Abstract

The consideration of sustainable issues in construction waste management has gained attention in the sector over the last decade. Nevertheless, this consideration has failed yet to create momentum and produce sensible changes in the industry. The few developed ideas have not been fully integrated with the primary goals of the industry. Aiming at addressing the antecedents towards the implementation of sustainable best practices, we performed a systematic literature review of 234 publications in the last 20 years. The literature review intends to shed light on the construction waste management by exploring its current practices, its triggers and its barriers.

Access provided by Autonomous University of Puebla. Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

The construction industry, whether considered as civil engineering or large infrastructure projects, plays a critical role in enhancing the economic growth and livelihoods of local communities and society at large (Moraes et al., 2020). Ghisellini et al. (2018) compliments the construction sector for a critical role in propping up the economy and improving the employment level. For example, in Brazil, the construction sector is regarded as the pillar of the economy as it contributes approximately 14% of the gross domestic product (GDP) and the largest generator of employment (Paz & Lafayette, 2016). Furthermore, the growth of construction activities is attributed to housing needs and infrastructure development projects to sustain the urban population increase and large-scale urbanisation and urban renewal programs (Begum et al., 2007b; Yuan, 2013; Lam et al., 2019; Kolaventi et al., 2019; Wu et al., 2019; Nunes & Mahler, 2020).

Construction activities have accelerated rapidly in both developing and developed countries in the last 20 years. The rapid growing developments in the construction sector (especially in developing countries) are significant contributors to Construction Waste (CW) being landfilled (Jain et al., 2020). Globally, the industry generates over 10 billion tons of CW and contributes about 35% of waste to landfills (Wang et al., 2019; Ghaffar et al., 2020). In the EU, the construction industry is responsible for approximately 30% of the total solid waste generated from all economic activities (European Commission, as cited in Ghisellini et al., 2018). The industry is considered one of the largest waste generators hence the prioritisation of CWM. (Del Río Merino et al., 2010).

In all, although the sector provides many benefits to societies, the massive waste generated by the construction and demolition activities has adverse social and environmental impacts if not properly managed (Ding et al., 2016; Chen et al., 2019). A large amount of construction waste has extensive social, economic and environmental repercussions (Wu et al., 2016). For example, the Chinese construction sector is facing problems of CW due to the increase in the construction activities and the ineffective CWM systems (Yuan, 2013). The increasing construction demands have led to an enormous depletion of natural resources and the production of vast amounts of CW, which mainly impact the environment (Faleschini et al., 2016; Bakchan et al., 2019; Zhang et al., 2019; Bakchan & Faust, 2019).

The environmental effects are due to the sheer size of waste generated, poor land practices poor planning and management, greenhouse gas emissions, low awareness of waste reduction and pollutants (Del Río Merino et al., 2010; Faleschini et al., 2016; Wu et al., 2019; Ghaffar et al., 2020; Oliveira et al., 2019; Guerra et al., 2019; Jain et al., 2020; Vilventhan et al., 2019). The CW disposed on the environment may lead to detriments in human health (especially residents and waste workers) such as respiratory impacts, reduction of lung function in children and premature deaths (Wang et al., 2015; Mahpour, 2018; Oliveira et al., 2019).

As a result, the construction sector is under scrutiny to enhance Sustainable construction waste management (CWM) practices. Several studies suggest that albeit the well-developed strategies, advanced technologies to combat CW generation, policies and awareness of CWM, there is a lack of holistic implementation in the sector (Yuan & Shen, 2011; Ajayi et al., 2015; Wu et al., 2016; Ghisellini et al., 2018). In consequence, this study aims to assess the antecedents and current CWM practices to establish practical measures to enhance CWM best practices. Rapid calls for action to protect the environment are encouraged to avoid landfill failures such as the CW landslide in Shenzhen (Ding et al., 2016) and other environmental impacts of dumping untreated CW (Guerra et al., 2019). Therefore, the research question guiding the study is as follows: What are the current practices and antecedents of construction waste management that help the achievement of circular economy?

2 Theoretical Background

2.1 Construction Waste Management

CWM is essential in protecting the environment and conserving the rapidly depleting non-renewable natural resources for the generations to come. Sustainability in the construction sector is vital to support the rapid growth with minimum harm to the environment. Sustainability is “development that meets the needs of the present without compromising the ability of future generations to meet their own needs” (WCED, 1987; as cited in Sabini, 2016, p. 1). Therefore, the growing pressure to push towards the development of effective CWM practices in the construction industry to promote sustainable construction. According to Shen et al. (2010; as cited in Ghisellini et al., 2018, p. 427), sustainable construction is “implementing construction projects that involve less harm to the environment (minimising CW generation), increased reuse of CW in the production of construction materials (waste management), beneficial to the society, and profitable to the company”. Manowong (2012) states that the concept of sustainable development requests for a balanced drive to achieve environmental, economic and social objectives. The sustainable development for CWM is required to reduce the use of natural resources and close the waste management loop in construction. Seadon (2010; as cited in Ghaffar et al., 2020, p. 2) states, “a sustainable waste management system requires vigorous feedback loops and is concentrated on processes to divert wastes from disposal and convert them to secondary raw materials”.

Lam et al. (2019) defines CW as “anything generated as a result of construction (or renovation and demolition) and then abandoned, regardless of whether it has been processed or stockpiled”. The CW is generated from building and infrastructure material such as concrete, metals, plastics, timber, asphalt, soil, bricks, tiles and glass (Lu et al., 2016a; Blaisi, 2019). CW is generated during all the stages of the construction lifecycle. CW affects the social, economic and ecological aspects of society, and their appreciation is vital in the successful implementation of CWM practices (Blaisi, 2019; Kolaventi et al., 2019). The CW generated can be reused, processed to recycled materials and the remaining unrecyclable waste is hauled to landfill sites. Construction and demolition (C and D) waste is also known as CW (Lu et al., 2015). The terms are used interchangeably in this study.

The construction waste arises from activities such as land excavation/formation, roadworks, site clearance and civil works (Rodríguez et al., 2007; da Rocha & Sattler, 2009; Yuan & Shen, 2011; Jin et al., 2019; Bakchan et al., 2019). Furthermore, CW generation may be due to extraction of raw materials, manufacture of materials, material cutting to meet construction requirements, damages of material during transportation and construction, and demolition due to construction errors and changes (Del Río Merino et al., 2010; Lu et al., 2016a; Wang et al., 2019).

2.2 Circular Economy Model in Construction Waste Management

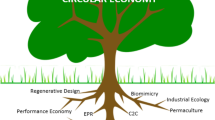

The circular economy (CE) is defined as “an industrial system that is restorative or regenerative by intention and design. It replaces the end of life concept with restoration, shifts toward the use of renewable energy, eliminates the use of toxic chemicals impairing reuse, and aims at eliminating waste through the superior design of materials, products, systems, and business models” (Ellen MacArthur Foundation 2016; as cited in Mahpour, 2018, p. 216). CE provides a platform to develop economic patterns aimed at an increased efficiency of production and consumption of resources. The concept seeks to substitute the conventional production and consumption of materials based on continuous growth and increased processing of CW to new resources (Jin et al., 2019). CE is an emerging end of pipe practice towards minimising the CW adverse impacts to the environment such as degradation and exhaustion of resources (Jin et al., 2019; Mahpour, 2018). Bakshan et al. (2015) identify the diminishing natural resources and challenges of siting new landfills (particular in land-limited and continuously developing urban areas) as the primary drivers towards circular economy in construction. The closed-loop practices of CE ensure CW reuse or recycle rather than disposal in landfills (Zhang et al., 2019). CE minimises CW by integrated recycling of CW into secondary or new resources for the construction industry or other industries (Mahpour, 2018; Huang et al., 2018; Ghaffar et al., 2020; Jain et al., 2020). The implementation of CE in construction is a challenge due to limited research (Jin et al., 2019).

