Abstract

Passive treatment is a promising, green technology that is increasingly being used for mine drainage treatment. However, several challenges remain concerning its implementation in locations where the temperature of the water remains cold year round and bacterial growth is limited by the low temperatures. The impacts of cold on the activity of sulfate-reducing bacteria (SRB) and the subsequent removal of Cd and Zn from acid mine drainage were studied by conducting static tests at 4.5 °C over a 90 day period. Different sources of carbon were tested to support native SRB: molasses, methanol, and a mix of molasses/methanol at different concentrations. The reactors were monitored biweekly, and the pH, oxido-reduction potential, and residual concentrations of Zn, Cd, sulfate, and total organic carbon were measured. The use of carbon sources clearly improved bacterial activity and consequently, the removal of Cd and Zn by precipitation as sulfide. Up to 94.8% of the Zn and up to 99.4% of the Cd were removed after 90 days, reducing metal concentrations below the discharge limits ([Cd] < 50 µg/L and [Zn] < 500 µg/L). The molasses + methanol mix was slightly more efficient than either. These findings indicated that native SRB might be used successfully to treat metal-contaminated mine water.

摘要

硫酸盐生物还原法 (SRB) 作为有潜力的矿山废水处理技术,正被越来越广泛地用作传统处理方法的可替代方法。该方法在终年寒冷和细菌生活受限区域的应用仍面临挑战。利用4.5℃条件下90多天的静态试验研究了低温对SRB活性和酸性废水镉和锌去除率的影响。SRB系统加入了糖浆(molasses,Mo)、甲醇(methanol)和糖浆与甲醇不同浓度混合物的碳源。SRB反应器大小为1升,监测频率每两周一次,监测项目包括pH值、氧化-还原电位(ORP)及锌、隔、硫酸盐和总有机碳的残余浓度。碳源的使用明显提高了细菌活性和硫化物沉淀态隔、锌去除率。反应90天后,锌去除率94.8%,镉去除率99.4%,镉和锌浓度分别低于50µg/L和500µg/L的废水排放标准。研究表明,本地硫酸盐还原菌能成功处理含重金属矿井废水。

Zusammenfassung

Die passive Behandlung von Bergbauabwasser durch Sulfat-reduzierende Bakterien (SRB) ist eine vielversprechende grüne Technologie, welche zunehmend als Alternative zu konventionellen Behandlungsmethoden eingesetzt wird. Es besteht jedoch noch weiterer Entwicklungsbedarf bei Anwendungen unter kühleren Klimabedingungen, wo die Wassertemperaturen über das gesamte Jahr niedrig sind und somit das Bakterienwachstum begrenzen. Der Einfluss niedriger Temperaturen auf die auf die Aktivität von SRB in saurem Grubenabwasser und die Auswirkung auf den Cd- und Zn-Entzug werden durch 90-tägige statische Tests bei 4.5 °C untersucht. Dabei wird der Einfluss unterschiedlicher Kohlenstoffquellen (Melasse (Mo), Methanol (MeOH), Mo/MeOH-Mischung) zusätzlich untersucht. Die ein Liter großen Reaktionsgefäße wurden zweimal in der Woche auf den pH-Wert, das Oxidations/Reduktionspotenzial (ORP) sowie auf Zn-, Cd-, Sulfat- und TOC- (Gesamter Organischer Kohlenstoff) Gehalte untersucht. Die Verwendung von zusätzlichen Kohlenstoffquellen erhöhte die Bakterienaktivität deutlich und wirkt sich somit auch auf die Metallfällung von Cd und Zn aus, wobei die Metalle als Sulfid gefällt werden. Bis zu 94.8% des Zn und 99.4% des Cd sind nach 90 Tagen gefällt worden, was zu Metallkonzentrationen unterhalb der Abflussgrenzwerte ([Cd] < 50 µg/L und [Zn] < 500 µg/L) führte. Die Nutzung der Mo+MeOH-Mischung war effizienter als die Verwendung von Melasse oder MeOH alleine. Diese Ergebnisse zeigen, dass die ursprünglich vorkommenden SRB erfolgreich bei der Behandlung schwermetallhaltigen Grubenabwassers eingesetzt werden könnten.

Resumen

El tratamiento pasivo, utilizando bacterias sulfato-reductoras (SRB), es una tecnología verde y promisoria que está siendo usada en forma creciente como alternativa para el tratamiento de drenajes de minas en lugar de métodos convencionales. Sin embargo, muchos desafíos aún existen para su implementación en climas fríos donde la temperatura del agua permanece fría todo el año por lo que el crecimiento bacteriano está limitado. A través de ensayos estáticos realizados a 4,5 C por 90 días, se estudió el impacto de las bajas temperaturas sobre la actividad de SRB y la consecuente remoción de Cd y Zn desde drenaje ácido de minas (AMD). Se ensayaron diferentes fuentes de carbono para el crecimiento de SRB: molasas (Mo), metanol (MeOH) y una mezcla de Mo/MeOH a diferentes concentraciones. Los reactores de 1 L de capacidad fueron monitoreados cada dos semanas y se midieron el pH, el potencial de óxido-reducción (ORP) y las concentraciones residuales de Zn, Cd, sulfatos y carbono total orgánico (TOC). El uso de fuentes de carbono mejora claramente la actividad bacteriana y consecuentemente la remoción de metales (Cd y Zn) por precipitación de sulfuros. Se removió arriba de 94,8% de cinc y arriba de 99,4% of cadmio después de 90 días, resultando en una reducción de las concentraciones de metales debajo de los límites de descarga ([Cd] < 50 µg/L y [Zn] < 500 µg/L). La mezcla Mo+MeOH fue ligeramente más eficiente que Mo o MeOH por separado. Estos resultados indicaron que las SRB podrían ser usadas exitosamente en el tratamiento de las aguas de descarga de minas contaminadas con metales pesados.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The increasing need for metals and minerals has led to the development of many new mines, including in northern Canada. These mines often produce water that is contaminated that requires specific management and treatment during the construction, operation and closure of a mine to protect the North’s sensitive environment.

Production of acid mine drainage (AMD) at abandoned or active mine sites has been widely studied. Indeed, the extraction and processing of base and precious metals from sulfide-ore deposits generate large quantities of fine-grained tailings and waste rock. These have a mineral content less than the economic threshold required to process them, but must be excavated to gain access to the ore deposit (Moncur et al. 2015; Nordstrom et al. 2015). Thus, AMD can be produced from tailings storage facilities, waste rock piles, underground tunnel walls, or sub-aerial deposits where sulfide minerals are thermodynamically unstable (Lindsay et al. 2015; Morin and Hutt 2001; Potvin 2009).

The production of AMD is considered to be temperature limited due to the diminished activity of Fe(II)—oxidizing microbes at low temperature (Gault et al. 2015). However, the heat generated by sulfide oxidation may elevate temperatures sufficiently to permit the oxidation of sulfide minerals by ferric iron even in cold environments (Bigham and Nordstrom 2000; Ninteman 1978). Although AMD is not specifically defined in terms of pH, most AMD has a pH of 2–6 (Nordstrom et al. 2015). If released into the natural environment, AMD can be a major source of water pollution, with devastating effects on the environment, including lakes and river acidification (Espana et al. 2005). Mining companies commonly use active treatment technologies to treat contaminated effluent when the production of contaminated drainage cannot be stopped or controlled (Aubé 2003; Aubertin and Bussière 2001; Johnson and Hallberg 2005). In the Yukon Territory, active treatment is usually used to treat AMD from both active and closed mines due to the low temperatures and the lack of efficiency of some passive treatments. Indeed passive treatment systems (PTS) face challenges in cold climates, including hydraulic failure due to freezing, reduced microbial activity, and increased water flow during spring melt (Ness et al. 2014). However, the use of active treatment technologies results in high treatment costs and requires labour. This can be challenging when the mines close, making it a less sustainable option for long-term management of mine-impacted water, especially in remote locations.

