Abstract

Yeasts have been used for centuries for the leavening of bread. The main emphasis on the selection of yeast strains has been in relation to wheat products. This study is the first evaluation of different yeasts coming from the baking and brewing industry in a gluten-free system. Five different yeast strains (US-05, WB-06, T-58, S-23 and baker’s yeast) of the species Saccharomyces cerevisiae were evaluated for their suitability to leaven gluten-free dough. A wide range of dough quality characteristics such as the time and temperature-dependent rising behaviour, the chemical composition of the dough and the pH were determined. In addition to this, the bread quality attributes like, volume, texture, structure, aroma and flavour were evaluated. Obtained results indicated different activity levels between the selected yeast strains. Doughs prepared with US-05 showed a slower dough rise during proofing and a decreased height, in comparison to the baker’s yeast control. The application of WB-06 and T-58, however, resulted in a faster dough rise and increased dough height with greater gas cells (p < 0.05). These observations were also found in the baked breads, where these two yeasts reached a higher specific volume and a softer breadcrumb than the baker’s yeast bread (p < 0.05). Statistical analysis revealed strong correlations (p < 0.05) between activity level, dough properties and bread properties. Results obtained showed that the selected yeast strains reached different level of activity due to diverse preferences in temperature, time and sugars. Yeast strains which originated from the brewing industry were found to be suitable for gluten-free bread making.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The preparation of bread by yeast fermentation is one of the oldest biochemical processes in the world [1]. Saccharomyces cerevisiae (or baker’s yeast) is the commonly used yeast, which is the primary leavening agent in bread products [2]. Fermentation plays a key role in the bread-making process, as it can improve texture, structure, taste and flavour in the final product [2]. In recent years, the effect of yeast modification and replacement by alternative yeast strains in the bread-baking process has become a topic of interest. Studies focused on the harvesting time of baker’s yeast at different physiological phases [3] or the replacement of baker’s yeast by beer yeasts [4]. Beer yeast strains are known to have optimized metabolism suitable for beer making in terms of flavour compounds and alcohol production. On the other hand, baker’s yeast focuses on a fast fermentation and uniform dough leavening due to carbon dioxide production [5]. Studies by Heitmann et al. [4, 6] demonstrated that the use of different S. cerevisiae strains showed significant differences to the commonly applied baker’s yeast in wheat bread. It also was found that brewer’s yeast can improve quality parameters like the texture, structure and the aroma profile of bread.

However, people who suffer from coeliac disease or other gluten-related disorders cannot consume these products. For these individuals, a gluten-free diet is currently the only treatment for these disorders [7]. A recent study by Tsatsaragkou et al. [8] stated that the gluten-free bread market still faces the main challenges of improving technological quality parameters’ bread technology quality, an extension of shelf life and a balanced nutritional value. The application of different yeast strains from the brewing and baking industry in gluten-free breads is a novel approach. It is believed that the different strains influence the final gluten-free bread properties due to different gas cell expansion and interactions. Not only the influence on the dough and bread parameters but also aroma and flavour profile of breads can be influenced by the application of different yeasts and their individual fermentation process [9]. Bircher et al. [10] identified a wide range of aroma-active volatiles within the yeast metabolism. The change of this flavour and aroma profiles, using different yeasts has become a further topic of commercial interest. Since some of the aroma profiles are considered as quality parameters for bread products [10,11,12], especially, the aroma and flavour profiles of gluten-free breads are still considered as improvable by the consumers. Hence, the modification of these profiles by the application of different yeasts could improve the perception and acceptance of gluten-free products.

To the author’s knowledge, this study is the first study to apply different yeast strains which are commonly used in the brewing industry in a gluten-free bread system. During the fermentation process yeast produces mainly carbon dioxide and ethanol, but also secondary metabolites, such as glycerol, organic acids and flavour compounds, which have an impact on the final product quality [13]. The effects of yeast on bread quality characteristics include the volume, structure, flavour and shelf life of each fermented product [2]. Based on the specific characteristics of various S. Cerevisiae yeast strains, the authors believe that their application will have significant influence on final gluten-free bread quality (Table 1). The main differences between the yeast strains are the optimum temperatures and their different tolerances to temperature changes. The optimal temperature for baker’s yeast is higher than in comparison to the beer yeasts. Despite the lower optimum temperatures for the yeast strain S-23 and T-58 for fermentation, these two strains are described to have a faster fermentation at higher temperatures, which are close to the optimum temperature of baker’s yeast. A further important characterising of yeasts is the metabolism of different sugars of the various yeasts. Especially in a very refined system such as that of a gluten-free formulation, sugar sources are limited and usually constructed of mainly complex sugars. These sugars are usually only accessible to yeast fermentation when degraded by enzymes to smaller fermentable sugars. The gluten-free system in this study creates such case which consists of limited amounts and varieties of sugar and further does not contain added enzymes for the breakdown of the complex sugars. The main component in the system is potato starch, which consists of about 92% total starch, 1% damaged starch, 0.02% protein and no lipids. Additionally, no enzyme activity (α- and β-amylase) was determined in this potato starch. This gluten-free bread system is very refined and does not offer as many nutrients for yeast metabolism as the conventional wheat bread system. However, effects on the gluten-free bread quality parameters by the application of the various yeasts were expected. Therefore, five yeast strains of the S. cerevisiae family, namely, US-05, T-58, S-23, WB-06 and a control baker’s yeast have been selected and their effect on dough and final bread quality have been analysed. This study will broaden the understanding of the yeast on gluten-free dough characteristics, bread quality parameters and sensory attributes.

