Abstract

A comprehensive understanding of deformation characteristics and control measures for large-scale foundation pits in soft soil regions is of increasing importance to their risk assessment, design, and construction. In this study, the influences of the thickness of soft soil on the deformation of foundation pits are discussed based on statistical data from 24 foundation pits in floodplain areas of Nanjing, China. The mean maximum ground surface settlement around the pit in floodplain areas of Nanjing was 0.38%H, and the maximum ground surface settlement was observed at 0.48H. The maximum influence scope of ground surface settlement was about 3.5H, and the average maximum horizontal displacement of supporting structures was 0.23%H. On this basis, a model of ground surface settlement around the pit according to excavation depth for foundation pits in floodplain areas is derived. In addition, the influence scope around the pit and relevant control measures are proposed for the protection of surrounding underground structures and roads.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

With the acceleration of urbanization and demand for infrastructure in China over the past decade, construction units are being required to make use of existing land resources more effectively (Lin et al. 2021a; Qiu 2020). Infrastructure construction in coastal regions is a potential solution (Sengupta et al. 2018). Increasing numbers of large-scale foundation pits are being constructed for infrastructure in coastal areas (Luo et al. 2015; Wu et al. 2015a). However, these areas have sensitive geological conditions due to soft soils and complex surrounding environments, which create challenges for the design and deformation control of foundation pits (Gaone et al. 2018; Mindel et al. 2015; Shen et al. 2014). Soft soils are extensively distributed in the Yangtze River floodplain regions and have the characteristics of low shear strength, high compressibility, high moisture content, and low permeability coefficient, which are problematic for engineering projects (Almeida et al. 2013; Cai et al. 2017; Ding et al. 2019). In addition, dense urban buildings, underground pipelines, and crossing roads further increase the difficulty of controlling the deformation of soil around the pit made in soft soil strata (Wu et al. 2015b). Frequent accidents occur during the excavation of foundation pits, which have two main sources: (1) buckling and failure of the foundation pit’s supporting system (Tan et al. 2020) and (2) the environmental effects of pit excavation, including ground surface settlement and deformation of adjacent buildings or structures (Tan et al. 2020). During excavation, a number of accidents can occur. Moreover, it has a serious social impact and leads to economic losses (Lin et al. 2021b). In July 2005, the collapse of a deep excavation caused by improper management resulted in three deaths and four injuries (Chen et al. 2006). In September 2008, a large-scale deep excavation collapse at Xianghu station on Hangzhou Metro Line 2 resulted in 21 deaths, 24 injuries, and 49.61 million CNY in direct economic losses (Chen et al. 2015). In June 2019, a foundation pit collapse on Dongge Road, Nanning, Guangxi damaged a nearby road (Chin et al. 2019). Therefore, designers and constructors must fully understand the deformation characteristics of foundation pit projects and implement detailed mitigation measures to assure the safety of the supporting system and the surrounding environment.

Foundation pit deformation can differ significantly due to regional differences in strata and the surrounding environment (Wang et al. 2018). Since foundation pit projects have very strong regional characteristics and high risks, design and construction experience is critical. It is essential to summarize the deformation characteristics of foundation pit projects according to the region and define corresponding control measures. The main soft soil areas relevant to foundation pit projects in China are concentrated in Shanghai (Shen et al. 2014; Tan and Wang 2013a, 2013b; Zhou et al. 2010), Hangzhou (Chen et al. 2015; Lin et al. 2020), Tianjin (Wu et al. 2019; Zeng et al. 2019), Fuzhou (Yang and Kong 2020), Guanghou (Elbaz et al. 2018), and Shenzhen (Cui et al. 2018; Huang et al. 2020). Researchers have studied the influence of thickness of soft soil on foundation pit deformation and ground surface settlement around the pit characteristics and distributions, as well as the deformation characteristics of supporting structures (Shen et al. 2014; Tan and Wang 2013a, 2013b; Yang and Kong 2020; Yang and Liu 2017). However, different regions present unique deformation characteristics related to the local soft soil layers. Only a few studies have examined deformation characteristics in floodplain areas of Nanjing (Di et al. 2016; Xia et al. 2006; Zhou et al. 2016). Moreover, these studies have only analyzed the deformation features of single foundation pit and have not proposed detailed mitigation measures. Hence, it is essential to investigate the statistical deformation characteristics of foundation pits and propose relevant mitigation measures for soft soil strata in floodplain areas of the Yangtze River in Nanjing.

Mitigation measures may include control of settlement in the surrounding area, deformation of the supporting structure, and bottom heaves (Ahmad et al. 2019; Di et al. 2019; Ding et al. 2018; Kazantsev and Kochneva 2017; Xu et al. 2018; Zhou et al. 2010). However, such measures must be chosen according to the deformation responses of different types of pipelines and roads. Recently, foundation pit deformation control and optimization measures have attracted increasing attention. Wang et al. (2012) controlled settlement due to dewatering of buildings surrounding a foundation pit by combining barricade curtains and inverted wells. Xu et al. (2016) reported that it is much more challenging to control the deformation of a foundation pit supporting structure with a two-level support than one with a three-level support. Zhou et al. (2010) applied an underground continuous concrete wall as a waterproof curtain to relieve dewatering-induced deformation of a foundation pit. Other measures used to relieve soil compression and ground surface settlement due to dewatering include deep cement mixing piles (Chen et al. 2013; Huang and Han 2009; Yamashita et al. 2018), diaphragm walls (Tan and Wang 2013a; Waichita et al. 2019; Yamashita et al. 2016), jet grouting piles (Njock et al. 2018; Thiyyakkandi et al. 2017; Wang et al. 2013), steel sheet piles (Kimura et al. 2007; Underwood 2020), and artificial recharge (Hussain et al. 2019; Khosravi et al. 2018; Zhang et al. 2017). Such measures focus on the deformation characteristics of foundation pits; however, no studies have thoroughly elaborated construction control, dewatering control, and pipeline and road protection measures. Good control measures will decrease safety risks while increasing the stability of foundation pits.