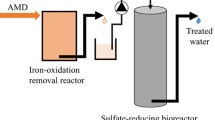

Passive treatment systems (PTS) offer a promising alternative to conventional active treatment. PTS are based on chemical and biological reactions that naturally occur in the environment and offer a potential sustainable option for long-term mine drainage treatment during and after mine closure. PTS are defined as technologies that use natural materials to promote natural chemical and biological processes and require less maintenance once installed than conventional processes (Johnson and Hallberg 2005; Younger et al. 2002). More specifically, PTS allow the removal of contaminants from water using biological or geochemical processes. The process requires limited or no power or chemicals after construction and can last for decades with minimal human maintenance (Gusek and Wildeman 2002). Among the PTS, bioremediation techniques using microorganisms, including sulfate-reducing bacteria (SRB), are increasingly being used, even though many of them require periodic active management to sustain desired conditions and processes, rendering them semi-passive (Martin et al. 2009).

Sulfate-reducing passive bioreactors (SRPB) represent a passive or semi-passive treatment system applicable to metal mine drainage effluents and have been extensively studied (Hashim et al. 2011; Johnson and Hallberg 2005; Neculita et al. 2007; Ness et al. 2014; Nordin 2010). Biological sulfate reduction results in the reduction of sulfate into sulfide and leads to a decrease in dissolved metal contents due to the production of metal sulfide precipitates. In addition, the production of bicarbonate can lead to an increase in pH (Egiebor and Oni 2007; Hulshof et al. 2003; Jin et al. 2008; Neculita 2008; Ziemkiewicz et al. 2003). Equations 1 and 2 present the reactions of the reduction of sulfate into sulfide and the precipitation of metal as sulfide that occur in an SRPB. Their performances depend on three major parameters: the hydraulic retention time, the SRB/substrate mixture, and the initial metal concentrations in the AMD (Neculita et al. 2008).

Dissimilatory sulfate reduction is accomplished, in the absence of oxygen, by SRB that decompose simple organic compounds using sulfate as a terminal electron acceptor. One mole of sulfate is reduced to hydrogen sulfide for every two moles of carbon oxidized (Eq. 3; Hammer 1989):

where *CH2O represents a simple organic molecule such as acetate.

Good management of physical and chemical conditions is essential to the growth and effectiveness of SRB. Few SRB have been reported as cold-tolerant, and the low temperatures encountered in the northern climate can challenge SRB growth. Thus far, most species of SRB that have been isolated and described are mesophilic. However, several researchers have shown that bacterial metabolic activity is possible at low temperature but that it requires specific adaptations (Cavicchioli 2006; Robador et al. 2009). The most important of these adaptations is the ability of bacteria to synthesize enzymes with high catalytic activities at low temperatures (Feller and Gerday 2003; Robador et al. 2009). The performance of SRPB might be affected by the low temperature that could be encountered in the North (4–5 °C) all year long. However, Janin and Harrington (2015) monitored anaerobic column bioreactors at 3 and 6 °C at a laboratory scale for more than 1 year to study their capacity to decrease the concentrations of metals present in water (As, Cd, Cu, Se, and Zn). Their results showed that, even if the temperature affected the performance of the bioreactors, native bacteria from northern environments were successful at low temperatures when liquid carbon substrate was provided to the bioreactors.

The efficiency of passive bioreactors depends on the activity of bacteria, which is mainly controlled by the composition of the reactive mixture. The carbon sources used for rapid growth of SRB can be simple organic compounds such as calcium lactate, ethanol, sucrose, glucose, and lactoserum (Luptáková and Macingova 2012; Tsukamoto 1999). Alternative cheap carbon sources containing complex organic compounds such as organic waste (manure, compost) and cellulose (hay, straw) have also been studied. However, hydrolysis of the carbon substrate is required before SRB can use these more complex sources of carbon as an energy source, so they potentially have the ability to support SRB growth over longer periods of time (Drury 2006). Such an attribute can be attractive for the design of a treatment system at mine closure. Moreover, the sorption of metals (Cd, Zn) on solid organic materials may even act in a complementary manner when a carbon source such as biochar or wood chips is used (Janin and Harrington 2013). Removal efficiencies in the range of 90–100% were obtained with initial concentrations of 521 ± 93 mg/L for Cd and 5525 ± 60 mg/L for Zn. Waybrant et al. (1998, 2002) showed that greater efficiencies were obtained when a mixture of several carbon sources (wood chips, sawdust, composted municipal sewage sludge, and leaf compost) was used compared to a single organic carbon source (like methanol) (Neculita et al. 2007; Zagury et al. 2007). According to numerous studies on the development of SRB, the optimum pH range for SRB growth is between 6.8 and 7.5 (Rees et al. 1995; Rozanova et al. 2001; Sievert and Kuever 2000; Wang et al. 2013), although some SRB are known to survive in extremely low pH waters (Neculita 2008; Tsukamoto 1999). Still, the use of SRB has some limitations and very high dissolved metals concentrations in an AMD may have an inhibitory effect of on SRB (Cabrera et al. 2006). In addition, the initial concentration of calcium in the AMD must be considered too as high concentrations leads to the risk of gypsum (CaSO4) or ettringite (Ca6Al2(SO4)3(OH)12·26H2O) precipitation (Tolonen et al. 2015).

The objective of this study was to examine the activity of SRB in mine water in the presence of different carbon sources (molasses, methanol, and a mix thereof) to enhance the performance of in situ PTS based on the activity of native SRB and the precipitation of Zn and Cd as sulfides. Methanol is well-known for its ability to support bacterial growth (Tsukamoto 1999) and is a relatively cheap bulk chemical widely used in biotechnological processes (Dijkhuizen et al. 1985). Sobolewski (2010) used other liquid carbon sources, such as ethylene glycol, to provide tangible benefits for bioreactors treating mine water. According to his results, microbial activity can be maintained at temperatures below 4 °C, allowing the operation of such bioreactors in cold climates.

This in situ PTS was intended to reduce metal contamination in the Silver King Mine drainage in the Keno Hill Silver district mine site (Yukon Territory). The experiments were conducted at laboratory scale at temperatures of 4–5 °C to replicate the conditions of the underground mine water system. If PSRB could be demonstrated to be effective in cold climates, it could be used at many northern mine sites that are struggling with AMD.

Materials and methods

Mine water, waste rocks and inoculum sampling and characterization

This laboratory scale project is part of a larger experiment conducted with Alexco Resource Corporation mining company which has injected carbon sources in a 110 m deep borehole located at Silver King, in the United Keno Hill Mines,YT, in order to support the growth of native SRB to lower cadmium and zinc contamination in ground water flowing through the old mining tunnels. Since this laboratory batch test experiment’s purpose was to bring scientific evidences of the feasibility of Alexco’s project, it had been decided to work with MIW from the borehole and wastes rocks from the Silver King Mine site.

Mine water characterization

Mine-impacted water (MIW) was collected in April 2014 from the Silver King Mine site. This water was sampled monthly between February 2007 and March 2016 by the Alexco Resource Corporation mining company. The metal concentrations were determined by Agat Laboratories (Whitehorse, YT, Canada).

Waste rock characterization

The waste rocks were collected at the Silver King Mine site in April 2014 from two different waste rock piles (WR1 and WR2) that were built when the Silver King Mine tunnels were excavated (personal discussion with Alexco 2014). The waste rock samples were collected in a 20 L bucket and stored in cold storage. Each bioreactor used during these experiments was filled with 100 mL of the waste rock from each pile (WR1 and WR2). The waste rock used in the different experiments were sieved through a 3.18-mm-opening sieve (VWR Scientific, Mississauga, ON, Canada). A complete characterization (particle size distribution, metal contents, AMD production) of the waste rock samples was performed to determine the potential risk of AMD production.

