Abstract

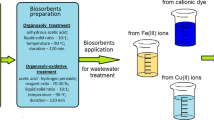

Vinasse is one of the most polluting effluents in the sugar–alcohol industry due to its physicochemical properties. The common methods of treatment are not able to supply all the volume generated, and therefore, efforts are needed to obtain new technologies that are efficient in the management of this waste. So, this work aims to evaluate sugarcane bagasse and peanut shell, as renewable adsorbents, for the removal of organic matter, pH, and turbidity found in vinasse effluent. Commercial activated carbon was used to compare the data. Experimental assays were conducted using the adsorbents under three different concentrations (1:12.5 g L−1; 2:25.0 g L−1; 3:37.5 g L−1) at 3, 6, 12, 24, and 48 h of treatment, under controlled temperature (25 °C) and rotation (200 rpm). The bioadsorbents were able to promote significant removal of organic matters, showing natural adsorbent properties without any previous activation. Major COD removal (63.88%) was observed for the commercially activated carbon after 48 h of treatment and concentration of 37.5 g L−1. For the peanut shell and sugarcane bagasse, the major COD removal was 50.94% and 45.35%, respectively, after 48 h of treatment and concentration of 12.5 g L−1. The final effluent exhibited high residual COD content, indicating the necessity to use a second treatment in sequences, such as biodigestion or ozonolysis.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Brazil is the major ethanol producer in the global market, and it has a key participation in sugarcane agribusiness. According to the CONAB (National Supply Company of Brazil), the harvest of 2019/20 (CONAB 2020) produced 35.6 billion liters of ethanol. Contrary to what occurred in the 2019/2020 season, when the harvest was marked by a record in biofuel production, there was a strong reversal with the reduction in demand for fuels. Thus, the total ethanol production was 32.8 billion liters in the 2020/2021 harvest (CONAB 2021a) and an estimated 24.8 billion for the third 2021/22 harvest report (CONAB 2021b). The sugar–alcohol industry plays a crucial role in the Brazilian economy and technological and social development, with large arable areas, edaphoclimatic conditions favorable to sugarcane, long-term experience, and existing commercial technology (Freitas and Kaneko 2011; Walter et al. 2011; CONAB 2020).

The expansion of the sugar–alcohol industry brought to light problems involving the waste and effluents generated, such as bagasse, straw, filter cake, and boiler ash. Among the effluents created during the process, the vinasse configures as the most polluting due to its physicochemical properties and its greater volume generated, where 11 to 15 L of vinasse are generated for every one liter of ethanol produced (Mutton et al. 2010; Rocha et al. 2012; Lima 2013; Sadeghi et al. 2016). Taking into account the high Brazilian ethanol production, the volume of vinasse generated is worrisome.

The vinasse effluent presents dark brown color and high turbidity, harming the aquatic ecosystem where it was discarded. It is composed primarily of water, organic compounds, suspended solids, and other pollutants. Besides its high chemical oxygen demand (12,000–200,000 mg L−1) or biochemical oxygen demand (45,000–100000 mg L−1), vinasse has high contents of nitrogen, phosphorus, and potassium, which turn them to be considered toxic and may lead to contamination and eutrophication of the site of disposal (Kannan et al. 2006; Lima 2013; Santos et al. 2014; Sadeghi et al. 2016; Fagier et al. 2016). The low pH, electric conductivity, and chemical elements present in sugarcane vinasse may cause changes in the chemical and physical–chemical properties of soils, rivers, and lakes (Christofoletti et al. 2013), and its incorrect disposition into the environment without treatment represents an environmental and public health risk (Chingono et al. 2018).

Among the existent provisions for vinasse, fertigation deserves attention for being the most used technique nowadays. It irrigates and fertilizes the ground, and it provides reduction of the input costs. However, the addition of vinasse in natura to the soil may create various negatives effects such as salinization and organic overload (Laime et al. 2011; Fuess et al. 2017). With the impediment of the release of vinasse in waterways and directly to the soil due to the creation of laws and standards aimed at reducing environmental impacts, the question about the destination of vinasse has become the target of much technological research (Laime et al. 2011; Christofoletti et al. 2013).

Some technologies have been studied in an attempt to solve the vinasse problem such as anaerobic biodigestion (Silva and Abud 2016; Fuess and Zaiat 2018; Fuess et al. 2018; Palacios-Bereche et al. 2020), fertirrigation (Fuess et al. 2018; Nakashima and de Oliveira Junior 2020), concentration (Cortes-Rodríguez et al. 2018; Nakashima and de Oliveira Junior 2020; Palacios-Bereche et al. 2020), composting (Madejón et al. 2001; Wang et al. 2017), combustion and incineration (Cortez and Brossard Pérez 1997; Akram et al. 2015), animal feed manufacturing, and use in construction, and recycling in fermentation and yeast production (Mutton et al. 2010; Laime et al. 2011; Rocha et al. 2012). However, these methods are not able to supply all the volume generated from this effluent, and therefore, efforts are needed to obtain new technologies that are efficient in the management of this waste.

Therefore, adsorption appears as an option for the reduction of organic matter found in the vinasse effluent, being one of the most used and diversified methods (Cunha and Aguiar 2014; El‐Sayed et al. 2019). The use of commercial activated carbon as an adsorbent possesses a great interest for different industry sectors; however, the final cost of the production of this adsorbent and its complex regeneration makes its application on a large scale impracticable. Such fact leads to increase interest in searching for new precursors of low cost and easy obtainment to be used as an adsorbent (Gupta et al. 2011; Cazetta et al. 2014).

The benefit of using renewable adsorbents is the low cost of the raw material, being obtained from industrial, urban, forestry, and agricultural disposals. Besides the economical aspect, the fact that these materials are biodegradable ensures environmental advantages for their use (Boniolo et al. 2010; Brandão et al. 2010; Zhou and Haynes 2012). Although the need for chemical or physical treatment to increase adsorption potential, the use of lignocellulosic adsorbents (also known as bioadsorbents) presents satisfactory and promising results regarding the diminution of contaminants found in residual water (CONAMA 2011; Wan et al. 2017).

An alternative, of low cost, for the sugar–alcohol industries would be the use of bioadsorbents from the residues of vinasse treatment, “performing the residual treatment with residues” (Wan et al. 2017). Specifically, for the vinasse treatment, the sugarcane bagasse and the peanut shell become interesting biomass. For the first, due to the fact of being an important residue of the sugar and alcohol industry (Ge et al. 2017; Ejaz and Sohail 2021) and both (bagasse and vinasse) are available simultaneously at the same site, dismissing expenses in logistics. As for the second, to aggregate value to this residue of low density and great volume. Moreover, as much as the peanut shell is not a residue of the sugar–alcohol process, it is usually nonedible, has great availability and has natural adsorptive properties (OuYang et al. 2014; Taşar et al. 2014; Largitte et al. 2016; Taşar and Özer 2019).

Several studies have evaluated these two residues as adsorbents (Raymundo et al. 2010; Zhang et al. 2013; Quintero et al. 2016; Chingono et al. 2018; Feiqiang et al. 2018; Mahanta et al. 2019; Tomul et al. 2020); however, all go through a process of chemical or physical activation. This increases the costs of these materials and makes them less attractive in the treatment of vinasse. An alternative would be to use them in natura, without any pre-treatment, and evaluate their performance in the adequacy of vinasse characteristics (COD, pH, and turbidity). In addition, the use in natura favors the subsequent burning of these materials in boilers (most common use) and even adds combustion heat to these residues (Seixas et al. 2016). Thus, in this work sugarcane bagasse and peanut shell were evaluated as a potential adsorbent for the removal of organic matter found in vinasse effluent. Commercial activated carbon was also used in the adsorption assays for comparison motives.

Material and methods

Vinasse characterization

The vinasse was acquired at Biosev – Lagoa da Prata Unit, located in the state of Minas Gerais, Brazil. The effluent was collected after the distillation process, without being subjected to any other treatment according to ABNT protocol (NBR 9898/87). It was characterized in natura regarding the pH using a pH meter Digimed DM-22, turbidity using a turbidimeter HI 98703, COD (chemical oxygen demand), and Solids Series by the methodology of Standard Methods for the Examination of Water and Wastewater (APHA 2012). For the COD, the standard closed reflux colorimetric method was used to determine the organic matter content. The readings of absorbance were conducted by using a spectrophotometer (Ionlab IL-592) at the wavelength of 600 nm. The analytic curve was built from the potassium biphthalate standard solution, and the vinasse sample was homogenized and diluted 50 times.