This study used data from 24 soft soil foundation pit projects in Yangtze River floodplain areas to analyze hydrogeological conditions and deformation characteristics. Specifically, we looked at the influences of the thickness of the soft soil on foundation pit deformation, ground surface settlement around the pit characteristics, and distribution characteristics, as well as the deformation characteristics of supporting structures. Finally, measures to control foundation pit deformation in floodplain areas of Nanjing are proposed. The results provide a guidance for the design and construction of soft soil foundation pits in river floodplain areas.

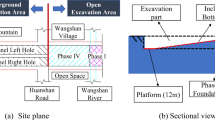

Foundation pit engineering background in floodplain areas of Nanjing

There are dense municipal pipelines, crossing roads, and buildings in floodplain areas of Nanjing, which create high requirements for construction-related environmental control and protection measures for foundation pit projects. The sedimentary stratigraphy in floodplain areas of Nanjing is closely related to the shifting of river channels, i.e., the complex stratigraphic belt formed by ancient river and lake. Soil deposition is a typical “dual sediment” structure. Soil sediments are mainly composed of floodplain-phase fine sediments and coarse riverbed sediments. A deep, thick sludge layer also contains silty sands. In this study, engineering data from 24 soft soil foundation pits in floodplain areas of Nanjing were used to analyze deformation characteristics and deformation control measures. The geographical location of soft soil foundation pits in floodplain areas of Nanjing is shown in Fig. 1.

Foundation pit support types

Soil parameter indexes of typical strata in floodplain areas of Nanjing are shown in Table 1. These data were obtained from the laboratory and field tests, such as the piezocone penetration test, triaxial test, water content test, and consolidation test. Obviously, muddy soil has a relatively high porosity ratio, high moisture content, and small permeability coefficient (Cai et al. 2017). The permeability coefficient is greatly different from that of the underlying sandy soil layer. These characteristics of muddy soil determine the appropriate foundation pit support type and dewatering mode. Selection of the supporting structures is closely related to the surrounding environment, geological conditions, and excavation depth. The engineering details of some of the foundation pits in floodplain areas of Nanjing are listed in Table 2. With increasing excavation depth, the lateral soil pressure over the supporting structure increases, and, eventually, the cantilever supports can no longer prevent foundation pit deformation. Cast-in-place concrete supports are commonly used in soft soil foundation pits. They have the characteristics of high rigidity and integrity, flexible layout, high construction quality, and flexible applicability to many types of soft soil foundation pits with irregular plane shapes. In floodplain areas of Nanjing, common foundation pit supporting structures include soil nailing supports, gravity-type barricades, cantilever supports with cast-in-situ bored piles, cantilever supports with manual hole digging piles, bored piles + concrete supports, digging piles + steel supports, combined supports, soil mixing wall (SMW) construction, and diaphragm walls.

Hydrogeological conditions

The main rivers include the Yangtze River and Shijiu Lake. According to hydrogeological survey, pore water is the main underground water type in floodplain areas of Nanjing. There is a great difference in permeability between the upper soft soil layer and middle and lower sandy soils in floodplain areas of Nanjing. The underground water in the sandy soil layer has a micropressure bearing capacity. Therefore, attention will be focused on dewatering problems in foundation pit projects in floodplain areas of Nanjing. Dewatering and waterproof schemes must be formulated by considering the location and scope of water areas surrounding the foundation pit, including the buried depth, thickness, and permeability of underground aquifers, seasonal variation in local underground water levels, and drainage conditions.

Ground water aquifer

The underground water distribution in floodplain areas of Nanjing is closely related to the Yangtze River, and the level is generally high, at about 1.5-m depth. There is an approximately 370 km2 surface water area in floodplain areas of Nanjing, indicating abundant water resources. In floodplain areas of Nanjing, a phreatic layer exists in the near-surface fill stratum, which belongs to an aquitard. Water supplementary sources at about 1-m depth mainly include atmospheric precipitation and domestic water. The underground water level is sensitive to seasonal changes. Specifically, there is a high underground water level during rainy seasons, and the maximum annual variation reaches 1 m (Chen 2019).

Confined water

A sand layer confines the water-bearing aquifer in floodplain areas of Nanjing, which contains silty-fine sand and middle-coarse sand mixed with cobbles and gravel. There are significant differences among the confined water aquifers in terms of permeability, and the confined water aquifers bear micropressure. Silty clay mixed with silt has low permeability and can be used as a waterproof roof. However, foundation pit design and construction in floodplain areas should consider the fact that silty-fine sands in a waterproof roof might form hydraulic channels connected with the sand layer, thus causing piping problems.

Bedrock fissure water

Mudstone and siltstone are the main underground bedrocks in floodplain areas of Nanjing. There is an extensive development of closed fissures, and most are filled with gypsum, thus having poor permeability. Bedrock fissure water generally influences foundation pit excavation only slightly (Chen 2019).

