Abstract

The objective of this study was to assess the combined effect of guar gum (GG) and water content (WC) on the rheological properties of batter, and the physicochemical and textural properties of bread. Batches of gluten-free bread used a base formulation of rice (50%), maize (30%) and quinoa flour (20%), with different levels of GG (2.5, 3.0 or 3.5%) and water (90, 100 or 110%) in a full factorial design. Higher GG doses (p < 0.001) tended to produce batters of lower stickiness, work of adhesion and cohesive strength; yet, of higher firmness, consistency, cohesiveness and viscosity index. These batters yielded loaves of lower (p < 0.001) specific volume and baking loss; and crumbs of lower (p < 0.001) aw, pH, mean cell area, void fraction, mean cell aspect ratio; and higher (p < 0.001) hardness, adhesiveness, springiness, cohesiveness, chewiness, resilience, mean cell density, cell size uniformity and mean cell compactness. The sticker and less consistent batters produced with higher WC rendered larger bread loaves of softer and more cohesive and springy/resilient crumbs with greater mean cell size and void fraction. Gluten-free loaves of good appearance in terms of higher specific volume, lower crumb hardness, higher crumb springiness, and open grain visual texture were obtained in formulations with 110% WC and GG doses between 2.5 and 3.0%.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The market of gluten-free (GF) bakery products has considerably grown; prompted not only by the people suffering coeliac disease and other gluten-related disorders; but also by a new segment of consumers who have chosen to consume GF foods as a lifestyle choice or for health reasons [1]. Among the bakery products, bread is a major staple food consumed daily all over the world [1]. However, eliminating gluten seems a technological challenge as it gives rise to products with compromised quality [2]. To overcome this, a number of hydrocolloids have been studied as gluten replacers. Guar gum (GG) is a polysaccharide, obtained from Cyamopsis tetragonoloba beans. Its solutions are highly viscous at low concentrations and useful in thickening, stabilization and water binding applications [3]. In breadmaking, GG is used to improve mixing and recipe tolerance; to extend the shelf life of products through moisture retention and to improve quality of baked products such as volume, texture and colour (3–5). Optimising textural and sensory attributes, researchers have recommended doses of GG in GF bread, that, in general, range between 0.25% and 3.0% (flour weight), yet this is strongly linked to bread formulation and water content [3,4,5]. The protein network formed by GG has been found to be similar to the gluten structure, and when added to rice–wheat flour, it increases water absorption, dough development time, dough stability and viscosity [6, 7].

Research interest in quinoa, a GF Andean grain, has been renewed due to its high nutritional and functional values. Apart from its good proximate composition profile, (protein ~ 13.0%, lipids ~ 6.0%), quinoa whole flour is rich in dietary fibre (~ 16.0%, with ratios of insoluble dietary fibre/soluble dietary fibre higher than 8:1), phenolic acids, flavonoids and α-linolenic acid; suggesting that quinoa flour can be employed as an ingredient to enrich food systems [8, 9]. Rice flour, another commonly GF ingredient, is usually preferred because of its colourlessness, nutritional characteristics, mild taste, low hypoallergenic properties [10], low levels of sodium and easy digestibility [11]. Rice proteins have relatively poor functional properties, yet they can be enhanced in combination with quinoa proteins in breadmaking. Maize flour also contributes to GF breadmaking since their dietary fibre has been found to produce higher loaf volume and lower crumb hardness as compared to GF bread without coarse maize flour [2]. The objective of this study was to enhance the quality attributes of GF bread formulated with a mixture of quinoa, rice and maize flours by understanding the effect of guar gum, used as gluten replacer, on the rheological properties of batter and the physicochemical and textural properties of the baked loaves.

Materials and methods

GF breadmaking process

Quinoa flour was obtained from a commercial mixture of saponin-free white quinoa varieties: Salcedo INIA and Juli (grains mixture composition: 10.1% moisture, 13.6% protein, 3.2% crude fat, 3.1% ashes and 70% carbohydrates, particle size ~ 1 mm). Quinoa grains were milled in a laboratory disc mill (Faema, Spain), and then sieved through a rotating sifter. The quinoa flour had a particle size < 315 µm measured using a test sieve (Retsch, Germany) and a vibratory sieve shaker (Retsch AS200 basic, Germany). Quinoa flour (8.8% moisture, 12.9% protein, 5.0% fat, 2.2% ashes, and 71.1% carbohydrates) was kept in polyethylene containers and maintained at room temperature (⁓20 °C) conditions during its use.

