Abstract

For an open-pit mine, the slope must remain stable throughout the life of mining operation, and it follows that an optimized ultimate pit limit (UPL) should have the slope stability commensurate with economic benefit. In the Shuguang gold and copper mine, a geostatistics-block-based method is used to characterize the heterogeneous mechanical properties of rock mass. Then, the detailed slope stability analyses for four possible slope configuration designs using heterogenous mechanical parameter block model are performed to determine the steepest safe slope angle, and the steepest safe slope angle is next used for the UPL optimization. Compared with the original UPL assuming the rock mass is homogeneous in the same lithology, the slope angle for the optimized UPL has an average 1° to 6° increase, and the optimized UPL can bring 15.84 million tons of ore and reduce 20.83 million tons of waste rock. The result indicated that the application of geostatistics can make practical use of geotechnical information to improve slope stability, and slope configurations, and thereby optimize the UPL and so bring economic benefit.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

For a large open-pit mine, a single degree increase of slope angle will save million dollars of stripping cost; unfortunately, the economic benefits gained can be negated by a major slope failure (Lily 2002). The optimization of a UPL is the balance between safety (decrease the slope angle to improve slope stability) and economy (increase the slope angle to minimize stripping cost). In general, slope designers must reconcile making the pit slopes as steep as possible to reduce the stripping ratio with the conflicting requirement for flatter slopes to ensure stability (Khalokakaie et al. 2000). Since the design of an optimum open-pit requires an estimate of a set of average and safe slope angles, the steepest safe angle should be identified firstly. The steepest safe slope angle is treated as constraints in the UPL optimization process, and they are defined in terms of the block unit that must be removed to provide access to a particular UPL. Traditionally, the stability of a slope has been determined on vertical sections in which the location and rock mass quality within it are known. In optimal pit design, however, the position of the pit wall is unknown until the UPL has been determined, yet to determine the optimum UPL, an estimate of pit slope angles is required. The slope stability is strongly affected by the slope structure and rock mass properties where the slope is located. Thus, a detailed description of the ore body and the surrounding waste rock are needed, both the grade information and mechanical parameters.

Rock mass is a mixture of many mineral grains, cement, and discontinuities, and it is one of the most complex solid materials formed in the natural world through geological evolution and geological tectogenesis over billions of years. Consequently, natural rock material is generally heterogeneous, discontinuous, and anisotropic (Jaeger and Cook 2007). The heterogeneous nature of rock implies that most rock properties tend to vary in a wide range, even for the same lithology in the same mine or quarry, which has a fundamental influence on the stability and failure phenomenon of rock mass (Hoek 2007). Various methods have been proposed to address the heterogeneity of rock mass. Figure 1 illustrates four main numerical methods to characterize the heterogeneity of rock mass including (1) method based on digital image processing (Yue et al. 2003; Chen et al. 2007; Yu et al. 2016; Yu et al. 2018); (2) method based on statistical distribution (Tang 1997; Fenton and Griffiths 2008; Cao et al. 2010; Pinheiro et al. 2018); (3) method based on rock mass quality classification (Barton et al. 1974; Deere and Deere 1989; Barclay 1989; Irigaray et al. 2003); and (4) method based on geostatistical theory (Stavropoulou et al. 2007; Eivazy et al. 2017; Mayer and Stead 2017).

In situ experience has shown that abundant geological data are essential to build a heterogeneous numerical model. However, expensive drilling cost (more than $30–$50 per meter in China) limits the availability of geological data (the spacing between exploration lines is often 200 m or 100 m in non-coal mines). Based on the assumption of many geological parameters following geostatistical distribution, the geostatistics-based method is an effective tool for the numerical modeling of heterogeneous rock mass using limited geological data (Goovaerts 1997). However, as mentioned by Eivazy et al. (2017), there are just a few number of studies applying geostatistical simulation methods to model geomechanical properties of rock masses, and the majority of these studies overlook the anisotropy of the geological data. Moreover, the applicable conditions of the geostatistical analysis are ignored which may result in high uncertainties. In this article, the anisotropy of geostatistical distribution is considered in the block-based numerical model, and the size and shape of block units are specially selected. Besides, the extensions and defects of the geostatistics-based method are discussed in detail.

In this article, by collecting specific geological data during the exploration period, an anisotropic semivariogram was built for geological strength index (GSI) in the Shuguang gold and copper mine. A heterogenous mechanical parameter block model was established using the ordinary kriging (OK) interpolation and Hoek-Brown method. In order to optimize the UPL, several possible slope configurations were identified in terms of available mining equipment, and detailed slope stability was carried out to determine the steepest safe slope angle. An average of 1° to 6° of increasing of slope angle can effectively excavate the rock mass with fragile mechanical parameters and thus improve the slope stability. The result indicated optimized UPL considering the heterogeneity of rock masses has not only led to improvements in slope safety but also has led to costing savings.

Engineering background

Project overview

The Shuguang gold and copper mine is located approximately 75 km away from Hunchun City, China. The mine, with a length of approximately 1300 m from east to west and a width of 1000 m from south to north, is suffering the threat of rock landslides. The 3D geological model is presented in Fig. 2; the lithology of the Shuguang gold and copper mine can be divided into three categories: granite, granodiorite, and diorite. The mineral compositions of the three similar lithologies are the same, including feldspar, quartz, and mica, but in different proportions. Besides, there are three main fracture zones located in the northern pit, which will bring a negative influence to the slope stability. The spatial distribution of those three fracture zones has been identified by the geological investigation, and all that information are presented in the 3D geological model.

