Abstract

The requirements for the production of optimized Zea mays transglutaminase (TGZo) using Pichia pastoris GS115 (pPIC9K-tgzo) were optimized in this study. Plackett–Burman design was used to screen variables that significantly influence TGZo production. Oleic acid, methanol, and loading volume were identified as the most significant parameters. Central composite design was employed to determine the optimal level of these three parameters for TGZo production. Results showed that 1078 mU/mL of TGZo activity and 7.6 mg/L of TGZo production were obtained under conditions of 0.07% oleic acid, 1.31% methanol, and 7.36% loading volume. To explore the functional characteristics of TGZo, it was used in yogurt. It was found that the addition of TGZo could produce yogurt with stronger acid gel and higher consistency, cohesiveness, index of viscosity, and apparent viscosity than the untreated product. Therefore, TGZo can be used as a substitute for microbial transglutaminase in the yogurt, even in the food industry.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Transglutaminase (TGase, protein-glutamine γ-glutamyltransferase, EC 2.3.2.13) is a transferase that catalyzes the acyl transfer reaction between the γ-carboxamide group in glutamine residues and various primary amines in polyamine [1]. This enzyme is widely used in the food industry. Cross-linking in proteins by TGase leads to the change of protein functionalities such as water-holding capacity, solubility, gelation property, emulsifying capacity, and nutritional value [2]. Guinea pig liver TGase (GTG) was the first TGase used in food to enhance texture, but GTG required Ca2+ for its activation, which led to protein precipitation in some foods containing casein, soybean globulin, or myosin [3]. In addition, the scarce source as well as the extensive purification procedure led to the search for alternative microbiological sources such as Streptoverticillium sp., Streptomyces sp., Bacillus subtilis, Candida albicans, and other organisms [4]. Microbial transglutaminase (MTG) is Ca2+ independent and shows lower substrate specificity as compared to animal TGase. Because of these advantages and low cost of production by fermentation technology, MTG from S. mobaraensis is commercially available and mostly used as an efficient cross-linking enzyme in the food industry.

Because of the difficulties in separation and purification, the research of plant TGase is far behind that of other species. The activity of plant TGase was first observed in pea seedlings in 1987 [5]. Plant TGase has its own unique characteristics. The molecular weight of TGase is different in plants, ranging from 39 to 80 kDa [6,7,8,9]. Ca2+ addition seems to be unnecessary as it sometimes enhances the TGase activity; however, at a relatively high concentration, it becomes an inhibitor [6,7,8,9,10]. Plant TGase has the same substrate-specific site as animal TGase and MTG, such as pepsin, fibrinogen, and insulin. However, it could also recognize some specific-substrate sites that have not been described for TGase from other sources, such as cellulase, creatine kinase, apoproteins of the antenna complex, and rubisco [5, 7].

The research on plant TGase has been hampered by their complicated separation and purification procedures from natural sources and by the lack of deoxyribonucleic acid and amino acid sequences as reported in the available databases. Till date, only two recombinant plant TGases, AtPng1p from Arabidopsis thaliana [11] and Zea mays transglutaminase (TGZ) from maize [12], have been reported, and the research has primarily focused on recombinant maize TGase. We expressed Zea mays transglutaminase gene (tgz) in Escherichia coli and P. pastoris, wherein the yield of TGZ was 1.41 [13] and 1.44 mg/L [14], respectively. We further optimized the tgz gene using SOEing-PCR according to the codon bias of P. pastoris, and the yield of TGZ achieved was 4.4 mg/L [15]. The characterization of TGZo was studied and the result showed that TGZo had higher thermostability and wider range of pH than MTG from S. mobaraensis and S. hygroscopicus [16]. These results indicated that TGZo is suitable for food processing.

The fermentation conditions of recombinant P. pastoris were found to have great influence on the production of heterologous proteins [17]. However, the conventional single-parameter optimization methods often fail to determine the optimal conditions of protein production. Owing to the interaction of various factors that are ignored [18], an effective method is needed to resolve this problem. Plackett–Burman (P–B) design and the response surface methodology (RSM) are efficient ways to optimize all variable parameters and thus eliminate the drawbacks of traditional methods. P–B design can identify the significant factors among several variable parameters [19]. Moreover, RSM, including regression analysis, can build models to study the mutual interactions between factors and determine the optimal condition of variables [20]. This method had been successfully employed for the optimization of multiple variables in many bioprocesses [21].