GF breads were elaborated with rice flour (10.4% moisture, 7.6% protein, 0.7% fat and 78.5% carbohydrates, particle size < 180 µm), maize flour (11.5% moisture, 5.4% protein, 2.1% fat and 78.3% carbohydrates, particle size < 180 µm), sunflower oil, white sugar and refined salt purchased from a local supermarket (Bragança, Portugal). Instant yeast (Saccharomyces cerevisiae lyophilized, Instaferm Lallemand, EU) and GG (E412) were provided by TecPan (Mirandela, Portugal). All batches were produced using a base formulation of rice flour (50%), maize flour (30%) and quinoa flour (20%) to which sunflower oil (6% flour weight), white sugar (3% flour weight), refined salt (1.5% flour weight), instant yeast (3% flour weight), GG (2.5, 3.0 or 3.5% flour weight) and water (90, 100 or 110% flour weight) were added following a standardised procedure. Demineralised water (pH = 6.8) kept at 5 °C overnight was used. The instant yeast was rehydrated and activated at 30 °C and 85% of relative humidity (RH) for 15 min in a chamber. After mixing dry ingredients for 2 min at speed 1, liquid ingredients were added and mixed for an additional 5 min at speed 4 in a professional food processor (SilverCrest SKMP-1200, Germany) equipped with a batter blade.

Portions of ⁓280 g were then poured into oiled and floured 520-ml capacity tins, and allowed to proof at 30 °C and 85% of relative humidity for 60 min in a climatic chamber (Climacell 222, Germany). Afterwards, all moulds from the same batch were placed in a pre-heated convection oven (Princess, 2000 W, The Netherlands) for 60 min at 190 °C. Bread loaves were un-moulded after 2 h. All analyses were performed after 24 h. All batter and crumb rheology parameters were obtained using a texture analyser TA-XT plus implemented with the Exponent software version 6.1.11.0 (Stable Micro Systems, UK). For calibration, a 5-kg load cell for stickiness analysis, and a 30-kg load cell for back-extrusion for the TPA analyses were used.

Rheological properties of GF batter

For analysis of the rheological properties of batter, ⁓175 g was used. For the batter stickiness analysis, ⁓5 g batter was weighed in a SMS/Chen–Hoseney stickiness cell (A/DSC) screwed to a SMS/Chen–Hoseney stickiness rig [12]; and then examined by the texture analyser using a 25-mm perspex cylinder probe (P/25P), while parameters were set at: pre-test speed 0.5 mm/s, test speed 0.5 mm/s and post-test speed 10 mm/s, trigger force 5 g, applied force 40 g, contact time 0.1 s and return 4 mm. After rotating the cell screw once to extrude a 1-mm-high batter sample, the perspex cap was placed over the exposed sample surface to minimise moisture loss, whilst allowing the batter surface to rest for 30 s to release the stress produced by extrusion (Ghodke 2009). Ten repetitions were done for each GF batter formulation. Three stickiness analysis parameters were obtained: batter stickiness (STIba, in g), work of adhesion (ADHba, in g·s), and batter cohesive strength (SCOba, in mm) [3, 13].

The back-extrusion analysis was performed using a 35-mm-diameter perspex flat probe (model A/BE), a standard size back-extrusion cylindrical container (50 mm-diameter, capacity of ⁓115 g) and a backward extrusion rig (model A/BE). The container was filled with ⁓85 g of batter (75% full). The settings of the assessment were: pre-test speed 1 mm/s, test speed 2 mm/s and post-test speed 2 mm/s, trigger force 10 g, penetrated to a depth of 15 mm and then returned to starting position [12, 14]. Four repetitions were tested from each batch of GF batter. Several back-extrusion parameters were obtained: firmness (FIRba, in g), consistency (CONba, in g·s), cohesiveness (COHba, in g), and viscosity index (VISba, in g·s). Since COHba and VISba are calculated from the negative region of the back-extrusion profile curve, the higher the negative values, the more cohesive and viscous the batter, respectively.

Physicochemical bread quality properties

Loaf-specific volume and baking loss

The GF loaf volume (ml) was determined using a modified standard rapeseed displacement method 10-05 [15], using quinoa seeds instead of rapeseeds. The mould used to do the measurement was a parallelepiped with dimension of 10.4 cm × 10.4 cm × 7.5 cm (width × length × height). The loaf-specific volume (ml/g) was calculated as loaf volume divided by loaf weight measured 24 h after baking [16]. Baking loss was computed as [initial loaf weight before baking—the loaf weight after 24 h baking × 100]/initial loaf weight before baking [17, 18].

Water activity, pH and colour

Water activity (aw) of the bread crumb was determined according to Machado-Alencar et al. [19], measured at 20 °C using an AquaLab (4TE Decagon, USA). Measurements were taken from four central slices from each loaf. Then, pH was measured according to Bhatt and Gupta [17]. Crust colour was measured on five different zones of the top of the entire loaf, while crumb colour was measured on the centre of five slices per each loaf using the L*, a* and b* parameters according to colour space CIELab system, with a colorimeter CR-400 (Konica Minolta, chroma meter, Japan) which was calibrated using a white ceramic plate reference (L* = 94.57, a* = − 0.46 and b* = 3.88) before each measurement. Additionally, the total colour difference (ΔE) of bread was determined as the following: \(\varDelta E{=[\left({L}_{0}-L\right)+\left({a}_{0}-a\right)+\left({b}_{0}-b\right)]}^{0.5}\), where: L0 = 100, a0 = 0 and b0 = 0 [20, 21].