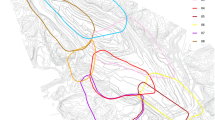

As shown in Fig. 3a, the pit was divided into six zones due to the different engineering geological conditions including rock mass quality, hydrogeology, and the grade information. In the UPL optimization process, different steepest safe slope angles can be used for each geological zone. The engineering geological zoning is very popular in the large open-pit mine because it has a good adaptability to complex geological condition and improves rock stability and brings economic benefit. By assuming the rock mass is homogeneous in the same lithology, the original slope angle ranges from 38° to 44° (slope angle is 40.5° in the northern slope). A conservative slope design was adopted to guarantee the slope stability, and part of the ore body was left in the UPL. Even though the factor of safety obtained by routine stability analyses using homogeneous mechanical parameters indicates that the slope remains in a stable situation, shallow landslides continuously occurred on the northern slope which has a negative influence on mining activities, shown in Fig. 3b. The significant heterogeneous characteristic of the rock mass has been identified as one of the main causes of rock landslides.

Since there are several potential ore bodies around the Shuguang gold and copper mine, grade information shown in this article are confidential and therefore cannot be disclosed, especially specific details concerning the amount of mineral resources. As shown in the Fig. 3a, a research area was selected in the northern slope. Even the mechanical analyses and UPL optimization were carried out on the whole pit, only the information located on the selected research area was present. Besides, a representative profile was selected as an example to perform detailed slope stability analyses. As shown in Fig. 3b, the representative profile was located at the center of landslide zone and perpendicular to the slope surface.

Engineering geological investigation

As shown in Fig. 4, from the year of 2014 to 2016, a total of 355 geological boreholes with a spacing of 100 m were drilled in the Shuguang gold and copper open-pit mine with the purpose of resource management, and the slope surface was a three-dimensional (3D) image obtained from a drone (oblique photography). 32,324 samples collected from the boreholes were assayed to obtain the grade information, both gold and copper. Since two kinds of metal, gold and copper, are contained in the ore body, an equivalent grade of gold (dAu) is defined with the following equation:

Fortunately, geological logging was performed in the exploration period, and the rock quality designation (RQD) has been recorded. In this article, the GSI was used to quantify the rock mass quality since it is the essential input for the Hoek-Brown method. The GSI can be obtained according to the simple transformation prospered by Hoek et al. (2013):

where JCond89 is the joint condition rating, ranging from 0 to 30, which represents the surface condition of discontinuity, and can get its suggested value from Bieniawski’s (1989) previous work. Here we assumed JCond89 equals to a constant (12 for granite, 10 for granodiorite, 8 for diorite, and 18 for fracture zone) in each lithology for convenience. Finally, 4556 measurement points were placed in the pit and each has its unique GSI (see Fig. 5). Besides, photogrammetry measurement of rock exposure was carried to get detailed discontinuity geometric information, including orientation, frequency, trace length, and spacing, from metric 3D images (see Fig. 6). Such information was necessary for the size effect analysis of jointed rock mass in the “Establishment of block model” section.

Ultrasonic wave velocity test

The loose ring range test system was used to obtain the ultrasonic wave velocity of the rock mass. The basic principle of this technique can be found in the reference (Mccann and Entwisle 1992). A typical borehole was selected to implement the ultrasonic wave velocity test in the landslide area, using the discrete sampling interval of 0.5 m. As shown in Fig. 7, the ultrasonic wave velocity of rock mass keeps increasing with the depth and remains relatively stable when the depth reaches 24 m. Considering that the unit size of mechanical parameter block model is 12 m, which requires determining the average ultrasonic wave velocities at 12 m intervals (see the detailed analysis in the “Establishment of block model” section), here we divided the rock mass into several layers parallel to the slope surface and assumed that the ultrasonic wave velocities remain a constant in each layer (i.e., 2.91 km/s, 5.01 km/s, and 5.45 km/s).

Laboratory experiment

Cores with different types of lithologies were taken from the boreholes (cores taken from the exploration boreholes have been stored in a special warehouse), and then cores are cut into rock samples. Finally, more than 350 rock specimens of the three different lithologies and fracture zones were obtained. The rock cylinders were 100 mm in height and 49 mm in diameter, and they were thoroughly checked to avoid any visible flaws. The acoustic wave velocities of the specimens were investigated using an ultrasonic tester. Specimens with large discreteness were excluded.

The physical properties of the samples, including density, porosity, and ultrasonic velocity, and the mechanical properties of the samples, including Young’s modulus, Poisson’s ratio, uniaxial compression strength (UCS), Brazilian tensile strength (BTS), cohesion, and internal friction angle, were measured. The number of rock samples, mean, and standard deviation of the basic mechanical parameters of those intact rock samples are listed in Table 1. Since the rock samples including granite, granodiorite, and diorite are igneous rock, thus, there is no inherent anisotropy observed in the laboratory experiment.