3 Methodology

We decided to adopt a systematic literature review (SLR) which Kitchenham and Charters (2007, p. 1) defines as “a means of identifying, evaluating and interpreting all available research relevant to a particular research question, or topic area, or phenomenon of interest”. The literature review identifies as a critical methodology for assessing the trend developments of a particular research discipline (Yuan & Shen, 2011). According to Kitchenham and Charters (2007), systematic reviews aim to synthesise and compare evidence across studies to answer specific research questions that consolidate or confirm practices, policies or theoretical relationships. A repeatable unbiased search strategy is applied to capture relevant literature around a particular topic rigorously. Therefore, the systematic review has been arguably the most efficient and high-quality method for identifying, evaluating and interpreting literature (Kitchenham & Charters, 2007).

To find the relevant journals for the systematic literature review, keyword searches were performed within the areas of abstract, title and keywords in the Scopus database. The following keywords are used to gather the papers related to the research topic: “construction waste management”, “construction and demolition waste” and “C and DW management”. These produced 243 papers (as of March 2020), as shown in Table 3.1.

For the sample selection, the three keyword searches were combined using the Boolean Operator “OR”. After connecting the keyword searches obtained, duplicate papers were removed, bringing the number of documents (n = 234). Figure 3.1 shows the number of journals published each year, from the year 1994 to 2020, and it shows an exponential increase with notable spikes in some years. This increase in the number of publications reflects the relevance of this literature review.

The top 12 journal sources with the most publications (over three publications) on the keyword search are shown in Tables 3.2 and 3.3. The research will focus on the four most prominent sources, that is, references with the most publications from the keyword search results: (1) Resources Conservation and Recycling, (2) Journal of Cleaner Production (JCLP), (3) Waste Management and (4) Waste Management and Research. Therefore, the final number of papers used in this research study is 78 from the four journals with the highest number of publications.

The final sample used in this research consists of 78 journals from four different sources, as shown in Fig. 3.2.

The journals are from the year 2004 to March 2020 and shown off according to the number of journals published per year by each source in Fig. 3.3. There has been a constant increase in the occurrence of the keywords over the past 16 years, which is, evidence that authors have been researching more around the subject of “construction waste management”. Consequently, the final four journal sources have at least one publication in the past 3 years.

The authors with the leading number of journals are shown in Fig. 3.4. The sample points out that the predominant authors are Lu, W and Li, J. The figure shows authors with a minimum of two journals within the literature review sample.

CWM practises may differ from one country to another; this literature review may be biased towards the dominant nation of publication. Dahlbo et al. (2015, p. 335) state, “the volumes, composition and quality of CW vary between sites, regions and countries, and no general composition can be presented.” Consequently, The CWM knowledge developed in one region is not easily adapted and applied to the other areas without considering their contextual differences (Saez et al., 2013). Thus, the need to highlight the sample of journals used by country/territory is shown in Fig. 3.5.

The performance of the analysis of the journals on the research design used, and the results are as shown in Fig. 3.6. The results identified case studies (n = 22), which further divides into single case studies (n = 15) and multiple case studies (n = 7), as the most adopted approach in CWM related research, followed by empirical analysis (n = 20).

The results indicate that all the journals (n = 78) are within the environmental science area of study (see Fig. 3.7). The results are favourable as the research mainly seeks to emphasise on a CWM system with less negative impacts on the environment.

As the research question sought to explore the practices, drivers and barriers of CWM, the SLR approach is adopted to gather a set of relevant papers. For the content analysis of the documents, NVivo is used to create three critical nodes extracted from the research question. These parent nodes are practices, triggers and barriers to CWM, further broken down to specific subtopics (child nodes) which are sorting, recycling, landfill, green building, disposal, CWR, CE, bill of quantities, education, legislation, technical, market economy, behaviours and attitudes. Then the papers were analysed for concepts and content relating to the identified nodes.

The relevant content in the data sample was identified and coded to their respective nodes. NVivo word frequency query was performed on the nodes for 100 most frequently occurring words (with stemmed words) with a minimum length of five letters. Therefore, Fig. 3.8 shows the word cloud generated from the search results. The word cloud gives an overview of dominating concepts as well as the visual representation of what the discussion section seeks to address.

4 Discussion

The findings and discussions section reviews the selected papers based on the data analysis across three major categories. (1) What are the current CWM practices? (2) What are the factors that contribute to the implementation of sustainable CWM best practices? (3) What are the factors that impede the adoption of Sustainable CWM best practices? Table 3.3 below shows the number of papers used to produce each category and the main message each category attempts to address.

4.1 What Are the Current CWM Practices?

This section looks at the standard CWM practices in the construction sector and considers the justification and effects of its implementation. The construction sector is under pressure to promote more effective CWM practices at the site level, guided by the 3Rs (Reduce, reuse, recycle) principle (Tam & Tam, 2006; Huang et al., 2018; Bakchan et al., 2019). In the same vein, Yang et al. (2017; as cited in Ghisellini et al., 2018) suggest the adoption of 4R principle (Reduce, reuse, recycle and recover) combined with adequate disposal to alleviate pressure in landfills.

The extensive studies on CW recommend the adoption of a waste management hierarchy that prioritises the 3Rs in descending order of environmental and economic preferences (Begum et al., 2007a; Yuan & Shen, 2011; Rodríguez et al., 2015). The studies highlight the need for devising of the 3R principle to manage the waste by firstly attempting to implement best practices with the least negative impacts on the sustainability dimensions of CWM. The CWM needs to be implemented as part of project management roles to effectively achieve waste reduction (Begum et al., 2007a).

4.1.1 Construction Waste Reduction/Minimisation (CWR) Practices

CWR helps to minimise waste generation and increases waste recycling and reuse rates (Won et al., 2016; Ding et al., 2016). There is a need for the construction industry to shift its focus to CWR practices to improve CWM, as the last-resort waste treatment of disposal cannot satisfy the sustainable development requirements of circular economy. Countries are transitioning to adopt the measures necessary to promote CWR as its benefits outweigh other waste management practices (Rodríguez et al., 2007). CWR is the priority as it is considered the most effective practice in reducing CW generated, preventing waste disposal and has the lowest adverse environmental impacts (Tam & Tam, 2006; Yuan & Shen, 2011; Al-Sari et al., 2012; Yuan, 2012; Wang et al., 2015; Ding et al., 2016; Wu et al., 2016; Huang et al., 2018).

Begum et al. (2007a) emphasise that improper CWM, excessive wastage of raw materials and low awareness of the waste reduction result in lack of consideration given to CWR measures during the planning and design phases. The practice offers benefits of minimising CW generation and cost-saving from cutting transportation, recycling and disposal fees. The CWR practices identified in the literature divide into two groups, which are source reduction and end of pipe waste reduction.

4.1.1.1 Source Reduction

Begum et al. (2007a, p. 91) define source reduction as “any activity that reduces or eliminates the generation of waste at the source, usually within a process”. Source reduction practices are measures such as adopting low-waste technologies and on-site material management to minimise waste production before its generation (Ding et al., 2016; Ghisellini et al., 2018). Waste reduction at the source is recommended as the first step in avoiding waste generation (Won et al., 2016). Studies suggest the implementation of CWR at the start from the planning and design phase and source management during construction/deconstruction phase (Zhang et al., 2019). CWR implementation throughout the project lifecycle (design, planning, construction and deconstruction/demolition phases) is as follows:

4.1.1.2 During the Planning Phase

Estimation of the waste generated by construction activities is the most common waste reduction practice during the planning phase. The evaluation of the amount of CW that will be generated by construction activities is needed mainly for planning purposes (Lam et al., 2019). The construction projects generate continuous streams of waste that need systematic planning and management to enhance circular economy (Lu et al., 2016b). The estimations assist in the planning of ways of reducing waste generation by implementing alternative methods with less waste output.