Waterproof structure

Since most foundation pits in floodplain areas of Nanjing lie in urban areas, dewatering and waterproof schemes should consider not only regional geological characteristics but also the adverse impacts of dewatering on surrounding pipelines, railways, and roads. If the thickness of the sandy soil and silty soil layer is relatively high, a combination of a hanging curtain and pit dewatering is applied. If the thickness of the sandy soil and silty soil layer is small, a fully closed waterproof scheme is adopted. If the main strata are soft soil layers, a combination of supporting piles plus a barricade waterproof structure and pit dewatering is adopted. The underground water level can be lowered and quicksand and piping damage prevented by using appropriate dewatering or waterproofing schemes. Common waterproofing structures in Nanjing include waterproof curtain walls, deep stirring piles, thin-walled continuous walls, waterproof piles, and compaction grouting.

Analysis of foundation pit deformation characteristics in floodplain areas of Nanjing

The deformation characteristics of foundation pits in floodplain areas of Nanjing were summarized through investigation of 24 foundation pits and statistical analysis of monitoring data. The thickness of soft soil, horizontal displacement of the supporting structure, horizontal displacement of soft soil, and ground surface settlement of 24 foundation pits are obtained by the drilling technology, measuring scale, field displacement sensors, and buried settlement points.

Effects of thickness of the soft soil on foundation pit deformation

Ground surface settlement around the pit

Soft soil layers in floodplain areas can affect ground surface settlement around foundation pits to some extent. Thickness of the soft soil in this study was defined as the sum of the thickness of the layer of silty clay and silty clay mixed with silty soil above the supporting structure bottom. Due to differences in the depth and thickness of the soft soil, the thickness of the soft soil and ground surface settlement around the pit must be redefined as the normalized thickness of soft soil (hs/Hw) and the normalized ground surface settlement around the pit (δvm/H) (Tan and Wang 2013a). In these two expressions, hs is the thickness of the soft soil layer above the supporting structure bottom, Hw is the supporting structure depth, δvm is the maximum ground surface settlement around the pit, and H is the foundation pit excavation depth. The relationship between the normalized thickness of the soft soil and normalized maximum ground surface settlement around the pit is shown in Fig. 2. Obviously, the overall growth trends are consistent, although the data points are relatively scattered. The maximum ground surface settlement is positively related to the thickness of the soft soil layer. \( {\left({\delta}_{vm}/H\right)}_2=0.44\left(\frac{h_s}{H_w}\right)+0.07 \) was determined according to the two outermost data points below all data points, and these two data points are close to most of the data points, which can show the development trend of most data. Similarly, \( {\left({\delta}_{vm}/H\right)}_1=0.46\left(\frac{h_s}{H_w}\right)+0.35 \) was determined according to the two outermost data points above all data points. About 86% of the data fluctuates between lines \( {\left({\delta}_{vm}/H\right)}_1=0.46\left(\frac{h_s}{H_w}\right)+0.35 \) and \( {\left({\delta}_{vm}/H\right)}_2=0.44\left(\frac{h_s}{H_w}\right)+0.07 \) in Fig. 2, and the shadow area represents the main distribution zone of the relationship between ground surface settlement around the pit and thickness of the soft soil in floodplain areas of Nanjing.

Horizontal displacement of supporting structures

The relationship between hs/Hw and the normalized maximum horizontal displacement of the supporting structure (δhm/H) is shown in Fig. 3, where δhm is the maximum horizontal displacement of the supporting structure. hs/Hw = 0.4 was determined by the distribution of data point. Obviously, data points over 0.4 are very discrete. A positive relationship is observed between hs/Hw and δhm/H, but about 90% of the data is concentrated in the region where hs/Hw is less than 0.4. Some dispersed data points show that the thickness of the soft soil is relatively small when the maximum horizontal displacement of the supporting structure is relatively high, indicating that the thickness of the soft soil is not the only influence on the maximum horizontal displacement. The determination criteria of hm/Hw = 0.85 and hs/Hw = 0.6 are similar to hs/Hw = 0.4 in Fig. 3. The relationship between hs/Hw and the location of the normalized maximum horizontal displacement of the supporting structure (hm/H) is shown in Fig. 4. Clearly, 80% of the hm/H values are less than 0.85. The hm/H value increases with increases in hs/Hw, showing significant fluctuation of the growth rate. Moreover, all monitoring data generally fluctuate in the region where hs/Hw < 0.6.

Ground surface settlement around the pit characteristics and distribution pattern

Factors, i.e., the foundation pit dewatering, excavation of adjacent foundation pit, insufficient depth of anchor into soil, and time effect, can affect the ground surface settlement around the pit. Based on data related to soft soil foundation pits, Peck (1969) reported that the maximum ground surface settlement around the pit (δvm) is greater than 1%H. However, Wong et al. (1997) analyzed a foundation pit in Singapore and concluded that the mean δvm = 0.24%H. The relationship between the maximum ground surface settlement around the pit (δvm) and excavation depth (H) in floodplain areas of Nanjing is shown in Fig. 5. The δvm = 0.38%H was determined according to the maximum correlation coefficient. With increasing excavation depth, the maximum ground surface settlement around the pit increases gradually up to δvm = 1.93%H and the mean δvm = 0.38%H. When the excavation depth exceeds 17 m, δvm drops suddenly to about 25 mm. This is mainly because the foundation pit applies a combination of diaphragm wall and four reinforced concrete supports for stability, which decreases the ground surface settlement around the pit. The relationship between the location of the normalized maximum ground surface settlement around the pit (xvm/H) and excavation depth (H) is shown in Fig. 6. It shows that the maximum ground surface settlement around the pit is mainly located within 0.2–0.75H. According to statistical analysis, the average xvm in floodplain areas of Nanjing is 0.48H.