Rheological properties of GF bread crumb

The characterisation of the textural properties of bread crumb was carried out by means of the texture profile analysis (TPA). The GF loaves were sliced using an electric slicer (Bosch MAS4000W, Germany) to obtain 20-mm thickness. The two extreme slices of each loaf were discarded, and cylindrical crumb samples of 30 mm-diameter were cut off from the centre of each slice. Four sub-samples were analysed per loaf. For the TPA, a 36-mm-diameter aluminium probe (model P/36R) was used. The analysis was run at: pre-test speed 1 mm/s, test speed 2 mm/s and post-test speed 2 mm/s, trigger force 5 g, 50% sample deformation (strain) and double compression (with a gap of 30 s between the two cycles). The TPA parameters obtained were: hardness (HARbr, in g), adhesiveness (ADHbr, in g·s), springiness (SPRbr, dimensionless), cohesiveness (COHbr, dimensionless), resilience (RESbr, dimensionless), and chewiness (CHEbr, in g) [22].

Bread crumb image analysis

Slices of bread were scanned (Canon Pixma MG-2550, Vietnam) using the IJ Scan Utility software (version 2.0.12, Canon, Japan) in grey level at −10% brightness, + 15% contrast and 350 dpi resolution. Using the ImageJ software (v.1.51j8, Wayne Rasband, National Institute of Health, USA), the centre of the image was cropped into a 3.8 cm × 3.8 cm field-of-view (with a spatial resolution of 1 cm = 138 pixels); and saved without any image compression in TIF format for posterior analysis. For each formulation, 32 images (4 loaves × 4 slices × 2 sides of the crumb) were acquired. Several grain crumb features were computed using the binary segmentation procedure based on the k-means clustering algorithm, proposed in Gonzales-Barron and Butler [23, 24], and were coded in Matlab software ver. R2015a [25]. These were: mean cell area (MCA, mm2); mean cell density (CDE, cells/mm2); cell size uniformity (UNI, dimensionless), calculated as the rate between the number of cells ≤ 5 mm2 and number of cells > 5 mm2; void fraction (VFR, dimensionless), calculated as the proportion of the two-dimensional space occupied by the cells; mean cell compactness (COM, dimensionless), with compactness defined as the ratio of the cell area of a circle having the same perimeter; and mean cell aspect ratio (ARA, dimensionless), with aspect ratio defined as the ratio of the major axis to the minor axis of a cell.

Statistical analyses

The effects of GG (three doses tested: 2.5, 3.0 or 3.5%) and WC (three levels tested: 90, 100 or 110%) were evaluated using a full factorial design; thus, producing nine batches of GF bread. Analyses of variance were applied to assess the effect of GG, WC and their interaction on the response variables: baking loss, pH, aw, batter stickiness and back-extrusion. For the response variables: specific volume, crust and crumb ΔE, TPA and bread crumb image features, a linear mixed model was fitted instead to assess the main effects of GG dose and WC, and their interaction, assuming that measurements taken from the same loaf were correlated.

All two models were tested for the normality of residuals using standard diagnostics to ensure that all dependent variables met the assumptions of normal distribution. When the effects were significant (α = 0.05), Tukey’s Honest Significant Difference test was performed. Additionally, Kenward–Roger correction was applied for reducing small sample bias [26]. Statistical analyses were conducted using the packages “plyr”, “ggplot2”, “lme4” and “lmerTest” for the linear models; and the packages: “rmisc”, “rcmdmisc”, “plyr”, “ggplot2”, “car”, “multcompView” and “lsmeans” for the linear mixed models implemented in the R software version 3.3.3 [27].

Results and discussion

Rheological properties of GF batter

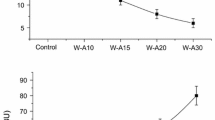

Both, GG and WC affected the rheology of GF batter, as implied by the results of the batter stickiness (Fig. 1) and the back-extrusion (Fig. 2) properties. The batter stickiness properties of STIba, ADHba and SCOba ranged from 33.56 to 45.33 g, from 3.11 to 4.78 g·s and from 2.26 to 3.38 mm, respectively. At a constant GG level, higher WC consistently (p < 0.001) increased the STIba, ADHba and SCOba measurements, while at a constant WC level, higher GG contents consistently (p < 0.001) decreased the stickiness properties (Fig. 1). According to Table 1, GF batters with higher GG content were significantly less sticky, as demonstrated by the low values of STIba (36.1 g), ADHba (3.80 g·s) and SCOba (2.74 mm) for treatments with 3.5% GG, compared with 2.5% GG (41.5 g, 4.64 g·s and 3.49 mm, respectively) and 3.0% GG (39.1 g, 4.15 g·s and 3.12 mm, respectively). On the other hand, as expected, the treatments with the highest WC (110%; p < 0.001) gave stickier batters (41.7 g, 4.59 g·s and 3.19 mm) than treatments with 90% WC (36.3 g, 3.74 g·s and 2.62 mm, respectively) and 100% WC (38.7 g, 4.26 g·s and 2.86 mm, respectively). The flour’s water absorption has an effect on batter stickiness for high water absorption reduces stickiness and produces stiff batters [28].

