Abstract

The polysaccharide WL gum is produced by the marine microorganism Sphingomonas sp. WG and presents great commercial utility potential in many industries especially in oil industries. However, the high fermentation cost limits its wide application. Therefore, an efficient production system at a lower cost was established using beet molasses to partially replace the commonly used carbon sources. Four different molasses were screened and their composition was investigated. One-factor design and RSM statistical analysis were employed to optimize the WL gum fermentation medium. The effects of molasses on the rheological properties and gene expression of WL gum were also investigated. The results showed that the pretreated beet molasses generated both high broth viscosity and WL gum production (12.94 Pa·s and 11.16 g/L). Heavy metal ions and ash were found to be the key factors in unpretreated and pretreated molasses affecting WL production. The cost-efficient production medium contained (g/L): sucrose 61.79, molasses 9.95, yeast extract 1.23, K2HPO4 1, MgSO4 0.1, ZnSO4 0.1 and the WL gum production reached 40.25 ± 1.15 g/L. The WL gum product WL-molasses showed the higher apparent viscosity, and viscous modulus and elastic modulus than WL-sucrose and WL-mix, which might be related to its highest molecular mass. The higher expressional level of genes such as pgm, ugp, ugd, rmlA, welS, and welG in WL gum synthesis in the mixed carbon source medium caused the high production and broth viscosity. This work provided a cost-efficient method for WL gum production.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Microbial exopolysaccharides (EPS), such as xanthan, gellan, welan, and alginate, have good physical and chemical properties (Gansbiller et al. 2020; Freitas et al. 2017; Barcelos et al. 2020). They are important industrial biopolymers with important commercial values, especially as thickener, tackifier, stabilizer, and emulsifier agents in food, oil, agriculture, and pharmaceutical industries (Rana and Upadhyay 2020). The sphingan is a group of EPS produced by the genus of Sphingomonas with similar linear backbone structures as glucose-glucuronic acid-glucose-rhamnose/mannose, and most of them can be used as the thickening, chelating, emulsifying, and stabilizing agents in many fields (Huang et al. 2022). For example, welan gum is a typical sphingan with rhamnose or mannose as the side chain and presents good rheological properties and high thermostability. Therefore, it has many industrial applications, such as concrete additives and enhanced oil recovery (Kaur et al. 2014). The structural variations of sphingans affect the interactions between the interchains and therefore show an obvious influence on their physiochemical properties (Fialho et al. 2008; Xu et al. 2019). New isolates of Sphingomonas might produce useful sphingans with novel structures and good rheological characteristics (Huang et al. 2022). Marine microorganisms are important resources to produce polysaccharides with unique functions and good resistance to adverse conditions (Finore et al. 2014) because they survive in complex environments with low temperatures, high pressure, and high salinity. In our previous work, the bacterium Sphingomonas sp. WG was screened from the sea mud in Jiaozhou Bay at a depth of 40 m due to its capacity to produce the sphingan WL gum (Li et al. 2016a). WL gum is composed of neutral sugars L-mannose, D-glucose, and L-rhamnose at a molar ratio of 1:2.28:2.12, 13% glucuronic acid, and 6.52% O-acyl group (Li et al. 2016a). It possesses higher apparent viscosity, viscoelasticity, and better resistance to high salinity than welan gum at the same concentration (Ji et al. 2020). Due to its pseudoplasticity, WL gum can be used in many industries, such as food, ink, concrete, and oil industries (Li et al. 2016a). For example, it can be used in enhanced oil recovery field as the flooding agent because its enhanced displacement efficiency was comparable to hydrolyzed polyacrylamide (HPAM) and its diluted fermentation broth presented even higher displacement efficiency than HPAM (Ji et al. 2020).

However, high production costs limit the application of most EPS (Rehm 2010). Normally, the fermentation materials, especially carbon sources, occupy a large proportion of the total production cost. Thus, using cheap carbon sources, especially renewable ones, is a feasible way to reduce production costs (Jiang et al. 2009). As the main by-product of the sugar industry, more than 40,000 tons of molasses are produced in China every year. However, most molasses was discarded directly and aggravated environmental water pollution (Yin et al. 2019). Interestingly, molasses is rich in nutrients, including sugars (mainly sucrose, glucose, and fructose) and a small amount of nitrogen sources, vitamins, and trace metals (Wu et al. 2009). Therefore, molasses is a typical low-cost carbon source and has been used in the fermentation process of several metabolites, such as gluconic acid, citric acid, butyric acid, welan gum, levan, and xanthan (Sharma et al. 2008; Ren et al. 2006; Jiang et al. 2009; Li et al. 2020; Gojgic-Cvijovic et al. 2018; Kalogiannis et al. 2003). Thus, molasses may be a kind of good cheap carbon sources for WL gum production.

To explore the feasibility of molasses as the carbon source in WL gum fermentation process, the effects of four different molasses were investigated, and the key components in molasses that influence the WL gum production and the fermentation broth viscosity were analyzed through the composition assay of different molasses. Based on these results, a high-efficiency and low-cost production system was established by combining the cheap carbon source molasses and the efficient carbon source sucrose. Besides, the rheological behavior and molecular mass of WL gum samples were investigated to confirm the influence of molasses on WL gum properties. Finally, the expressional levels of genes in the WL gum biosynthesis pathway were analyzed to reveal the possible mechanism of the enhanced production using the cost-efficient system.

