Abstract

Retrogradation kinetics of chestnut starches from three different regions of Korea were investigated during storage at 4 °C. The retrogradation properties were determined using four DSC characteristics: glass transition temperature (\( {\text{T}}_{\text{g}}^{\prime } \)), ice melting enthalpy (ΔHi), amylopectin melting enthalpy (∆Hr) and degree of retrogradation (DR). The Gongju (GJ) starch showed the highest gelatinization enthalpy (∆Hg) value, followed by Gwangyang (GY) and Hadong (HD). \( {\text{T}}_{\text{g}}^{\prime } \) of all samples gradually increased with increasing storage time, while ∆Hi decreased as the storage time increased. ∆Hr of all samples significantly increased after 2 days of storage. DR, calculated based on ∆Hg and ∆Hr, showed a similar tendency with ∆Hr. The retrogradation rates of three chestnut starches were analyzed using the Avrami equation, and the time constants (1/k) were obtained. GY, GJ and HD showed the fastest retrogradation rate in \( {\text{T}}_{\text{g}}^{\prime } \), ∆Hi, and ∆Hr, respectively suggesting that each sample experienced different retrogradation kinetics in different region.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Chestnut starch is used to make cookies, bread, and ‘mook’ (a traditional Korean food), among others [1,2,3]. Such products containing chestnut starch generally require a heating process such as baking, boiling or steaming. Thus, chestnut starch products are consumed after gelatinization and the retrogradation of starch during storage. China is the number one chestnut producing country in the world followed by Korea, and Gongju-si, Gwangyang-si, and Hadong-gun are the major chestnut cultivation regions. The consumption of chestnut is limited in Korea and it is important to find the potentials of chestnut starch to increase the industrial use of chestnut.

“Retrogradation” is the non-equilibrium thermoreversible recrystallization process of gelatinized starch involving three steps: nucleation, propagation and maturation [4]. Retrogradation is involved in the short-term recrystallization of amylose followed by the long-term recrystallization of amylopectin [5]. Retrogradation of starch occurs via two kinetically separable processes: (1) rapid gelation of amylose through the formation of double helical chain segments, followed by helix-helix aggregation, and (2) slow recrystallization of the amylopectin chains [6].

Crystallization of amorphous materials is kinetically controlled by the glass transition temperature (Tg). Tg is the second-order phase transition temperature where the glassy state is transformed into the rubbery state. Near the glass transition temperature, nucleation occurs, whereas propagation occurs at a higher temperature, up to melting [7]. In a frozen system, the glass transition temperature of the maximally freeze-concentrated state is called \( {\text{T}}_{\text{g}}^{\prime } \), where it is independent from the initial solute concentration [8, 9]. Similar to Tg, it cannot form crystals because the mobility of the molecules is restricted below \( {\text{T}}_{\text{g}}^{\prime } \), However, the rate of crystallization and free volume increases exponentially between the glass transition temperature and initial melting temperature of ice (\( {\text{T}}_{\text{m}}^{\prime } \)) [10, 11]. \( {\text{T}}_{\text{m}}^{\prime } \) corresponds to a temperature at which ice formation ceases as a result of kinetic limitations [12]. It has been reported that Tg’ and \( {\text{T}}_{\text{m}}^{\prime } \) occur simultaneously, such that the glass transition and initial ice melting are the same temperature [13]. Thus, Tg and \( {\text{T}}_{\text{g}}^{\prime } \) provide crucial information on the quality, stability, and optimum storage temperature of food systems. There have been many studies about the factors that affect retrogradation kinetics, such as the ratio of amylose/amylopectin, water content, origin of the starch, storage conditions, concentration of the gel and the various components [14,15,16]. Lipids, carbohydrates, salts, and proteins can also play a role in the starch retrogradation [17]. Recrystallization is influenced not only by the aggregation of amylopectin, which consists mainly of a double helix structure and crystalline regions in the granule, but also the glass transition of the amorphous regions. Recrystallization by complex constituents leads to starch retrogradation, which consequently suggests that the kinetics of starch retrogradation are time- and temperature-dependent. To determine the glass transition temperature and crystalline melting enthalpy, differential scanning calorimetry (DSC) is generally used.

