Abstract

In view of the special aptitudes of the yeast population in both rice wine production and dough fermentation, in this study, the characteristics of dough fermented with rice wine prepared from mixed Saccharomycopsis fibuligera SF7 and Saccharomyces cerevisiae SC1 (JFC) were evaluated and compared with those of dough fermented directly with the two yeast co-cultures (FC). Dough inoculated with JFC showed higher acidity, reducing sugar content and leavening activity than dough fermented with FC. The water distribution pattern and pasting properties of the JFC-fermented dough changed dramatically after fermentation, and the dough microstructure and extensibility were improved. The steamed bread made with JFC-fermented dough had improved specific volume and showed similar volatile compound profiles to that made with commercial Jiuqu. These results indicated that mixed S. fibuligera SF7 and S. cerevisiae SC1 could be used as defined starter cultures in rice wine preparation for steamed bread production.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Steamed bread is a type of fermented wheat-based staple food in China and has a history spanning over two millennia. Traditionally, the steamed bread production process involves mixing the dough, fermentation, re-mixing, shaping, leavening and steaming (Luangsakul et al., 2009). Of these, fermentation is the crucial step in the process and is largely influenced by the type of starter used (Chang et al., 2020; Luangsakul et al., 2009). In addition to Jiaozi and sourdough, rice wine is also widely used in China as a starter for the preparation of steamed bread, as it is rich in yeast and natural enzymes (Huang et al., 2017). Rice wine is a traditional glutinous rice product fermented with the starter Jiuqu (koji) (Sun et al., 2020). Many studies have been conducted to improve the quality of steamed bread such as specific volume, texture, shelf life, nutritional value and sensory properties using this traditional rice wine fermentation biotechnology (Ai-Lati et al., 2018; Sun et al., 2020). However, most of these efforts focused on the optimization of processing parameters and the environmental factors affecting dough fermentation and product quality. There are few studies on the influence of microorganisms in Jiuqu in steamed bread production.

The microbiota in Jiuqu was mainly dominated by the amylolytic strains (Rhizopus genus, Mucor sp. and S. fibuligera) and alcohol-producing strains (S. cerevisiae, Candida glabrata and Pichia burtonii) (Cai et al., 2018; Jeyaram et al., 2008). Although the various microorganisms occurring in Jiuqu endow products with diverse quality characteristics (Son et al., 2018), it is unfortunately difficult to maintain a stable microbial community in the starter (Cai et al., 2018), which affected the final properties of rice wine and the quality of steamed bread (Kim et al., 2015). Recently, it has been found that defined starter cultures can be used as one of the approaches to improve the consistency of traditional fermented foods (Aryashad et al., 2023; Luangsakul et al., 2009; Zhao et al., 2023). However, to date, no study has investigated the technological performance of microbial cultures from Jiuqu in the dough fermentation, which may be useful in improving the quality of steamed bread.

Among the various types of microorganisms, yeasts play an important role in determining the CO2 production, acidification and rheological properties of the dough, thus strongly influencing the quality attributes of the final product, such as texture and flavor (Condessa et al., 2022; Li et al., 2019b). Considering the ecological importance of yeasts in both rice wine and dough fermentation, suitable yeast strains could be selected to design mixed starters for rice wine production, which could further positively contribute to the quality of steamed bread. Traditional rice wine fermentation is a typical process of simultaneous saccharification and fermentation. Two types of yeast, namely Saccharomycopsis fibuligera and Saccharomyces cerevisiae are involved in these stages (Lv et al., 2015). S. fibuligera is a representative producer of amylolytic enzymes among yeasts (Cai et al., 2018). However, it showed poor gas production capacity. On the contrary, the efficient utilization of the carbon sources and production of CO2 is a crucial attribute of S. cerevisiae (Li et al., 2019a). Therefore, a synergistic combination of S. fibuligera with S. cerevisiae, could be used to produce rice wine for dough fermentation. However, until now little information is available on this crucial aspect.