First, the samples were sieved to determine the particle size distribution: >10; 10–2; 2–1; 1–0.250; 0.250–0.125, and <0.125 mm. Then, each sample was crushed using a jaw crusher and ground using an impact disc mill (Bleuler-Mill, NAEF, Los Angeles, CA, USA) to obtain a median grain size of 28.4 ± 1.8 μm. X-ray diffraction (XRD) analysis (Siemens D5000 diffractometer, Berlin, Germany) was then performed on each sample at Laval University (Québec, QC, Canada) to identify the major crystalline phases. Scans were taken for 2θ ranging from 5° to 65° with increments of 0.02° s−1 using a Cu anode.

The chemical composition of each waste rock sample was determined after heat activation in a muffle furnace (Furnatrol 133, Thermolyne Sybron Corporation, Milwaukee, WI, USA) at 1000 °C for 30 min. Solid samples were then fused using metaborate lithium prior to analysis (Corporation Scientifique Claisse, Québec, QC, Canada). The liquid samples were analyzed using inductively coupled plasma-atomic emission spectrometry (ICP-AES; Vista AX CCO Simultaneous ICP-AES, Palo Alto, CA, USA).

A Sobek test was conducted to determine the neutralizing potential (NP) of the waste rock samples following the procedure described in the reference method US EPA-600 and in Sobek et al. (1978). The samples were mixed in the same proportions as those used for the bioreactors, and a fizz test was conducted with 0.5 g of waste rock onto which a few drops of a solution of HCl (1/3) were added. The results of the fizz test provided information on the volume and normality of HCl required for the digestion of 2 g of the waste rock for NP determination (no fizz: 20 mL of 0.1 M HCl; slight fizz: 40 mL of 0.1 M HCl; moderate fizz: 40 mL of 0.5 M HCl; strong fizz: 80 mL of 0.5 M HCl). The digestion for the Sobek test was conducted by heating the pulp (waste rock sample and HCl solution) at 90 °C until gas bubbling stopped. Once the digestion was complete, the solution was titrated with a solution of NaOH of known normality to pH 7.0 to determine the NP of the rock sample. The acid generation potential (AP) was determined from the percentage of sulphur in the waste rock samples, following Eq. 4 (Sobek et al. 1978).

The percentage of sulfur in the waste rock samples was determined using a TruSpec® Micro apparatus (St. Joseph, Michigan, USA). To perform this analysis, between 1 and 3 mg of the waste rock were subjected to combustion at 1200 °C for 200 s under a pressure of 12 PSI.

The net neutralization potential (NNP) was then calculated by subtracting the AP from the NP according to Eq. 5 (Sobek et al. 1978), and the neutralization potential ratio (NPR) was calculated according to Eq. 6 (Sobek et al. 1978).

where NNP represents the net neutralization potential; NP represents the neutralizing potential; AP represents the acid generation potential (kg/t); and NPR represents the neutralization potential ratio.

Sediment sampling

Sediment was collected from Crystal Creek, located in the Keno Hill mining district between Keno and Mayo (YT, Canada). The sediment was shoveled from the bottom of the creek, collected in a 20 L bucket, and stored in cold storage (15 °C). The presence of SRB in this creek’s sediment has been documented in baseline studies by Alexco during the remediation and maintenance of the historic mining district. Londry (2013) conducted a technical assessment of the potential microbial roles in metal removal for the Galkeno 900 bioremediation project conducted by Alexco using microbial molecular (DNA) and culturing techniques. It showed SRB were present within sediments collected in several creeks located in the United Keno Hill Mines area. The sediment collected from that study have been used as an inoculum for the experiments conducted as part of this study.

Experimental design and operation

Bioreactors were built using 1 L low-density polyethylene (LDPE) bottles to replicate the conditions of an in situ water treatment system in the underground tunnels. Each bottle was filled with 200 mL of waste rock, 850 mL of mine-impacted water, 5 mL of inoculum, and variable amounts of liquid carbon (molasses, methanol and a mixture of molasses/methanol). Deionized water was then added to make up the volume of the bottles to ensure that the systems were anoxic. The bioreactors were stored at 5 °C and monitored over 90 days. All bioreactors were prepared in triplicate to ensure the quality of the results and to compare the performances of the different sources of carbon with respect to the bacterial activities and metal removal using statistical tests. The duration of the experiment was not predetermined. However, the experiment was stopped when the TOC was completely depleted, which was achieved after 90 days of incubation.

The sources of liquid carbon used in this study were molasses (Crosby’s 100% Natural Fancy Molasses; Crosby Molasses Company Limited, St. John, NB, Canada), methanol (certified ACS; Fisher Scientific, Fair Lawn, NJ, USA), and a mix of both (50/50, v/v). The experiments were carried out using two different concentrations of the carbon sources: 77 mg/L (C1) or 154 mg/L (C2). The C1 concentration was determined according to Eq. 1 and accounted for two moles of carbon for each mole of sulfate present in the mine drainage effluent. The C2 concentration was fixed at twice the concentration of C1 to assess the effect of carbon concentration on the activity of bacteria and on the removal of metals from the mining water.

Table 1 provides an overview of the experimental design used in this bioreactor study with the C1 and C2 concentrations. Various control bioreactors were monitored (Table 2) to assess the impact of the presence of waste rocks in the mine water (CT4) or DIW (CT3), and the presence of air (CT6) and inoculum (CT5) in the bioreactors. Two other controls were prepared to allow us to evaluate the evolution of the bioreactors when nothing was added (CT1 and CT2). All controls were prepared in duplicate except CT4 “Waste rocks + MIW”.

Batch bioreactor monitoring

During these experiments, various parameters were followed in both the bioreactors and control samples to determine the influence of the carbon source and its concentration on SRB activity and consequently, Cd and Zn removal. The oxido-reduction potential (ORP) was the first parameter determined in each bioreactor prior to sampling. This parameter was quantified without mixing the water to reduce the variability of the measurement. Samples for the analysis of sulfate were collected using a 20 mL capacity bottle and stored in a freezer until analysis. Samples for carbon determination were collected in a 20 mL capacity bottle and acidified with H2SO4 (2%, v/v) before analysis. The pH was measured in the 20 mL carbon samples prior to acidification to avoid the risk of contamination between samples. For determination of the Zn and Cd contents, 20 mL samples were collected and stored in a bottle at 4 °C after acidification using HNO3 (2%, v/v). For each sampling, the total volume collected was approximately 60 mL. After each sampling, the 1 L bioreactors and controls were filled to the top using DIW, to eliminate air and maintain anoxic conditions. The sampling period started at t = 0 days and continued biweekly over a 90 day period (14, 26, 47, 69, and 90 days).

Analytical methods

The metal concentrations were analyzed by atomic absorption (AA) using flame for Zn and graphite furnace for Cd (Perkin Elmer PinAAcle 900 T, Waltham, MA, USA). At the beginning of each series of measurements, a calibration curve, prepared from SCP Science Cd AA Standard and SCP Science Zn AA Standards, was analyzed. Control standards were prepared from a mixed standard (PerkinElmer GFAAS, Waltham, MA, USA) to ensure the quality of the results. The AA detection limits were determined as 0.05 µg/L for Cd and 2 µg/L for Zn. For rock characterization, metal concentrations were determined by ICP-AES using a Varian (model AX CCO Vista Simultaneous ICP-AES, Palo Alto, CA, USA). Calibration solutions were prepared using certified solutions (SCP Science, Baie-D’Urfé, QC, Canada), and control standards (SCP Science Multi items, Baie-D’Urfé, QC, Canada) were analyzed every 20 samples to validate the results.