The treatments of GF bread studied produced batters of variable viscosity. The back extrusion analysis values ranged for FIRba from 757 to 2170 g, for CONba from 4262 to 12,093 g·s, for COHba from − 580 to − 1645 g, and for VISba from − 1369 to − 4825 g·s. Higher (3.5%) GG contents increased (p < 0.001) FIRba (1694 g), CONba (9615 g·s), COHba (− 1321 g) and VISba (− 3640 g·s) of batters compared to results obtained from treatments with 2.5% GG (1079 g, 6072 g·s, − 831 g, − 2060 g·s, respectively) and 3.0% GG (1256 g, 7398 g·s, − 1028 g, − 2871 g·s, respectively) (Table 2). On the other hand, higher (110%) water levels had an opposite effect, reducing (p < 0.001) FIRba (979 g), CONba (5735 g·s), COHba (− 783 g) and VISba (− 2018 g·s) of batters. Using the same level of water (110%), Sciarini et al. [29] obtained lower batter firmness values, from 50.8 to 1252 g, for a mixture of maize/soy (90:10) and rice/soy (80:20), respectively. They concluded that rice/soy mixtures required higher force to extrude, because soy proteins have the ability to absorb cold water, resulting in a decrease of free water in the batter mixture. In our case, quinoa proteins may have lent even a greater cold water absorption capability, hence producing batters of higher firmness than those with soy proteins.

All of the batter properties presented significant interaction between WC and GG (Tables 1, 2), which can be also visualised in Figs. 1 and 2, whereby the effect of guar on batter rheology was more discernible at lower water contents. For instance, for the work of adhesion property, at a constant WC of 110%, the change in GG from 2.5 to 3.5% increased ADHba by ~ 7%, while at the lowest WC of 90%, the increase was higher at ~ 42%. Therefore, formulating bread with higher doses of GG may bring about greater and undesired variations in texture quality, if WC is not optimised. GG, consisting of galactose and mannose units, has the capacity to dissolve in polar solvents, forming strong hydrogen links; creating a highly viscous colloidal dispersion on complete hydration; such high viscosities may adversely affect the physico-chemical properties and sensory acceptability of foods [30]. Moreover, Funami et al. [31] and Horstmann et al. [32] explained the link between a high number of branches of GG and increased interactions with water. The higher the molecular weight (GG has between 100,000 and 2,000,000 Da), the greater the water holding capacity due to the higher radius of gyration (i.e., water around the hydrocolloid) [32].

Comparing between 1.5 and 2.5% of GG in a GF fresh filled pasta batter, Sanguinetti et al. [33] also observed that a higher dose of GG resulted in a more cohesive, springier and harder batter. Sabanis and Tzia [16] and Turkut et al. [18] reported that higher consistency values and viscosity index in their GF batters led to lower specific volume. This finding was corroborated in the present study, where 3.5% GG doses produced loaves of lower specific volume (1.5 ml/g) compared to those obtained from treatments with 2.5% GG (1.8 ml/g) (Fig. 3).

Physicochemical properties of GF bread

The specific volume, baking loss, pH and aw values of GF breads are summarised in Table 3, while side photographs of loaves produced varying GG and WC are displayed in Fig. 3.

Loaf-specific volume and baking loss

Specific volume was affected (p < 0.001) by guar, hydration and their interaction (Table 3). The specific volume of bread ranged from 1.39 to 1.98 ml/g, decreasing (p < 0.001) with higher GG content, and increasing (p < 0.001) with higher WC. Specific volumes between 4 and 5 ml/g are usual for wheat breads depending on the formulation, breadmaking method and the use or not of sourdough; however, values between 1.33 and 2.40 ml/g are expected for GF bread [34, 35]. Similarly, Mohammadi et al. [6] working with 2.0–3.0% GG obtained mean loaf-specific volumes of 2.1 and 1.9 ml/g, respectively, using a GF matrix of rice flour (~ 41%), maize starch (~ 31%), water (59.5% and 62.7%, respectively), soy flour (~ 10%), sodium caseinate (~ 5%), oil (~ 4%), sugar (~ 4%), inulin (~ 2%), salt (~ 1%), dried instant yeast (~ 1%) and DATEM (~ 0.2%), while Conte et al. [5] obtained a higher specific volume (2.42 ml/g) for a formulation of 1.5% GG and 90% WC in a matrix of GF rice flour (50%), maize starch (50%), psyllium fibre (1.5%), sunflower oil (6%), yeast (3%), salt (1.8%) and sugar (3%).

According to Hager et al. [34], one important parameter in GF breadmaking, known to strongly influence consumer’s choice, is loaf specific volume, because from an economic standpoint, a high ratio of volume per weight is desired. The positive impact of high WC was evident in the specific volume of GF breads, which can be explained by the plasticiser effect of water which contributes to the extensional properties of the batter during mixing, allowing the hydration of the particles [36]. Nonetheless, Han et al. [28] reported that excessive water can be detrimental as it causes overexpansion during baking resulting in collapsed loaves. Onyango et al. [37] explained that, as gas leaks out of the bubbles, it forces its way through the weakly connected particles and channels formed by gas pressing the particles apart. Since, in our experiments, small-sized bread loaves were mostly associated to lower baking losses, we can conclude that, regardless of the GG dose, batters with low WC tended to proof insufficiently, resulting in bread loaves of lower volume.