In this study, the use of mixed S. fibuligera SF7 and S. cerevisiae SC1 isolated from Jiuqu in the production of steamed bread was investigated. The characteristics of dough fermented with rice wine prepared from mixed yeasts (JFC) and the quality of steamed bread were studied and compared with those fermented directly with mixed yeasts (FC). This study is the first to extensively investigate the use of mixed S. fibuligera SF7 and S. cerevisiae SC1 isolated from Jiuqu in steamed bread production and is relevant for the future preparation and development of effective defined starter cultures.

Materials and methods

Materials

Wheat flour (10.73% protein, 0.37% ash, 0.75% fat and 13.9% moisture) was obtained from Jinyuan Flour Co., Ltd. (Zhengzhou, Henan, China). Glutinous rice (6.58% protein, 0.35% ash, 0.74% fat and 14.02% moisture) was supplied by Xingwang Rice Co., Ltd. (Wuchang, Heilongjiang, China). Two Jiuqu starters were obtained from Shaoguan, Guangdong, China (GS) and Yanbian, Jilin, China (JY), respectively, which was mainly composed of Rhizopus oryzae, S. fibuligera and S. cerevisiae. Instant dry yeast (S. cerevisiae) was Angel brand (Yichang, Hubei, China). S. fibuligera SF7 and S. cerevisiae SC1 were isolated from Jiuqu GS samples using the classical spread plating method (Luangsakul et al., 2009) on WL agar plate. Isolates were identified by partial sequencing of the internal transcribed spacer (ITS) regions. The GeneBank accession numbers for the ITS sequences of SF7 and SC1 are PP510614 and PP510615, respectively. Yeasts were grown in YPD medium at 30 °C and harvested at early stationary phase by centrifugation at 3000 r/min.

Preparation of rice wine

Rice wine was prepared as previously described (Sun et al., 2020). For the mixed yeast-inoculated sample, glutinous rice (500 g) was washed and then soaked in sterile distilled water (500 mL) at 30 °C for 12 h. After steaming for 45 min and cooling to room temperature, yeast cell suspension (cell number of S. cerevisiae SC1 and S. fibuligera SF7 was 1:1) in 500 mL sterile distilled water was added to the steamed glutinous rice (about 2 × 107 CFU/g rice) and immediately mixed. The mixture was then fermented in Bilon cabinet (HWS180, Shanghai, China) at 30 °C and 85% relative humidity (RH) for 24 h. For the rice wine prepared with Jiuqu starter, Jiuqu (1.5% (w/w) of the glutinous rice) was added as starter instead of mixed yeasts.

Full dough fermentation

To prepare the rice wine fermented dough, wheat flour (500 g) and rice wine (20% on flour basis) were first mixed with water (the total water content was limited to 45% on flour basis) using a mixer (Hauswirt HM790, Qingdao, China) and stirred for 10 min. The dough was then fermented at 30 °C and 85% RH for 8 h to produce rice wine dough. For the steamed bread fermented with mixed yeasts, yeast cells (2 × 107 CFU/g flour) were inoculated, and the water was 45% of the flour. A dough without yeast was prepared as control.

Cell population and chemical determination of dough

The sample for the determination of the microbial count, pH, total titratable acid (TTA), reducing sugars and ethanol content of the dough was prepared as previously described (Cai et al., 2018; Zhou and Li, 2021). The colony forming unit (CFU) count was assessed on WL agar containing chloramphenicol (0.1 g/L) for yeast and on MRS agar supplemented with natamycin (0.1 g/L) for lactic acid bacteria (LAB) (Palacios et al., 2008). S. cerevisiae SC1 and S. fibuligera SF7 was identified by its distinct colony color (Supplementary Fig. S1). The pH was measured using a Leici REX pH meter (Shanghai, China). The TTA was defined as the amount (mL) of 0.1 N NaOH to titrate the solution to a final pH of 8.5 (Aryashad et al., 2023). The 3,5-dinitrosalicylic acid method was used to measure reducing sugar content (Miller, 1959). The alcohol content was determined by the potassium dichromate oxidation method (Crowell and Ough, 1979).

Fermentation behavior of dough

The fermentation behavior of dough was determined in a rheofermentometer (Li et al., 2019b). After 8 h of fermentation, the dough was remixed with 10% wheat flour and 4.5% water (on the fully fermented dough basis) for 8 min. Then, 315 g of the dough was placed in the F3 rheofermentometer (Chopin, Villeneuve-La-Garenne, Cedex, France) and fermented at 35 °C for 3 h.