Experimental

Materials

Potato starch was supplied by Emsland, Germany; pea protein by Roquette, France; pectin by Cp Kelco, Germany; sugar by Siucra Nordzucker, Ireland; salt by Glacia British Salt Limited, UK. Instant active dry Baker’s yeast was obtained from Puratos, Belgium; Dry yeast s-23, T-58, us-05 and wb-06 were supplied by Fermentis Division of S. I. Lesaffre, France. All the yeasts applied in this study belonged to the species S. cerevisiae. All chemicals were supplied by Sigma-Aldrich, Arklow, Ireland.

Compositional analysis

The total starch content of potato starch was determined according to AACC Method 76-13.01. The alpha- (AACC Method 22-02.01) and beta (K-BETA3)-amylase activities were determined using commercially available enzyme kits, supplied by Megazyme, Ireland. The total nitrogen content of the starch sample was determined according to the Kjeldahl method (MEBAK 1.5.2.1). To convert the nitrogen content into the protein content, the factor of 6.25 was used. The air oven method (AACC Method 44-15A) was applied to determine the moisture content of the samples. The determination of the lipid content was performed according to the Soxlet-method (AACC Method 30-25.01) with a pre-digestion of the samples in HCl to release bound lipids.

Cell count

Cell viability (cfu/g) of the yeast powders was analysed by suspending 1 g freeze-dried yeast in 10 mL distilled water. From this stock solution, serial dilutions were prepared with Ringer’s solution and spread on malt extract agar (Merck, Germany) plates and incubated aerobically for 2 days at 25 °C. Plates with 30–300 colonies were selected for yeast cell counts.

Total available carbohydrates

The total available carbohydrate level from freeze-dried dough and breadcrumb samples was determined spectrophotometrically using an enzyme kit (K-TSTA) supplied by Megazyme, Ireland.

Sugars and acids

Sugar levels of dough and breadcrumb were analysed for glucose and fructose by an Agilent 1260 high-performance liquid chromatography system (HPLC) with a Hi-Plex H+ column (Agilent, Cork, Ireland) coupled to a refractive index detector (RID) at 35 °C. The sugars were extracted with distilled water for 20 min under shaking and then centrifuged at 3000g for 10 min. The HPLC analysis was performed at 30 °C column temperature with water (HPLC-grade) at a flow rate of 0.6 mL/min. The analyses of citric acid, succinic acid and acetic acid were analysed with the same system, but with small modifications. Diode-array detection (DAD) and the HiPlex H+ Column at 65 °C were used to detect the acids. Samples were eluted with 0.005 M H2SO4 at a flow rate of 0.5 mL/min.

Dough and bread crumb pH measurement

Dough pH before and after proofing was measured according to the AACC method 02-52.

Time- and temperature-dependent rising behaviour of dough

The measurements were conducted using an Anton Paar MCR rheometer with the TruStrain™ option. A confined measuring system (CMS) was placed on the inset plate (I-PP25) of a plate–plate system (Fig. 1b). The CMS is a stainless-steel cylinder with the height of 33 mm and the inner diameter of 25 mm. A Peltier temperature device (PTD) was used as well as a convention temperature device (CTD) for temperature control (Fig. 1b). To mimic the proofing properties, the PTD was set at 30 °C for 45 min with a constant normal force (FN) which was set to 0.00 N to ensure permanent contact between sample and upper plate. For determination of the oven spring and the determination of yeast activity during the baking process the temperature was increased to 90 °C with a heat rate of 4 °C /min. Recorded and calculated parameters were the max height (mm), which is the maximum height the dough reached during the measurement. Further the slope during the fermentation process (Slope 30 °C) and then during the baking process (Slope 90 °C) for determination of yeast activity was calculated. Also, the max height temperature (TMH) (°C) was recorded and used as an indicator for the heat tolerance of the various yeasts.