Preparation and characterization of the adsorbents

The sugarcane bagasse and the peanut shell were obtained from local producers, in plantations in the city of Conselheiro Lafaiete, Minas Gerais, Brazil. They were washed using potable water to remove the coarse impurities pursued by simultaneous washings with distilled water. Subsequently, they were dried at 100 °C for 2 h and then at 65 °C for 38 h. The dried bagasse was ground and classified using a vibrating sieve to obtain a particle size less than 14 µm. The crushed sample was then washed with distilled water and dried at 65 °C for 18 h.

The lignocellulosic adsorbents and the commercial analytical standard activated carbon (Êxodo Científica) were characterized. The apparent specific mass was determined according to Brazilian technical standards of determination of apparent specific mass (ABNT 1991). The point of zero charge (pHPZC) was obtained from the 11-points method described by Robles and Regalbuto (2004). The thermogravimetric analysis (TG) was performed on an analyzer DTG-60H of the series C30574800329TK, with air flux of 50 mL min−1 at a heating rate of 10 °C min−1, at 30 to 900 °C. The settlement of superficial groups was made by infrared spectrometry (IV-TF) on a device SHIMADZU using an anhydrous KBr disk. The surface area and porosity were determined by N2 adsorption–desorption analysis (Nova 1200e) at a preparation temperature of 80 °C under a vacuum. Crystalline phases were determined by X-ray diffraction (XRD) in a Rigaku diffractometer (Miniflex 600) operating with CuKα radiation. The goniometer velocity was 1.0° min−1 to the crystalline phases detection at angles from 5° to 90°. The adsorbents’ pH was measured using the methodology described by Huff and Lee (2016), adding 1 g of carbon to 10 ml of distilled water on the Erlenmeyer. The glasses jars were agitated at 110 rpm at 28 °C using a refrigerated incubator (Nova Técnica) for 1 h, and the pH was measured using a pH meter (Digimed DM-22).

Vinasse treatment with activated carbon and bioadsorbents

The vinasse was treated using activated carbon and bioadsorbents of sugarcane bagasse and peanut shell. The assays were performed with the addition of different masses of each adsorbent (0.625 g, 1.25 g, and 1.875 g) at 50 mL of vinasse effluent. The three concentrations were called 1 (12.5 g L−1), 2 (25.0 g L−1), and 3 (37.5 g L−1). Then, they were placed in a shaker (Nova Técnica), with controlled temperature and rotation of 25 °C and 200 rpm, respectively. Four different times intervals (3, 6, 12, 24 e 48 h) were selected for monitoring the adsorption process. Elapsed each time, a sample of the treated effluent was collected and filtered under vacuum conditions, using an 8-µm filter paper, posteriorly it was characterized for its pH, turbidity, and COD, as previously described.

Kinetic models were evaluated to investigate the adsorption mechanism and determine the rates involving adsorption in solid superficies in a solid/liquid adsorption system (Aksu and Tezer 2000; Mesquita et al. 2017). The data were fitted to the four commonly used kinetic models: pseud-first-order, pseud-second-order, intraparticle diffusion, and Elovich equation.

The pseudo-first-order model was one of the first established rate equations for adsorption (Eq. 1), also called the Lagergren equation (Lagergren 1898), and based on the capacity of solids.

In this equation, K1 is the pseudo-first-order adsorption rate constant (min−1), qe is the amount adsorbed in equilibrium (mg g−1), qt is the amount adsorbed in time t (mg g−1), and t is time (min). Integrating Eq. 1 and applying the boundary conditions (t = 0 → qt = 0; t = t → qt = qt), Eq. 2 is obtained. Therefore, you can determine the value of K1 from a graph of ln(qe − qt) versus t (Aksu and Tezer 2000; Li et al. 2020).

The pseudo-second-order model (Eq. 3) is also based on the adsorption capacity of the solid phase and demonstrates the behavior of the process throughout the contact time range (Crini and Badot 2008). It allows predicting the behavior over the whole range of adsorption and is in agreement with an adsorption mechanism being the rate-controlling step (Aksu and Tezer 2000; Li et al. 2020).

In this equation, K2 is the pseudo-second-order adsorption rate constant (g mg−1 min−1). Integrating Eq. 3, applying contour conditions (t = 0 → qt = 0; t = t → qt = qt), and linearizing, Eq. 4 is obtained.

The values of K2 and qe can be obtained through the intercept and the slope of the curve shown in the graph of t/qt versus t.

Elovich equation has been used in some chemisorption processes and slow adsorption kinetics processes. Its linearized shape is given by Eq. 5 (Öztürk and Malkoc 2014; Li et al. 2020)

In this equation, α is the initial rate of adsorption (mg g−1 min−1), β is related to the extent of surface coverage and activation energy for chemisorption (g mg−1).

If intraparticle diffusion is the determining factor of velocity, the intraparticle diffusion model (Eq. 6) should be evaluated and the adsorbed removal varies with the square root of time (Li et al. 2020).

In this equation, Kdiff is the intraparticle diffusion rate constant (mg g−1 min−0.5), C is a constant related to diffusion resistance (mg g−1) and is related to the thickness of the boundary layer (Li et al. 2020).

Results and discussion

Vinasse characterization

The physical–chemical characteristics of crude vinasse effluent are shown in Table 1. The acidic character presented is due to, most of the sulfuric acid addition to the must during the ethanol fermentation (Rocha et al. 2012). Furthermore, the low pH is related to the presence of organic acid in crude vinasse, such as acetate, maleate, citrate, and lactate (Huff and Lee 2016). The CONAMA (The National Environment Council of Brazil) Resolution n° 430/2011 (CONAMA 2011), which provides for conditions and patterns of effluent discharges, requires that the pH of the effluent is between 5 and 9 so that it can be disposed of in a water body. Thus, the pH of 4.16 presented by vinasse indicates the need for a treatment stage to adapt this parameter.

The high concentration of organic compound found in crude vinasse, expressed by its COD value of 42,527.78 mg L−1, is the major factor responsible for the elevated polluting potential of this effluent. The most common organic compounds found in crude vinasse and, consequently, the ones that contribute to a high COD value are ethanol, glycerol, sucrose, glucose, fructose, lactate, acetate, maleate, citrate, oxalate, among others (Parnaudeau et al. 2008; Doelsch et al. 2009).

Crude vinasse effluent presented turbidity of 1390 NTU. Compared with the CONAMA (The National Environment Council of Brazil) Resolution n° 357/2005 (CONAMA 2005), which provides the classification of water bodies and environmental guidelines for its framework, it determines that the freshwaters classes I, II e III exhibit turbidity of 40, 100 and 100 NTU, respectively. In other words, the effluent presents turbidity far above the recommended by the legislation. Thus, if vinasse is released into the water body without prior treatment, it can cause difficulty in penetrating sunlight, impairing photosynthesis and, consequently, the entire aquatic ecosystem (Von Sperling 1996).

The crude effluent exhibited 25,578.67 mg L−1 of total solids, which corresponds to 2.56% of its composition. The volatile solids correspond to the organic matter, and the steady solids represent the inorganic. The predominance of organic solid regarding the inorganic in the vinasse composition (65.9 and 34.1%, respectively) is noted. This predominance is related to the high content of organic compounds, evidenced by the elevated COD value. In contrast, inorganic solids are represented mostly by potassium, sulfur, calcium, nitrogen, phosphorus, and magnesium (Lima 2013).

Vinasse in natura presented a brown and dark color (Fig. 1) and a characteristic sweet odor. In general, when in contact with air, it undergoes oxidation and is associated with the putrefaction of organic matter present in its composition promoting an unpleasant smell (Rolim et al. 2013). Both color and turbidity are mainly caused by the presence of suspended particles and a colloidal state in the effluent (Lima 2013). In vinasse, most of the substances responsible for these characteristics are of organic origin. Its coloring can be attributed mainly to the thermal degradation of reducing sugars and amino compounds and the formation of melanoidins and polyphenolic compounds (Wedzicha and Kaputo 1992; Francisca Kalavathi et al. 2001; Kannan et al. 2006; Mohana et al. 2007).