The data on waste streams allows the construction companies to identify processes that generate significant streams of waste and help them adopt appropriate waste reduction technologies and methods (Li et al., 2016). The data also can help in deducing or estimating the impacts of a construction project on sustainable development. Further, the precise estimation of CW is necessary for the government to establish effective policies, guidelines, strategies and codes of practice towards circular economy (Li et al., 2016).

According to a survey executed to academics, lack of reliable data hinders them from making informed decisions in a bid to enhance CWM (Blaisi, 2019). The survey hints on the need for accurate estimates to draw up the relevant practices required to combat the vast CW generation. Developing an effective CWM plan needs identifying, quantifying and classification (quality) of CW streams generated and their appropriate destinations during different phases of construction (Bakshan et al., 2015; Dahlbo et al., 2015; Paz & Lafayette, 2016; Bakchan & Faust, 2019; Guerra et al., 2019). The forecasting of CW generation streams at different construction phases assist the project stakeholders in planning for best CW handling practices (Lu et al., 2015, 2016b; Bakchan & Faust, 2019).

The reliable data on generated CW estimation from construction sites is critical in improving CWM (Wang et al., 2019). Consequently, various ways of measuring and estimating CW generation involving different tools have emerged in the sector (Ajayi et al., 2015). Li et al. (2016) proposed a CW estimation model based on mass principle and work breakdown structure for building construction projects. Villoria Saez et al. (2011; as cited in Paz & Lafayette, 2016) developed an empirical model for estimating the waste generated, by creating several indicators relating to the amount of waste generated and the total constructed area of the building. Further, Lu et al. (2016b), used the S-curve model to forecast waste generation in construction projects. Other studies (Won et al., 2016; Guerra et al., 2019) show that there is the potential use of building information modelling (BIM) technology to reduce CW generation. The studies propose BIM uses like design validation, quantity take-off and prefabrication, which will, in turn, reduce design errors, ordering surplus material and offcuts waste.

In this respect, studies argue that existing CW estimation methods have limitations as some are time-consuming to implement, lack ways of verification or provide rough estimations, which are insufficient for developing informed CWM plan (lack of precision). Again, some rely on regional databases, which may not be compatible with studies from other regions (Bakchan & Faust, 2019; Guerra et al., 2019). Therefore, to improve the CW estimation, the construction companies need to have a reliable, user-friendly tool to estimate the quantity of CW generated during the different stages of a construction project (Gangolells et al., 2014).

On the other hand, Ajayi et al. (2015), state that the procurement stage is vital for CWM planning as it links with causes of CW such as improper material storage, double handling and packaging materials. Begum et al. (2007a) argue that the procurement of extra construction materials is due to the lack of consideration of CWR during the planning and design stage. Estimations of quantities of materials required are therefore vital as to minimise waste generation due to surplus materials, as well as damaged materials due to double handling and on-site storage. Accurate estimates of the number of materials are needed to prevent long periods of on-site storage (Gangolells et al., 2014). Likewise, a good logistics agreement with suppliers, such as just in time ordering, reduced packaging and appropriate ordering to minimise offcuts waste, could promote CWR during the planning phase (Ajayi et al., 2015; Vilventhan et al., 2019). Other studies (Tam & Tam, 2006; Wang et al., 2019) as well encourage the sector to return the packaging materials to suppliers for reuse.

4.1.1.3 During the Design Phase

Implementing CWR by design plays a vital role in avoiding CW production at the source (Li et al., 2015). Saez et al. (2013) argue that typically the practices adopted at the design stage of a construction project are aimed at appropriate CWM rather than targeting CWR. Nevertheless, the account of CWR at the design stage is the most sustainable practice. Ghisellini et al. (2018) highlight that the early stages of design in construction projects have the best chances of maximum CWR.

Some studies assert that the roles of designers towards CWR are not apparent under regulations, resulting in architects neglecting designs with waste minimisation (Wang et al., 2015). Ghisellini et al. (2018), for good measure, point out that previous studies focused on waste minimisation strategies and technologies, while there was an apparent omission of the designer’s role consideration. However, a survey by Yuan (2012) concluded that poor CWR in Shenzhen is due to the designers’ lack of awareness of its benefits. Another study by Osmani et al. (2008; as cited in Saez et al., 2013) indicated that architects presume CW to be mainly generated during the construction phase and barely during the design phase. However, Li et al. (2015), argue that the reduction of CW can be at both design and construction phases.

Del Río Merino et al. (2010) states that when designing infrastructure or building projects, the stakeholders should consider the potential CW generation in the project decisions they make. This consideration will ensure the reduction of the volume of CW generated by future demolition and enhance material reuse. Lam et al. (2019) contend that architects and engineers may appreciate the need for CWR if there is a presentation of the potential amount of CW to be generated by their designs in the BOQ (bill of quantities). This presentation can be useful in minimising CW produced by making waste-reducing changes before the actual construction begins. Similarly, a survey in Spain shows that construction companies consider the introduction of salvaged materials from old buildings in the design phase to minimise waste generation (Gangolells et al., 2014).

As stated by Innes (2004; as cited in Won et al., 2016), inappropriate design decision-making and design changes may increase the volume of CW generated up to 33%. Another study conducted by Saez et al. (2013) shows that one-third of CW generated is due to design decisions at the design stage. Likewise, Won et al. (2016) contend improper design and unexpected design changes as the major causes of CW generation. Additionally, Cheng et al. (2015; as cited in Won et al., 2016) propose that the use of integrated building design can avoid design changes and errors. Ajayi et al. (2015) recommend optimising designs to the industry’s standards to facilitate the reuse of its removed materials in another optimised project. The design optimisation will significantly prevent waste production due to material offcuts. Moreover, Wang et al. (2015) found that the incorporation of fabricated components during design has the most substantial influence on waste reduction.

4.1.1.4 During the Construction/Deconstruction Phase

The green building practices are implemented during construction and demolition activities to help conserve resources and minimise the CW harm to the environment. USEPA (2018; as cited in Chethana et al., 2018, p. 722) defined green or sustainable building as “the practice of creating and using healthier and more resource-efficient models of construction, renovation, operation, maintenance and deconstruction”. According to Chen et al. (2019), green building is the construction sector’s mitigation measure to challenges such as exhaustion of non-renewable natural materials, water and air pollution, greenhouse gas emissions and human-induced global warming. Lu et al.’s (2018) study analysed the effects of green building on CWR using the Hong Kong accredited green building accrediting system. The results proved a 36.19% waste reduction in demolition activities.

Because of adopting more sustainable materials and methods, green building projects incur higher costs than traditional methods. Thereby the industry is less willing to have fewer profits due to adopting the green building methods. A study by Chen et al. (2019) confirms that green building costs are higher than conventional building by a range of 0.4–6% of the total cost. However, green building institutes disseminate that there may be a payoff of those higher prices in the future through improved environmental performance which results in lower utility bills and higher property value (Lu et al., 2018). Furthermore, the author suggests that in addition to social and environmental benefits of green building, there is a potential increase in construction and waste transport cost savings.

On the other hand, there is a proposal of implementing architectural technologies such as the use of prefabricated materials to assist in minimising the waste generated during construction (Saez et al., 2013; Wang et al., 2015; Won et al., 2016; Zhang et al., 2019). The study by Bakchan and Faust (2019) suggests that prefabrication, as a replacement of on-site production, is one of the most effective technologies in waste reduction. The prefabricated components include staircases, large panel formworks, thin panel walls, recycled scaffolding and hoardings (Wang et al., 2015; Ding et al., 2016). Accordingly, evidence shows that the use of precast or prefabricated materials promotes effective waste reduction as there is a minimisation of CW generation due to site mixing and offcuts (Ajayi et al., 2015; Lam et al., 2019). Jaillon et al. (2009; as cited in Won et al., 2016), found out that CW was reduced by 52% in Hong Kong, as an impact of using prefabricated materials. Huang et al. (2018) advocate for precast construction technologies as they reduce pollution during construction and demolition activities, and besides they enhance the recovery and reuse of materials without destructive dismantling of buildings. However, the industry struggles to promote prefabricated materials (mainly concrete) due to structural stability concerns (Wang et al., 2019). Thereupon a robust structural stability check should be put in place when manufacturing the prefabricated materials.