Starch recrystallization and retrogradation play an important role in food industries because food degeneration can be associated with these processes, and they are consequently, related to food storage stability. Previous studies have reported the retrogradation and glass transition of commercial starches such as corn and rice starch. These works mainly reported the physicochemical changes of retrograded starch. However, there have only been a few studies related to the retrogradation kinetics of the crystal and amorphous regions in chestnut starch during storage. In this study, the changes in the crystalline region, freezable water and the amorphous region during storage were investigated by monitoring the glass transition temperature (\( {\text{T}}_{\text{g}}^{\prime } \)), ice melting enthalpy (∆Hi), amylopectin melting enthalpy (∆Hr) and degree of retrogradation (DR) of chestnut starches, respectively. The objective of this study is to investigate the retrogradation kinetics of these DSC transitions using the Avrami equation, considering the change and mobility of starch molecules in order to facilitate the use of chestnut starch. This information will be useful in future chestnut starch applications in various industries.

Materials and methods

Materials

Chestnuts were purchased from three different regions representing the most popular chestnut production areas in Korea: Gonju-si (GY), Gwangyang-si (GY), and Hadong-gun (HD). Chestnut starches were prepared according to Lee et al. [18] and Kim et al. [19], which isolated starches using a partially modified alkaline method. Sliced chestnut fruits were put in distilled water (1:3, w/v). After that, the chestnuts were ground using a mixer (Waring blender 38BL19, Waring commercial, New Hartford, NY, USA) and filtered through a 60-mesh sieve. Next, the slurry was washed out with a 0.2% NaOH solution to remove protein and was incubated at 25 °C for 24 h for precipitation. After the supernatant was removed, the precipitate was washed with distilled water repeatedly until a biuret reaction did not occur. Finally, the isolated chestnut starch was dried at room temperature and milled using a mortar, and then passed through a 100-mesh sieve.

Gelatinization and retrogradation properties

Gelatinization and retrogradation properties of chestnut starches were analyzed using a differential scanning calorimetry (DSC 4000, Perkin Elmer Inc., Waltham, MA, USA) calibrated with indium and zinc. A DSC thermogram was analyzed by Pyris software (version 11.1.0.04.88., Perkin Elmer., Inc., Waltham, MA, USA). Twenty milligrams of chestnut starch suspension (1:2, w/w, d.b.) was placed in an aluminum pan and hermetically sealed. The sealed empty aluminum was used as a reference. The sample was gelatinized by heating from 25 to 120 °C at 5 °C/min. The onset temperature (To), peak temperature (Tp), conclusion temperature (Tc) and gelatinization enthalpy (∆Hg) were obtained from the DSC thermogram curve using the method of Baik et al. [15].

The gelatinized DSC sample pans were stored for 0, 1, 2, 3, 4, 5, 6, 7, 10 and 14 days at 4 °C. After storage, samples were cooled down quickly to −70 °C using liquid nitrogen and reheated from −70 to 120 °C at a rate of 5 °C/min. Pans were re-weighed before and after the experiment to inspect whether water in the pan leaked during the heating and storing process. The glass transition temperature (\( {\text{T}}_{\text{g}}^{\prime } \)), ice melting enthalpy (∆Hi), and amylopectin melting enthalpy (∆Hr) were analyzed by the same method with gelatinization [15]. In addition, the degree of retrogradation (DR) was calculated using the following equation.\( {\text{T}}_{\text{g}}^{\prime } \)

Retrogradation kinetics

The Avrami equation has been widely used to detect the retrogradation rate of gelatinized starch or starch gel systems. Retrogradation kinetics of gelatinized chestnut starch were modeled using the following Avrami equation [14]

where θ is the region of uncrystallized material remaining after time t. EL, Et and E0 are \( {\text{T}}_{\text{g}}^{\prime } \), ∆Hi, ∆Hr and DR at 14 days, time t and day 0, respectively. k is the rate constant and n is the Avrami exponent.