Adsorbent’s characterization

The characteristics of surface area, total porous volume, and average porous diameter determined by N2 adsorption–desorption tests for activated carbon, sugarcane bagasse, and peanut shell are shown in Table 2.

As expected, commercial activated carbon presented the highest values for surface area, since both sugarcane bagasse and peanut shell did not go through any activation processes. The values are similar to other studies in the literature that also used commercial activated carbon (Dąbrowski et al. 2005; Kumar et al. 2010; Zanella et al. 2015b, a; Haro et al. 2017; Franco et al. 2017). Even without activation, the peanut shell presented a good surface area, but with a relatively low pore volume. A typical mesoporosity is present for both activated carbon and peanut shell, according to the IUPAC classification (2–50 nm). However, according to Tomul et al. (Tomul et al. 2020), prepared biochars have a large amount of microporous that do not present major changes even with thermal treatments. For Murali et al. (2019), peanut shell has immensely good physical–chemical properties, such as high porosity, high surface area, and high electrical conductivity.

Sugarcane bagasse showed a low surface area and macroporosity, according to the IUPAC classification (> 50 nm). Other works have also found the average porous diameter greater than 100 nm for this material in natura (Sousa et al. 2012; Quintero et al. 2016; Mortari et al. 2018; Correa-Navarro et al. 2020). It is important to note that according to Sousa et al. (2012), having large pores does not rule out the use of materials as an adsorbent, since very small pores can be inaccessible depending on the size of the molecules that want to be removed. Another point that these authors raise is that the greater total specific surface area will not only indicate the highest reactivity of the activated carbon. Based on this and knowing that vinasse is a mixture of water, organic matter in the form of organic acids, and cations such as K, Ca, and Mg (Mutton et al. 2010; Laime et al. 2011; Christofoletti et al. 2013), which possibly have several large chain molecules, the in natura bagasse can be an adsorptive potential.

Aiming at a better comprehension of the commercial activated carbon, sugarcane bagasse, and peanut shell properties, characteristics such as apparent density, crystalline structures, point of zero charge (PZC), pH, loss of mass with temperature, and surface groups were also analyzed.

The apparent density of the commercial activated carbon, sugarcane bagasse, and peanut shell was 0.53 g cm−3, 0.10 g cm−3, and 0.34 g cm−3, respectively. The three adsorbents showed low density, demonstrating the importance of agitation during treatment to promote an efficient contact between the adsorbent and the effluent because vinasse has a density similar to that of water (Franco et al. 2017).

The pHPZC for the commercial activated carbon, sugarcane bagasse, and peanut shell was 6.4 ± 0.2, 7.12 ± 0.09, and 7.35 ± 0.08, respectively. The adsorbents, in general, develop charges at the solid/liquid interface due to the dissociation or adsorption of ions from the solution. The characterization of these charges is important concerning the applications of the materials as an adsorbent. The cations’ adsorption is favored by pH > pHPZC, while the anion adsorption is favored by pH < pHPZC (Wang et al. 2011; pdf-103027-43026).

Knowing that the pH of the crude vinasse used in the present work was 4.16, thus presenting values lower than the pHPZC for all studied adsorbents. Therefore, the surface charge of the characterized adsorbents was positive, being ideal for the adsorption of molecules that presented a negative charge in the solution.

While the PZC allows obtaining information about the interactions of the bone char surface with the medium, the evaluation of the interaction with a standard medium allowed obtaining the pH of the adsorbents due to protolytic processes occurring during the immersion of the samples (László et al. 2006). The activated carbon presented an alkaline characteristic (pH = 8.67 ± 0.04), while the sugarcane bagasse (pH = 4.85 ± 0.05) exhibited a more acidic characteristic than the peanut shell (pH = 6.10 ± 0.04). This occurs mainly from the decoupling (hydration) of acids and bases groups presented at the adsorbent surface and the distribution of hydronium ions on an electric double layer (Bagreev et al. 2001).

The amorphous-like structure of the bioadsorbents was determined by the XRD (Fig. 2). The three adsorbents presented a peak of higher intensity em 22° (002) that demonstrates an irregular pairing of (micro) graphitic planes (Yoshizawa et al. 1996; Turk Sekulic et al. 2019; Murali et al. 2019). Commercial activated carbon and peanut shell samples demonstrate a small peak at 43° (100), also referring to (micro) graphitic planes, but indicating the availability of formation of honeycomb structures in carbons (Murali et al. 2019; Tomul et al. 2020). These bands are characteristic of starch materials due to the presence of cellulose, lignin, hemicelluloses (Quintero et al. 2016; Murali et al. 2019). Other peaks may represent some inorganic components, such as quart, whewellite, and calcite minerals (Dehkhoda et al. 2014; Gong et al. 2019; Tomul et al. 2020). In fact, the peak around 27° in commercial activated coal suggests the structure of calcite in the sample (Tomul et al. 2020), possibly more representatively due to the calcination that this sample suffered.

The FTIR spectrums for the three studied adsorbents are shown in Fig. 3. All had shown large and strong bands at 3432 cm−1, which is due to the hydroxyl group –OH (presented in macromolecules as cellulose, hemicellulose, and lignin) and an adsorption band at 2928 cm−1, attributed to the stretch vibration of C–H presented in the cellulose (Feng et al. 2013; Yue et al. 2013). Thus, the presence of “free” hydroxyl groups is higher for sugarcane bagasse than for commercial activated carbon (Taşar and Özer 2019), corroborating with the pH analyses of adsorbents. The observed bands at 1030 cm−1 were attributed to the glycosidic deformation of C–H with the ring vibration and bend of the OH, indicating a β-glycoside bond between glucose and cellulose (Pehlivan et al. 2013; Banerjee et al. 2017). These bands indicate the existence of cellulosic components in the three adsorbents (Garg et al. 2019; Taşar and Özer 2019; Ansari et al. 2021; Ejaz et al. 2021), being more evident in the case of lignocellulosic adsorbents (sugarcane bagasse and peanut shell). The change in the intensity of these bands and peaks suggest structural modification, reduction in the quantity and/or breakdown of cellulose, hemicellulose and lignin bonds (Ejaz et al. 2019; Ansari et al. 2021).

The sugarcane bagasse and the peanut shell exhibited an absorption peak at 1742 cm−1 attributed to the stretching vibration of the carboxyl group, which indicates the existence of ketones or lignin esters. The peaks at 1419 cm−1 are from the bending vibration of CH2 and were creating a small band (Feng et al. 2013; Banerjee et al. 2017). The peak around 1324 cm−1 is due to the stretching vibration of C–N, which corresponds to the amine groups in the structure of the adsorbent (Bhaduri et al. 2016). The band reduction by minor wavelengths of 1000 cm−1 is due, among other effects, to the decreased glycosidic bonds (Li et al. 2016). Furthermore, the small bands at 1457 and around 1164 cm−1 were attributed to the coupling interaction –C–O– and OH of the stretching vibrations –COOH e C–N (Pehlivan et al. 2013). For the sugarcane bagasse, the peak at 1154 cm−1 is attributed to the C=S group. For the activated carbon, the peaks at 1539 cm−1 were from the combination of the stretching vibrations of C=C and C=N (Aziz et al. 2009).

From the FTIR analysis, it is noticed that the peanut shell presents the curves with intermediate intensities indicating a cellulosic matrix less intense than the sugarcane bagasse (Feng et al. 2013; Yue et al. 2013). In fact, the N2 adsorption–desorption tests demonstrate a more porous structure for peanut shell, but not as porous as commercial activated carbon, which presented a surface area 10 times larger. However, the surface characteristics of adsorbents strongly interfere in the vinasse adsorption process along with the specific area of the samples (Seixas et al. 2016), indicating the possibility of functional groups of sugarcane bagasse and peanut shell allowing interactions with different effluent molecules (Bansal et al. 1988; Seixas et al. 2016). The functional groups present in adsorbents can be binding to organic acids (in large quantity in vinasse) (Seixas et al. 2016). The anionic form of melanoidins could be adsorbed through electrostatic interaction between carboxylic and amino groups (Bai and Abraham 2002; Park et al. 2005; Sánchez-Galván et al. 2015).

