Abstract

Creating “green” organo-mineral fertilizers with a porous structure requires a systematic approach to the development of granules composition, method of agglomeration and determination of the optimal technological parameters for implementing the process. The samples of encapsulated organo-mineral fertilizers were obtained in a laboratory setup based on a pan-granulator. Six types of fertilizer samples based on urea in a phosphate shell with various types of plasticizers and additional components were proposed. The influence of the organic modifier and plasticizer composition on the nanopores characteristics of phosphate-containing shell was investigated. The study of the phosphate-containing shell structure showed that location and structure of the nanopores and micropores depends on the type of plasticizer and the addition of components such as "Avatar" and biochar. The obtained boundary layers also have nanopores to ensure gradual moisture penetration to the core during the prolonged diffusion of nutritional elements from the N-containing part of the core and slow dissolution of the organic shell. According to the results of the structural analysis of the coatings, it was determined that the most successful is the composition with the addition of biochar and the use of calcium humate as a plasticizer, which makes it possible to create a nanoporous organo-mineral shell. The results of such work will be the base for optimization of the apparatus construction calculation as a part of technological scheme based on pan-granulator. The novelty and effectiveness of this technical solution has been confirmed during vegetative agrochemical tests. The eco-constructive impact of new types of fertilizers on the environment was estimated. The proposed novel composition of fertilizers with biochar-phosphate shell in the series of agrochemical vegetative tests showed the largest increase in yield, improves their quality and increased the humus content in the soil. The necessity of technological transformational changes in the industry and agriculture, based on the concept of innovative green proactivity, has been substantiated to accelerate the green transition and achieve sustainable development goals. The compliance of new types of fertilizers with the stakeholders’ needs (producer, consumer, state and society) has been estimated, which showed the full relevance of the green innovation to all market actors, the high potential of the marketing need, and the high expected level of its acceptance by the market. Hence, it has been concluded, that given market feasibility, further implementation of an ecologically oriented innovative business project aimed at obtaining “green” encapsulated fertilizer with a nanoporous structure should be kept on carrying out.

Graphical Abstract

Obtaining of “green” encapsulated fertilizers with nanoporous structure

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The nanoporous structure of a granule or its shell is a prerequisite for ensuring specific characteristics when applied to specific industries or when used in the national economy. The size, depth, number and shape of the pores affect the parameters of the absorption or retention capacity of granules of porous ammonium nitrate, the absorption capacity of adsorbents, catalyst activity, etc. (Artyukhov 2020b). At the same time, the current direction of research by scientists is to study the effect of additives on the creation of a specific developed nanoporous structure and assess the influence of various factors on the course of the granule formation process and the granules obtaining technology (Artyukhov 2019). Previous research of this work authors team members allowed us to propose multiple ways to control the process of pore formation in the production of porous ammonium nitrate (Artyukhov 2020a; Obodiak 2020). In this work, the following research on obtaining a developed nanoporous structure of a granule (shell) of nitrogen-phosphate organo-mineral fertilizers (Vakal 2021; Yanovska 2022) is proposed (Fig. 1).

Numerous studies have described in detail the physical–chemical properties of fertilizer granules obtained by different methods (Cole et al. 2016; Jasinskas et al. 2016; Qiao et al. 2016; Xiaoyu et al. 2013; Zinkevičienė et al. 2021), as well as the environmental and economic effects of their utilization in agriculture (Gil-Ortiz 2020; Savci 2012; Tomaszewska et al. 2002). Based on analysis of such indicators as efficiency, environmental pollution/protection, duration of nutrient release, and costs (including labor costs), controlled or slow-release fertilizers technology has been justified as economically preferable for agricultural industry (Irfan et al. 2018; Lawrencia et al. 2021; Tomaszewska et al. 2002; Wang et al. 2012).

Obtaining organic-mineral fertilizers with a nanoporous shell structure, in addition to solving the main task—ensuring controlled solubility of fertilizers in the soil, also allows solving the problems of accelerating the green transition of Europe (European Commission 2019) and achieving sustainable development goals based on the concept of innovative advance. To replace MDG 7 "Environmental Sustainability" and MDG 8 "Global Partnership for Development," defined in the Millennium Development Goals in 2015, came to SDG 12 "Responsible Consumption and Production," SDG 13 "Climate Mitigation," SDG 15 "Protecting and restoring the terrestrial ecosystem," SDG 17 "Partnership for Sustainable Development," defined in the 2030 Agenda for Sustainable Development (Brown & Hinsley, 2019; Crisp 2016; Friedrich 2016; Reinert 2020; Sachs 2012). Expanding and detailing the goals of sustainable development indicates the emergence of new global problems and the fact that some tasks of the Millennium Development Goals have not been solved, which requires the formation of environmental management system on a fundamentally new basis (Prokopenko et al. 2021). In addition, the 2030 Agenda for Sustainable Development SDG 9 "Industry, Innovation and Infrastructure" defines the relationship between measures and tools to ensure the achievement of the above SDGs (Grieco & Palou-Rivera 2020). Such an integrated approach to the creation of the landscape and favorable conditions for solving the problem of reducing man-made load can be very effective in agricultural production and related industries that provide this direction.

The functional diversity of microorganisms is 3.8% greater in organic fertilizers that in NPK fertilizers (Bebber and Richards 2022). It is generally known that organic matter is a key component of the soil, affecting its physical, chemical, and biological properties, contributing to its normal functioning, on which the survival of mankind depends. Benefits from higher soil organic matter content include improved soil quality by increasing water and nutrient retention, resulting in higher crop productivity in vivo. Thus, the carbon accumulation processes in the soil are a vital ecosystem function arising from the interaction of ecological processes. In this regard, the lack of an organic component in plant fertilization must be compensated for with additional high-carbon resources. One of the options for such resources is biochar (Green Carbon), which is primarily an effective soil substrate that increases soil fertility, reducing its hardness and density. At the same time, the roots penetrate the soil more easily and grow better. In addition, a special habitat is created for soil microorganisms and fungi, which ensures plant health.