Statistical analysis

All experiments were repeated at least three times. All data were expressed as the mean ± standard deviation (SD). Pearson’s correlation coefficient analysis and experimental data were analyzed using analysis of variance (ANOVA). Duncan’s multiple range test was used to assess significant differences among experimental mean values (p < 0.05). All statistical computations and analysis were conducted using SAS version 8.02 for Windows (SAS Institute, Inc., Cary, NC, USA).

Results and discussion

Gelatinization properties of chestnut starches

Gelatinization properties of chestnut starch samples are presented in Table 1. The endothermic transition temperatures (To, Tp and Tc) of all samples were observed between 59 and 72 °C. These endothermic transition temperatures were higher than chestnut starches isolated from var. Longal (To = 57.1 °C, Tp = 61.9 °C, Tc = 67.9 °C) [20] and C. mollisima B. (To = 55.0 °C, Tp = 62.9 °C, Tc = 67.6 °C) [21]. There was a significant difference (p < 0.05) in onset temperature between GY and the other two samples. The gelatinization temperature indicates the perfection of the double helical structure and extent of linking of the amylose or amylopectin micelles that were formed [22, 23]. GY had a more perfect double helical structure including crystals and stronger bonding within molecules, which required more energy to collapse the crystalline structure. The amylose content of starch was also correlated with the initial gelatinization temperature. When amylose-rich starch is gelatinized, more energy is required to melt it [5, 24]. According to the relationships between the chain-length distribution of amylopectin and gelatinization temperature were investigated [23, 25], the amount of unit chains with DP 6–10 had a negative correlation with gelatinization temperature because short chains were restricted to form a double helical structure.

Retrogradation properties of chestnut starches

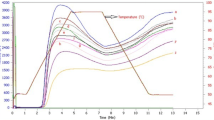

The changes of glass transition temperature (\( {\text{T}}_{\text{g}}^{\prime } \)), during storage at 4 °C are shown in Fig. 1(A). The initial glass transition temperature of GJ, GY, and HD was −7.43, −7.28 and −7.16 °C, respectively. As the storage time increased, the \( {\text{T}}_{\text{g}}^{\prime } \) of all samples gradually increased to around −6 °C. An increase of \( {\text{T}}_{\text{g}}^{\prime } \) during storage is possibly due to amylopectin recrystallization. After gelatinization, the starch gels were in an unstable state, and tended to shift to a more stable state during storage. Water molecules were incorporated into the crystal lattices of starch crystals during recrystallization. Consequently, the amount of freezable water and mobile water decreased, as the value of \( {\text{T}}_{\text{g}}^{\prime } \) increased [26, 27].

The differences of \( {\text{T}}_{\text{g}}^{\prime } \) during 14 days of storage (\( \Delta {\text{T}}_{\text{g}}^{\prime } \)) were 1.74, 1.41 and 1.23 °C for GJ, GY, and HD, respectively. The \( \Delta {\text{T}}_{\text{g}}^{\prime } \) of GJ during storage was the highest among the three samples followed by GY and HD. It has been previously reported that each of the starch samples have different amylose and amylopectin content [18]. Amylopectin in GJ may have greater ability to hold much more water inside the starch crystal, resulting in the biggest \( \Delta {\text{T}}_{\text{g}}^{\prime } \). Another possible explanation would be the inter-locking effects of the amorphous chains between the amylopectin branch and amylose phase.

Figure 1(B) shows the changes in ice melting enthalpy (∆Hi) during storage at 4 °C. ∆Hi suggests how much freezable water is in the water-starch system under freezing. ∆Hi decreased during storage at 4 °C for 2 weeks in all samples. GJ, GY and HD showed similar ∆Hi values on day 0; however, the degree of decrease was significantly different (p < 0.05) during storage. The decrease of ∆Hi during retrogradation is also due to the incorporation of water molecules into the starch crystal and matrix. A certain amount of free water changes to bound water during retrogradation resulting in an increase of the unfreezable water fraction and a decrease in ∆Hi [15].

