Abstract

The need to reduce waste generation and resource extraction arising from the traditional linear economy system is gaining the attention of scholars, organisations and governments. A potential alternative is the circular economy concept, which can minimise waste, keep materials in circulation through reuse and recycling principles and consider the environmental, social and economic benefits of products. The circular economy evolved from some conflicting concepts and theories to a linear economy. The purpose of this study is therefore to identify those concepts and theories and to explore their potential contributions to the construction industry. To achieve the objective of the study, a semi-systematic review of extant literature was conducted. The results indicated that 14 concepts including cradle to cradle, regenerative design, biomimicry, performance economy, industrial ecology and reverse logistics are the pillars of the circular economy. The findings revealed that all the concepts share similar characteristics with the circular economy and are relevant to the construction industry, especially for environmental protection. Seven (50%) of the pillars are applicable for reuse and recycling, six (42.8%) for resource efficiency, three (21.4%) for design and two (14.3%) for service models. However, it is hoped that the results of this study will contribute to the body of knowledge on the circular economy concept and waste management. The development of a framework for the identification of suitable concepts for the construction industry is recommended for future studies.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Background of the study

Concern about waste generation, resource consumption and energy inefficiency resulting from construction activities, and processes have become major issues in the construction industry around the globe. As a result, a lot of research has focused in recent years on the need to eliminate waste and minimise energy and resource consumption by using sustainable concepts. Waste, being an inevitable by-product on construction projects (Abarca-Guerrero et al. 2017) has been shown to be directly linked to the conventional construction method (Abdelhamid 2014). Since this method encourages the construction of primary structural elements on site, the volume of waste and resource consumed has increased. The traditional method of construction uses natural resource materials that are then disposed of during deconstruction or demolition. While this construction method be compared to the linear economy concept (i.e. “take-make-use-dispose”), which is considered as unsustainable (Xinan and Yanfu 2011), high waste volume, resource and energy inefficiency need to be addressed in order to achieve sustainable construction.

Several authors (Murray et al. 2017; Qian and Wang 2016) proposed the circular economy concept as a substitute for the linear economy. Extensive research has been conducted on the prospects of the circular economy to minimise waste and improve energy and resource efficiency. For example, recent studies (Alhola et al. 2019; Graedel et al. 2019) revealed that the circular economy concept has economic, environmental and social benefits including resource productivity, conservation of natural resources and income gap closure. The circular economy could be the perfect economy model to achieve sustainable development (SD). As demonstrated in the manufacturing industry (Hayashi et al. 2019; Ünal and Shao 2019) and textile industry (Balanay and Halog 2019; Weber 2019), the circular economy concept encourages the 3R principles (reduce, reuse and recycle) and take-back schemes while decoupling economic growth from resource consumption.

More recently, Rajput and Singh (2019) established the link between the circular economy and industry 4.0. Likewise, Akinade and Oyedele (2019) developed a BIM-based computational tool for accurate waste prediction. These studies suggest that the circular economy, a sustainable concept for minimising construction waste is gaining traction. The challenges of the circular economy have also been addressed by many authors; in 2016, Ghisellini and colleagues identified some challenges based on the CE principles. Xue et al. (2010) identified key obstacles to the adoption and implementation of the circular economy including lack of technology, expertise and understanding, unawareness and lack of government funding. Likewise, Tunn et al. (2019) observed that the introduction of business models could change production and consumption patterns while unlocking socio-economic and environmental benefits of the circular economy. Despite the advantages and evidence of successful application of the circular economy in various sectors of the economy, its practical application in the construction industry is limited due to lack of understanding of its roots and little attention paid to its potential contributions. Though the circular economy is not a stand-alone concept; it relies on some pillars or roots for its success. Therefore, identifying these pillars could be the key factor in its adoption, especially in the construction industry. Similarly, highlighting the potential contributions of the circular economy concept may expedite its implementation. It is against this backdrop that this paper aims to describe the circular economy pillars, which are also known as circular economy roots or schools of thought. The study was guided by the following research questions.

-

i.

How many circular economy pillars can be identified from the literature?

-

ii.

What are the contributions of the circular economy pillars to the construction industry?

This study shows that implementing the circular economy in the construction industry would not only reduce environmental pollution arising from waste, it could improve social and economic characteristics of the industry. The next section describes the methodology, while the section that followed describes the potential applications of the circular economy pillars to the construction industry. Implications and limitations of the study are highlighted in the last section.

Methodology

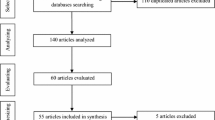

The research design adopted for this study was a semi-systematic review. This type of review is also known as traditional literature review (Onwuegbuzie and Frels 2016) or the narrative review (Wong et al. 2013). Snyder (2019) clarified that the semi-systematic review aims to recognise and explain all study patterns theoretically important to the subject under consideration through meta-narrative synthesis. In addition, the semi-systematic review was adopted for this study because it gives a clear and crucial, yet factual overview of existing knowledge on the subject (Onwuegbuzie and Frels 2016). In conducting the review, the generic six-step literature review process was followed, including the formulation of research questions, literature search, screening, study assessment, data extraction and data analysis (Templier and Paré 2015).

For the purpose of this study, the first step was the formulation of the research questions to guide the review process. The research questions guided the type of information and search terms sought in the literature. It also aided the selection and analysis of the relevant studies. The second step involved an exhaustive search of extant literature on google scholar and various electronic databases (such as scopus, web of science, science direct and directory of open access journals) for relevant information based on the research questions. A number of terms and texts relating to the circular economy concepts were appropriately combined in the search. The results of the search revealed several published and unpublished articles on the subject. It was also found that many definitions have been used for the circular economy concept and that its application has spanned a wide range of sectors.

As a third step, the screening process included the application of inclusion criteria (history, roots and application of the circular economy concepts) to identify potential studies eligible for review on the basis of their relevance. Following the screening process, all prospective studies were assessed for scientific quality including their research design, methods and findings. The next step involved the extraction of data from studies that passed the assessment. To extract data, the articles were read and reviewed in order to identify the pillars of the circular economy concept. As a final step, data extracted from the included studies were collated, analysed and synthesised. Content analysis was performed as a commonly used technique for narrative review (Snyder 2019) to determine the circular economy pillars. The findings contribute to the body of knowledge and are presented in the next section.

The circular economy pillars

The circular economy definition varies but most of them convey the principal idea—waste does not exist. This study employs Liu’s (2012, p. 256), definition of the circular economy, which is described as “an economy system which is characterised by principle of sustainable growth and depends less on depletion of natural resources than traditional economies through the mechanism of recycling the waste output of its system”. The circular economy is regenerative by design and intention, whose aim is to design out waste and as such depends solely on waste mitigation and reduction (Schulte 2013) and therefore stimulates innovation throughout the industry (European Commission 2014a). Consequently, there is a clear indication that the circular economy is dependent on established sustainability concepts to achieve its overarching goal of sustainable development. The sustainable concepts (Fig. 1) can be described as pillars supporting the circular economy; they are identified and described in the following sections.

Source: Ogunmakinde (2019)

Circular economy roots.

Industrial ecology

Industrial ecology (IE) was conceptualised by Ayres, Frosh and Gallopolous in the late 1980s (Damen 2012) but without specific or standard definition. As a result, different definitions have evolved with a general emphasis on energy and material flow through industrial systems. For instance, Graedel and Allenby (2011, p. 41) described IE as “the study of technological organisms, their use of resources, their potential environmental impacts and the ways in which their interactions with the natural world could be restricted to enable global sustainability”. According to Lowe (2001), it is an approach that integrates human systems with natural systems, minimises energy, materials use and ecological impacts of human activities to achieve sustainability. IE focuses on energy and material flow through the entire production system as well as its interplay with the biosphere (Graedel and Allenby 2002). As emphasised by Damen (2012), the concept studies the compatibility between industrial and local natural systems to monitor the flow of materials. IE is aimed at “optimising energy and materials, pollution and waste reduction through an economically viable transformation of industrial by-products or waste into inputs, with the ultimate goal of enabling industrial systems that mimic natural ecosystems” (CIRAIG 2015, p. vi). Similarly, it creates closed-loop processes, eliminates unwanted by-products and uses waste as a resource through technological innovations (Ellen MacArthur Foundation 2013a; Erkman 1997).