By the thermogravimetric analysis (Fig. 4), the total mass loss was 87.4%, 96.1%, and 97.3% for the commercial activated carbon, the sugarcane bagasse, and the peanut shell, respectively. All the adsorbents were decomposed thermally in three stages. The first stage, around 200 °C, corresponds to the intrinsic and extrinsic water vaporization of the samples (Wu et al. 2012; Lins et al. 2020). The mass loss at this stage was 10% for all three adsorbents.

The second stage corresponds to a large thermal decomposition. For the sugarcane bagasse and the peanut shell, it starts at 200 °C and finishes at 500 °C, and it refers to the organic matter degradation. The two bands of DTG, that comprehend the region with greater mass loss, are related to hemicellulose, lignin, and cellulose degradation. The first between 220 and 340 °C is considered the first hemicellulose decomposition zone and the outset of cellulose decomposition. At this range, the mass loss was 44.1% for the sugarcane bagasse and 62.27% for the peanut shell. The second, between 340 and 500 °C, may be related to lignin and cellulose decomposition. The entire decomposition finishes at 450 °C, and the volatile compounds and the remaining residues are charred and released (Wu et al. 2012). At this range, the mass loss was 41.62% for the sugarcane bagasse and 25.08% for the peanut shell. In the third stage, from 500 to 900 °C, it occurs a small mass loss due to the eventual carbonization of the residue, and a stable mass is noticed for a time until the end of heating.

For the activated carbon, the decomposition range of cellulose, hemicellulose, and lignin has only 10% mass loss, corroborating with the FTIR analysis. The second stage for this adsorbent is reported between 400 and 660 °C, and it shows a mass loss of 76.3%. The commercial activated carbon exhibited thermal stability, and it started to be degraded at larger temperatures than 400 °C. Likely, pyrolysis may occur at this temperature.

Vinasse treatment by adsorption

The graphics of Fig. 5 display the organic load ratio (C/C0) during the vinasse treatment time using three adsorbents at different concentrations (1, 2, and 3), as defined in item 2.3. This ratio is defined as the concentration of the organic compound for a certain time (C) by the initial organic compounds concentration (C0). According to the data presented in Fig. 5, assays using activated carbon presented higher adsorption efficiency for the removal of organic matter than the lignocellulosic adsorbents. Because carbon adsorbents undergo physical and/or chemical activation processes, it is noticed that the behavior of the curves for the commercial activated carbon was similar for the three tested proportions (12.5 g L−1, 25.0 g L−1, and 37.5 g L−1), with increased COD removal with increased adsorbent proportion.

Knowing that the initial COD (C0) was 42,527.78 mg L−1, the COD values after 3 h and 48 h were similar and inferior to the COD values obtained after 6, 12, and 24 h for the commercial activated carbon, indicating organic matter variations during the adsorptive process until it reaches equilibrium. Oscillations in the data and similar behaviors of the curves were also observed in studies involving the treatment of vinasse with different adsorbents from those evaluated in this study (Caqueret et al. 2008; Hadavifar et al. 2016; Chingono et al. 2018). The highest organic matter removal obtained was 63.88% after 48 h of adsorption using 37.5 g L−1 (Fig. 5c); on the other hand, removal efficiencies of 58.14% and 57.48% were observed after 3 h of adsorption using the proportion of 25.0 g L−1 (Fig. 5b) and 37.5 g L−1 (Fig. 5c), respectively.

Regarding the lignocellulosic adsorbents, the peanut shell exhibited a more efficient behavior in organic matter removal than the sugarcane bagasse. The treatments with bioadsorbents of peanut shell presented a tendency to decrease the COD during the adsorption process, showing efficiencies of 50.94% (Fig. 5a), 45.74% (Fig. 5b) and 46.46% (Fig. 5c) during the 48 h of adsorption assays.

As for the treatments using sugarcane bagasse, the highest removal efficiencies were also observed after 48-h reaching values of 45.35% (Fig. 5a) and 44.75% (Fig. 5b). On the other hand, the adsorption assays using concentration 3 (Fig. 5c) exhibited low removal efficiency of approximately 17%. The inferior removal efficiencies observed for concentration 3 (Fig. 5c) can be associated with the low density presented by the bioadsorbents, thus occupying higher volumes, which may difficult for mass transfer during the adsorption process.

Although the studied adsorbents showed promising potential in reducing the organic matter found in crude vinasse effluent, it is worthy to notice that the residual COD values after adsorption treatment are still relevant for all cases. For example, a concentration of residual organic matter of approximately 15,000 mg L−1 was observed at the end of the adsorption process using activated carbon under optimum operational conditions.

On the other hand, peanut shell and sugarcane bagasse, without passing through any physical or chemical activation process, were able to remove significant quantities of organic matter. Although the minimum requirements from the environment legislation were not attained, the vinasse treatment by bioadsorption can be turned technically possible when associated with a posterior treatment state, acting as a pre-treatment.

In the investigation of the adsorption kinetics, it was found that the pseudo-second-order model was the one that best fit the data, with R2 higher than 0.95. Table 3 shows the R2 values obtained for all kinetic models evaluated in this work. As the pseudo-first-order, Elovich equation, and intraparticle diffusion models had a low R2, their regressions were not presented in this work. The regressions obtained for the pseudo-second-order model are shown in Fig. 6, and Table 4 demonstrates the values of adsorptive capacity in the balance and constant of the pseudo-second-order adsorption rate (g mg−1 min−1).

It is verified that the adsorptive capacity in equilibrium calculated by the pseudo-second-order model is higher, in all adsorbent concentrations, for commercial activated carbon. In fact, better performance of this adsorbent was expected due to its larger surface area caused by thermal activation (Caqueret et al. 2008, 2012; Daragon et al. 2014; Seixas et al. 2016; Taşar and Özer 2019). Meanwhile, the peanut shell had better adsorptive capacity than sugarcane bagasse, except at concentration 2. The peanut in natura presented good prospects by the characterization and was proven by its greater removal of COD from vinasse. The bagasse, even with a low surface area, ensured a small but expressive performance for a material without any treatment. This indicates a great potential for use since both are residues of the same industry and can apply it as a pre-treatment of vinasse, with a possible increase in its calorific capacity.

A graph of pH behavior over time for the treatment of vinasse with activated carbon and bioadsorbents in natura is shown in Fig. 7. None of the treatments were able to approximate the pH of the effluent to neutrality. This inefficiency can be justified by the fact that both adsorbents present a positive surface load when in contact with vinasse (pH 4.10) and, due to this, are unable to adsorption H+ ions, which are responsible for the high acidity of vinasse. The treatments with bioadsorbents practically did not alter the pH of the effluent, while the treatments with activated carbon, even if little, promoted an increase in the pH of vinasse of 3.56% (concentration 1), 9.02% (concentration 2) and 13.66% (concentration 3). This difference occurs due to the difference between the pHs of adsorbents, which are 4.85 for sugarcane bagasse, 6.10 for peanut shell, and 8.67 for activated carbon. The alkaline character of the commercial activated carbon (as demonstrated before) was responsible for the slight increase in the pH of vinasse, and the higher the amount of adsorbent used, the higher the final pH (Bagreev et al. 2001; László et al. 2006; Huff and Lee 2016).

A graph of turbidity behavior over time for the treatment of vinasse with activated carbon and bioadsorbents in natura is shown in Fig. 8. It is observed that, in general, activated carbon obtained better results for the removal of turbidity from vinasse. In addition, the treatment with the bioadsorbents showed greater oscillation over time when compared to the treatment with activated carbon.