Biochar provides environmental and economic benefits by increasing soil fertility up to 30% while reducing water consumption. Biochar is the highest quality fertilizer that exists today, as it stops the process of soil degradation, preventing many global environmental and economic problems. Thanks to the active ions contained in biochar fertilizer, carbon does not evaporate into the external environment but remains in the soil for a long time, easily absorbed by plant roots. Thus, the amount of greenhouse gases in the atmosphere decreases, and at the same time, the threat of the greenhouse effect and global warming decreases (Marrero 2020).

The soil properties and cowpea yield responses to biochars (BCs), applied in combination with nitrogen-phosphorus-potassium (NPK) fertilizers, were investigated (Rafael 2019). All biochars were applied at a rate of 0.9% (weight/weight), and biochar was combined with half and full doses of NPK fertilizers. The introduction of biochar as an organic amendment in these soils help to increase fertilizer efficiency and crop productivity. Biochar is considered a valuable resource for problematic soils to retain nutrients increase soil pH. By increasing soil pH, biochar improves nutrient availability to plants. Application of biochars increased N, P, and K use efficiency by cowpea. A combination of biochar and fertilizer is a sustainable approach to optimize fertilizer efficiency. Farmers can reduce fertilizer application and consequently the cost of food production, by increasing biochar application in the acid soil studied (Rafael 2019).

A field experiment on sandy clay loam soil with biochar combined with NPK showed the increase of soil pH, total nitrogen, available phosphorus, total organic carbon, and effective cation exchangeable capacity compared with the NPK fertilizer and the farmyard manure (Apori et al. 2021).

A resource for obtaining biochar can be wood, products of its processing, crop residues, and other organic waste (branches, leaves, straw, peat, etc.). At the same time, a significant environmental problem of the disposal of organic production and consumption waste can be solved (Mihalcova et al. 2021).

The creation of a new method for obtaining organic-mineral fertilizers will allow:

-

- To ensure the efficient use of biochar as one of the products of biomass utilization;

-

- To combine the targeted and directed impact on the soil of mineral and organic components;

-

- The use of biochar slows down soil degradation, eliminates excess substances from the soil that slow down the development of the root system of plants, stabilizes the soil, ensures the retention of nutrients and moisture in the soil, and transport routes for mycorrhiza;

-

- To create conditions for the dosed release of nutrients into the soil due to the developed porous structure of the organic shell;

-

- To ensure the penetration of moisture to the core of the granule (mineral fertilizer), due to the developed porous structure of the organic shell.

The originality of this work is the creation of a new method for the production of “green” encapsulated fertilizers with nanoporous structure based on biochar properties by encapsulating the urea prill into the organo-mineral phosphate-containing shell.

The novelty of this work is the application of a complex approach to the formation and investigation of the quality of organo-mineral fertilizers that were modified by biochar. It was investigated as an element of developed nanoporous shell structure formation, which is important for soil moisture penetration for the following dissolution of granule core and prolonged release of nutrition components. Biochar was also investigated as an element that has a positive impact on plant growth.

Vegetation studies carried out by the authors on the cultivation of spring barley on typical chernozem using nitrogen and phosphorus-potassium fertilizers modified with biochar confirmed the data of foreign scientists (Marrero 2020; Rafael 2019) and showed that the presence of biochar in the granule increases the use of nutrients by plants. The results of these experiments made it possible to develop a phosphate-containing coating composition for nitrogen fertilizer prills with the introduction of 10% biochar into the formulation. The presented results of studies of the obtained organo-mineral structure of the phosphorus-containing shell are a continuation of the authors’ work on the development of environmentally friendly fertilizers.

Experimental

The experimental research methodology was developed in (Yanovska 2022), and this work is modified considering the peculiarities of the organo-mineral fertilizer composition.

Materials

We used a commercial fraction of prilled urea with a size of 2–3 mm, containing 46.2% nitrogen, as the core of the granule. To form a phosphate-containing shell, a powder of phosphate-glauconite concentrate of the Novo-Amvrosiivsky deposit, with a fraction of less than 0.2 mm, was used. Chemical composition of the phosphate-glauconite concentrate: mass fraction of total phosphates in terms of P2O5 gen.—15.0%, mass fraction of assimilable phosphates in terms of P2O5 assim.—13.1%, mass fraction of K2O—1.5%, mass fraction of water—1.27%. The coating composition of the fertilizer samples was additionally made with the microelement complex "Avatar" and Biochar. Ballast potassium and calcium humates obtained on a model homogenizer, and potassium-magnesium (Kalimag) solution (K2SO4 Mg2SO4) were used as plasticizers. The solutions of potassium and calcium humates were filtered through a 0.125-mm sieve. The chemical composition of potassium and calcium humates and Kalimag solution is presented in Table 1.

Biochar characteristics are shown in Table 2.

Methods

The samples of encapsulated organo-mineral fertilizers were obtained in a laboratory setup based on a disk granulator (Fig. 2).

The installation consists of phosphate bunker 1, bunker of microelement complex “Avatar” or Biochar 2, mixer 3, dispenser 4, potassium-magnesium solution tank 5, potassium or calcium humate solution tank 6, potassium-magnesium mixing tank with humate 7, urea granules feed unit 8, nozzle 9, pan-granulator 10 and tray for granulated product 11. The consumption of urea, phosphate-glauconite concentrate, and potassium humate was determined by the gravimetric method using a VLKT-500 balance. Screening of the encapsulated product was carried out on an RKF-2U device with the release of a commercial fraction (2–5) mm. The resulting product samples were dried in a SNOL-3.5.3.5.3.5 / 3.5-I1 drying oven. The strength of the obtained encapsulated samples was determined on an IPG-1 M device according to standard methods. Physicochemical studies of the resulting product were carried out.