IE has three dimensions, which are proactive, analytical and methodological, according to Erkman (1997), cited by Chiu and Geng (2004). It is proactive because it offers ideas to companies, policy makers and government on ways to achieve sustainable development (SD) (Chiu and Geng 2004). It is analytical since it seeks to gather information on the workability of industrial systems, whereas methodologically, IE focuses on regulatory frameworks and interactions with the ecosystem. The practical aspect of IE involves how companies use it to improve their performance or how policy makers use it to develop SD road maps (Graedel and Allenby 2002). This implies that its principles are applicable to products, companies, organisations, provinces, regions and cities. For example, Su et al. (2013) revealed that IE underpinned the creation of eco-industrial parks in China and has been argued to be responsible for the exchange of by-products and common resources between independent companies (Zhu et al. 2007). That is, waste from one company becomes raw materials for another and, as such, creates a closed loop and reduces the extraction of virgin materials. The industrial symbiosis in Kalundborg, Denmark, is a practical example of IE (Damen 2012), which engages “traditionally separate industries in a collective approach to competitive advantage involving physical exchange of materials, energy, water and by-products” (Chertow 2007 p. 120). IE creates synergy between industries while reducing environmental impacts through techniques including life cycle cost (LCC) and life cycle analysis (LCA) (Hauschild et al. 2005) in compliance with set standards such as ISO14001, ISO9001 and ISO26000 (Jabbour 2013).

Several authors (Ellen MacArthur Foundation 2013a; Yuan et al. 2006) have argued that the circular economy originates from industrial ecology. Murray et al. (2017) note that IE and the circular economy share lineage with much overlap. However, the transition of IE to circular economy may be seen as revolutionary vision for industrial systems (Iung and Levrat 2014) because of the integration between human and natural systems. In addition, Saavedra et al. (2017) maintain that without IE concepts and tools such as industrial symbiosis, circular economy would be impossible. Therefore, IE concentrates on protecting the environment and reducing waste at the firm level, promotes inter-firm industrial symbiosis and encourages the development of eco-industrial parks at state or federal levels. IE is relevant to the construction industry in two ways—industrial symbiosis and eco-industrial parks. The former ensures synergy between different industries where by-product or waste from one becomes resource for another (Boons 2013). For instance, agricultural by-products may be used in the production of construction materials (e.g. sawdust is used in light weight concrete (Aciu and Cobirzan 2013)). On the other hand, eco-industrial park allows communities or industries to share resources, services and facilities. These include centralised waste management services, shared waste management infrastructure and waste recovery through industrial symbiosis (Freitas and Magrini 2017).

Cradle to cradle

Stahel, one of the progenitors of the circular economy, referred to the linear economy as "Cradle to Grave" and CE as "Cradle to Cradle" and (Giarini and Stahel 1989). Walter R. Stahel coined the term "cradle to cradle" in the 1970s. It became popular, however, through the work of Michael Braungart and William McDonough entitled “Cradle to Cradle: Remaking the way we make things”. The present industrial economy model of “take-make-waste-dispose” known as “cradle to grave (C2G)” cannot provide required solutions to the sustainability challenges currently facing the world (McDonough and Braungart 2002). The C2G model is unsustainable hence, the development of the "cradle to cradle" (C2C) model which creates goods and services by generating economic, social and ecological values thus making it sustainable (Preston 2012). Therefore, it can be argued that the C2C model is the exact reverse of the C2G model. However, McDonough and Braungart (2010) described it as a closed-loop production model where materials are recycled to minimise waste.

According to McDonough et al. (2003, p. 435), C2C is an industrial model, which ensures products are designed to be “commercially productive, socially beneficial and ecological intelligent”. As such, C2C is a design method that enables "design for abundance" (McDonough and Braungart 2002) whose main focus lies on eco-effectiveness (Braungart et al. 2007). This is quite different from traditional product design which focuses on reducing negative impacts on the environment (eco-efficiency) (Ellen MacArthur Foundation 2013b). C2C design philosophy is founded on two premises (Persson 2015), which are:

-

Product design for durability, disassembly and refurbishment. It involves the application of the principle of eco-design where renewable materials replace non-renewable materials, toxic and hazardous materials are eliminated, and reuse of products is emphasised (McDonough and Braungart 2002).

-

Modern circular and regenerative forms of consumption. It requires a shift towards a service-based consumption model where buyers are now users (McDonough and Braungart 2002).

In C2C, all materials are considered as nutrients which could either be technical (e.g. metals, polymers and alloys) or biological (e.g. food or wood) where the former can be recycled or reused while the latter can be composted or consumed (European Commission 2014a). To avoid complications off reuse and recycling processes, the components of technical and biological materials are not designed to interact (Löfgren and Enocson 2014). However, these components can be sorted for reuse, recycling and composting as necessary. The more products are recycled or reused, the less energy and raw materials are used—and less waste is generated. C2C also addresses energy and water inputs in addition to materials and “builds on three key principles: ‘Waste equals food’, ‘Use current solar income’ and ‘Celebrate diversity’” (Ellen MacArthur Foundation 2013b, p. 30). Conversely, Amelung and Martens (2008) criticised C2C as being a technical fix which concentrates on technological and material solutions while neglecting societal and cultural dimensions. Similarly, Reijnders (2008) argued that C2C could contribute negatively to the environment due to increased emissions from biological nutrients. These criticisms reveal the deficiency in the concept and suggests the need for a concept that is holistically sustainable.

C2C provides leverage for the circular economy (Linder et al. 2017) and is a pre-requisite for it because it ensures products are manufactured for reuse or recycling (Persson 2015). More so, Esposito et al. (2017) revealed that C2C is synonymous with circular economy. Therefore, C2C incorporated in the circular economy will prevent loss of valuable materials, reduce cost of production and manage waste and pollution as well as provide job opportunities ( Mirabella et al. 2014). As a sustainable concept, Geisendorf and Pietrulla (2018) argued that C2C can be applied to the built environment. C2C in construction emphasises use of renewable energy, reuse and recycling of materials. For instance, materials deconstructed from a building can be used in parts or as a whole in another building or they can be recycled.

Biomimicry

Biomimicry, an innovation approach that utilises nature’s systems, processes, elements, tested patterns and strategies in solving societal or human challenges (Andrews 2015). The term ‘biomimicry’ is a combination of two words, ‘bio’ (nature) and ‘mimicry’ (imitate), which simply means to imitate nature. Andrews (2015) described biomimicry as a concept imitating nature, where nutrients are obtained from the decomposed organic materials for future organisms. Examples include: birds research to aid human flight (Ellen MacArthur Foundation 2013b) referred to by Benyus (1997) as “innovation inspired by nature” or good design inspired by nature (Pawlyn 2011). Therefore, biomimicry is an inspiration for designers. Biomimicry is dependent on three core concepts (Ellen MacArthur Foundation 2013b, p. 31), which are:

-

“Nature as model”: Human problems are solved by imitating the shapes, methods, structures and techniques of a natural model.

-

“Nature as measure”: ecological criteria are used to determine the sustainability of innovations.

-

“Nature as mentor”: teaches important lessons.