Materials and Methods

Bacterial Strains, Culture Medium, and Conditions

Sphingomonas sp. WG (CCTCC No M2013161) was used to produce WL gum. The solid LB medium in per liter contained (g): tryptone 5.0, yeast extract (YE) 10.0, NaCl 10.0, agar 20.0. The seed medium in per liter contained (g): glucose 10.0, YE 1.0, tryptone 5.0, K2HPO4 2.0, MgSO4 0.1. The initial fermentation medium was the same as our previous work and contained glucose 67.0 g/L, YE 3.4 g/L, K2HPO4 3.0 g/L, and MgSO4 0.1 g/L (Li et al. 2018). The strain maintained in LB medium was inoculated in the seed culture medium and cultured at 28 °C for about 24 h. Then the activated cells were transferred into 50 mL seed culture medium to obtain the seeds for fermentation. The fermentation of WL gum was conducted as follows: 2.5 mL of the activated strain was added to a 250-mL Erlenmeyer flask containing 50 mL of fermentation medium and cultured at 32.5 °C, 175 rpm for 72 h.

Molasses Pretreatment

Cane molasses was purchased from Guangxi Liuzhou Molasses Factory. Beet molasses was purchased from Harbin Ying ma Biotechnology Co., Ltd. Soy molasses and cottonseed molasses were purchased from Tianjin Li fa long Chemical Technology Co., Ltd. The method of phosphoric acid and polyacrylamide was used to treat the molasses (Li et al. 2020). In brief, 1 L of diluted molasses (with a carbohydrate concentration at 50–60°Bx) was heated and boiled for 10 min, and centrifuged at 8000 rpm for 10 min to remove the insoluble impurities and protein. The metal ions and colloids were precipitated for about 12 h by adjusting the pH of the supernatant to 3.0 using phosphoric acid, and centrifuged at 8000 rpm for 10 min to remove the precipitation. Then the pH of the supernatant was adjusted to 7.0 by calcium hydroxide and polyacrylamide. The solution was heated in a 70 °C water bath for 30 min and centrifuged at 8000 rpm for 10 min. The supernatant was used as the pretreated molasses in the next experiment.

Determination of the Content of Various Substances in Molasses

The metal ions in molasses were determined using an inductively coupled plasma optical emission spectrometer using the multielement standard mixture at 1 mg/mL (Cu, Fe, K, Mg, Ni, Zn, Al, As, Cd, Co, Cr, Mn, Pb, and Sr) to evaluate the metal ion content in molasses (Wada et al. 2017). The sugar composition was determined by HPLC with a differential detector and ZORBAX NH2 column (4.6 × 250 mm, 5 µm). The mixed sugar standard solutions (glucose, sucrose, and fructose) at the concentration of 5 mg/mL, 10 mg/mL, 20 mg/mL, and 40 mg/mL were used to evaluate the sugar content in molasses (Norman et al. 1981). The colloid content was determined according to the method of isoelectric point precipitation by 0.1 mol/L of hydrochloric acid. Then the precipitation was dried to a constant weight to calculate the colloid content (Li et al. 2020). The ash content was determined after the molasses was completely carbonized and burned in a muffle oven (Mortensen et al. 1989).

Optimization of the Fermentation Medium by the Single-Factor Method and Response Methodology

The influence of inorganic salts was investigated at the concentrations: K2HPO4 at 0–5 g/L, and both MgSO4 and ZnSO4 at 0–0.5 g/L (Li et al. 2018). The effects of different carbon sources, including cheap carbon sources (soy molasses, beet molasses, cottonseed molasses, and cane molasses) and high-efficiency carbon sources (glucose and sucrose), were studied at a concentration of 67 g/L. The molasses-sucrose ratios were set at 0:7, 1:6, 2:5, 3:4, 4:3, 5:2, 6:1, and 7:0 with a total sugar concentration of 70 g/L. The concentration of the YE was optimized from 1 to 10 g/L.

The Box-Behnken design (BBD) was performed with Design-Expert version 11.0 to optimize the concentration of sucrose, molasses, and YE. The analysis of variance (ANOVA) was carried out with Design-Expert version 11.0 software to predict the regression coefficients of each linear, quadratic, and interaction effect and validate the model (Li et al. 2018).

Analytical Methods in the Fermentation Process

The biomass was evaluated by the absorbance at 600 nm. The viscosity of the fermentation broth was determined at 1 rpm with the rotor of LV 3 on an ULTRA rheometer (Kim et al. 2012). WL gum production was determined by ethanol precipitation and centrifugation after the fermentation broth was heated at 80 °C for 10 min and calculated as g/L (Xu et al. 2017).

Rheological Properties of WL Gum

The WL gum samples with sucrose, molasses, and the mixed sucrose and molasses as the carbon source were prepared as described in the previous work (Li et al. 2020, 2022). At first, the EPS sample was precipitated by adding 4 times of ethanol to the fermentation broth. The precipitated sample was swollen in pure water and was supplemented with twice the volume of isopropanol containing 5% NaCl. The mixture was stirred for 2 h, and the EPS was precipitated again to remove water-soluble protein. The resulting polysaccharide precipitate was washed with isopropanol:ultrapure water solutions at ratios of 7:3, 8:2, and 9:1, respectively. Finally, the polysaccharide was dissolved and dialyzed in the dialysis bag with the cut-off Mw of 8000–14,000 Da for 2 days and freeze-dried.

The Haake MASII Rheometer (Germany) was used to analyze their rheological properties at a concentration of 0.1% (w/w). The shear rate was set in the range of 0.1 to 1000 s−1 for the steady-state rheological experiment. A strain sweep ranging from 0.01 to 100% was performed at the frequency of 1.0 Hz to find the linear viscoelastic region of WL gum samples. Storage modulus (G′) and loss modulus (G″) in the range of 0.1–100 Hz (25 °C) were determined using the oscillatory frequency sweep and analyzed by HAAKE Rheowin Job Manager software (Ji et al. 2020).

Determination of Molecular Mass

The molecular mass of WL gum was determined by gel permeation chromatography (GPC) analysis on an HLC-8320GPC EcoSEC (Tosoh Corporation, Japan) equipped with a TSKgel GMPWXL column (13 μm, 7.8 mml.D. × 30 cm) and a differential detector. The injection volume was 30 µL, and the column temperature was 35 °C. The mobile phase was 0.1 mol/L NaNO3, and the flow rate was set at 0.55 mL/min. Dextrans with different molecular masses were used as standards to obtain the standard curve.