Modeling heterogeneity of rock mass mechanical parameters

Establishment of block model

In this article, the block model is used to execute the geostatistical analysis and OK spatial interpolation. The establishment of block model simplifies the topology relationship, with less computer memory and computing time being needed. Block-based methods have stood the test of time and have been implemented in many in situ engineering endeavors, especially in the resource management of open-pit mines. Many studies show that the shape and size of block unit will affect the accuracy of valuation (Caers 2005). Without loss of generality, we set the shape of the block unit as cube, and the representative elementary volume (REV) of jointed rock mass is set as a reference to the size of block unit. Besides, the size of block unit should be adjusted corresponding to various in situ engineering scenarios. A suitable example is that the block unit size can be adjusted to the integral multiple or division of the bench height in an open-pit mine.

As mentioned in the “Engineering geological investigation” section, photogrammetry measurement was employed to obtain the discontinuity data from exposed rock masses. Based on the statistical discontinuity parameters including orientation, frequency, trace length, and spacing, several 2D discrete fracture network (DFN) models with different size were generated using the open source code ADFNE, shown in Fig. 7. The ADFNE, written in MATLAB, can seamlessly handle a variety of needs including fracture generations, simulation, characterization, and data exchange (importing and exporting). The generation process of DFN is trying to reproduce the natural discontinuities in the numerical model with random method, and the ADFNE code can do it efficiently and accurately.

The RFPA2D code (Tang 1997) was used to investigate the size effect of jointed rock mass. In the RFPA2D numerical model, the intact rock and discontinuities are represented as rock element and joint element. Table 2 summarizes the mechanical parameters of the rock and joint elements used in the calculation. The mechanical parameters of the rock element were obtained by laboratory tests shown in the “Laboratory experiment” section. The parameters of joint elements are relatively lower than those of the rock element. The quantitative ratios of mechanical properties, such as elastic modulus and strength between joint element and rock element, can be considered as a constant. In previous studies, the ratio has generally been set at 1–20% (Li et al. 2009; Xu et al. 2013). In this article, the ratio of deformation parameters is set at 10%, and the ratio of strength parameters is set at 3.3% according to the reference (Zhou et al. 2018).

The REV of a statistically homogeneous rock mass is defined as the minimum volume beyond which any submass behaves essentially like the whole rock mass. Figure 8a presents the relationships between the elastic modulus and the UCS with the sample sizes. As one may expect (Masanobu 1988), both the elastic modulus and the UCS decreased gradually with the increasing size of the DFN model. The elastic modulus approaches constant when the size is larger than 11 m, and UCS becomes stabilized when the size reach to 12 m. These results indicate that the REV of the jointed rock mass should be 12 m.

Rock masses cut by one or several regularly spaced joint sets are anisotropic in addition to being discontinuous. This phenomenon is called joint-induced anisotropy and usually happens when there are several sets of preferred joint plane. Generally, this induced anisotropy may decline until it disappears with the increase of scale (Amadei 1996). The anisotropic mechanical properties of the selected REV are studied. Figure 8b shows the schematic for anisotropy study rotated every 15° clockwise using uniaxial compressive tests. The anisotropic rock mass rating (ARMA), defined as the ratio between maximum and minimum of attributes, maintains in a low level both for the UCS (1.131) and elastic modulus (1.064). According to the classification proposed by Saroglou et al. (2018), rock mass can be considered isotropic when ARMA ranges from 1.0 to 1.1 and fairly anisotropic when ARMA ranges from 1.1 to 2.0. Thus, in the Shuguang gold and copper mine, rock mass can be considered homogeneous and isotropic when the size approach to 12 m (REV).

The investigation domain is then discretized as a total of 68,707 block units (see Fig. 10 and Fig. 11). The block model is a form of spatially referenced database that provides a means for modeling a 3D body from sampling points and interval data. However, these are interpolated values rather than true measurements. A block model consists of cells (block units) of a specified size which at the core of the block center contain a centroid at which all the data is stored as attributes, i.e., grade, lithology, GSI, mechanical parameters, etc. This centroid point is what all data is reported on.

Geostatistical analysis and spatial interpolation of GSI

Samples collected from the same domain have strong similarities when they are spatially close, and this similarity tends to decline until it disappears with increasing distance. The attributes that have a location associated with each observation are called regionalized variables (Olea 1994). An experimental semivariogram, which is used to measure the spatial variation of the regionalized variable, is defined as half of the average squared difference between two attribute values separated by vector hi:

where γ(h) is the semivariogram function, X(zi) and X(zi + hi) are the values of regionalized variable in the location of zi and zi + hi, and n(hi) is the number of sampling pairs. The experimental semivariogram is plotted on a x − y plot with the x-axis being the lag hi and γ(hi) on the y-axis. The experimental semivariogram consists of a set of discrete points and is often fitted as a mathematical model. Common semivariogram models can be found in the reference (Olea 2000).

By assuming GSI following the geostatistical law (refer to the discussion), the experimental semivariogram of GSI is calculated according to Eq. 3. The experimental semivariogram of GSI values along different directions is presented in Fig. 9 with the bullets, and the search for pairs has been performed along the major, semi-major, and minor direction at a lag of 6 m. The data in Fig. 9 reveal that the semivariogram of GSI can be fitted as a combination of a spherical model and a random model:

where C is the nugget, which is noted as a difference at a sample separation distance of zero; δ is the sill, which equals to the difference between the maximum difference of sample pairs and the nugget; and α is the range, which represents the maximum distance which sample pairs can be said to have some relationship to their separation distance.