The concentration of sulfate was determined using the EPA 9038 (turbidimetric) reference method. The detection limit for sulfate using this method was estimated as 5 mg/L. Total organic carbon (TOC) was measured using a Skalar Formacs HT instrument (Skalar, Breda, Netherlands). Calibration curves for TOC were controlled daily using a TOC control (AccuSPEC TOC Standard 1000 mg/L, AccuSPEC TIC Standard 1000 mg/L, SCP Science, Baie-D’Urfé, QC, Canada). The detection limit of the TOC measurement was estimated as 2 mg/L.

The pH was measured using a pH meter (Epoxy body electrode, Oakton, Brisbane, Australia) equipped with a double junction Ag/AgCl electrode (Cole Parmer, Montréal, QC, Canada). The pH meter was calibrated daily using certified buffer solutions (pH 10.00, 7.00, and 4.00, Fisher Scientific, Montréal, QC, Canada). ORP measurements were performed using a double junction electrode ORP (59001-77, Cole Parmer, Montréal, QC, Canada). Calibration of the ORP meter was performed using a certified ORP Standard solution (Thermo Fisher Scientific, Waltham, MA, USA). The pH and ORP probes were rinsed with DIW between each sample.

Statistical analysis

The experiments carried out with molasses, methanol, and a mix of both as carbon sources were performed in triplicate (n = 3). Statistical tests were used to determine whether the carbon sources had a significant impact on metal removal. The mean values and standard deviation were calculated for each batch of experiments carried out on the same carbon source sample under the same experimental conditions.

The t value calculated from the equations defined by Coudert et al. (2014) was then compared to a threshold defined by the t Student table for a confidence level (α) of 0.5% and a degree of freedom (df) of 4. If the t values exceeded the threshold value, t (α = 0.5%, df = 4) = 2.776, the mean values were considered significantly different.

Results and discussion

Mine-impacted water and waste rock characterization

Composition of the waste rock samples

Sample were collected from two different waste rock piles at the Keno Hill mine site, Yukon Territory (YT, Canada). The two types were mixed (50/50, v/v) in this study to represent the geology of the underground tunnels generating the mine drainage. The particle size distribution and chemical composition of the different waste rocks are presented in Table 3. The two samples had a similar particle size distribution, with coarse material (>10 mm) accounting for the largest fraction of the soil, i.e. 45.4% for WR1 and 40.8% for WR2. It was also observed that the weight percentages decreased with a decrease in particle size for both samples. The smallest fraction (<0.125 mm) represented 11.4 and 13.9% for WR1 and WR2, respectively.

According to our results, the loss on ignition (LOI) ranged from 0.99 to 9.59%, depending on the sample and particle size. LOI was higher in the fine fraction (<0.125 mm) than in the coarse fractions for both samples. Indeed, for WR1, LOI was 1.12% for the >10 mm fraction and 9.59% for the fine fraction (<0.125 mm). These results indicated that the fine fraction contained larger amounts of carbonates and sulfur which were lost during the ignition at 1000 °C. According to the chemical composition of the waste rock samples expressed as oxides (Table 3), silicon dioxide (SiO2) was the predominant component in the both samples. The SiO2 contents ranged between 98 and 73.2% for WR1 and between 96.3 and 59.1% for WR2, depending on the solid fraction. The predominance of SiO2 showed that the two samples were mainly quartz. Moreover, as the particles became finer, the proportion of other metal oxides increased. In the finer fractions, the increase in aluminum and potassium oxides highlighted the presence of clay in these fractions as kaolinite (Al2Si2O5(OH)4) or illite (K,H3O)(Al,Mg,Fe)2(Si,Al)4O10[(OH)2,(H2O)]. The main contaminants, Cd and Zn, in the mine drainage were not present as oxides in a large proportion of the waste rock samples.

Mine-impacted water characteristics

Table 4 presents the main parameters examined in the characterization of the mine-impacted water. This characterization was spread over 5 years (from Feb 2007 to March 2014). A total of 98 samples were collected for metal analysis and pH determination and 68 samples for sulfate concentration. The concentration limits for the discharge of the effluent into the environment that applied to the Keno Hill Silver district (Water Use Licence QZ12-057 delivered 30 Jan 2013) are also presented in Table 4 for comparison.

During this time period, the average arsenic concentration was calculated to be 36 ± 11 µg/L, which was below the discharge limit of 100 µg/L. The average iron and sulfate concentrations were calculated to be 19.6 ± 5.2 and 426 ± 182 mg/L, respectively. The average Cd concentration was calculated to be 12 ± 8 µg/L and the average Zn concentration was calculated to be 860 ± 197 µg/L, exceeding the discharge limit of 500 µg/L for Zn.

The MIW had an initial Ca concentration of 152.3 ± 42.7 mg/L. The mine water collected at Silver King may have contained minor amounts of gypsum or ettringite precipitates, but likely not enough to affect the overall process (Fajtl et al. 2002).

The MIW had a pH of approximately 7.3 ± 0.5 over the 5 year period. It can be assumed that carbonate minerals were present in the old mine tunnels, and that they helped reduce acidity and maintain the pH at a near-neutral value. As the MIW is groundwater from the mine site, the MIW’s temperature is stable at around 5 °C (Alexco’s data).

Evaluation of the potential of metal leaching from waste rock samples

The Sobek test was conducted to evaluate the NP of the waste rock samples. The strength of the effervescence roughly corresponded to the amount of reactive carbonates and was considered a “slight” fizz. After titration, the NP of the mixed waste rocks was estimated as 20 kg CaCO3/t, and the AP was estimated as 9.37 kg CaCO3/t. The NNP was approximately 10.6 kg CaCO3/t, and the NPR was estimated as 2.13. According to Price et al. (1997), a rock sample is “likely” to generate ARD when the NPR value is less than 1. If the NPR value is between 1 and 2, the sample can “possibly” generate ARD, especially if the NP is insufficiently reactive or is depleted at a faster rate than sulfides. Between values of 2 and 4, the ARD risk is “low” and the sample is not considered as potentially ARD generating unless there is significant preferential exposure of sulfides along fracture planes, or extremely reactive sulfides in combination with insufficiently reactive NP are present in the rock sample. Finally, when the NPR exceeds four, the sample is not considered as having ARD-generating potential. Hence, with a NPR value of 2.13, the calculated NPR showed a “low” risk for ARD generation according to Price et al. (1997), but was very close to having a “possible” risk of ARD generation.

Figure 1 presents the residual concentrations of Zn (a), Cd (b), and SO4 2− (c) and the pH in the control samples during the entire exposure time of the experiments. The concentrations of both Zn and Cd measured in the control “Waste Rocks + DIW” indicated that the combined waste rocks released 784 ± 121 µg/L of Zn and 22.2 ± 4.0 µg/L of Cd after 90 days. The sulfate concentration was approximately 252 ± 19 mg/L and the pH was reduced from 7.0 to 3.1 ± 0.3. The release of metals, sulfate, and the production of acidity is typical of AMD (Akcil and Koldas 2006). Hence, the waste rock used in the present study showed a good potential to produce AMD as the concentrations of both Zn and Cd exceeded the discharge limits and the pH was very acidic. This observation agreed with the results from the Sobek tests, which were at the limit between “low” and “possibly” acid generating, and the elevated concentrations of Zn (860 ± 197 µg/L) and Cd (12 ± 8 µg/L) observed over 5 years of monitoring of the well water from the old tunnels.