Microstructure analysis

Scanning electron microscopy (SEM) (Quanta 200, FEI, Hillsboro, USA) was used to evaluate the morphology of the dough, and the microstructure of the protein network was visualized by confocal laser scanning microscopy (CLSM) (FV3000, Olympus, Japan) (Zhou and Li, 2021). Dough samples (10 µm) for CLSM were stained with rhodamine B 0.01% (w/v) and were observed at an excitation wavelength of 561 nm.

Water distribution and migration

The T2 relaxation time of the proton distribution in the dough was measured using a low-field NMR (LF-NMR) spectrometer (MicroMR-CL-I, Shanghai Niumag Electronics Technology Co. Ltd., Shanghai, China) with the Carr-Purcell-Meiboom-Gill (CPMG) pulse sequence (Li et al., 2019a).

Pasting property and X-ray diffraction (XRD) pattern

The pasting property of the doughs was determined by using a Rapid Visco Analyzer (RVA) (RVA-TM, Perten, Huddinge, Sweden) (Chang et al., 2020). The sample (3.5 g) and deionised water (25 g) were placed in an aluminium can and mixed for 30 s to form homogenised suspension. The canister was then placed in the RVA and subjected to the test.

The wide-angle XRD patterns of the doughs were obtained on a D8-Advance XRD instrument (Bruker AXS Inc., Karlsruhe, Germany) at 40 kV.

Steamed bread making and evaluation

The steamed bread was prepared as described previously (Sha et al., 2023). Wheat flour (40 g), water (18 g) and fully fermented dough (400 g) were mixed for 8 min. After rolling 20 times on the surface pressure machine, the dough was divided into pieces (100 g). The chunks were then molded and shaped into round dough balls. After proofing at 35 °C for 40 min at 85% relative humidity, the doughs were steamed for 30 min.

After cooling for 1 h, the qualities, including texture, specific volume and volatile components of the steamed bread were evaluated. Texture profile analysis (TPA) was performed using TA.XT2i (Stable Micro Systems, Ltd., Godalming, UK) as reported (Ai-Lati et al., 2018). The rapeseed displacement method was used to determine the specific volume of steamed bread (Yeh et al., 2009). The volatile components of steamed bread fermented with yeast and rice wine were determined by solid-phase microextraction (SPME) and gas chromatography coupled to mass spectrometry (GC/MS), following the methods of a previous report (Li et al., 2019a). The volatile compounds were subjected to principal component analysis (PCA) using Origin 2018 (Origin Lab Corp., Northampton, USA).

Data analysis

Statistical analysis was performed using SPSS version 19.0 (SPSS Inc., Chicago, USA) and the data are presented as mean ± SD based on triplicate analyses. One-way analysis of variance (ANOVA) and Duncan’s multiple range comparison test were used to determine the significant differences between two samples at the 0.05 level.

Results and discussion

Microbiological and chemical properties of fermented dough

The microbial population, pH, TTA, reducing sugars and ethanol content of dough fermented with rice wine prepared from the mixed S. fibuligera SF7 and S. cerevisiae SC1 (JFC) were compared with those of dough fermented directly with the mixed yeasts (FC) and spontaneously fermented dough (SF) (Table 1). In both JFC and FC doughs, the number of yeasts is much higher than that of LAB, indicating that the yeast is the dominant microbial group in the dough. The pH of FC dough was found to be around 5.04, which was higher than that of JFC. In contrast, a significantly higher TTA value was observed in the JFC dough (p < 0.05). The results suggested that more acidifying metabolites such as lactic acid were produced during the fermentation of JFC dough and confirmed its high number of LAB (Table 1).