The concept of biomimicry has been criticised as a weak sustainability concept because it encourages biological pretence rather than biological reality, and it employs technology in achieving what nature achieves (Murray et al. 2017). However, it is very relevant to the concept of the circular economy because its objectives encompass sustainability (Benyus 2007) and has been referred to as an example of circular economy (Andrews 2015). Being a nature inspired design solution, it is relevant to the construction industry especially in architectural designs. Practical example of where it has been used is Beijing Olympic stadium inspired by natural bird’s nest. According to Pawlyn (2011), Biomimicry in construction takes three forms—biomorphic, bio-utilisation and biophilia. Biomorphic involves direct mimicking of nature (e.g. design of building to look like a natural object such as leaf, ant or landscape); bio-utilisation encompasses use of natural objects to provide benefits such as comfort (e.g. use of trees to screen fenestrations); and biophilia suggests a form of bond between humans and other living beings (e.g. use of floras to create comforting environment) (Pawlyn 2011).

Regenerative design

Literally, the term “regenerate” means “create again” which, in the context of the circular economy, refers to the use of existing materials to create new ones. It is a process-oriented systems theory developed in the late 1970s by John T. Lyle (Regenerative Leadership Institute 2015). According to Geisendorf and Pietrulla (2018), regenerative design relies on systems theory and closed-loop input and output models for the design of products and services. This system generates no waste by restoring, reusing and revitalising its sources of energy and materials which ensures that its output is greater than or equal to its inputs (Regenerative Leadership Institute 2015). Lieder and Rashid (2016) argued that regenerative design can be achieved through biomimicry which is applicable in human habitation including buildings, urban environment, industry, social systems and economics. Therefore, regenerative design is aimed at developing an effective collaboration between humans and other species while waste materials are reintroduced into the system by creating a new product. Regenerative design is different from sustainable design in that the latter ensures products are designed to last long but does not regenerate or create new product (Regenerative Leadership Institute 2015). In the construction industry, it ensures buildings provide and enhance quality of life by providing better conditions and ensuring healthy relationships between the physical, built and environment. Likewise, it ensures better conditions, increased biodiversity and prevent environmental pollution (Nugent et al. 2016).

Blue economy system

The blue economy was initiated by Gunter Pauli (Ellen MacArthur Foundation 2013b). It depicts the future of mankind being a social structure that follows a systematic process whose name was derived from the earth’s sky and ocean’s blue colour in the absence of pollution (Pauli 2011). Kathijotes (2013, p. 8) described it as “the new system of ocean-based green economy that interweaves creative neo-science and technologies with the ocean” which preserves the oceans by ensuring its sustainability. Similarly, Brein (2015) referred to it as an economic philosophy that derived knowledge from the formation, production and consumption of the natural systems. Geisendorf and Pietrulla (2018) however argued that blue economy is not only economically viable but could solve societal issues by creating new job opportunities while protecting the environment thereby making it a sustainable approach. This was supported by Pauli (2010) who described blue economy as innovative and creative which promotes new business models by proffering scientific solutions to environmental problems through ecosystems. The blue economy is based on twenty-one founding principles, with an increasing focus on gravity being the principal energy source. When applied to human challenges, it must ensure that solutions are determined by their local environment (Ellen MacArthur Foundation 2013a). Conversely, Geisendorf and Pietrulla (2018, p. 774) modified the 21 basic principles of the blue economy into six principles (Blue Economy 2016), which are:

-

It must be local.

-

It should be efficient in terms of materials or resources.

-

Systemic approach to the imitation of the natural environment. For example, Algae house in Germany incorporates microalgae (living matter) into its design.

-

Lucrative strategies by optimising and generating “multiple cash flows” (Blue Economy 2016, p. 1).

-

Satisfaction of “all basic needs” (Blue Economy 2016, p. 1).

-

Creating change through an innovative culture.

Based on these principles, the blue economy has the potential to contribute to developing the circular economy concept. It has however been addressed as a vital source of inspiration and a concept that overlaps with the circular economy (Geisendorf and Pietrulla 2018). Blue economy’s contribution to construction is by protecting the ocean through sustainable activities while carrying out construction works such as boat and ship building, harbour development and offshore wind farms on the ocean.

Performance economy

Stahel introduced the concept ‘performance economy’ in 1986 and has been used interchangeably with ‘functional economy’ (CIRAIG 2015). According to Stahel (2010), performance economy is driven by an emphasis on economic and quality usage and efficiency in use (not production); optimising existing stocks; selling goods as services and automatic profitability when material, waste, carbon and energy costs increase or labour costs decrease. Stahel disclosed that when this is apparent, high performance service, more jobs and greater value will be achieved.

Stahel (2010) claimed that the primary objectives of the performance economy are the extension of product lifecycle, long-lived goods, reprocessing, resource conservation, increased wealth, job creation and reduction in resource consumption. He emphasised selling of goods as services because it is sustainable and preventative as the cost of risk, and waste is absorbed by manufacturers. He argued that a product-service approach would decrease environmental pollution resulting from the production and consumption of new products. Furthermore, Stahel emphasised that selling goods as services will integrate time, achieve highest resource efficiency and security, maintain ownership of material, exploit sufficiency and prevention as profit strategies and lead to designs of new products for return and reuse of goods and components. Selling goods as services have been described as profitable and a competitive business model of the circular economy (Stahel 2010, 2013). With a focus on circularity through maximum use value (Geisendorf and Pietrulla 2018), sustainability will be enhanced and products will have longer lifespan. Design is the bedrock of the performance economy and as such, it should be carefully considered to achieve desired results. Similarly, implementation of product-service systems requires a holistic approach to achieve success. Therefore, effectiveness (“doing the right thing”) of product design and implementation must be distinguished from efficiency (“doing them right”) (CIRAIG 2015) to define stakeholders’ roles. Mont (2002) suggested that companies manufacturing products must change processes and organisational structures while consumers must be willing not to own a product but to use its service. It is relevant to the construction industry in that it emphasises the need to use a product’s service rather than owning the product. For example, carpets may be leased to building occupants while producers or manufacturers take responsibilities for its maintenance.

Eco-efficiency

Eco-efficiency, a management philosophy coined in 1992 (Willard 2002) refers to “doing more with less” (Braungart and McDonough 2009, p. 51), is described as an approach that reduces material toxicity, velocity and volume in the production process (Ellen MacArthur Foundation 2013b). It aims to reduce adverse environmental impacts resulting from manufacture and use of materials (McDonough and Braungart 2002) which allows for healthy competition among companies in minimising waste through reuse and recycling approaches. The major facets of eco-efficiency include minimisation of energy, waste, emissions, water and use of virgin resource; extension of operation and product life; incorporation of lifecycle principles; reuse and recycling of end-of-life products and improved service speed (Srinivas 2015). Through these approaches, eco-efficiency contributes to environmental sustainability while achieving economic benefits resulting from lower production costs. As a result, Ghisellini et al. (2016) described eco-efficiency as a business concept which concentrates on environmental and economic dimensions of sustainability. However, it has been criticised for not resolving root problems with different systems (Iung and Levrat 2014) and for neglecting the social dimension of sustainability (Ghisellini et al. 2016) but Ren (2007) suggested that eco-efficiency is a good indicator to measure CE activities. In buildings, it relates the performance (e.g. indoor condition, service life, adaptability, safety, comfort, accessibility and usability) and conformity (e.g. location, space and service) with environmental pressures (Häkkinen et al. 2002).

