlichen empirischen Formel sowie der Strukturunterschiede der Eigenschaften der überlagernden Schichten der jurassischen bzw. permokarbonen Kohlereviere. Im jurassischen Kohlerevier können geschichtete und integrierte Schichten unterschieden werden.

Resumen

La investigación sobre la altura de la zona fracturada con agua fluyente (HWFFZ) es importante para la seguridad de las minas y la conservación ecoambiental regional en el campo de carbón Jurásico del noroeste de China. Utilizando la mina de carbón de Cuimu como un caso de estudio, se realizaron medidas in situ, cálculo de teoría mecánica y simulación numérica para analizar la regularidad de la HWFFZ en esta área. Un sistema de imagen de la pared del agujero de perforación con una fuente de luz, nos permitió examinar el tamaño y la forma de las fisuras intuitivamente, y determinar el límite superior de la HWFFZ. Por teoría mecánica, los estratos superpuestos en la zona de tensión decreciente fueron considerados en forma simplificada como una placa rectangular sujetada; la fórmula para calcular HWFFZ se obtuvo comparando el valor de la deflexión final de la placa delgada y la altura del espacio libre en la parte inferior del estrato. Además, se simuló el desarrollo dinámico de la HWFFZ utilizando software realista de análisis de procesos de fallas (RFPA). Las características inusuales de la HWFFZ fueron analizadas desde dos aspectos: la inaplicabilidad de la fórmula empírica tradicional y la diferencia de la estructura de los estratos superpuestos de las cuencas carboníferas del Jurásico y del Permiano. Estos estratos se pueden dividir en capas estratificadas e integradas en la cuenca de carbón del Jurásico.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Coal, the primary energy source in China, contributes to about 70% of the country’s energy production and is thus important in China’s economic development (Zhang et al. 2009a, b). With the gradual depletion of coal resources in eastern China, the development of coal resources has shifted to the arid and semi-arid region of northwestern China, which has a fragile eco-geological environment (Li et al. 2013a, 2015). The abundant reserves of the Jurassic coal seams there accounts for over 25% of China’s proven recoverable reserves (Li et al. 2000a, b; Wang et al. 2010). However, the large-scale development of coal mining there is damaging the ecological environment and public health, causing water shortages, water pollution, vegetation death, and high human health risk (Adam and Paul 2000; Andreas and Nikola 2011; Kendorski 1993; Li et al. 2013b, 2014, 2016; Li and Qian 2011; Qiao et al. 2017; Wu and Sun 2016; Zhang et al. 2009a, b; Zhang and Peng 2005). Therefore, water conservation is necessary for the sustainable development of coal resources in northwestern China.

There are three distinct zones (a caved zone, a fracture zone, and a continuous deformation zone) of disturbance in overburden strata, based on the deformation and failure characteristics of overlying strata (Palchik 2002). The combined thickness of the caved and fractured zones is the water-flowing fractured zone (WFFZ), which water can flow through. The key to conserving water during mining is to ensure that the WFFZ doesn’t link with the overlying aquifer or land surface. Therefore, an accurate determination of the height of the WFFZ (HWFFZ) has important theoretical and practical significance to the safe exploitation and ecological environment of northwestern China.

The empirical formulae and evaluation methodology of the HWFFZ was deduced based on measured results (Hu et al. 2012; Palchik 2003). Adhikary and Guo (2014) summarized the methods of measuring mining-induced strata permeability and carried out underground hydrogeological monitoring and measurements. Karacan and Goodman (2009) studied hydraulic conductivity changes and influential factors in longwall overburden by slug tests in gob gas vent holes, which is conducive to estimating the HWFFZ. Mining parameters affecting HWFFZ have been simulated in numerical and physical simulations, providing a basis for safe mining (Ding et al. 2014; Liu et al. 2015; Zhang et al. 2016, 2013). The concepts of an interlayer stratum (Gao et al. 2012) and geometry-independent and -dependent roof fractures have been theoretically modelled to estimate the height of the de-stressed zone above the mined panel roof in longwall mining (Majdi et al. 2012). Rezaei et al. (2015) presented a time-dependent energy model to calculate mining-induced stress over gates and pillars. In addition, the relationship between HWFFZ and mining parameters has been determined (Shi et al. 2012; Zhao et al. 2015).