Quantitative Real-Time PCR (qRT-PCR) Assays

qRT-PCR was performed to detect the expressional level of 13 genes (ugp, rmlA, pgm, ugd, welB, welC, welD, welE, welG, welK, welL, welQ, welS) according to our previous work (Li et al. 2018). The 16S rRNA gene was chosen as the reference, and the relative changes in gene expression were calculated using the 2−ΔΔCt method. At least three replicates were performed for each sample.

Data Analysis

All experiments were carried out in triplicate, and the data are represented as the average of three replicates with standard error. A t-test was applied for statistical analysis, and the p value < 0.05 was considered statistically significant.

Results

The Effects of Molasses as the Carbon Source in WL Gum Fermentation

Four commonly used molasses including soy molasses, beet molasses, cottonseed molasses, and cane molasses were screened to find the suitable molasses for WL gum fermentation (Fig. 1A). The highest WL gum production was 7.75 g/L when beet molasses was used while the lowest production was 5.00 g/L with cane molasses. The fermentation broth viscosity obtained using beet and cottonseed molasses was higher than that of soy and cane molasses (only 0.12 Pa·s). On the whole, the WL gum production and broth viscosity using molasses as the cheap carbon source were relatively low. It was found that some components in molasses, such as ash, colloids, and heavy metals, showed negative effects on bacterial growth and the fermentation process. Therefore, pretreatment of molasses was necessary for WL gum fermentation. As shown in Fig. 1B, the broth viscosity and WL gum production using the molasses medium increased significantly after pretreatment. The viscosity and WL gum production using cane molasses was 7.12 Pa·s and 10.25 g/L, which was about 59.33-fold and 1.86-fold of the unpretreated cane molasses. After pretreatment, the WL gum production of all molasses showed no significant difference and was higher than 10 g/L. The highest WL gum production reached 11.17 g/L using cottonseed molasses. Interestingly, the broth viscosity of different molasses exhibited significant difference. The highest broth viscosity was obtained with beet molasses (12.94 Pa·s), followed by the cottonseed molasses and cane molasses (8.36 and 7.12 Pa·s, respectively) and the lowest was obtained with soy molasses (3.66 Pa·s). Beet molasses gave both high broth viscosity and WL gum production; therefore, beet molasses was chosen in next experiments. Considering the effects of molasses composition on WL gum production process, the main components of molasses were analyzed to find the key factors that affect the fermentation result.

Optimization of carbon sources. A Effects of different raw molasses on WL gum production. B Effects of different molasses after pretreatment on WL gum production. C Effects of different concentrations of K2HPO4 on WL gum production. D Effects of different concentrations of MgSO4 on WL gum production. E Effects of different concentrations of ZnSO4 on WL gum production (“*” indicated p < 0.05, “**” indicated p < 0.01)

Fermentable sugar is the most important nutrient in molasses. Normally, glucose, fructose, and sucrose are the main sugars of molasses (Ai et al. 2015) and their contents in different molasses are shown in Table 1. Beet molasses and soy molasses mainly contained sucrose (74.03% and 69.27%, respectively), while cane molasses did not contain sucrose whose sugar composition was fructose and glucose (52.40% and 47.60%, respectively). Cane molasses did not contain glucose and it was composed of 65.09% fructose and 34.91% sucrose.

Besides sugars, colloids, ash, and heavy metal ions took a certain proportion of unpretreated molasses (Table 2). It was observed that the unpretreated molasses contained high colloid contents in the range of 4.89–6.38%. After pretreatment, the collides were effectively removed through heat and isoelectric point precipitation method and the colloid content ranged from 0.62 to 1.23% in different molasses. Considering the little colloid content, it may not be the main factor in pretreated molasses for WL gum fermentation. The ash content in raw soy molasses was the highest while in beet molasses was the lowest. After pretreatment, the ash removal rates of different molasses were very similar (about 44–57%) and therefore, the ash content of soy molasses was still the highest and that of beet molasses was the lowest. The heavy metal content of molasses differed among molasses. The heavy metal ion content of cane molasses was 0.6%, about 47.4% higher than that of beet molasses and cottonseed molasses and 55.7% higher than that of soy molasses. Some heavy metals such as Cr, Cu, and Ni were sneaked into the molasses production process from processing equipment, raw materials, or contaminants during the sugar production process (Table S1), and they showed a toxic effect on microorganism’s enzymatic activity even at low concentration (Ciosek et al. 2020). After pretreatment, the total heavy metal ions in cottonseed, beet, cane, and soy molasses were reduced by 34%, 78%, 81%, and 41%, respectively. The pretreatment removed most heavy metal ions in beet molasses and cane molasses. However, the removal effect of cottonseed molasses and soy molasses was poor. According to the contents of ash and colloid, it was speculated that the presence of ash and colloid inhibited the precipitation of metal ions.

Considering the fact that the molasses had salts itself, the supplementation concentration of inorganic salts might be different from using glucose as the sole carbon source (Li et al. 2018). Therefore, the effects of three important inorganic salts such as K2HPO4, MgSO4, and ZnSO4 that have been proved to promote the fermentation of sphingan WL gum at certain concentration (Li et al. 2018) were investigated (Fig. 1C–E). Similar to our previous work, the maximal WL gum production and fermentation broth viscosity were obtained when the concentration of MgSO4 and ZnSO4 was at 0.1 g/L. However, the optimal addition concentration of K2HPO4 was reduced from 3 to 1 g/L, which may be related to the higher K+ content in molasses (Table S1).