Eco-effectiveness

Eco-effectiveness concentrates “on the development of products and industrial systems that maintain or enhance the quality and productivity of materials” (Braungart et al. 2007, p. 1). It implies doing the appropriate things in terms of systems, services, products and materials rather than reducing inappropriate things (Braungart et al. 2007). Thus, eco-effectiveness is the alternative to eco-efficiency. Ellen MacArthur Foundation (2013b) alleged that eco-effectiveness allows for strong association between products, their materials, environment and economic growth. This suggests that product design plays a vital role in achieving the change related to eco-effectiveness. Therefore, products should be designed to incorporate sustainability principles such as the life cycle concept of ‘cradle-to-cradle’ suggested by Braungart and McDonough (2009). Furthermore, McDonough and Braungart (2008) observed that eco-effective designers widen their horizons by considering the overarching purpose of products rather than their primary functions. They also reflect on products’ immediate and future goals, effects and systems (e.g. cultural, commercial and ecological). Several studies (Ellen MacArthur Foundation 2013b; McDonough and Braungart 2002) have found eco-effectiveness to positively integrate the environment, economic and social dimensions of sustainability and as such, recommended it for the circular economy. In construction, it offers opportunities for manufacturers, suppliers and professionals to rethink material production, supply and consumption, respectively. It also encourages use of materials with less environmental impacts, sustainable supply chain management, sustainable consumption and sustainable construction via redesigning of the production and consumption systems.

Material passports

According to Gaspar, Juliào and Tjahjono (2018), lack of information about a product increases consumers’ doubt about its performance, value for money and reduces purchase intention. Therefore, the need for consumers to has detailed information about products led to the development of material passports described by Merrild et al. (2016) as the link between physical elements and digital models. Product information may be transmitted to consumers in different ways by providing clear and comprehensive contents. For instance, D’Souza et al. (2006) suggested the use of environmental labelling which may consist of symbols or messages which communicate benefits and characteristics of products to consumers. In building construction, Jones and Comfort (2018) referred to material passports as “electronic sets of data that describe those characteristics of building materials, products and product systems that enable value recovery from materials” (p. 8–9). Material passports are gaining more attention among construction organisations due to their ability to provide supplementary information about the physical and chemical property of products. Future development of materials used and to be used, respectively, in their projects are also provided (Arcadis 2017). More so, all available materials and resources stored in the material bank (a resource library for materials) may be tracked and reused (Minunno et al. 2018). Therefore, materials and resources recorded can be disseminated across stakeholders in the industry (Jones and Comfort 2018). This concept supports the circular economy by providing information about materials and resources which makes the application of circular economy principles effortlessly.

Reverse logistics

Reverse logistics (RL), also known as green recycling (Ying and Li-jun 2012), are the opposite of conventional logistics which deals with how products or goods are conveyed to consumers. RL is about how used or damaged products are returned to the producers or manufacturers. De Brito and Dekker (2004, p 5) described RL as “the process of planning, implementing and controlling backward flows of raw materials, in process inventory, packaging and finished goods, from a manufacturing, distribution or use point, to a point of recovery or point of proper disposal”. As shown in Fig. 2, products returned by consumers can be re-introduced in a reverse direction of the manufacturing process. Additional processes such as refurbishing (Ravi et al. 2005) and remanufacturing (Kim et al. 2006) may be included in the re-introduction of products, depending on the level of damage.

Source: Adopted from Findlow (2016)

Reverse logistics.

Aside from preventing the environmental pollution associated with reverse logistics, economic gains resulting from maximal recycling of materials (Ying and Li-jun 2012) and efficient customer relationships via return policies and stable customer base (Geisendorf and Pietrulla 2018) are tenets of RL which position it as a sustainable concept. The challenges of RL are embedded in returns management in relation to customer retention (Daugherty et al. 2002) and asset tracking and recovery management (Esposito et al. 2017). Although, these challenges may pose a threat to circular economy, the main goal of RL is to close the loop of product lifecycles which is vital to the circular economy concept (Le Moigne 2014). It is quite relevant to the construction industry in a manner that it encourages reuse and recycling of materials (e.g. off-cut of reinforcement bars) which can be returned to the manufacturers.

Zero emission

Three phases are involved in controlling and reducing emissions from industrial production (Srinivas 2015). They are:

-

End-of-pipe treatment—application of technologies to clean up emissions after they have been generated (Srinivas 2015).

-

Cleaner production—application of techniques and strategies at the production stage to avoid pollution, reduce costs and prevent risks (Srinivas 2015).

-

Zero emissions—involves alteration of production technologies and strategies to reduce resource inputs and consumption (Srinivas 2015).

According to Pauli (1997, 2010), the concept of ‘zero emissions’ describes an industrial system where all material inputs are used by emulating natural cycles. As an industrial process, it advocates a shift from traditional models associated with waste to a more integrated systems where materials are used extensively (Song et al. 2015). Zero emission, when addressed from the environmental point of view, aims to proffer solutions to pollution emanating from industrial production by eliminating waste. This may be achieved through a zero emission strategy (Figge et al. 2014) which ensures optimal use of materials to maximise their value while preventing environmental pollution. Materials in a zero-waste system are circular indicating that they are used multiple times until they reach their end-of-life which implies their effective utilisation (Murphy and Pincetl 2013). From a business perspective, zero emission presents competitiveness among companies. For instance, productivity in terms of labour, capital and raw materials vary. However, they are expected to create jobs and revenue by minimising resources and consumption. The zero emissions concept has been applied by several businesses such as Toyota, Fuji Xerox, NEC, Epson and Hewlett Packard (Greyson 2007; Matete and Trois 2008). Therefore, industries would have to re-organise their production systems to allow for resource effectiveness and efficiency. In construction, it involves application of strategies that will ensure continuous use of material waste to prevent environmental pollution.

Permaculture

The term "permaculture" is described as "the conscious design and maintenance of agriculturally productive ecosystems, which have diversity, stability and resilience of natural ecosystems" (Ellen MacArthur Foundation 2013b, p. 31). It is a social system that encompasses all aspects of human living such as food, shelter, water and climate. Its branches include: environmental design, ecological design and engineering, construction and integrated water resource management, all of which transform into sustainable agriculture, sustainable architecture, regenerative and self-maintained habitats (Mars 2005). It draws elements from traditional sustainable agriculture, agroforestry, conservation agriculture, organic agriculture, sustainable livestock management, agro-ecology and modern innovations and principles (Ellen MacArthur Foundation 2013b) and ensures that recycled materials are used in preference to new materials in construction based on the fact that they are relatively cheap building products (Regenerative Leadership Institute 2015). Overall, permaculture infuses natural building and agriculture into a single human eco-system by ensuring that human activities do not have negative impacts on the environment (Regenerative Leadership Institute 2015). Its implication for construction is that the balance of natural ecosystem or living organisms should be uninterrupted due to construction activities. In addition, damages to existing natural system resulting from such activities should be rebuilt or re-established.

Natural capitalism

Natural capital is the global inventory of natural resources, including water, air, minerals, geology, soil and other species that make life possible (Srinivas 2015). For instance, the soil produces food while plants are used for several other things such as medicine, fuel and building materials. According to Hawken et al. (2013), natural capitalism through the adoption of new technologies in product design, aims to increase the lifespan of resources and productivity of natural capital. Businesses may reinvest in natural capital using their savings which would promote regeneration of natural resources. Similarly, Hawken et al. (2013) suggest that waste should be eliminated through closed-loop production that is biologically motivated by returning them into the ecosystem or reusing them as raw material for another product. This positions natural capitalism as an environmentally sustainable concept by preventing environmental pollution. To achieve socio-economic sustainability, Hawken et al. (2013, p. 134) advised that the common sale-of-good model (an exchange of goods between seller and buy at an agreed price) should be substituted for a “service-and-flow” business model which increases resource productivity while offering great value to customers (Maxwel et al. 2006). Natural capitalism has the capacity to contribute to achieving sustainability which makes it an important concept of the circular economy. Its application within construction sector suggests that through the adoption of eco-design principles, building materials can easily be disassembled and reused.

