Abstract

The color stability and quality changes of red pepper powder of various initial moisture content (7%, 10%, and 13%) and packaged with different materials, low-density polyethylene (LDPE) and nylon layered polyethylene (Ny/PE) film pouches or plastic and glass bottles, were compared during storage at 20 °C for 126 days. In the 7% moisture content sample packaged in LDPE film and plastic bottles, the L* and b*-values increased from 48.2 ± 0.7 and 15.4 ± 1.1 to 65.2–65.9 and 29.5–30.3, respectively, while the a*-value decreased from 26.1 ± 0.7 to 14.2–15.9, indicating a noticeable color change from red to orange. However, the decrease in the capsaicinoid and free sugar content of red pepper powder over time was found to have no significant correlation with moisture content and packaging type. As a result, the color change during the long-term storage of red pepper powder was greatly influenced by the initial moisture content and gas permeability of the packaging material.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Red pepper (Capsicum annuum L.) is one of the most widely used seasoning vegetables and is utilized as a natural food coloring and seasoning agent due to its attractive red color, unique sweetness, and peculiar spicy taste (Choi et al., 2023; Rhim and Hong, 2011). It is also an excellent source of essential nutrients and phytochemicals such as carotenoids, phenolic compounds, and vitamins (Kim et al., 2006). Red pepper fruits have a varied amount of bioactive compounds depending on the variety/cultivar, ripening stage, and growing condition (Iqbal et al., 2015). Red pepper has not only been used to make traditional Korean foods such as hot pepper paste and kimchi for over 400 years but has also been used as the main seasoning for various dishes (Hong et al., 2023).

Typically, red peppers are stored in dried pods or powder form for long-term storage. However, caking, hardening, or discoloration may occur depending on the variety, light, moisture content, and packaging conditions (Aguilera et al., 1995; Jung and Lee, 2007). Color is the most important quality attribute in determining the product value of red pepper powder, so it is crucial to minimize the discoloration of red pepper during storage and distribution. Red pepper powder contains a significant amount of amino acids and reducing sugars, so it easily turns dark red due to the non-enzymatic browning of the pepper. Meanwhile, the color of the carotenoids in peppers changes to yellow–red as they are auto-oxidized by surrounding oxygen during storage (Rhim and Hong, 2011). Paprika powder stored in transparent bottles at 20 °C for 4 months was reported to have a decrease in the ASTA (American Spice Trade Association) values, which is generally evaluated as an oil-extracted color and a representative color quality index, with an increase in hue angles, indicating that the color changed from red to orange (Tepić and Vujičić, 2004).

Color stability is known to be determined by the processing conditions for obtaining peppers and storage conditions after processing (Ordóñez-Santos et al., 2014). In order to prevent discoloration of red pepper powder due to oxidation, it is essential to limit oxygen transfer by maintaining its moisture content at an optimal level or packaging it with materials with high gas-barrier properties (Lee et al., 2003). In Korea, the moisture content of hot pepper powder is regulated to 15.0% or less (Ministry of Food and Drug Safety, 2023), but in commercial products, the moisture content is reported to vary from 7 to 16% (Jeong et al., 2013). Most red pepper powder products are usually packaged in flexible plastic film pouches and sturdy containers such as glass or plastic bottles. However, relatively little research has been done on the effects of pre-storage/initial moisture content and packaging material on the color quality of red pepper powder during long-term storage.

Therefore, the main purpose of this study was to test the effect of initial moisture content and packaging on the color stability of red pepper powder to provide basic data for estimating shelf-stable processing and packaging conditions at room temperature.