Bread production

Bread samples were prepared according to Horstmann et al. [14]. The formulation of the various breads included: 2% pectin, 2% pea protein, 2% salt, 4% sugar and 75% water based on starch weight. Amounts of yeasts were added according to their cell viability (Table 2). Dry ingredients were mixed and yeast was suspended in warm water (27 °C) and regenerated for a period of 10 min. Mixing was carried out with a k-beater (Kenwood, Havant, UK) at low disk speed (level 1 of 6) for 1 min in a Kenwood Major Titanium kmm 020 Mixer (Kenwood, Havant, UK). After the first mixing, the dough was scraped down from the bowl walls. A second mixing step of 2 min at higher disk speed (level 2 of 6) was applied. 300 g of batter were weighed into baking tins of 16.5 cm × 11 cm × 7 cm and placed in a proofer (KOMA, Netherlands) for 45 min at 30 °C and 85% relatively humidity (RH). The proofed samples were then baked for 45 min at 220 °C top and bottom heat in a deck oven (MIWE, Germany), previously steamed with 0.4 L of water. The breads were cooled for 2 h prior to analysis.

Bread analysis

The specific volume of the bread was determined using a Vol-scan apparatus (Stable Micro System, UK). The specific volume is calculated on the basis of loaf volume and weight. An image analysis system (Calibre Control International Ltd., UK) was used to analyse the breadcrumb structure, chosen parameters were the cell diameter and the number of cells per slice area. Crumb firmness was analysed using a Texture Profile Analyser (TA-XT2i, Stable Micro Systems, Godalming, England) with a 25 kg load cell, which compresses the breadcrumb with a 20 mm aluminium cylindrical probe. Bread samples were sliced into 20 mm slices and analysed with a test speed of 5 mm/s and a trigger force of 20 g, compressing the middle of the breadcrumb to 10 mm. The measurement with the various parameters was conducted on the baking day and 24 h after baking to monitor the staling process. Baked breads were stored in polythene bags (polystyrol-ethylene venyl alcohol-polyethylene).

Extraction of volatile aroma compounds by thermal desorption (TD) and quantification using GC–MS

To extract volatile compounds, samples were prepared by weighing 0.1 g of bread crumb into a clean glass thermal desorption (TD) tube to concentrate the volatile aroma compounds in a gas stream prior to injection (Perkin Elmer Turbomatrix 650). Subsequently, the aroma compounds were absorbed at 90 °C for 10 min. For the quantification of the aroma-active volatiles, a gas chromatography–mass spectrometry (GC–MS, Agilent 5977B MSD) with a Rxi 624-Sil 20 m column and helium as a carrier gas was used. The details for the temperature profile are: start temperature: 35 °C (4 min) with an increase of 15°C/min to 220 °C (hold 1 min). The total run time was 17.3 min. For the detected compounds, a database search was conducted. The aroma compounds detected and analysed in this study by GC–MS TD were ethanol, acetic acid, 2,3-butanediol and 1-hydroxy-2-propanone.

Sensory analysis

Aroma profile analysis on bread samples was performed by a trained panel (training over 2 weeks based on reference sample) consisting of ten panellists. Training began by generating a consensus vocabulary for attributes and descriptors based on the control sample. The sensory evaluation was performed by each panellist individually in an isolated booth. All trainings and sensory analyses were performed in a sensory panel room at 21 ± 1 °C. Agreed descriptors are listed in Online resource 1. For the descriptive aroma profile, each breadcrumb sample was cut into slices (thickness 2 cm) and presented to panellists 90 min after baking. The sensory scale was based on an unstructured line scale to describe the intensity of rated sensory attributes.

Statistical analysis

All measurements were performed at least in triplicate. The significance of the results was analysed using one-Way ANOVA (R version 3.0.1). The level of significance was determined at p < 0.05. In addition, Pearson correlation analysis (R version 3.0.1) was applied to find correlation between yeast properties and the results of the baked products.

Results and discussion

Cell count

The viability of freeze-dried yeast cells was analysed to standardise the inoculum level of yeast for the baking of the various breads. The control yeast S. cerevisiae baker’s yeast had a cell count of 1.06E+09 cfu/g. The beer yeasts showed lower cell count in decreasing order: S. cerevisiae WB-06 7.16E+08 cfu/g; S. cerevisiae T-58 5.5E+08 cfu/g; S. cerevisiae S-23 5.18E+08 cfu/g and S. cerevisiae US-05 4.74E+08 cfu/g. Comparable results were found by Heitmann et al. [4]. The addition levels of the yeast in the dough formulation were based on the concentration usually reached by the control yeast (S. cerevisiae baker’s yeast) (Table 1). When dried yeasts are used in bread, the non-viable cells need to be considered, since non-viable cells can release glutathione as a stress response [15,16,17]. In wheat doughs, the release of glutathione has a strong reducing effect which ultimately leads to a modification of the viscoelastic gluten network [16, 18]. Glutathione was further applied in a gluten-free formulation and found to improve rice flour-based bread quality parameters [19]. The analysed bread system showed interactions between glutathione and the rice protein ‘glutelin’ resulted in an improvement of the volume and crumb structure of the bread. However, based on the lack of gluten, rice flour and glutelin in the used formulation in this study, the effect of glutathione on bread parameters was neglected.