Study of the surface morphology and internal structure of the granule (linear size and shape of pores, surface microrelief of various objects) was carried out using a scanning electron microscope SEO-SEM Inspect S50-B.

Characterization

Experimental studies on the production of biochar from oak and ash waste were carried out in laboratory conditions by pyrolysis in the absence of oxygen in a muffle furnace at a temperature of 600 °C for 48 h. Analytical studies of the obtained product showed the content of non-volatile carbon 91.01%, volatile matter 4.53%, ash 4.46%, and pH 10.1.

An electron micrograph of biochar is shown in Fig. 3.

The study of the biochar composition showed its developed porous structure and the presence of a large number of nano-sized micropores, which is of great importance for sorption processes. The porous structure and high pH content of biochar can reduce soil acidity, nutrient leaching, and the need for fertilizers and irrigation when used as a fertilizer component. In terms of its indicators, biochar is close to the indicators of charcoal according to that it can be considered as a sorption additive in the fertilizer composition.

A cycle of studies on the development of a phosphate-containing coating composition with the introduction of a sorption additive in the form of biochar revealed the need for its grinding to 200 microns and determined that the maximum amount that can be introduced into the coating without significant loss of granule strength is 10%. Test vegetation experiments to determine the agrochemical effectiveness of encapsulated organo-mineral fertilizer of prolonged action based on carbamide and phosphate-containing coating with different biochar content showed that the agrochemical effect from the use of biochar in the coating composition is already noticeable when it is applied at 1%.

Considering the components of the phosphate-containing coating from the point of view of their granulation (agglomeration), it should be noted that its main component is a powdered phosphate-glauconite concentrate of fine grinding. After its preliminary grinding, it is advisable to modify the coating composition with biochar. In this case, the grinding size should be no more than 300 microns, as for a phosphate concentrate, or less than this particle size. The introduction of calcium humate into the composition of the coating in the form of a plasticizer in the process of agglomeration of the powder coating is effectively implemented on the rolling surface, for example, of a plate granulator. In comparison with a drum granulator, the use of a disk granulator allows you to visually observe the agglomeration process and the hydrodynamics of such an apparatus. The granules, having reached a certain size of the coating thickness, roll out through the side of the disk. The advantage of the disk granulator, compared to the drum granulator, is the technological ability to regulate the coating thickness and the residence time of the granules in the apparatus and the lower metal consumption of the structure.

The process of encapsulating urea granules was carried out as follows. Powder of phosphate-glauconite concentrate was fed onto carbamide granules pre-moistened with a plasticizer (potassium, calcium humate, or Kalimag) in a granulator tray. The coating was applied by the mechanism of powder agglomeration with parallel moistening with a plasticizer. The microelement complex "Avatar" or biochar in an amount of 5% and 10% by weight of the powder was added to the phosphate powder. The ratio of the coating weight to the carbamide weight was maintained at 1.2. The pelletizing process on the plates was monitored visually. The moisture content of the encapsulated urea at the outlet of the pelletizer tray was 6.42%. The wet granules were dried for 3 h at 65 °C. The product was dispersed with the release of a commercial fraction of 2–5 mm.

Due to the additional introduction of liquid potassium and calcium humate, potassium-magnesium solution, and more uniform wetting of the granule surface during its encapsulation, the surface of the phosphate-containing coating had a denser structure and visually differed from the samples of previous batches.

The chemical composition of fertilizers is presented in Table 1. As can be seen from this table, all samples differed in the amount of P2O5, N, K2O and the type of plasticizer. Due to this, the strength of the granules varies from 1 to 2.1 MPa.

As it could be seen from this table, all samples varied by amount of P2O5, N, K2O and type of plasticizer. Due to this, density of the granules varies from 1 to 2.1 MPa.

Authors can confirm that all relevant data are included in the article and its supplementary information files. Additional data are available on request to corresponding author.

Results and discussion

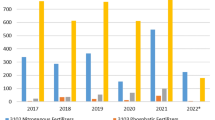

Achieving the sustainable development goals of Ukraine requires an integrated approach to the implementation of environmentally sound technologies in all industries and agriculture (Kotenko et al. 2019; Kurbatova 2018; Kurbatova et al. 2020; Trypolska et al. 2021). For many years, powerful factors of environmental pollution and irrational use of natural resources have been operating on the territory of the country, which is due to many reasons. First of all, the fact that Ukraine, whose area is 14.5% of the land area of the country ЄC (Fig. 4) and whose population is only 1% of the world's population, accounts for about 5% of the world's production and processing of mineral resources. The low level of environmental friendliness and perfection of technologies for processing mineral raw materials, in particular, the production of fertilizers, and their ineffective use leads to a rapid increase in the technogenic load on the environment, which is characterized, first of all, by the pollution of natural components of the environment and the intensification of soil degradation processes, 71.3% of which in the structure of the land fund of Ukraine are agricultural lands (Fig. 5) (Land Directory 2020; Prokopenko 2020; Shkola et al. 2016). All this increases the formation of greenhouse gases in the atmospheric air and is accompanied by the release of a significant amount of hazardous chemical compounds and complexes into the environment (Fig. 6).