For all treatments using the three adsorbents, most of the results showed at least 50% of turbidity removal. However, in only 3 treatments vinasse presented turbidity lower than 100 NTU, the maximum value allowed by CONAMA Resolution n° 357/05, Brazil (CONAMA 2005). All these treatments were with activated carbon, with a final turbidity of 20.3 NTU (concentration 1 with 48 h; 98.5% removal), 55.8 NTU (concentration 2 with 48 h; 96.0% removal) and 67.1 NTU (concentration 1 with 24 h; 95.2% removal). Among the treatments with peanut shell, in general, the best results were obtained from treatments with the concentration of adsorbent/effluent, at times of 6, 24, and 48 h, which presented, respectively, final turbidity of 195 NTU (86.0% removal), 176 NTU (87.3% removal) and 206 NTU (85.2% removal). For sugarcane bagasse, the best removals occurred with 6 h for concentrations 1 and 2 (91.4% and 85.1%, respectively) and 48 h for concentration 3 (80.4%).

It is observed that, in general, the amount of adsorbent directly influences the removal of turbidity, so a higher adsorbent/effluent ratio allows obtaining lower turbidity values at each given time (Seixas et al. 2016; Hadavifar et al. 2016; Petta et al. 2017). Time also had a great influence on the removal process. After the solid/liquid contact time of 3 h, the removal rate decreased tending to remain constant after 24 h. This behavior was expected because at the beginning of the adsorption process there are a large number of free pores that decrease with the time of the adsorption process. After a certain time, adsorbent saturation occurs and the removal rate tends to remain constant (Srivastava et al. 2006; Safari et al. 2018; Taşar and Özer 2019). T. The values for sugarcane bagasse in natura showed quite irregular data, mainly due to its natural character, with low surface area, large pores, and for not having performed any heat or chemical treatment in it (Seixas et al. 2016).

Conclusion

Alternative adsorbents, such as agro-industrial residues, have the potential to be used as a bioadsorbent for the removal of organic matter found in different industrial effluents due to their high adsorption capacity. In this work, sugarcane bagasse and peanut shell were tested for their ability to adsorb contaminants found in vinasse effluent. According to the obtained results, these were capable to remove between 45 and 50% of the total organic matter, without any previous physical and/or chemical activation. Commercial activated carbon obtained better results for the removal of turbidity from vinasse, but the efficiency of up to 87.3% and 91.4% were achieved with the peanut shell and sugarcane bagasse, respectively. None of the treatments were able to approximate the pH of the effluent to neutrality. The kinetic model of pseudo-second-order was the best that adjusted to the data. Further studies must be conducted to optimize the operational conditions of the adsorption assays using these renewable residues, aiming to elevate their removal efficiency of organic matter.

Data availability

The data used in this study can be provided by the corresponding author on reasonable request.

References

ABNT (1991) NBR 12076/1991 - Carvão ativado pulverizado: Determinação da massa especifica aparente. Assoc Bras Normas Técnicas, Rio Janeiro

Akram M, Tan CK, Garwood R, Thai SM (2015) Vinasse—a potential biofuel—cofiring with coal in a fluidised bed combustor. Fuel 158:1006–1015. https://doi.org/10.1016/j.fuel.2015.06.036

Aksu Z, Tezer S (2000) Equilibrium and kinetic modelling of biosorption of Remazol Black B by Rhizopus arrhizus in a batch system: effect of temperature. Process Biochem 36(5):431–439. https://doi.org/10.1016/S0032-9592(00)00233-8

Ansari M, Zafar U, Ejaz U, Sohail M, Pirzada A, Aman A (2021) Comparison of composting of chemically pretreated and fermented sugarcane bagasse for zero-waste biorefinery. J Mater Cycles Waste Manag 23(3):911–921. https://doi.org/10.1007/s10163-021-01176-w

APHA (2012) Standard methods for the examination of water and wastewater. Americam Public Health Association, Washington

Aziz A, Elandaloussi EH, Belhalfaoui B, Ouali MS, De Ménorval LC (2009) Efficiency of succinylated-olive stone biosorbent on the removal of cadmium ions from aqueous solutions. Colloids Surf B Biointerface 73(2):192–198. https://doi.org/10.1016/j.colsurfb.2009.05.017

Bagreev A, Adib F, Bandosz TJ (2001) pH of activated carbon surface as an indication of its suitability for H2S removal from moist air streams. Carbon 39(12):1897–1905. https://doi.org/10.1016/S0008-6223(00)00317-1

Bai RS, Abraham TE (2002) Studies on enhancement of Cr(VI) biosorption by chemically modified biomass of Rhizopus nigricans. Water Res 36(5):1224–1236. https://doi.org/10.1016/S0043-1354(01)00330-X

Banerjee M, Bar N, Basu RK, Das SK (2017) Comparative study of adsorptive removal of Cr(VI) ion from aqueous solution in fixed bed column by peanut shell and almond shell using empirical models and ANN. Environ Sci Pollut Res 24(11):10604–10620. https://doi.org/10.1007/s11356-017-8582-8

Bansal RC, Donnet J-B, Stoeckli F (1988) Active carbon, 1st edn. Marcel Dekker, New York

Bhaduri D, Saha A, Desai D, Meena HN (2016) Restoration of carbon and microbial activity in salt-induced soil by application of peanut shell biochar during short-term incubation study. Chemosphere 148:86–98. https://doi.org/10.1016/j.chemosphere.2015.12.130

Boniolo MR, Yamaura M, Monteiro RA (2010) Biomassa residual para remoção de íons uranilo. Quim Nova 33(3):547–551. https://doi.org/10.1590/S0100-40422010000300010

Brandão PC, Souza TC, Ferreira CA, Hori CE, Romanielo LL (2010) Removal of petroleum hydrocarbons from aqueous solution using sugarcane bagasse as adsorbent. J Hazard Mater 175(1–3):1106–1112. https://doi.org/10.1016/j.jhazmat.2009.10.060

Caqueret V, Bostyn S, Cagnon B, Fauduet H (2008) Purification of sugar beet vinasse—adsorption of polyphenolic and dark colored compounds on different commercial activated carbons. Bioresour Technol 99(13):5814–5821. https://doi.org/10.1016/j.biortech.2007.10.009

Caqueret V, Cagnon B, Bostyn S, Fauduet H (2012) Removal of dark coloured and polyphenolic compounds of sugar beet vinasse by adsorption onto activated carbons: application to a crosscurrent adsorption process. Can J Chem Eng 90(2):403–411. https://doi.org/10.1002/cjce.20550

Cazetta AL, Azevedo SP, Pezoti O, Souza LS, Vargas AMM, Paulino AT, Moraes JCG, Almeida VC (2014) Thermally activated carbon from bovine bone: optimization of synthesis conditions by response surface methodology. J Anal Appl Pyrolysis 110:455–462. https://doi.org/10.1016/j.jaap.2014.10.022

Chingono KE, Sanganyado E, Bere E, Yalala B (2018) Adsorption of sugarcane vinasse effluent on bagasse fly ash: a parametric and kinetic study. J Environ Manage 224:182–190. https://doi.org/10.1016/j.jenvman.2018.07.042

Christofoletti CA, Escher JP, Correia JE, Marinho JFU, Fontanetti CS (2013) Sugarcane vinasse: environmental implications of its use. Waste Manag 33(12):2752–2761. https://doi.org/10.1016/j.wasman.2013.09.005

CONAB (2020) Acompanhamento da Safra Brasileira de Cana-de-Açúcar - Safra 2019/20. In: Obs. Agrícola. http://www.conab.gov.br. Accessed 28 Mar 2022

CONAB (2021a) Acompanhamento da Safra Brasileira de Cana-de-Açúcar - Safra 2020/21. In: Obs. Agrícola. http://www.conab.gov.br. Accessed 28 Mar 2022

CONAB (2021b) Acompanhamento da Safra Brasileira de Cana-de-Açúcar - Safra 2021/22. In: Obs. Agrícola. http://www.conab.gov.br. Accessed 28 Mar 2022

CONAMA (2005) Resolution 357/2005. In: Cons. Nac. do Meio Ambient. https://www.braziliannr.com/brazilian-environmental-legislation/conama-resolution-35705/. Accessed 25 Mar 2022

CONAMA (2011) Resolution 430/2011. In: Cons. Nac. do Meio Ambient. http://www.mma.gov.br/port/conama/res/res11/res43011.pdf. Accessed 25 Mar 2022