As shown in Fig. 1(B), the ∆Hi of GY shows that freezable water transformed into unfreezable water from day 3 to day 6, while the transformation of GJ and HD happened on day 1 or 2. These differences might allow the crystals to form differently. The crystals that were formed more perfectly confined the freezable water firmly in lattices and restricted water mobility due to the hydrogen bonds. Furthermore, the extent and degree of the amorphous phase combined with the crystalline region can determine the amount of freezable water.

The changes in amylopectin melting enthalpy (∆Hr) and degree of retrogradation (DR) during storage at 4 °C are shown in Fig. 1(C) and 1(D), respectively. The ∆Hr and DR of chestnut starches retrograded at 4 °C exhibited similar trends with \( {\text{T}}_{\text{g}}^{\prime } \) [Fig. 1(C) and 1(D)]. Amylopectin retrogradation occurred over a long time due to the branched structure. Most recrystallization under 4 °C occurred during the first 2 days of storage. Particularly, GY showed a drastic increase from 0.76 to 5.30 J/g during the second day of storage. This can be regarded as the recrystallization of GY, which occurred briskly, followed by GJ and HD under 4 °C. After the second day of storage, retrogradation of all samples progressed continuously, but the rate was slow. The final ∆Hr of GJ, GY and HD were 8.28 J/g, 8.09 J/g and 8.07 J/g, respectively. These values are similar to the results of Xing Zhou et al. [7] and Y. Vodovotz et al. [8]. In case of HD, ∆Hr on day 1 was significantly lower (p < 0.05) than GJ and GY. Imperfect crystals were formed during day 1, resulting in relatively lower ∆Hr compared to those of GJ and GY. However, as storage time progressed, HD also developed stable crystallites like the other two samples.

The amylopectin melting enthalpy was typically affected by moisture content and temperature. Commonly, the retrogradation was not shown when the moisture content was below 20% and above 90%. With low moisture content, the mobility of molecules was restricted, thereby inhibiting crystallization; however, with high moisture content, there were dilute effects and the molecules had no chance to re-aggregate. According to several studies, the maximum enthalpy was obtained at 50–60% moisture content and bell-shaped curves were exhibited by plotting enthalpy against moisture [28, 29]. The typical temperature conditions for storage were at 4, 25, 30 or 40 °C, along with temperature cycling. At 4 °C, the mobility of molecules was processed more actively than at other temperatures, so the recrystallization of amylopectin was faster. Under temperature cycling of 4 and 30 °C, the DSC thermograms of the starch showed narrower peaks and higher melting onset temperatures relative to the starch stored at a constant temperature of 4 °C. During temperature cycling, more homogeneous crystallites were formed because at 30 °C, unstable crystallites might be melted, reformed, and enhanced by the propagation step [7, 15].

Furthermore, some authors have focused on the effects of the amylopectin unit-chain length distribution [10, 30, 31]. According to Vandeputte et al., an amylopectin chain with DP 6–9 and DP > 25 restrained amylopectin retrogradation. On the contrary, chain lengths with DP 12–22 showed a positive correlation with amylopectin recrystallization [31]. Based on this result, it was estimated that GY might have relatively more amylopectin with chain lengths of DP 6–9 and DP > 25. However, there are also large uncertainties because the thermal behavior of starch is much more complex, involving steps such as melting, glass transition, and granule structure.

DR is often calculated as the ratio of ∆Hr to ∆Hg [Fig. 1(D)]. The DR of all samples had similar value on day 0; however, HD had the highest value followed by GY and GJ. Although the DR value of HD and GY were shown to be nearly 70%, that of GJ finished below 50% on day 14. The DR of GJ was most likely influenced by the relatively high ∆Hg value. Additionally, it is possible that the degree of starch retrogradation was affected by the botanical origin of the starch and amylose/amylopectin molecules [32, 33].

Retrogradation kinetics

The change in \( {\text{T}}_{\text{g}}^{\prime } \), ∆Hi, ∆Hr and DR within the first five days of storage, which had an exponentially linear relationship with time, can be analyzed using the Avrami equation, and the results are shown in Fig. 2A. The Avrami exponents (n) of chestnut starch gels obtained by plotting log[-ln{(EL − Et)/(EL − E0)}] against the log of time were close to 1.0.