Material and methods

Experimental materials

Cleaned and dried red pepper (Capsicum annuum L.) of the Asian pod type (cultivar: Keum-Dang) was purchased from the Yeongyang Red Pepper Trade Corp. (Yeongyang, Korea). The pepper had a pod length of 12–14 cm, a pod weight of 11–13 g, and pungency levels of 500–1000 Scoville heat units. For the pouch packaging, two types of plastic packaging films, low-density polyethylene (LDPE) and nylon laminated polyethylene (Ny/PE), were procured from Ihlshin Chem. Co. (Ansan, Korea) and Taeyang Chem. Co. (Seoul, Korea), respectively. LDPE film had an average thickness of 60 μm, a water vapor transmission rate (WVTR) of 7.8 ± 0.4 g/m2 day, and O2 transfer rate (OTR) of 2,433 ± 73 mL/m2 day atm, and Ny/PE film showed the average thickness of 70 μm, the WVTR of 4.5 ± 0.8 g/m2 day, and OTR of 54.8 ± 2.7 mL/m2 day atm. Film thickness was determined using a micrometer (Dial thickness gauge #7326, Mitutoyo Co., Kawasaki, Japan) at an accuracy of 1.0 μm. The WVTR was measured at 25 °C, 90% RH using a Permatran-W (Model 3/33, Mocon Inc., Minneapolis, MN, USA) following the ASTM F1249 (2013) method, and the OTR was determined at 25 °C, 0% RH using an Oxygen Permeation Analyzer (Model 8001, Systech Illinois Inc., Johnsburg, IL, USA) according to the ASTM D3985 (2010) method. In addition, two types of rigid jar containers, transparent polyethylene terephthalate (PET) bottles with polypropylene (PP) caps (DaeHan PET Co., 230 mL, EZ-150, Yongin, Korea) and glass bottles with metal caps (Kumbi Co., 240 mL, SG-125, Seoul, Korea), were used for the packaging test. The thickness and surface area of the plastic bottles used were approximately 2.0 mm and 170 cm2, and those of the glass were about 3.5 mm and 180 cm2, respectively. Plastic bottles are semi-permeable to gas, while glass bottles are almost impermeable.

Preparation of the red pepper powder

The seeds of dried pepper fruits were manually separated from the pods. A rolling mill (Kyongchang Machinery Co., Gwangju, Korea) was used to crush the seeds and pods separately. Then, a Ro-Tap sieve shaker (Cheonggesa, CG-213, Seoul, Korea) was utilized to pass the powdered pods through a standard sieve (ASTM mesh #30). The powdered pods were mixed with finely ground seeds at a fixed ratio of 90% pods and 10% seeds. The initial moisture content of the red pepper powder (mean particle size: 0.3–0.4 mm) was adjusted to approximately 7%, 10%, and 13% (dry basis) through additional drying using a 60 °C drying oven or freeze dryer (Il-Sin Co., Seoul, Korea) as determined by the preliminary trial and error method.

Packaging and storage

Based on the preliminary experiments, storage tests were designed to separately investigate the effects of initial moisture contents and packaging type on red pepper powder. Approximately 45 g of red pepper powder samples with different pre-storage moisture contents at the level of 7, 10, and 13% were packed in the LDPE film pouch to examine the effect of the initial moisture contents. Two types of plastic film pouches (11 × 16.5 cm) and container jars (internal volumes of approximately 230–240 mL) were used for packaging the red pepper samples with the 7–13% moisture contents to investigate the effect of the packaging type. Film pouches were sealed securely using a thermal impulse sealer (Sambo Tech Corp., SK-310, Gimpo, Korea), and the container jars were sealed with manual twist capping. Test samples were stored in darkness at 20 ± 2 °C and 75–80% RH for over 4 months, and their color and quality attributes were periodically analyzed. Storage tests were independently conducted in duplicate.

Moisture content and water activity

Moisture content (MC) was determined by drying red pepper powder samples in a vacuum oven at 60 °C for 24 h (AOAC, 1995). A water activity (Aw) meter (Novasina AG, MS1, Lachen, Switzerland) was used to measure Aw in triplicate at 20 ± 2 °C after equilibrating the pepper samples with aqueous saturated salt solutions.