The structure of the land fund of Ukraine (developed by authors based on data (Prokopenko 2020))

Sectoral shares of net emissions in EU-27 in 2014–2019, % of kt from the 'Total net emissions with international transport (EEA) along Sectors (developed by authors based on data (European Environment Agency 2021)

According to the head of the state environmental inspectorate Andriy Malovanyi, referring to the calculations of researchers of the international organization Global Footprint Network, Ukraine, has been living in ecological debt since August 8, 2021 (Malovanyi 2021). It means the use of more domestic resources than the Ukrainian environment can restore in a year. At the same time, changes in climatic conditions for growing crops, a significant decrease in the application of doses of organic fertilizers negatively affect the processes of maintaining the necessary fertility of domestic soils and lead to their gradual degradation. Consequently, increasing the level of ecological and food safety, which are components of national security, requires the introduction of innovative methods, as defined in (Domashenko et al. 2017), and the transformation of existing approaches to the production and application of mineral and organic fertilizers.

The surface morphology and cross section of the granules are shown in Fig. 7. SEM morphology of mineral fertilizer samples, consisting of a carbamide core and a phosphate shell with different chemical composition and types of plasticizers are presented in Table 1.

Carbamide core does not include pores. Micropores and nanopores are included in phosphate-containing shell in all types of carbamide-phosphate samples. Nanopores in samples 5 and 6 are placed parallel to the granule core. As it can be seen at Fig. 1 (samples 5 and 6). At the samples, 1, 3, 4 pores are perpendicular to the carbamide core. The nanopores structure could be connected with the type of plasticizer and addition of such components like “Avatar” (sample 4) and biochar (samples 5 and 6). (Yanovska 2022, Yanovska 2021a, Yanovska 2021b).

As it was concluded from structure analysis, the most successful composition is with addition of biochar (samples 5 and 6). The composition of the samples 5 and 6 include biochar addition to the shell with potassium humate as plasticizer and 10% of biochar with calcium humate as plasticizer, respectively. Their microstructure is compared at Fig. 8. The composition with 10% biochar addition into phosphate shell with calcium humate as a plasticizer (sample 6) was more successful for obtaining of nanoporous shell. The addition of biochar into phosphate coating of the granule increases the attachment between granule of carbamide and phosphate shell and makes structure of interface more uniform.

The obtained results are completely agreed with the literature (Apori et al. 2021). The combined application of biochar with organic resources decreases the decomposition and mineralization of the organic resources, causing the slow release of nutrients to the soil environment. Biochar addition to the NPK fertilizer and manure decreased the apparent ammonification and ammonium loss because of the temporary adsorption of NH4+ onto the biochar surface. The Co-application of biochar with NPK increased available soil phosphorus, nitrogen (Apori et al. 2021).

As we can see from the results presented in Table 1, the density of samples 5 and 6 is decreased slightly compared with samples without biochar but it does not influence on the agricultural application.

Nanoporous structure of biochar is presented in Fig. 7 (sample 6). Micrographs of the elemental distribution in samples 5 and 6 are also presented in Fig. 8.

The elemental composition: Ca, P, Si, O, C is existed for both samples. Additional elements are following: N, S, Al, Fe, K, Mg, Na. The distribution of elements in the granule volume proved absence of mutual penetration between core and shell. Such structure is successful for step-by-step dissolution of the granule and release of the components into the soil.

The results of the investigation (Fig. 8) are completely agreed with the literature (Agbede 2021) where biochar and poultry manure increased soil total N, available P, and exchangeable K, Ca, and Mg concentrations compared with the control. Application of biochar alone improved soil pH, K, Ca, and Mg better than the NPK fertilizer. Combined application of NPK fertilizer, biochar and poultry manure at sub-optimal rates gave higher soil N, P, K, Ca, and Mg concentrations, higher plant, number of leaves, root length, root diameter, and fresh carrot root yield compared with NPK fertilizer or biochar or poultry manure alone (Agbede 2021).

Vegetation test results

The formulation of encapsulated organo-mineral fertilizer with the prolonged release with the addition of biochar to the phosphate-containing shell was developed and tested during vegetation studies. The introduction of ingredients with a low carbonic trace potentially improves ecological safety, as it allows to have a higher coefficient of exploitation.

Vegetation research on barley cultivation with the use of encapsulated organo-mineral fertilizers was carried out according to the standard method, in comparison with the application of traditional fertilizers, which showed the prospects of this direction of work. The following samples were taken for research: 1—control without fertilizers; 2—urea; 3—encapsulated with phosphate-containing shell urea with a plasticizer of potassium humate (recipe 2, Table 3); 4—encapsulated with phosphate-containing shell urea with a plasticizer of calcium humate (recipe 1, Table 3); 5—urea encapsulated with a phosphate-containing shell of 10% biochar, with a plasticizer of calcium humate (recipe 6, Table 3).

According to the results of the experiment, a preliminary conclusion can be made that when fertilizers are applied, the transformation of carbon into organic matter increases the quality and fertility of the soil due to water and nutrient retention, which leads to greater agricultural productivity. Processing of the experimental results showed an increase in green mass of barley samples compared to the control for urea sample—44%, in encapsulated fertilizer sample 3 by 42%, in sample 4 by 32%, and in sample 5 by 80%, and the best property of sample 5 to tolerate dry growing season.

The comparative studies of different compositions of the phosphate-containing shell of encapsulated organo-mineral fertilizers of prolonged action confirmed their agrochemical efficiency and prospects for further use in view of environmental safety. The introduction of the following components into fertilizers: phosphorite flour, potassium, and calcium humates, and biochar, allows you to get a total fertilizer with a low carbon footprint.

The content of nitrogen, phosphorus, and potassium in the samples of barley plants was determined by the method of atomic emission spectrometry. The results of the analysis are shown in Fig. 9.

Based on the analysis of graphs, there is a certain correlation between the increase in yield of the developed composition of fertilizer with biochar and a small amount of nitrogen accumulated in plants, which may indicate a decrease in nitrate content in barley. The prolonged action of fertilizers has increased the period of supply of nutrients to plants and their gradual release. Thus, nitrogen and phosphorus fertilizers were used to increase green mass and its quality. Accumulation and retention of potassium in barley samples are necessary for the further development of vegetative organs.