Compared with the SF dough, the reducing sugar content of the FC dough was lower, whereas a higher content was observed in the JFC dough. The changes in reducing sugar content in the dough are determined by the imbalance between starch hydrolysis by the action of amylase and carbohydrate consumption by the yeast species. S. cerevisiae can consume carbohydrates remarkably (Li et al., 2019a), so the higher yeast count in FC dough (Table 1) implied that most of the hydrolysis sugar was used to support microbial growth and gas production during wheat dough fermentation. Conversely, the lower S. cerevisiae population in the dough and higher amylase activity in the rice wine led to an increase in reducing sugar content (Huang et al., 2017). The ethanol content of the FC and JFC samples was 2.15 mg/g and 1.43 mg/g dough, respectively, higher than that of the SF dough. This may be due to the predominance of the S. cerevisiae population in the dough, which is known to be the most efficient ethanol producer (Cai et al., 2018).

Fermentation behavior of dough

The fermentation behavior of the fermented doughs was investigated using a rheofermentometer (Table 2). The results show that the JFC dough had a higher CO2 production (617 mL) and a comparable gas retention coefficient (RC) compared with the FC dough. Additionally, the maximum gas formation time (min) (T'1) occurred later in the JFC dough. This indicated that the gas production rate of the JFC dough continued to increase throughout the whole fermentation process. The final dough height (h) and the time to maximum development (T1) confirmed the increased dough development of the JFC dough. Therefore, although the maximum height of CO2 production (H′m) of the JFC dough was lower, the dough resulted in a higher dough development (Hm) than the FC dough.

The fermentation behavior of dough is fundamentally determined by the CO2 production and gas retention capacity of the dough, which was accordingly controlled by several different factors, e.g., yeast count and activity, available carbon source, gluten network structure and acidification level of the dough (Li et al., 2019a; Moroni et al., 2012). Although the S. cerevisiae count in the JFC dough was slightly lower, an adequate carbon source (reducing sugar content), and an appropriate acidification level from the LAB microflora could be favorable for its CO2 generating capacity (Table 1). It was reported that the appropriate amount of organic acids obtained from LAB fermentation can improve the rheological properties and gas retention of the dough (Palacios et al., 2008). In addition, dough acidification could increase the CO2 production activity of the yeast, allowing for better dough development (Moroni et al., 2012). Therefore, the use of rice wine made from mixed yeasts resulted in a better dough development behavior than the dough fermented directly with mixed yeasts of S. fibuligera SF7 and S. cerevisiae SC1.

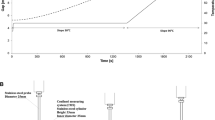

Water distribution of dough

Water distribution and migration in the fermented dough was obtained by LF-NMR (Fig. 1). In our system, the T2 was divided into three populations: T21 (0.02–0.5 ms), T22 (0.5–30 ms) and T23 (50–200 ms), representing water molecules tightly bound, less tightly bound and weakly bound to the solids, respectively (Huang et al., 2017). The dough directly fermented with mixed yeasts (FC) showed minimal changes in the T2 relaxation time profile after fermentation (Fig. 1A). However, when rice wine was used as a starter, both their distribution patterns and peak times shifted dramatically (Fig. 1B). It can be observed that after fermentation, T22 of JFC dough became a broader peak and there is a tendency to form a new peak. Meanwhile, the peak time of the proton population decreased dramatically. These changes suggest that dough fermentation with rice wine decreased water mobility and increased water–solid interactions, which may make them more compatible (Li et al., 2018). This redistribution of water may be due to the hydrolysis of starch molecules and acidification during the dough fermentation (Huang et al., 2017; Lu et al., 2022). The maltooligosacchardies degraded from the amorphous regions of starch have the ability to disrupt water interactions with starch, which is important for the distribution of water molecules (Zhang et al., 2019). Acidification during dough fermentation could also affect the glycosidic bonds in the starch granules, increasing their water-binding capacity (Falade et al., 2014).

Microstructure and elongation properties of dough

SEM and CLSM were used to observe the microstructure of the dough (Fig. 2). The FC and JFC dough groups at 0 h both showed a typical dense structure with fewer voids. Starch granules were found to be embedded in the gluten network and tightly bound to the gluten. After fermentation, JFC dough showed larger gas holes compared to FC samples, and some embedded starch granules detached from the gluten matrix. The gas cells observed internally in the JFC dough indicated a better ability of the structure to trap CO2 produced during the fermentation. The weakened adhesion between starch granules and gluten could be beneficial for the formation of gluten network in the dough.