The ground surface settlement distribution around the pit is shown in Fig. 7. The x-coordinate refers to the ratio between the horizontal distance to the foundation pit (x) and its excavation depth (H), while the y-coordinate refers to the ratio between the ground surface settlement around the pit at different positions (δv) and excavation depth (H). Peck curve zoning is shown in Fig. 7. According to the soil layer conditions, the settlement curve is divided into Zones I, II, and III. Zone I represents the ground surface settlement around the pit in sandy soil, hard clay, and soft clay conditions. Zone II represents ground surface settlement around the pit in soft clay and extremely soft clay conditions. Zone III represents ground surface settlement around the pit in relatively deep, thick soft clay and extremely soft clay conditions. Obviously, most practical monitoring data on δv from the floodplain areas of Nanjing is concentrated in Zone I. Therefore, a model of ground surface settlement around the pit for the floodplain areas of Nanjing was constructed, which has the exponential function:

In addition, it can be seen from the distribution of ground surface settlement around the pit that the settlement of local foundation pits is less than that of statistics from Peck (1969). This reveals that rows of piles and diaphragm walls can decrease settlement more effectively than steel sheet piles. Soft soil foundation pits with excavation depths < 15 m in floodplain areas of Nanjing generally adopt a combination of bored piles and inner supports, diaphragm wall supports, and the new cement mixed wall (SMW) method. These supporting structures have relatively high integral rigidity and can decrease settlement more than flexible supporting structures like steel sheet piles. According to the data, the maximum influence scope of settlement in floodplain areas of Nanjing is about 3.5H.

Deformation characteristics of supporting structures

The relationship between the maximum horizontal displacement (δhm) of supporting structures and foundation pit excavation depth (H) is shown in Fig. 8. Clearly, the monitoring data are generally distributed between δhm1 = 0.08%H and δhm2 = 0.67%H. When the excavation depth is < 18 m, δhm is positively related to the excavation depth. However, δhm is relatively small (about 35.5 mm) at excavation depths > 18 m. This is mainly attributed to the strong deformation constraint conferred by the combination of the diaphragm wall and four lines of reinforced concrete. According to statistical analysis, the mean maximum horizontal displacement of supporting structures is 0.23%H. Similar results for the horizontal displacement of supporting structures were gained for soft clay foundation pits in Masuda, Japan (0.3%H) (Masuda 1993). In addition, other scholars have gained different results, such as 0.1–0.15%H (Wong et al. 1997), 0.16%H (Long 2001), 0.48%H (Moormann 2004), and 0.40%H (Ou et al. 1993).

The relationship between the location of the maximum horizontal displacement (yhm) of supporting structures and foundation pit excavation depth (H) is shown in Fig. 9. Most data points fall near yhm = 0.6H, indicating that the maximum horizontal displacement of most foundation pits in floodplain areas of Nanjing occurs at middle to lower excavation depths. At depths of 5–10 m, the location is close to the ground surface, and the region where these data points lie in adopts cantilever supports. Foundation pit projects with cantilever supports are characterized by the maximum horizontal displacement occurring on the top of supporting structures. Besides, it was found through monitoring data that the horizontal displacement characteristics of supporting supports combining bored piles with a single line of reinforced concrete for foundation pits with excavation depths < 10 m in floodplain areas of Nanjing were similar to those of foundation pits with cantilever pile supports.

Deformation control for foundation pit projects in floodplain areas of Nanjing

Deformation of foundation pits involves many factors, including the shape of the foundation pit, excavation depth, and the existence of underground water (Moormann 2004; Tan and Wang 2013b). It is impossible to have uniform deformation standards due to the different geological conditions in different regions. According to the construction experiences of foundation pit projects in floodplain areas of Nanjing over the years, basic deformation standards have been defined, which include (1) cumulative horizontal displacement in different stages of no more than 15–45 mm, (2) horizontal displacement rate < 0.5 mm/day, and (3) cumulative settlement of buildings < 10 mm and settlement rate < 0.3 mm/day.

Foundation pit construction control measures

There are two main causes of ground surface settlement around the pit. (1) Excavation-induced unloading causes deformation of the supporting structure, while plastic heave at the bottom of the foundation pit and dewatering cause consolidation settlement of the surrounding soil (Zhang et al. 2013). (2) Construction factors, such as the poor-quality mud protection, strata soil loss caused by pumping from wells, dynamic loads during construction (Wu et al. 2019). Therefore, the influences of construction on foundation pit deformation can be significantly relieved by adopting positive control measures.