Total starch

The total starch content of the doughs and breads was analysed to identify difference in the yeast performance. No significant differences between the total starch contents in the dough were found (Table 2). However, differences in the starch content of the final breads were detected. This indicates different activities of the various yeast strains during processing. Breads baked with the S. cerevisiae strains T-58 (75.97%) and S-23 (78.57%) showed the significant lowest amount of total starch. The control baked with S. cerevisiae baker’s yeast had the significant highest amount of total starch left (87.27%), suggesting a lower activity. Heitmann et al. [4] analysed the application of beer yeast strains in wheat bread and also found baker’s yeast to have the highest amount of starch left in the final bread. The authors mentioned that the lower content of total starch in the breads prepared with beer yeast resulted from their higher enzyme activities in comparison to baker’s yeast, which degrade starch into more fermentable sugars [20]. The values in the study by Heitmann et al. [4] showed lower total starch values, which is explained by the higher concentration of starch in this study as explained earlier in the introduction.

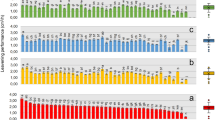

Sugars and acids

The analysis of fermentable sugars like glucose and fructose showed fluctuation and significant differences amongst the different yeasts (Table 3). All the yeasts showed a decrease in glucose and fructose after baking, confirming that all the yeast strains have metabolic activity. The sugar contents in the final bread of fructose and glucose showed the lowest values in the formulations with the addition of T-58, suggesting a higher activity in comparison to the other yeasts. This functionality is hypothesised by the authors to be the result of the higher temperature tolerance and fast fermentation at higher temperatures in comparison to the remaining yeast strains (Table 1). It is well known that yeast activity can be influenced by many factors such as the pre-growth conditions of yeast, dough fermentation conditions, dough ingredients and the genetic background of the various yeast strains [21]. The acid analysis (citric acid, succinic acid, lactic acid and acetic acid) of the dough and bread samples formulated with the different yeasts did not find detectable quantities. Only quantities of acetic acid were found in bread samples as part of volatile compound analysis (Table 4). The detection of acetic acid during the volatile compound analysis is explained by the different detection limits of the two used detection methods. GC–MS used for the volatile compound analysis can detect compounds in ppm quantities while the detection limit of the HPLC is significantly higher. Acetic acid values measured by the GC were observed to be four times higher in bread crumbs baked with S. cerevisiae S-23 in comparison to the remaining yeasts. The lowest value was found in breadcrumbs of breads baked with US-05, which overall showed low amounts of volatile compounds. Acetic acid contributes to the overall aroma of baked goods [22]. Its organoleptic descriptors are vinegar, pungent and sour; hence, the differences in the amounts of acetic acid are assumed to influence the sensory evaluation. These small quantities, however, are not considered to affect the dough and bread properties or to contribute to the flavour or aroma profile. Based on the refined gluten-free system in this study in addition to the limited amount of oxygen in a dough system, the acid analysis suggests that the metabolic pathways of the various yeasts followed the alcoholic fermentation, rather than the TCA cycle [6]. As discussed earlier, the refined system was considered to not provide enough nutrients for the yeast to synthesise metabolites like acids.

pH values

Changes in pH of the dough before and after proofing and in the final bread are shown in Table 2. The various S. cerevisiae yeast strains showed significant differences in the pH development over the bread-making process. Overall it was observed that the doughs decreased in pH during fermentation and increased after baking. US-05 and S-23 had the significantly highest pH before proofing. Doughs formulated with S. cerevisiae T-58 showed the significant lowest pH. Also, after proofing, T-58 showed the lowest and US-05 the highest pH. The effect of acids on pH in this study was excluded since they were not detected. Thus, the effect of CO2 production is assumed to be the main cause for the changes in pH [23]. After the baking process, an increase in the pH values in all the baked breads was observed. Even though the pH increased, the lowest pH was found for breads formulated with T-58. The significant highest pH value was reached by breads containing the yeast strain WB-06 followed by US-05. The effect of the pH increase after baking is explained by the loss of carbon dioxide and linked carbonic acid. Reduction in pH indicates CO2 and ethanol production by the yeasts. The more active the yeasts, the more sugars are fermented, and the more CO2 is produced, dropping the pH in the dough [24].