When the regionalized variable exhibits different characteristics in various direction, the semivariogram is anisotropic. Anisotropy is usually characterized through geometric, zonal, or separable models, and these elementary models of anisotropy can be composed to provide more complex anisotropies (Allard et al. 2016). In the Shuguang gold and copper mine, only geometric anisotropy is taken into consideration. Geometric anisotropy occurs when the range, but not the sill, of the semivariogram changes in different directions. The iso-surface of the geometric anisotropic semivariogram is an ellipsoid in the 3D space defined by three principle directions (major axis, semi-major axis, and minor axis). One way in which geometric anisotropy can be identified is by calculating and plotting experimental directional semivariogram. Differences in experimental variograms computed using different directions could be an indication of anisotropy, and the general steps for determining the geometric anisotropic semivariogram can be found in the reference (Nakaya et al. 2002). In this article, following the methodology previously stated, the anisotropic semivariogram ellipsoid parameters of GSI are listed in Table 3.

In this article, the OK method is employed to estimate unknown values from sampled data using the obtained anisotropic semivariogram. The OK method, developed by Danie Krige and Georges Matheron in 1960s, is an unbiased, optimal, and linear valuation method under certain conditions (Olea 2000). A key feature of the OK method is that it uses any spatial correlation that may exist between sample points to inform the weighting of the effects of sample points on a prediction point. The weights are generated by the semivariogram for the geological domain for the block being estimated. In essence, the OK method is a spatial-based regression approach to obtain the optimum weighting to apply to the samples informing the block estimate. As shown in Fig. 10, each block unit gets its individual GSI value through the OK spatial interpolation.

Generation of the heterogenous mechanical parameter block model

In this article, the Hoek-Brown method (Hoek and Carranza-Torres 2002) is used to evaluate the mechanical parameters of rock mass in each block unit. The Hoek-Brown method starts from the properties of intact rock and then introduced factors to reduce these properties, and it has been widely accepted and applied in many rock projects around the world. The Hoek-Brown method can give smooth continuous transitions for the entire range of GSI values, which means the Hoek-Brown method can handle rock mass with clear heterogeneity range from poorly interlocked rock mass (GSI < 25) to very well interlocked rock mass (GSI > 75) in a rock slope engineering. Four kinds of parameters, including intact rock parameters (density, UCS, and material constant), GSI of rock mass, disturbance factor, and buried depth of rock mass, are required in the Hoek-Brown method. Laboratory tests and geological observations can provide a rigorous and unambiguous input for the analysis. As the output of Hoek-Brown method, the deformation (elastic modulus) and strength parameters (compressive strength, tensile strength, cohesion, and friction) of rock masses are obtained. Those mechanical parameters are next used in the slope stability analyses with limit equilibrium method (LEM).

For an open-pit mines, the properties of rock mass are particularly sensitive to engineering disturbance, including blast damage and stress relaxation, which is considered in the Hoek-Brown criterion. The Hoek-Brown criterion has given simple recommended values for the disturbance factor D in different operating conditions (Hoek 2012). Ideally, numerical modeling should include several layers parallel to the slope surface, with a decreasing disturbance factor assigned to each layer (Hoek 2012). In situ experience show that the ultrasonic wave velocity can effectively reflect the rock mass loosening and damage caused by engineering disturbance. Therefore, it is practicable for the wave velocity to be utilized to determine the disturbance factor. To achieve this goal, drilling boreholes are set in the direction along the vertical wall to measure the wave velocity. A comparison of the wave velocity before and after the excavation or the deep and shallow rock mass can be used to determine the disturbance factor and its extension. In addition, the Hoek-Brown method suggests that the elastic modulus Em can be estimated using the following equation:

For an undisturbed rock mass, the disturbance factor D = 0, and the elastic modulus is EUD; the elastic modulus is ED for a damaged rock mass with a disturbance factor D:

Recall that the elastic modulus of rock mass and its ultrasonic wave velocity can be related via:

where vp is the ultrasonic wave velocity, ρ is the density of rock mass, and μ is the Poisson ratio. The average ultrasonic wave velocity is vUD for the undisturbed rock mass, and vD for the damaged rock mass. The disturbance factor can be determined from Eq. 6 and Eq. 7 as:

where K = (vD/vUD)2. To ensure D ≤ 1, the K is set to 0.5 when (vD/vUD)2 < 0.5.

In the Shuguang gold and copper mine, we assumed that the whole pit follows the same ultrasonic wave velocity test result with the typical borehole, shown in Fig. 7. Equation 8 is employed to obtain the disturbance factor D, and vUD = 5.45km/s. Following the velocity test result, two layers parallel to the open-pit surface, with buried depth 12 m and 24 m, are assigned with the disturbance factor 1.00 and 0.31. However, in the heterogenous numerical modeling, this level of sophistication is not justified, especially the spatial variability of disturbance factor is ignored. In fact, the selection of disturbance factor D is still a challenge problem in the heterogenous numerical model when applying the Hoek-Brown method.