As shown in Table 2, Avrami exponents (n) and time constants (1/k) of all chestnut starches during storage at 4 °C for 5 days were observed. The n value indicates the mode of crystalline. Values between 1.0 and 2.0 indicate that crystalline development is rod-like with instantaneous and sporadic nucleation. According to Mclver et al., for sporadic nucleation, more rapid cooling will lead to more nuclei being formed during the cooling period [34]. For \( {\text{T}}_{\text{g}}^{\prime } \) and ∆Hi, the Avrami exponent (n) of GJ and GY were in the range of 1.55–1.99, indicating rod-like growth from instantaneous and sporadic nucleation. On the other hand, the Avrami exponent of HD in ∆Hi were shown to be 0.42, indicating that the crystallites of HD were not yet perfect to determine the crystallization mode after 5 days.

Assuming that the Avrami exponent is 1.0, the rate constant 1/k can be determined from the plot of ln(EL − Et) versus storage time (Fig. 2B). At \( {\text{T}}_{\text{g}}^{\prime } \), GY (4.8) had the fastest retrogradation kinetic (1/k), followed by HD (5.94) and GJ (6.42). Considering this result, molecules in GY were more unstable and had more translational mobility under the isothermal 4 °C While GJ had the fastest retrogradation kinetic in ∆Hi, it indicated that freezable water in the granules was used to incorporate crystalline the most in GJ. In cases of ∆Hr and DR, the retrogradation rate of HD was fastest. Because HD had large amounts of amylopectin, it recrystallized easily, connecting the branched structure more easily. Another explanation is the chain-folded polymer model by Lauritzen and Hoffman et al. [35]. In chain-folded polymers, the crystalline regions are made up of lamellae, where the chains are placed in adjacent positions, perpendicular to the surface of the lamellae. The reason for the difference in retrogradation kinetics in the respective chestnut starch gels might be attributed to the complexity of the thermal behavior of starches during heating. Presumably, there are differences in the major elements involved in retrogradation in each phase that are expected to have multiple interactions, such as starch-lipid interaction.

Correlation analysis

The results of the Pearson correlations between \( {\text{T}}_{\text{g}}^{\prime } \), ∆Hi, ∆Hr and DR of the chestnut starches cultivated in three different regions are shown in Table 3. The \( {\text{T}}_{\text{g}}^{\prime } \) value was negatively correlated with ∆Hi. It can be supposed that changes in the amount of freezable water influenced not only \( {\text{T}}_{\text{g}}^{\prime } \), but also ∆Hi. As the free water was incorporated into the crystalline lattices, the \( {\text{T}}_{\text{g}}^{\prime } \) increased, whereas ∆Hi decreased as the freezable water was reduced.

In the correlation between \( {\text{T}}_{\text{g}}^{\prime } \) and ∆Hr, HD was shown to have a high value, indicating a good correlation (0.9192), while GJ (0.7769) and GY (0.7904) had low values. These results indicate that the molecules of both amorphous and crystalline regions in HD had a tendency to shift more towards a stable state during storage at 4 °C than those of GJ and GY. ∆Hi was shown to have relatively poor correlation with ∆Hr. The values of HD and GJ were found to be -0.8295 and -0.8843, respectively, and GY had a correlation coefficient of -0.7246, the lowest value. ∆Hr and DR had a good correlation, with values above 0.99. The value of ∆Hr is reflected in the DR, because DR was calculated using ∆Hr. Although GJ and GY are the same okkwang cultivar, there was a significant difference in the correlation of ∆Hi and ∆Hr. This result suggests that properties of amylose and amylopectin were affected by the cultivation area and environmental conditions such as growth temperature, day-length, rainfall, soil composition, and so on.