Establishment of the Cost-Efficient Production System of WL Gum

Although molasses could be applied in WL gum production with low cost, the WL production and viscosity were relatively low compared with the reported production (33 to 39.95 g/L). Therefore, it was necessary to establish a cost-efficient production system. Our previous work indicated that glucose could be used as an efficient carbon source for WL gum fermentation (Li et al. 2018). However, it was found that sucrose was an optimal carbon source for pullulan and welan gum production (Li et al. 2020; Yoon et al. 2012). Therefore, to find the efficient carbon source for Sphingomonas sp. WG, the effects of glucose and sucrose as the sole carbon source on WL gum production were analyzed. As shown in Fig. 2A, the biomass, viscosity of fermentation broth, and the WL gum production obtained on sucrose were higher than glucose. At the same time, the price of sucrose was slightly lower than that of glucose. Therefore, sucrose was chosen as an efficient carbon source conducive to the fermentation of Sphingomonas sp. WG. Sequentially, different molasses:sucrose ratios were employed to find the optimal ratio (Fig. 2B). Compared with sucrose as the sole carbon source, the supplementation of a small amount of beet molasses resulted in enhanced biomass, broth viscosity, and WL gum production. The ratio of beet molasses:sucrose at 1:6 yielded the highest WL gum production and the broth viscosity (39.25 g/L and 45.92 Pa·s). However, as the ratio of molasses increased, the harmful materials such as ash and salt ions, accumulated and inhibited the bacteria growth and the synthesis of EPS. When the ratio of beet molasses:sucrose reached 4:3, the broth viscosity and WL gum yield were significantly decreased. Therefore, the concentration of beet molasses and sucrose was about 10 g/L and 60 g/L, respectively.

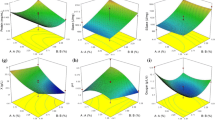

Optimization of the cost-efficient WL gum production medium through single-factor design. A Effects of efficient carbon sources on WL gum production. B Effects of beet molasses:sucrose ratio on WL gum production. C Effects of different concentrations of YE on WL gum production. D Response surface plot of molasses and sucrose; E Response surface plot of YE and sucrose; F Response surface plot of YE and molasses (“*” indicated p < 0.05, “**” indicated p < 0.01)

Besides carbon sources, nitrogen sources are another essential nutrient for microbial fermentation. Our previous work proved that YE was the optimal nitrogen source among nine different nitrogen sources (Li et al. 2018) and its effects were also investigated in this work. The highest WL gum production was obtained at 3 g/L (Fig. 2C). When the proportion of nitrogen source was higher, more metabolic flux was used for bacterial growth and thereby may affect the accumulation of metabolites (Xu et al. 2020), in contrast, when the nitrogen source was insufficient, it was not conducive to the growth of the bacteria and the biosynthesis of the target products.

Finally, to further optimize the medium composition, BBD center combination experiment and RSM analysis were carried out based on the statistical analysis of the PB design in our previous work. The p values for glucose and YE for WL gum production was < 0.01, indicating that carbon and nitrogen sources were highly significant (Li et al. 2018). Therefore, molasses, sucrose, and YE were selected in the BBD experiment, and their concentration range was chosen based on the results of the single-factor design (Table 3). The regression simulation analysis of variance using the WL gum production as the response value was performed (Table 4). The model’s p value (< 0.0001) was extremely significant. The regression equation was Y = 38.29 − 0.63A + 1.76B + 2.64C + 0.82AB + 1.74AC + 1.1BC − 9.26A2 − 5.6B2 − 6.16C2. The correlation coefficient R2 = 0.9933 indicated that the model could explain up to 99.93% of the variability; the modified coefficient of determination R2adj = 0.9848, suggesting that the model fit well with the actual situation. The values of the second-order of the model were less than 0.0001, demonstrating that the effects were extremely significant. The p value for AB was higher than 0.05, suggesting the absence of a significant interaction between the two carbon sources. In contrast, the p value for AC and BC was significant, indicating that the interaction between carbon and nitrogen sources was significant. The three-dimensional response surface plots of molasses and sucrose, molasses and YE, and sucrose and YE against WL production are shown in Fig. 2D–F. The model’s optimal concentrations of sucrose, molasses, and YE were 61.79 g/L, 9.95 g/L, and 1.23 g/L, and the predicted maximum yield of WL gum was 38.75 g/L. Thus, the final optimized medium composition composed of sucrose 61.79 g/L, molasses 9.95 g/L, YE 1.23 g/L, K2HPO4 1 g/L, MgSO4 0.1 g/L, and ZnSO4 0.1 g/L.

The experimental verification of the simulation was carried out, and the yield of WL gum was 40.25 ± 1.15 g/L. The relative error with the predicted value was about 3.9%, validating the model’s adequacy. The WL gum productivity and yield were 0.559 ± 0.016 g/L/h and 0.561 ± 0.016 g/g, respectively. The obtained WL gum production, WL gum productivity, and WL gum conversion yield were equal to that in our previous work (Li et al. 2018).

Effects of the Molasses on the Rheological Behavior and Molecular Mass of WL Gum

The WL gum obtained with sucrose, molasses, and mixed carbon sources were designated as WL-sucrose, WL-molasses, and WL-mix, and their rheological behaviors were tested. As shown in Fig. 3A, the apparent viscosity of three WL gum samples under the shear rate at 7.34 s−1 was relatively stable over time. As the shear rate increased in the range of 0.001 to 1000 s−1 (Fig. 3B), the viscosity of the three WL gum samples continued to decrease, which was in consistence with WL gum produced with glucose (Ji et al. 2020). More interestingly, differently from the trend of broth viscosity, WL-molasses had the highest viscosity, followed by WL-sucrose, and WL-mix was the lowest at the same shear rate. The difference between the WL gum solution viscosity and the broth viscosity was probably attributed to the significant changes in EPS concentration. The mixed medium had the highest WL gum production, followed by the sucrose medium, and the lowest molasses medium. Thus, although WL-molasses had the highest viscosity, the viscosity of its fermentation broth was the lowest.