Few authors have researched the HWFFZ in the northwestern Jurassic coalfield. Ning et al. (2016) assessed the developed height of the fracture zone by measuring water leakage and then put forward a method to evaluate ways to conserve water. Wei et al. (2016a, b) studied the formation and height of the interconnected fractured zone after extraction of thick coal seams with weak overburden in northwestern China by numerical analysis and a field test. Zhang et al. (2014) researched mining-induced fractures from overlying strata to the surface using radon detection. Fan et al. (2011) studied the dynamic propagation and distribution of overlying fractures in horizontal and vertical planes caused by longwall mining in a shallow coal seam in the Shendong mine area. Wang et al. (2012) predicted the HWFFZ for a shallow coal seam covered with thin bedrock and thick windblown sands. Although these research results provide an important theoretical basis, it is not enough for safe, large-scale mining of the Jurassic coal seam in northwestern China. For this reason, borehole video camera field observation, mechanical theory calculation, and numerical simulation were used to study the HWFFZ based on the geological and mining conditions of the 210303 coalface in the Cuimu colliery. The difference of the HWFFZ in the Jurassic and Carboniferous Permian coalfields was also analyzed.

Study Area

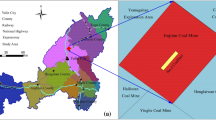

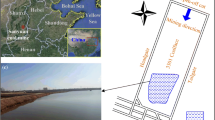

The Cuimu colliery is located northeast of Baoji City, Shaanxi Province (Fig. 1a, b), which belongs to the Shaanxi Yonglong Energy Development Limited Liability Co. The coal mine uses a single-level shaft development; its production capacity is 4.0 Mt/a and its anticipated service life is 66 years. From top to bottom, the stratigraphic succession consists of Quaternary, Neogene, Cretaceous, and Jurassic strata. Table 1 shows the aquifers and aquicludes in the study area: the early Cretaceous pore phreatic aquifer of the Luohe formation (K1 l), the aquicludes of the middle Jurassic Yan’an formation (J2 y), the upper Pleistocene Malan loess (Q3 m), and the Pliocene Baode clay (N2 b). The main minable seam is the no. 3, which belongs to the Jurassic Yan’an formation.

The strike and inclined length of the 210303 coalface is 792.5 km and 200 m, respectively (Fig. 1c). The coal seam dip is sub-horizontal with a mining thickness of 8.2 m, at a depth that ranges from 540 to 600 m. Two water inrush accidents occurred during mining of the 210303 working face. It was concluded that at least part of the water was derived from the Cretaceous aquifer by analyzing the degree of mineralization of a water sample, which means that the HWFFZ linked with the Cretaceous aquifer. However, according to China’s eastern Carboniferous Permian mining experience, the HWFFZ should not have reached the Cretaceous strata. Therefore, we carried out the following research to determine the HWFFZ in the Jurassic coalfield of northwestern China.

Methodology

In order to accurately determine the HWFFZ in northwestern China’s Jurassic coalfield, an on-site test was carried out using a television borehole wall imaging system with a light source. Then, the HWFFZ was calculated based on the theory of plates and shells (Xu 1982). Finally, the dynamic development of the HWFFZ was simulated using RFPA software (Tang 1997).

Borehole Video Camera Field Observation

We used the television borehole wall imaging system to observe the fracture characteristics of the overlying strata to judge the top boundary of the HWFFZ. The distance between the G5 borehole and the open-off cut of the 210303 coalface is 539.93 m, and the G5 borehole is located at the center of the inclined direction in the coalface (Fig. 1c). The G5 borehole was drilled from the ground surface down to the underground coalface after the coal seam had been mined for 2 months. The elevation of the borehole orifice and coal seam floor is 1261.9 and 685 m, respectively. Therefore, the buried depth of the coal seam is 576.9 m.