In the control “MIW only”, when no creek sediment was used, the initial Zn concentration decreased from 868 to 446 ± 9 µg/L after 90 days. The Cd concentration fell from 10.9 to 5.1 ± 0.1 µg/L, and the ORP decreased from 157 to 35 ± 11 mV during the same period. When the mine-impacted water was not in contact with the waste rock, the pH remained neutral during the 90 day experiment, anoxic conditions were generated, metal concentrations decreased, and a 9.5% decrease in sulfate (421 to 381 ± 12 mg/L) was observed. Because gypsum and ettringite precipitation is unlikely to occur at low initial Ca concentration, the decrease of both metals and sulfate suggests that native SRB were likely present in the mine water and able to grow, consume sulfate to some extent, and foster metal precipitation as sulfides. Moreover, the negative redox potential values measured in the control was optimal for the growth of SRB (optimal values around −100 to −200 mV) (Abhilash et al. 2015; Gibert et al. 2002; Hao et al. 1996). These results are in accordance with others who have reported the presence of native SRB in AMD (e.g. Groudev et al. 1978; Ledin and Pedersen 1996). Londry (2013) also reported the presence of many species of SRB at the Keno Hill mine site. Meanwhile, Fortin et al. (2000) found native SRB in AMD at a pH below 2. It is noteworthy that both Cd and Zn concentrations were passively reduced below the discharge limits at the Bellekeno site without the addition of any chemicals. However, given that the bioreactors were filled with DIW after each sampling event to maintain anoxic conditions, the diminution of Zn and Cd concentrations in the control ‘MIW only’ may have been due to dilution.

On the other hand, when the MIW was in contact with the waste rock (CT4), the potential action of the native SRB was not enough to reduce the Zn and Cd concentrations to acceptable levels. Indeed, the Zn and Cd levels actually increased by 177% (from 868 to 1546 µg/L for Zn) and by 283% (from 10.9 to 32.6 µg/L for Cd), whereas the sulfate concentration increased by 147% (from 421 to 644 mg/L of sulfate). The increase in sulfate and the pH decrease from 7.0 to 3.4 in this control might be indicative of sulfide mineral oxidation in the waste rock (WR1 and/or WR2). Moreover, it appeared that the ORP was high (approximately 362 mV) after the experimental period (90 days). Not surprisingly, this control (“Waste Rocks + MIW”) clearly indicated that if the mine water was in contact with the waste rock, similar to the groundwater flowing through the old tunnels, leaching of Cd and Zn was likely to occur, releasing detrimental amounts of contaminants in water. This showed that as long as the water flows through the tunnels in contact with the mine rock, water treatment will be required. Diverting the water from the tunnels is not considered a viable option because the tunnels were driven into the groundwater, so long-term mine water treatment will be required to remove metals at this site.

Performances of carbon sources with respect to SRB activity and metal removal from mine drainage

Impact of carbon sources on SRB activity

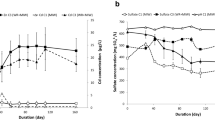

Different carbon sources, i.e. molasses, methanol, and a mix of both, were tested to assist bacterial growth (Table 1). The first series of experiments were carried out with a carbon concentration defined by the molar ratio of sulfate to carbon (Eq. 3). Figure 2 presents the residual concentration of carbon and sulfate during the 90 day experiment when molasses, methanol, or a mix of molasses and methanol were added to the bioreactors at the same initial carbon concentration (C1 = 77 mg/L).

Complete carbon depletion was observed after 90 days when molasses was used, either on its own or mixed with methanol (Fig. 2a). When methanol was used as the sole carbon source, the concentration of carbon was only reduced from 77 to 5.9 mg/L after 90 days. According to these results, we noticed than the consumption of carbon was slightly faster for the experiments carried out in the presence of molasses alone than for the experiments conducted with methanol alone or a mix of methanol/molasses. Indeed, after 47 days, the t values calculated when comparing the experiments with molasses alone versus methanol alone and molasses versus molasses/methanol were 3.27 and 4.92 (higher than the threshold value, t (α = 0.5%, df = 4) = 2.776), respectively; indicating that the source of carbon had a significant effect on the consumption of carbon by SRB. Methanol has been used as an electron donor in denitrification (Germonpre et al. 1991; Weijma 2000), and is a well-known, reliable carbon source that supports bacterial growth. However, it can also be toxic to some microbes, or they might require an acclimation period (Tsukamoto 1999). Indeed, alcohols are toxic to microorganisms at high concentrations, presumably because they damage the cell membrane and inhibit glycolytic enzymes (Dürre et al. 1988; Weijma 2000). As alcohol toxicity towards bacteria decreases with a decrease in the length of the carbon chain, it may be speculated that methanol toxicity will not occur at concentrations below 10 g/L (Weijma 2000). In the present study, the methanol concentration used was 77 mg/L, which is far below the toxicity limits defined by Weijma (2000). Therefore, the most probable reason that can explain why the consumption of methanol was slower than molasses after 47 days is that sugars are generally consumed more rapidly by bacteria. Indeed, SRB are able to metabolize low molecular weight organic compounds such as organic acid, alcohol, and amino acids (Gould et al. 2012). Moreover, the most critical limiting factor for microbial activity is the amount of labile metabolizable carbon available from an added organic carbon source, such as molasses (Gibert et al. 2004; Gould et al. 2012; Neculita et al. 2007; Zagury et al. 2007).

Sulfate concentrations increased from 358 to 545–626 mg/L during the first 2 weeks of the experiment in all bioreactors (Fig. 2b). This release of sulfate might be due to sulfide oxidation in the early stages of the experiments, which was also supported by high ORP values, in the range of 249–346 mV (data not shown). Alternatively, the increase in sulfate may be due to dissolution of sulfate salts in or on the waste rock used in this experiment. Similar sulfate release from waste rock was observed in the control “Waste Rocks = DIW”, as described earlier (Fig. 1c). After 14 days, the sulfate concentrations started to decrease and continued to do so over the 90 day experiment. Indeed, the sulfate decreased from 576 to 284 mg/L (50.7%) when molasses was used as a carbon source, from 588 to 322 mg/L (45.2%) when methanol was used, and from 556 to 280 mg/L (49.6%) when the molasses and methanol mix was used. Literature values for sulfate consumption in similar batch test bioreactors were faster, but were generally conducted at a more optimal temperature (T = 25 °C) for the growth of SRB (Glombitza 2001; Tsukamoto and Miller 1999). Indeed, Tsukamoto and Miller (1999) observed an 88% diminution of sulfate in column bioreactors after 180 days of experiments at 23–26 °C, whereas Glombitza (2001) reported a diminution of 90% after 20 days (T = 30 °C).

The decrease in sulfate observed in all bioreactors might have been due to the reduction of sulfates into sulfides in the presence of SRB. Indeed, SRB are a ubiquitous group of microbes, and known to be present in the Keno Hill mine area (Londry 2013). A bioreactor was constructed and operated in the Keno Hill Silver District at the Galkeno 900 adit in May 2008; organic substrate was initially added to support microbial growth until sulfate reduction by SRB became the predominant microbial activity in the reactor (Alexco 2012).

Moreover, an obvious decrease in ORP was observed between days 14 and 69 (data not shown). The minimum ORP reached −68.3 mV for the experiments with molasses, −15 mV for those with methanol, and −130 mV for those with the molasses-methanol mix. The decrease in ORP to negative values indicated that the media became anoxic and that sulfides were being formed. The decrease of ORP was a good indicator of the presence of SRB, as was the visible formation of black precipitates (FeS) and the classic smell of H2S. When SRB are present in a low oxygen environment, they are able to catabolize sulfate, releasing sulfide under optimal ORP values ranging from −100 to −300 mV (Gibert et al. 2002; Gloyna 1972; Harerimana et al. 2010). After 69 days of experimentation, the ORP increased in every batch test, reaching positive values for some of them (in the case of molasses and methanol). This sudden increase in ORP may be due to the low amounts of carbon remaining in the bioreactors. On the other hand, in every batch test, the pH remained between 7.0 and 5.2, optimal pH conditions for SRB activity (Wang et al. 2013). All of these results (consumption of both carbon and sulfate, decrease in ORP, and favorable pH conditions) support the hypothesis that SRB were active in the mine drainage and/or inoculum in all of the bioreactors (Luptakova 2007; Wang et al. 2013). Moreover, the results seemed to indicate that SRB activity was more favorable with molasses alone than with methanol alone or the molasses-methanol mix, due to the faster and higher consumption of carbon and sulfate throughout the duration of the experiments.