Rheological behaviors and molecular mass of WL gum. A Steady shear flow curves of WL-sucrose, WL-molasses, and WL-Mix. B Rheological properties of WL gum samples obtained with different carbon sources. C Viscosity as a function of scan frequency. D The effect of different carbon sources on molecular mass

To further investigate the rheological properties of different WL gum samples, a frequency scanning was performed. The linearity domain of each sample was measured before measuring the viscoelastic modulus of the samples and the selected strain was 1%. Following our previous observation (Ji et al. 2020), the storage modulus (G′) of all WL gum samples was higher than their loss modulus (G″) within the frequency region of 0.1–100 Hz (Fig. 3C). Notably, similarly to the apparent viscosity, the WL-molasses showed the highest G′ and G″ and WL-mix with the lowest G′ and G″.

As a macromolecule, molecular mass plays a crucial role in the rheological properties of EPS. It was affected by many factors such as culture medium, dissolved oxygen, and additives (Ai et al. 2015; Norman et al. 1981). As shown in Fig. 3D, the molecular mass of WL-sucrose, WL-molasses, and WL-mix was 2.77 × 107 Da, 3.64 × 107 Da, and 1.86 × 107 Da, respectively, suggesting that the molecular mass of WL-molasses was the highest while that of the WL-mix was the lowest.

The Effects of Molasses on the Expressional Levels of Genes Involved in WL Gum Biosynthesis

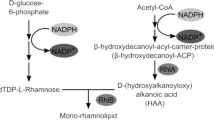

To find the influence of different carbon sources on WL gum biosynthesis, the expression level of 13 genes related to nucleotide-sugar precursor synthesis, assembly of tetrasaccharide repeating unit, polymerization, and export of the polysaccharide, was investigated (Li et al. 2018). As shown in Fig. 4, compared with sucrose (the control group), the relative expressional levels of four genes (pgm, ugp, ugd, and rmlA) obtained using the mixed carbon sources (the experimental group) were increased. At the same time, the expressional levels of two genes, welS and welG, in the polymerizing process were also increased with a relative expressional level higher than 20-fold. The expressional level changes of the four glycosyltransferases encoding genes increased at different degrees. The changes of the relative expressional levels of the glycosyltransferases WelB and WelK, corresponding to the transfer of the first glucose, and glucuronic acid, were higher than that of the glycosyltransferases WelL and WelQ corresponding to the transfer of the second glucose and rhamnose. Furthermore, the transcriptional levels of welC and welE that may involve in chain length regulation in the mixed medium were increased. The higher expressional levels of those genes in WL gum biosynthesis might be related to the enhanced WL gum production in the mixed medium.

The effects of molasses on the expressional levels of genes in WL gum biosynthesis. A Expressional level of genes involved in WL gum synthesis through qRT-PCR analysis using 16S rRNA gene as the internal standard. The relative changes in gene expression were calculated using the 2−ΔΔCt method. B Schematic representation of the proposed mechanism for higher WL gum production on mixed carbon source. Red arrows indicated the expressional levels significantly increased. Dashed arrow indicated multi-steps that were not determined by qRT-PCR

Discussion

As the by-product of sugar manufacture, molasses always contain a verity of nutrient substances such as fermentable sugars, trace elements, and inorganic salts (Castañeda-Ayarza and Cortez 2017), which is beneficial for many EPS fermentation such as xanthan (Kalogiannis et al. 2003), gellan gum (Banik et al. 2007), and welan gum (Ai et al. 2015; Li et al. 2020). Besides, the molasses composition is affected by both the raw materials and the manufacture process (Stoppok and Buchholz 2008). Therefore, four kinds of molasses were screened and their composition was investigated to find the key factors that affected the WL production. Sugars in molasses are the first concerned factor because they are not only the major constituent for the building of cellular materials but also an energy source for polysaccharide synthesis (Xu et al. 2015). According to previous research, glucose was better for WL gum production than fructose (Li et al. 2018), and sucrose was proved to be better than glucose. Therefore, the preference of Sphingomonas sp. WG was supposed to be sucrose > glucose > fructose. So, we inferred that the more sucrose in molasses, the higher efficiency for Sphingomonas sp. WG to produce WL gum. However, cottonseed molasses yielded a higher broth viscosity and WL gum production than soy molasses, although it did not contain sucrose. The possible reason was that the influence of other harmful substances, such as colloids, metals, and ash in molasses exceeded that of sugar composition. The colloid and ash contents in cottonseed and beet molasses were different, but their heavy metal ion content was very similar and the WL gum production and broth viscosity using these two molasses were similar. In the other respect, cane and beet molasses contained similar colloid, but the heavy metal ion content of cane molasses was about 47.4% higher than that of beet molasses. Compared with beet molasses medium, both broth viscosity and WL gum production decreased dramatically on cane molasses. Heavy metals may decrease the enzyme activity, and it was observed that some heavy metal ions such as Cu2+, Pb2+, and Hg2+ showed high toxicity on microorganisms even at low concentrations (Wang et al. 2007; Malamis et al. 2012; Soares and Soares 2012). Therefore, it indicated that the heavy metal ions were the key factor in molasses before pretreatment, affecting the results of WL gum fermentation.