Detailed data on the hydrogeological and surrounding environmental conditions must be obtained before construction. Meanwhile, the influences of the construction on underground pipelines, roads, railways, and buildings should be estimated. To reduce the influences of foundation pit construction on deformation and the surrounding environment, the following countermeasures are recommended:

-

(1)

The floodplain areas of Nanjing should be zoned according to the degrees of influence of the foundation pit excavation. The horizontal scope of influence is generally 1–4H. According to the construction experiences of soft soil foundation pits in Shanghai, Li (2006) defined scopes of strong (plastic zone), weak (elastic zone), and zero influence. Different construction countermeasures were adopted to assure the safety of foundation pits. Similarly, we divided the scope of influence into Zones A (0–1.0H), B (1.0–2.5H), and C (>2.5H) according to statistical data from the floodplain areas of Nanjing. Zone A is most influenced by foundation pit construction, where underground buildings and pipelines deform greatly. It is suggested that monitoring and control over underground pipelines and roads are strengthened in Zone B, and settlement should be closely monitored. For Zones A and B, we suggest predicting the deformation of underground pipelines and roads before construction, adopting protection measures, and strengthening monitoring. The underground pipelines and roads in Zone C are influenced the least, and, generally, no special measures are needed.

-

(2)

Optimization of the construction process. Before the construction of project, the organization and implementation plan of overall division and section construction shall be prepared. Organize experts to discuss the excavation of retaining structure, soil excavation, construction technology and process deployment of main structure by pit, zone, and section. The construction scheme of the supporting structure should be determined according to the sequence of soil excavation. Full consideration should be paid to the corner effect of foundation pit during the excavation process. To avoid over-excavation, manual excavation should be considered when the excavation of foundation pit is close to the calculated excavation depth. During zone-based excavation of soil layers, one must consider the progress of support installation. Moreover, we suggest excavating foundation pits in strict accordance with the construction scheme and with timely setting of supports. According to the established plan, the slope repair and protection measures of soil platform shall be implemented, the drainage measures at the top and toe of slope shall be improved, and the long-term ponding at the top and toe of slope shall be strictly prohibited.

-

(3)

Reverse construction. Many projects in floodplain areas of Nanjing have adopted reverse construction methods. According to practical monitoring data, using reverse construction methods, the horizontal deformation of diaphragm walls and the ground surface settlement around the pit are significantly less than when using other techniques.

-

(4)

Strengthening the supporting structure. The horizontal displacement of diaphragm walls, bottom plastic heave, and ground surface settlement around the pit can be relieved by increasing the buried depth or rigidity of the supporting structures. It is beneficial for the supporting structure to enter the rock strata. Moreover, inserting the bottom of the supporting structure into sandy soil layers should be avoided.

-

(5)

Strengthening dynamic monitoring. We suggest timely dynamic monitoring of the deformation, deformation rates, and axial forces occurring at different parts of a foundation pit project to determine the states of various parameters during construction, predict the next construction state, further optimize the construction scheme, and maintain engineering safety.

Control measures for foundation pit dewatering

The average distance from the underground water level to the surface in floodplain areas of Nanjing is 0.5–0.7 m. There is a thick, saturated, silty clay layer over the upper soil layers with a moisture content of about 37–47%. Moreover, soil layers are mainly mixed with silt layers. Therefore, control over underground water during foundation construction is vital (Shaqour et al. 2008).

Foundation pit projects in floodplain areas of Nanjing mainly apply the well-point dewatering method. Well-point dewatering method can reduce water content in soil, promote soil consolidation, improve foundation strength, reduce lateral displacement and settlement of soil slope, stabilize slope, reduce uplift of base soil, reduce earthwork excavation, shorten construction period, improve engineering quality, and ensure construction safety. In order to reduce the impact on the surrounding buildings, the well-point dewatering method can not carry out long-term continuous pumping work, and intermittent pumping work is needed. This method can lower underground water levels surrounding the foundation pit, increase the effective stress of soil layers, trigger consolidation, and thereby produce ground surface settlement around the pit. Greatly differential settlement may cause cracking and settlement of adjacent buildings, roads, railways, and public municipal pipelines to different extents (Khosravi et al. 2018). To decrease the influences of dewatering on foundation pit deformation, the following technological measures can be adopted:

-

(1)

Field data on geological factors, including the stratigraphic distribution, fossil river courses, and underground water distribution, must be determined accurately before implementing the well-point dewatering method. Moreover, the distributions of different types of adjacent pipelines, and, especially, railways and underground tunnels, and the basic and structural forms of buildings, need to be determined.

-

(2)

If a deep foundation pit project reinforces the soil, the soil layer strength is increased, and the moisture content and permeability of the soil may change accordingly. The number of practical well points should be adjusted according to the practical situation.

-

(3)

When there are protection buildings surrounding a foundation pit, the dewatering system should be set as far away from them as possible. It should also include a recharge system to maintain the underground water level below protection buildings and avoid their settlement. Notably, the recharge system must be designed in detail, including the setting of water-level observation wells, distances between recharge wells and dewatering wells, and the diameters and depths of recharge wells. The recharge facilities can also include recharge sand well or recharge sand grooves.

-

(4)

The dewatering depth and pumping amount should be controlled to prevent quicksand and piping. During well-point dewatering and pit dewatering, close attention should be paid to construction progress to ensure that the dewatering curved surface is 0.5–1.0 m below the excavation surface.

-

(5)

Well points in the pit should be closed in a timely manner. Besides, attention should be paid to closing of de-pressuring well points inserted into the confined aquifer. This is because poor closing of wells can easily cause abrasive blasting and water security accidents.

-

(6)

Strengthening of monitoring. The groundwater level, pumping amount, deformation of adjacent roads and pipelines, and ground surface settlement within the influence scope of the foundation pit should be monitored carefully during the dewatering period and for a period after construction.