Mechanical Theory Calculation

Calculating Ultimate Deflection of Plate-Shaped Strata

Before mining, the natural stress of the rock surrounding the coal seam is balanced. After mining, the abutment pressure of the coalface can be divided into a stress invariant zone (I and I′), a reduced stress zone (II), and an increased stress zone (III) (Supplemental Fig. 1). Without considering the influence of the broken angle of the overlying strata, we studied the strata above the reduced stress zone. Based on large-scale longwall mining practices in northwestern China, the overlying strata thickness of the Jurassic coal seam is much less than the strike length of the reduced stress zone of the coalface, such that the ratio of the thickness of each overlying stratum and the strike length of the reduced stress zone (a) is less than 1/5. Therefore, each overlying stratum can be regarded as the rectangular thin plate with four clamped edges, allowing the thin plate approach (Xu 1982) to be used. Figure 2 shows the thin plate mechanical model of an overlying stratum.

In Fig. 2, the X and Y coordinate axes are made on the upper surface of an overlying stratum along the strike and inclined direction of the coalface; the point of intersection is O. The lateral load on a stratum is composed of two parts. One part is the weight of the overlying strata, γH, where γ is the bulk density of the overlying strata, KN/m3 and H is the buried depth of the overlying strata, m. The other part is the reduced stress zone caused by mining pressure, which can be simplified as a linear triangular load, q 1 = γH(1 − x/a), where x is the distance to the point O along the X coordinate axis. The lateral total load on the rectangular thin plate with four clamped edges is q = γHx/a. The boundary conditions of the thin plate mechanical model of the overlying strata are:

It is supposed that the deflection function of the overlying strata is represented by Eq. (2):

where m and n are positive integers. This deflection function satisfies the boundary conditions. The coefficient of the deflection function A mn can be calculated based on the principle of minimum potential energy (Huang 1987), as shown in Eq. (3):

where a is the strike length of each overlying stratum and the strike length of the reduced stress zone of the coalface, m; b is the width of each overlying stratum, m; D is the bending stiffness of the thin plate, \(D=\frac{{Eh_{i}^{3}}}{{12(1 - {\mu ^2})}}\); h i is the thickness of a stratum, m; and μ is the Poisson’s ratio of a stratum.

Hence, the deflection function of overlying strata is shown in Eq. (4):

Due to the rapid convergence of the series in Eq. (4), we selected positive integers m = n = 1 to simplify the calculation and we then proved that the results met the project’s accuracy requirements. Therefore, the deflection function is shown in Eq. (5):

The maximum deflection function of the plate-shaped strata does not mean that the strata have failed. It is therefore necessary to calculate the ultimate deflection of the plate-shaped strata. The thin rock plate limit span of the strike and inclined length is a m and b m , respectively, and depends on the physical and mechanical properties of the strata, its thickness, load, and other factors. When σ t > [σ t ], the thin plate is broken. At this time, the a m , b m of the thin plate size is the limiting size. The computational formula derived based on the tensile strength is shown in Eq. (6) (Huang 1987):

where k is the shape coefficient of a thin plate, and

Therefore, the ultimate deflection function of overlying strata is shown in Eq. (8):

Judging the HWFFZ

The free space formed after mining will be filled with the collapsed overlying strata. The free space height can be obtained from Eq. (9) if the HWFFZ has broken expansion characteristics and the bending zone does not:

where S i is the free space height of the i layer stratum, m; M is the mining thickness of a coal seam, m; h j is the thickness of the j layer stratum, m; and k j is the broken expansion coefficient of the j layer stratum. The HWFFZ depends on the ultimate deflection of a stratum ω jmax and its lower free space height, S i . If ω jmax < S i , the stratum will be broken, increasing the HWFFZ. Otherwise, the height of WFFZ will be stable.

Numerical Simulation

This conceptual model was the basis of simulation analysis and evaluation research (Liu et al. 2017). Based on a geological prototype, the engineering geology conceptual model (Supplemental Fig. 2) was established by rational abstraction and simplification. The dynamic height of the fractured overlying strata in the 210303 working face was simulated based on realistic failure process analysis (RFPA). Based on the actual geological data, the length and height of the numerical model are 600 m (Fig. 3). The left and right boundaries of the model are horizontally restricted, the upper boundary is a free boundary, and the bottom boundary is fully constrained. The model of the left and right boundary coal pillar is 200 m. Step by step excavation was carried out in the model. The distance of each cut and the total excavation was 10 and 300 m, respectively.