To improve the WL gum production, it was necessary to remove the harmful components, especially the heavy metals, in the molasses through the pretreatment process of molasses. Li et al. (2020) compared six different pretreatment methods and found that the molasses pretreated with phosphoric acid and polyacrylamide method generated the highest welan gum production. Therefore, the phosphoric acid and polyacrylamide method was chosen in this work. The contents of colloid, ash, and heavy metals notably decreased after pretreatment, and the WL gum production and fermentation broth viscosity increased significantly, as expected. Comparing the effects of different molasses, the WL gum production and broth viscosity with cottonseed molasses were slightly higher than those of cane molasses. The colloid and ash contents in cottonseed molasses and cane molasses were similar, while the heavy metal ion content in cottonseed molasses was much higher than that in cane molasses. Therefore, the heavy metal ions were not the main factor in molasses after pretreatment. For the other two molasses, beet and soy molasses, the contents of colloid and heavy metal ions were similar, but the ash content was 4.81% and 8.23%, respectively. With the higher ash content, the soy molasses broth viscosity was only 28.27% of the beet molasses. Overall, it suggested that the ash content was the key factor in pretreated molasses for WL gum production. In the next experiment, the novel methods with higher ash content removal rate may be explored in molasses pretreatment. Based on the screening results, the beet molasses was chosen as the cheap carbon source combining with sucrose as the efficient carbon source to establish a cost-efficient production system using a stepwise strategy. The WL gum production reached 40.25 ± 1.15 g/L, which was very close to our previous work (Li et al. 2018). However, the raw material cost for every ton of WL gum will save 709 dollars according to the current market price. Therefore, it may promote the industrial production of WL gum.

Normally, polysaccharides with different rheological behaviors can be used in different fields. For example, high-viscosity polysaccharides were used as oil-displacing agents in the petroleum industry and additives in the concrete industry (Isik and Ozkul 2014). The rheological properties were influenced by the cultural medium and conditions. Li et al. (2020) found that welan gum produced from cane molasses had similar rheological properties to sucrose. Interestingly, in this work, we observed that both the apparent viscosity and the viscoelasticity of WL-molasses were higher than that of WL-sucrose, which might broaden the application of WL gum. Molecular mass was one important factor that may influence the rheological properties. Two low acyl gellan gum fragments with molecular mass at 1.2 × 105 Da and 2.5 × 104 Da were prepared using β-glucosidase and presented less gel-like behaviors than undigested low acyl gellan gum (Baawad et al. 2021). Similarly, low-molecular-weight welan gum (about 68 kDa) synthesized by Sphingomonas sp. mutant ΔsrtW showed lower viscosity, storage modulus (G′), and loss modulus (G″) than that of the native welan gum (Zhao et al. 2021). Different WL gum samples with a gradient molecular mass change (from 4.70 × 106 to 1.45 × 106 Da) digested by the specific lyase WelR were prepared and the apparent and intrinsic viscosity, the viscous modulus (G″), and elastic modulus (G′) decreased as the molecular mass decreased (Li et al. 2022). In this work, the higher molecular mass of WL-molasses than WL-sucrose may lead to its higher rheological properties. The effects of molasses on the molecular mass of welan gum were also detected, and the molecular mass of welan gum from cane molasses was higher than that of glucose (Ai et al. 2015). Differently, it was found that the molecular mass of xanthan gum was decreased with increasing molasses concentration (Kalogiannis et al. 2003).

Therefore, the influence of molasses on the expressional level of genes in WL gum biosynthesis was investigated by qRT-PCR to find the possible reason for the enhancement of WL gum production and the molecular mass changes. Like other sphingans, the biosynthetic pathway of the WL gum included three sequential steps: nucleotide sugar precursor synthesis, assembly of tetrasaccharide repeating units by specific glycosyltransferases, and polymerization and export of the polysaccharide (Schmid et al. 2014). The genes such as pgm, ugp, and ugd for synthesizing nucleotide sugar precursor UDP-glucose and UDP-glucuronic acid are dispersed on the genome of Sphingomonas sp. WG. Four genes rmlABCD for dTDP-rhamnose may be clustered as an operon (Li et al. 2016b). Therefore, the expressional level of rmlA was detected as the representative of the operon. The notably increased expression levels of these genes in the mixed carbon source medium suggested that more corresponding nucleotide-sugars were synthesized. Besides the genes for nucleotide sugar precursor, other genes involved in the assembly of the repeating unit and polymerization and secretion process were clustered in different orientations on the genome (Li et al. 2016b). Therefore, the expressional levels of most genes increased at different degrees. welS and welG encoding the flippase and polysaccharide polymerase played important roles in the polymerizing process (Tocilj et al. 2008). Therefore, their higher expression indicated the enhancement of the polymerization and export of polysaccharides. welC and welE properly encode proteins belonging to the protein-polysaccharide co-polymerases and regulate the polysaccharide chain length (Moreira et al. 2004). It was found that their homologous gene gelC and gelE were critical for synthesizing high molecular mass gellan gum (Moreira et al. 2004). However, beyond expectation, the transcriptional levels of welC and welE in the mixed medium were not decreased compared with that in the sucrose medium, which showed an opposite trend to the molecular mass changes. The molecular mass regulation was speculated to be very complicated and related to many enzymes such as WelC, WelE, WelS, WelG, and the special lyase WelR (Moreira et al. 2004; Zhao et al. 2022). The mechanism of chain length regulation needs further investigation in the next work. The higher gene expressional levels in WL gum biosynthesis may lead to increased WL gum production in the mixed medium.

Conclusion

The cost-efficient WL gum production with molasses and sucrose as the cheap and efficient carbon source was investigated. Beet molasses was proved to be the optimal carbon source among four molasses. The ash content was the main factor in the pretreated molasses. The optimized medium contained (g/L): sucrose 61.79, molasses 9.95 g, YE 1.23, K2HPO4 1, MgSO4 0.1, ZnSO4 0.1, and the WL gum production reached 40.25 ± 1.15 g/L. The rheological behavior and molecular mass of WL-molasses were the highest. The higher gene expression in WL gum synthesis caused the high production. This work provides a cost-efficient WL gum production method.

Data Availability

The original contributions presented in the study are included in the article/Supplementary Material. Further inquiries can be directed to the corresponding authors Hu Zhu and Jiqian Wang.