Baking loss ranged from 12.8 to 18.0%, increasing (p < 0.001) with higher WC, and decreasing (p < 0.001) with higher GG content (Fig. 4). However, although higher GG amounts (3.5%) reduce baking loss, it can negatively affect the volume of loaves (Fig. 4). Lower baking loss values (13.5%) were obtained for 3.5% GG formulations, compared to those obtained from formulations with 2.5% GG (16.4%) and 3.0% GG (14.9%) (Table 3). On the other hand, there was a proportional relationship between added water and baking loss; namely, 90, 100 and 110% of WC resulted in baking losses of 13.7, 15.0 and 16.2%, respectively. As observed by Onyango et al. [37], formulations with high water contents gave mixtures that resembled batters, whereas those with low water amounts gave batters that lacked elasticity. Breads made from batters containing high water contents had higher volumes than those made from batters containing low water amount.

Water activity (a w), pH and colour

As expected, according to Table 3, the amount of free water in the crumb decreased with the addition of higher concentrations of GG (p < 0.001) and lower WC amounts (p < 0.001). The aw ranged from 0.9777 to 0.9914. Lower values of aw (0.9798) were obtained for 3.5% GG, compared with aw values obtained from treatments with 2.5% GG (0.9872) and 3.0% GG (0.9838). On the other hand, 90, 100 and 110% of WC resulted in progressively increasing aw values of 0.9808, 0.9834 and 0.9866, respectively. Since microbial stability of GF breads could be compromised by high aw, treatments with higher GG and lower WC amounts would be desired.

In relation to the pH parameter, bread acidity was also influenced by the addition of GG (p < 0.001) and WC (p < 0.001), with more acidic crumbs produced by higher doses of GG and lower doses of WC. GF breads showed a pH from 6.54 to 6.63. Lower pH values (6.58) were obtained for treatments with 3.5% GG, compared with pH values obtained from treatments with 2.5% GG (6.59) and 3.0% GG (6.59). On the other hand, 90% WC (6.55) resulted in slightly less acidic crumbs, compared with pH values obtained from treatments with 100% WC (6.58) and 110% WC (6.63).

All the GF bread crumb samples showed negative a* and positive b* values, indicating yellow-greenish hues, while bread crust samples showed positive a* and b* values, suggesting yellow-reddish hues. The colorimetric values of crust ΔE ranged from 39.6 to 45.7, whereas for crumb ΔE ranged from 37.8 to 38.6 (Fig. 4). When proportions of WC (p < 0.001) increased, the crust ΔE increased. However, the GG showed a quadratic effect on crust ΔE, while the crumb ΔE increased only by effect of lower amounts of WC (p < 0.001). Lee and Coates [38] and Motta-Romero et al. [21] stated that overall colour changes greater than 2 (ΔE > 2) indicate a clear colour difference for consumers. For example, the formulation with 3.0% GG and 90% WC compared to the 3.5% GG and 90% WC had a crumb ΔE (0.22) smaller than the crust ΔE (4.15). Therefore, consumers would be able to recognise the difference of colour between these two formulations only by appreciating the crust.

Rheological properties of GF bread crumb

All parameters of the TPA (HARbr, ADHbr, SPRbr, COHbr, CHEbr and RESbr) were affected (p < 0.001) by GG, WC (except for ADHbr, WC had no significant effect) and their interaction (Table 4). Having produced firmer and more viscous batters, lower WC levels consequently yielded tougher breads (Fig. 5). According to the TPA, loaves with the lowest WC (90%) were significantly harder (HARbr = 8813 g), chewier (CHEbr = 3216 g), and less cohesive (COHbr = 0.472), springy (SPRbr = 0.800) and resilient (RESbr = 0.196) than the treatments with 100 and 110% WC. However, the addition of higher amounts of water can improve crumb texture, since the 110% WC treatments produced softer breads, with lower values of HARbr (2540 g) and CHEbr (1257 g), and higher values of SPRbr (0.896), COHbr (0.552) and RESbr (0.241), compared to those obtained from the lower WC treatments of 90 and 100%.

According to Cornejo and Rosell [11], high springiness values are preferred because it is related to the bread freshness and elasticity; a reduction in resilience or springiness characterises loss of elasticity, because both properties indicate the ability of a material to return to its original shape after stressing. In our work, the highest springiness was reached with a combination of 2.5% GG and 110% WC; this is, the lowest dose of GG and the highest amount of water (Fig. 5). As reported by Onyango et al. [37], cohesiveness characterises the extent to which a material can be deformed before it ruptures, and reflects the internal cohesion of the material. Bread crumb with high cohesiveness is desirable because it forms a bolus, instead of disintegrating during mastication, whereas low cohesiveness indicates increased susceptibility of the bread to fracture or crumble. In this study, GF bread with amounts of 3.5% GG and 110% WC attained the highest cohesiveness.