Time- and temperature-dependent rising behaviour of dough

The evaluation of dough rising behaviour is a commonly determined parameter in wheat doughs to achieve constant dough quality. The measurement is usually conducted with the aid of the rheofermentometer. This machine, however, showed limitations in analysing gluten-free batters due to their liquid nature.

Therefore, a new method was established using the Anton paar® rheometer attached with the TruStrain™ system, allowing the determination of the dough rise and providing a prediction tool for yeast activity (Fig. 1). Analysed parameters were the max height, the slope during the fermentation process (Slope 30 °C), the baking process (Slope 90 °C) and max height temperature (TMH) (Table 2). It was found that doughs formulated with S. cerevisiae T-58 had the highest dough rise in comparison to the other strains. The lowest dough rise was observed for US-05. The temperature at which the maximum height was reached indicates that the control yeast reached its maximum height significantly earlier than the remaining yeasts. The yeast strains S-23 and WB-06 reached their maximum height at significantly higher temperatures. The different temperatures to reach the max height are not correlated but can be explained by the different activities of the yeast strains and their preferred temperatures (Table 1) [25]. The slope during the fermentation phase (FP) at 30 °C presented T-58 as the most active yeast with a slope twice as high as the control, which is the second most active strain. The authors hypothesise that this high activity is the result of the temperature optimum for fast fermentation (32 °C). The explanation why S-23 and WB-06 reached a higher height than the control is due to their increase in activity at higher temperatures (Slope BP). This high increase would suggest a more pronounced oven spring as usually observed during the baking process. The differences in the optimal fermentation temperatures and metabolism of sugar affected the chemical and technological properties of the gluten-free dough. When optimal conditions are provided, yeast can work at its full potential. This was confirmed by reduced levels of sugars in the final bread and the pH development of the bread-making process. Correlation analysis revealed strong negative correlations between the pH and dough rise (r 0.921, p < 0.001). The correlation is explained by the produced CO2, which is decreasing the pH due to its carbonic acid and the expansion of gas cells accelerating the dough rise [4, 23]. The production of CO2 is considered as an indicator for yeast activity [4]. The more CO2 and ethanol are produced by yeast, the more active it is considered. The differences in the activity between the various yeast strains can be explained by the negative correlations between the remaining sugars in the final bread and the dough rise (r − 0.879, p < 0.001). This is due to the metabolism of the different yeasts, which ferment the available sugars and produces CO2 [13]. The more sugars are fermented, the more CO2 is produced and the higher is the dough rise. Overall the method showed similarities to rheofermentometer results found by Heitmann et al. [4] who applied beer yeast strains to wheat breads. In their study, it was also observed that T-58 had the highest activity and US-05 the lowest which was explained by a slower fermentation of sugars. The obtained results of the various yeast strains show the suitability of the method for gluten-free doughs. It is further hypothesised that it can be used as an indicator for the final bread properties.