References

Ai HX, Liu M, Yu PR, Zhang SZ, Suo YK, Luo P, Li S (2015) Improved welan gum production by Alcaligenes sp. ATCC31555 from pretreated cane molasse. Carbohydr Polym 129:35–43

Baawad A, Rice C, Hamil T, Murphy K, Park J, Kim DS (2021) Molecular weight effects of low acyl gellan gum on antioxidant capacity and rheological properties. J Food Sci 86:4275–4287

Banik RM, Santhiagu A, Upadhyay SN (2007) Optimization of nutrients for gellan gum production by Sphingomonas paucimobilis ATCC-31461 in molasses based medium using response surface methodology. Bioresource Technol 98:792–797

Barcelos MCS, Vespermann KAC, Pelissari FM, Molina G (2020) Current status of biotechnological production and applications of microbial exopolysaccharides. Crit Rev Food Sci Nutr 60:1475–1495

Castañeda-Ayarza JA, Cortez LAB (2017) Final and B molasses for fuel ethanol production and some market implications. Renew Sust Energ Rev 70:1059–1065

Ciosek A, Fulara K, Hrabia O, Satora P, Poreda A (2020) Chemical composition of sour beer resulting from supplementation the fermentation medium with magnesium and zinc ions. Biomolecules 10:1599

Fialho AM, Moreira LM, Granja AT, Popescu AO, Hoffmann K, Sa-Correia I (2008) Occurrence, production, and applications of gellan: current state and perspectives. Appl Microbiol Biotechnol 79:889–900

Finore I, Di Donato P, Mastascusa V, Nicolaus B, Poli A (2014) Fermentation technologies for the optimization of marine microbial exopolysaccharide production. Mar Drugs 12:3005–3024

Freitas F, Torres CA, Reis MA (2017) Engineering aspects of microbial exopolysaccharide production. Bioresource Technol 245:1674–1683

Gansbiller M, Schmid J, Sieber V (2020) Rheology of sphingans in EPS–surfactant systems. Carbohydr Polym 248:116778

Gojgic-Cvijovic GD, Jakovljevic DM, Loncarevic BD, Todorovic NM, Pergala MV, Ciric J, Loos K, Beskoski VP, Vrvic MM (2018) Production of levan by Bacillus licheniformis NS032 in sugar beet molasses-based medium. Int J Biol Macromol 121:142–151

Huang HL, Lin JZ, Wang WD, Li S (2022) Biopolymers produced by Sphingomonas strains and their potential applications in petroleum production. Polymers (Basel) 14:1920

Isik IE, Ozkul MH (2014) Utilization of polysaccharides as viscosity modifying agent in self-compacting concrete. Constr Build Mater 72:239–247

Ji SX, Li H, Wang GH, Lu T, Ma WZ, Wang JQ, Zhu H, Xu H (2020) Rheological behaviors of a novel exopolysaccharide produced by Sphingomonas WG and the potential application in enhanced oil recovery. Int J Biol Macromol 162:1816–1824

Jiang L, Wang JF, Liang SZ, Wang XN, Cen P, Xu ZN (2009) Butyric acid fermentation in a fibrous bed bioreactor with immobilized Clostridium tyrobutyricum from cane molasses. Bioresource Technol 99:3403–3409

Kalogiannis S, Iakovidou G, Liakopoulou-Kyriakides M, Kyriakidis DA, Skaracis GN (2003) Optimization of xanthan gum production by Xanthomonas campestris grown in molasses. Process Biochem 39:249–256

Kaur V, Bera MB, Panesar PS, Kumar H, Kennedy JF (2014) Welan gum: microbial production, characterization, and applications. Int J Biol Macromol 65:454–461

Kim GO, Kim N, Kim DY, Kwon JS, Min BH (2012) An electrostatically crosslinked chitosan hydrogel as a drug carrier. Molecules 17:13704–13711

Li BC, Li H, Liu JL, Zhang ZM, Chen MQ, Yue L, Lu W, Ji SX, Wang D, Zhu H, Wang JQ (2022) Enzymatic degradation, antioxidant and rheological properties of a sphingan WL gum from Sphingomonas sp. WG. Int J Biol Macromol 210:622–629

Li H, Jiao X, Sun YJ, Sun SW, Feng ZM, Zhou WL, Zhu H (2016a) The preparation and characterization of a novel sphingan WL from marine Sphingomonas sp. WG Sci Rep 6:37899

Li H, Li J, Zhou WL, Jiao X, Sun YJ, Shen YL, Qian J, Wang JQ, Zhu H (2018) An efficient production of a novel carbohydrate polymer sphingan WL. J Chem Technol Biot 93:3472–3482

Li H, Zhu H, Sun SW, Feng ZM, Sun YJ, Zhou WL (2016b) Biological production of welan gum. In: Luque R and Xu CP(ed) Biomaterials - Biological Production of Fuels and Chemicals 73–94

Li QW, Zhou Y, Ke CZ, Bai YX, Liu XL, Li SB (2020) Production of welan gum from cane molasses by Sphingomonas sp. FM01. Carbohydr Polym 244:116485

Malamis S, Katsou E, Daskalakis N, Haralambous KJ (2012) Investigation of the inhibitory effects of heavy metals on heterotrophic biomass activity and their mitigation through the use of natural minerals. J Environ Sci Heal A 47:1992–1999

Moreira LM, Hoffmann K, Albano H, Becker A, Niehaus K (2004) The gellan gum biosynthetic genes gelC and gelE encode two separate polypeptides homologous to the activator and the kinase domains of tyrosine autokinases. J Microbiol 8:43–57

Mortensen AB, Wallin H, Appelqvist LA, Everitt G, Gref CG, Jacobsen J, Jensen K, Jepsen OM, Johansen IL, Julshamn K (1989) Gravimetric determination of ash in foods: NMKL collaborative study. J Assoc Off Anal Chem 72:481–483

Norman WH, Sirimanne P, Day WR (1981) High-performance liquid chromatographic separation of carbohydrate oligomers. J Chromatogr A 207:439–444