In fact, the heterogeneity of rock mass mechanical parameters is affected by many issues including rock properties (lithology, mineral composition, cementation, etc.), discontinuity properties (rock mass quality, joint surface condition, etc.), and external disturbance (weathering, blasting, unloading, hydrogeology, etc.). In this article, only the spatial distribution of rock mass quality GSI, lithology, and external disturbance are taken into consideration. Other issues (including properties of intact rock) are simplified as constant in each lithology. MATLAB codes were developed to implement the Hoek-Brown method in each block unit. As shown in the Fig. 11, both the deformation and strength parameters have a strong heterogeneity even in the same lithology.

Validation of the heterogenous mechanical parameter block model

The block model can easily transform into a finite element mesh if necessary. As shown in Fig. 12, the smooth lithologic interface is represented by a jagged interface in the block model, which will lead to a local stress concentration in the finite element analysis. As reported by Cai and Kaiser (2018), the lithologic interface has a significant influence on the overall stiffness of an engineering rock mass. Thus, block units that intersect with the lithologic interface need be remeshed. A block unit is divided into several parts by the lithologic interfaces, and each part shares the same GSI value but different lithology in the Hoek-Brown method. The node coordinates and topology can be extracted from the block model and then be written into any element mesh file format.

To validate the established mechanical parameter block model for heterogeneous rock mass, the slope stability analysis was performed in the representative profile. The Morgenstern method embedded in the software SLOPE/W is used to search the critical slip surface with the lowest factor of safety. In this process, the Mohr-Coulomb methods are used to get the resistance force and the nonlinear failure criteria are ignored. Thus, only cohesion, friction angle, and density are considered in the slope stability analyses process. The single bench landslide occurred in the northern pit with a height of 12 m. Compared with the resolution (block unit is 12 m in cube) of the mechanical parameter block model, the landslide area is relatively small. In fact, opportune disposal measures were executed after the landslide immediately, and we cannot find a landslide case that crosses several benches in the northern pit. Still, the analysis for the shallow landslide can verify the heterogenous mechanical parameter block model to some extent.

A detailed geological investigation was carried out in the representative profile, shown in Fig. 13. Geological boreholes and surface photography have indicated the rock layers and GSI of rock masses. Especially, the fracture zones were determined which have a negative influence on the slope stability. Besides, two water table measurement wells and the water outlet point have given a rough estimation for the water table line which was taken into consideration in the calculation.

As shown in Fig. 14, when assuming the rock mass is homogeneous in each lithology and the average strength properties are used in the calculation, the factor of safety is estimated at 1.16 and hence the slope is considered remaining in a safe state. However, the factor of safety decreases to 0.96 when the heterogenous mechanical parameter block model is taken into consideration, revealing landslide tends to occur which is consistent with in situ investigations. The result indicated that the geostatistics-based mechanical parameter block model can represent the natural fact of rock mass more effectively, compared with simple lithology partitioning.

Slope stability analyses of homogeneous and heterogeneous rock mass. (a) Homogeneous rock mass. (b) Heterogeneous rock mass. Color in each block represents cohesion that shares the same legend with Fig. 11. Water table line in pink and critical slip surface in white

Optimization of the UPL

Determination for the steepest safe slope angle

As shown in Fig. 15, according to the available mining equipment including drilling rig, power shovel, and mining truck, four possible slope configuration designs (A, B, C, and D) in the northern pit were proposed, and the slope design dimensions (bench height, bench width, bench face angle, and ramp width) are listed in Table 4. Each design will bring its unique UPL and thus different location and veins of slope, shown in Fig. 15. In general, the slope angle of a UPL should be as steep as possible within the premise of safety (Bye and Bell 2001). According to the service life of the final slope, the allowed safety factor for the overall slope is set at 1.30. Since any engineering disaster may bring an irreparable consequence, the stability for partial slope including interramp slope and single bench are taken into consideration. After communication with the in situ engineers, the slope stability for interramp slope and single bench is checked to avoid potential landslide, and the allowed safety factor is set at 1.15 and 1.05 for interramp slope and single bench, respectively.

Slope stability analysis of four possible slope geometry designs. (a) Homogenous rock mass. (b) Heterogenous rock mass. High water table line in pink, low water table line in white, and potential landslide with lowest safety factor in gray. Color in each block represents cohesion that shares the same legend with Fig. 11. Safety factor pairs are calculated under high water table and low water table with drainage measures, and unacceptable safety factors are marked in red

Many studies indicated that the seismic loads and water table hav a significant influence on the slope stability. Here, the seismic load is set at 0.1 g both in horizontal and vertical according to the suggestion from in situ engineers. Two kinds of water table condition are taken into consideration; the high water table line in pink is obtained by field measurement, and the low water table line in white is an assumption with drainage measures. Besides, we assume that the disturbance factor is aligned with the ultrasonic wave velocity test for each slope geometry. Both the homogenous and heterogeneous mechanical parameter block model are utilized to examine the stability of open-pit slopes in different slope deigns.

The slope stability analysis result for four possible slope configurations is shown in Fig. 15, and the safety factor pairs for two kinds of water table condition are recorded. The safety factor of the overall slope continues decreasing with the increase of slope angle when assuming the rock mass is homogenous, and the unacceptable safety factors are marked in red in Fig. 15. The slope design A and B features the constraints of safety factor in different situation. Thus, a steepest safe angle 41.2° (corresponding to slope design B) is determined in the original UPL optimization program.