Pipeline protection measures

Horizontal displacement of supporting structures caused by excavation of foundation pits can influence adjacent pipelines significantly (Yang and Kong 2020). Different pipelines have different responses to control measures, and horizontal forces should be considered in pipeline deformation. Grouting reinforcement at the bottom of pipelines can control settlement effectively but does not control horizontal deformation significantly. In foundation pits, reinforcing soils in passive zones can control the horizontal deformation of pipelines to some extent.

If the cumulative settlement of pipelines is too large or the settlement rate changes suddenly, more monitoring points should be set and grouting measures should be adopted in a timely manner to control continuous deformation of pipelines. If pipelines are lifted up, grouting pressure should be adjusted in a timely manner to ensure the normal use of pipelines and the safety of foundation pits.

Whether compaction grouting should be applied to pipelines near foundation pits is decided according to monitoring data. Suspension reinforcement should be applied to pipelines that run through foundation pits and cannot be moved. If tap water pipelines run through the upper part of a foundation pit, they must be removed. The settlement threshold of underground pipelines should be assessed in a timely manner by considering the settlement value, settlement rate, and differential settlement.

Besides, pipeline protection schemes are formulated according to the bearing capacity of underground buried pipelines with different rigidities to deformation (Liu et al. 2020). For reinforced concrete pipelines that are sensitive to deformation, it is necessary to determine their direction, position, and interface types before excavation and pre-determine the protection scheme in addition to the supporting reinforcement. Plastic or rubber pipelines with low rigidity require corresponding protection measures if there will be high rotation during construction.

Conclusions

In this study, the geological engineering conditions and supporting types of foundation pits in floodplain areas of Nanjing were analyzed. A statistical analysis of detailed geological exploration data and monitoring data from 24 foundation pits in floodplain areas of Nanjing was carried out. The deformation characteristics and control measures of foundation pits in floodplain areas of Nanjing were investigated. Some conclusions can be drawn:

-

(1)

The supporting types of typical soft soil foundation pits and the hydrogeological conditions in floodplain areas of Nanjing were summarized thoroughly. Common support types and waterproof and dewatering structures were analyzed and discussed.

-

(2)

In floodplain areas of Nanjing, the maximum ground surface settlement around the pit of foundation pits, maximum horizontal displacement of supporting structures, and maximum buried depth of walls are positively related to the thickness of the soft soil.

-

(3)

The mean maximum ground surface settlement around the pit in floodplain areas of Nanjing was 0.38%H, and the maximum ground surface settlement was observed at 0.48H. The distribution pattern of ground surface settlement around the pit in floodplain areas of Nanjing was determined. The maximum influence scope of ground surface settlement was about 3.5H, and the average maximum horizontal displacement of supporting structures was 0.23%H.

-

(4)

To decrease construction influences on the deformation of foundation pits and the surrounding environment, the influence scope of pit excavation should be zoned and appropriate control measures applied to the different zones. Moreover, the environmental influences of foundation pit dewatering were discussed and control measures proposed. Finally, protection measures for controlling the deformation of underground pipelines and surrounding roads were proposed.

Data availability

All data, models, and code generated or used during the study appear in the submitted article.

References

Ahmad I, Tayyab M, Zaman M, Anjum MN, Dong X (2019) Finite-difference numerical simulation of dewatering system in a large deep foundation pit at Taunsa Barrage, Pakistan. Sustainability 11(3):694

Almeida M, Hosseinpour I, Riccio M (2013) Performance of a geosynthetic-encased column (GEC) in soft ground: numerical and analytical studies. Geosynth Int 20(4):252–262

Cai G, Zou H, Liu S, Puppala AJ (2017) Random field characterization of CPTU soil behavior type index of Jiangsu quaternary soil deposits. Bull Eng Geol Environ 76(1):353–369

Chen Y. (2019). "Study on design parameters and deformation control of deep foundation pit in soft soil area of Nanjing flood land based on CPTU data. " Master Thesis, Southeast University, Nanjing.

Chen W, Wu YJ, Peng ZB (2006) Monitoring of rescue of a foundation pit and technical analysis of its collapse in Guangzhou. Chin J Undergr Space Eng 6(2):1034–1039 (in Chinese)

Chen JJ, Zhang L, Zhang JF, Zhu YF, Wang J-H (2013) Field tests, modification, and application of deep soil mixing method in soft clay. J Geotech Geoenviron 139(1):24–34

Chen R, Li Z, Chen Y, Ou C, Hu Q, Rao M (2015) Failure investigation at a collapsed deep excavation in very sensitive organic soft clay. J Perform Constr Facil 29(3):04014078

Chin YT, Shen SL, Zhou AN, Chen J (2019) Foundation pit collapse on 8 June 2019 in Nanning, China: a brief report. Safety 5(4):68

Cui X, Ye M, Zhuang Y (2018) Performance of a foundation pit supported by bored piles and steel struts: a case study. Soils Found 58(4):1016–1027

Di H, Zhou S, Xiao J, Gong Q, Luo Z (2016) Investigation of the long-term settlement of a cut-and-cover metro tunnel in a soft deposit. Eng Geol 204:33–40

Di H, Guo H, Zhou S, Chen J, Wen L (2019) Investigation of the axial force compensation and deformation control effect of servo steel struts in a deep foundation pit excavation in soft clay. Adv Civil Eng 2019:1–16