Results

Borehole Video Camera Field Observation

Video camera images of the G5 borehole are shown in Fig. 6. When the borehole television observation depth reached 321.06 m, ring-like horizontal bed-separations occurred (Fig. 4a), but no water flowed through them, due to uneven subsidence caused by the different rock mechanics properties in the Luohe formation. As the observation depth continued to increase, vertical fractures first appeared at 378.38 m (Fig. 4b), showing water conductivity. Subsequently, the density of the vertical fractures increased with depth (Fig. 4c). Hence, 378.38 m was judged as the top boundary of the HWFFZ. The HWFFZ was calculated by:

where H li is HWFFZ, m; H is the vertical depth between the borehole orifice and coal seam floor, m; M is the mining thickness, m; G is the vertical depth between the top boundary of the HWFFZ and borehole orifice, m; and W is the compression value of the fracture zone during drilling, m. Based on drilling experience, W was taken as 0.2 m. After calculation, H li = 190.51 m.

Mechanical Theory Calculation

Based on the drilling core test, the physical and mechanical parameters of the overlying strata in the 210303 coalface are shown in Supplemental Table 1. The theoretical calculation of the HWFFZ was carried according to the above calculation method. Based on the experiment and field test, the broken expansion coefficient of the mudstone and sandstone were 1.035 and 1.030, respectively.

Taking the overlying 2nd coarse-grained sandstone stratum as an example, the physical and mechanical parameters of the 2nd stratum are: a = 200 m, b = 200 m, σ t = 1.02 MPa, γ = 21.9 KN/m3, E = 7840 MPa, H = 572.1 m, h 1 = 4.34 m, and μ = 0.25. First, the free space height of the second stratum was calculated based on Eq. (9):

Then, the ultimate deflection of the 2nd stratum ω jmax was calculated based on Eq. (8). The surface map of this deflection function was obtained using MathCAD software (Ji 2002), as shown in Fig. 5. In Fig. 5, the maximum ultimate deflection of the second stratum is 0.21 m, i.e. ω jmax = 0.21 < S 1 = 8.1265 m. So, the second stratum was destroyed (Supplemental Table 1). Other strata were similarly calculated; the failure state is shown in Supplemental Table 1. Eventually, it was concluded that the HWFFZ was 189.7 m and the ratio of the HWFFZ and mining thickness was 23.13:1.

Numerical Simulation

The HWFFZ dynamic development process is shown in Fig. 6. The first caving of the immediate roof occurred when the coalface advanced to 30 m. When the excavation was 45 m, the basic roof began to collapse, forming the first weighting. At that time, the HWFFZ was 18 m (Fig. 6b). The first periodic weighting happened when the coalface advanced to 60 m, and the HWFFZ was 84.1 m (Fig. 6c). As the coalface advanced, the HWFFZ increased gradually. When the coalface advanced to 170 m, the maximum HWFFZ was 192.1 m. Subsequently, the HWFFZ no longer increased, but the scope of the HWFFZ gradually increased. At the end of mining, the HWFFZ was still 192.1 m and its developmental morphology was saddle-shaped. In addition, bed-separation fissures appeared in the Cretaceous Luohe formation (Fig. 6d). To ensure mine safety, the final HWFFZ was 192.1 m, based on the field measurements, theoretical analysis, and numerical simulation.

Discussion

The revival of Silk Road will demand more coal resources, posing a great deal of pressure on groundwater and mine safety in northwestern China (Li et al. 2015, 2017). The ratio of the HWFFZ and the mining thickness of the Jurassic coal seam in northwestern China ranges from 20 to 28, which is very different than that of the Carboniferous Permian coal seam in mid-eastern China, where it ranges from 10 to 15 (Li et al. 2000a, b, 2012). Miao et al. (2011) simulated the height of the water-conducting fractured zone in undermined rock strata of the Bulianta Coal Mine and illustrated the conspicuous discrepancy of the height of the water-conducting fractured zone predicted by the traditional method from that actually observed. Xu et al. (2009) proposed that the primary key stratum plays an important role in controlling the HWFFZ. This paper analyzed the abnormality of the HWFFZ from two aspects: the inapplicability of the traditional empirical formula and the difference of the overlying strata structure between the Jurassic and the Carboniferous Permian coalfields.