Cornejo and Rosell [11] achieved, for GF bread elaborated with different long grain rice flours, lower values for hardness (ranged from 361 to 1105 g) and springiness (ranged from 0.68 to 0.80), and comparable values for resilience (from 0.20 to 0.35), chewiness (from 914 to 2066 g) and cohesiveness (from 0.44 to 0.67). Likewise, Onyango et al. [37] obtained, for GF bread elaborated with different rice, cassava, potato and maize starches–sorghum ratios, comparable TPA values for firmness (i.e., hardness) from 760 to 4862 g and chewiness (from 666 to 2383 g), although they measured higher values for cohesiveness (from 0.563 to 0.756), springiness (from 0.875 to 0.997) and resilience (from 0.328 to 0.438). Conte et al. [5] obtained lower HARbr (3.79 N, i.e., 386 g), and higher COHbr (0.60), SPRbr (0.99) and RESbr (0.31) for a formulation of 1.5% GG and 90% WC in a matrix of GF rice flour (50%), maize starch (50%), psyllium fibre (1.5%), sunflower oil (6%), yeast (3%), salt (1.8%) and sugar (3%).

Image analysis features of crumb grain

Digital images of GF crumb grain showed visual differences among the nine formulations (Fig. 6). Whereas higher WC formulations produced more open grain textures, lower WC formulations produced the opposite, closer crumbs of smaller pores. Such differences were statistically corroborated in all of the image grain features analysed. Values were in the range of 0.60–2.21 mm2 for MCA; 0.18–0.36 cells/mm2 for CDE; 8.46–157.3 for UNI; 0.189–0.358 for VFR; 0.767–0.803 for COM; and 1.526–1.703 for ARA.

Higher doses of GG produced loaf slices of lower MCA, VFR and ARA values (p < 0.001), and higher CDE, UNI and COM (p < 0.001). At a constant level of water in the formulation, increasing GG doses only produces smaller bread loaves. These smaller loaves tend to have a compact or close visual grain texture, formed of a greater number of cells, but of smaller size. As a consequence, the cell size uniformity is greater but the void fraction is lower. Smaller loaves of denser or more compact texture also present the characteristic of having more rounded cells (i.e., higher cell compactness) and less elongated cells (i.e., lower mean cell aspect ratio). Loaves of lower GG contents (2.5%) presented crumbs of larger pores, with higher values of MCA (1.55 mm2), VFR (0.31) and ARA (1.67), and therefore lower values of CDE (0.24 cells/mm2), UNI (19.7) and COM (0.77) compared to those obtained with higher GG levels of 3.0 and 3.5% (Table 5; Fig. 7).

On the other hand, when higher proportions of WC (110%) were added, the opposite was observed; that is, values of CDE (0.23 cells/mm2), UNI (15.4) and COM (0.770) were lower (p < 0.001), while values of MCA (1.67 mm2), VFR (0.32) and ARA (1.67) were higher than those obtained with the lower WC treatments of 90 and 100%. This signifies that, when loaves undergo a better proofing, expanding more during fermentation and baking, facilitated by the greater amount of water, the final visual texture of the bread crumb has altogether a different crumb grain. As breads are formulated with a constant GG dose and increasing WC levels, crumb grains tend to appear more open; in other words, the crumb is made of cells of greater size and less compact and more elongated shape. This in turn leads to a less uniform grain (since the number of large cells is greater) and a higher void fraction.

A denser bread crumb grain can also be effectively evaluated by the measurements of cell size uniformity and mean cell compactness or mean cell aspect ratio. Notice that higher values of UNI and COM were obtained with higher amounts of GG (3.5%) and lower values of WC (90%), corresponding in both cases to a denser crumb structure (Fig. 7). Thus, when during proofing and baking, batter expands more and steadily, a greater number of large cells is produced, therefore bringing down the ratio small-to-large cells (UNI), while due to coalescence, the large cells tend to be more elongated and less compact, thereby bringing down the values of COM.

From the nine formulations, the more open crumb grain was attained by the formulation with 2.5% GG and 110% WC (MCA value of 2.21 mm2; Fig. 7), whereas the formulation with 3.5% GG and 90% WC produced the smallest mean cell size (0.60 mm2), characterising the denser structure obtained, which was also reflected by the lowest specific volume of this formulation (1.39 ml/g; Fig. 3). According to de la Hera et al. [36], if GF breads are elaborated with excessive water, large holes can appear in the crumb, as was also attested in our experiments for the formulation GG2.5/WC110 (Fig. 7).

In this study, using GG as the only batter thickener, it was possible to obtain crumbs with open grain structures at a high level of water (110%) and a low level of GG (2.5%). The presence of larger cells can also be linked to a spongier crumb structure, which is a desirable quality property yet not typically found in gluten-free breads. Similar to our findings were those reported by Schober, Messerschmidt, Bean, Park, & Arendt [39], who encountered that sorghum bread with a fine crumb structure was tougher than bread with a coarse and open crumb structure. In this study, it was possible to obtain crumbs of open grain in bread loaves formulated with high levels of water and low levels of GG. It is important to indicate that, in this study, the GG dose and water content were not statistically optimised, yet, with the experimental design used, a good understanding of their combined effects of the rheological and textural properties of the GF bread was achieved. Further studies can be conducted to optimise the formulation. In addition, it is desirable to elucidate the effects of other hydrocolloids such as hydroxypropyl methylcellulose or carboxymethylcellulose, and their synergistic behaviour with GG in quinoa-based GF bread.