Extended producer responsibility

Thomas Lindhqvist introduced the concept, ‘extended producer responsibility’ (EPR) in Sweden in 1990 and described it as “an environmental protection strategy to reach an environmental objective of a decreased total environmental impact of a product, by making the manufacturer of the product responsible for the entire life cycle of the product and especially for the take-back, recycling and final disposal” (Lindhqvist 2000, p. ii). Responsibilities for products from inception (i.e. material sourcing and production) to completion (i.e. recycling or disposal) are entrusted to producers within the EPR framework. EPR encompasses ownership, economic responsibility, liability, informative responsibility and physical responsibility with ownership being the overarching variable (Lindhqvist (2000) cited in CIRIAG (2015)). Ownership of products therefore suggests producers’ liability throughout the lifecycle of products and producers are expected to take actions to prevent waste. The OECD (2016) claimed that shifting product responsibility to producers and providing them with incentives to encourage eco-design of products are the main features of EPR. More so, the incentives are to encourage the application of the 3R principles on products including disposal of waste.

EPR has been described as a concept consistent with the "polluter pays principle" (Ghisellini et al. 2016; Lindhqvist 2000) and as an economic tool that ensures products and materials flow in circularity (Manomaivibool and Hong 2014). According to the OECD (2016), initiatives such as innovative disposal fees, take-back schemes, return and earn, standards and a mix of downstream subsidies and upstream taxes are instruments used to shift product liability to producers. Though EPR has the capacity to reduce waste, it has been criticised for its lack of influence on eco-design and redesign of products as well as lack of materials choice and reduction of toxins (Lifset et al. 2013). However, it is an important aspect of cleaner production which is one of the core areas of the circular economy.

Applications of the circular economy pillars to the construction industry

Characteristics of the circular economy concept can be summarised to include environmental protection, closing the loop, resource efficiency, design and service model (Geisendorf and Pietrulla 2018). However, these characteristics can indeed be adapted to the construction industry to enhance performance, competitiveness and sustainability. Table 1 reveals how each pillar ranks across the five characteristics of the circular economy concept. It can be deduced from the results that all the pillars share at least one similar characteristic of the circular economy, which further confirms their relationship. The pillars exhibiting only one out of the five characteristics are considered to have a weak relationship, while those with two, three and four characteristics are deemed to have strong, stronger and strongest relationships, respectively. This implies that the contribution of each pillar to make up the circular economy concept varies. Nonetheless, they are all important and applicable to the construction industry. Table 1 provides a summary of the potential contributions of the circular economy pillars to the construction industry. It is evident from the findings that all pillars can provide environmental protection. In addition, seven (50%) of the pillars can improve reuse and recycling, while six (42.8%) can ensure resource efficiency. Three (21.4%) of the pillars can contribute to the design of products or materials, while the remaining two can be adopted for service model. The subsequent sections offer a detailed description of how the characteristics of the circular economy concept contribute to the construction industry.

Environmental protection

It is evident that all circular economy concepts offer priority to the environment and are driven by the need to reduce environmental degradation, such as pollution. Though the construction industry is struggling to reduce its carbon footprint from waste-generating activities and materials, application of the circular economy pillars would not only reduce waste but encourage the use of renewable materials, thus lowering the negative environmental impact. One of the potential reasons for considering, adopting and implementing circular economy in the construction industry is its environmental impacts, which has been regarded as a novel solution (Persson 2015). The construction industry is material and process-oriented, which indicates that a large amount of materials (renewable and non-renewable) are consumed in a project. With the adoption of the circular economy, non-renewable resources such as fossil, water, minerals and fuels can be conserved; environmental impacts can be reduced through efficient material and energy use including less water discharge; use of toxic materials can be avoided; local ecosystems can be recovered; and the lifespan of landfill can be extended (Geng et al. 2012). By using renewable sources of energy, the circular economy will minimise input–output flow of virgin materials thereby reducing emissions and waste (Korhonen et al. 2018). In addition, an expected decline in the use of virgin materials for industries including construction and automotive by 32% and 53% by 2030 and 2050 was predicted by the Ellen MacArthur Foundation and McKinsey Centre for Business and Environment in 2015. This suggests an imminent decline in environmental degradation as a result of industrial activities. More importantly, adoption of the circular economy pillars in the construction industry can minimise material waste (European Commission 2017; Ghisellini et al. 2016; Lieder and Rashid 2016); save costs (Moon and Holton 2011); enhance resource efficiency (Jones and Comfort 2018; Korhonen et al. 2018; Prieto-Sandoval et al. 2018); reduce environmental pollution (Jawahir and Bradley 2016; Prieto-Sandoval et al. 2018); improve eco-efficiency (Yuan et al. 2006); prevent environmental poverty (Zhijun and Nailing 2007); and enhance energy efficiency (Ghisellini et al. 2018; Korhonen et al. 2018). In lieu of the positive environmental impacts of the circular economy pillars, it is therefore expedient that construction professionals understand them, identify those that are suitable for their projects and establish ways of implementing them.

Closing the loop

In the construction industry, circular economy pillars such as IE, C2C, regenerative design, eco-efficiency, eco-effectiveness, reverse logistics and zero emissions can enhance closing material loop by reuse and recycling. Closing the loop implies that no material is left hanging in the cycle. Several authors (Allwood et al. 2012; Brown and Buranakarn 2003; Stahel 2016) have considered material reuse as a key approach for closing the loop. Likewise, recycling of products or their component parts could ensure their continuous use over time. This would enhance material recovery and maximise the product value. In construction, a whole building and its components parts can be reused as noted by Al-Obaidi et al. (2017). Most construction materials (e.g. steel, concrete, aluminium and wood) can be recycled at the end of their useful lives suggesting that recycling is important in closing the material loop. Repair and refurbishment of materials can also be considered in ensuring closed loop. Broken materials or structures can be repaired while old materials can be restored. More so, a complete building can be restored as revealed by Vilches et al. (2017). Aside closing the material loop, repair, reuse and recycling of materials could also be effective in energy savings. For instance, Ng and Chau (2015) found that material reuse and recycling could save 6.22% and 54% of embodied energy, respectively. Prefabrication of materials or component parts can be a veritable approach in closing material loop in the construction industry. With prefabrication, building components are produced off-site and are assembled on site. This allows for appropriate inventory of materials (Minunno et al. 2018) and waste materials emanating from the production process can be returned into the system thereby ensuring no material leftovers. Therefore, it is important that materials or products are designed for ease of conversion, reuse and recycling. This would reduce the amount of waste that are sent to landfill. The implication is for construction professionals to incorporate into their design the circular economy pillars identified to enhance closing material loop in their design and to ensure that durable materials are specified for construction projects.

Resource efficiency

As shown in Table 1, C2C, IE, zero emissions, eco-efficiency, eco-effectiveness and natural capitalism are circular economy pillars that can improve resource efficiency. Ness (2008) observed that resource efficiency entails reducing resources while maintaining simultaneous improvements in both economic and social dimensions. It is an important concept for the circular economy because it focuses on the longevity of products (Persson 2015), which allows for reuse and recycled without losing value. Therefore, the goal of resource efficiency in the circular economy concept is to bring diverse actors or stakeholders to work together on reducing resource input in a production system. As a result, this concept contributes to achieving sustainability. In construction, resource input may be reduced when different actors work together. For example, supervisors closely monitoring operatives could ensure materials are not used in excess of what is required. Similarly, contractors working closely with sub-contractors to ensure effective use of materials. During procurement of materials, construction professionals can work with suppliers and manufacturers to ensure resource efficiency in the production line. Conversely, green supply chain management can be employed to enhance resource efficiency in construction due to its ability to reduce pollution (Ying and Li-jun 2012). Since the construction industry relies heavily on material, the success of the circular economy pillars identified to enhance resource efficiency would depend on whether material waste is seen as a resource. Therefore, it is important for construction professionals to understand that products and their components are resources that may become raw materials for another product or industry.