Rana S, Upadhyay LSB (2020) Microbial exopolysaccharides: synthesis pathways, types and their commercial applications. Int J Biol Macromol 157:577–583

Rehm BH (2010) Bacterial polymers: biosynthesis, modifications and applications. Nat Rev Microbiol 8:578–592

Ren NQ, Li JZ, Li BK, Wang Y, Liu S (2006) Biohydrogen production from molasses by anaerobic fermentation with a pilot-scale bioreactor system. Int J Hydrogen Energ 31:2147–2157

Schmid J, Sperl N, Sieber V (2014) A comparison of genes involved in sphingan biosynthesis brought up to date. Appl Microbiol Biotechnol 98:7719–7733

Sharma A, Vivekanand V, Singh RP (2008) Solid-state fermentation for gluconic acid production from sugarcane molasses by Aspergillus niger ARNU-4 employing tea waste as the novel solid support. Bioresource Technol 99:3444–3450

Soares EV, Soares HMVM (2012) Bioremediation of industrial effluents containing heavy metals using brewing cells of Saccharomyces cerevisiae as a green technology: a review. Environ Sci Pollut R 19:1066–1083

Stoppok E, Buchholz K (2008) Sugar‐based raw materials for fermentation applications. Biotechnology: products of primary metabolism (second edition) 6:4–29

Tocilj A, Munger C, Proteau A, Morona R, Purins L, Ajamian E, Wagner J, Papadopoulos M, Bosch LVD, Rubinstein JL, Féthière J, Matte A, Cygler M (2008) Bacterial polysaccharide co-polymerases share a common framework for control of polymer length. Nat Struct Mol Biol 15:130–138

Wada A, Nonose N, Ohata M, Tsutomu M (2017) Determination of ultra-trace metal impurities in high-purity cadmium using inductively coupled plasma mass spectrometry after matrix separation with anion exchange resin. Anal Sci 33:357

Wang YP, Shi JY, Wang H, Lin Q, Chen XC, Chen YX (2007) The influence of soil heavy metals pollution on soil microbial biomass, enzyme activity, and community composition near a copper smelter. Ecotox Environ Safe 67:75–81

Wu LT, Wu SS, Qiu JJ, Xu CX, Li S, Xu H (2009) Green synthesis of isomaltulose from cane molasses by Bacillus subtilis WB800-pHA01-palI in a biologic membrane reactor. Food Chem 229:761–768

Xu L, Qiu Z, Gong HJ, Zhu CF, Li ZJ, Li YJ, Dong MZ (2019) Rheological behaviors of microbial polysaccharides with different substituents in aqueous solutions: effects of concentration, temperature, inorganic salt and surfactant. Carbohydr Polym 219:162–171

Xu XP, Nie ZM, Zheng ZY, Zhu L, Zhan XB (2017) Production and rheological properties of welan gum produced by Sphingomnas sp ATCC 31555 with different nitrogen sources. J Mol Microbiol Biotechnol 27:55–63

Xu XP, Nie ZM, Zheng ZY, Zhu L, Zhan XB (2020) Effect of different nitrogen sources on the viscosity and rheological properties of welan gum produced by Sphingomonas sp. ATCC 31555. J Texture Stud 51:642–649

Xu XY, Dong SH, Li S, Chen XY, Wu D, Xu H (2015) Statistical experimental design optimization of rhamsan gum production by Sphingomonas sp. CGMCC 6833. J Microbiol 53:272–278

Yin FW, Zhu SY, Guo DS, Ren LJ, Ji XJ, Huang H, Gao Z (2019) Development of a strategy for the production of docosahexaenoic acid by Schizochytrium sp. from cane molasses and algae-residue. Bioresource Technol 271:118–124

Yoon SY, Hong E, Kim S, Lee P, Kim M, Yang H, Ryu Y (2012) Optimization of culture medium for enhanced production of exopolysaccharide from Aureobasidium pullulans. Bioprocess Biosyst Eng 35:167–172

Zhao M, Hu Y, Yao H, Huang JS, Li S, Xu H (2022) Sustainable production and characterization of medium molecular weight welan gum produced by a Sphingomonas sp. RW Carbohydr Polym 289:119431

Zhao M, Zhang H, Xu XQ, Li S, Xu H (2021) A strategy for the synthesis of low-molecular-weight welan gum by eliminating capsule form of Sphingomonas strains. Int J Biol Macromol 178:11–18

Funding

This work was financially supported by the National Natural Science Foundation of China (31800075 and U1805234), 863 Program (2015AA020925), Program for Innovative Research Team in Science and Technology in Fujian Province University, 100 Talents Program of Fujian Province, Fujian-Taiwan Science and Technology Cooperation Base of Biomedical Materials and Tissue Engineering (2021D039), Natural Science Foundation of Fujian Province of China, Fundamental Research Funds for the Central Universities and the Development Fund of State Key Laboratory of Heavy Oil Processing (20CX02202A), Engineering Research Center of Industrial Biocatalysis, and Fujian Province Universities (Grant No. ERCIB2020-01).

Author information

Authors and Affiliations

Contributions

Hui Li, Jiqian Wang, and Hu Zhu conceived the idea, directed the work, and drafted the manuscript. Jianlin Liu and Hui Li designed experiments, guided data analysis, and wrote a manuscript draft. Jianlin Liu and Xuanyu Zhang performed the fermentation experiments. Shaohua Ma and Dong Wang performed the rheological properties and molecular mass analysis. Lin Yue and Wei Lu performed the qRT-PCR experiments and Ziyu Zhu analyzed the results. All authors reviewed the manuscript.

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, J., Li, H., Zhang, X. et al. Cost-Efficient Production of the Sphingan WL Gum by Sphingomonas sp. WG Using Molasses and Sucrose as the Carbon Sources. Mar Biotechnol 25, 192–203 (2023). https://doi.org/10.1007/s10126-022-10193-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10126-022-10193-1