Impact of carbon sources on cadmium and zinc removal using SRB

Figure 3 presents the residual concentrations of Cd and Zn measured in each experiment. According to these results, it appeared that both Cd and Zn concentrations initially increased from 9.29 to 25.3 µg/L and from 738 to 1533 µg/L, respectively, during the 14 first days of the experiments. These results are in accordance with the evolution of Cd and Zn concentrations observed in the controls (Fig. 1), which was probably due to the oxidation of sulfide minerals present in the waste rock samples and the leaching of metals, sulfate, and acidity as defined by AMD production and highlighted with the CT4 control.

After 14 days of experimentation, the concentrations of both Cd and Zn started to decrease, irrespective of the carbon source. Indeed, after 90 days, the residual Cd concentrations in the effluent were approximately 1.4, 3.2, and 0.9 µg/L for the assays performed in the presence of molasses, methanol, and molasses/methanol, respectively. The residual concentrations of Zn after 90 days were approximately 160, 550, and 9.0 µg/L in the presence of molasses, methanol, and molasses/methanol, respectively. This decrease might be due to the reduction of sulfate to sulfide by SRB (Fig. 2b) and the precipitation of Cd and Zn as sulfide precipitates. After 90 days of experimentation, the residual concentrations of Cd and Zn were below the regulatory discharge limit ([Cd] <50 µg/L and [Zn] <500 µg/L), indicating that the addition of a liquid carbon source was useful in significantly decreasing both Cd and Zn concentrations.

However, when comparing the results with the carbon sources used, it appeared that the best removal yields were obtained for the experiments performed with the mix of molasses and methanol, allowing the removal of 94.6% of the Cd and 99.1% of the Zn after 90 days. According to the t-Student tests (results not shown), the carbon source did not appear to significantly influence Cd and Zn removal after 90 days, but it did significantly affect the removal kinetics. Indeed, after 47 days of experimentation, Zn removal was significantly higher for the experiments performed with the molasses/methanol mix than with molasses (t value of 4.06) or methanol alone (t value of 3.77). This is accordance with the observations of Mayes et al. (2011). Indeed, in their column experiments, Mayes et al. (2011) added methanol to the complex organic carbon sources (waste shells) to reduce Zn levels, which were increasing. Similar to the present study, Gandy and Jarvis (2012) conducted a laboratory-scale column at the relatively cold temperature of 8.4 °C. Their columns contained a mixture of carbon sources (compost, wood chips, and activated sludge, along with limestone gravel) to treat mine water with an initial Zn concentration of 2–2.5 mg/L. Gandy and Jarvis (2012) removed approximately 96% of the Zn from 2 to 2.5 mg/L to an average of 0.14 mg/L total zinc and 0.08 mg/L dissolved Zn in the effluent water, with an initial hydraulic residence time of approximately 19 h. There was an immediate decrease in dissolved Zn after the addition of methanol. According to these results, the molasses/methanol source significantly reduced the retention time required in the bioreactor, which is an important parameter to consider for the design of an efficient and economically viable passive bioreactor.

Influence of the concentration of carbon added to the SRPB on Cd and Zn removal efficiencies

Additional experiments were carried out in triplicate to determine the influence of the concentration of the carbon source on SRB activity and thereby the removal of Cd and Zn. Figure 4 presents the removal yields obtained for Cd and Zn for the experiments performed with different concentrations of carbon (C1 = 77 mg/L and C2 = 154 mg/L). These results were compared with the removal yields measured for the control CT1, which was conducted under the same conditions but without the addition of carbon, to determine how metal removals were affected when native SRB were not supported by any additional source of carbon.

When no carbon was added, only 45.2% of the Zn and 51.1% of the Cd were removed after 90 days. On the other hand, when molasses was used at the C1 concentration, the Zn decreased from 1533 to 160 µg/L after 90 days (89.4% removal). During the same period, the Cd decreased from 25.3 to 1.4 µg/L, (94.6% removal). When molasses was used at the higher concentration (C2), the Zn decreased from 1455 to 8.7 µg/L after 90 days (99.4% removal), whereas the Cd decreased from 19 to 0.8 µg/L (96% removal). It appears that the addition of molasses at the C2 concentration slightly enhanced SRB activity and removal of Cd and Zn as sulfides compared with the C1 concentration. Moreover, the concentration of sulfate was reduced from 576 to 284 mg/L with C1 and from 545 to 363 mg/L with C2 using molasses. At day 69, the ORP values were estimated as −68 mV under C1 and as −180 mV under C2, which might indicate higher SRB activities (Gloyna 1972; Harerimana et al. 2010). This would explain the better metal removal with C2 than C1.

Similarly, when methanol was added at the C1 concentration, the Zn concentration decreased from 1436 to 554 µg/L after 90 days (62.1% removal), whereas the Cd concentration decreased from 22 to 3.2 µg/L, (87.5% removal). When methanol was added at the C2 concentration, the removal yields obtained for both Cd and Zn were slightly better (64.8% for C2 versus 62.1% for C1 for Zn and 96.4% versus 87.5%, respectively, for Cd). Indeed, after 90 days of experimentation, the concentrations of Zn and Cd decreased from 1 572 to 559 µg/L and from 23 to 0.9 µg/L, respectively. During the same period, the sulfate concentration was reduced from 588 to 322 mg/L under C1 and from 618 to 264 mg/L under C2. On day 69, the ORP values were approximately −15 mV (C1) and −98 mV (C2). According to these results, it appeared that the methanol concentration used in these experiments (C1 = 77 mg/L and C2 = 154 mg/L) did not influence SRB activity and therefore the removal of Cd and Zn.

Finally, when the mix of molasses and methanol was used, the concentration of Zn decreased from 1403 to 9 µg/L at the C1 concentration and from 1505 to 13 µg/L at the C2 concentration. According to these results, up to 99.1% of the Zn was removed after 90 days, irrespective of the carbon concentration used. The Cd concentration decreased from 17 to 0.9 µg/L at the C1 concentration and from 21 to 0.6 µg/L at the C2 concentration. At the C1 concentration, more than 94.7% of the Cd was removed, whereas up to 97.6% of Cd was removed in response to the C2 concentration. These results were in accordance with the evolution of the residual concentration of sulfates, indicating that the consumption of SO4 2− was higher under C2 than C1. Indeed, the concentration of sulfate was reduced from 555 to 280 mg/L under C1 and from 626 to 171 mg/L under C2. On day 69, the ORP values were approximately −65 mV (C1) and −93 mV (C2). These results suggest that the use of the C2 concentration for the molasses and methanol mix was more favorable for SRB activity, leading to a slight but not significant improvement in Cd and Zn removal.

In conclusion, increasing the concentration of carbon from 77 to 154 mg/L in the bioreactors improved metal removal by 10% (when molasses was used as the carbon source), 2.7% (when methanol was used), and 0% (when the mixture was used) for Zn and by 1.4% (for molasses), 8.9% (for methanol) and 2.9% (for the mixture) for Cd. It is interesting to note that a significant increase in the amount of carbon added to the bioreactors did not generate a significant improvement in the removal of either Cd or Zn. Hence, SRB do not consume more carbon than they need, according to Eq. 3.

Conclusions

Passive treatment systems are a promising alternative to conventional mine water treatment. They may be used during operation as well as in the post-closure period to allow a secure and economically viable treatment of the contaminated mine drainage. Batch test bioreactors were designed at a laboratory scale and operated for 90 days at 4.5 °C to determine whether cold temperatures hindered the growth and activity of SRB in water from the Keno Hill mine site (Yukon Territory), which was contaminated with Cd and Zn. To promote bacterial growth, different carbon sources such as molasses, methanol, and a mix of both were added to each batch test at different concentrations based on the molecular ratio relative to sulfate.