The influence of pure biochar and urea encapsulated with a phosphate-containing shell of 10% biochar, with a plasticizer of calcium humate (Sample 6) in the soil composition, were also investigated. As a soil, the typical chernozem from Sumy (Ukraine) region with following composition (Table 4) was used for agricultural experiments.

The soil used in the study contained nitrogen in the optimal amount, an increased level of phosphorus, and an average level of potassium. Therefore, the soil sample can be classified as almost optimal in terms of agrochemical parameters.

To identify the biological effectiveness of promising granular fertilizers and their components, agricultural tests were conducted, during which the nitrogen content in the soil was increased almost 2–4 times, phosphorus and potassium—1.5–7 and 3.25 times, respectively (Table 5).

After applying fertilizers, the soil was moistened to reach 70% humidity from the lowest moisture content, 25 spring barley seeds were sown in quadruplicate. Germination and maintenance of the growth of barley plants were carried out at a temperature of 20 °C and on a 12-h light day. Plant measurements were taken on the 30th day of vegetation, and an agrochemical analysis of the soil was carried out after growing barley plants. The results of the agrochemical soil analysis are shown in Table 6.

Plants grown by the addition of various fertilizers were collected, and biometric measurements (length of sprouts and roots, leaf surface area) were carried out with them. After that, samples were dried and weighed. Statistical processing of the obtained parameters from the examined plants showed significant differences in plants from different variants of applying fertilizers and their components by dry weight.

In the application of biochar (25 mg/kg of soil) and Sample 6, a tendency to increase the weight of spring barley seedlings was revealed. Due to the prolonged effect of these granular fertilizers, it is advisable to study their effectiveness at the later stages of spring barley plants' development under field research conditions.

To determine the role of the main components on the accumulation of dry weight in barley seedlings, a correlative analysis was conducted between the amounts of individual components of granulated fertilizers applied to the soil and the dry weight of barley seedlings.

The closest relationships were between the accumulation of dry weight and the introduction of biochar, phosphorus, and potassium. Under these conditions of the experiment, nitrogen played a less significant role in the accumulation of seedling weight at the initial stage of barley growth.

So, at the juvenile stages of growth and development, biochar, phosphorus, and potassium had a more significant influence on the accumulation of barley biomass. Thus, the result of these fertilizer components on plant formation was 31.6%, 20.7%, and 21.3%, respectively.

The foliar diagnosis was carried out for the content of nitrogen, phosphorus, potassium, calcium, magnesium, and trace elements for more detailed identification of the role and mechanism of action of the studied granular fertilizers and their components on the accumulation of the dry weight of plants and nutrients in spring barley seedlings. According to the results of foliar diagnostics, it was found that the most amount of nitrogen was accumulated in the biomass of plants under the condition of applying fertilizers with biochar with a plasticizer based on calcium humate (Sample 6).

Assessment of compliance of novel “green” encapsulated fertilizers with the stakeholder’s needs, given the achievement of sustainable development goals

Searching for new sustainable markets is a crucial issue for innovative enterprises, given that all economic actors’ competition becomes more intensive (Kovtunenko et al. 2019a, b). To reduce various risks impact, assessment of market prospects of innovative products at the business analysis stage of the innovation life cycle is an essential criterion for making management decisions on the feasibility of further project implementation. To estimate the compliance of new types of fertilizers with all stakeholders needs (producer, consumer, state, and society), the methodology explored in the work (Prokopenko et al. 2012) has been used. According to the aforesaid mode, three groups of experts representing each category of stakeholders, namely producer, consumer, state, and society, have been formed. Using the expert method, the evaluation characteristics of novel fertilizer corresponding to the needs of the relevant stakeholders groups have been identified.

To assess compliance with the needs of consumers, the following groups of indicators have been analyzed:

X11—Value / expected value of a new type of fertilizer;

X12—Savings when using;

X13—Complex composition of fertilizer;

X14—Environmental friendliness (level of threat of excessive accumulation of nitrates in plants and crops);

X15—Suitability for use in specific conditions;

X16—Frequency of application;

X17—The level of moisture content of granules in the soil;

X18—Convenience, ease of use (for continuous application, to a given depth and distance from the row when sowing different crops);

X19—No need for additional costs (for the purchase of appropriate equipment for fertilizers implementation);

X20—Efficiency (increasing the quantity and quality of the crop).

The following weights were determined for aforesaid groups of indicators: X11—0.17; X12—0.09; X13—0.1; X14—0.05; X15—0.09; X16—0.07; X17—0.11; X18—0.06; X19—0.12; X20—0.14.

To assess compliance with manufacturers’ needs, the following groups of indicators have been analyzed. The weights of indicators are indicated in parentheses:

X21—Reduction of environmental taxes and fines (0.08);

X22—Ability to expand existing markets and enter new markets (0.18);

X23—Ensuring the health of employees (0.08);

X24—Increase in profits (0.15);

X25—Reduction of production costs (0.15);

X26—Production safety (including environmental protection) (0.09);

X27—Improving the status of the enterprise (through the introduction of environmentally friendly production technologies and the transition to clean energy) (0.08);

X28—Energy independence of production (providing the introduction of its own energy generating capacity on renewable energy sources) (0.09);

X29—the possibility of attracting foreign investment for business development (0,1).