When the heterogeneous mechanical parameter block model is taken into consideration, the safety factor for the overall slope of slope design A is minimum even the slope angle remains at a low level. The slope stability gets much improvement in slope design B, C, and D. A higher slope angle can effectively excavate the fracture zone, and the bottom strong rock mass is exposed which brings a higher safety factor. Especially, the slope remains stable from every single bench to overall slope in design C under different water table condition. Finally, the result of the limit equilibrium method considering heterogeneity can give a steepest safe angle (43.6°) for the northern pit.

UPL optimization

As one of the most popular UPL optimization method, Lerchs-Grossmann (LG) algorithm (Lerchs and Grossmann 1965; Hustrulid and Kuchta 1998) uses graph theory to yield the optimum final pit outline. In this article, the LG algorithm embedded in the mining software Whittle is employed to perform the UPL optimization. This model requires defining, assessing, and assuring many important parameters used in the feasibility study and that may have relevant consequences over the future results of the project. The selection of such parameters is a complex engineering decision due to their enormous economic impact on the mining operation, as they will significantly affect the mine design and planning. The economic parameters of the UPL optimization are listed in Table 5, and the price unit is Chinese yuan.

As shown in Fig. 16, compared with the original UPL, the slope angle of the new UPL has an average 1° to 6° increases. The stripping ratio is decreased from 0.92t/t in the original UPL to 0.53t/t in the new UPL. The cutoff equivalent grade of gold (dAu) in the current economic parameters is 0.38g/t. Besides, zone IV is divided into two new geological zones with different slope angle. Finally, the new UPL considering geostatistics-based heterogeneous mechanical parameter block model can bring 15.84 million tons of ore and reduce 20.83 million tons of waste rock. In addition, the slope angle can be further steepened if drainage and reinforcement measures are applied.

In fact, the Shuguang gold and copper mine is a large multi-origin magmatic hydrothermal deposit. As shown in Fig. 17, metallogenic hydrothermal fluids will preferentially enter the fractured rock mass, and the contamination further reduces the rock mass quality. The fractional crystallization of metallogenic hydrothermal allows the formation of deposits. This special mineralization leads to a phenomenon that the higher the grade, the worse the rock mass quality. As shown in Fig. 18, there is a linear negative correlation between equivalent grade and GSI of rock masses.

To keep the slope in a safe state, the original UPL design is trying to decrease the slope angle by leaving some low-grade ores in the pit. The new UPL prefers to excavate the low-grade ore body with fragile mechanical properties. Due to the specific genesis of deposit, the new UPL can improve slope stability and bring economic benefit. Until the end of 2019, the new UPL design has been carried out in the Shuguang gold and copper mine more than 2 years. No new landslide records have proven the rationality of the geostatistics-based heterogenous mechanical parameter block model.

Discussion

Applicable conditions of the geostatistics-block-based method

The appropriate spatial scale and object for proper application of the geostatistics-based analysis should be defined at first. In other words, the object must follow certain geostatistical rules within the scale of investigation. Since rock masses in the Shuguang gold and copper mine are similar in lithology, geological structure, and geological age, we believe that the application of geostatistical analysis in this article is appropriate. As for the suitable objects for the geostatistical analysis, grade and mineral composition are the most reliable parameters, which have been proven by numerous studies (Rendu 1978), and they have been widely applied in the mineral resource management. Besides, many researchers demonstrated that geostatistical methods can be used for the analysis of discontinuity (Priest 1993) and rock mass quality (Stavropoulou et al. 2007; Egaña and Ortiz 2013; Mayer and Stead 2017). Other parameters, such as porosity and density (Maliva 2016), also follow geostatistical distribution, even though they are not discussed in this article.

In rock engineering, the discontinuities are divided into five classes (I, II, III, IV, and V), and this classification can be found in literature (Cai 2002). Since different scales of discontinuities have different mechanical properties, thus different analyses methods are used. In an open-pit mine, small-scale discontinuities (class IV and V), size ranges from 100 m to 101 m, are called statistical discontinuity. Rock masses containing those statistical discontinuities are considered equivalent continuous medium using the Hoek-Brown method. Large-scale discontinuities (I, II, and III) ranging from hundred meters to several kilometers have a fundamental influence on the slope stability and control the failure pattern. Those large-scale discontinuities prefer to cross several strata and should reflect in the 3D geological model and be treated as a special lithology.

Extensions and defects of the geostatistics-based method

It is inevitable that the established mechanical parameter block model using the geostatistical method remains an error, and we attempt to identify and reduce the errors. For the geological valuation process, we can adopt different spatial interpolation methods based on the abundance of geological data. OK interpolation is employed to handle geological parameters with abundant measurement data. The inverted distance weighting (IDW) method is applied when limited measurement data are available (Ferreira et al. 2017; Sajid et al. 2013; Myers 1994). We believe that the valuation error can be controlled effectively with enough natural geological data and a precise geostatistical valuation process. Another error source is the inaccuracy of the Hoek-Brown method, which is the key to this method. Since the Hoek-Brown method is a semiquantitative empirical method, the mechanical parameters obtained by the Hoek-Brown method are more of an estimation than an accurate measurement. Although a detailed geological investigation and sufficient laboratory experiments may help us obtain a more reliable result, further studies should be launched to mitigate this error. A feasible way to solve this problem is to perform additional correction based on back analysis using the monitoring data.