Color and ASTA value

The apparent color measurement of red pepper powder was conducted with a Chroma Meter (Konica-Minolta, CR-400, Osaka, Japan) by using the CIE L*a*b* color space. The color difference (ΔE*) between the shown color and the original color of the pepper sample was evaluated as follows:

Red pepper powder of 10 g was placed in a transparent sample container (Φ50 mm PP Petri dish), and each sample was read at least 6 times.

The ASTA value was measured following the method of the American Spice Trade Association (ASTA, 2004). 50 mL of acetone was quantitatively added to 100 mg of red pepper powder, and then the vortex-mixed suspension was kept in a refrigerator at 0 °C for 16 h. The absorbance measurement for the clear extract was carried out with a spectrophotometer (Jasco, V-550, Tokyo, Japan) at 460 nm. The ASTA value was evaluated as follows:

where the instrument correction factor, If = (NIST A460 for the glass filter)/(Lab A460 of the glass filter), was calculated using a standard solution of ammonium, cobalt sulfate, and potassium dichromate (Kim et al., 2008).

Chemical analyses

The chemical analyses of the red pepper powder samples, including ascorbic acid, capsaicinoids, and free sugar contents, were performed according to previously reported methods (Hong et al., 2023). For analysis of ascorbic acid, 25 mL of metaphosphoric acid solution (10 g/100 mL) was added to 2 g of red pepper powder with mixing for 30 min at room temperature and additionally mixed with 75 mL of metaphosphoric acid solution (5 g/100 mL) for 2 h. The ascorbic acid extract was filtered with a filter paper (Whatman, No. 2, Maidstone, UK) and passed again through a PVDF micro-filter (Millipore, 0.22 μm, Billerica, MA, USA). The filtrate was analyzed for ascorbic acid using an HPLC (Jasco, Tokyo, Japan) equipped with a model PU980 pump, a model UV975 detector, and an XTerra™ RP18 column (Waters Co., 5 μm, 4.6 × 150 mm, Milford, MA, USA). The detector wavelength was set at 254 nm, and the column temperature was kept at 40 °C. The mobile phase was 0.05 N KH2PO4/MeOH (65:35 v/v) at a flow rate of 0.8 mL/min with an injection volume of 20 μL.

For extraction of capsaicinoids, 20 mL of acetonitrile was added to 4 g of red pepper powder with vortex-mixing for 2 min. The supernatant (1.0 mL) was diluted 10 times with distilled water and filtered using the C18 Sep-pak (Waters Co., Milford, MA, USA). Then, 4 mL of acetonitrile and 1.0 mL of acetonitrile with 1% acetic acid were sequentially passed into the Sep-pak filter to elute absorbed capsaicinoids. The eluent of 20 μL was injected into an HPLC (Jasco, PU2089 & UV2075 + , Tokyo, Japan) equipped with an XTerra™ MS C18 column (Waters, 5 μm, 4.6 × 150 mm) and a guard-column (Millipore, Waters Guard-Pak™, Billerica, MA, USA) with the column temperature of 35 °C. The detector wavelength was fixed at 280 nm, and MeOH/water (70:30 v/v) was used as the mobile phase at a flow rate of 1.0 mL/min. The total capsaicinoid content was estimated as a sum of capsaicin and dihydrocapsaicin in samples.

To extract free sugars, 40 mL of ethanol (80%, v/v) was added to 2 g of red pepper powder with vortex-mixing for 2 min. The sugar-extracted solution was filtered with a PVDF micro-filter (Millipore, 0.45 μm). The filtrate was analyzed for free sugars using an HPLC (Jasco, PU2089 & RI2031+, Tokyo, Japan) system equipped with a Carbohydrate Amino (NH2) column (Waters, 10 μm, 3.9 × 300 mm) kept at 35 °C. The injection volume was 20 μL, and acetonitrile/water (87:13 v/v) was used as the mobile phase at a flow rate of 1.2 mL/min. The free sugar content was determined by combining the amounts of glucose and fructose.