To assess compliance with the needs of the state and society, the following groups of indicators, the weights of which are indicated in parentheses, have been analyzed:

X31—Increasing the level of security (including environmental, food, energy, and national) (0.15);

X32—Growth of the national economy (0.12);

X33—Growth of global competitiveness of the country (0,12);

X34—Ensuring the health of the nation (0.11);

X35—Filling the state budget and increasing revenues to the state budget (0.1);

X36—Increasing the number of jobs (0.1);

X37—Increasing the level of social responsibility of business (0,1);

X38—Accelerating the achievement of sustainable development goals (0,1);

X39—Accelerating the "green" transition of the national economy (0,1).

The assessment of the degree of compliance of the novel fertilizer characteristics with the stakeholders’ needs has been based on the analysis of compliance with these needs of certain characteristics on a scale from 0 to 4, where 0—it does not comply, 4—it fully complies.

Based on the evaluation above indicators obtained, estimates of compliance of the novel “green” fertilizer with the needs of consumers (O1), producers (O2), and public and state institutions (O3) have been calculated, namely O1 = 3.84; O2 = 3.9; O3 = 3.91. The reliability of obtained estimates of compliance of a new type of fertilizer with the needs of stakeholders—producer (δ1), the consumer (δ2), state, and society (δ3), calculated by the standard deviation formula, is, respectively, δ1 = 0.072; δ2 = 0.17; δ3 = 0.103.

Given the reliability of estimates, the calculated integrated index of compliance of novel “green” fertilizers with all stakeholders’ needs is Oint = 3.88 ± 0.115, which corresponds to a high level of stakeholders’ satisfaction and indicates the acceptability of production and launch of new fertilizers.

Conclusions

The results of studies of the nanoporous structure of the shell of organic-mineral fertilizers show that due to the selection of the granulation method, the optimal encapsulation parameters, and the composition of the shell, the formation of a developed network of nanopores is a process that can be controlled. The novelty of this research is that a highly effective organo-mineral fertilizer with a prolonged action was produced by encapsulating the urea prill into the organo-mineral phosphate-containing shell.

Thus, biochar as a component of the organo-mineral fertilizer shell makes it possible to create a porous structure for efficiently assimilating nutrients and the chronologically necessary introduction of organic and mineral elements into the soil. The technological parameters of the formation of the fertilizer shell obtained in this work make it possible to ensure its sufficient strength and reliable attachment to the granule core. At the same time, the results of studying the morphology of each fertilizer zone (shell, boundary layer, and core) allow us to state that due to the optimal selection of the fertilizer production technology, the porous structure of the shell and boundary layer is uniform. This fact, along with data on the porosity of the shell and boundary layer, makes it possible to predict the release rate of nutrients into the soil. The properties of the porous shell are a "marker" of the kinetics of dissolution of nutrients in the soil since the efficiency of soil moisture retention in the shell and the amount of soil moisture that enters the granule depend on the volume of pores and their size.

Studies of the phase and chemical composition and crystal structure of complex fertilizers were performed using spectrometry and electron microscopy of various types, which allowed to determine the quality of contact of the shell with the granule core and its properties.

The results of agrochemical vegetation studies showed that the green mass of barley samples was higher than the control in the sample with encapsulated phosphate-containing coating with calcium humate and biochar of more than 80%, and the best property of the sample to tolerate dry growing season. The limitation could be connected with an application to other plant species, so additional recommendations should be given depending on the type of soil and requirements according to nutritional components.

The contribution of this study is the production of a new type of fertilizer that has an eco-constructive impact on the environment, and fully complies with the stakeholders’ demand, which indicates the feasibility of bringing it to market. Launching a novel “green” fertilizer will enable to increase the national security and global competitiveness of Ukraine, and accelerate the achievement of the Sustainable Development Goals and Climate Neutrality.

References

Agbede TM (2021) Effect of tillage, biochar, poultry manure and NPK 15–15–15 fertilizer, and their mixture on soil properties, growth and carrot (Daucus carota L.) yield under tropical conditions. Heliyon 7:e07391. https://doi.org/10.1016/j.heliyon.2021.e07391

Apori SO, Byalebeka J, Murongo M, Ssekandi J (2021) Effect of co-applied corncob biochar with farmyard manure and NPK fertilizer on tropical soil Resources. Environ Sustain 5:100034. https://doi.org/10.1016/j.resenv.2021.100034

Artyukhov AE, Artyukhova NO (2019) Technology and the main technological equipment of the process to obtain NH4NO3 with Nanoporous structure. Springer Proc Phys 221:585–594. https://doi.org/10.1007/978-3-030-52268-1_13

Artyukhov AE, Vakal SV, Yanovska AO, Shkola VY, Vakal VS, Yarova TY (2020) The investigation of nanoporous structure morphology and elemental composition of organo-mineral fertilizer granules. J Nano- Electron Phys 12(6):06039–06044

Artyukhov A, Artyukhova N, Krmela J, Krmelova V (2020b) Complex designing of granulation units with application of computer and software modeling: Case “Vortex granulator.” IOP Conf Ser: Mater Sci Eng 776(1):012016

Bebber DP, Richards VR (2022) A meta-analysis of the effect of organic and mineral fertilizers on soil microbial diversity. Appl Soil Ecol 175:104450–104459. https://doi.org/10.1016/j.apsoil.2022.104450

Brown A, Hinsley S (2019) Compatible sustainable development goals. Lancet Planet Health 3(8):E340–E340. https://doi.org/10.1016/S2542-5196(19)30132-9

Cole JC, Smith MW, Penn CJ, Cheary BS, Conaghan KJ (2016) Nitrogen, phosphorus, calcium, and magnesium applied individually or as a slow release or controlled release fertilizer increase growth and yield and affect macronutrient and micronutrient concentration and content of field-grown tomato plants. Sci Hortic 211:420–430. https://doi.org/10.1016/j.scienta.2016.09.028

Crisp LN (2016) One World Health: An Overview of Global Health, 1st edn. CRC Press, Boca Raton