Conclusions

Higher amounts of guar gum, in gluten-free bread formulated with a mixture of rice, maize and quinoa flours, have in principle the capacity to retain more water. However, at a constant water level, higher doses of guar gum produce less sticky batters of increased firmness, work of adhesion, consistency and viscosity index, which settle into baked loaves of reduced specific volume with a more cohesive, springy, adhesive, chewy, resilient and firm crumb texture. On the other hand, higher doses of water content produce stickier batters of reduced firmness and consistency that converts into baked loaves of greater specific volume with softer and less chewy and more cohesive, adhesive, resilient and springy crumb texture. The highest water content of 110% and GG between 2.5 and 3.0% produced loaves of good quality in terms of high specific volume, low hardness, high springiness, low chewiness, low mean cell density, low cell size uniformity, high void fraction and low mean cell compactness.

References

Foschia M, Horstmann S, Arendt EK, Zannini E (2016) Nutritional therapy—facing the gap between coeliac disease and gluten-free food. Int J Food Microbiol 239:113–124

Naqash F, Gani A, Gani A, Masoodi FA (2017) Gluten-free baking: combating the challenges—a review. Trends Food Sci Technol 66:98–107

Ghodke SK (2009) Effect of guar gum on dough stickiness and staling in chapatti-an Indian unleavened flat bread. Int J Food Eng 5(3):article 7

Moreira R, Chenlo F, Torres MD (2013) Effect of chia (Sativa hispanica L.) and hydrocolloids on the rheology of gluten-free doughs based on chestnut flour. LWT-Food Sci Technol 50(1):160–166

Conte P, Del Caro A, Balestra F, Piga A, Fadda C (2018) Bee pollen as a functional ingredient in gluten-free bread: a physical-chemical, technological and sensory approach. LWT-Food Sci Technol 90:1–7

Mohammadi M, Azizi M-H, Neyestani TR, Hosseini H, Mortazavian AM (2015) Development of gluten-free bread using guar gum and transglutaminase. J Ind Eng Chem 21:1398–1402

Sahraiyan B, Naghipour F, Karimi M, Davoodi MG (2013) Evaluation of Lepidium sativum seed and guar gum to improve dough rheology and quality parameters in composite rice-wheat bread. Food Hydrocoll 30(2):698–703

Pellegrini M, Lucas-Gonzales R, Ricci A, Fontecha J, Fernández-López J, Pérez-Álvarez JA, Viuda-Martos M (2018) Chemical, fatty acid, polyphenolic profile, techno-functional and antioxidant properties of flours obtained from quinoa (Chenopodium quinoa Willd) seeds. Ind Crops Prod 111:38–46

Elgeti D, Nordlohne SD, Föste M, Besl M, Linden MH, Heinz V, Jekle M, Becker T (2014) Volume and texture improvement of gluten-free bread using quinoa white flour. J Cereal Sci 59(1):41–47

Renzetti S, Rosell CM (2016) Role of enzymes in improving the functionality of proteins in non-wheat dough systems. J Cereal Sci 67:35–45

Cornejo F, Rosell CM (2015) Physicochemical properties of long rice grain varieties in relation to gluten free bread quality. LWT-Food Sci Technol 62(2):1203–1210

Devi PB, Kavitake D, Shetty PH (2016) Physico-chemical characterization of galactan exopolysaccharide produced by Weissella confusa KR780676. Int J Biol Macromol 93:822–828

Agrahar-Murugkar D, Gulati P, Kotwaliwale N, Gupta C (2015) Evaluation of nutritional, textural and particle size characteristics of dough and biscuits made from composite flours containing sprouted and malted ingredients. J Food Sci Tech 52(8):5129–5137

Juszczak L, Witczak T, Ziobro R, Korus J, Cieślik E, Witczak M (2012) Effect of inulin on rheological and thermal properties of gluten-free dough. Carbohydr Polym 90(1):353–360

AACC International (2000) Method 10-05, approved methods of the AACC, 10th edn. American Association of cereal chemists, St. Paul

Sabanis D, Tzia C (2010) Effect of hydrocolloids on selected properties of gluten-free dough and bread. Food Sci Technol Int 17(4):279–291

Bhatt SM, Gupta RK (2015) Bread (composite flour) formulation and study of its nutritive, phytochemical and functional properties. J Pharmacogn Phytochem 4(2):254–268

Turkut GM, Cakmak H, Kumcuoglu S, Tavman S (2016) Effect of quinoa flour on gluten-free bread batter rheology and bread quality. J Cereal Sci 69:174–181