The cross-linking effect of MTG on milk protein has been widely studied. It was reported that the addition of MTG could improve the viscosity, hardness, gel strength, and stability of yogurt [22]. Moreover, because of the establishment of ε-(γ-glutamyl) lysine links, the syneresis of yogurt was reduced, a smooth surface was formed, and the quality of yogurt was improved [23]. The aim of this study was to improve the production of TGZo and research the influence of this plant TGase on the properties of set-style yogurt. In this study, first the fermentation factors for the expression of TGZo in P. pastoris GS115 were optimized using P–B design and central composite design (CCD). Then, the purified TGZo was added into milk yogurt and the physicochemical quality attributes were compared with those of MTG.

Materials and methods

Materials

The cow milk was purchased from Mengniu (Harbin, China). Milk fat and protein content were 3.7 and 3.0%, respectively. A probiotic yogurt starter (Yo-Mix 161 LYO 375 DCU) was obtained from Danisco (Beijing, China). MTG was extracted from S. mobaraensis DSM40587 and the specific activity was 2.9 U/mg [24].

Microorganism, medium, and culture

Recombinant strain P. pastoris GS115 (pPIC9K-tgzo) (his+mut+) was stored in 20% glycerol at −80 °C [15]. The recombinant strain was grown in a BMGY medium at 30 °C for 24 h as the growth phase. The cells were then induced in the BMMY medium for 96 h at 28 °C. Further, 0.5% methanol was added to the BMMY medium every 24 h to sustain the methanol level. After centrifugation, supernatants were harvested as crude TGZo.

BMGY: 1% yeast extract, 1% glycerol, 1.34% YNB, 2% peptone, 4 × 10−5% biotin, and 100 mmol/L phosphate buffer, pH 6.0. BMMY: 1% yeast extract, 1.34% YNB, 2% peptone, 0.5% methanol, 4 × 10−5% biotin, and 100 mmol/L phosphate buffer, pH 6.0. Metal ions: CuSO4·5H2O 6 g/L, FeSO4·6H2O 0.65 g/L, H3BO3 0.02 g/L, ZnCl2 3 g/L, MnSO4·7H2O 3 g/L, KI 0.09 g/L, and CoSO4 0.5 g/L.

Enzyme activity assay

The activity of recombinant TGZo was determined by a colorimetric method [25] with modifications. The reaction mixture including 50 μL buffer (0.04 mol/L N-CBZ-Gln-Gly, 0.04 mol/L NaOH, 0.08 mol/L Tris–HCl buffer (pH 8.0), 0.02 mol/L hydroxylamine, and 0.002 mol/L GSH) and 50 μL enzyme solution were incubated for 10 min at 37 °C. Then, the absorbance at 525 nm was measured using a microplate reader (BioTek, USA) after adding 50 μL stop solution (3 mol/L HCl, 0.7 mol/L trichloroacetic acid, and 0.2 mol/L FeCl3·6H2O) to terminate the reaction. One unit of activity was defined as the amount of TGase that caused the formation of 1 μmol hydroxamic acid at 37 °C per min. Protein concentrations were calculated using a Bradford Protein Assay Kit (Beyotime, Shanghai, China) and bovine serum albumin was used as a standard.

Plackett–Burman design

In this study, fermentation conditions including induction time, initial pH, methanol concentration, biomass, loading volume, metal ions, and oleic acid were studied using P–B design to confirm the variables that significantly influenced TGZo production. Each factor was tested at a low level (−1) and a high level (+1). The values of −1 and +1 were chosen according to a single-factor experimental result (data not shown). Table 1 shows the variables and their corresponding values used in the experiment. The eleven factors including four dummy variables to calculate the standard error were evaluated in twelve experimental trials (Table 2). Results of regression analysis showed that the variables with confidence levels above 95% had a significant influence on TGZo production; thus, these variables were used for CCD. The first-order model of P–B design is as follows:

where Y is the response (TGZo activity), β 0 is the intercept, β i is the linear coefficient, χ i is the value of the variable, and k is the number of input variables.