Ding Z, Jin J, Han TC (2018) Analysis of the zoning excavation monitoring data of a narrow and deep foundation pit in a soft soil area. J Geophys Eng 15(4):1231–1241

Ding J, Wan X, Zhang C, He Z, Zhao L (2019) Case study: ground improvement of Yangtze River floodplain soils with combined vacuum and surcharge preloading method. Int J Geomech 19(12):05019008

Elbaz K, Shen SL, Tan Y, Cheng WC (2018) Investigation into performance of deep excavation in sand covered karst: a case report. Soils Found 58(4):1042–1058

Gaone F, Gourvenec S, Doherty J (2018) Large-scale shallow foundation load tests on soft clay—at the National Field Testing Facility (NFTF), Ballina, NSW, Australia. Comput Geotech 93:253–268

Huang J, Han J (2009) 3D coupled mechanical and hydraulic modeling of a geosynthetic-reinforced deep mixed column-supported embankment. Geotext Geomembr 27(4):272–280

Huang W, Wen K, Liu D, Dong Q, Li J, Li Y, Li L (2020) Experimental study on influence of excess pore water pressure and unloading ratio on unloading mechanical properties of marine sedimentary soft soils. Ocean Eng 195:106680

Hussain F, Hussain R, Wu RS, Abbas T (2019) Rainwater harvesting potential and utilization for artificial recharge of groundwater using recharge wells. Processes 7(9):623

Kazantsev AI, Kochneva AA (2017) Ground of the geodesic control method of deformatons of the land surface when protecting the buildings and structures under the conditions of urban infill. Ecol Environ Conserv 23(2):876–882

Khosravi M, Khosravi MH, and Ghoreishi Najafabadi SH (2018). "Determining the portion of dewatering-induced settlement in excavation pit projects." Int J Geotech Eng 1-11.

Kimura M, Inazumi S, Too JKA, Isobe K, Mitsuda Y, Nishiyama Y (2007) Development and application of H-joint steel pipe sheet piles in construction of foundations for structures. Soils Found 47(2):237–251

Li Z (2006). " Study on environmental impact and protection of deep foundation pit construction of underground complex." Doctoral dissertation, Tongji University, Shanghai.

Lin C, Huang M, Nadim F, Liu Z (2020) Embankment responses to shield tunnelling considering soil-structure interaction: case studies in Hangzhou soft ground. Tunn Undergr Space Technol 96:103230

Lin SS, Shen SL, Zhou A, Xu YS (2021a) Risk assessment and management of excavation system based on fuzzy set theory and machine learning methods. Autom Constr 122:103490

Lin SS, Shen SL, Zhou A, Xu YS (2021b) Novel model for risk identification during karst excavation. Reliab Eng Syst Saf 209:107435

Liu LL, Cai GJ, Zhang J, Liu XY, Liu K (2020) Evaluation of engineering properties and environmental effect of recycled waste tire-sand/soil in geotechnical engineering: A compressive review. Renew Sust Energ Rev 126:109831

Long M (2001) Database for retaining wall and ground movements due to deep excavations. J Geotech Geoenviron 127(3):203–224

Luo CY, Shen SL, Han J, Ye GL, Horpibulsuk S (2015) Hydrogeochemical environment of aquifer groundwater in Shanghai and potential hazards to underground infrastructures. Nat Hazards 78(1):753–774

Masuda T (1993). "Behavior of deep excavation with diaphragm wall." Doctoral dissertation, Massachusetts Institute of Technology.

Mindel I, Sevostyanov V, Trifonov B, Ragozin N (2015) Response of saturated soft soils to dynamic impact accompanying earthquakes. Water Res 42(7):958–969

Moormann C (2004) Analysis of wall and ground movements due to deep excavations in soft soil based on a new worldwide database. Soils Found 44(1):87–98

Njock PGA, Chen J, Modoni G, Arulrajah A, Kim YH (2018) A review of jet grouting practice and development. Arab J Geosci 11(16):459

Ou CY, Hsieh PG, Chiou D-C (1993) Characteristics of ground surface settlement during excavation. Can Geotech J 30(5):758–767

Peck RB (1969) Deep excavations and tunneling in soft ground. Proc 7th ICSMFE 1969:225–290

Qiu X (2020). China 40 years infrastructure construction, Springer.

Sengupta D, Chen R, Meadows ME (2018) Building beyond land: an overview of coastal land reclamation in 16 global megacities. Appl Geogr 90:229–238

Shaqour, Fathi M, Hasan, Syed E (2008) Groundwater control for construction purposes: a case study from Kuwait. Environ Geol 53(8):1603–1612

Shen SL, Wu HN, Cui YJ, Yin ZY (2014) Long-term settlement behaviour of metro tunnels in the soft deposits of Shanghai. Tunn Undergr Space Technol 40:309–323

Tan Y, Wang D (2013a) Characteristics of a large-scale deep foundation pit excavated by the central-island technique in Shanghai soft clay. I: Bottom-up construction of the central cylindrical shaft. J Geotech Geoenviron 139(11):1875–1893

Tan Y, Wang D (2013b) Characteristics of a large-scale deep foundation pit excavated by the central-island technique in Shanghai soft clay. II: Top-down construction of the peripheral rectangular pit. J Geotech Geoenviron 139(11):1894–1910