Bread results

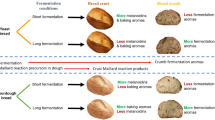

One of the most important quality parameters and the first impression for the consumer is the appearance of a product. Figure 2 illustrates cross sections and surface images of the baked breads with the different yeasts. It can be observed, that breads baked with the ale yeast US-05 showed reduced loaf volume and smaller average cell pore size. Bread baked with WB-06 and S-23 showed a closer resemblance to the control bread in terms of size and cell pore size. The effect of T-58, however, showed a bigger loaf volume and big gas cells in comparison to the control bread (baker’s yeast). A more detailed description of the quality parameters is presented in Table 3. The images of the breads containing the different yeasts depicted in Fig. 2 indicate significant differences between the bread. The specific volume and its related appearance is the most important bread quality parameter which has a high influence on the consumers quality perception [26]. The differences of the specific volume are significant and show the breads baked with T-58 showed the highest loaf volume (Table 3). The other applied yeasts either had no significant differences (WB-06) or resulted in inferior bread characteristics (S-23, US-05) particularly relating to the volume of the breads. Next, to the influence of the yeast, a key role for the rise of a bread is the dough consistency. After mixing and heating, the dough can facilitate the entrapment of produced gas and the expansion of the gas cells [27]. The cell structure of bread is a key quality criterion which can be related to crumb hardness and the specific volume. The development of crumb structure and gas cells expansion initially starts during fermentation, when CO2 and ethanol are produced as products of the yeast metabolism. In the baking process, the produced ethanol evaporates with some of the water and helps the expansion of gas cells and ultimately the loaf rise [23]. Cell structure of bread is a key quality criterion which can be related to crumb hardness and the specific volume. Parameters chosen for the crumb structure were the number of cells, cell diameter and the number of cells per slice area. The application of the ale yeast US-05 was the only yeast which increased the number of cells significantly in comparison to the baker’s yeast (control). The addition of the remaining yeast led to breads with a lower number of cells when compared to the control. The combination of the number of cells and their development of crumb structure and gas cell expansion initially starts during fermentation, when CO2 and ethanol are produced as products of the yeast metabolism. In the baking process, the produced ethanol evaporates with some of the water and helps the expansion of gas cells and ultimately the loaf rise [23]. This explains the results of breads baked with US-05, which despite their high number of cells, but because of their small crumb cell diameter, led to small loaf volume. The opposite effect was found in breads containing T-58. The breads showed the lowest number of cells; however, these cells showed the significant highest cell diameter resulting in breads with the significant highest specific volume (Table 3). The number off cells/slice area (mm2) gives the ratio of cells per mm2 on the bread. Breads baked with US-05, S-23 showed the highest ratio in comparison to the control. No significant differences were found between WB-05 and the control. The significant lowest value was found in breads baked with T-58. Texture is a further important quality characteristic for consumer acceptance [25]. The process of increasing hardness over time is known as staling and has been claimed to affect the flavour of a bread [28]. Hardness of the breadcrumb was chosen to determine textural parameters. The hardness was measured 2 and 24 h after baking. Both measurements of hardness showed significant differences between the bread samples baked with the various yeast strains. Further observations showed that all bread samples increased in hardness. Measurements conducted after 2 h of baking showed that breads baked with S-23, WB-06 and T-58 had a significant softer breadcrumb texture in comparison to baker’s yeast. T-58, however, showed the significant lowest hardness in comparison to all applied yeast strains. Bread baked with the yeast strain US-05 showed the significant highest hardness. Similar observations were made by Heitmann et al. [4], who also showed that wheat breads formulated with the yeast strain US-05 had the highest hardness after baking. A similar order of hardness of the different breads baked with the various yeast strains was observed after 24 h. Breads baked with US-05 resulted in the significant highest hardness. The applied yeast S-23 and T-58 showed the significant lowest hardness in comparison to the other yeasts, with T-58 having still the significant softest breadcrumb. The application of WB-06 resulted in breads which showed now similar results to the control baker’s yeast, indicating a faster staling process. The differences of the varies breads in crumb hardness are hypothesised to be caused by the crumb structure. The hardness of breadcrumb is measured by compression over a certain area (probe diameter 20 mm). Due to the significant difference in cell diameter, different areas of cell walls are compressed. Hence, it is suggested that breads with high cell diameter provide less cell walls for the measuring probe to compress resulting in less resistance and a lower measurement of hardness. Correlations between dough properties and the final bread properties were found (r > 0.8). The dough rise had strong correlations between the crumb cell structure, in particular with the cell diameter (r 0.937, p < 0.001). This was explained by the production of CO2, which expands the crumb cells and in turn increases the dough rise. Based on this, it can be expected to find correlations between the dough rise properties of the doughs and the specific volume of the various breads (r 0.844, p < 0.001). The found correlation suggests that the dough rise measurement offers the potential to be used as prediction tool for the final volume of baked breads and yeast activity. Correlation analysis also confirmed the discussed connection between cell structure and texture. After baking, a higher number of cells were positively correlated with the hardness of the breadcrumb 2 h (r 0.870, p < 0.001) and 24 h (r 0.929, p < 0.001). This suggests that the increase in cells increased the number of cell walls which in turn strengthens the breadcrumb and results in higher hardness values. A further correlation was found for the specific volume and the bake loss (r 0.802, p < 0.001). This correlation has also been found in a previous study [14] and is known to be caused by a greater specific volume which offers a greater surface area for water to evaporate.

Volatile aroma compounds analysis

The identification of the aroma compounds revealed ethanol and acetic acid as the only components being detected in all the breadcrumb samples (Table 4). Ethanol, which is the most produced volatile compound during bread fermentation, was also found in this study to be the main compound. The S. cerevisiae yeast strain T-58 was found to have produced almost twice as much ethanol in comparison to the other yeast strains. The high activity of T-58 was also earlier discussed during the dough-rise measurement and the lower pH in the final bread. Overall it is suggested that it is due to its tolerance to high temperature [4]. Further detected aroma compounds in some of the bread samples were 2,3-butanediol and 1-hydroxy-2-propanone. 2,3-butanediol is a metabolite of alcoholic fermentation, which was found in breads fermented with the yeast strains S-23 and T-58. The metabolic pathway for the production of 2,3-butanediol by yeast was reported to be the oxidative decarboxylation and enzymatically reduction of 2-acetolactate [29]. The production of 2,3-butanediol is discussed to increase ethanol production [30]. However, in this study this effect could not be confirmed. The aroma compound 1-hydroxy-2-propanone was found in breads baked with S-23. This compound is a product of Maillard reaction and created by the reaction between reducing sugars and amino acids, mainly proline [31]. The presence was explained by the pea protein present in the used gluten-free system. A study by Heitmann et al. [4], who applied the same yeasts and conducted the same method for aroma compound determination in a wheat bread found further compounds such as isobutyric acid, 1-hexanol, 2-phenylethanol and 3-methyl-1-butanol. The lower diversity of aroma compounds found in the current study is suggested to be caused by the metabolic pathways of the various yeasts, which followed the alcoholic fermentation, rather than the TCA cycle. To produce significant amounts of aroma compounds, conditions like amino acid composition, glucose supply and oxygen must be provided [32]. The refined system in this study based on pure potato starch, lacks on nutrients for the yeast growth and the connected metabolite production. Due to the lack of alpha-amylase activity of potato starch [33], no glucose can be generated by degrading the starch. A low content of damaged starch, due to the extraction process of potato starch further prevents the generation of glucose [34].