Microorganisms

For microbiological tests, 100 mL of 0.85% NaCl sterile physiological solution was added to 10 g of red pepper powder aseptically taken from the packaged samples and mixed in an aseptic sampling bag (NASCO, Whirl PakⓇ B01195, Fort Atkinson, WI, USA) with gently shaking. After diluting the mixed solution with 0.1% sterile peptone water (Difco Lab., Detroit, MI, USA), portions (1 mL) of the serially diluted solutions were plated on appropriate culture media in Petri dishes. The plate count agar (Difco Lab.) and the Chromocult agar (Merck, Darmstadt, Germany) media were used to cultivate the mesophilic aerobes and the coliform bacteria, respectively. Microbial viable cells were counted after incubation of the agar media at 37 °C for 2 days and presented as colony-forming units per mass of the pepper samples (CFU/g).

Statistical analysis

All the results of the physicochemical and biological properties of red pepper powder were calculated on a dry weight basis and expressed as the average of at least 6 measurements with the standard deviation (SD). Significant differences in data among experimental treatments were analyzed using the general linear model (GLM) procedure and the least significant difference (LSD) test at the probability level of 5% (SAS Institute Inc., ver. 9.3, Cary, NC, USA).

Results and discussion

Effect of initial moisture content on the color quality of red pepper powder

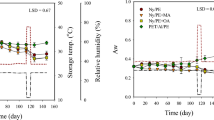

Changes in the physicochemical and microbiological properties of red pepper powder packaged in LDPE film with three different initial moisture contents (MC about 7, 10, and 13%) were evaluated by measuring quality attributes before and after storage for 126 days, and the results were presented in Table 1. Since moisture content is a crucial factor affecting other quality attributes, changes in the MC of the pepper sample were monitored periodically during the storage period (Fig. 1). The pre-storage/initial moisture contents of the red pepper samples were 6.7, 10.3, and 12.5 g water/100 g dry matter. The measured MC of red pepper powder with the medium (10%) and high (13%) levels of initial MC increased slightly after storage, but the difference was not significant (p > 0.05). However, the MC value of red pepper powder with the low (7%) level of initial MC increased significantly up to 9.9 g water/100 g dry matter. The water activity of all the pepper samples also increased significantly after storage. The increment of MC and water activity in dried red pepper powder is mainly attributed to moisture absorption through film permeation from the environmental condition (20 ± 2 °C and 75–80% RH) for the storage test. Taking into account the WVTR of the packaging film used (LDPE: 7.8 ± 0.4 g/m2 day at 25 ℃, 90% RH), theoretically, a few grams of water could be slowly migrated from the environment into the film pouch during storage depending on water vapor pressure gradients between inside and outside of the package. The microbial cell counts of the pepper samples, including mesophilic aerobes and coliforms, remained consistent and showed no significant change after storage of 126 days. On the other hand, the contents of capsaicinoids, ascorbic acid, and free sugars for all the pepper samples tended to decrease to some extent with time, resulting in approximately 10–15% significant reduction of capsaicinoids, 1–11% loss in ascorbic acid, and 5–7% significant decline in free sugars, respectively. Nonetheless, the overall biochemical changes in red pepper powder were not significantly different among MC treatments.