In this study, there was a significant difference in the ∆Hg of chestnut starches, largely influenced by various factors such as granule size and perfection of the crystal structure. According to the properties of starch retrogradation, \( {\text{T}}_{\text{g}}^{\prime } \), ∆Hr and DR were shown to increase gradually, while ∆Hi was shown to decrease during storage. The results of the retrogradation rate of GJ, GY and HD in four transition phases were shown to be inconsistent. The different measuring standards were applied in \( {\text{T}}_{\text{g}}^{\prime } \) (amorphous area), ∆Hi (freezable water), ∆Hr (crystalline area) and DR (the relative ration of ∆Hg and ∆Hr). Thus, these characteristics were independent and interdependent on one another in terms of the retrogradation. There was especially good correlation between \( {\text{T}}_{\text{g}}^{\prime } \) and ∆Hi, suggesting that the amount of freezable and unfreezable water influenced the glass transition and ice formation of chestnut starch gels. Although all starch gels were stored in the same temperature and period, GJ had the lowest degree of retrogradation compared to GY and HD. The chestnut starch gels showed variation in recrystallization due to differences in variety and cultivation area.

References

Shao Ying, Wei, Zongfeng (2009) Effect of chestnut powder on bake quality and anti-aging of bread. J. China Brewing. 9, 044

Joo SY., Antioxidant activity and quality characteristics of chestnut cookies. J. Korean Soc. Food Cult. 28: 70–77 (2013)

Kim SK, Jeon YJ, Lee BJ, Kim YT, Kang OJ, Sensory evaluation and retrogradation properties of chestnut mook. J. Korean Soc. Food Sci. Nutr. 24: 601–605 (1995).

Slade L, Levine H. Recent advances in starch retrogradation. Industrial polysaccharides. 387–430 (1987)

Ronda F, Roos YH., Gelatinization and freeze-concentration effects on recrystallization in corn and potato starch gels. Carbohyd Res. 343: 903–911 (2008)

Orford PD, Ring SG. Carroll V, Miles MJ, Morris VJ. The effect of concentration and botanical source on the gelation and retrogradation of starch. J. Sci. Food Agr. 39: 169–177 (1987)

Zhou X, Baik BK, Wang R, Lim ST. Retrogradation of waxy and normal corn starch gels by temperature cycling. J. Cereal Sci. 51: 57–65 (2010)

Vodovotz Y, Chinachoti P. Glassy-rubbery transition and recrystallization during aging of wheat starch gels. J. Agric Food Chem. 46: 446–453 (1998)

Tananuwong K, Reid DS. Differential scanning calorimetry study of glass transition in frozen starch gels. J Agric Food Chem. 52: 4308–4317 (2004)

Silverio J, Fredriksson H, Andersson R, Eliasson AC, Åman P. The effect of temperature cycling on the amylopectin retrogradation of starches with different amylopectin unit-chain length distribution. Carbohyd Polym. 42: 175–184 (2000)

Slade L, Levine H. A food polymer science approach to selected aspects of starch gelatinization and retrogradation. Frontiers in carbohydrate research. 1: 215–270 (1989)

Roos Y, Karel M. Amorphous state and delayed ice formation in sucrose solutions. Int. J. Food Sci. Tech. 26, 553–566 (1991)

Roos Y, Karel M. Water and molecular weight effects on glass transitions in amorphous carbohydrates and carbohydrate solutions. J. Food Sci. 56: 1676–1681 (1991)

Jouppila K, Kansikas J, Roos Y. Factors affecting crystallization and crystallization kinetics in amorphous corn starch. Carbohydr Polym. 36: 143–149 (1998)

Baik MY, Kim KJ, Cheon KC, Ha YC, Kim WS. Recrystallization kinetics and glass transition of rice starch gel system. J. Agric. Food Chem. 45: 4242–4248 (1997)

Germani R, Ciacco CF, Rodriguez‐Amaya DB. Effect of sugars, lipids and type of starch on the mode and kinetics of retrogradation of concentrated corn starch gels. Starch‐Stärke. 35, 377–381(1983)

Wang S, Li C, Copeland L, Niu Q, Wang S. Starch Retrogradation: A Comprehensive Review. Compr. Rev. Food Sci. F. 14, 568–585 (2015)