Machado-Alencar NM, Steel CJ, Alvim ID, Carvalho de Morais E, Andre-Bolini HM (2015) Addition of quinoa and amaranth flour in gluten-free breads: temporal profile and instrumental analysis. LWT-Food Sci Technol 62(2):1011–1018

Razavizadegan-Jahromi SH, Karimi M, Yazdi FT, Mortazavi SA (2014) Response surface optimization of Barbari bread-making process variables: interrelationship of texture, image and organoleptic characteristics; using image analysis for quality and shelf life prediction. J Food Process Preserv 38(4):1608–1621

Motta-Romero H, Santra D, Rose D, Zhang Y (2017) Dough rheological properties and texture of gluten-free pasta based on proso millet flour. J Cereal Sci 74:238–243

Martínez MM, Gómez M (2017) Rheological and microstructural evolution of the most common gluten-free flours and starches during bread fermentation and baking. J Food Eng 197:78–86

Gonzales-Barron U, Butler F (2006) A comparison of seven thresholding techniques with the k-means clustering algorithm for measurement of bread-crumb features by digital image analysis. J Food Eng 74(2):268–278

Gonzales-Barron U, Butler F (2008) Discrimination of crumb grain visual appearance of organic and non-organic bread loaves by image texture analysis. J Food Eng 84(3):480–488

Matlab software (2015) “Version R2015a”. Natick. Massachusetts, The MathWorks Inc., USA

McNeish DM, Harring JR (2017) Clustered data with small sample sizes: comparing the performance of model-based and design-based approaches. Commun Stat Simul Comput 46(2):855–869

R Core Team (2018) R: a language and environment for statistical computing. R Foundation for Statistical Computing, Vienna, Austria. http://www.R-project.org/. Accessed 4 Feb 2018

Han HM, Cho JH, Kang HW, Koh BK (2012) Rice varieties in relation to rice bread quality. J Sci Food Agric 92(7):1462–1467

Sciarini LS, Ribotta PD, León AE, Pérez GT (2010) Influence of gluten-free flours and their mixtures on batter properties and bread quality. Food Bioprocess Tech 3(4):577–585

Giri S, Banerji A, Lele SS, Ananthanarayan L (2017) Effect of addition of enzymatically modified guar gum on glycemic index of selected Indian traditional foods (idli, chapatti). Bioact Carbohydr Dietary Fibre 11:1–8

Funami T, Kataoka Y, Omoto T, Goto Y, Asai I, Nishinari K (2005) Food hydrocolloids control the gelatinization and retrogradation behavior of starch. 2a. Functions of guar gums with different molecular weights on the gelatinization behavior of corn starch. Food Hydrocoll 19(1):15–24

Horstmann SW, Axel C, Arendt EK (2018) Water absorption as a prediction tool for the application of hydrocolloids in potato starch-based bread. Food Hydrocoll 81:129–138

Sanguinetti AM, Secchi N, Del Caro A, Fadda C, Fenu PAM, Catzeddu P, Piga A (2015) Gluten-free fresh filled pasta: The effects of xanthan and guar gum on changes in quality parameters after pasteurisation and during storage. LWT-Food Sci Technol 64(2):678–684

Hager A-S, Wolter A, Czerny M, Bez J, Zannini E, Arendt EK, Czerny M (2012) Investigation of product quality, sensory profile and ultrastructure of breads made from a range of commercial gluten-free flours compared to their wheat counterparts. Eur Food Res Technol 235(2):333–344

Marti A, Marengo M, Bonomi F, Casiraghi MC, Franzetti L, Pagani MA, Iametti S (2017) Molecular features of fermented teff flour relate to its suitability for the production of enriched gluten-free bread. LWT-Food Sci Technol 78:296–302

de la Hera E, Rosell CM, Gómez M (2014) Effect of water content and flour particle size on gluten-free bread quality and digestibility. Food Chem 151:526–531

Onyango C, Mutungi C, Unbehend G, Lindhauer MG (2011) Modification of gluten-free sorghum batter and bread using maize, potato, cassava or rice starch. LWT-Food Sci Technol 44(3):681–686

Lee H, Coates GA (2003) Effect of thermal pasteurization on Valencia orange juice color and pigments. LWT-Food Sci Technol 36(1):153–156

Schober TJ, Messerschmidt M, Bean SR, Park S-H, Arendt EK (2005) Gluten-free bread from sorghum: quality differences among hybrids. Cereal Chem 82(4):394–404

Acknowledgements

Eng. Encina-Zelada acknowledges the financial aid provided by the Peruvian National Programme of Scholarships and Student Loans (PRONABEC) in the mode of PhD grants (Presidente de la República-183308). The authors are grateful to Eng. Andrea Oliveira from Prodipani, Portugal, for her kind advice and providing breadmaking ingredients.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Research involving human participants and/or animals

This article does not contain any studies with human or animal subjects.

Rights and permissions

About this article

Cite this article

Encina-Zelada, C.R., Cadavez, V., Monteiro, F. et al. Physicochemical and textural quality attributes of gluten-free bread formulated with guar gum. Eur Food Res Technol 245, 443–458 (2019). https://doi.org/10.1007/s00217-018-3176-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-018-3176-3