For further development, at the end of the lifespan of a construction project, the infrastructure or building has to be deconstructed or appropriately demolished to minimise waste production. Ajayi et al. (2015) contend that deconstruction differs from demolition, as it involves careful dismembering of the building components in an attempt to salvage them for reuse and recycling. Rodríguez et al. (2007) note that the demolition activities are not recommended for material recovery as they result in mixed wastes that are not suitable for reuse or recycle. Zhang et al. (2019) encourage the local authorities to enforce regulations for demolition licensing, which the contractor receives after notifying and getting approval to proceed with demolitions. The authorisation ensures necessary measures are put in place for the careful dismantling of buildings to promote reuse and recycle of materials.

4.1.1.5 End of Pipe Waste Reduction

The implementation of a detailed CWM plan requires a productive CW streams handling procedure and adoption of project management strategies to help in achieving the planned CWM objectives (Bakchan & Faust, 2019). After the unavoidable CW generation, there is the implementation of the end of pipe treatment strategy to reduce the amount of CW disposed of in landfills (Yuan & Shen, 2011). End of pipe waste reduction measures are sorting, reuse and recycle after the waste has been created (Ding et al., 2016; Ghisellini et al., 2018). The practices of recycling and reuse of CW are the best methods in mitigating CW problems at the end of the pipe and is the responsibility of practitioners in the field (Duan & Li, 2016).

4.1.1.6 Reuse

Reuse is salvaging construction materials to use them more than once. Yuan and Shen (2011) identify reuse as the best sustainable option after source reduction because it requires minimum processing and energy use. The energy savings by reusing salvaged materials is higher than recycling (da Rocha & Sattler, 2009). In like manner, reusing materials leads to a reduction in carbon emissions (Chen et al., 2019), has less adverse environmental impacts and might result in cost savings. The reuse of materials may include using the material either for the same function or as secondary aggregates (Ling & Leo, 2000; as cited in Yuan & Shen, 2011). The adoption of material reuse is a way of diverting CW from landfills (Ajayi et al., 2015). The recovered materials can be reused for primary or secondary functions in the construction sector or other industries to reduce the CW produced into the environment. Paz and Lafayette (2016) argue that despite substantial amounts of CW are reusable, construction companies in Brazil improperly dispose the CW causing a series of economic, social and environmental problems. Paz et al. (2018) articulate that almost all CW generated can be reused; hence the industry should strive to produce the minimal possible CW. In the bargain, the construction buildings or infrastructure have to be carefully dismantled or deconstructed to enable the reuse of their components (Ajayi et al., 2015). Finally, the non-reusable waste material must be either recycled for new articles or disposed at landfills as a last resort if untreatable (Yuan & Shen, 2011).

4.1.1.7 Recycling

Recycling is defined as the recovery and reuse of what would otherwise be waste material (Begum et al., 2007a). The recovery of CW material involves processing it into new materials by using recycling technologies such as carbonisation of CW (Huang et al., 2018) and dry or wet recycling (Jain et al., 2020). The CW is recycled to produce derivative materials, which can replace virgin materials (Ajayi et al., 2015). Conservation of tons of natural materials is possible if a proper recycling system is adopted to produce quality-recycled materials (Kolaventi et al., 2019).

Lockrey et al. (2018) suggest that recycling can be treated as a process of CWM and material production and thus enhances sustainable construction. Again, Lockrey et al. point out that successful recycling depends on the generated revenue from the resale of recycled materials. Dahlbo et al. (2015) contend that an increase in recycling should be promoted by environmental and economic benefits to support Sustainable CWM. Nevertheless, there is weak competitiveness of recycled materials industry to that of virgin materials due to the unwillingness to use recycled materials and lack of supporting regulatory measures (Del Río Merino et al., 2010; Faleschini et al., 2016). Blaisi (2019) encourages governments to impose taxes on virgin materials to increase the industry use of recycled materials.

Jia et al. (2017) point out that of the waste generated in the Chinese construction industry, only approximately 5% is recycled. The low recycling rate is alarming, as China is the biggest waste producer (Wang et al., 2019). Saez et al. (2013) point out that the recycled material use is widely accepted in the construction sector, although only 8% of the surveyed construction agents in Spain implement it, due to quality standards. Therefore, to maintain competitive quality standards, according to many contemporary pieces of research the recommended replacement of natural aggregates is 50% (Kolaventi et al., 2019; Zhang et al., 2019). Moreover, to improve the quality of recycled materials, Dahlbo et al. (2015) counsel enhancing sorting, separation and processing of CW.

Sorting is separating the waste based on their characteristics, components for their reuse, recycling and disposal (Ghisellini et al., 2018). The recycling is beneficial when there is an efficient implementation of on-site sorting, and the transportation distance of CW from source to recycling facilities is under 30 km (Penteado & Rosado, 2016). Studies show that sorting is a useful measure for reducing the volume of CW to landfills by promoting higher rates of reuse and recycling (Ghisellini et al., 2018). Another study in Hong Kong found an increase in diversion of waste going to landfills as a result of on-site sorting practices (Dahlbo et al., 2015). Consequently, sorting might have barriers such as increased costs, lack of sorting space and lack of market for recycled materials (Gangolells et al., 2014; Ding et al., 2016).

According to Huang et al. (2013; as cited in Ghisellini et al., 2018), the hypothesis of a high recycling CWM system shows alleviation of virgin material use and generation of CW. Huang et al. further confirm the need to improve recycling and reduce material demand by prolonging construction project lifespan to reduce CW generation rates. The practice alleviates the environmental impacts caused by the rapid extraction of non-renewable natural materials (Del Río Merino et al., 2010; Kolaventi et al., 2019; Jain et al., 2020), greenhouse gas emissions (Zhang et al., 2019) and the hazards of disposing CW to landfills (Del Río Merino et al., 2010). Likewise, studies point out that recycling provides relief to landfills that are quickly filling up due to the massive CW production by the construction industry (Wang et al., 2019; Lockrey et al., 2018).

4.1.2 Landfill

Landfills are arguably the most common and traditional practice in CWM that require large areas of land. Although current research (circular economy) focuses towards a diversion of CW from landfills, however, the method is still widely used around the world (Ghaffar et al., 2020). Studies confirm that landfill space for CW disposal is scarce, particularly in and around continuously developing metropolitan urban areas (Yuan et al., 2011; Wu et al., 2016; Bakshan et al., 2015). Moreover, Jia et al. (2017) argued that due to the increased urban construction activities, there are challenges of finding sites for the disposal of huge volumes of CW. Again, Jin et al. (2019) point that the need to release pressure on landfills and promote waste diversion practices, to close the circular economy loop, is driving sustainable development in the construction sector.

In consequence, there are recommendations for hiking the dumping fees to enhance the landfill diversion rate and mitigate landfill impacts on the environment. The environmental impacts may include air and water pollution, leaching of non-inert waste and longer transportation distances (Del Río Merino et al., 2010; Ghisellini et al., 2018). Ding et al. (2016) note that the 2015 landslide accident in a landfill in Shenzhen proves the imbalance between the construction waste landfilling demand and limited landfill areas. Such incidents aid the adoption of CE practices. Likewise, due to the filling up of landfills, there is also a need to build engineered landfills which are more expensive. These economic impacts to the industry tend to support the diversion of CW to recycling plants and use of CW reduction practices (Wang et al., 2004; Zhang et al., 2019).