According to our results, the mine drainage initially contained 10.93 µg Cd/L and 868 µg Zn/L, leached due to sulfide mineral oxidation in the waste rock. As these concentrations exceed the discharge limits for Zn, an efficient passive treatment should be developed to protect the Nordic environment. The consumption of the carbon sources and the sulfate in the mine drainage observed during these experiments highlighted the presence of native SRB in the SRPB. The addition of liquid carbon sources to the SRPB decreased both Cd and Zn concentrations to below the discharge limits established for the Silver King Adit mine site (<50 µg Cd/L and <500 µg Zn/L). After 90 days, the Zn and Cd concentrations decreased from 1455 to 8.7 µg/L (up to 99.4% reduction) and from 21 to 0.6 µg/L (up to 97.6% reduction), respectively, when molasses + methanol was used as the carbon source. These reductions were presumably due to their precipitation as sulfides (ZnS and CdS). Moreover, it appeared that the molasses/methanol mix was slightly more efficient for both SRB growth and metal removal than molasses or methanol alone. A significant increase in the amount of carbon (C1 = 77 mg/L and C2 = 154 mg/L) in the bioreactors did not generate a significant improvement of either Cd or Zn removal, indicating that SRB do not consume more carbon than they need. These findings indicated that native sources of SRB might be successfully used to treat mine water contaminated with metals.

References

Akcil A, Koldas S (2006) Acid mine drainage (AMD): causes, treatment and case studies. J Clean Prod 14(12):1139–1145

Alexco (2012) Galkeno 900 sulphate—reducing bioreactor 2008–2011 operations: Final report. Yukon Water Board, Technical report QZ12–057, Yukon, Canada

Aubé B, Zinck J, Eng M (2003) Lime treatment of acid mine drainage in Canada. In: Brazil–Canada Seminar on Mine Rehabilitation. Brazil–Canada Seminar on Mine Rehabilitation, Florianópolis, Brazil, pp 1–12

Aubertin M, Bussière B (2001) Meeting environmental challenges for mine waste management. Geotech News 19(3):21–26

Bigham JM, Nordstrom DK (2000) Iron and aluminum hydroxysulphates from acid sulphate waters. Rev Mineral Geochem Mineral Soc Am 40:351–403

Cabrera G, Pérez R, Gomez JM, Abalos A, Cantero D (2006) Toxic effects of dissolved metals on Desulfovibrio vulgaris and Desulfovibrio sp. strains. J Hazard Mater 135(1):40–46

Cavicchioli R (2006) Cold-adapted archaea. Nat Rev Microbiol 4:331–343

Coudert L, Blais JF, Cooper P, Mercier G, Janin L, Gastonguay L (2014) Demonstration of the efficiency and robustness of an acid leaching process to remove metals from various CCA-treated wood samples. J Env Manag 132:197–206

Dijkhuizen L, Hansen TA, Harder W (1985) Methanol, a potential feedstock for biotechnological processes. Trends Biotechnol 3:262–267

Drury WJ (2006) Modeling of sulfate reduction in anaerobic solid substrate bioreactors for mine drainage treatment. Mine Water Environ 19(1):19–29

Dürre P, Bahl H, Gottschalk G (1988) Membrane processes and product formation in anaerobes. Handbook for Anaerobic Fermentations. Dekker, New York City, pp 187–206

Egiebor NO, Oni B (2007) Acid rock drainage formation and treatment: a review. Asia-Pac J Chem Eng 2:47–62

Espana JS, Pamo EL, Santofimia E, Aduvire O, Reyes J, Barettino D (2005) Acid mine drainage in the Iberian Pyrite Belt (Odiel river watershed, Huelva, SW Spain): geochemistry, mineralogy and environmental implications. Appl Geochem 20(7):1320–1356

Fajtl J, Tichý R, Ledvina R (2002) Gypsum precipitation—a medium to control sulphate pollution of freshwater sediment leachates. Water Air Soil Pollut 135(1–4):141–156

Feller G, Gerday C (2003) Psychrophilic enzymes: hot topics in cold adaptation. Nat Rev Microbiol 1:200–208

Fortin D, Roy M, Rioux JP, Thibault PJ (2000) Occurrence of sulfate-reducing bacteria under a wide range of physico-chemical conditions in Au and Cu–Zn mine tailings. FEMS Microbiol Ecol 33(3):197–208

Gandy CJ, Jarvis AP (2012) The influence of engineering scale and environmental conditions on the performance of compost bioreactors for the remediation of zinc in mine water discharges. Mine Water Environ 31(2):82–91

Gault GBF, Gammon P, Fortin D (2015) A geochemical characterization of cold-water natural acid rock drainage at the Zn–Pb XY deposit, Yukon, Canada. Appl Geochem 62:35–47

Germonpre R, Liessens J, Verstraete W (1991) Fluidised bed denitrification of drinking water with methanol-pilot plant experience. International Symp: Environmental Biotechnology, Oostende, Belgium, 22–25 Apr 1991

Gibert O, De Pablo J, Cortina JL, Ayora C (2002) Treatment of acid mine drainage by sulphate-reducing bacteria using permeable reactive barriers: a review from laboratory to full-scale experiments. Rev Env Sci Biotechnol 1(4):327–333

Gibert O, De Pablo J, Cortina JL, Ayora C (2004) Chemical characterisation of natural organic substrates for biological mitigation of acid mine drainage. Water Res 38(19):4186–4196

Glombitza F (2001) Treatment of acid lignite mine flooding water by means of microbial sulfate reduction. Waste Manag 21(2):197–203

Gloyna EF (1972) Waste stabilization ponds. World Health Organization, Geneva

Gould W, Cameron R, Morin L, Bedard P, Lortie L (2012) Effect of lactate/acetate and glucose amendment on low temperature performance of anaerobic bioreactor treating simulated mine drainage. Proc, 9th International Conference on Acid Rock Drainage (ICARD), Ottawa, pp 178–187

Groudev SN, Genchev FN, Gaidarjiev SS (1978) Observations on the microflora in an industrial copper dump leaching operation. In: Metallurgical Applications of Bacterial Leaching and Related Microbiological Phenomena, vol 253. Academic Press, New York, pp 253–274

Gusek J, Wildeman T (2002) A new millennium of passive treatment of acid rock drainage: advances in design and construction since 1988. Proc, National Meeting of the American Soc for Mining and Reclamation, Lexington, KY, USA

Hammer DA (1989) Constructed wetlands for wastewater treatment: municipal, industrial and agricultural. CRC Press, Boca Raton

Hao OJ, Chen JM, Huang L, Buglass RL (1996) Sulfate-reducing bacteria. Crit Rev. Environ Sci Technol 26:155–187

Harerimana C, Harbi B, Vasel JL, Delvigne F, Thonart P, Crine M (2010) Development of a stoichiometric model of the sulphate-reduction by the sulphate-reducing bacteria in anaerobic lagoons. Biotechnol Agron Soc Environ 14(2):577–582 (in French)

Hashim MA, Mukhopadhyay S, Sahu JN, Sengupta B (2011) Remediation technologies for heavy metal contaminated groundwater. J Environ Manag 92(10):2355–2388

Hulshof AHM, Blowes DW, Ptacek CJ, Gould WD (2003) Microbial and nutrient investigations into the use of in situ layers for treatment of tailings effluent. Environ Sci Technol 37:5027–5033

Janin A, Harrington J (2013) Passive treatment of mine drainage waters: the use of biochar and wood products to enhance metal removal efficiency. In: Proceedings 2013 Northern Latitudes Mining Reclamation Workshop and 38th Annual Meeting of the Canadian Land Reclamation Association Overcoming Northern Challenges, pp 90–99

Janin A, Harrington J (2015) Performances of lab-scale anaerobic bioreactors at low temperature using Yukon native microorganisms. In: Proceedings of the mine water solutions in extreme environments, Vancouver, pp 519-532