Inapplicability of Traditional Empirical Formula

The traditional HWFFZ empirical formula was proposed by Liu Tianquan in the early 1980s based on regression statistical analysis of data from mid-eastern China’s Carboniferous Permian coalfield (State Administration of Work Safety 2009). The traditional empirical formula shown in Eq. (11) is based on the overlying strata strength of the 210303 coalface, following the method described by the National Bureau of Coal Industry of China (2000):

The calculated height of the HWFFZ is 54.64 m, based on a mining thickness of 8.2 m, which is obviously less than the above determined results. This is because in the early 1980s, mining thickness was less than 3 m, mining was conducted by blasting or conventional mining, and the inclined length of the coalface was less than 120 m in the Carboniferous Permian coalfield. However, in the Jurassic coalfield, the mining thickness is greater, the mining is totally mechanized, and the inclined length of the coalface exceeds 180 m. Therefore, the traditional empirical formula is not applicable to northwestern China’s Jurassic coalfield.

Comparing Overlying Strata Structure Characteristics

The deformation and failure of overlying strata is related to the structural characteristics of the overburden strata. Figure 7 compares the structural characteristics of the overlying strata of the Jurassic and Carboniferous Permian coalfields. Tectonic movement has little influence on the overlying strata of the Jurassic coal seam; the rock mass integrity is good and there are only compact, nearly-horizontal bedding joints with good continuity, and no vertical joints (Fig. 7a). However, the tectonic movement has strong influence on the overlying strata of the Carboniferous Permian coal seam in northwestern China, forming a series of bedding surface, joints 1 and joints 2 in the coal-bearing strata, which present block or cataclastic structure with poor integrity of overlying strata, as shown in Fig. 7b.

The rock quality designation (RQD) is the ratio between the length of a drill core (at least 10 cm long) and the drilling depth. The higher the RQD, the better the rock integrity. Based on drilling cores of strata unaffected by mining, statistics suggest that the RQD of strata overlying the Jurassic coal seam generally exceeds 90% (Supplemental Fig. 3, Shilawusu Colliery sky3 drill, Inner Mongolia), while the RQD value of the Carboniferous Permian coal overburden is about 40% (Supplemental Fig. 4, Yangliu Colliery R414-3 drill, An’hui). According to “Specification for hydrogeological engineering geological exploration in a mining area” (State Bureau of Technical Supervision 1991), when the RQD is between 90 and 100%, the rock mass has good integrity; when it is between 25 and 50%, the rock mass has poor integrity. Therefore, the Jurassic coal overburden strata are relatively study, while the Carboniferous Permian coal overburden strata consist of structural blocks.

Classifying Overlying Strata Structure of the Jurassic Coal Seam

Fully understanding the differences between the overlying strata structure of the two coalfields can greatly improve the accuracy of strata deformation failure analysis. Based on geological mapping, in-mine observations, and an in situ test, we divided the overlying strata of the Jurassic coalfield into two types: an integrated structure and a layered structure.

-

(1)

Integrated Structure

The integrated structure mainly refers to the sandstone of the Yan’an and Zhiluo formations, but also includes the relatively thick siltstone with calcareous cementation. The layered overlying strata are thick and most of the individual strata contain very thick bedding. In addition, the structural plane is mainly layered joints, mostly closed, and its spacing generally exceeds 2.0 m, meeting the requirements of fracture surface spacing greater than 1.5 m per the “Code for Geotechnical Investigation” (Ministry of Construction of the PRC and General Administration of Quality Supervision, Inspection and Quarantine of the PRC 2009). The integrated structure appears mostly in the basic roof of the coal, and is a relatively good rock mass with high integrity and stability.