Design

Biomimicry, regenerative design and eco-effectiveness are the circular economy pillars that can contribute to design as shown in Table 1. The goal of these pillars when implemented in construction is to design out waste, which can be achieved if building materials were designed to be durable, reused and recycled (Andrews 2015) and construction projects designed to be deconstructed (Desai and Mital 2005). By designing buildings with durable materials and high-quality specifications, their longevity can be increased, which in the long run would decrease maintenance cost (Rizos et al. 2017). The Ellen MacArthur Foundation (2013a) outlined some design conditions for consideration during design, including design for durability, design for easy end-of-life sorting, design for ease of manufacturing, material selection, separation of materials for reuse and use of standardised components. In addition, design strategies such as design for off-site construction, design for material optimisation, design for waste-efficient procurement, design for flexibility and deconstruction, design for reuse and recovery, design for product attachment and trust, design for product durability, design for standardisation and compatibility, design for upgradability and adaptability and design for disassembly and reassembly (Bakker and Hollander 2013; Esposito et al. 2018) have the capability to extend the lifespan of products and ensure their circularity in the construction industry. These design strategies can stem waste generation and improve resource efficiency. Therefore, it is important for designers (architects and engineers) to not only consider aesthetics and functionality but rather, consider the end-of-life of the product when designing. Furthermore, design techniques for waste minimisation should be considered throughout the design cycle. Understanding the specific CE pillars (biomimicry, regenerative design and eco-effectiveness) could assist designers in developing strategies to achieve circularity in design.

Service models

As shown in Table 1, natural capitalism and performance economy are two key circular economy pillars that prioritise product as a service rather than product ownership. Product as a service (PaaS) is a model that is applicable to the construction industry. In this model, building components such as doors and windows can be offered as a service to clients, which indicates that clients have no responsibility for its maintenance. This is contrary to the common ownership model where the client owns the building and its components. In PaaS model, the liability lies with the company offering the components as a service, thereby taking full responsibility for maintenance and replacement of worn out parts. According to Rizos et al. (2017), implementation of the PaaS model can be through performance agreements, lease, rentals and pay-per-use. Zuidema (2015) noted that building components and parts can be leased or rented, which further stressed the PaaS model as a suitable for the construction industry. The producer takes responsibility for improving product quality, performance and value (Gregson et al. 2015). This could save construction costs and minimise resource extraction and in the long run, reduce environmental footprint of the industry. The PaaS model would encourage development of durable products and materials. This implies the need for the industry to encourage a shift from the current ownership model to the PaaS model. Therefore, it is important for construction professionals to explore several ownership and service models to further understand their applicability in the industry.

Conclusion

This study has identified 14 pillars of the circular economy concept and their potential application to the construction industry. It discussed concepts including industrial ecology, cradle to cradle, biomimicry, regenerative design, blue economy system, performance economy, eco-efficiency, eco-effectiveness, material passports, reverse logistics, zero emission, permaculture, natural capitalism and extended producer responsibility. The study indicates that the contribution of each pillar to the circular economy concept varies and are categorised as weak, strong, stronger and strongest relationship. This paper reveals that all the concepts can mitigate pollution thereby ensuring environmental protection, which is vital for the construction industry. Through reuse and recycling of materials, the C2C, eco-efficiency, zero emission, reverse logistics, regenerative design and IE can enhance closing the material loop. Resource efficiency in the construction industry can be achieved through the circular economy pillars such as zero emission, eco-effectiveness, natural capitalism eco-efficiency, IE and C2C, if material waste is seen as a resource. In addition, Biomimicry, regenerative design and eco-effectiveness can reduce waste through design if they are incorporated early in the design phase. While natural capitalism and performance economy prioritise product ownership, they can enhance the production of durable products or materials. The study revealed the need for the construction industry to devise means of incorporating the circular economy pillars into activities ranging from design to actual construction. This could ensure that the environmental degradation commonly associated with construction activities are duly considered and minimised in the process. In addition, the key implication of this study is for construction professionals to update their knowledge base on the circular economy pillars through further training. It is assumed that the adoption and application of the circular economy pillars in construction activities can be strengthened by understanding their potentials. Overall, the contribution of this study is that it summarises the pillars of the circular economy concept and identifies the level of knowledge on their implementation in the construction industry. This study has some limitations, which offer perspectives for future research. Firstly, the study did not specify how and when to apply the concept in the construction industry. Therefore, future study may focus on the application of the concept from the pre-construction to post-construction phases. Secondly, the study is limited in its comparison of the circular economy pillars. Future studies may compare the circular economy pillars in order to evaluate the appropriate concepts for each phase of construction. Lastly, the study lacks a framework and strategies for the implementation of the circular economy concept in the construction industry. Future study efforts should concentrate on the development of a framework for the identification of suitable concepts. Also, appropriate strategies for implementation at different phases of construction may be explored.

References

Abarca-Guerrero L, Maas G, van Twillert H (2017) Barriers and motivations for construction waste reduction practices in Costa Rica. Resources 6(4):69

Abdelhamid MS (2014) Assessment of different construction and demolition waste management approaches. HBRC J 10(3):317–326

Aciu C, Cobîrzan N (2013) Use of agricultural products and waste in the building materials industry. ProEnvironment/ProMediu 6:15

Akinade OO, Oyedele LO (2019) Integrating construction supply chains within a circular economy: an ANFIS-based waste analytics system (A-WAS). J Clean Prod 229:863–873

Alhola K, Ryding SO, Salmenperä H, Busch NJ (2019) Exploiting the potential of public procurement: opportunities for circular economy. J Ind Ecol 23(1):96–109

Allwood JM, Cullen JM, Carruth MA, Cooper DR, McBrien M, Milford RL et al (2012) Sustainable materials: with both eyes open (p 64). UIT Cambridge Limited, Cambridge, UK

Al-Obaidi K, Wei S, Ismail M, Kam K (2017) Sustainable building assessment of colonial shophouses after adaptive reuse in Kuala Lumpur. Buildings 7(4):87

Amelung B, Martens P (2008) Wankele wieg (cradle to cradle). Milieudefensie Mag Amsterdam: Vereniging Milieudefensie 37(5):28–29

Andrews D (2015) The circular economy, design thinking and education for sustainability. Local Econ Local Econ 30(3):305–315

Arcadis (2017) Top 5 resources. From supply to demand (in Dutch). http://edepot.wur.nl/422138. Accessed 25 Nov 2019

Bakker C, Hollander M (2013) Six Design Strategies for Long Lasting Products in Circular Economy. http://www.theguardian.com/sustainable-business/six-design-strategies-longer-lasting-products. Accessed 4 March 2018

Balanay R, Halog A (2019) Tools for circular economy: Review and some potential applications for the Philippine textile industry. In Circular Economy in Textiles and Apparel (pp 49–75). Woodhead Publishing.