Jin S, Fallgren PH, Morris JM (2008) Biological source treatment of acid mine drainage using microbial and substrate amendments: microcosm studies. Mine Water Environ 27:20–30

Johnson DB, Hallberg KB (2005) Acid mine drainage remediation options: a review. Sci Total Environ 338(1):3–14

Ledin M, Pedersen K (1996) The environmental impact of mine wastes—roles of microorganisms and their significance in treatment of mine wastes. Earth Sci Rev 41(1):67–108

Lindsay MB, Moncur MC, Bain JG, Jambor JL, Ptacek CJ, Blowes DW (2015) Geochemical and mineralogical aspects of sulfide mine tailings. Appl Geochem 57:157–177

Londry K (2013) Microbiology of metals attenuation: United Keno Hill Mines. Technical report, edmonton waste management centre of excellence, Canada

Luptakova A (2007) Importance of sulphate-reducing bacteria in environment. Nova Biotechnol 7(1):17–22

Luptakova A, Macingova E (2012) Alternative substrates of bacterial sulphate reduction suitable for the biological-chemical treatment of acid mine drainage. Acta Montan Slovaca 17(1):74–80

Martin AJ, Jones R, Buckwalter-Davis M (2009) Passive and semi-passive treatment alternatives for the bioremediation of selenium from mine waters. In: Keevil NB (ed), Proceedings, British Columbia Mine Reclamation Symposium University of British Columbia, Vancouver, pp 12–31

Mayes WM, Davis J, Silva V, Jarvis AP (2011) Treatment of zinc-rich acid mine water in low residence time bioreactors incorporating waste shells and methanol dosing. J Hazard Mater 193:279–287

Moncur MC, Ptacek CJ, Lindsay MB, Blowes DW, Jambor JL (2015) Long-term mineralogical and geochemical evolution of sulfide mine tailings under a shallow water cover. Appl Geochem 57:178–193

Morin KA, Hutt NM (2001) Prediction of minesite-drainage chemistry through closure using operational monitoring data. J Geochem Explor 73(2):123–130

Neculita CM (2008) Passive biological treatment of acid mine drainage: carbon sources, metal removal mechanisms and ecotoxicity. PhD thesis, Polytechnic School of Montreal, QC, Canada (in French)

Neculita CM, Zagury GJ, Bussière B (2007) Passive treatment of acid mine drainage in bioreactors using sulfate-reducing bacteria. J Environ Qual 36(1):1–16

Neculita CM, Zagury GJ, Bussière B (2008) Effectiveness of sulfate-reducing passive bioreactors for treating highly contaminated acid mine drainage: I. Effect of hydraulic retention time. Appl Geochem 23(12):3442–3451

Ness I, Janin A, Stewart K (2014) Passive treatment of mine impacted water in cold climates: a review. Yukon Research Centre, Yukon College. http://www.yukoncollege.yk.ca/research. Accessed 01 March 2016

Ninteman DJ (1978) Spontaneous oxidation and combustion of sulphide ores in underground mines, a literature survey. US Bureau of Mines Internal Circular, Washington DC

Nordin (2010) Evaluation of the effectiveness of biological treatment of mine waters. MPERG Report 2010–4, Laberge Environmental Services, Mining and Petroleum Environment Research Group, Yukon, Canada

Nordstrom DK, Blowes DW, Ptacek CJ (2015) Hydrogeochemistry and microbiology of mine drainage: an update. Appl Geochem 57:3–16

Pandey BD, Natarajan KA (eds) (2015) Microbiology for minerals, metals, materials and the environment. CRC Press, Boca Raton

Potvin R (2009) Evaluation at different scales of the performances of passive treatment systems for effluents heavily contaminated by acid mine drainage. PhD thesis, University of Quebec in Abitibi-Témiscamingue, Abitibi-Témiscamingue, QC, Canada [in French]

Price WA, Morin K, Hutt N (1997b) Guidelines for the prediction of acid rock drainage and metal leaching for mines in British Columbia: Part II—recommended procedures for static and kinetic testing, Proc, 4th ICARD, Vancouver, BC, p 15–30

Rees GN, Grassia GS, Sheehy AJ, Dwivedi PP, Patel BK (1995) Desulfacinum infernum gen. nov., sp. nov., a thermophilic sulfate-reducing bacterium from a petroleum reservoir. Int J Syst Bacteriol 45(1):85–89

Robador A, Brüchert V, Jørgensen BB (2009) The impact of temperature change on the activity and community composition of sulfate-reducing bacteria in arctic versus temperate marine sediments. Environ Microbiol 11(7):1692–1703

Rozanova EP, Tourova TP, Kolganova TV, Lysenko AM, Mityushina LL, Yusupov SK, Belyaev SS (2001) Desulfacinum subterraneumsp. nov., a new thermophilic sulfate-reducing bacterium isolated from a high-temperature oil field. Microbiology 70(4):466–471

Sievert SM, Kuever J (2000) Desulfacinum hydrothermale sp. nov., a thermophilic, sulfate-reducing bacterium from geothermally heated sediments near Milos Island (Greece). Int J Syst Evolut Microbiol 50(3):1239–1246

Sobek AA, Schuller WA, Freeman JR (1978) Field and laboratory methods applicable to overburdens and minesoils. US EPA 600/2-78-054, Cincinnati

Sobolewski A (2010) Benefits of using liquid carbon sources for passive treatment systems. In: Proceedings International Mine Water Association Sym—Mine Water and Innovative Thinking, Sydney, NS, Canada, pp. 279–282

Tolonen ET, Rämö J, Lassi U (2015) The effect of magnesium on partial sulphate removal from mine water as gypsum. J Environ Manag 159:143–146

Tsukamoto TK (1999) Alcohol Enhanced, Passive Bioreactors for Treatment of Acid Mine Drainage. University of Nevada, Reno, NV, USA

Tsukamoto TK, Miller GC (1999) Methanol as a carbon source for microbiological treatment of acid mine drainage. Water Res 33(6):1365–1370

Wang H, Chen F, Mu S, Zhang D, Pan X, Lee DJ, Chang JS (2013) Removal of antimony (Sb (V)) from Sb mine drainage: biological sulfate reduction and sulfide oxidation–precipitation. Bioresource Technol 146:799–802

Waybrant KR, Blowes DW, Ptacek CJ (1998) Selection of reactive mixtures for use in permeable reactive walls for treatment of mine drainage. Environ Sci Technol 32(13):1972–1979

Waybrant KR, Ptacek CJ, Blowes DW (2002) Treatment of mine drainage using permeable reactive barriers: column experiments. Environ Sci Technol 36(6):1349–1356

Weijma J (2000) Methanol as electron donor for thermophilic biological sulfate and sulfite reduction. PhD thesis, Wageningen University, the Netherlands

Younger PL, Banwart SA, Hedin RS (2002) Mine water: hydrology, pollution, remediation. Springer, The Netherlands

Zagury GJ, Neculita C, Bussiere B (2007) Passive treatment of acid mine drainage in bioreactors: short review, applications, and research needs. In: Proceedings 60th Canadian geotechnical conference and 8th joint CGS/IAH-CNC specialty groundwater conference, Ottawa, ON, Canada, pp 1439–1446

Ziemkiewicz PF, Skousen JG, Simmons J (2003) Long-term performance of passive acid mine drainage treatment systems. Mine Water Environ 22:118–129

Acknowledgements

Sincere thanks are extended to the MITACS and Natural Sciences and Engineering Research Council of Canada for their financial contributions and Alexco for the technical support they provided.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nielsen, G., Janin, A., Coudert, L. et al. Performance of Sulfate-reducing Passive Bioreactors for the Removal of Cd and Zn from Mine Drainage in a Cold Climate. Mine Water Environ 37, 42–55 (2018). https://doi.org/10.1007/s10230-017-0465-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10230-017-0465-1