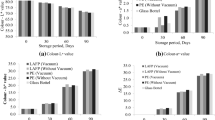

The apparent color changes of red pepper powder during storage were monitored using a CIE L*a*b* color system, as shown in Fig. 2A. The L* (lightness), a* (redness), and b* (yellowness) values of all the pepper samples packaged in LDPE film changed during storage, which showed three distinctive changing steps. At the beginning of storage, the color value changed noticeably from 0 to 42 days, then remained relatively stable from 42 to 70 to 84 days, and finally showed significant changes again as the storage period passed. The former step of color change in red pepper powder would probably be associated with the increased MC caused by moisture absorption from the surrounding atmosphere, and the latter change could be mainly due to the degradation of red color pigments in the pepper samples. However, there was a notable difference in color changes in the pepper samples with different initial MCs. For medium (10%) and high (13%) initial MC samples, L*, a*, and b* values changed little after 84 days of storage. The color value increased by approximately 2 to 5 units compared to the initial level, but this color change was not significant. In contrast, red pepper powder with a low initial MC (7%) had a wider range of color values and more distinct color changes than other samples during the entire storage period. In particular, in the late storage period, the a* value significantly decreased from 28.3 ± 0.7 to 15.9 ± 0.9, while the b* value increased from 22.7 ± 0.3 to 30.3 ± 0.3, indicating an increase in yellow color and a decrease in red color. As a result, the overall color difference (ΔE*) values of the 10 and 13% MC samples were 5.5 ± 0.3 and 6.0 ± 0.4, while the ΔE* value of the 7% MC sample was 24.3 ± 0.7 at the end of storage.

As a typical color quality index, the ASTA value is closely associated with the pigment content of colored pepper or paprika (Hong et al., 2023). Changes in the ASTA values according to different initial MC treatments were recorded during storage (Fig. 2B). The original ASTA color values of the prepared pepper samples ranged from 110.8 ± 2.4 to 135.2 ± 8.5, increasing with lowering the pre-storage/initial MCs. The measured values are in good agreement with ASTA values of 107–118 in dried red pepper (Kim et al., 2006; Hong et al., 2023). The overall ASTA values had a decreasing tendency in all the pepper samples during storage. The final retention rates of ASTA in red pepper powder with 10 and 13% MC were around 75 and 82%, respectively. This result indicated that their colors were considerably stable for a long period of storage. However, the ASTA value of the 7% initial MC sample decreased significantly down to about 21% of the original value at the end of storage. The ASTA color of red pepper was reported to be mainly due to carotenoids such as capsanthin, capsorubin, β-cryptoxanthin, β-carotene, and zeaxanthin (Kim et al., 2004). Accordingly, a significant decrease in the ASTA value of the 7% MC treatment could be mostly caused by the destruction of carotenoid components in the pepper sample. Such color changes were confirmed by the visual observation (Fig. 3A). Among the carotenoids, capsanthin and capsorubin are major red colorants, and the others are yellow-orange pigments. Ordóñez-Santos et al. (2014) also revealed that the color values of paprika, including L*, a*, b*, C*, and ASTA, were proportional to the carotenoid content.

The moisture content and water activity of dried red pepper are reportedly critical factors affecting pigment stability. When red paprika powder of various MCs was stored at 19–24 °C for 4 months, an orange-yellow hue (55–60°) was noticed in the samples with 6 and 9% of the MC, and a reddish-orange hue (35–45°) was found in the samples with 12–18% of the MC (Osuna-Garcia and Wall, 1998). The amount of carotenoids was also higher in the red pepper powder sample with an Aw of 0.66 than that with an Aw of 0.14 after storage for 197 days at room temperature (Lee et al., 1992). The ASTA value of red pepper powder stored at 25 °C remained high and stable in the Aw range of 0.2–0.4, but it decreased below Aw of 0.2 (Rhim and Hong, 2011). Similarly, in this study, the color of red pepper powder with the initial MC of 10% (Aw of 0.25) and 13% (Aw of 0.33) remained relatively consistent for 126 days. However, the surface color of the pepper sample with the 7% initial MC (Aw of 0.12) changed significantly from red to yellow. The monolayer moisture content is generally recognized as a criterion for minimizing quality loss and securing food safety during long-term storage. Moisture levels above the monolayer MC in a dehydrated food are known to have resistance against oxidation caused by light or oxygen. In this study, the color change of red pepper powder with the 7% initial MC could be attributed to the lower MC than the monolayer MC during storage at 20 °C. The monolayer MC of dry red pepper was reported in the range of 0.092 to 0.122 g water/g solid at 25 °C and decreased with increasing temperature (Kaleemullah and Kailappan, 2007; Rhim and Hong, 2011). The present result confirmed that the color quality of red pepper powder could be effectively maintained for a long period of storage by controlling the moisture content around 10–13% (Aw of 0.25–0.34).