Correa-Navarro YM, Giraldo L, Moreno-Piraján JC (2020) Biochar from fique bagasse for remotion of caffeine and diclofenac from aqueous solution. Molecules 25(8):1849. https://doi.org/10.3390/molecules25081849

Cortes-Rodríguez EF, Fukushima NA, Palacios-Bereche R, Ensinas AV, Nebra SA (2018) Vinasse concentration and juice evaporation system integrated to the conventional ethanol production process from sugarcane—heat integration and impacts in cogeneration system. Renew Energy 115:474–488. https://doi.org/10.1016/j.renene.2017.08.036

Cortez LAB, Brossard Pérez LE (1997) Experiences on vinasse disposal: part III: combustion of vinasse—fuel oil emulsions. Brazilian J Chem Eng 14(1):9–18. https://doi.org/10.1590/S0104-66321997000100002

Crini G, Badot P-M (2008) Application of chitosan, a natural aminopolysaccharide, for dye removal from aqueous solutions by adsorption processes using batch studies: a review of recent literature. Prog Polym Sci 33(4):399–447. https://doi.org/10.1016/j.progpolymsci.2007.11.001

Cunha FS, Aguiar AP (2014) Methods for the removal of phenolic derivatives from aqueous effluents. Rev Virtual Química. https://doi.org/10.5935/1984-6835.20140052

da Mesquita PL, Cruz MAP, Souza CR, Santos NTG, Nucci ER, Rocha SDF (2017) Removal of refractory organics from saline concentrate produced by electrodialysis in petroleum industry using bone char. Adsorption 23(7–8):983–997. https://doi.org/10.1007/s10450-017-9917-y

Dąbrowski A, Podkościelny P, Hubicki Z, Barczak M (2005) Adsorption of phenolic compounds by activated carbon—a critical review. Chemosphere 58(8):1049–1070. https://doi.org/10.1016/j.chemosphere.2004.09.067

Daragon G, Trouvé G, Schönnenbeck C, Leyssens G (2014) Recovery of an agro-industrial vinasse by adsorption on different wood materials: parametric study at laboratory scale. BioResources. https://doi.org/10.15376/biores.9.4.7984-8001

de Sousa JC, Pereira NC, de Carvalho MLM, Ferro R (2012) Production and characterization of water-steam activated carbons made from sugarcane bagasse and molasses pellets. Acta Sci Technol. https://doi.org/10.4025/actascitechnol.v34i1.8999

Dehkhoda AM, Ellis N, Gyenge E (2014) Electrosorption on activated biochar: effect of thermo-chemical activation treatment on the electric double layer capacitance. J Appl Electrochem 44(1):141–157. https://doi.org/10.1007/s10800-013-0616-4

Doelsch E, Masion A, Cazevieille P, Condom N (2009) Spectroscopic characterization of organic matter of a soil and vinasse mixture during aerobic or anaerobic incubation. Waste Manag 29(6):1929–1935. https://doi.org/10.1016/j.wasman.2008.12.009

Ejaz U, Sohail M (2021) Sugarcane bagasse: a promising substrate for solid-state fermentation. Green sustainable process for chemical and environmental engineering and science. Elsevier, pp 1–13

Ejaz U, Muhammad S, Ali FI, Hashmi IA, Sohail M (2019) Methyltrioctylammonium chloride mediated removal of lignin from sugarcane bagasse for themostable cellulase production. Int J Biol Macromol 140:1064–1072. https://doi.org/10.1016/j.ijbiomac.2019.08.206

Ejaz U, Wasim AA, Khan MN, Alzahrani OM, Mahmoud SF, El-Bahy ZM, Sohail M (2021) Use of ionic liquid pretreated and fermented sugarcane bagasse as an adsorbent for Congo red removal. Polymers (Basel) 13(22):3943. https://doi.org/10.3390/polym13223943

El-Sayed SA, Ismail MA, Mostafa ME (2019) Thermal decomposition and combustion characteristics of biomass materials using TG/DTG at different high heating rates and sizes in the air. Environ Prog Sustain Energy 38(4):13124. https://doi.org/10.1002/ep.13124

Fagier MA, Ali EA, Tay KS, Abas MRB (2016) Mineralization of organic matter from vinasse using physicochemical treatment coupled with Fe2+-activated persulfate and peroxymonosulfate oxidation. Int J Environ Sci Technol 13(4):1189–1194. https://doi.org/10.1007/s13762-016-0963-x

Feiqiang G, Xiaolei L, Xiaochen J, Xingmin Z, Chenglong G, Zhonghao R (2018) Characteristics and toxic dye adsorption of magnetic activated carbon prepared from biomass waste by modified one-step synthesis. Colloids Surf Physicochem Eng Asp 555:43–54. https://doi.org/10.1016/j.colsurfa.2018.06.061

Feng Y, Dionysiou DD, Wu Y, Zhou H, Xue L, He S, Yang L (2013) Adsorption of dyestuff from aqueous solutions through oxalic acid-modified swede rape straw: adsorption process and disposal methodology of depleted bioadsorbents. Bioresour Technol 138:191–197. https://doi.org/10.1016/j.biortech.2013.03.146

Francisca Kalavathi D, Uma L, Subramanian G (2001) Degradation and metabolization of the pigment—melanoidin in distillery effluent by the marine cyanobacterium Oscillatoria boryana BDU 92181. Enzyme Microb Technol 29(4–5):246–251. https://doi.org/10.1016/S0141-0229(01)00383-0

Franco MAE, Carvalho CB, Bonetto MM, de Soares RP, Féris LA (2017) Removal of amoxicillin from water by adsorption onto activated carbon in batch process and fixed bed column: kinetics, isotherms, experimental design and breakthrough curves modelling. J Clean Prod 161:947–956. https://doi.org/10.1016/j.jclepro.2017.05.197

Freitas LC, Kaneko S (2011) Ethanol demand in Brazil: regional approach. Energy Policy 39(5):2289–2298. https://doi.org/10.1016/j.enpol.2011.01.039

Fuess LT, Zaiat M (2018) Economics of anaerobic digestion for processing sugarcane vinasse: applying sensitivity analysis to increase process profitability in diversified biogas applications. Process Saf Environ Prot 115:27–37. https://doi.org/10.1016/j.psep.2017.08.007

Fuess LT, Rodrigues IJ, Garcia ML (2017) Fertirrigation with sugarcane vinasse: foreseeing potential impacts on soil and water resources through vinasse characterization. J Environ Sci Heal Part A 52(11):1063–1072. https://doi.org/10.1080/10934529.2017.1338892

Fuess LT, Garcia ML, Zaiat M (2018) Seasonal characterization of sugarcane vinasse: assessing environmental impacts from fertirrigation and the bioenergy recovery potential through biodigestion. Sci Total Environ 634:29–40. https://doi.org/10.1016/j.scitotenv.2018.03.326

Garg D, Kumar S, Sharma K, Majumder CB (2019) Application of waste peanut shells to form activated carbon and its utilization for the removal of acid yellow 36 from wastewater. Groundw Sustain Dev 8:512–519. https://doi.org/10.1016/j.gsd.2019.01.010

Ge M, Du M, Zheng L, Wang B, Zhou X, Jia Z, Hu G, Jahangir Alam SM (2017) A maleic anhydride grafted sugarcane bagasse adsorbent and its performance on the removal of methylene blue from related wastewater. Mater Chem Phys 192:147–155. https://doi.org/10.1016/j.matchemphys.2017.01.063

Gong X, Zhao R, Peng M, Wang D (2019) Experimental study on NO removal by surface activated bamboo charcoal. Atmos Pollut Res 10(2):474–479. https://doi.org/10.1016/j.apr.2018.09.007

Gupta VK, Agarwal S, Saleh TA (2011) Chromium removal by combining the magnetic properties of iron oxide with adsorption properties of carbon nanotubes. Water Res 45(6):2207–2212. https://doi.org/10.1016/j.watres.2011.01.012