Path of steepest ascent

The direction of steepest ascent is determined via TGZo production by decreasing or increasing the values of significant factors. The base point was initiated from the center of the P–B design. The steepest ascent path was performed until the TGZo production did not increase further.

Response surface methodology

A CCD of RSM with three factors and five levels (Table 3) was used to further determine the values of oleic acid, methanol, and loading volume. The 20 experiments conducted in this study are shown in Table 3. A second-order model used to fit the response to the independent variables is shown in Eq. 2:

where Y is the predicted response (TGZo activity), β 0 is the intercept, β i is the linear effect, χ i and χ j are independent variables, β ii is the quadratic effect, β jj is the interaction between χ i and χ j , and k is the number of variables.

Cross-linking effect of TGZo on milk yogurt

The cow milk was pasteurized at 95 °C for 5 min. Then, milk samples were rapidly cooled to 42 °C in ice water. TGZo was added at different concentrations (0, 0.25, 0.5, and 1 U/g protein for milk) and MTG was a positive control. The samples were then inoculated with 0.04% probiotic yogurt starter culture (YO-MIXTM, Yoghurt Cultures, Yo-Mix 161 LYO 375 DCU, Danisco, Beijing, China). The samples were incubated at 42 °C for about 3.5 h until the pH reached 4.6, then the yogurt was cooled and placed at 4 °C for 2 days. The yogurt-added TGZo and MTG were examined for physicochemical characteristics including texture, apparent viscosity, and syneresis. Texture and apparent viscosity were analyzed according to the method of Li et al. [15]. Syneresis was determined using the method described by Farnsworth et al. [26].

Data analysis

Experimental design and regression analysis were conducted using Design-Expert.V8.0.6 (Stat-Ease Inc., Minneapolis, USA). SPSS 14.0 was chosen for statistical analyses and Duncan’s post-test was used for the analysis of variance (ANOVA).

Result and discussion

Plackett–Burman design

P–B design is an efficient method to screen ignificant variables among a large number of factors [27]. Eleven factors (including four dummy variables) were analyzed to select the significant variables that affect TGZo production. TGZo activity changed extensively from 80.73 to 718.75 mU/mL (Table 2). Based on the statistical analysis, a first-order model was obtained from the P–B analysis result:

The coefficient R2 of this model was 0.9890, indicating that this model could explain 98.9% variability in the response. Because the contribution of biomass for TGZo production was low (only 0.046), this factor was neglected when analyzed by ANOVA. The analysis result indicated that oleic acid, methanol, and loading volume have the greatest impact on TGZo production (Table 1).

In the P. pastoris expression system, methanol is known as an inducer for the expression of heterologous proteins. Moreover, it is also utilized as a carbon source for the growth of P. pastoris. Methanol and oxygen molecules are required in the medium for the expression of alcohol oxidase 1 promoter in the peroxisome [28].

Peroxisome is a central metabolism organelle that can utilize methanol as a carbon source for P. pastoris growth [29]. The formation of peroxisome in methylotropic yeast is influenced by the carbon source and other culture conditions [30]. Moreover, oleic acid is a kind of carbon source that can induce the formation of peroxisome [31]; therefore, we chose oleic acid and methanol as a co-carbon source in the induction phase of P. pastoris. In the anabolism and catabolism of P. pastoris, methanol is a substrate with high oxygen demand; therefore, the oxygen concentration somehow affects the productivity of the target protein. Oxygen limitation negatively affects the expression of target genes, and its level is found to be a critical parameter for high cell density and protein production [32]. Liquid in the Erlenmeyer flask was shaken on the shaker generated a gas–liquid mixing and dispersion, which effectively dissolved oxygen in the air. The liquid volume had a direct relationship with the dissolved oxygen concentration and was found to be a significant factor that affected TGZo production in this experiment. Therefore, oleic acid, methanol, and loading volume were chosen for the next optimization to achieve maximum TGZo production.

Path of steepest ascent

P–B design results showed that the effects of oleic acid, methanol, and loading volume were negative, thus decreasing the level of these variables and resulting in higher TGZo production. The origin of the path was considered as the center point of the P–B design. It was found that the highest TGZo activity was 952.38 mU/mL, whereas the significant variables were oleic acid 0.07%, methanol 1.4%, and loading volume 8%. Therefore, this point was chosen for CCD.