Only the addition of sucrose in the recipe provides a limited amount of glucose after degradation, as seen in Table 2. Hence the main reason for the switch to alcoholic fermentation is assumed to be caused by the liquid batter, which causes depletion of oxygen. Based on these conditions, it is hypothesised that the yeast during fermentation switched to the alcoholic fermentation, rather than following respiration.

Descriptive sensory evaluation

For the descriptive analysis of the breadcrumb samples, a total of 12 attributes split into aroma and flavour were chosen. The descriptors are listed in Online resource 1. The sensory evaluation of the aroma did not show significant differences between the baked breads with the various yeast strains (data not shown). The outcome of this analysis is explained by the low production of volatile compounds and acids. The used gluten-free system lacks sufficient and or specific nutrients for the yeast to metabolise and produce other products than ethanol and acetic acid. The lack of nutrients for the yeast in a gluten-free system can be confirmed by the volatiles found in wheat-based system, applying the same yeast strains [30]. In a wheat system, higher amounts of volatile aroma compounds were found and hence differences in sensory profiles were reported. The outcome of the sensory evaluation suggests that the yeasts can be interchangeably used without affecting the flavour and aroma profile. This allows focussing on the techno-functional effects of the yeast strains on the dough and final bead.

Conclusion

This study was conducted to investigate the effect of different S. cerevisiae yeast strains on a gluten-free bread formulation. Although only strains of S. cerevisiae were applied, differences in dough and bread quality parameters were observed. Differences in sugar metabolism and preferred fermentation temperatures lead to diverse activity levels and performance of the various yeasts. These differences in activity had major changes in the dough performance and ultimately in the bread-baking characteristics. The application of the yeast strain US-05 showed a decrease in loaf volume and a high increase in crumb hardness in comparison to the control yeast. On the contrary T-58 resulted in the bread with the highest loaf volume and the softest bread crumb. The yeast strain WB-06 showed the closest resemblance to the breads baked with the control yeast strain baker’s yeast. Pearson analysis showed significant correlations between yeast activity indicators such as pH and remaining levels of sugar and the dough rise parameters (r > 0.70) (Online resource 2). These in turn correlated with loaf volume crumb structure and texture of the baked breads (r > 0.75). Volatile aroma compound analysis detected only low amounts of volatiles which explained no significant difference in the results of the descriptive sensory. The low production of volatiles was explained to be caused by the refined gluten-free system in this study, which lacks nutrients for the yeast metabolism. In summary, it was found that the different yeasts only affected the technological properties rather than the flavour and aroma profile of the baked breads. This was found to be due to the yeast-specific activities and properties. The performed study demonstrated the suitability of different yeast strains of S. cerevisiae in the application of gluten-free bread.

References

Linko Y-Y, Javanainen P, Linko S (1997) Biotechnology of bread baking. Trends Food Sci Technol 8(10):339–344

Fleet GH (2007) Yeasts in foods and beverages: impact on product quality and safety. Curr Opin Biotechnol 18(2):170–175

Rezaei MN et al (2014) Harvesting yeast (Saccharomyces cerevisiae) at different physiological phases significantly affects its functionality in bread dough fermentation. Food Microbiol 39:108–115

Heitmann M, Zannini E, Arendt EK (2015) Impact of different beer yeasts on wheat dough and bread quality parameters. J Cereal Sci 63:49–56

Amendola J, Rees N (2003) Understanding the art and science of baking. Wiley, Hoboken

Heitmann M, Zannini E, Arendt E (2018) Impact of Saccharomyces cerevisiae metabolites producedduring fermentation on bread quality parameters: a review. Critical reviews in food science and nutrition 58(7):1152–1164

Koehler P, Wieser H, Konitzer K (2014) Celiac disease and gluten: multidisciplinary challenges and opportunities. Academic Press, Cambridge