SEM and CLSM micrographs of (A, B) the dough fermented with mixed yeast (FC) and (C, D) the dough fermented with rice wine made with mixed yeasts (JFC) (A, C) before and (B, D) after fermentation (8 h) (insets in SEM micrographs are the image of representative CLSM micrographs). (E, F) Elongation properties of FC and JFC dough. Different letters above bars in figure show significant difference (p < 0.05)

The CLSM results showed that a similar gluten structure was found in FC and JFC doughs prior to fermentation, which contained distinct protein aggregation domains. After fermentation, irregular gluten networks and a number of sites of protein aggregation were observed in the FC dough. In contrast, the protein network in the JFC dough had a more homogeneous distribution, with few large protein aggregation sites. Therefore, rice wine fermentation results in a more evenly distributed and more continuous gluten structure, which could be fully stretched. The results were in line with the dough rheological behaviors of the JFC dough, which was characterized by higher dough strength and extensibility (p < 0.05) (Fig. 2E, F). The acidification and hydration of the gluten proteins in the dough may modify the hydrophobic and/or electrostatic interactions that are important for the aggregation and development of the three-dimensional gluten network (Sha et al., 2023; Sun et al., 2020; Wieser, 2007).

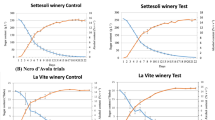

Pasting properties of dough

The pasting properties of the doughs were measured by RVA (Fig. 3). For the FC dough, the RVA profile after fermentation was slightly higher than that at 0 h, indicating that the viscosity parameters increased after fermentation. On the contrary, the fermented JFC dough showed significantly decreased viscosity parameters as compared with the unfermented dough. Research has shown that many factors can influence the gelatinisation properties of starch, such as starch structure, available moisture, starch-protein interactions and other components (Chang et al., 2020; De Bondt et al., 2020). It was found that the diffraction doublet of the XRD patterns at 2θ 17.1° and 18.1° of the JFC dough appeared to be weaker and became less distinguishable after fermentation compared with the FC dough (Fig. 3). Thus, the reduced pasting parameters of the fermented JFC dough could be due to the altered starch structure. On the other hand, the changes could be caused by the reduced connectivity between gluten and starch granules, changes in the water distribution pattern and partial hydrolysis of starch during the fermentation stage (Ai-Lati et al., 2018; Huang et al., 2017; Li et al., 2018; Zhou and Li, 2021). In addition, sugars could also affect the gelatinization of the starch granules (De Bondt et al., 2020). As starch is the most abundant component in wheat flour, differences in the pasting properties of starch after fermentation could affect dough and product quality.

Steamed bread quality

The qualities of steamed bread made from JFC dough (MJFC) were evaluated and compared with those made from FC dough (MFC), commercial yeast (CY) and Jiuqu GS and JY (MGS and MJY) (Fig. 4). The MJFC had the highest specific volume and the lowest chewiness value compared with the other samples (Fig. 4A). Specific volume is considered the most important parameter of bread as higher values are correlated with better quality (Na et al., 2024). It reflects the amount of gas produced by the yeast, the characteristics of the gluten network and the gas retention capacity of the dough (Huang et al., 2017). The higher specific volume and lower crumb chewiness of MJFC could be attributed to the higher CO2 production capacity and acidification level of the JFC dough, which is conducive to the gas cell expansion and improvement of the gluten network strength. High specific volume and softer texture are preferred characteristics of steamed bread by consumers in China, which resulted in a slightly higher sensory score for MJFC (Supplementary Table S1).