Response surface methodology

Based on the above results, CCD was employed to determine the optimum values of three independent factors (oleic acid, methanol, and loading volume). The five coded levels of three parameters and TGZo activity as response values are shown in Table 3. By multiple regression analysis, the second-order polynomial equation for TGZo production was built and shown as below:

where Y is the predicted TGZo activity, X1 is oleic acid, X2 is methanol, and X3 is the loading volume.

According to the analysis, the F-value of this model was 151.65, and the lack of fit F-value was 16.61. These results indicated that the experimental data were all in good agreement with the theoretical model. The p value (p < 0.0001) and lack of fit (0.0039) also supported this result. The coefficient of determination R2 was used to check the quadratic regression equations. The value of R2 was 0.9927, indicating that this model could explain 99.27% variability in the response. This value implied that the accuracy and general ability of this second-order model was good. The values of adjusted determination coefficient (Adj R2 = 0.9862) and predicted determination coefficient (R2 = 0.9428) also confirmed the accuracy of this polynomial model. The coefficient variation was 7.41%, indicating that this fermented experiment was highly credible.

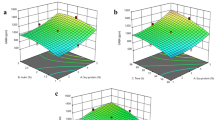

Response surface curves are plotted to calculate the value of each independent factor for maximum response and to explain the relation of the factors. Three-dimensional response surface curves are shown in Fig. 1. Each figure presents the interaction between the two variables while the other variable was set to zero level. The results predicted by this model indicated that the maximum value of TGZo production could be obtained when the oleic acid, methanol, and loading volume were 0.07, 1.31, and 7.36%, respectively. The maximum predicted TGZo activity was 1029 mU/mL.

To validate the adequacy of the above results, three independent experiments were conducted using the predicted optimal conditions. The activity of TGZo was 1078 ± 6.55 mU/mL, which is consistent with the predicted value. This result demonstrated the accuracy and reliability of the response model. After purification, TGZo production was 7.6 mg/L, which was 73% higher than the production before optimization [15].

Cross-linking effect of TGZo on milk yogurt

To estimate the effect of TGZo on the functional properties of yogurt, MTG was chosen as a positive control. TGZo and MTG were added to the cow milk and some physicochemical characteristics of yogurt were evaluated through texture analysis, apparent viscosity, and syneresis.

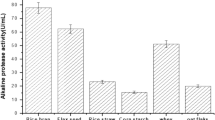

Texture analysis is a significant way to estimate the quality of yogurt. Its evaluation parameters include four parts (firmness, consistency, cohesiveness, and index of viscosity). The results of texture analysis are shown in Table 4. The four evaluation indicators of yogurt catalyzed by TGZo were significantly higher than the sample without the enzyme. This increase may be due to the formation of ε-(γ-glutamyl) lysine bonds catalyzed by TGZo [33], and these covalently cross-linked polymers stabilized the yogurt gel network [34]. However, the effect of TGZo on milk yogurt was lower as compared with that of MTG (Table 4). This may be related to the characterization of TGZo. The thermostability of TGZo and MTG is similar, but TGZo has considerably lower activity and stability in acid condition compared with MTG [15, 16].

According to Fig. 2(A), the apparent viscosity of yogurt increased with the addition of TGZo and MTG. Moreover, the effect of these two enzymes was similar when milk was treated with 0.25–0.5 U/g TGZo or MTG protein. However, the value of MTG-catalyzed yogurt was significantly improved by the addition of 1 U/g protein. Similar results were found by texture analysis (Table 4). Owing to the enzymatic cross-linking effect of milk protein, the strength of the gel resistance to breaking was increased.

Syneresis is a familiar phenomenon in yogurt. It refers to whey separation and gel shrinkage, and TGase is used to prevent yogurt syneresis. Syneresis of yogurt catalyzed by two enzymes was lower than that of control samples (Fig. 2B). Syneresis of TGZo-treated yogurt increased slightly as compared to that of the sample catalyzed by MTG with 0.25–0.5 U/g protein, which was inconsistent with the previous report [16]. This may be attributed to the addition of metal ions and oleic acid in the expression, which changed the catalytic properties of TGZo. However, two samples treated with different enzymes had similar syneresis at 1 U/g protein.