This article indicated that the heterogeneity of rock mass plays an important role in the UPL optimization. Geostatistics-based method can give a precise characterization for the natural heterogenous rock mass. Stability analysis considering heterogenous properties of rock mass can get a more reasonable slope angle, which can improve the slope stability as well as bring economic benefits. Besides, the block model is an effective tool in characterizing the heterogeneity of rock masses. In fact, the block model for ore grade (mineral composition) has been widely applied in the open-pit mine especially in the optimization of pit limit using computer-assisted hand methods. Geological data, mechanical parameters, and mining information can share the same data format and be stored in the same block model.

Conclusion

With the continuous resource development, deep open pit is the tendency of surface mine; the increasing complexity of UPL design in heterogeneous rock masses necessitates the application of more advanced models considering the large variations of rock properties. This article proposes a geostatistics-block-based method to characterize the heterogeneous mechanical parameters of rock mass. The UPL optimization considering heterogeneous rock properties in the Shuguang gold and copper open-pit mine can not only improve the slope stability but also bring economic benefits.

-

(1)

By collecting specific geological data (especially rock mass quality GSI and ultrasonic wave velocity) in the exploratory boreholes, the combination of geostatistical analysis and the Hoek-Brown method allows us to obtain more detailed heterogeneous mechanical parameters from limited measurements. The error of the heterogeneous mechanical parameter block model can be controlled in a reasonable range when sufficient geological data are available.

-

(2)

Compared with the homogeneous mechanical parameters field, the slope stability analysis of the rock landslide is more appropriate using heterogeneous mechanical parameter block model. The results have verified the rationality of geostatistics-block-based method and indicated that heterogeneity is an indispensable part of engineering analysis.

-

(3)

In the Shuguang gold and copper mine, a new optimized UPL design was proposed by considering the geostatistics-based heterogenous rock properties. Due to the specific genesis of deposit, the UPL limit can effectively excavate the fragile rock mass; the slope angle and safety factor are both increased. Although site-specific, this optimization process considering heterogeneity of rock properties can be useful for similar situations.

References

Allard D, Senoussi R, Porcu E (2016) Anisotropy models for spatial data. Math Geosci 48:305–328

Amadei B (1996) Importance of anisotropy when estimating and measuring in situ stresses in rock. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts 33(3):293–325

Barclay RMR (1989) The effect of reproductive condition on the foraging behavior of female hoary bats, Lasiurus cinereus. Behav Ecol Sociobiol 24:31–37

Barton N, Lien R, Lunde J (1974) Engineering classification of rock masses for the design of tunnel support. Rock Mech 6:189–236

Bieniawski ZT (1989) Engineering rock mass classification. Wiley Interscience, New York

Bye A, Bell F (2001) Stability assessment and slope design at Sandsloot open pit, South Africa. Int J Rock Mech Min Sci 38(3):449–466

Caers J (2005) Petroleum geostatistics. Society of Petroleum Engineers, Richardson

Cai MF (2002) Rock mechanics and rock engineering. Science Press, Beijing

Cai M, Kaiser P (2018) Rockburst support reference book, volume I: rockburst phenomenon and support characteristics. MIRARCO - mining innovation. Laurentian University, Sudbury (Ontraio, Canada)

Cao WG, Zhao H, Li X, Zhang YJ (2010) Statistical damage model with strain softening and hardening for rocks under the influence of voids and volume changes. Can Geotech J 47:857–871

Chen S, Yue ZQ, Tham LG (2007) Digital image based approach for three-dimensional mechanical analysis of heterogeneous rocks. Rock Mech Rock Eng 40:145–168

Deere DU, Deere DW (1989) Rock quality designation (RQD) after twenty years. U.S. Army Corps Engrs. Contract Report GL-89-1. Vicksburg, MS: Waterways Experimental Station.

Egaña M, Ortiz JM (2013) Assessment of RMR and its uncertainty by using geostatistical simulation in a mining project. J GeoEng 8:83–90

Eivazy H, Esmaieli K, Jean R (2017) Modeling geomechanical heterogeneity of rock masses using direct and indirect geostatistical conditional simulation methods. Rock Mech Rock Eng 50:3175–3195

Fenton GA, Griffiths VD (2008) Risk assessment in geotechnical engineering. John Wiley & Sons, New York

Ferreira IO, Rodrigues DD, Santos GRD, Rosa LMF (2017) In bathymetric surfaces: IDW or kriging? Boletim de Ciências Geodésicas 23:493–508

Goovaerts P (1997) Geostatistics for natural resource evaluation environmental. Oxford University Press, New York

Hoek E (2007) Practical rock engineering. www.rocscience.com

Hoek E (2012) Blast damage factor D. Technical Note for RocNews, Winter 2012 Issue, RocScience. www.rocscience.com

Hoek E, Carranza-Torres C (2002) Hoek-Brown failure criterion—2002 edition. In: Proceedings of the fifth North American rock mechanics symposium