Benyus JM (1997) Biomimicry: Innovation inspired by nature. Biomimicry Institute, Missoula

Benyus JM (2007) 12 sustainable design ideas from nature. TED, California

Blue Economy (2016) Website. Principles. http://www.blueeconomy.eu/page/the-principles-of-blue-economy/

Boons F (2013) Ecological modernization and industrial ecology: The handbook of global companies. Wiley, Hoboken, pp 388–402

Braungart M, McDonough W (2009) Remaking the way we make things: cradle to cradle. Vintage, London

Braungart M, McDonough W, Bollinger A (2007) Cradle-to-cradle design: creating healthy emissions–a strategy for eco-effective product and system design. J Clean Prod 15(13–14):1337–1348

Brown MT, Buranakarn V (2003) Emergy indices and ratios for sustainable material cycles and recycle options. Resour Conserv Recycl 38(1):1–22

Chertow MR (2007) “Uncovering” industrial symbiosis. J Ind Ecol 11(1):11–30

Chiu A, Geng Y (2004) Adaptation of industrial ecology in Asian developing countries. J Clean Prod 12:1037–1045

CIRAIG (International Reference Center for the Life Cycle of Products Processes and Services) (2015) Circular economy: A critical literature review of concepts. Montreal, Québec, Canada: Bibliothèque et Archives nationales du Quebec (BAnQ)

Damen MA (2012) A resource passport for a circular economy: An assessment of the possible content and format of a resources passport in order to successfully contribute to the achievement of the circular economy. Dissertation, University of Utrecht

Daugherty PJ, Myers MB, Richey RG (2002) Information support for reverse logistics: the influence of relationship commitment. J Bus Log 23(1):85–106

De Brito MP, Dekker R (2004) A framework for reverse logistics. In: Reverse logistics. Springer, Berlin, Heidelberg, pp. 3–27

Desai A, Mital A (2005) Incorporating work factors in design for disassembly in product design. J Manufact Technol Manage 16(7):712–732

D’Souza C, Taghian M, Lamb P (2006) An empirical study on the influence of environmental labels on consumers. Corp Commun Int J 11:162–173

Ellen MacArthur Foundation (EMF) (2013a) Towards circular economy: economic and business rationale for an accelerated transition, vol 1. Ellen MacArthur Foundation, United Kingdom

Ellen MacArthur Foundation (EMF) (2013b) Towards the circular economy: opportunities for the consumer goods sector, vol 2. Ellen MacArthur Foundation, United Kingdom

Erkman S (1997) Industrial ecology: an historical view. J Clean Prod 5(1–2):1–10

Esposito M, Tse T, Soufani K (2017) Is the circular economy a new fast-expanding market? Thunderbird Int Bus Rev 59(1):9–14

Esposito M, Tse T, Soufani K (2018) Introducing a circular economy: new thinking with new managerial and policy implications. California Manage Rev 60(3):5–19

European Commission (EC) (2014a) Towards a Circular Economy: A Zero Waste Programme for Europe. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. European Commission, Brussels

European Commission (EC) (2017) The role of waste-to-energy in the circular economy. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions

Figge F, Young W, Barkemeyer R (2014) Sufficiency or efficiency to achieve lower resource consumption and emissions? The role of the rebound effect. J Clea Prod 69:216–224

Findlow F (2016) Reverse Logistics in a Circular Economy. CERASIS, Texas

Freitas LA, Magrini A (2017) Waste management in industrial construction: investigating contributions from industrial ecology. Sustainability 9(7):1251

Gaspar M, Julião J (2018) Tjahjono B (2018) Circular economy in a multiple helix perspective: a review. Management and Marketing (MAC-EMM, Economics, p 121

Geisendorf S, Pietrulla F (2018) The circular economy and circular economic concepts—a literature analysis and redefinition. Thunderbird Int Bus Rev 60(5):771–782

Geng Y, Fu J, Sarkis J, Xue B (2012) Towards a national circular economy indicator system in China: an evaluation and critical analysis. J Clean Prod. https://doi.org/10.1016/j.jclepro.2011.07.005

Ghisellini P, Cialani C, Ulgiati S (2016) A review on circular economy: the expected transition to a balanced interplay of environmental and economic systems. J Clean Prod 114(2016):11–32

Giarini O, Stahel WR (1989) The limits to certainty—facing risks in the new service economy. Mass Kluwer Academic, Boston.

Graedel TE, Allenby BR (2002) Hierarchical metrics for sustainability. Environ Qual Manage 12(2):21–21

Graedel TE, Reck BK, Ciacci L, Passarini F (2019) On the spatial dimension of the circular economy. Resources 8(1):32

Gregson N, Crang M, Fuller S, Holmes H (2015) Interrogating the circular economy: the moral economy of resource recovery in the EU. Econ Soc 44(2):218–243

Greyson J (2007) An economic instrument for zero waste, economic growth and sustainability. J Clean Prod 15(13):1382–1390

Häkkinen T, Huovila P, Tattari K (2002) Eco-efficient building process. In: från International conference of sustainable building, pp. 23–25

Hauschild M, Jeswiet J, Alting L (2005) From life cycle assessment to sustainable production: status and perspectives. CIRP Ann 54(2):1–21

Hawken P, Lovins AB, Lovins LH (2013) Natural capitalism: the next industrial revolution. Routledge, Ambingdon

Hayashi H, Kitamura M, Nagasawa SY, Suga T (2019) Hayashi H, Kitamura M, Nagasawa SY, Suga T (2019) Circular economy in business strategy of manufacturing company in technologies and eco-innovation towards sustainability I. Springer, Singapore

Iung B, Levrat E (2014) Advanced maintenance services for promoting sustainability. Procedia CIRP 22:15–22

Jabbour CJC (2015) Environmental training and environmental management maturity of Brazilian companies with ISO14001: empirical evidence. J Clean Prod 96:331–338

Jawahir IS, Bradley R (2016) Technological elements of circular economy and the principles of 6R-based closed-loop material flow in sustainable manufacturing. Procedia Cirp 40(1):103–108

Jones P, Comfort D (2018) The construction industry and the circular economy. Int J Manag Cases 20(1):4–15

Kathijotes N (2013) Keynote: Blue economy-environmental and behavioural aspects towards sustainable coastal development. Proc Soc Behav Sci 101:7–13

Kim K, Song I, Kim J, Jeong B (2006) Supply planning model for remanufacturing system in reverse logistics environment. Comput Ind Eng 51(2):279–287

Korhonen J, Honkasalo A, Seppälä J (2018) Circular economy: the concept and its limitations. Ecol Econ 143:37–46

Le Moigne R (2014) L’Économie circulaire. Dunod, France

Lieder M, Rashid A (2016) Towards circular economy implementation: a comprehensive review in context of manufacturing industry. J Clean Prod 115:36–51

Lifset R, Atasu A, Tojo N (2013) Extended producer responsibility: national, international and practical perspectives. J Ind Ecol 17(2):162–166

Linder M, Sarasini S, van Loon P (2017) A metric for quantifying product-level circularity. J Ind Ecol 21(3):545–558

Lindhqvist T (2000) Extended producer responsibility in cleaner production: Policy principle to promote environmental improvements of product systems. Lund University, Sweden

Liu JYS (2012) Circular economy and environmental efficiency–the case of traditional Hakka Living system. Pro Soc Behav Sci 57:255–260

Löfgren J, Enocson H (2014) Textile and recycling initiatives–A step towards a circular economy. Göteborgs universitet, Gothenburg

Lowe DG (2001) Local feature view clustering for 3D object recognition. Paper presented at the computer vision and pattern recognition, 2001. CVPR 2001. Proceedings of the 2001 IEEE computer society conference

Manomaivibool P, Hong JH (2014) Two decades, three WEEE systems: how far did EPR evolve in Korea’s resource circulation policy? Resour Conserv Recycl 83:202–212

Mars R (2005) The basics of permaculture design. Chelsea Green Publishing, Vermont

Matete N, Trois C (2008) Towards zero waste in emerging countries–a South African experience. Waste Manage 28(8):1480–1492

Maxwell D, Sheate W, Van Der Vorst R (2006) Functional and systems aspects of the sustainable product and service development approach for industry. J Clean Prod 14(17):1466–1479

McDonough W, Braungart M (2002) Cradle to cradle: rethinking the way we make things. North Point, NY

McDonough W, Braungart M (2008) 3 Remaking the way we make things: creating a new definition of quality with cradle-to-cradle design. The International handbook on environmental technology management 33.