(A) Comparison of the quality of steamed bread prepared with commercial yeast (CY), mixed yeast (MFC), rice wine fermented with mixed yeasts (MJFC), and rice wine fermented with Jiuqu GS and JY (MGS and MJY). (B) Score plot of PCA showing the aroma compounds formed in the steamed bread samples fermented with CY, MFC, MJFC, MGS and MJY. Different letters above the bars indicate differences in the same quality parameter between the samples (p < 0.05)

PCA was used to get an overview of the differences in the volatile compounds of the steamed bread samples fermented with different starters. As shown in Fig. 4B, the accumulated contribution of the first two principal components was 71.2% and the steamed breads fermented with different starters could be well separated on the score plot, demonstrating the differences in their volatile profiles. The samples MJFC and MGS were grouped together, and closer to MJY, indicating the analogous volatile flavors of the three types of steamed bread compared to those of CY and MFC. The difference in volatile profiles between MGS and MJY may be due to the difference in other microbial populations such as LAB in the two Jiuqu in addition to yeast (Zhao et al., 2023). These results suggest that satisfactory quality can be obtained when rice wine fermented with mixed yeast is used as a dough starter to make steamed bread.

References

Ai-Lati A, Liu S, Li X, Qian B, Shan Y, Zhou Z, Peng L, Ji Z, Mao J, Zou H, Yu Y, Zhu S. Effect of Chinese rice wine sludge on the production of Chinese steamed buns. Journal of Food Processing and Preservation. 42: e13572 (2018)

Aryashad M, Sadeghi A, Nouri M, Ebrahimi M, Kashaninejad M, Aalami M. Use of fermented sprouted mung bean (Vigna radiata) containing protective starter culture LAB to produce clean-label fortified wheat bread. International Journal of Food Science and Technology. 58: 3310-3320 (2023)

Cai H, Zhang T, Zhang Q, Luo J, Cai C, Mao J. Microbial diversity and chemical analysis of the starters used in traditional Chinese sweet rice wine. Food Microbiology. 73: 319-326 (2018)

Chang X, Huang X, Tian X, Wang C, Aheto JH, Ernest B, Yi R. Dynamic characteristics of dough during the fermentation process of Chinese steamed bread. Food Chemistry. 312: 126050 (2020)

Condessa BMB, Da Silva KV, Da Silva JFM, de Morais PB, Leal Zimmer FMA, de Almeida AF, Niculau EDS, Nogueira KL, Santos CCAD. Performance of wild Saccharomyces and Non-Saccharomyces yeasts as starter cultures in dough fermentation and bread making. International Journal of Food Science and Technology. 57: 3046-3059 (2022)

Crowell EA, Ough CS. A modified procedure for alcohol determination by dichromate oxidation. American Journal of Enology and Viticulture. 30: 61-63 (1979)

De Bondt Y, Liberloo I, Roye C, Goos P, Courtin CM. The impact of wheat (Triticum aestivum L.) bran on wheat starch gelatinization: A differential scanning calorimetry study. Carbohydrate Polymers. 241: 116262 (2020)

Falade AT, Emmambux MN, Buys EM, Taylor JRN. Improvement of maize bread quality through modification of dough rheological properties by lactic acid bacteria fermentation. Journal of Cereal Science. 60: 471-476 (2014)

Huang L, Chen X, Rui X, Li W, Li T, Xu X, Dong M. Use of fermented glutinous rice as a natural enzyme cocktail for improving dough quality and bread staling. Rsc Advances. 7: 11394-11402 (2017)

Jeyaram K, Singh WM, Capece A, Romano P. Molecular identification of yeast species associated with ‘Hamei’ — A traditional starter used for rice wine production in Manipur, India. International Journal of Food Microbiology. 124: 115-125 (2008)

Kim SA, Yun SJ, Jeon SH, Kim NH, Kim HW, Cho TJ, Lee SH, Hwang IG, Rhee MS. Microbial composition of turbid rice wine (Makgeolli) at different stages of production in a real processing line. Food Control. 53: 1-8 (2015)

Li M, Sun Q, Han C, Chen H, Tang W. Comparative study of the quality characteristics of fresh noodles with regular salt and alkali and the underlying mechanisms. Food Chemistry. 246: 335-342 (2018)

Li Z, Li H, Song K, Cui M. Performance of non-Saccharomyces yeasts isolated from Jiaozi in dough fermentation and steamed bread making. LWT-Food Science and Technology. 111: 46-54 (2019a)

Li Z, Song K, Li H, Ma R, Cui M. Effect of mixed Saccharomyces cerevisiae Y10 and Torulaspora delbrueckii Y22 on dough fermentation for steamed bread making. International Journal of Food Microbiology. 303: 58-64 (2019b)