Tsatsaragkou K et al (2017) Improving carob flour performance for making gluten-free breads by particle size fractionation and jet milling. Food Bioprocess Technol 10(5):831–841

Lai H, Lin T (2006) Bakery products: science and technology. Bak Prod Sci Technol 3–65

Birch AN et al (2013) Influence of commercial baker’s yeasts on bread aroma profiles. Food Res Int 52(1):160–166

Birch AN, Petersen MA, Hansen ÅS (2014) Aroma of wheat bread crumb. Cereal Chem 91(2):105–114

Pico J, Bernal J, Gómez M (2015) Wheat bread aroma compounds in crumb and crust: a review. Food Res Int 75:200–215

Randez-Gil F, Sanz P, Prieto JA (1999) Engineering baker’s yeast: room for improvement. Trends Biotechnol 17(6):237–244

Horstmann S, Foschia M, Arendt E (2017) Correlation analysis of protein quality characteristics with gluten-free bread properties. Food Funct 8(7):2465–2474

Penninckx MJ (2002) An overview on glutathione in Saccharomyces versus non-conventional yeasts. FEMS Yeast Res 2(3):295–305

Verheyen C et al (2015) The contribution of glutathione to the destabilizing effect of yeast on wheat dough. Food Chem 173:243–249

Reed G (2012) Yeast technology. Springer Science & Business Media, New York

Delcour J, Hoseney RC (2010) Principles of cereal science and technology authors provide insight into the current state of cereal processing. Cereal Foods World 55(1):21–22

Yano H (2010) Improvements in the bread-making quality of gluten-free rice batter by glutathione. J Agric Food Chem 58(13):7949–7954

White C, Zainasheff J (2010) Yeast: the practical guide to beer fermentation. Brewers Publications, Boulder

Struyf N et al (2017) Bread dough and baker’s yeast: an uplifting synergy. Compr Rev Food Sci Food Saf 16(5):850–867

Frasse P et al (1993) The influence of fermentation on volatile compounds in French bread dough. LWT-Food Sci Technol 26(2):126–132

Verheyen C, Jekle M, Becker T (2014) Effects of Saccharomyces cerevisiae on the structural kinetics of wheat dough during fermentation. LWT-Food Sci Technol 58(1):194–202

Sluimer P (2005) Principles of bread making: functionality of raw materials and process steps. American Association of cereal chemists, St. Paul, MN, pp 42–48

Cauvain SP, Young LS (2016) Technology of breadmaking. Springer, New York

Hager A-S et al (2012) Investigation of product quality, sensory profile and ultrastructure of breads made from a range of commercial gluten-free flours compared to their wheat counterparts. Eur Food Res Technol 235(2):333–344

Morreale F, Garzón R, Rosell CM (2017) Understanding the role of hydrocolloids viscosity and hydration in developing gluten-free bread. A study with hydroxypropylmethylcellulose. Food Hydrocoll 77:629–635

Gray J, Bemiller J (2003) Bread staling: molecular basis and control. Compr Reviews Food Sci Food Saf 2(1):1–21

Wainwright T (1973) Diacetyl—A review: Part I—analytical and biochemical considerations: Part II—brewing experience. J Inst Brew 79(6):451–470

Heitmann M et al (2017) Correlation of flavor profile to sensory analysis of bread produced with different Saccharomyces cerevisiae originating from the baking and beverage industry. Cereal Chem 94(4):746–751

Tressl R et al (1993) Formation of proline- and hydroxyproline-specific Maillard products from [1–13C] glucose. J Agric Food Chem 41(4):547–553

Otterstedt K et al (2004) Switching the mode of metabolism in the yeast Saccharomyces cerevisiae. EMBO Rep 5(5):532–537

Horstmann SW et al (2016) Fundamental study on the impact of gluten-free starches on the quality of gluten-free model breads. Foods 5(2):30

Horstmann SW, Lynch KM, Arendt EK (2017) Starch characteristics linked to gluten-free products. Foods 6(4):29

Acknowledgements

The authors want to thank Tom Hannon for his technical and Kieran Lynch for editorial support. Further thanks goes to Concept Life Sciences, UK for the volatile compound analysis. The work for this study was part of the PROTEIN2FOOD project. This project has received funding from the European Union’s Horizon 2020 research and innovation programme under Grant agreement No 635727.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interest.

Compliance with ethics requirements

This article does not contain any studies with human or animal subjects.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Horstmann, S.W., Atzler, J.J., Heitmann, M. et al. Impact of different S. cerevisiae yeast strains on gluten-free dough and bread quality parameters. Eur Food Res Technol 245, 213–223 (2019). https://doi.org/10.1007/s00217-018-3154-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-018-3154-9