Domashenko M, Shkola VY, Kuchmiyov A, Kotenko O (2017) Innovative marketing strategies to provide ecological safety at regional and global levels. Marketing and Management of Innovations 4: 367–373. https://mmi.fem.sumdu.edu.ua/journals/2017/4/367-373. Accessed 20 November 2021

European Commission (2019, 11 December). The European Green Deal. https://eur-lex.europa.eu. Accessed 20 November 2021

European Environment Agency (2021) EEA greenhouse gases - data viewer. Data viewer on greenhouse gas emissions and removals, sent by countries to UNFCCC and the EU Greenhouse Gas Monitoring Mechanism (EU Member States). https://eur-lex.europa.eu/. Accessed 20 November 2021

Friedrich MJ (2016) Sustainable development goals launched. JAMA 315(7):647. https://doi.org/10.1001/jama.2016.0608

Gil-Ortiz R, Naranjo MÁ, Ruiz-Navarro A, Atares S, García C, Zotarelli L, Bautista S, Vicente O (2020) Enhanced agronomic efficiency using a new controlled-released. Polym-Coat Nitrogen Fertil Rice Plants 9:1183. https://doi.org/10.3390/plants9091183

Grieco B, Palou-Rivera I (2020) Advanced Manufacturing Progress: Achieving Sustainable Development Goals. AlChE. https://www.aiche.org/resources/publications/cep/2020/april/advanced-manufacturing-progress-achieving-sustainable-development-goals. Accessed 30 April 2020

Irfan SA, Razali R, KuShaari K, Mansor N, Azeem B (2018) A review of mathematical modeling and simulation of controlled-release fertilizers. J Control Release 10(271):45–54. https://doi.org/10.1016/j.jconrel.2017.12.017 (Epub 2017 Dec 22 PMID: 29274697)

Jasinskas A, Pekarskas J, Kucinskas, V.; Aboltins, A. Investigation of natural magnesium mineral fertilizer granulation and determination of granule qualitative indicators. In Engineering for Rural Development 2016, Proceedings of the 15th International Scientific Conference Proceedings, Jelgava, Latvia, 25–27 May 2016; ASU Publishing Center: Akaemija, Lithuania, 2016; pp. 647–652.

Kotenko O, Domashenko M, Shkola V (2019) Production costs decreasing by introduction of energy-efficient technologies within the enterprise’s counter-crisis management strategy. International Journal of Ecological Economics and Statistics 40(3): 88–97. http://www.ceser.in/ceserp/index.php/ijees/article/view/6232. Accessed 20 November 2021

Kovtunenko K, Kovtunenko Y, Shatskova L, Yatsenko M, (2019a) Management mechanism as an independent element of the food industry enterprise innovative activity expenditures management system. Journal of Hygienic Engineering and Design 28: 73–80. http://dspace.opu.ua. Accessed 20 November 2021

Kovtunenko K, Filippova S, Poberezhets O, Kovtunenko Yu, Stepanchenko A (2019b) Adaptation of the logistics system of food industry enterprises in conditions diversification of activities. Journal of Hygienic Engineering and Design 27: 108–113. http://dspace.opu.ua/jspui/handle/123456789/9124 Accessed 20 November 2021

Kurbatova T (2018) Economic benefits for producers of biogas from cattle manure within energy co-operatives in Ukraine. Int J Sustain Energy Plann Manag 18:69–80. https://doi.org/10.5278/ijsepm.2018.18.5

Kurbatova T, Sotnyk I, Kubatko O, Ye B, Arakpogun E, Roubik H (2020) State support policy for renewable energy development in emerging economies: the case of Ukraine. Int J Global Environ 19(1–3):26–52. https://doi.org/10.1504/IJGENVI.2020.114864

Land Directory of Ukraine 2020. (2020). AgroPolit.com. https://agropolit.com/storage/2020/Zemelniy_dovidnyk_2020.pdf?utm_source=mailchimp&utm_campaign=0300ccc2e1f0&utm_medium=page. Accessed 20 November 2021

Lawrencia D, Wong SK, Low DYS, Goh BH, Goh JK, Ruktanonchai UR, Soottitantawat A, Lee LH, Tang SY (2021) Controlled release fertilizers: a review on coating materials and mechanism of release. Plants (basel) 10(2):238. https://doi.org/10.3390/plants10020238

Malovanyi A (2021) Ukraine began to live in debt in nature. Ukrinform.ua.

Marrero T (2020) Influence of particle size on Biochar porosity (2020) Wakefieldbiochar.com.

Mihalcova B, Koraus A, Prokopenko O, Hvastova J, Frenákova M, Gallo P, Beata B (2021) Effective management tools for solving the problem of poverty in relation to food waste in context of integrated management of energy. Energies 14:4245. https://doi.org/10.3390/en14144245

Obodiak V, Artyukhova N, Artyukhov A (2020) Calculation of the residence time of dispersed phase in sectioned devices: Theoretical basics and software implementation. Advances in Design, Simulation and Manufacturing II. DSMIE 2019. Lecture Notes in Mechanical Engineering 813–820. https://doi.org/10.1007/978-3-030-22365-6_81

Prokopenko OV, Shkola VYu (2012) Controlling of the ecological and economic enterprise security on the bases of ecomarketing. Marketing and Management of Innovations 4: 337–346 https://mmi.fem.sumdu.edu.ua/sites/default/files/mmi2012_4_337_346.pdf. Accessed 20 November 2021

Prokopenko O, Toktosunova C, Sharsheeva N, Zablotska R, Mazurenko V, Halaz L (2021) Prospects for the Reorientation of Investment Flows for Sustainable Development under the Influence of the COVID-19 Pandemic. Problemy Ekorozwoju 16(2): 7–17. https://doi.org/10.35784/pe.2021.2.01

Prokopenko O (Eds) (2020) Agriculture of Ukraine: Statistical collection for 2019. State Statistics Service of Ukraine, Kyiv.