Lee JW, Choi HW, Seo DH, Park JD, Kum JS, Kim BY, Baik MY (2015) Isolation and characterization of starches from chestnuts cultivated in three regions of Korea. Starch-Stärke 67: 585–594

Kim YD, Choi OJ, Shim KH, Cho IK. Physicochemical properties of chestnut starch according to the processing method. J. Korean Soc. Food Sci. Nutr. 35: 366–372 (2006)

Cruz BR, Abraão AS, Lemos AM, Nunes FM. Chemical composition and functional properties of native chestnut starch (Castanea sativa Mill). Carbohydr Polym. 94: 594–602 (2013)

Zhang W, Chen H, Wang J, Wang Y, Xing L, Zhang H. Physicochemical properties of three starches derived from potato, chestnut, and yam as affected by freeze‐thaw treatment. Starch‐Stärke. 66: 353–360 (2014)

Okechukwu PE, Anandha Rao M. Kinetics of cowpea starch gelatinization based on granule swelling. Starch‐Stärke. 48: 43–47 (1996)

Kitahara K, Fukunaga S, Katayama K, Takahata Y, Nkazawa Y, Yoshinaga M, Suganuma T. Physicochemical properties of sweetpotato starches with different gelatinization temperatures. Starch‐Stärke, 57: 473–479 (2005)

Singh N, Singh J, Kaur L, Sodhi NS, Gill BS. Morphological, thermal and rheological properties of starches from different botanical sources. Food Chem. 81: 219–231 (2003)

Noda T, Takahata Y, Sato T, Suda I, Yamakawa O. Relationships between chain length distribution of amylopectin and gelatinization properties within the same botanical origin for sweet potato and buckwheat. Carbohydr Polym. 37: 153–158 (1998)

Ablett AH. Studies of the glass transition in malto-oligomers. The glassy state in foods 1992.

Whittam M, Noel T, Ring S, Melting behaviour of A-and B-type crystalline starch. Int. J. Biol. Macromol. 12: 359–362 (1990)

Jang J, Pyun Y, Effect of moisture level on the crystallinity of wheat starch aged at different temperatures. Starch‐Stärke. 49: 272–277 (1997)

Longton J, LeGrys G. Differential scanning calorimetry studies on the crystallinity of ageing wheat starch gels. Starch‐Stärke. 33: 410–414 (1981)

Kohyama K, Matsuki J, Yasui T, Sasaki T. A differential thermal analysis of the gelatinization and retrogradation of wheat starches with different amylopectin chain lengths. Carbohydr Polym. 58: 71–77 (2004)

Vandeputte G, Vermeylen R, Geeroms J, Delcour J. Rice starches. III. Structural aspects provide insight in amylopectin retrogradation properties and gel texture. J. Cereal Sci. 38: 61–68 (2003)

Fredriksson H, Silverio J, Andersson R, Eliasson, AC, Åman P. The influence of amylose and amylopectin characteristics on gelatinization and retrogradation properties of different starches. Carbohydr Polym. 35: 119–134 (1998)

Varavinit S, Shobsngob S, Varanyanond W, Chinachoti P., Naivikul, O., Effect of amylose content on gelatinization, retrogradation and pasting properties of flours from different cultivars of Thai rice. Starch‐Stärke. 55: 410–415 (2003)

McIver RG, Axford DWE, Colwell KH, Elton GAH. Kinetic study of the retrogradation of gelatinised starch. J. Sci. Food Agric. 19: 560–563 (1968)

Lauritzen Jr JI, Hoffman JD. Extension of theory of growth of chain‐folded polymer crystals to large undercoolings. J. Appl. Phys. 44: 4340–4352 (1973)

Acknowledgement

This research was supported by Main Research Program (E0164800-02) of the Korea Food Research Institute (KFRI) funded by the Ministry of Science, ICT & Future Planning.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Oh, SM., Choi, HW., Kim, BY. et al. Retrogradation kinetics of chestnut starches cultivated in three regions of Korea. Food Sci Biotechnol 26, 663–670 (2017). https://doi.org/10.1007/s10068-017-0103-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10068-017-0103-5