References

Lorand L, Graham RM. Transglutaminases: crosslinking enzymes with pleiotropic functions. Nat. Rev. Mol. Cell Biol. 4: 140–156 (2003)

Kieliszek M, Misiewicz A. Microbial transglutaminase and its application in the food industry. A review. Folia Microbiol. 59: 241–250 (2014)

Jaros D, Partschefeld C, Henle T, Rohm H. Transglutaminase in dairy products: chemistry, physics, applications. J. Texture Stud. 37: 113–155 (2006)

Lin YS, Chao ML, Liu CH, Chu WS. Cloning and expression of the transglutaminase gene from Streptoverticillium ladakanum in Streptomyces lividans. Process Biochem. 39: 591–598 (2004)

Icekson I, Apelbaum A. Evidence for transglutaminase activity in plant tissue. Plant Physiol. 84: 972–974 (1987)

Kang H, Cho YD. Purification and properties of transglutaminase from soybean (Glycine max) leaves. Biochem. Biophys. Res. Commun. 223: 288–292 (1996)

Margosiak SA, Dharma A, Bruce-Carver MR, Gonzales AP, Louie D, Kuehn GD. Identification of the large subunit of ribulose 1, 5-bisphosphate carboxylase/oxygenase as a substrate for transglutaminase in Medicago sativa L.(Alfalfa). Plant Physiol. 92: 88–96 (1990)

Serafini-Fracassini D, Del Duca S, Beninati S. Plant transglutaminases. Phytochemistry. 40: 355–365 (1995)

Villalobos E, Santos M, Talavera D, Rodrıguez-Falcón M, Torné J. Molecular cloning and characterization of a maize transglutaminase complementary DNA. Gene. 336: 93–104 (2004)

Signorini M, Beninati S, Bergamini CM. Identification of transglutaminase activity in the leaves of silver beet (Beta vulgaris L.). J. Plant Physiol. 137: 547–552 (1991)

Della Mea M, Caparrós-Ruiz D, Claparols I, Serafini-Fracassini D, Rigau J. AtPng1p. The first plant transglutaminase. Plant Physiol. 135: 2046–2054 (2004)

Carvajal P, Gibert J, Campos N, Lopera O, Barberà E, Torné JM, Santos M. Activity of maize transglutaminase overexpressed in Escherichia coli inclusion bodies: An alternative to protein refolding. Biotechnol. Prog. 27: 232–240 (2011)

Li H, Cui Y, Zhang L, Luo X, Fan R, Xue C, Wang S, Liu W, Zhang S, Jiao Y, Du M, Yi H, Han X. Production of a transglutaminase from Zea mays in Escherichia coli and its impact on yoghurt properties. Int. J. Dairy Technol. 68: 54–61 (2015)

Li H, Cui Y, Zhang L, Yi H, Han X, Jiao Y, Du M, Fan R, Zhang S. Heterologous expression and purification of Zea mays transglutaminase in Pichia pastoris. Food Sci. and Biotech. 23: 1507–1513 (2014)

Li H, Zhang L, Cui Y, Luo X, Xue C, Wang S. Expression of soluble recombinant transglutaminase from Zea mays in Pichia pastoris. World J. Microb. Biot. 29: 939–947 (2013)

Li H, Zhang L, Cui Y, Luo X, Xue C, Wang S, Jiao Y, Zhang S, Liu W, Fan R. Characterization of recombinant Zea mays transglutaminase expressed in Pichia pastoris and its impact on full and non-fat yoghurts. J. Sci. Food Agric. 94: 1225–1230 (2014)

Huang H, Yang P, Luo H, Tang H, Shao N, Yuan T, Wang Y, Bai Y, Yao B. High-level expression of a truncated 1, 3-1, 4-β-D-glucanase from Fibrobacter succinogenes in Pichia pastoris by optimization of codons and fermentation. Appl. Microbiol. Biotechnol. 78: 95–103 (2008)

Liu S, Fang Y, Lv M, Wang S, Chen L. Optimization of the production of organic solvent-stable protease by Bacillus sphaericus DS11 with response surface methodology. Bioresource Technol. 101: 7924–7929 (2010)