Effect of packaging type on the color quality of red pepper powder

Changes in the physicochemical and microbiological properties of red pepper powder with the low (7%) level of initial MC and four different packaging treatments were examined by analyzing quality attributes before and after storage for 126 days, and the results were listed in Table 2. The MC and Aw of the pepper samples increased significantly in all packaging treatments. However, the degree of increase varied depending on the packaging type. Both MC and Aw increased the least in the samples packaged with the glass jar, followed by the plastic jar, the Ny/PE film, and the LDPE film after storage. Dependence of the changes in MC and Aw on packaging type would be mainly attributed to the difference in the water vapor barrier property of the packaging materials used. During storage, red pepper powder in the LDPE package could gain more film-permeated moisture from the environmental condition than that in the Ny/PE package, considering a significant difference in the measured WVTRs of both LDPE and Ny/PE films. Although the measurement data on the WVTRs of the glass and plastic jars are not determined, it is generally known that rigid bottle containers have much higher barrier properties against water vapor and gas than flexible film pouches, probably due to a thickness gap in both packaging types. The glass and plastic jars had individual components in their caps and closure lining materials, possibly leading to different gas barrier properties. In fact, the glass bottles paired with the plastisol-coated metal caps, but the PET bottles matched the PP caps covered with a soft polyethylene foam sheet.

Nevertheless, it is assumed that the increased MC of red pepper powder in the glass bottle packaging occurred due to water absorption from the surroundings during the sample preparation and packaging process. The number of microbial viable cells in red pepper powder, such as mesophilic aerobes and coliforms, did not change before and after storage, and there was no significant difference depending on the packaging treatment. Meanwhile, chemical quality factors such as capsaicinoid, ascorbic acid, and free sugar contents decreased somewhat after the entire storage period, but significant differences were not observed depending on the packaging treatment.

The L*, a*, and b* values of red pepper powder with the initial MC of 7% and various packaging treatments were monitored during the storage period, and the results are depicted in Fig. 4A. The surface color change of red pepper powder was greatly affected by the packaging type. The color change of the three-stage pattern was also observed in the red pepper samples packaged in the plastic jar, as in the LDPE film treatment. However, such a pattern of color changes was not evident in the samples packaged in the Ny/PE film and the glass jar. Considering that the discoloration of dried red pepper is directly related to its water activity and oxidation of carotenoids, noticeable changes in the L*, a*, and b* values of red pepper powder in the period of 0 to 28 days might be due to the increased MC caused by water absorption from the environmental condition. On the other hand, the oxidation of color pigments by available oxygen permeated through the packaging materials from the surrounding atmosphere probably occurred, leading to significant color changes in the samples with the LDPE film and plastic jar treatments in the later storage period. Although the color values of the samples with the Ny/PE film and glass jar treatments gradually increased to some extent during storage, notable color changes could not be observed (Fig. 3B). However, the a* value of the samples in the LDPE film and the plastic jar decreased by approximately 10 units compared to the original level at the end of storage. The total color difference (ΔE*) of the samples in the gas barrier packaging (Ny/PE film and glass jar) was less than 10.0 after storage, whereas that of the samples in the gas permeable packaging (LDPE film and plastic jar) was in the range of 24.3–25.6. The ΔE* values of red pepper powder packaged in the LDPE film and the plastic jar were about three times higher than those packaged in the Ny/PE film and the glass jar.