4.1.3 Illegal Dumping/Fly-Tipping

Illegal dumping refers to the intentional and unlawful disposal of waste in unauthorised areas to avoid landfill fees or to save time and costs of transportation to landfills (Lu et al., 2018). Extensive literature links illegal dumping to the landfill practice, as is triggered by lack of landfill space (Manowong, 2012), longer transportation routes to landfill sites (Blaisi, 2019) or higher landfill fees (Zhang et al., 2019). Again, Mahayuddin et al. (2008; as cited in Paz et al., 2018), argue that the lack of waste collection system at construction sites in Brazil leads to illegal dumping.

Consequently, the governments or regulatory boards should set penalties and improve the supervision of CW disposal along with an effective Sustainable CWM plan to minimise illegal dumping (Ghisellini et al., 2018). Chen et al. (2019) propose that unlawful dumping can be decreased more effectively under public participation with the government providing supervision hotlines and information platforms for convenient communications to report illegal dumping activities.

4.2 What Are the Factors That Contribute to the Implementation of Sustainable CWM Best Practices?

CWM practices towards CE have increasingly gained awareness within the construction industry and different practices and policies to enhance the system have been implemented. Thereupon this category discusses the factors, found in the literature, that drive the industry towards sustainable practices and its promotion. Table 3.4 shows an overview of the effects of country context that determines their stance on CWM practices. According to Li et al. (2018), the most significant measures to promote CWM practices are training contractors, enforcing effective regulations and increasing public awareness. These elements are grouped into legislation and regulations, and training and education.

4.2.1 Legislation and Regulations

The CWM depends on policies and regulations, which impose economic or administrative measures that promote the overall implementation, and effectiveness of CWR practices (Wang et al., 2015; Ding et al., 2016; Blaisi, 2019). points out the lack of precise and detailed CWM regulations for the construction industry in China hinders the adoption of the best practices. Regulation can enhance a positive attitude that focuses on sustainable best practices in CWM (Blaisi, 2019). The CWM professionals view the role of the government legislations and support of CE as the most critical contribution towards CWR (Ghisellini et al., 2018; Ghaffar et al., 2020). Saez et al. (2013) point out that some countries are developing laws to establish a framework for CWM and production to promote the 3R principle. Similarly, other studies suggest the government should take an active approach by providing practical guidelines, policies and laws that support the construction industry in implementing CE practices (Begum et al., 2007a, b; Lu et al., 2016a; Zhang et al., 2019).

For example, the EU has fully committed to achieving a goal of 70% reduction in total CW generation by 2020 (Moraes et al., 2020). Moreover, in the UK, there is a legislative framework that requires the development of a mandatory solid waste management plan (SWMP), before the commencement of the actual construction works, for construction projects valued above £300,000 (Ajayi et al., 2015). The SWMP includes statements of strategies used before construction to ensure waste minimisation and waste management practices during and after the construction phase. However, Zhang et al. (2019), encourages the government to adopt the balanced stakeholder approach to ensure the construction stakeholders’ views and interests consideration in formulating and implementing of CWM policies. The incorporation of stakeholders’ opinions in the decision-making process will assist in coming up with the best acceptable strategies within the industry (Blaisi, 2019).

Zhang et al. (2019) argue that recent studies suggest improvement of company policies towards sustainability than legislation enforcement. However, for the company policies to change, there should be an economic benefit, hence legislation to incentivise waste reduction is necessary to enhance the improvement of company policies. The law triggers companies to assume a reactive approach (end of pipe practices) to CWM. At the same time, incentives will encourage companies to adopt proactive (source reduction) policies to CW reduction. Therefore, improvement of company policies should be considered on top of government legislations.

The studies point that the government or local authorities enforcing legislation and regulations in the construction sector such as penalties for illegal dumping with strict supervision (Lu et al., 2015; Huang et al., 2018; Blaisi, 2019), progressive taxation for waste disposal (Chen et al., 2019; Wang et al., 2019), economic incentives for waste reduction (Ghaffar et al., 2020) and motivating their attitudes and behaviours towards effective CWM (Begum et al. 2007a) are the primary drivers towards CE model. The legislation and regulations in this study divide into four subsections which are the enactment of a mandatory standard CWM mode, incentivising the CWR practices, penalising illegal activities such as fly-tipping and finally taxation of virgin materials through the increase of waste disposal charges.

4.2.2 CWM Plan

CWM plan is a guide to the industry on how to handle different waste streams as well as minimising waste production. Existing studies show that an effective CWM plan, in the form of strategies to reduce waste production and raw materials extraction, results in substantial economic benefits to the construction sector (Ajayi et al., 2015; Wu et al., 2019). Blaisi (2019) advocates for CWM guideline documents to provide information on how the construction sector should comply with regulations as well as include best practices. Furthermore, Tam and Tam (2006), vouches for the mandatory enactment of a CWM plan so that all stakeholders can share the same goal of adopting circular economy. Notably due to the high number of construction activities, there is a need for a compulsory CWM plan that will propel the whole sector to CE practices. Rodríguez et al. (2015) highlight that the main aim of a CWM plan is to set apart the direct link between economic growth and the increase in the volume of CW generated to mitigate the associated environmental impacts.

The lack of CWM plan for every construction phase impedes the continuous improvement of best practices (Paz & Lafayette, 2016). Moreover, research by Vilventhan et al. (2019) observed the lack of on-site CWM planning as one of the primary causes of waste generation. Therefore, for example in Spain, a waste management model includes a waste management report developed during the design phase and a waste management plan developed during the construction work planning phase (Saez et al., 2013). These documents include descriptions of CWM best practice measures of the 3Rs and final disposal of waste. Jin et al. (2019) state that currently there are still needs of developing a more comprehensive performance measurement mechanism for C and D waste management or a suitable C and D waste management guide adopted in a particular organisational or local context.

Bakchan et al. (2019) recommend the development of a CWM plan that also enhances the efficiency of meeting the planned project management objectives. The author suggests the alignment of the joint project objectives with sustainability objectives at the planning phase to bridge the gap between project priorities and CE. The integration of project objectives and sustainable objectives is termed sustainable project management (SPM) (Sabini et al., 2019). Silvius and Schipper (2014a; as cited in Sabini et al., 2019, p. 822) define SPM as “the planning, monitoring and controlling of project delivery and support processes, with consideration of environmental, economic and social aspects of the life-cycle of the project’s resources, processes, deliverables and effects, aimed at realising benefits for stakeholders, and performed in a transparent, fair and ethical way that includes proactive stakeholder participation”.

4.2.3 Incentives

The studies show that the introduction of economic incentives stimulates a CW diversion from landfills by subsidising waste reduction, recycling and reuse practices (Manowong, 2012; Jia et al., 2017; Huang et al., 2018; Wang et al., 2019). Tax incentives given to contractors conforming to the CE practices are critical in driving the construction industry towards sustainability best practices (Mak et al., 2019). Begum et al. (2007a) vouch for the rewarding of construction stakeholders to urge the implementation of 3Rs to improve CWM. According to a survey carried out in mainland China (Wu et al., 2016), the participants agreed that economic benefits together with governmental supervision play a critical role in the implementation of CWM best practices.

A pilot program of using recycled materials in Shenzhen construction projects recommends the development of appropriate assessment systems to frequently measure the performance of companies in using recycled materials (Yuan, 2012). Thereupon rewards are for companies with better returns; as a result, this can work as a mechanism to push the construction sector into implementing recycling practices and the use of recycled materials in their projects. Gangolells et al. (2014) indicate the noticeable significant improvements in Spain due to introduced regulations that promote on-site sorting of CW and allows the use of recycled materials.

The Hong Kong government imposed contractual clauses to provide financial incentives for CW reduction (Lu et al., 2015). The incentivising increases competition across the sector, which may result in a significant increase in recycled material use and minimise waste generation. Correspondingly, it boosts the innovativeness of companies by pushing them to further research into sustainable practices to meet the waste targets set by law (Ghaffar et al., 2020). Huang et al. (2018) argue that most of the economic incentives in China are for CW treatment companies. Therefore, in the case of China, construction companies are not motivated to use waste minimisation technologies and techniques.