Kim HS, Lee AY, Jo JE, Moon BC, Chun JM, Choi G, Kim HK. Optimization of ultrasound-assisted extraction of quercitrin from Houttuynia cordata Thunb. using respon sesurface methodology and UPLC analysis. Food Sci. Biotechnol. 23: 1–7 (2014)

Patil SA, Surwase SN, Jadhav SB, Jadhav JP. Optimization of medium using response surface methodology for L-DOPA production by Pseudomonas sp. SSA. Biochem. Eng. J. 74: 36–45 (2013)

Roukas T, Niavi P, Kotzekidou P. A new medium for spore production of Blakeslea trispora using response surface methodology. World J. Microb. Biot. 27: 307–317 (2011)

22. Şanlı T, Sezgin E, Deveci O, Şenel E, Benli M. Effect of using transglutaminase on physical, chemical and sensory properties of set-type yoghurt. Food Hydrocolloid. 25: 1477–1481 (2011)

Yüksel Z, Erdem Y. The influence of transglutaminase treatment on functional properties of set yoghurt. Int. J. Dairy Technol. 63: 86–97 (2010)

Zhang L, Zhang L, Yi H, Du M, Ma C, Han X, Feng Z, Jiao Y, Zhang Y. Enzymatic characterization of transglutaminase from Streptomyces mobaraensis DSM 40587 in high salt and effect of enzymatic cross-linking of yak milk proteins on functional properties of stirred yogurt. J. Dairy Sci. 95: 3559–3568 (2012)

Grossowicz N, Wainfan E, Borek E, Waelsch H. The enzymatic formation of hydroxamic acids from glutamine and asparagine. J. Biol. Chem. 187: 111–125 (1950)

Farnsworth JP, Li J, Hendricks GM, Guo MR. Effects of transglutaminase treatment on functional properties and probiotic culture survivability of goat milk yogurt. Small Ruminant Res. 65: 113–121 (2006)

Mohana S, Shrivastava S, Divecha J, Madamwar D. Response surface methodology for optimization of medium for decolorization of textile dye Direct Black 22 by a novel bacterial consortium. Bioresource Technol. 99: 562–569 (2008)

Kim S, Warburton S, Boldogh I, Svensson C, Pon L, d’Anjou M, Stadheim TA, Choi BK. Regulation of alcohol oxidase 1 (AOX1) promoter and peroxisome biogenesis in different fermentation processes in Pichia pastoris. J. Biotechnol. 166: 174–181 (2013)

Antonenkov VD, Grunau S, Ohlmeier S, Hiltunen JK. Peroxisomes are oxidative organelles. Antioxid. Redox Signal 13: 525–537 (2010)

Sakai Y, Oku M, van der Klei IJ, Kiel JA. Pexophagy: autophagic degradation of peroxisomes. BBA-Mol. Cell. Res. 1763: 1767–1775 (2006)

Erdmann R, Blobel G. Giant peroxisomes in oleic acid-induced Saccharomyces cerevisiae lacking the peroxisomal membrane protein Pmp27p. J. Cell Biol. 128: 509–523 (1995)

Khatri NK, Hoffmann F. Impact of methanol concentration on secreted protein production in oxygen-limited cultures of recombinant Pichia pastoris. Biotechnol. Bioeng. 93: 871–879 (2006)

Ozer B, Avni Kirmaci H, Oztekin S, Hayaloglu A, Atamer M. Incorporation of microbial transglutaminase into non-fat yogurt production. Int. Dairy J. 17: 199–207 (2007)

Gauche C, Tomazi T, Barreto PLM, Ogliari PJ, Bordignon-Luiz MT. Physical properties of yoghurt manufactured with milk whey and transglutaminase. LWT- Food Sci. Technol. 42: 239–243 (2009)

Acknowledgements

This work was supported by the National Nature Science Foundation of China (Grant No. 31601496 and 31301545), China Postdoctoral Science Foundation (Grant No. 2014M560244), International Postdoctoral Exchange Fellowship Program of China (Grant No. 20150082) and Heilongjiang Postdoctoral Foundation (Grant No. LBH-Z13042).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Li, H., Cui, Y., Zhang, L. et al. Optimization of recombinant Zea mays transglutaminase production and its influence on the functional properties of yogurt. Food Sci Biotechnol 26, 723–730 (2017). https://doi.org/10.1007/s10068-017-0083-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10068-017-0083-5