The ASTA value of the pepper sample also showed a very similar pattern to the a* value in the middle and late stages of storage (Fig. 4B). ASTA values decreased slightly in the Ny/PE film and glass bottle treatments, while in the LDPE film and plastic bottle treatments they decreased significantly to approximately 10% of the original value at the end of storage. In general, yellow carotenoids, including xanthophylls, zeaxanthin, β-cryptoxanthin, and β-carotene, are more easily and quickly oxidized than red carotenoids, such as capsanthin and capsorubin (Giuffrida et al., 2014; Pérez-Gálvez and Mínguez-Mosquera, 2001). In contrast, capsanthin contained in the Korean red pepper was reportedly degraded most rapidly, followed by β-carotene, β-cryptoxanthin, and zeaxanthin. The capsanthin content of the pepper powder was reduced by about 61% of the initial concentration after storage of 6 months; meanwhile, zeaxanthin, β-cryptoxanthin, and β-carotene decreased by less than 30% of the original contents (Kim et al., 2004). Capsanthin becomes colorless after oxidative degradation, but the degradation products of β-carotene, zeaxanthin, and β-cryptoxanthin still have a yellow color (Ötles and Çagindi, 2007).

As a consequence, the yellowish color developed after long-term storage of the pepper samples in the gas-permeable packaging could be caused by the faster oxidative degradation of the red pigments like capsanthin and the remaining yellow pigments from the degradation of β-carotene, β-cryptoxanthin, and zeaxanthin. Typically, packaging materials with high gas-barrier properties are recommended for packing dried red pepper products in order to prevent discoloration. The previous study also demonstrated that the color change of red pepper powder was influenced by the oxygen permeability of the packaging films rather than the water vapor permeability (Lee et al., 2003).

In conclusion, significant changes in red pepper powder were not observed in the quality attributes, including capsaicinoids, ascorbic acid, free sugars, and microbial viable cell count after storage of 126 days at 20 °C. However, the L*a*b* color and ASTA values showed significant changes depending on the initial MC and packaging type. The apparent color of the pepper samples with initial MC of 10 and 13% remained stable even in gas-permeable LDPE packages, while the apparent color of the low initial MC (7%) sample changed from red to yellow. During packaging processing, packaging materials with high gas-barrier properties, such as Ny/PE film and glass bottles, showed little color change even after long-term storage. The present study revealed that the discoloration of red pepper powder is closely associated with the initial MC and oxygen permeation within the packaging. Therefore, red pepper powder should be processed by controlling its moisture contents around 10–13% (Aw of 0.25–0.34) of the monolayer MC and hermetically sealed using high gas-barrier packaging to ensure color and quality stability during storage and distribution.

References

Aguilera JM, Del Valle JM, Karel M. Caking phenomena in amorphous food powder. Trends in Food Science and Technology. 6: 149-155 (1995)

AOAC. Official Methods of Analysis of AOAC International. 16th ed. Association of Official Analytical Chemists, Arlington, VA, USA (1995)

ASTA. Extractable color in capsicums and their oleoresins. Official Analytical Method of the American Spice Trade Association. 2nd ed. Analytical method 20.1. American Spice Trade Association, Englewood Cliffs, NJ, USA (2004)

ASTM D3985. Standard test method for oxygen gas transmission rate through plastic film and sheeting using a coulometric sensor. ASTM International, West Conshohocken, PA, USA (2010)

ASTM F1249. Standard test method for water vapor transmission rate through plastic film and sheeting using a modulated infrared sensor. ASTM International, West Conshohocken, PA, USA (2013)

Choi MH, Kim MH, Han YS. Physicochemical properties and antioxidant activity of colored peppers (Capsicum annuum L.). Food Science and Biotechnology. 32: 209-219 (2023)

Giuffrida D, Dugo P, Torre G, Bignardi C, Cavazza A, Corradini C, Dugo G. Evaluation of carotenoid and capsaicinoid contents in powder of red chili peppers during one year of storage. Food Research International. 65: 163-170 (2014)

Hong SI, Lee HH, Rhim JW. Effects of packaging and temperature abuse on the quality of red pepper (Capsicum annuum L.) powder. Food Science and Biotechnology. 32: 1893-1900 (2023)