4.2.4 Fines/Penalties

The failure to comply with the imposed regulations is an offence punishable by law (Lu et al., 2016a), usually by enacted fines or penalties. Penalties are punishments enforced to effectively reduce illegal dumping of CW and encourage waste reduction practices (Huang et al., 2018). Accordingly, the research by Jia et al. (2017) indicates that imposing penalties will see a significant decrease in illegal dumping. In like manner, Chen et al. (2019) found that putting charges for unlawful dumping is insufficient, thus urges governments to improve the supervisory intensity and management level. Likewise, Blaisi (2019) indicates that fines and penalties may increase the recycling of CW but may alike lead to illegal dumping if there is a lack of enforcement and intense supervision.

4.2.5 Waste Disposal Charges/Landfill Taxes

Waste disposal charge increase may be adopted to promote the practice of recycling and other CW reduction strategies in the sector (Stenis, 2005; Begum et al., 2007a; Lam et al., 2019). Tax measures have assisted governments across many nations in diverting large volumes of CW from landfills to end of pipe treatment methods (Ajayi et al., 2015). The studies suggest that CW disposal charging scheme may reduce landfill area, decrease CW generation, enhance waste recycling practices by taxing virgin raw materials, increasing landfill fees and subsidising processing of recycled materials (Dahlbo et al., 2015; Ding et al., 2016; Wang et al., 2019; Blaisi, 2019). For instance, to avoid landfill taxes in Hong Kong, the contractors tend to focus on CW reduction, reuse and recycling (Lu et al., 2015). Likewise, Blaisi (2019), states that the United Kingdom (UK) has seen a decrease in landfill waste due to the rise in landfill taxes. Similarly, high landfill taxes in Denmark and the Netherlands have highlighted an increase in waste recovery (Mak et al., 2019).

Huang et al. (2018), also recommends introducing incentives that will push the construction sector to engage in CWR practices as well as increasing the disposal cost of CW. However, studies suggest that regulations such as progressive taxation for waste disposal might unintendedly promote illegal dumping (Stenis, 2005; Blaisi, 2019). For example, Germany experienced a surge in illegal dumping because of increasing landfill charges beyond market viability for the construction sector (Ried, 2000; as cited in Blaisi, 2019). As a result, the inflation of the taxation fees has to be constrained to avoid inspiring illegal dumping practices (Tam et al., 2014). Moreover, Wang et al. (2019) argue that the implementation of the waste disposal charges has not yet triggered subcontractors to change towards CW reduction methods. Despite that, some evidence suggests that waste disposal charges are useful largely. According to Yuan (2011; as cited in Gangolells et al., 2014), the increase in waste disposal fees leads to CWM benefits such as a decrease in illegal dumping, discounts in waste treatment fees due to better on-site sorting, use of more sustainable materials, practices and construction methods. Ultimately, there has to be a balance in the waste disposal fees to avoid triggering fly tipping.

4.2.6 Training and Education

Training sessions are provided to stakeholders to raise awareness towards appropriate CWM practices in minimising waste generation (Bakchan & Faust, 2019). Several studies imply that a lack of knowledge regarding the impacts of CW and awareness of the benefits of CWR makes the construction industry less interested in CWM (Del Río Merino et al., 2010; Yuan, 2012; Bakshan et al., 2017; Ding et al., 2016). A study conducted by Li et al. (2018) reveals that knowledge has a great deal of influence over the behaviour of the construction sector towards CW reduction.

Del Río Merino et al. (2010) state that in the case of Spain, no initiatives have been launched for education and awareness programmes for stakeholders in the sector. Again, a survey on the awareness of CE concept in the Chinese construction sector indicates that clients, designers and subcontractors are the least informed (Huang et al., 2018). The evidence above shows the need for educational intervention within the industry to raise awareness and promote best practices. Furthermore, Ghaffar et al. (2020) add that the challenge of adopting cleaner production is in changing the mind-sets of stakeholders and overcoming technical issues. Thereupon, efforts should be put in view of training and educating stakeholders of the sector to promote proactive measures in CWM. Zhang et al. (2019) suggest that more efforts are towards training and education, high level of engagement and supervision of stakeholders.

Begum et al. (2007a) highlight that the need to consider on-site staff training is vital to trigger environmental awareness and thus, promote CWM best practices. Consequently, the results of a survey amongst local contractors in Malaysia show that employees with a higher level of CW education can influence the contractor’s attitude towards Sustainable CWM (Begum et al., 2009). In addition, Li et al. (2015), recommend visual demonstration of the adverse impacts of large volumes of CW generation or successful CWR projects to motivate decision-makers towards the adoption of Sustainable CWM best practices. For good measure, Gangolells et al. (2014) contend the support of efforts for sharing information on how to adopt the best practices at minimum cost. Sabini et al. (2017) pointed out the importance of the critical role played by professional institutions in developing and disseminating sustainable best practices. Likewise, Ghaffar et al. (2020) recommend the need for the industry stakeholders to adopt more robust dissemination strategy to share their practices.

4.3 What Are the Factors That Impede the Adoption of Sustainable CWM Best Practices?

The section looks at the factors that hinder the implementation of CE in waste management found in the literature review research. The study by Saez et al. (2013) classified drawbacks to the use of CWM best practices as economic (extra costs for technologies and techniques required for application), time (more time devoted to CWM), on-site space (lack of space for sorting and separation of CW) and extra paperwork (inspection reports and control forms). Furthermore, recent studies highlight that stakeholders identified the main barriers to adopting CWM as the government regulations, poor recycling infrastructure, lack of education, the perception that CWM impedes new construction progress, lack of consideration of CWM at planning and design stage, and logistical bottlenecks (Lockrey et al., 2018; Bakchan et al., 2019). The study splits barriers into four categories, namely: technical, behavioural, legal and market restrictions, corresponding to Zhang et al. (2019).

4.3.1 Technical Barriers

According to Zhang et al. (2019), technical barriers refer to a lack of technical expertise, standards and guidelines to promote the CWM plan. Again, Mahpour (2018) recognised barriers to waste reduction as a lack of appropriate indicators to measure source reduction and reuse, poor employee engagement and zero awareness of circular economic initiatives. On the other hand, Ghisellini et al. (2018) point out that lack of prefabrication technology, higher costs of handling prefabricated components, lack of skill for design and construction of prefabricated buildings as the technical barriers to adopting prefabrication. In brief, without the proper technology and proper skills, it is impossible to achieve a CE. For that reason, the findings by Oliveira et al. (2019) accept that low technology sites fail in implementing measures towards waste reduction and recycling as seen in Southern Brazil. Thus, governments are encouraged to assist the sector with proper technology to promote sustainable practices (Zhang et al., 2019).

Yuan (2012) adds that longer transportation distances of CW to treatment facilities result in higher costs of CWM and ultimately diminish the contractor willingness attitude to diverting CW from landfills. However, Zhang et al. (2019) encourage decentralisation of recycling facilities and markets to reduce the distance travelled by contractors and consequently, reducing the CWM costs. Contractors in Shenzhen identified the poor on-site sorting of waste as the primary technical issue leading to the low efficiency of reuse and recycling practices (Yuan, 2013). The major hindrances to on-site sorting may be due to limited space, health and safety restrictions, extra costs related to sorting and equipment required and its interference with project schedule (Ghaffar et al., 2020). Additionally, Huang et al. (2018) discovered the key barriers to reuse of CW as lack of guidance for effective sorting and collection, lack of standards and competitive market, and inappropriate urban planning demolition.