-

(2)

Layered Structure

The layered structure is typically a thin or moderately thick layer, intercalated with mudstone, coal, carbonaceous mudstone, and other weak interlayers and locally sandwiched by moderately thick sandstone and siltstone. The structure is characterized by many-layered, alternating soft and hard strata and is generally cuboid and tabular due to the influence of various structural planes. The layered structure is relatively impermeable, but is vulnerable to softening by groundwater, disintegration, segregation etc. The structural instability is mainly due to bed separation or slippage along the slip surface after mining.

Based on an analysis of the overlying rock’s structural characteristics, the mechanical theory research of the HWFFZ in the Jurassic coalfield is more geared to plates and shells methodology, further verifying the reliability and accuracy of the mechanical theory calculation above. In other areas of the world, judgments should be based on local geological conditions, rather than relying solely on conventional rules or an empirical formula. Thus, a specific research approach based on the local geological conditions must be used to address specific issues and provide a scientific design basis for safe mining.

Conclusions

On-site measurements, theoretical analyses, and a numerical simulation were used to determine the HWFFZ in the 210303 coalface of the Cuimu colliery, and the inapplicability of traditional empirical formulas and the difference of overlying strata structure between the Jurassic and Carboniferous Permian coalfields were considered. The research findings are as follows:

-

1.

Based on our understanding of large-scale long wall coalface mining in northwestern China, we simplified the overlying strata of the coalface’s decreasing stress zone as four clamped rectangular plates, deriving the formula for calculating the HWFFZ by comparing the value of the ultimate deflection of the thin plate and the height of the free space in the lower part of the strata.

-

2.

Based on on-site measurements, theoretical analyses, and numerical simulation, the designated HWFFZ was 190.51, 189.7, or 192.1 m, respectively. To ensure safe mining, the HWFFZ was set at 192.1 m.

-

3.

Based on the inapplicability of the traditional empirical formula, the HWFFZ was analyzed from two aspects: the inapplicability of the traditional empirical formula and the different overlying strata structure of the Jurassic and the Carboniferous Permian coalfields. Then the overlying strata structure in Jurassic coalfield was divided into layered structure and integrated structure.

This research documents how the HWFFZ can be determined in similar coal mines and how, in the future, all methods should be based on a site’s engineering geological conditions. In addition, the corresponding empirical formulas should be derived based on the observed data and the local geological conditions, which can provide a scientific design basis for safe mining.

References

Adam PJ, Paul LY (2000) Broadening the scope of mine water environmental impact assessment: a UK perspective. Environ Impact Asses 20:85–96

Adhikary DP, Guo H (2014) Measurement of longwall mining induced strata permeability. Geotech Geol Eng 32(3):617–626

Andreas K, Nikola R (2011) Sustainable development of energy, water and environment systems. Water Resour Manag 10:33–39

Ding HD, Miao XX, Ju F, Wang X, Wang Q (2014) Strata behavior investigation for high-intensity mining in the water-rich coal seam. Int J Min Sci Technol 24:299–304

Fan GW, Zhang DS, Ma LQ (2011) Overburden movement and fracture distribution induced by longwall mining of the shallow coal seam in the Shendong coalfield. J Chin Univ Min Technol 40(2):196–201

Gao YF, Huang WP, Liu GL, Zhang SF, Zhu QM (2012) The relationship between permeable fractured zone and rock stratum tensile deformation. J Min Saf Eng 29(3):301–306 (Chinese)

Hu XJ, Li WP, Cao DT, Liu MC (2012) Index of multiple factors and expected height of fully mechanized water flowing fractured zone. J Chin Coal Soc 37(4):613–620 (Chinese)

Huang KZ (1987) Theory of plates and shells. Tsinghua university press, Beijing (Chinese)

Ji ZR (2002) Mathcad 2001. Tsinghua university press, Beijing (in Chinese)

Karacan CÖ, Goodman G (2009) Hydraulic conductivity changes and influencing factors in longwall overburden determined by slug tests in gob gas ventholes. Int J Rock Mech Min Sci 46(7):1162–1174

Kendorski FS (1993) Effect of high-extraction coal mining on surface and ground waters. In: Proceedings of the 12th conference on ground control in mining. West Virginia University, Morgantown