Hadavifar M, Younesi H, Zinatizadeh AA, Mahdad F, Li Q, Ghasemi Z (2016) Application of integrated ozone and granular activated carbon for decolorization and chemical oxygen demand reduction of vinasse from alcohol distilleries. J Environ Manage 170:28–36. https://doi.org/10.1016/j.jenvman.2016.01.009

Haro NK, Del Vecchio P, Marcilio NR, Féris LA (2017) Removal of atenolol by adsorption—study of kinetics and equilibrium. J Clean Prod 154:214–219. https://doi.org/10.1016/j.jclepro.2017.03.217

Huff MD, Lee JW (2016) Biochar-surface oxygenation with hydrogen peroxide. J Environ Manage 165:17–21. https://doi.org/10.1016/j.jenvman.2015.08.046

Kannan N, Karthikeyan G, Tamilselvan N (2006) Comparison of treatment potential of electrocoagulation of distillery effluent with and without activated Areca catechu nut carbon. J Hazard Mater 137(3):1803–1809. https://doi.org/10.1016/j.jhazmat.2006.05.048

Kumar PS, Vincent C, Kirthika K, Kumar KS (2010) Kinetics and equilibrium studies of Pb2+ in removal from aqueous solutions by use of nano-silversol-coated activated carbon. Brazilian J Chem Eng 27(2):339–346. https://doi.org/10.1590/S0104-66322010000200012

Lagergren S (1898) Zur theorie der sogenannten adsorption geloster stoffe. K Sven Vetenskapsakademiens Handl 24:1–39

Laime EM, Fernandes PD, de Oliveira DCS, de Freire EA (2011) Possibilidades tecnológicas para a destinação da vinhaça. Rev Trópica Ciências Agrárias e Biológicas. https://doi.org/10.0000/rtcab.v5i3.260

Largitte L, Brudey T, Tant T, Dumesnil PC, Lodewyckx P (2016) Comparison of the adsorption of lead by activated carbons from three lignocellulosic precursors. Microporous Mesoporous Mater 219:265–275. https://doi.org/10.1016/j.micromeso.2015.07.005

László K, Podkościelny P, Dąbrowski A (2006) Heterogeneity of activated carbons with different surface chemistry in adsorption of phenol from aqueous solutions. Appl Surf Sci 252(16):5752–5762. https://doi.org/10.1016/j.apsusc.2005.07.027

Li C, Chen N, Zhao Y, Li R, Feng C (2016) Polypyrrole-grafted peanut shell biological carbon as a potential sorbent for fluoride removal: Sorption capability and mechanism. Chemosphere 163:81–89. https://doi.org/10.1016/j.chemosphere.2016.08.016

Li X, Kuang Y, Chen J, Wu D (2020) Competitive adsorption of phosphate and dissolved organic carbon on lanthanum modified zeolite. J Colloid Interface Sci 574:197–206. https://doi.org/10.1016/j.jcis.2020.04.050

Lima HHS de (2013) Tratamento físico-químico da vinhaça por coagulação e adsorção em carvão ativado do bagaço da cana de açúcar. Master Dissertation, Federal University of Paraíba

Lins PVS, Henrique DC, Ide AH, da Duarte Silva JL, Dotto GL, Yazidi A, Sellaoui L, Erto A, Zanta CL, de Silva PE, Meili L (2020) Adsorption of a non-steroidal anti-inflammatory drug onto MgAl/LDH-activated carbon composite—experimental investigation and statistical physics modeling. Colloids Surf Physicochem Eng Asp 586:124217. https://doi.org/10.1016/j.colsurfa.2019.124217

Madejón E, Dı́az MJ, López R, Cabrera F (2001) Co-composting of sugarbeet vinasse influence of the organic matter nature of the bulking agents used. Bioresour Technol 76(3):275–278. https://doi.org/10.1016/S0960-8524(00)00126-7

Mahanta V, Raja M, Kothandaraman R (2019) Activated carbon from sugarcane bagasse as a potential positive electrode catalyst for vanadium redox flow battery. Mater Lett 247:63–66. https://doi.org/10.1016/j.matlet.2019.03.045

Mohana S, Desai C, Madamwar D (2007) Biodegradation and decolourization of anaerobically treated distillery spent wash by a novel bacterial consortium. Bioresour Technol 98(2):333–339. https://doi.org/10.1016/j.biortech.2005.12.024

Mortari DA, Torquato LDM, Crespi MS, Crnkovic PM (2018) Co-firing of blends of sugarcane bagasse and coal. J Therm Anal Calorim 132(2):1333–1345. https://doi.org/10.1007/s10973-018-6996-2

Murali G, Harish S, Ponnusamy S, Ragupathi J, Therese HA, Navaneethan M, Muthamizhchelvan C (2019) Hierarchically porous structured carbon derived from peanut shell as an enhanced high rate anode for lithium ion batteries. Appl Surf Sci 492:464–472. https://doi.org/10.1016/j.apsusc.2019.06.142

Mutton MA, Rossetto R, Mutton MJR (2010) Utilização agrícola da vinhaça. In: Bioetanol de cana-de-açúcar: P&D para produtividade e sustentabilidade. Blucher, São Paulo

Nakashima RN, de Oliveira JS (2020) Comparative exergy assessment of vinasse disposal alternatives: concentration, anaerobic digestion and fertirrigation. Renew Energy 147:1969–1978. https://doi.org/10.1016/j.renene.2019.09.124

OuYang XK, Yang LP, Wen ZS (2014) Adsorption of Pb(II) from solution using peanut shell as biosorbent in the presence of amino acid and sodium chloride. BioResources. https://doi.org/10.15376/biores.9.2.2446-2458

Öztürk A, Malkoc E (2014) Adsorptive potential of cationic basic yellow 2 (BY2) dye onto natural untreated clay (NUC) from aqueous phase: mass transfer analysis, kinetic and equilibrium profile. Appl Surf Sci 299:105–115. https://doi.org/10.1016/j.apsusc.2014.01.193

Palacios-Bereche MC, Palacios-Bereche R, Nebra SA (2020) Comparison through energy, exergy and economic analyses of two alternatives for the energy exploitation of vinasse. Energy 197:117231. https://doi.org/10.1016/j.energy.2020.117231

Park D, Yun Y-S, Park JM (2005) Studies on hexavalent chromium biosorption by chemically-treated biomass of Ecklonia sp. Chemosphere 60(10):1356–1364. https://doi.org/10.1016/j.chemosphere.2005.02.020

Parnaudeau V, Condom N, Oliver R, Cazevieille P, Recous S (2008) Vinasse organic matter quality and mineralization potential, as influenced by raw material, fermentation and concentration processes. Bioresour Technol 99(6):1553–1562. https://doi.org/10.1016/j.biortech.2007.04.012

Pehlivan E, Tran HT, Ouédraogo WKI, Schmidt C, Zachmann D, Bahadir M (2013) Sugarcane bagasse treated with hydrous ferric oxide as a potential adsorbent for the removal of As(V) from aqueous solutions. Food Chem 138(1):133–138. https://doi.org/10.1016/j.foodchem.2012.09.110

Petta L, De Gisi S, Casella P, Farina R, Notarnicola M (2017) Evaluation of the treatability of a winery distillery (vinasse) wastewater by UASB, anoxic-aerobic UF-MBR and chemical precipitation/adsorption. J Environ Manage 201:177–189. https://doi.org/10.1016/j.jenvman.2017.06.042

Quintero JA, Dávila JA, Moncada J, Giraldo OH, Cardona Alzate CA (2016) Análisis y caracterización de materiales amiláceos y celulósicos después de modificación enzimática. DYNA 83(197):44. https://doi.org/10.15446/dyna.v83n197.42729

Raymundo AS, Zanarotto R, Belisário M, Pereira MDG, Ribeiro JN, Ribeiro AVFN (2010) Evaluation of sugar-cane bagasse as bioadsorbent in the textile wastewater treatment contaminated with carcinogenic congo red dye. Brazilian Arch Biol Technol 53(4):931–938. https://doi.org/10.1590/S1516-89132010000400023

Robles JO, Regalbuto JR (2004) The engineering of Pt/carbon catalyst preparation for application on proton exchange fuel cell membrane (PEFCM)