Tan Y, Jiang WZ, Rui HS, Lu Y, Wang DL (2020) Forensic geotechnical analyses on the 2009 building-overturning accident in Shanghai, China: beyond common recognitions. J Geotech Geoenviron 146(7):05020005

Thiyyakkandi S, McVay M, Lai P, Herrera R (2017) Suitability of jetted and grouted precast pile for supporting mast arm structures. Can Geotech J 54(9):1231–1244

Underwood CA (2020) The use of steel sheet pile as permanent building foundation walls: lessons learned over 15 years of design in Minneapolis, Minnesota, USA. In: Proc., Geo-Congress 2020: University of Minnesota 68th Annual Geotechnical Engineering Conference. American Society of Civil Engineers, Reston, pp 68–77

Waichita S, Jongpradist P, Jamsawang P (2019) Characterization of deep cement mixing wall behavior using wall-to-excavation shape factor. Tunn Undergr Space Technol 83:243–253

Wang J, Feng B, Liu Y, Wu L, Zhu Y, Zhang X, Tang Y, Yang P (2012) Controlling subsidence caused by de-watering in a deep foundation pit. Bull Eng Geol Environ 71(3):545–555

Wang ZF, Shen SL, Ho CE, Kim YH (2013) Investigation of field-installation effects of horizontal twin-jet grouting in Shanghai soft soil deposits. Can Geotech J 50(3):288–297

Wang J, Deng Y, Ma R, Liu X, Guo Q, Liu S, Shao Y, Wu L, Zhou J, Yang T (2018) Model test on partial expansion in stratified subsidence during foundation pit dewatering. J Hydrol 557:489–508

Wong IH, Poh TY, Chuah HL (1997) Performance of excavations for depressed expressway in Singapore. J Geotech Geoenviron 123(7):617–625

Wu HN, Shen SL, Ma L, Yin ZY, Horpibulsuk S (2015a) Evaluation of the strength increase of marine clay under staged embankment loading: a case study. Mar Georesour Geotechnol 33(6):532–541

Wu YX, Shen SL, Xu YS, Yin ZY (2015b) Characteristics of groundwater seepage with cut-off wall in gravel aquifer. I: Field observations. Can Geotech J 52(10):1526–1538

Wu YX, Lyu HM, Han J, Shen SL (2019) Dewatering–induced building settlement around a deep excavation in soft deposit in Tianjin, China. J Geotech Geoenviron 145(5):05019003

Xia J, Huang GL, Yan SB (2006) Behaviour and engineering implications of recent floodplain soft soil along lower reaches of the Yangtze River in Western Nanjing, China. Eng Geol 87(1-2):48–59

Xu C, Chen Q, Wang Y, Hu W, Fang T (2016) Dynamic deformation control of retaining structures of a deep excavation. J Perform Constr Facil 30(4):04015071

Xu YS, Shen JS, Zhou AN, Arulrajah A (2018) Geological and hydrogeological environment with geohazards during underground construction in Hangzhou: a review. Arab J Geosci 11(18):544

Yamashita K, Hamada J, Tanikawa T (2016) Static and seismic performance of a friction piled raft combined with grid-form deep mixing walls in soft ground. Soils Found 56(3):559–573

Yamashita K, Shigeno Y, Hamada J, Chang DW (2018) Seismic response analysis of piled raft with grid-form deep mixing walls under strong earthquakes with performance-based design concerns. Soils Found 58(1):65–84

Yang J, Kong D (2020) Deformation of deep and large foundation pit in soft soil of Fuzhou Subway. Arab J Geosci 13(2):1–10

Yang X, Liu G (2017) Performance of a large-scale metro interchange station excavation in Shanghai soft clay. J Geotech Geoenviron 143(6):05017003

Zeng CF, Zheng G, Zhou XF, Xue XL, Zhou HZ (2019) Behaviours of wall and soil during pre-excavation dewatering under different foundation pit widths. Comput Geotech 115:103169

Zhang Z, Huang M, Wang W (2013) Evaluation of deformation response for adjacent tunnels due to soil unloading in excavation engineering. Tunn Undergr Space Technol 38:244–253

Zhang YQ, Wang J-H, Chen JJ, Li MG (2017) Numerical study on the responses of groundwater and strata to pumping and recharge in a deep confined aquifer. J Hydrol 548:342–352

Zhou N, Vermeer PA, Lou R, Tang Y, Jiang S (2010) Numerical simulation of deep foundation pit dewatering and optimization of controlling land subsidence. Eng Geol 114(3-4):251–260

Zhou S, Di H, Xiao J, Wang P (2016) Differential settlement and induced structural damage in a cut-and-cover subway tunnel in a soft deposit. J Perform Constr Facil 30(5):04016028

Funding

The authors are grateful to the National Key R&D Program of China (2020YFC1807200), the National Natural Science Foundation of China (41877231 and 42072299), Colleges and Universities in Jiangsu Province Plans to Graduate Research and Innovation (Grant No. KYCX19-0098), the Scientific Research Foundation of Graduate School of Southeast University (Grant No. YBPY1926), and the Project of Jiangsu Provincial Transportation Engineering Construction Bureau (CX-2019GC02).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, L., Cai, G., Liu, S. et al. Deformation characteristics and control for foundation pits in floodplain areas of Nanjing, China. Bull Eng Geol Environ 80, 5527–5538 (2021). https://doi.org/10.1007/s10064-021-02264-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-021-02264-9