Iqbal Q, Amjad M, Asi MR, Ariño A, Ziaf K, Nawaz A, Ahmad T. Stability of capsaicinoids and antioxidants in dry hot peppers under different packaging and storage temperatures. Foods. 4(2): 51-64 (2015)

Jeong MS, Ahn JJ, Akram K, Kim GR, Im JG, Kwon JH. Microbiological and physicochemical quality characterization of commercial red pepper powders. Journal of Food Hygiene and Safety. 28: 1-6 (2013)

Jung JW, Lee SK. Classification of discoloration types in dried red peppers and related causal factors. Horticulture, Environment, and Biotechnology. 48: 5-8 (2007)

Kaleemullah S, Kailappan R. Monolayer moisture, free energy change and fractionation of bound water of red chillies. Journal of Stored Products Research. 43(2): 104-110 (2007)

Kim S, Park J, Hwang IK. Composition of main carotenoids in Korean red pepper (Capsicum annuum L.) and changes of pigment stability during the drying and storage process. Journal of Food Science. 69: FCT39-44 (2004)

Kim S, Lee KW, Park J, Lee HJ, Hwang IK. Effect of drying in antioxidant activity and changes of ascorbic acid and colour by different drying and storage in Korean red pepper (Capsicum annuum L.). International Journal of Food Science and Technology. 41: 90-95 (2006)

Kim S, Ha TY, Park J. Characteristics of pigment composition and colour value by the difference of harvesting times in Korean red pepper varieties (Capsicum annuum L.). International Journal of Food Science and Technology. 43: 915-920 (2008)

Lee DS, Chung SK, Tam KJ. Carotenoid loss in dried red pepper products. International Journal of Food Science and Technology. 27: 179-185 (1992)

Lee SM, Park J, Kim S, Hwang IK. The changes of capsaicinoids and ASTA color value of red pepper powder packed with different packaging materials. The Korean Society of Food and Cookery Science. 19: 439-446 (2003)

Ministry of Food and Drug Safety. Standards and specifications for each food product (red pepper powder or shredded red pepper). Food Code (No. 2023-56). Available at: https://various.foodsafetykorea.go.kr/fsd/#/ext/Document/FC. Accessed Dec. 26, 2023.

Ordóñez-Santos LE, Pastur-García B, Romero-Rodríguez A, VÁzquez-Odériz L. Colour of hot paprika from the La Vera and Murcia regions packaged in different atmospheres during storage. International Journal of Food Science and Technology. 49: 217-223 (2014)

Osuna-Garcia JA, Wall MM. Prestorage moisture content affects color loss of ground paprika (Capsicum annuum L.) under storage. Journal of Food Quality. 21: 251-259 (1998)

Ötles S, Çagindi Ö. Carotenoids as natural colorants. pp. 51-70. In: Food Colorants: Chemical and Functional Properties. Socaciu C (ed). CRC Press, Inc., Boca Raton, FL, USA (2007)

Pérez-Gálvez A, Mínguez-Mosquera MI. Structure-reactivity relationship in the oxidation of carotenoid pigments of the pepper (Capsicum anuum L.). Journal of Agricultural and Food Chemistry. 49: 4864-4869 (2001)

Rhim JW, Hong SI. Effect of water activity and temperature on the color change of red pepper (Capsicum annuum L.) powder. Food Science and Biotechnology. 20: 215-222 (2011)

Tepić AN, Vujičić BL. Colour change in pepper (Capsicum annuum) during storage. Acta Periodica Technologica. 35: 59-64 (2004)

Acknowledgements

This work was supported financially by the Export Promotion Technology Development Program granted by the Ministry of Agriculture, Food and Rural Affairs, Republic of Korea and the Basic Research Project (E0211002-04) from the Korea Food Research Institute.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hong, SI., Lee, HH. & Rhim, JW. Effects of moisture content and packaging on color stability of red pepper (Capsicum annuum L.) powder. Food Sci Biotechnol 33, 2797–2806 (2024). https://doi.org/10.1007/s10068-024-01604-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10068-024-01604-1