Li WP, Duan ZH, Hua JM, Ye GJ, Zhao XJ (2000a) Evaluation of present geological environment and prediction of its variation caused by mining in Yushenfu mine area of north Shanxi. J Eng Geol 8(3):324–333 (Chinese)

Li WP, Ye GJ, Zhang L, Duan ZH, Zhai LJ (2000b) Study on the engineering geological conditions of protected water resources during coal mining action in Yushenfu mine area in the north Shaanxi Province. J Chin Coal Soc 25(5):449–454 (Chinese)

Li WP, Li T, Shang R (2012) Study on the structure variation and permeability change of overlying strata after large coal mining in northern Shaanxi. J Eng Geol 20(S):294–299 (Chinese)

Li PY, Wu JH, Qian H (2013a) Assessment of groundwater quality for irrigation purposes and identification of hydrogeochemical evolution mechanisms in Pengyang County, China. Environ Earth Sci 69(7):2211–2225

Li PY, Qian H, Wu JH, Zhang YQ, Zhang HB (2013b) Major ion chemistry of shallow groundwater in the Dongsheng coalfield, Ordos basin, China. Mine Water Environ 32(3):195–206

Li P, Qian H, Wu J (2014) Origin and assessment of groundwater pollution and associated health risk: a case study in an industrial park, northwest China. Environ Geochem Health 36(4):693–712

Li P, Qian H, Howard KWF, Wu J (2015) Building a new and sustainable “Silk Road economic belt”. Environ Earth Sci 74:7267–7270

Li PY, Li XY, Meng XY, Li MN, Zhang YT (2016) Appraising groundwater quality and health risks from contamination in a semiarid region of northwest China. Expo Health 8(3):361–379

Li P, Tian R, Xue C, Wu J (2017) Progress, opportunities, and key fields for groundwater quality research under the impacts of human activities in China with a special focus on western China. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-017-8753-7

Liu XS, Tan YL, Ning JG, Tian CL, Wang J (2015) The height of water-conducting fractured zones in longwall mining of shallow coal seams. Geotech Geol Eng 33: 693–700. https://doi.org/10.1007/s10706-015-9851-2

Liu SL, Liu WT, Yin DW (2017) Numerical Simulation of the lagging water inrush process from insidious fault in coal seam floor. Geotech Geol Eng Online. https://doi.org/10.1007/s10706-016-0156-x

Majdi A, Hassani FP, Nasiri MY (2012) Prediction of the height of destressed zone above the mined panel roof in longwall coal mining. Int J Coal Geol 98:62–72

Miao XX, Cui XM, Wang JA, Xu JL (2011) The height of fractured water-conducting zone in undermined rock strata. Eng Geol 120:32–39

Ministry of Construction of the PRC and General Administration of quality supervision, inspection and Quarantine of the PRC (2009) Code for Geotechnical Investigation. Beijing (in Chinese)

National Bureau of Coal Industry of China (2000) Pillar design and mining regulations under buildings, water, rails and major roadways. China Coal Industry Publ House, Beijing (in Chinese)

Ning JG, Liu XS, Tan YL, Wang J, Zhang M, Zhang LS (2015) Water-preserved mining evaluation in shallow seam with sandy mudstone roof. J Min Saf Eng 32(5):814–820 (Chinese)

Palchik V (2002) Influence of physical characteristics of weak rock mass on height of caved zone over abandoned subsurface coal mines. J Environ Geol 42(1):92–101

Palchik V (2003) Formation of fractured zones in overburden due to longwall mining. Environ Geol 44(1):28–38

Qiao W, Li WP, Li T, Chang JY,K, Wang QQ (2017) Effects of coal mining on shallow water resources in semiarid regions: a case study in the Shennan mining area, Shaanxi, China. Mine Water Environ 36(1):104–113

Rezaei M, Hossaini MF, Majdi A (2015) Development of a time-dependent energy model to calculate the mining-induced stress over gates and pillars. J Rock Mech Geotech Eng 7(3):306–317