According to Dahlbo et al. (2015), the main barrier for recycling CW is the readily available virgin raw materials at low costs. Additionally, it is claimed that designers barely consider recycled materials during specifications, hence the low acceptance (Ajayi et al., 2015). Equivalently, Manowong (2012) adds that the process of reuse or recycling is considered to be costlier than buying raw materials. Furthermore, the ineffective CWM system, lack of advanced technology and weak recycled materials market are other major barriers (Huang et al., 2018). In like manner, the quality of recycled materials may be deficient relative to virgin materials. Some studies also hint high uncertainties or mistrust for the use of recycled materials for structural use (Faleschini et al., 2016; Huang et al., 2018; Zhang et al., 2019). It is recommended to test for the quality of recycled materials to ensure they comply with the construction standards. The examination of recycled materials can, however, be expensive. Thus, it may potentially offset the finances saved from recycling and reuse of CW (Ghaffar et al., 2020). The lack of profits might impede the industry’s adoption of CWM best practices.

Ultimately, the recycled materials may fail to meet the required standards for reuse. Thereupon a need for further research into the quality of recycled waste is vital. According to a survey conducted in the UK with relevant stakeholders of the construction industry by Ghaffar et al. (2020), the recycled materials may not be used due to structural concerns or somewhat restricted for non-structural usage (Zhang et al., 2019). Again, the testing may require expensive advanced technologies and be time-consuming, affecting the progress of other construction activities. As a result, there is limited use of recycled materials, and the CW is preferably disposed of in landfills to avoid economic loss.

The recycled materials should demonstrate on top of the quality aspect, the economic viability (cheaper than virgin materials), social acceptability and environmental friendliness (Lockrey et al., 2018; Duan & Li, 2016). Therefore, as far as current recycling is concerned, Lockrey et al. (2018) noticed that concrete waste is used in temporary roads and then later transferred to landfills. Zhang et al. (2019) contend that the recent studies confirm the suitability of recycled waste material as base and sub-base materials for road pavements, and fit for precast construction and high-performance concrete.

4.3.2 Attitudes and Behaviour Barriers

Begum et al. (2009, p. 322) define attitude as “a positive or negative feeling toward specific objects”, hence it exerts influence on behaviour (Al-Sari et al., 2012). According to Zhang et al. (2019, p. 14), behaviour barriers refer to “the attitudes and psychological perspectives which dictates human behaviour”. Some scholars have pointed out that human factors such as stakeholders’ attitude and behaviour influence the implementation of Sustainable CWM practices (Jia et al., 2017). Teo and Loosemore (2001; as cited in Begum et al., 2009) found that attitudes toward waste reduction are one of the major hindrances to Sustainable CWM. The most imperative behavioural barriers are the preference of CW disposal over recycling, poor quality perception of recycled materials, the spread of wrong information about recycled materials, lack of confidence in recycled materials and economic benefits of sustainable practices (Al-Sari et al., 2012; Zhang et al., 2019). Begum et al. (2009) state that contractor size, CWR problems, staff participation in training programs and waste disposal methods are vital factors that affect contractor attitudes in the sector.

Wu et al. (2017; as cited in Chen et al., 2019) point out government departments (legislation), construction contractors (competitors), economic viability and government supervision (regulations) as the main factors affecting contractors’ behaviour towards Sustainable CWM. Yuan and Shen (2011) suggest that among other reasons affecting the effectiveness of CWM is the different views between stakeholders in the sector. The stakeholders can be divided into two categories, the first being authorities, the general public and NGOs who have positive attitudes towards diverting waste from landfills. Then the second category of stakeholders is identified as the project main contractor and subcontractor who tend to focus on the economic benefits and overlook the negative impacts of CW generation. Appreciating and optimising the construction stakeholder’s behaviours is vital for improving CWR as the study by Li et al. (2018) revealed that knowledge had the most significant effect on CWM behaviour. Additionally, Loosemore et al. (2002; as cited in Ding et al., 2016) indicated the critical impact of human factors in CWR and contended that changing attitudes can minimise CW generation.

The studies imply that the enforcement of government guidelines should motivate the contractor’s attitudes and behaviours towards effective CWM (Begum et al., 2007a). For instance, in China, the policies have a function of regulating and controlling actions of stakeholders in the transition towards sustainable practices (Ghisellini et al., 2018). Some studies, (Al-Sari et al., 2012; Chen et al., 2019), observed that without governmental regulations and supervision the attitudes and behaviours of the construction sector is driven by the occurrence of a direct economic benefit. However, the studies that focus on the decision-making behaviours in CWM are still limited (Chen et al., 2019). For example, there are no currently available studies that consider the attention and functioning of the construction professionals and workforce towards CWM in India (Kolaventi et al., 2019).

The study conducted by Jia et al. (2017) revealed that knowledge had the most considerable influence on CWM behaviour. Thus it is crucial to understand contractor employees’ attitudes and actions to reduce waste generation effectively. Therefore, Al-Sari et al. (2012) point out that contractors with high numbers of unskilled workers have a negative influence on CWM. Bakshan et al. (2015) argued that there is an 83% probability of adopting CWM practices on-site when workers have a positive attitude to CWM. Kolaventi et al. (2019) highlight that most of the construction site workers are uneducated about sustainable practices, hence there is an urgent need for training them.

Consequently, the availability of training and awareness sessions is required to achieve positive attitudes of workers. Moreover, Chen et al. (2019) highlight the supervision intensity and costs, penalties, increased waste disposal costs and revenues from illegal dumping as significant factors influencing the behaviour of the construction industry. Although, Mak et al. (2019) suggest the implementation of waste disposal charges would motivate society’s behavioural change to consider and become aware of the benefits of adopting Sustainable CWM best practices.

On top of the attitudes and behaviours, poor communication within the construction industry is a common barrier that hinders the stakeholders from sharing ideas and methods towards CWM best practices. Jin et al. (2017; as cited in Zhang et al., 2019) highlight that improving communication amongst construction stakeholders concerning CWM will help in overcoming behavioural barriers. The results of Blaisi (2019) survey with academics showed a lack of data about the total amount of CW generated and methods of its management, which hinders their ability to make informed decisions towards waste reduction and disposal practices. Finally, there is a unique need for including all stakeholders in CWM decision-making by regulators or the government to influence their attitudes and behaviours by harmonising with their interests. As the study by Sabini et al. (2017) concluded that influences from other stakeholders are fundamental in integrating sustainability in project management.

4.3.3 Legal/Legislation Barriers

Legal barriers refer to the lack or absence of active policies, regulations and legislation to promote CWM best practices (Zhang et al., 2019). Ineffective government regulations and supervision prevent the implementation of waste reduction practices (Ghisellini et al., 2018). Yuan (2012) argues that, particularly in developing countries, project decision-makers focus on traditional project objectives, hence the weak regulatory environment and low implementation of CWM practices. Zhang et al. (2019) indicate that most of the current policies, specifically in China, tend to promote landfilling and down cycling but fail to address CWR in a sustainable approach.

Kolaventi et al. (2019) confirm that the Indian construction industry is well aware of the regulations for CWM. Despite that, still, there is no extensive use of the practices due to their weak enforcement and complexities of integrating them within the traditional systems. The government regulations are not strict and rigid enough to support waste reduction and environmentally sustainable CWM (Duan & Li, 2016). A study conducted by Ghisellini et al. (2018) in Shenzhen identifies the main weakness of practising Sustainable CWM as the lack of clarity on government regulations enhancing CW reduction and recycling, and responsibility of government departments in enforcing legislations.

4.3.4 Market/Economic Viability Barriers

Ghisellini et al. (2018) argue that the sector is profit-driven and economic viability is critical in the CWM decision making. Ghisellini et al. added that construction contractors instead pay attention to the cost, quality and schedule of the project as compared to CWR concerns. Studies by Yuan (2012) suggest the construction sector decision-makers emphasise more on cost, time, quality and safety (of the society) objectives, and less on the environment. Furthermore, Lu et al. (2015) point out that specifically the private construction sector emphasises more on time and cost-efficiency. Notably, the main motive of the construction industry is to generate economic benefits. As a result, the industry is reluctant to change as, in their view, sustainable approaches are time-consuming and tend to reduce profit margins.