Lu F, Zhu X, Tao H, Wang H, Yang Z. Controlling starch surface characteristics - Impact on dough formation in a reconstituted dough system. LWT-Food Science and Technology. 163: 113591 (2022)

Luangsakul N, Keeratipibul S, Jindamorakot S, Tanasupawat S. Lactic acid bacteria and yeasts isolated from the starter doughs for Chinese steamed buns in Thailand. LWT-Food Science and Technology. 42: 1404-1412 (2009)

Lv X, Cai Q, Ke X, Chen F, Rao P, Ni L. Characterization of fungal community and dynamics during the traditional brewing of Wuyi Hong Qu glutinous rice wine by means of multiple culture-independent methods. Food Control. 54: 231-239 (2015)

Miller GL. Use of dinitrosalycilic acid reagent for the determination of reducing sugar. Analytical Chemistry. 31: 426-428 (1959)

Moroni AV, Zannini E, Sensidoni G, Arendt EK. Exploitation of buckwheat sourdough for the production of wheat bread. European Food Research and Technology. 235: 659-668 (2012)

Na Y, Nam AY, Park SH, Lee SH. Production of fructooligosaccharide-containing bakery and sweet paste products using invertase. Food Science and Biotechnology. 33: 1189-1194 (2024)

Palacios MC, Haros M, Rosell CM, Sanz Y. Selection of phytate-degrading human bifidobacteria and application in whole wheat dough fermentation. Food Microbiology. 25: 169-176 (2008)

Sha HY, Wang QQ, Li ZJ. Comparison of the effect of exopolysaccharide-producing lactic acid bacteria from sourdough on dough characteristics and steamed bread quality. International Journal of Food Science and Technology. 58: 378-386 (2023)

Son EY, Lee SM, Kim M, Seo J, Kim Y. Comparison of volatile and non-volatile metabolites in rice wine fermented by Koji inoculated with Saccharomycopsis fibuligera and Aspergillus oryzae. Food Research International. 109: 596-605 (2018)

Sun X, Liu C, Wang Y. Influence of Na2CO3 on the quality of dough with rice wine sourdough and steamed bread. International Journal of Food Science and Technology. 55: 2261-2270 (2020)

Wieser H. Chemistry of gluten proteins. Food Microbiology. 24: 115-119 (2007)

Yeh LT, Wu ML, Charles AL, Huang TC. A novel steamed bread making process using salt-stressed baker's yeast. International Journal of Food Science and Technology. 44: 2637-2643 (2009)

Zhang L, Li Z, Qiao Y, Zhang Y, Zheng W, Zhao Y, Huang Y, Cui Z. Improvement of the quality and shelf life of wheat bread by a maltohexaose producing α-amylase. Journal of Cereal Science. 87: 165-171 (2019)

Zhao C, Su W, Mu Y, Luo L, Zhao M, Qiu S, Su G, Jiang L. Effects of Jiuqu inoculating Rhizopus oryzae Q303 and Saccharomyces cerevisiae on chemical components and microbiota during black glutinous rice wine fermentation. International Journal of Food Microbiology. 385: 110012 (2023)

Zhou M, Li Z. Characteristics of scalded dough fermented by co-cultures of Saccharomyces cerevisiae Y10, Wickerhamomyces anomalus Y13 and Torulaspora delbrueckii Y22. International Journal of Food Science and Technology. 56: 5923-5930 (2021)

Acknowledgements

This research was supported by the Open Project Program of National Engineering Research Center of Wheat and Corn Further Processing, Henan University of Technology (Grant No. NL2022009), Joint Fund of Science and Technology Research Project of Henan Province (Grant No. 232103810063), Henan Province Key R&D Special Project (Grant No. 221111112000).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, Z., Liu, T., Zhang, T. et al. Improved properties of dough fermented with rice wine prepared by mixed Saccharomycopsis fibuligera SF7 and Saccharomyces cerevisiae SC1. Food Sci Biotechnol (2024). https://doi.org/10.1007/s10068-024-01598-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10068-024-01598-w