Shi LQ, Xin HQ, Zhai PH, Li SC, Liu TB, Yan Y, Wei WX (2012) Calculating the height of water flowing fracture zone in deep mining. J Chin Univ Min Technol 41(1):37–41 (Chinese)

State Administration of Work Safety (2009) State administration of production safety supervision of China provisions on prevention and control of water in coal mines. China Coal Industry Publ House, Beijing (in Chinese)

State Bureau of Technical Supervision (1991) Specification for hydrogeological engineering geological exploration in mining area. Beijing (in Chinese)

Tang CA (1997) Numerical simulation of progressive rock failure and associated seismicity. Int J Rock Mech Min Sci 34(2):249–261

Wang SM, Huang QX, Fan LM, Yang ZY, Shen T (2010) Study on overburden aquiclude and water protection mining regionalization in the ecological fragile mining area. J Chin Coal Soc 35(1):7–13 (Chinese)

Wang LG, Wang ZS, Huang JH, Zhou DL (2012) Prediction on the height of water-flowing fractured zone for shallow seam covered with bedrock and thick windblown sands. J Min Saf Eng 29(5):607–612 (Chinese)

Wei JC, Wu FZ, Xie DL, Yin HY, Guo JB (2016a) Development characteristic of water flowing fractured zone under semi-cemented medium-low strength country rock. J Chin Coal Soc 41(4):74–983 (Chinese)

Wei JC, Wu FZ, Yin HY, Guo JB, Xie DL (2016b) Formation and height of the interconnected fractures zone after extraction of thick coal seams with overburden in western China. Mine Water Environ 36(1):59–66

Wu J, Sun Z (2016) Evaluation of shallow groundwater contamination and associated human health risk in an alluvial plain impacted by agricultural and industrial activities, mid-west China. Expo Health 8(3):311–329

Xu ZL (1982) Mechanics of elasticity. People’s Education Press, Beijing (Chinese)

Xu JL, Wang XZ, Liu WT, Wang ZG (2009) Effects of primary key stratum location on height of water flowing fracture zone. Chin J Rock Mech Eng 28(2):380–385 (Chinese)

Zhang JC, Peng SP (2005) Water inrush and environmental impact of shallow seam mining. Environ Geol 48:1068–1076

Zhang DS, Fan GW, Ma LQ, Wang A, Liu YD (2009a) Harmony of large-scale underground mining and surface ecological environment protection in desert district—a case study in Shendong mining area, northwest of China. Proc Earth Planet 1:1114–1120

Zhang DS, Liu YD, Wang XF (2009b) Water preserving mining technology for shallow coal seam with sand-bedrock type and classification of applicable conditions. China Univ of Mining and Technology Press, Xuzhou (Chinese)

Zhang YX, Tu SH, Bai QS, Li JJ (2013) Overburden fracture evolution laws and water-controlling technologies in mining very thick coal seam under water-rich roof. Int J Min Sci Technol 23:693–700

Zhang W, Zhang DS, Wu LX, Wang HZ (2014) On-site radon detection of mining-induced fractures from overlying strata to the surface: a case study of the Baoshan coal mine in China. Energies 7:8483–8507

Zhang GB, Zhang WQ, Wang CH, Zhu GL, Li B (2016) Mining thick coal seams under thin bedrock–deformation and failure of overlying strata and alluvium. Geotech Geol Eng 34:1553–1563

Zhao BC, Liu ZR, Tong C, Wang CL (2015) Relation between height of water flowing fractured zone and mining parameters. J Min Saf Eng 32(4):634–638 (Chinese)

Acknowledgements

The authors thank the 186 group of the Shaanxi Coalfield Geology Bureau and the Cuimu colliery for their support and permission to access data. Financial support was provided by the National Basic Research Program of China (973 Program) under Grant 2015CB251601, and the State Key Program of the National Natural Science Foundation of China (Grant 41430643).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Liu, S., Li, W. & Wang, Q. Height of the Water-Flowing Fractured Zone of the Jurassic Coal Seam in Northwestern China. Mine Water Environ 37, 312–321 (2018). https://doi.org/10.1007/s10230-017-0501-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10230-017-0501-1