In construction projects arguably clients do not allocate a budget for a proper CWM plan and hence there is a lack of market-driven benefits in adopting the best practices (Del Río Merino et al., 2010; Ding et al., 2016). Zhang et al. (2019) identify the high costs of CWM as one of the critical barriers to recycling. A survey among different construction stakeholders indicated that the return on investment (ROI) in diverting CW to recycling facilities is low (Jin et al., 2017; as cited in Ghisellini et al., 2018). The immature recycled materials market hinders the CWR practices, as the companies will not be able to compete in the market (Yuan, 2012; Ghaffar et al., 2020). Other studies identify the adoption of expensive cleaner technologies at the source, extra costs of recycling and the quality of recycled materials as the major hindrances to recycling practices (Yuan & Shen, 2011; Huang et al., 2018; Ghaffar et al., 2020).

Studies argue that from an economic standpoint recycling is implemented when the recycled materials are competitive to virgin materials in terms of cost, quantity and quality (Ghaffar et al., 2020; Blaisi, 2019). This competitiveness primarily occurs in areas with limited landfill space and sites where virgin materials are not available locally. For example, Jain et al. (2020) highlight that many regions of India will have to import sand from other countries if there is poor implementation of CW diversion methods. In this regard, the construction sector strives to focus on recycling and other CWR practices, as importing might result in high costs due to international tax and more extended transportation.

Ghisellini et al. (2018) contend that the initial cost of sustainable buildings is higher than conventional buildings, which discourages clients from investing in sustainable practices. Consequently, this brings about a reluctance to adopting sustainable practices as the main drivers of the sector is the profits (Bakchan et al., 2019). Wu et al. (2017; as cited in Chen et al., 2019) found that the construction sector’s behaviours are affected by economic viability. Ultimately, as long as the CWR solutions are not as economically viable as the traditional ones, we will not witness the adoption of CE best practices on a large scale (Ghaffar et al., 2020).

The adoption of sustainable best practices may benefit the industry economically due to cost-saving, mainly from the reuse of salvaged materials from demolition activities and the use of recycled waste materials in place of virgin materials. Bakchan and Faust (2019) contend that the lack of Sustainable CWM practices proves to cause budget overruns on top of poor environmental performance. Evidence points out that 5% of construction waste reduction can save up to £130 million in the UK construction sector (BRE 2003; as cited in Ajayi et al., 2015). Manowong (2012) identifies minimisation of raw materials use, waste reduction, fewer greenhouse emissions and cost saving from reuse or recycling of waste materials. Likewise, Wu et al. (2016) note that effective CWM is considered vital in “achieving the visions of landfill space conservation, environmental impact reduction, job opportunity creation, and project expense reduction (USEPA, 2013)”.

5 Conclusions

Waste management in construction has been a global issue that has brought to attention the need to come up with strategies to alleviate the environmental impacts of waste generation. Undoubtedly, the construction sector needs to adopt a system that will strive to consider all the three elements of the sustainability in harmony. In this literature review, Sustainable CWM was conceptualised through two main categories: triggers and barriers. Feasibility of the current and proposed strategies in Sustainable CWM is discussed.

The research provides evidence of global awareness of the 3R (reduce, reuse and recycle) principle as the significant CWM practice and finally landfilling as a last resort. The literature recommends the adoption of 3R in descending order of sustainability performance. The CW reduction principle is the eco-friendliest approach as it sought to reduce the production of CW at the source. The practice of estimating CW generation during the planning phase of construction projects is essential for developing a CWM plan that can reduce the waste generation. Various tools of CW estimation have emerged, although they lack reliability. Studies recommend the development and adoption of universally reliable and user-friendly estimation tools/methods, which can assist further in effective government legislation on minimising CW production.

Studies analysed indicate that when considered in the “design phase” there are the best chances to reduce waste. However, evidence from the very same research points that designers or architects lack awareness of the potential waste reduction at the design stage. When considered at that stage, the reduction in waste generated can be up for general construction projects. Another approach consists of the standardization of project design to facilitate reuse and recycling of material from old projects or buildings.

The introduction of precast or prefabricated materials during the construction stage promotes the CWM by minimising waste due to offcuts and site mixing. Similarly, the careful dismantling of old construction projects is advised, during the demolition phase, to reduce CW by furthering recovery of materials for reuse or recycle. More notable, the green building practices help significantly in reducing the waste produced during demolition activities. However, the green building practices are not highly implemented as they are considered more expensive than traditional building practices. There is a need to research on green building practices that are less expensive to trigger its implementation. Furthermore, a demolition-licensing scheme is encouraged to ensure proper regulations are in place during the demolition phase to maximise the salvaging of materials.

The production of CW is unavoidable, consequently, the end of pipe methods are adopted to divert waste from landfills. These end of pipe methods are mainly, reuse and recycle of CW. The reuse of salvaged CW is the priority as it is cost saving and has less environmental impact just like recycling. However, the literature suggest a lack of implementation in construction recycling practices (mainly for untrusted quality of recycled materials, poor technology and a lack of competitive market).

Another point emerged is the abundance of virgin materials, which hinders the sector from adopting recycling practices. Therefore, government regulations, such as imposing a tax on virgin materials, are encouraged to promote the recycled materials market. Ultimately, to facilitate reuse and recycling practices, proper on-site or offsite sorting practices must be adopted after careful demolition of infrastructure or buildings.

As a last resort, after all the waste reduction strategies have been implemented, the untreatable CW is disposed of in landfills. Landfills are the traditional and most widely used practice of disposing of CW. Studies recommend the diversion of CW from landfills as it has negative impacts on the environment and landfill space is filling up due to high CW production. Hiking of dumping fees has been put in place by governments to relieve the filling up of landfills (particularly in urban areas) and promote reuse or recycling of waste. On the other hand, the dumping fees should be monitored to avoid triggering the sector to illegal dumping as a way of escaping high landfill fees. However, the government supervision of CW disposal and setting of penalties will assist to decrease the illegal activities. Ultimately, for the legislations and regulations to be effective, the government has to involve the construction stakeholders’ views and interests in decision-making.

The construction sector is reluctant to adopt the Sustainable CWM as they can be time-consuming, and the profit margins tend to be small as compared to traditional methods. The government policies and regulations are the major factors contributing to implementing or neglecting of sustainable best practices. The studies identified a lack of government regulations and support as the major drawback to the use of CWM best practices. Thus, the extensive literature recommends enforcing robust regulations to support and direct the sector towards the sustainability best practices.

The governments must incentivise waste reduction to increase competition towards CE in the sector. These economic incentives have shown to improve the CW diversion from landfills. However, the lack of CWM plan before construction hinders effective waste management. The literature stresses the need for the mandatory requirement in CWM to be approved by local authorities before construction starts. The failure to comply with the government regulations results in fines or penalties. These fines have played a role in reducing illegal dumping. On the contrary, other studies suggest that if there is a lack of enforcement and supervision, the fines may lead to an increase in illegal dumping activities. Therefore, the government need to intensify the supervision of the sector as well as monitor the fines.

Moreover, technical barriers such as low technologies, long CW hauling distances to treatment sites and the quality of recycled materials hinder the Sustainable CWM practices. The companies without advanced prefabrication or recycling technology fail to integrate sustainable practices in their construction activities. In conclusion, the government is encouraged to support the industry by providing financial support for high-cost technologies. Similarly, governments should decentralise recycling facilities and markets for reducing the distance for waste transportation. Therefore, to improve the quality of recycled materials, effective sorting practices should be implemented and research suggests a maximum of 50% mix ratio of recycled materials with virgin materials. However, further research on improving the quality of recycled materials for structural usage is recommended as the studies reference its use mainly on non-structural elements.