Qiao MJ, Huang TH, Jiang JY, Fu YL (2016) Release characteristics and effects on eucalyptus tree growth of fertilizer from wood residue slow-release fertilizer shell. Wood and Fiber Science 48(4): 217–227. https://wfs.swst.org/index.php/wfs/article/view/2570/2325. Accessed 02 April 2022

Rafael R. B. A., Fernandez-Marcos M. L., Cocco S, Ruello M. L., Fornasier F., Corti G. Benefits of Biochars and NPK Fertilizers for Soil Quality and Growth of Cowpea (Vigna unguiculata L. Walp.) in an Acid Arenosol Pedosphere 29(3): 311–333, 2019 https://doi.org/10.1016/S1002-0160(19)60805-2

Reinert K (2020) From sustainable development goals to basic development goals. Ethics Int Aff 34(2):125–137. https://doi.org/10.1017/S0892679420000180

Sachs JD (2012) From millennium development goals to sustainable development goals. Lancet 379(9832):2206–2211. https://doi.org/10.1016/S0140-6736(12)60685-0

Savci S (2012) Investigation of effect of chemical fertilizers on environment. APCBEE Proc 1:287–292. https://doi.org/10.1016/j.apcbee.2012.03.047

Shkola VY, Domashenko MD, Kuchmiyov AV, Novak KS (2016) Fundamentals of the Ukrainian land fund management. Marketing and Management of Innovations 2: 235–345. https://mmi.fem.sumdu.edu.ua/journals/2016/2/235-245. Accessed 20 November 2021

The World Bank (2018a). Agricultural land (sq. km). https://data.worldbank.org/indicator/AG.LND.AGRI.K2?end=2018a&name_desc=true&start=2013 Accessed 20 November 2021

The World Bank (2018b). Agricultural land (% of land area). https://data.worldbank.org/indicator/AG.LND.AGRI.ZS?end=2018a&name_desc=true&start=2013 Accessed 20 November 2021

The World Bank (2018c). Land area (sq. km). https://data.worldbank.org/indicator/AG.LND.AGRI.ZS?end=2018b&name_desc=true&start=2013 Accessed 20 November 2021

Tomaszewska M, Jarosiewicz A (2002) Use of polysulfone in controlled-release NPK fertilizer formulations. J Agric Food Chem 50(16):4634–4639. https://doi.org/10.1021/jf0116808 (PMID: 12137488)

Trypolska G, Kruvda O, Kurbatova T, Andrushchenko O, Suleymanov C, Brydun Ye (2021) Impact of new renewable energy capacities on employment in Ukraine in 2021–2030. Int J Energy Econ Policy 11(6): 98–105. . https://doi.org/10.32479/ijeep.1163

Vakal S, Yanovska A, Vakal V, Artyukhov A, Shkola V, Yarova T, Dmitrikov V, Krmela J, Malovanyy M.(2021) Minimization of soil pollution as a result of the use of encapsulated mineral fertilizers. J Ecol Eng 22(1): 221–230. https://doi.org/10.12911/22998993/128965

Wang Y, Liu M, Ni B, Xie L (2012) κ-Carrageenan–sodium alginate beads and superabsorbent coated nitrogen fertilizer with slow-release, water-retention, and anticompaction properties. Ind Eng Chem Res 51:1413–1422. https://doi.org/10.1021/ie2020526

Xiaoyu N, Yuejin W, Zhengyan W, Lin W, Guannan Q, Lixiang Y (2013) A novel slow-release urea fertiliser: physical and chemical analysis of its structure and study of its release mechanism. Biosyst Eng 115:274–282. https://doi.org/10.1016/j.biosystemseng.2013.04.001

Yanovska A, Artyukhov A, Vakal S, Vacal V, Shkola V (2022) Encapsulated organic–mineral fertilizers with nanoporous structure. Appl Nanosci 12:1275–1283. https://doi.org/10.1007/s13204-021-01893-6

Yanovska A, Vakal S, Vakal V, Shkola, V, Dychenko T, Artyukhov A, (2021a) Influence of Shell’s Organic Components on the Structure and Characteristics of Nanopores in Organic Mineral Fertilizers. In: 2021a IEEE 11th International Conference Nanomaterials: Applications & Properties (NAP), 1–5. https://doi.org/10.1109/NAP51885.2021a.9568553

Yanovska GO, Vakal VS, Artyukhov AE, Shkola VY, Yarova TY, Vakal SV (2021b) Nanoporous Organo-Mineral Fertilizers Obtained by Using of Granule Shell Technology. In: Fesenko O., Yatsenko L. (eds) Nanomaterials and Nanocomposites, Nanostructure Surfaces, and Their Applications. NANO 2020. Springer Proceedings in Physics, vol 263. Springer, Cham. p. 207–222. https://doi.org/10.1007/978-3-030-74741-1_14

Zinkevičienė R, Jotautienė E, Juostas A, Comparetti A, Vaiciukevičius E (2021) Simulation of granular organic fertilizer application by centrifugal spreader. Agronomy 11(2):247. https://doi.org/10.3390/agronomy11020247

Acknowledgements

This article is prepared as a part of the research project "Formation of the environmentally safe long-acting fertilizers based on the phosphate raw material" (No. 15.01.09-20/22 GP-01) 0120U102003 financed by the state budget of Ukraine.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors of the following manuscript have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Vakal, S., Vakal, V., Artyukhov, A. et al. New method for obtaining “green” encapsulated fertilizers with nanoporous structure within the concept of sustainable development. Clean Techn Environ Policy 25, 963–977 (2023). https://doi.org/10.1007/s10098-022-02419-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-022-02419-6