Hoek E, Carter TG, Diederichs MS (2013) Quantification of the geological strength index chart. In: Proc. 47th U.S. Symposium on Rock Mechanics (USRMS), 13–672, San Francisco, CA

Hustrulid W, Kuchta M (1998) Open pit mine planning and design, 2nd edn. CRC Press, London

Irigaray C, Fernández T, Chacón J (2003) Preliminary rock-slope-susceptibility assessment using GIS and the SMR classification. Nat Hazards 30:309–324

Jaeger JC, Cook NGW (2007) Fundamental of rock mechanics. Sci Paperbacks 22:1102–1111

Khalokakaie R, Downd PA, Fowell RJ (2000) Incorporation of slope design into optimal pit design algorithms. Min Technol 109:70–76

Lerchs H, Grossmann IF (1965) Optimum design of open pit mines. Canad Inst Mining Bull 58:47–54

Li LC, Tang CA, Zhu WC, Liang ZZ (2009) Numerical analysis of slope stability based on the gravity increase method. Comput Geotech 36:246–1258

Lily P (2002) Open pit mine slope engineering: a 2002 perspective. In: 150 years of mining, Proceedings of the AusIMM Annual Conference, Auckland, New Zealand

Maliva RG (2016) Aquifer characterization techniques. Springer, Switzerland

Masanobu O (1988) A method for evaluating the representative elementary volume based on joint survey of rock masses. Can Geotech J 25:440–447

Mayer JM, Stead D (2017) A comparison of traditional, step-path, and geostatistical techniques in the stability analysis of a large open pit. Rock Mech Rock Eng 50:927–949

Mccann DM, Entwisle DC (1992) Determination of Young’s modulus of the rock mass from geophysical well logs. Geol Soc Spec Publ 65(1):317–325

Myers DE (1994) Spatial interpolation: an overview. Geoderma 62:17–28

Nakaya S, Yohmei T, Koike A, Hirayama T, Yoden T, Nishigaki M (2002) Determination of anisotropy of spatial correlation structure in a three-dimensional permeability field accompanied by shallow faults. Water Resour Res 38:1–14

Olea RA (1994) Fundamentals of semivariogram estimation, modeling, and usage. In: Stochastic Modeling and Geostatistics. AAPG Computer Applications, Tulsa

Olea RA (2000) Geostatistics for engineers and earth scientists. Boston, MA: Kluwer Academic Publishers

Pinheiro M, Emery X, Miranda T, Lamas L, Espada M (2018) Modeling geotechnical heterogeneities using geostatistical simulation and finite differences analysis. Minerals 8(2):1–19

Priest SD (1993) Discontinuity analysis for rock engineering. Chapman & Hall, London

Rendu JM (1978) An introduction to geostatistical methods of mineral evaluation. South African Institute of Mining and Metallurgy, Johannesburg, South Africa

Sajid A, Rudra R, Parkin G (2013) Systematic evaluation of kriging and inverse distance weighting methods for spatial analysis of soil bulk density. Can Biosyst Eng 55:1–13

Saroglou C, Qi SY, Guo SF, Wu FQ (2018) ARMR, a new classification system for the rating of anisotropic rock masses. Bull Eng Geol Environ 78:3611–3626

Stavropoulou M, Exadaktylos G, Saratsis G (2007) A combined three-dimensional geological-geostatistical-numerical model of underground excavations in rock. Rock Mech Rock Eng 40:213–243

Tang C (1997) Numerical simulation of progressive rock failure and associated seismicity. Int J Rock Mech Min Sci 34:249–261

Xu T, Ranjith PG, Wasantha PLP, Zhao J, Tang CA, Zhu WC (2013) Influence of the geometry of partially spanning joints on mechanical properties of rock in uniaxial compression. Eng Geol 167:134–147

Yu QL, Yang SQ, Ranjith PG, Zhu WC, Yang TH (2016) Numerical modeling of jointed rock under compressive loading using X-ray computerized tomography. Rock Mech Rock Eng 49:877–891

Yu QL, Zhu WC, Ranjith PG, Shao SS (2018) Numerical simulation and interpretation of the grain size effect on rock strength. Geomech Geophys Geo 4:157–173

Yue ZQ, Chen S, Tham LG (2003) Finite element modeling of geomaterials using digital image processing. Comput Geotech 30:375–397

Zhou JR, Wei J, Yang TH, Zhu WC, Li LC, Zhang PH (2018) Damage analysis of rock mass coupling joints, water and microseismicity. Tunn Undergr Sp Tech 71:366–381

Acknowledgments

We would like to thank Professor Peijun Guo and Dylan Liu from McMaster University for their help in English writing. We also would like to thank the anonymous reviewers for their constructive comments that helped improve this manuscript.

Funding

This work was supported by the National Key Research and Development Program of China (2016YFC0801602 and 2017YFC1503101), the National Science Foundation of China (U1903216 and U1710253), and the China Scholarship Council (201806080101).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, F., Yang, T., Deng, W. et al. Geostatistics-block-based characterization of heterogeneous rock mass and its application on ultimate pit limit optimization: a case study. Bull Eng Geol Environ 80, 1683–1700 (2021). https://doi.org/10.1007/s10064-020-02023-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10064-020-02023-2