Rocha MH, Neto AE, Salomon KR, Lora EES, Venturini OJ, Olmo OA, Rambla MAO (2012) Resíduos da produção de biocombustíveis: vinhaça e glicerina. In: Biocombustíveis: vol 2. Interciência, Rio de Janeiro 691–809

Rolim MM, Lyra MRCC, Duarte ADS, Fernandes PRM, De França Silva EF, Pedrosa EMR (2013) Influence of a vinasse-distributing lake on water quality of the groundwater. Ambient e Agua Interdiscip J Appl Sci. https://doi.org/10.4136/ambi-agua.1014

Sadeghi SH, Hazbavi Z, Harchegani MK (2016) Controllability of runoff and soil loss from small plots treated by vinasse-produced biochar. Sci Total Environ 541:483–490. https://doi.org/10.1016/j.scitotenv.2015.09.068

Safari M, Khataee A, DarvishiCheshmehSoltani R, Rezaee R (2018) Ultrasonically facilitated adsorption of an azo dye onto nanostructures obtained from cellulosic wastes of broom and cooler straw. J Colloid Interface Sci 522:228–241. https://doi.org/10.1016/j.jcis.2018.03.076

Sánchez-Galván G, Torres-Quintanilla E, Sayago J, Olguín EJ (2015) Color removal from anaerobically digested sugar cane stillage by biomass from invasive macrophytes. Water Air Soil Pollut 226(4):110. https://doi.org/10.1007/s11270-015-2386-6

Santos SC, Rosa PRF, Sakamoto IK, AmâncioVaresche MB, Silva EL (2014) Hydrogen production from diluted and raw sugarcane vinasse under thermophilic anaerobic conditions. Int J Hydrog Energy 39(18):9599–9610. https://doi.org/10.1016/j.ijhydene.2014.04.104

Seixas FL, Gimenes ML, Fernandes-Machado NRC (2016) Treatment of vinasse bt adsorption on carbon from sugar cane bagasse. Quim Nova. https://doi.org/10.5935/0100-4042.20160013

Silva CEDF, Abud AKDS (2016) Anaerobic biodigestion of sugarcane vinasse under mesophilic conditions using manure as inoculum. Ambient e Agua Interdiscip J Appl Sci 11(4):763. https://doi.org/10.4136/ambi-agua.1897

Von Sperling M (1996) Introdução à qualidade das águas e ao tratamento de esgotos, 3rd edn. Editora UFMG, Belo Horizonte

Srivastava VC, Swamy MM, Mall ID, Prasad B, Mishra IM (2006) Adsorptive removal of phenol by bagasse fly ash and activated carbon: equilibrium, kinetics and thermodynamics. Colloids Surf Physicochem Eng Asp 272(1–2):89–104. https://doi.org/10.1016/j.colsurfa.2005.07.016

Taşar Ş, Özer A (2019) A thermodynamic and kinetic evaluation of the adsorption of Pb(II) ions using peanut (Arachis Hypogaea) shell-based biochar from Aqueous Media. Polish J Environ Stud 29(1):293–305. https://doi.org/10.15244/pjoes/103027

Taşar Ş, Kaya F, Özer A (2014) Biosorption of lead(II) ions from aqueous solution by peanut shells: equilibrium, thermodynamic and kinetic studies. J Environ Chem Eng 2(2):1018–1026. https://doi.org/10.1016/j.jece.2014.03.015

Tomul F, Arslan Y, Kabak B, Trak D, Kendüzler E, Lima EC, Tran HN (2020) Peanut shells-derived biochars prepared from different carbonization processes: comparison of characterization and mechanism of naproxen adsorption in water. Sci Total Environ 726:137828. https://doi.org/10.1016/j.scitotenv.2020.137828

Turk Sekulic M, Boskovic N, Slavkovic A, Garunovic J, Kolakovic S, Pap S (2019) Surface functionalised adsorbent for emerging pharmaceutical removal: adsorption performance and mechanisms. Process Saf Environ Prot 125:50–63. https://doi.org/10.1016/j.psep.2019.03.007

Walter A, Dolzan P, Quilodrán O, de Oliveira JG, da Silva C, Piacente F, Segerstedt A (2011) Sustainability assessment of bio-ethanol production in Brazil considering land use change, GHG emissions and socio-economic aspects. Energy Policy 39(10):5703–5716. https://doi.org/10.1016/j.enpol.2010.07.043

Wan S, Wu J, He F, Zhou S, Wang R, Gao B, Chen J (2017) Phosphate removal by lead-exhausted bioadsorbents simultaneously achieving lead stabilization. Chemosphere 168:748–755. https://doi.org/10.1016/j.chemosphere.2016.10.142

Wang L, Zhang J, Wang A (2011) Fast removal of methylene blue from aqueous solution by adsorption onto chitosan-g-poly (acrylic acid)/attapulgite composite. Desalination 266(1–3):33–39. https://doi.org/10.1016/j.desal.2010.07.065

Wang X, Zhao Y, Wang H, Zhao X, Cui H, Wei Z (2017) Reducing nitrogen loss and phytotoxicity during beer vinasse composting with biochar addition. Waste Manag 61:150–156. https://doi.org/10.1016/j.wasman.2016.12.024

Wedzicha BL, Kaputo MT (1992) Melanoidins from glucose and glycine: composition, characteristics and reactivity towards sulphite ion. Food Chem 43(5):359–367. https://doi.org/10.1016/0308-8146(92)90308-O

Wu F, Zhang Y, Liu L, Yao J (2012) Synthesis and characterization of a novel cellulose-g-poly(acrylic acid-co-acrylamide) superabsorbent composite based on flax yarn waste. Carbohydr Polym 87(4):2519–2525. https://doi.org/10.1016/j.carbpol.2011.11.028

Yoshizawa N, Yamada Y, Shiraishi M, Kaneko K, Setoyama N (1996) Evaluation of accessible and inaccessible microporosities of microporous carbons. J Chem Soc Faraday Trans 92(12):2297. https://doi.org/10.1039/ft9969202297

Yue M, Zhang M, Liu B, Xu X, Li X, Yue Q, Ma C (2013) Characteristics of amine surfactant modified peanut shell and its sorption property for Cr(VI). Chin J Chem Eng 21(11):1260–1268. https://doi.org/10.1016/S1004-9541(13)60621-7

Zanella O, KrummenauerHaro N, Cristina Tessaro I, AmaralFéris L (2015a) Successive cycles of sorption/regeneration for granular activated carbon in the removal of nitrate ions. Desalin Water Treat 55(7):1908–1914. https://doi.org/10.1080/19443994.2014.928798

Zanella O, Tessaro I, Féris L (2015b) Nitrate sorption on activated carbon modified with CaCl2: equilibrium, isotherms and kinetics. Chem Ind Chem Eng Q 21(1–1):23–33. https://doi.org/10.2298/CICEQ130830001Z

Zhang Z, O’Hara IM, Kent GA, Doherty WOS (2013) Comparative study on adsorption of two cationic dyes by milled sugarcane bagasse. Ind Crops Prod 42:41–49. https://doi.org/10.1016/j.indcrop.2012.05.008

Zhou Y-F, Haynes RJ (2012) A comparison of organic wastes as bioadsorbents of heavy metal cations in aqueous solution and their capacity for desorption and regeneration. Environ Earth Sci 66(4):1137–1148. https://doi.org/10.1007/s12665-011-1321-4

Acknowledgements

This work was supported by the programs PIBIC and PIIC of Federal University of São João del Rei – Brazil (UFSJ) and Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brazil (CAPES, Finance Code 001).

Funding

This work was supported by the Federal University of São João del Rei/ UFSJ.

Author information

Authors and Affiliations

Contributions

FAL and ACSJ conducted the main experiments; FAL, BS, and RCZL wrote this manuscript; all authors contributed to the discussion of the manuscript results.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Consent for publication

Not applicable.

Consent to participate

Not applicable.

Ethical approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

de Aquino Lima, F., dos Santos Júnior, A.C., Sarrouh, B. et al. Application of sugarcane bagasse and peanut shell in natura as bioadsorbents for vinasse treatment. Clean Techn Environ Policy 26, 401–416 (2024). https://doi.org/10.1007/s10098-023-02636-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-023-02636-7