McDonough W, Braungart M (2010) Cradle to cradle: remaking the way we make things. MacMillan, London

McDonough W, Braungart M, Anastas PT, Zimmerman JB (2003) Peer reviewed: Applying the principles of green engineering to cradle-to-cradle design. Environ Sci Technol 37(23):434–441

Merrild H, Jensen KG, Sommer J (2016) Building a circular future. GXN, Sydney

Minunno R, O’Grady T, Morrison GM, Gruner RL, Colling M (2018) Strategies for applying the circular economy to prefabricated buildings. Buildings 8(9):125

Mirabella N, Castellani V, Sala S (2014) Current options for the valorization of food manufacturing waste: a review. J Clean Prod 65:28–41

Mont OK (2002) Clarifying the concept of product–service system. Journal of cleaner production 10(3):237–245

Moon D, Holton I (2011. Learning legacy, Lessons learned from the London 2012 Games construction project. https://tinyurl.com/hn3loo7

Murphy S, Pincetl S (2013) Zero waste in Los Angeles: Is the emperor wearing any clothes? Resour Conserv Recycl 81:40–51

Murray A, Skene K, Haynes K (2017) The circular economy: an interdisciplinary exploration of the concept and application in a global context. J Bus Ethics 140(3):369–380

Ness D (2008) Sustainable urban infrastructure in China: Towards a Factor 10 improvement in resource productivity through integrated infrastructure systems. Int J Sust Dev World Ecol 15(4):288–301

Ng WY, Chau CK (2015) New life of the building materials-recycle, reuse and recovery. Energy procedia 75:2884–2891

Nugent S, Packard A, Brabon E, Vierra S (2016) Living, regenerative and adaptable buildings. Whole Building Design Guide—a program of the National Institute of Building Science. https://www.wbdg.org/resources/living-regenerative-and-adaptive-buildings

OECD (2016) Extended producer responsibility: Updated guidance for efficient waste management. https://doi.org/https://doi.org/10.1787/9789264256385-en

Ogunmakinde OE (2019) Developing a Circular-Economy-Based Construction Waste Minimisation Framework for Nigeria. Dissertation, University of Newcastle

Onwuegbuzie AJ, Frels R (2016) Seven steps to a comprehensive literature review: a multimodal and cultural approach. Sage, Los Angeles

Pauli GA (1997) Zero emissions: The ultimate goal of Cleaner Production. J Clean Prod 5(1–2):109–113

Pauli GA (2010) The blue economy: 10 years, 100 innovations, 100 million jobs. Paradigm publications, Brookline

Pauli GA (2011) From deep ecology to the blue economy. A review of the main concepts related to environmental, social and ethical business that contributed to the creation of The Blue Economy 17.

Pawlyn M (2011) How can we build more efficient structures? Biomimicry in Architecture. RIBA Publishing, Marylebone, pp 9–35

Persson O (2015) What Is Circular Economy? – The Discourse of Circular Economy in the Swedish Public Sector. Dissertation, Uppsala University

Preston F (2012) A global redesign? Shaping the circular economy. Energy Environment and Resource Governance, Chatham House

Prieto-Sandoval V, Jaca C, Ormazabal M (2018) Towards a consensus on the circular economy. J Clean Prod 179:605–615

Qian G, Wang C (2016) Circular Economy Cities. In China's Eco-City Construction (pp 169–188). Springer, Berlin, Heidelberg

Rajput S, Singh SP (2019) Connecting circular economy and industry 4.0. Int J Inf Manage 49:98–113

Ravi V, Shankar R, Tiwari MK (2005) Analyzing alternatives in reverse logistics for end-of-life computers: ANP and balanced scorecard approach. Comput Ind Eng 48(2):327–356

Regenerative Leadership Institute R (2015) "What is Regenerative Design?". https://www.regenerative.com/regenerative-design. Accessed 8 March, 2016

Reijnders L (2008) Are emissions or wastes consisting of biological nutrients good or healthy? J Clean Prod 16(10):1138–1141

Ren Y (2007) The circular economy in China. J Mater Cycles Waste Manage 9(2):121–129

Rizos V, Tuokko K, Behrens A (2017) The Circular Economy: A review of definitions, processes and impacts. CEPS Research Report No 2017/8, April 2017

Saavedra YM, Iritani DR, Pavan AL, Ometto AR (2018) Theoretical contribution of industrial ecology to circular economy. J Clean Prod 170:1514–1522

Schulte UG (2013) New business models for a radical change in resource efficiency. Environ Innov Soc Trans 9:43–47

Snyder H (2019) Literature review as a research methodology: An overview and guidelines. J Bus Res 104:333–339

Song Q, Li J, Zeng X (2015) Minimizing the increasing solid waste through zero waste strategy. J Clea Prod. https://doi.org/10.1016/j.jclepro.2014.08.027

Srinivas H (2015) Eco-efficiency. https://www.gdrc.org/sustdev/concepts/04-e-effi.html. Accessed 20 October 2018

Stahel WR (2010) The performance economy. Palgrave Macmillan, London

Stahel WR (2013) Policy for material efficiency—sustainable taxation as a departure from the throwaway society. Philos Transac Royal Soc London Mat Phy Eng Sci 371(1986):20110567

Stahel WR (2016) A new relationship with our goods and materials would save resources and energy and create local jobs. Circ Econ Nat News 531(7595):435

Su B, Heshmati A, Geng Y, Yu X (2013) A review of the circular economy in China: moving from rhetoric to implementation. J Clean Prod. https://doi.org/10.1016/j.jclepro.2012.11.020

Templier M, Paré G (2015) A framework for guiding and evaluating literature reviews. Commun Associat Info Syst 37(6):112–137

Tunn VSC, Bocken NMP, van den Hende EA, Schoormans JPL (2019) Business models for sustainable consumption in the circular economy: an expert study. J Clean Prod 212:324–333

Ünal E, Shao J (2019) A taxonomy of circular economy implementation strategies for manufacturing firms: Analysis of 391 cradle-to-cradle products. J Clean Prod 212:754–765

Vilches A, Garcia-Martinez A, Sanchez-Montañes B (2017) Life cycle assessment (LCA) of building refurbishment: A literature review. Energy Build 135:286–301

Weber S (2019) A circular economy approach in the luxury fashion industry: a case study of eileen fisher. Springer, Singapore

Willard B (2002) The Sustainability Advantage. New Society, Canada

Wong G, Greenhalgh T, Westhorp G, Buckingham J, Pawson R (2013) RAMESES publication standards: meta-narrative reviews. BMC Med. https://doi.org/10.1186/1741-7015-11-20

Xinan L, Yanfu L (2011) Driving forces on China’s circular economy: from government’s perspectives. Energy Procedia 5:297–301. https://doi.org/10.1016/j.egypro.2011.03.051

Xue B, Chen X, Geng Y, Guo X, Lu C, Zhang Z, Lu C (2010) Survey of officials’ awareness on circular economy development in China: based on municipal and county level. Resour Conserv Recycl 54(12):1296–1302. https://doi.org/10.1016/j.resconrec.2010.05.010

Ying J, Li-jun Z (2012) Study on green supply chain management based on circular economy. Phys Procedia 25:1682–1688

Yuan Z, Bi J, Moriguichi Y (2006) The circular economy: a new development strategy in China. J Ind Ecol 10(1–2):4–8

Zhijun F, Nailing Y (2007) Putting a circular economy into practice in China. Sustain Sci 2(1):95–101

Zhu Q, Lowe EA, Wei YA, Barnes D (2007) Industrial symbiosis in China: a case study of the Guitang Group. J Ind Ecol 11(1):31–42

Zuidema RH (2015) Open building as the basis for circular economy buildings. In Proceedings of the Future of Open Building Conference. ETH Zürich.

Acknowledgements

This paper is part of the lead author's PhD study, funded by the University of Newcastle International Postgraduate Research Scholarship (UNIPRS) and the University of Newcastle Research Scholarship Central and Faculty (UNRSC50:50).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

Author declared that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ogunmakinde, O.E., Sher, W. & Egbelakin, T. Circular economy pillars: a semi-systematic review. Clean Techn Environ Policy 23, 899–914 (2021). https://doi.org/10.1007/s10098-020-02012-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-020-02012-9